Development and Evaluation of Modified Rotor–Stator Knives for Enhanced Fine Grinding of Chicken Meat–Bone Raw Material in Colloid Mill

Abstract

1. Introduction

2. Materials and Methods

3. Results

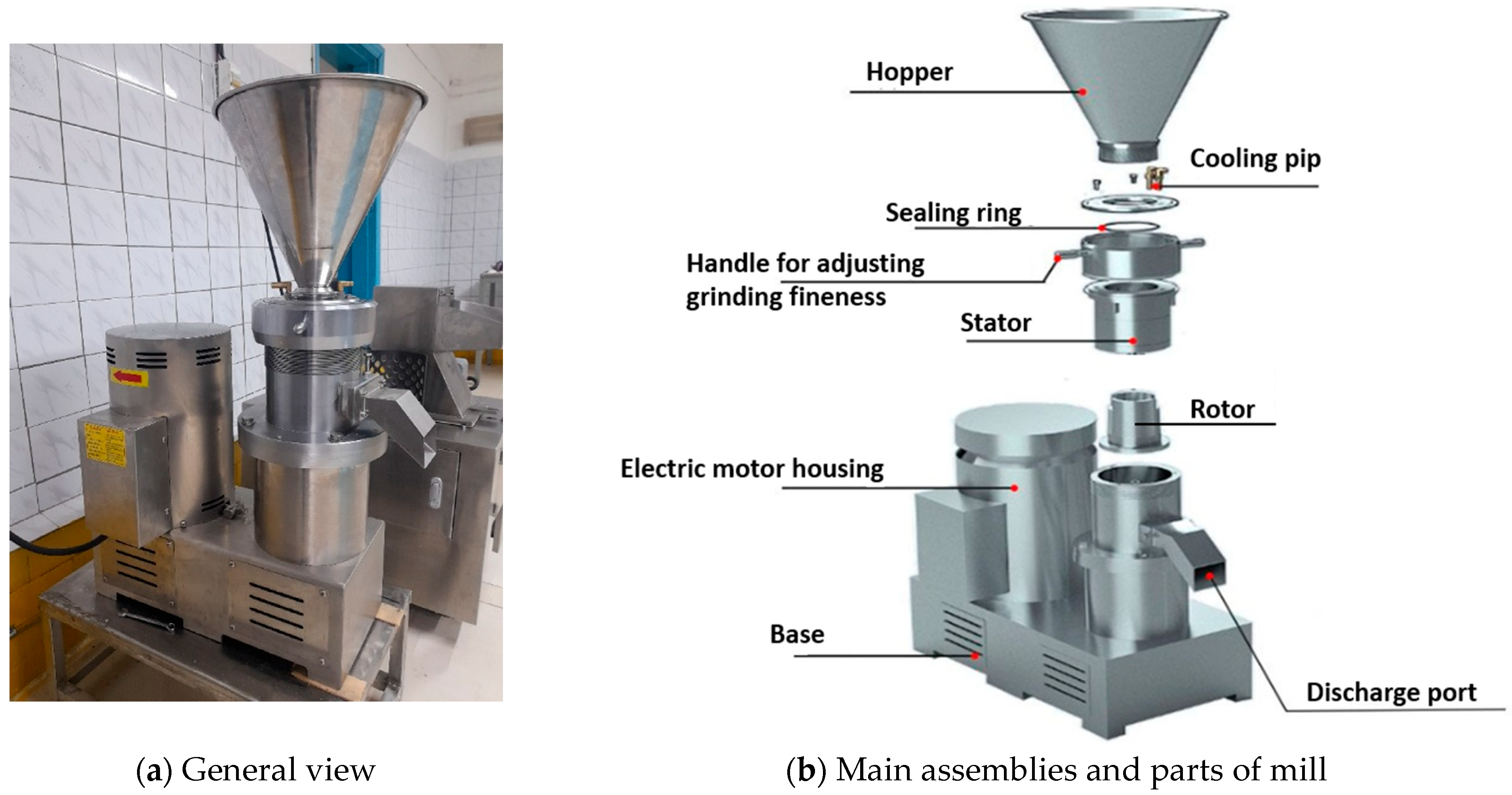

3.1. Main Design Characteristics of Cutting Part of Colloid Mill

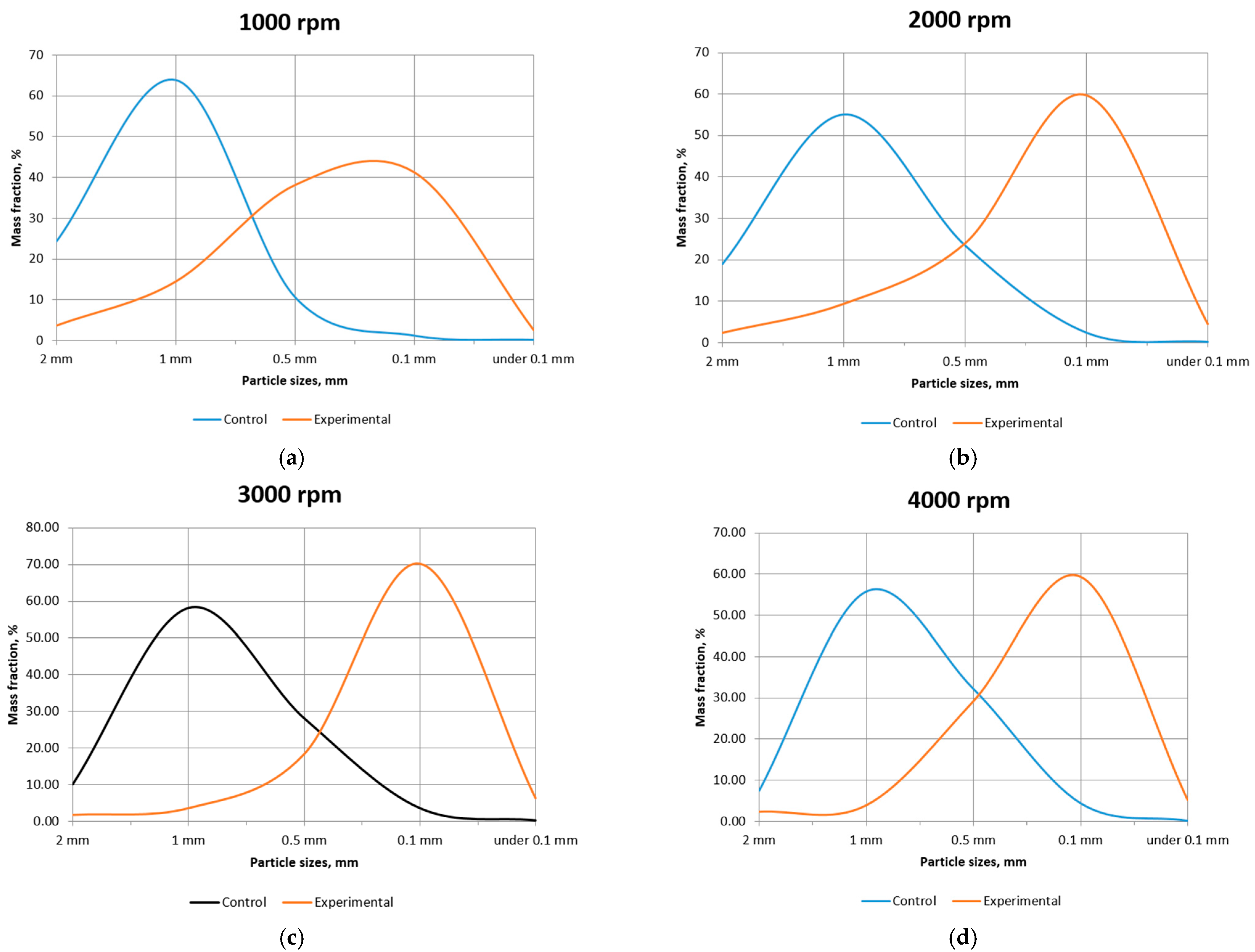

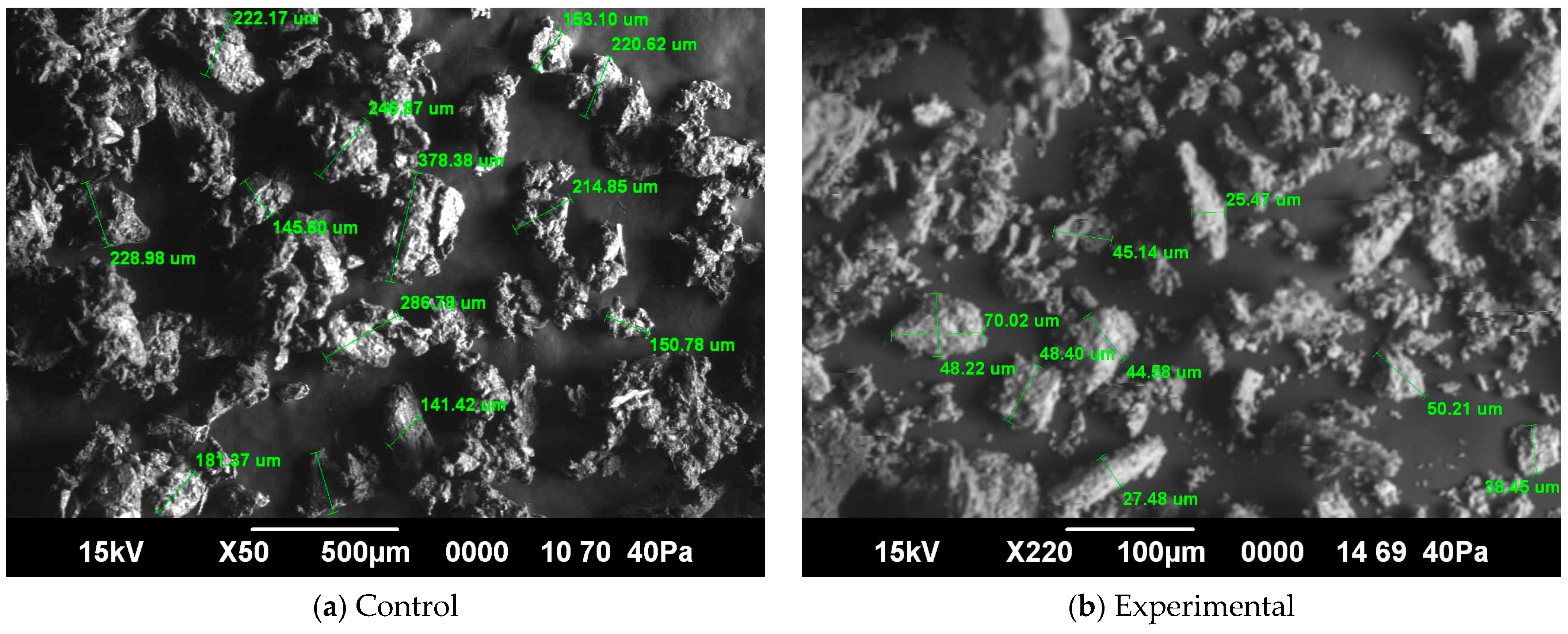

