Recent Developments in Additively Manufactured Crash Boxes: Geometric Design Innovations, Material Behavior, and Manufacturing Techniques

Abstract

1. Introduction

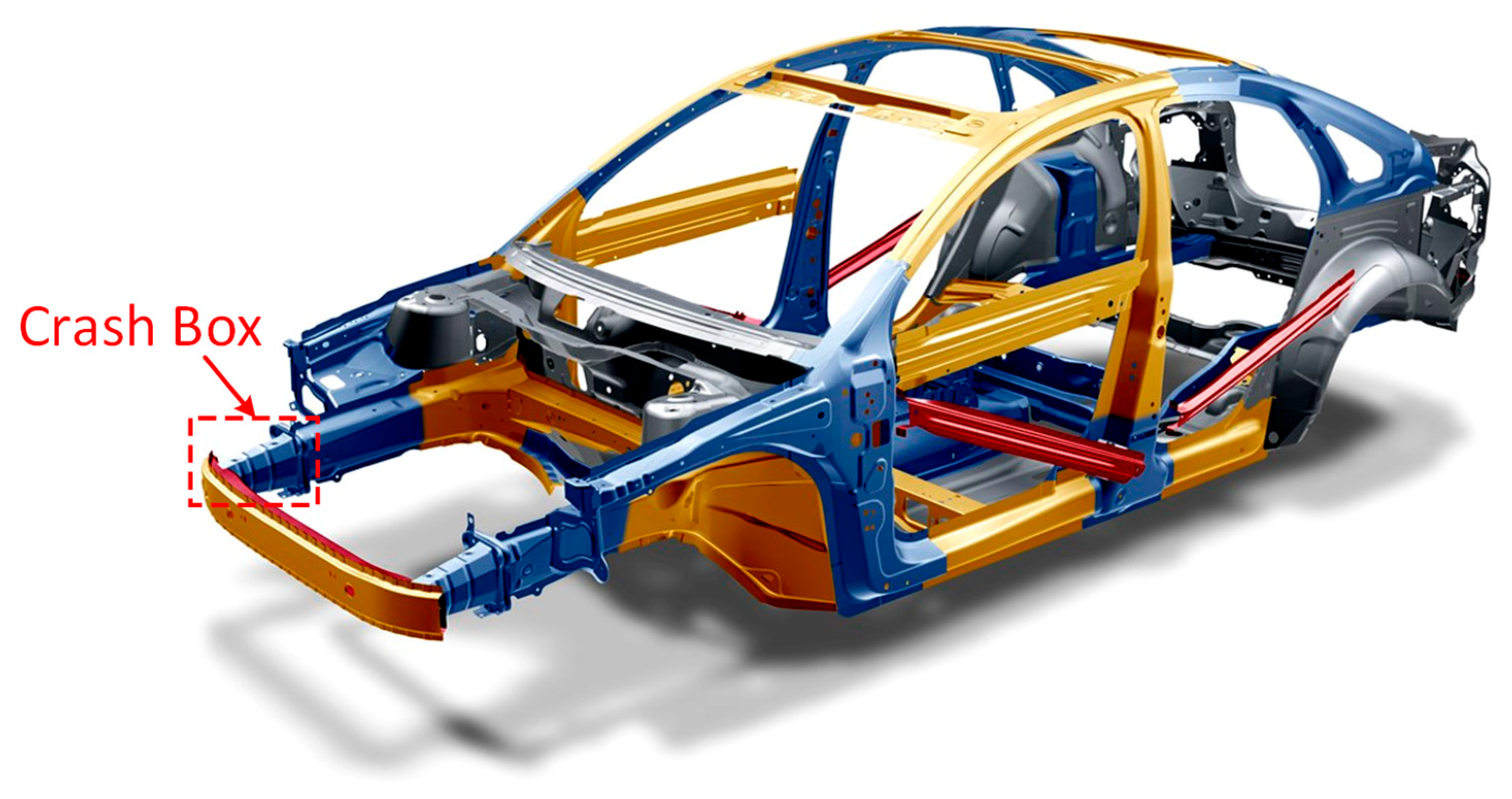

2. Crash Box Working Principle

3. Crash Box Performance Metrics

3.1. Total Energy Absorption,

3.2. Peak Crush Force,

3.3. Mean Crush Force,

3.4. Specific Energy Absorption,

3.5. Crush Force Efficiency,

4. AM Process

5. AM Processes

5.1. Stereolithography (SLA)

5.2. Material Jetting (MJT)

5.3. Selective Laser Melting (SLM)

5.4. Fused Deposition Modeling (FDM)

5.5. Other Techniques

6. Geometries Used in Additively Manufactured Crash Boxes

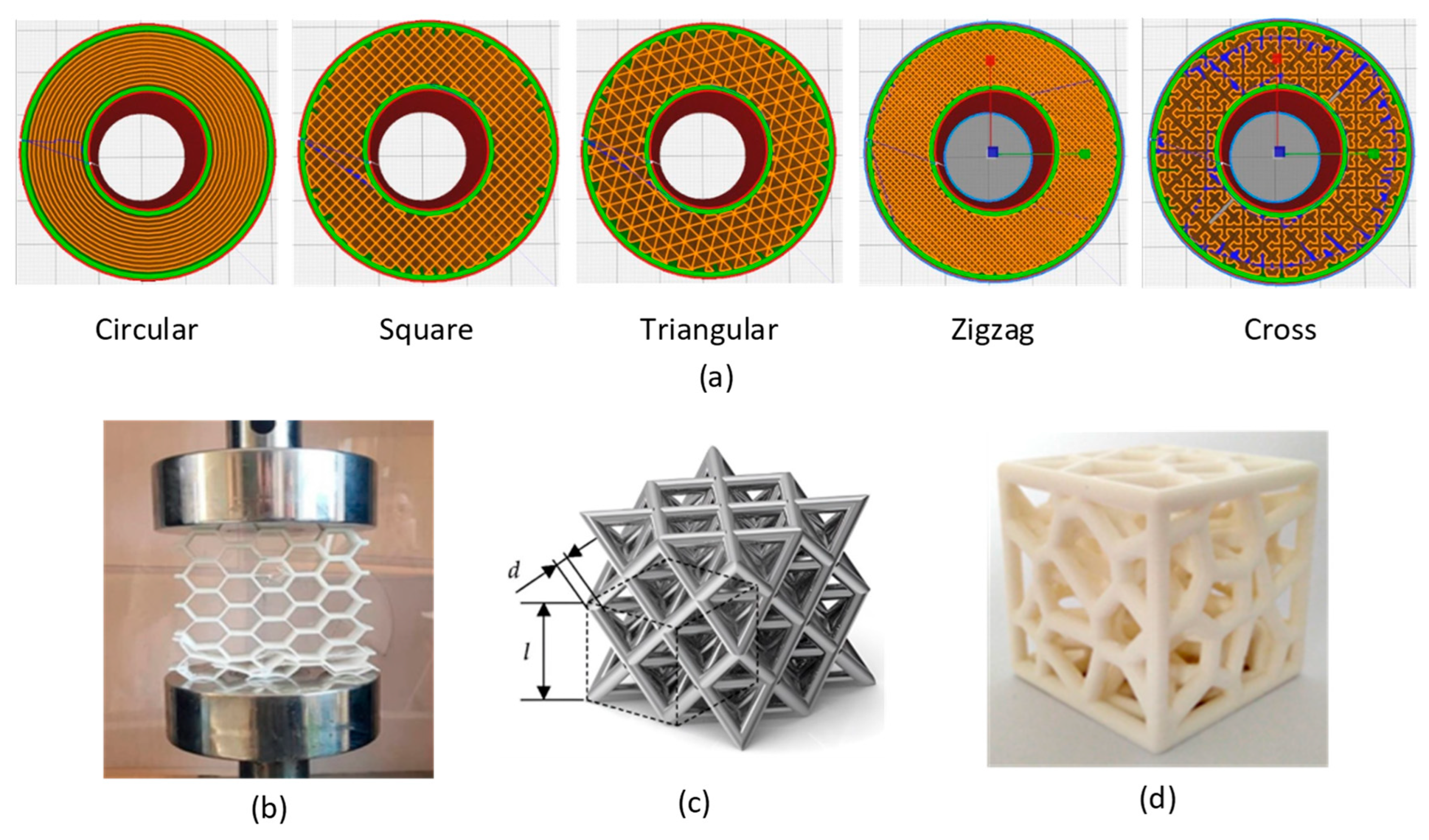

6.1. Tubular Structures

6.2. Origami-Inspired Structures

6.3. Lattice Structures

6.4. Bio-Inspired Structures

7. Materials Used in Additively Manufactured Crash Boxes

7.1. Polymers

7.2. Fiber-Reinforced Polymers

7.3. Metals

7.4. Multi-Material

8. AM Techniques for Crash Boxes

8.1. SLA

8.2. MJT

8.3. SLM

8.4. SLS

8.5. FDM

8.6. Hybrid Manufacturing Techniques

9. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Pradeep, S.A.; Iyer, R.K.; Kazan, H.; Pilla, S. Automotive Applications of Plastics: Past, Present, and Future. In Applied Plastics Engineering Handbook: Processing, Materials, and Applications, 2nd ed.; William Andrew Publishing: Norwich, NY, USA, 2017; pp. 651–673. ISBN 9780323390408. [Google Scholar]

- Omar, M.A. The Automotive Body Manufacturing Systems and Processes; John Wiley and Sons: Hoboken, NJ, USA, 2011; ISBN 9780470976333. [Google Scholar]

- Hanssen, A.G.; Langseth, M.; Hopperstad, O.S. Static and Dynamic Crushing of Circular Aluminum Extrusions with Aluminum Foam Filler. Int. J. Impact Eng. 2000, 24, 475–507. [Google Scholar] [CrossRef]

- Hanssen, A.G.; Langseth, M.; Hopperstad, O.S. Static and Dynamic Crushing of Square Aluminum Extrusions with Aluminum Foam Filler. Int. J. Impact Eng. 2000, 24, 347–383. [Google Scholar] [CrossRef]

- Acar, E.; Altin, M.; Güler, M.A. Evaluation of Various Multi-Cell Design Concepts for Crashworthiness Design of Thin-Walled Aluminum Tubes. Thin-Walled Struct. 2019, 142, 227–235. [Google Scholar] [CrossRef]

- Ma, J.; Dai, H.; Shi, M.; Yuan, L.; Chen, Y.; You, Z. Quasi-Static Axial Crushing of Hexagonal Origami Crash Boxes as Energy Absorption Devices. Mech. Sci. 2019, 10, 133–143. [Google Scholar] [CrossRef]