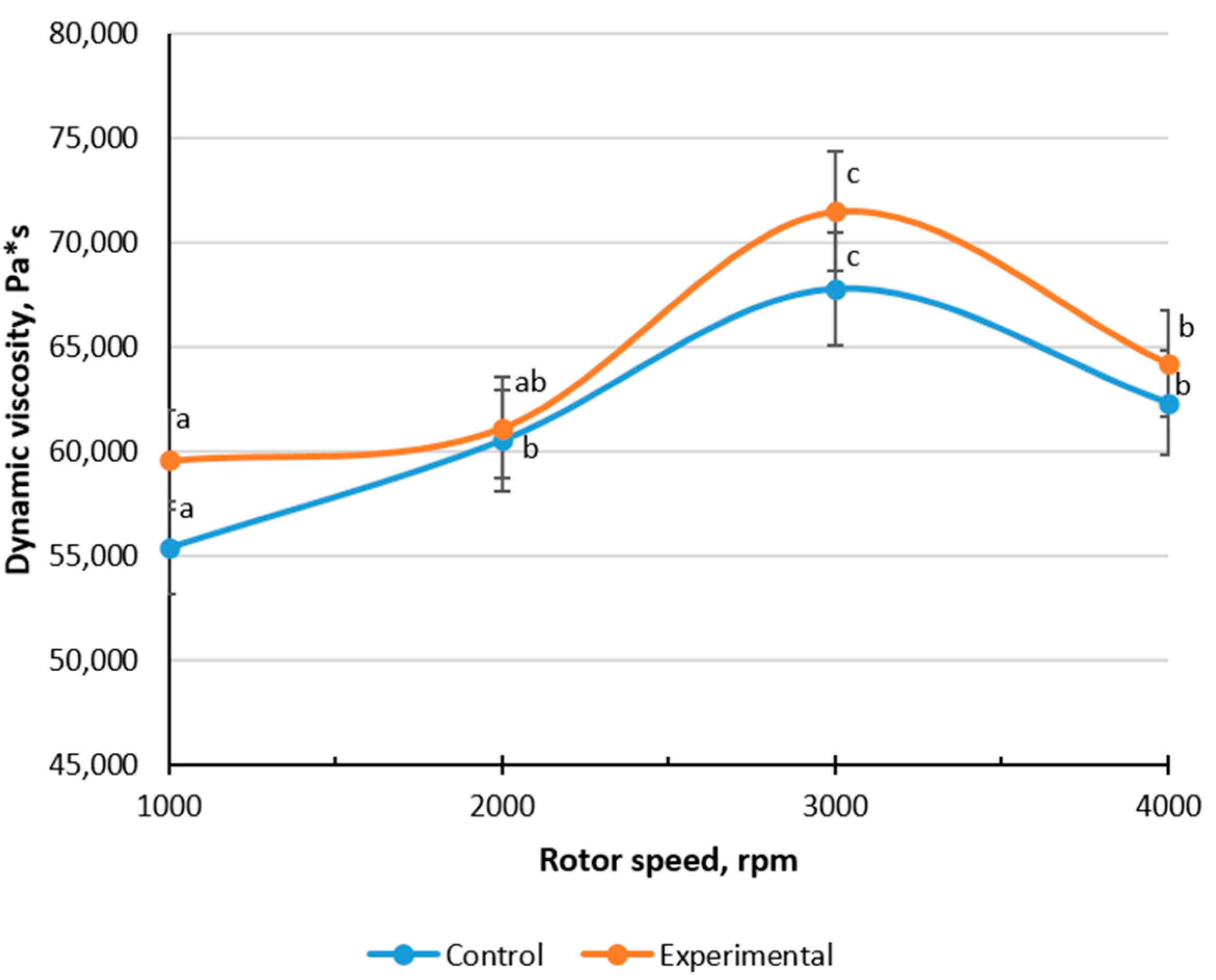

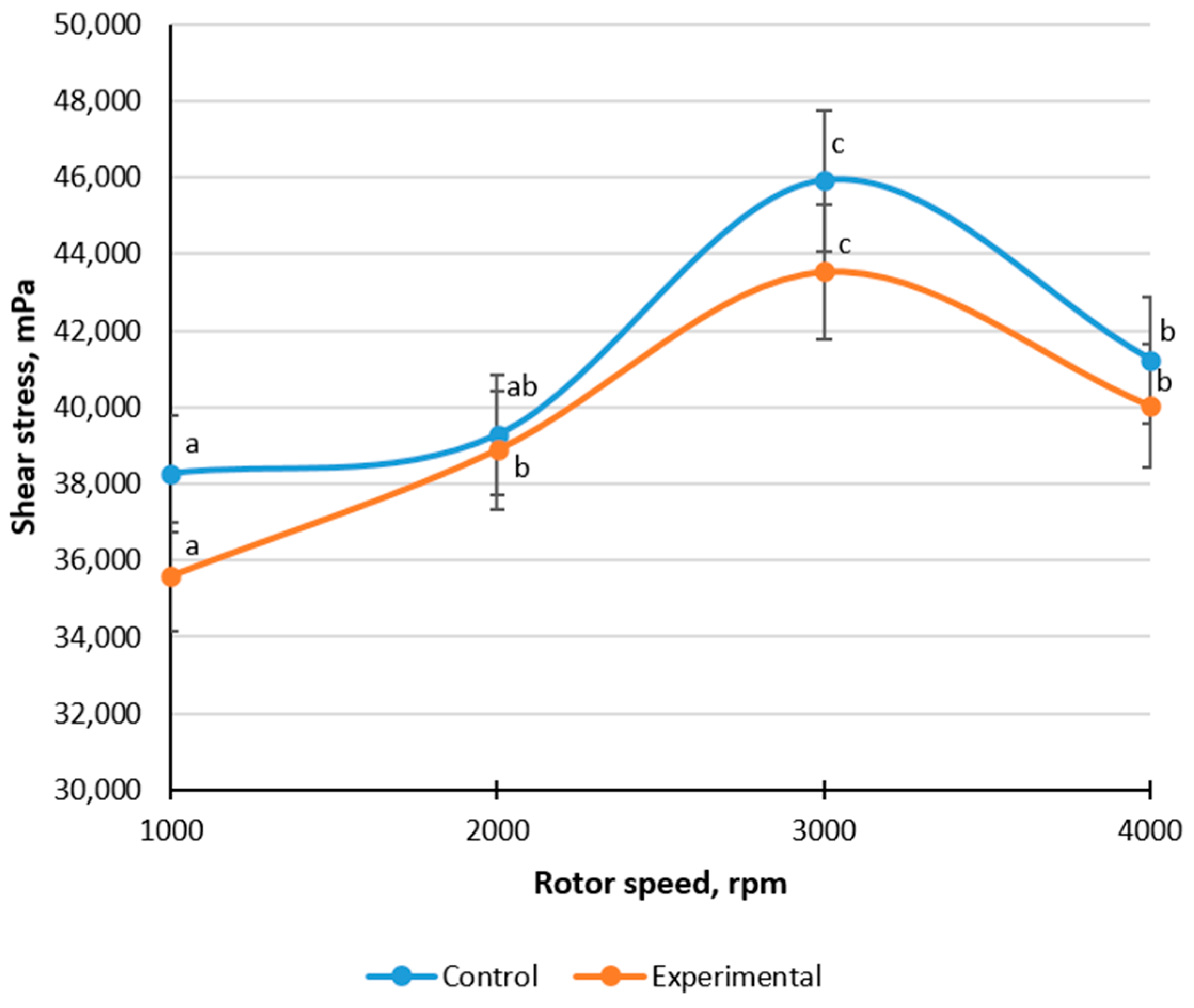

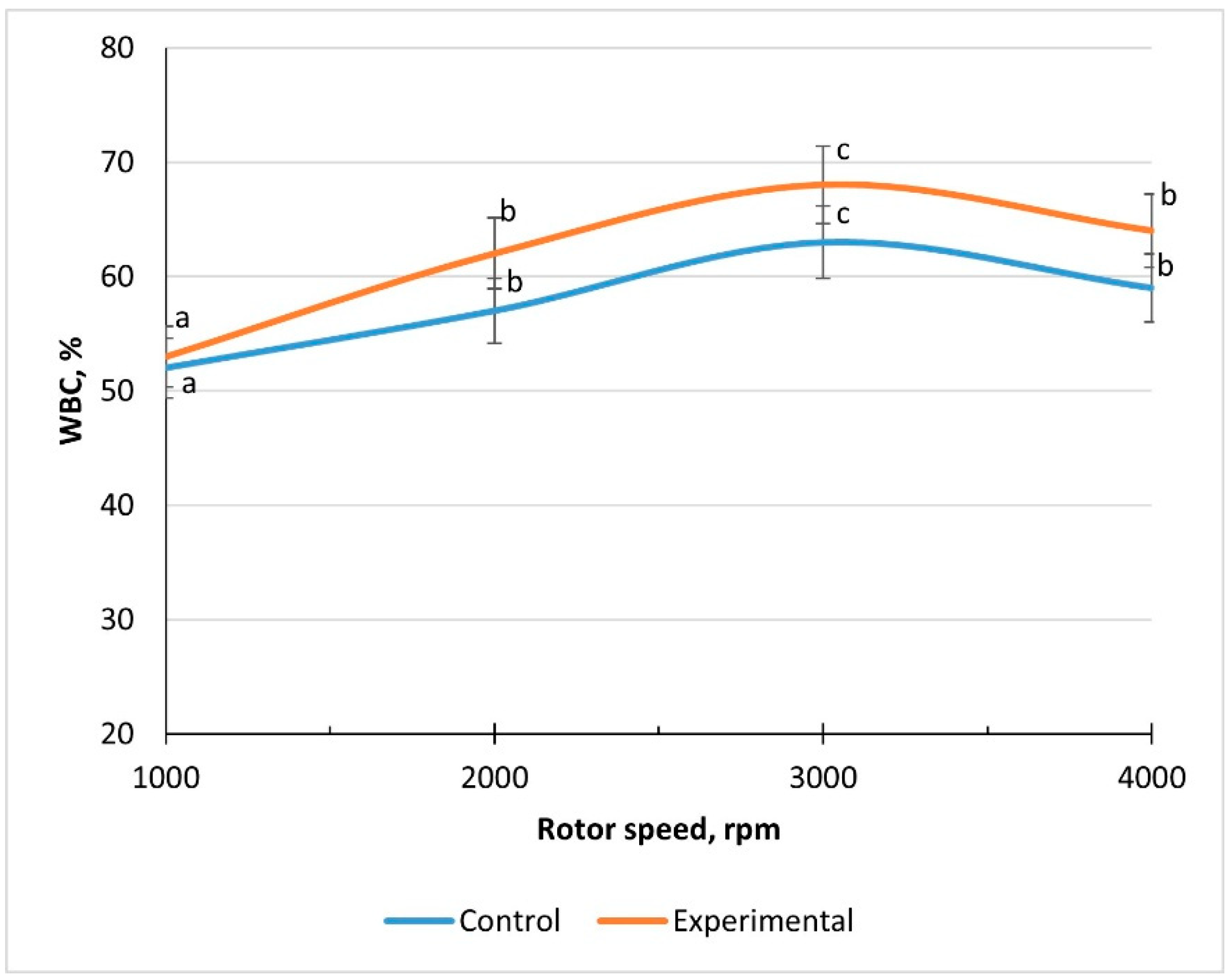

3.2. Changes in Performance of Colloid Mill Depending on Rotor Speed and Knife Design

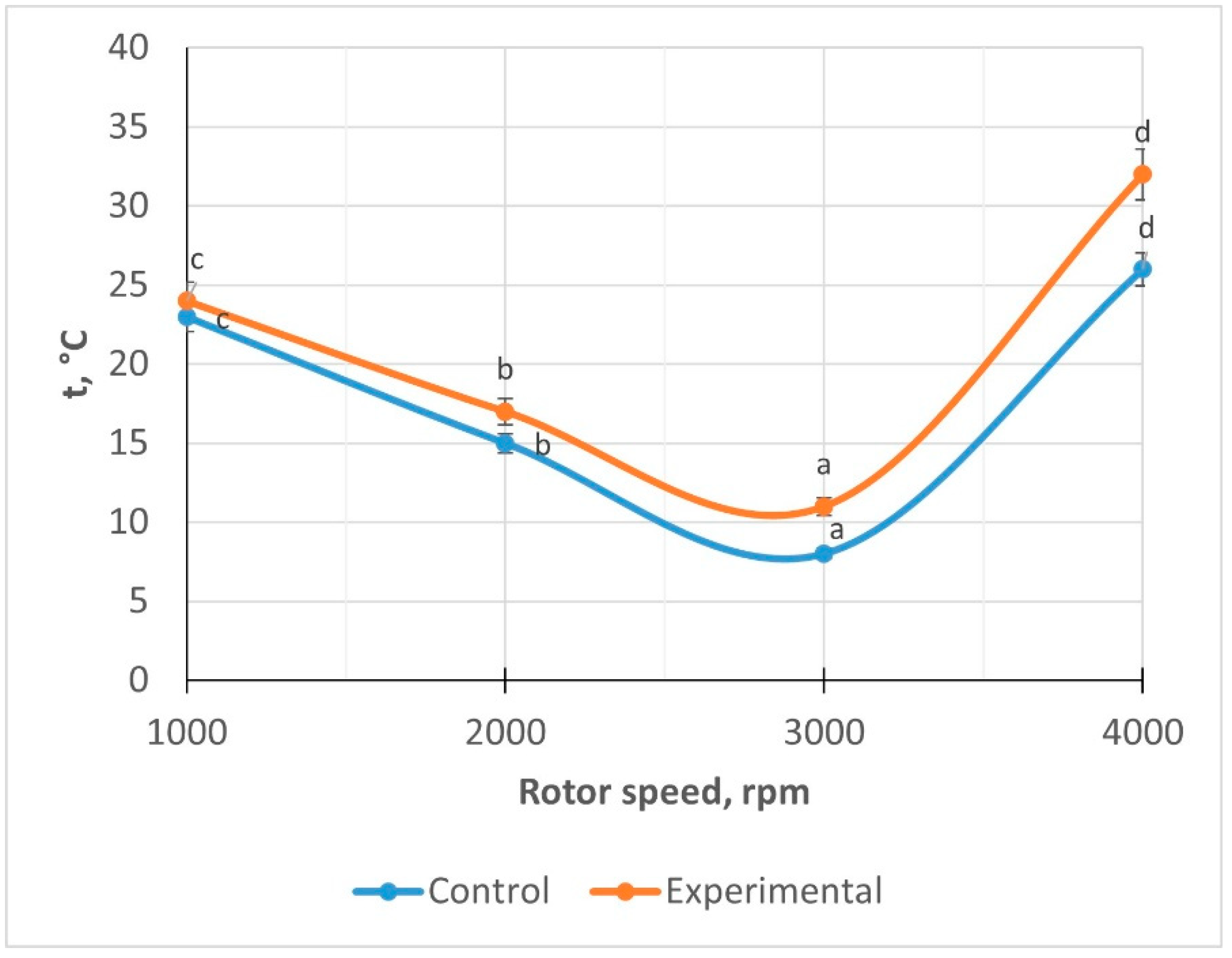

3.3. Study of Effect of Rotor Speed and Knife Design on Temperature of Meat-and-Bone Paste

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Poultry Meat Production in Kazakhstan Increased by Almost 10%. Available online: https://el.kz/ru/proizvodstvo-myasa-ptitsy-v-kazahstane-vyroslo-pochti-na-10_400010250/?utm_source (accessed on 30 April 2025).

- Zapata, L.; Cardona, S.; Manotas, S.; Narváez, F.; Restrepo, L.; Andrade, H.; Araya, P.; Simpson, R.; Castro, Ó. Valorization of the By-products of Poultry Industry (Bones) by Enzymatic Hydrolysis and Glycation to Obtain Antioxidants Compounds. Waste Biomass Valorization 2021, 13, 4469–4480. [Google Scholar] [CrossRef]

- Mokrejš, P.; Gál, R.; Pavlačková, J.; Janácová, D. Valorization of a By-Product from the Production of Mechanically Deboned Chicken Meat for Preparation of Gelatins. Molecules 2021, 26, 349. [Google Scholar] [CrossRef] [PubMed]

- Alibekov, R.; Alibekova, Z.; Bakhtybekova, A.; Taip, F.; Urazbayeva, K.; Kobzhasarova, Z. Review of the slaughter wastes and the meat by-products recycling opportunities. Front. Sustain. Food Syst. 2024, 8, 1410640. [Google Scholar] [CrossRef]

- Pap, N.; Mäkinen, S.; Moilanen, U.; Vahvaselkä, M.; Maunuksela, J.; Kymäläinen, M.; Pihlanto, A. Optimization of Valorization of Chicken MDCM to Produce Soluble Protein and Collagen Peptides. Appl. Sci. 2022, 12, 1327. [Google Scholar] [CrossRef]

- Mohamed, M.A.; Kassem, G.M.; Zahran, D.A.; Emara, M.T.; Mansour, N.K. Impact of mechanically recovered poultry meat (MRPM) on proximate analysis and mineral profile of traditional Egyptian luncheon. J. Radiat. Res. Appl. Sci. 2023, 16, 100521. [Google Scholar] [CrossRef]

- Bekeshova, G.; Ibragimov, N.; Kakimov, A.; Suychinov, A.; Yessimbekov, Z.; Kabdylzhar, B.; Tokhtarov, Z.; Zhumadilova, G.; Abdilova, G. Effect of Rotational Speed and Gap between Rotating Knives of the Grinder on the Yield Stress and Water-Binding Capacity of Fine Ground Chicken Bone. Appl. Sci. 2022, 12, 3533. [Google Scholar] [CrossRef]

- Maindarkar, S.; Dubbelboer, A.; Meuldijk, J.; Hoogland, H.; Henson, M. Prediction of emulsion drop size distributions in colloid mills. Chem. Eng. Sci. 2014, 118, 114–125. [Google Scholar] [CrossRef]

- Grudanov VYa Brench, A.A.; Torgan, A.B.; Datsuk, I.E.; Zelenko, S.A.; Vasilevskaya, V.V. Theoretical foundations of improving the quality and efficiency of the process of fine grinding of meat raw materials on emulsifiers. Food Ind. Sci. Technol. 2022, 15, 45–55. (In Russian) [Google Scholar] [CrossRef]

- Harter, A.; Schenck, L.; Lee, I.; Cote, A. High-shear rotor–stator wet milling for drug substances: Expanding capability with improved scalability. Org. Process Res. Dev. 2013, 17, 1335–1344. [Google Scholar] [CrossRef]

- Baikadamova, A.; Kakimov, A.; Yessimbekov, Z.; Suychinov, A.; Turagulov, R.; Orynbekov, D.; Zhumadilova, G.; Zharykbasov, Y. Studying the Process of Enzyme Treatment on Beef Meat-Bone Paste Quality. Appl. Sci. 2024, 14, 8703. [Google Scholar] [CrossRef]

- Antipova, L.V.; Glotova, I.A.; Rogov, I.A. Meat and Meat Products Research Methods; “KoloS” Publishing House: Moscow, Russia, 2001. [Google Scholar]

- Kapovsky, B.; Kuznetsova, T.; Lazarev, A.; Plyasheshnik, P. Energy-saving technology for fine grinding of food raw materials frozen in blocks. In E3S Web of Conferences; EDP Sciences: Les Ulis, France, 2021; Volume 279, p. 03009. [Google Scholar]

- Das, S.K.; Das, M. Fundamentals and Operations in Food Process Engineering; CRC Press: Boca Raton, FL, USA, 2019. [Google Scholar] [CrossRef]

- King, A.G.; Keswani, S.T. Colloid mills: Theory and experiment. J. Am. Ceram. Soc. 1994, 77, 769–777. [Google Scholar] [CrossRef]

- Gavrilov, T.A. Study of the efficiency of equipment for fine grinding of meat and fish feed. Polythematic Online Sci. J. Kuban State Agrar. Univ. 2013, 87, 112–122. [Google Scholar]

- Rogov, I.A.; Zabashta, A.G.; Kaziulin, G.P. General Technology of Meat and Meat Products; Kolos: Moscow, Russia, 2000; 367p. [Google Scholar]

- Titov, E.I.; Kosoy, V.D.; Dorokhov, V.P.; Azarova, N.G. Development of the theory of fine grinding of meat raw materials as the basis for process automation. Meat Ind. 2010, 7, 34–37. [Google Scholar]

- Dorokhov, V.P. Determination of rational modes of grinding minced meat of raw smoked sausages. Meat Ind. 2004, 11, 48–50. [Google Scholar]

- Zhao, Y.; Jia, D.; Huang, S.; Xiao, X.; Zhang, J.; Bai, J.; Zhu, Y. Application of barley flour processed by different methods as an alternative to fat in emulsion-type sausage. Food Bioeng. 2022, 1, 82–90. [Google Scholar] [CrossRef]

- Suchenko, Y.; Suchenko, V.; Mushtruk, M.; Vasyliv, V.; Boyko, Y. Changing the quality of ground meat for sausage products in the process of grinding. East. Eur. J. Enterp. Technol. 2017, 4, 56–63. [Google Scholar] [CrossRef]

- Sychevskyi, M.; Voitsekhivska, L.; Kopylova, K.; Verbytskyi, S.; Okhrimenko, Y. Criterial features of the structural characteristics of fine-textured poultry meat. Food Sci. Technol. 2021, 15, 2073–8684. [Google Scholar] [CrossRef]

- Berger, L.; Witte, F.; Tomašević, I.; Heinz, V.; Weiss, J.; Gibis, M.; Terjung, N. A review on the relation between grinding process and quality of ground meat. Meat Sci. 2023, 205, 109320. [Google Scholar] [CrossRef]

- Qiao, M.; Zhang, T.; Miao, M. Minced Beef Meat Paste Characteristics: Gel Properties, Water Distribution, and Microstructures Regulated by Medium Molecular Mass of γ-Poly-Glutamic Acid. Foods 2024, 13, 510. [Google Scholar] [CrossRef]

- Hills, B. Water transport and dynamics of foods. In The Chemical Physics of Food; Belton, P.S., Ed.; Blackwell Publishing Inc.: Oxford, UK, 2007; pp. 230–232. [Google Scholar]

- Barsov, H.A.; Bunin, I.A.; Yakhin, A.K. Justification of the constructive-technological scheme of the paste maker. In Abstracts of Reports of the Scientific and Industrial Conference of Orenburg State Agrarian University; Orenburg State Agrarian University: Orenburg, Russia, 1996; pp. 64–66. [Google Scholar]

- Kabulov, B.B.; Kakimov, A.K.; Kosoy, V.D.; Dorokhov, V.P.; Ryzhov, S.A.; Azarova, N.G. Rational parameters of grinding meat and bone raw material on rotary machines. Meat Ind. 2012, 5, 58–61. [Google Scholar]

- Sheng, J.; Gao, F.; Dong, Y.; Li, Q.; Xu, X.; Wang, H. Evaluating the effects of different preheating and reheating procedures on water-holding capacity and flavor in meat patties. Food Res. Int. 2025, 203, 115849. [Google Scholar] [CrossRef]

- Nasirov, Y.Z.; Konik, A.D.; Efimova, D.A.; Andreeva, A.A. Dynamics of moisture binding capacity of meat product. Technol. Food Process. Ind. Agro-Ind. Complex—Healthy Food Prod. 2023, 4, 42–45. [Google Scholar] [CrossRef]

- Gu, Q.; Guo, Z.; Zhang, Y.; Zhao, Y.; Zuo, H.; Huang, M.; Liu, Y.; Zhu, L. Investigating the Effects of Protein Thermal Denaturation on Water-Holding Capacity of Beef: Insights from Structural Dynamics. Int. J. Food Sci. Technol. 2025, 60, vvaf076. [Google Scholar] [CrossRef]

- Zielbauer, B.I.; Franz, J.; Viezens, B.; Vilgis, T.A. Physical Aspects of Meat Cooking: Time Dependent Thermal Protein Denaturation and Water Loss. Food Biophys. 2016, 11, 34–42. [Google Scholar] [CrossRef]

| Indicator | Characteristic |

|---|---|

| Capacity, kg/h | 80 |

| Electric power, kW | 4 |

| Overall dimensions, cm | 64 × 41 × 90 |

| Weight, kg | 150 |

| Hopper volume | 8 L |

| Rotor–Stator Type | Rotor Speed, rpm | |||

|---|---|---|---|---|

| 1000 | 2000 | 3000 | 4000 | |

| Control | 264.71 ± 4.91 a | 352.94 ± 3.99 b | 439.02 ± 8.41 c | 428.57 ± 4.27 c |

| Experimental | 240.00 ± 4.45 a | 333.33 ± 4.47 b | 400.00 ± 4.70 d | 375.00 ± 4.03 c |

| Rotor–Stator Type | Rotor Speed, rpm | |||

|---|---|---|---|---|

| 1000 | 2000 | 3000 | 4000 | |

| Control | 0.27 ± 0.00 a | 0.36 ± 0.01 b | 0.45 ± 0.01 c | 0.44 ± 0.01 c |

| Experimental | 0.24 ± 0.00 a | 0.34 ± 0.01 b | 0.41 ± 0.01 d | 0.38 ± 0.01 c |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yessimbekov, Z.; Turagulov, R.; Kakimov, A.; Suychinov, A.; Okuskhanova, E.; Baikadamova, A. Development and Evaluation of Modified Rotor–Stator Knives for Enhanced Fine Grinding of Chicken Meat–Bone Raw Material in Colloid Mill. Appl. Sci. 2025, 15, 7106. https://doi.org/10.3390/app15137106

Yessimbekov Z, Turagulov R, Kakimov A, Suychinov A, Okuskhanova E, Baikadamova A. Development and Evaluation of Modified Rotor–Stator Knives for Enhanced Fine Grinding of Chicken Meat–Bone Raw Material in Colloid Mill. Applied Sciences. 2025; 15(13):7106. https://doi.org/10.3390/app15137106

Chicago/Turabian StyleYessimbekov, Zhanibek, Rasul Turagulov, Aitbek Kakimov, Anuarbek Suychinov, Eleonora Okuskhanova, and Assemgul Baikadamova. 2025. "Development and Evaluation of Modified Rotor–Stator Knives for Enhanced Fine Grinding of Chicken Meat–Bone Raw Material in Colloid Mill" Applied Sciences 15, no. 13: 7106. https://doi.org/10.3390/app15137106

APA StyleYessimbekov, Z., Turagulov, R., Kakimov, A., Suychinov, A., Okuskhanova, E., & Baikadamova, A. (2025). Development and Evaluation of Modified Rotor–Stator Knives for Enhanced Fine Grinding of Chicken Meat–Bone Raw Material in Colloid Mill. Applied Sciences, 15(13), 7106. https://doi.org/10.3390/app15137106