- Yuan, L.; Shi, H.; Ma, J.; You, Z. Quasi-Static Impact of Origami Crash Boxes with Various Profiles. Thin-Walled Struct. 2019, 141, 435–446. [Google Scholar] [CrossRef]

- Wesselmecking, S.; Kreins, M.; Dahmen, M.; Bleck, W. Material Oriented Crash-Box Design—Combining Structural and Material Design to Improve Specific Energy Absorption. Mater. Des. 2022, 213, 110357. [Google Scholar] [CrossRef]

- Kaczyński, P.; Makuła, P. Constitutive Strength Model for Spot Joints of Thin-Walled Energy-Absorbing Elements. Eng. Struct. 2023, 292, 116592. [Google Scholar] [CrossRef]

- Mert, S.K.; Demiral, M.; Altin, M.; Acar, E.; Güler, M.A. Experimental and Numerical Investigation on the Crashworthiness Optimization of Thin-Walled Aluminum Tubes Considering Damage Criteria. J. Braz. Soc. Mech. Sci. Eng. 2021, 43, 1–22. [Google Scholar] [CrossRef]

- Güler, M.A.; Mert, S.K.; Altin, M.; Acar, E. An Investigation on the Energy Absorption Capability of Aluminum Foam-Filled Multi-Cell Tubes. J. Braz. Soc. Mech. Sci. Eng. 2023, 45, 541. [Google Scholar] [CrossRef]

- Chen, J.; Li, E.; Liu, W.; Mao, Y.; Hou, S. Crashworthiness Analysis of Novel Cactus-Inspired Multi-Cell Structures under Axial Crushing. Int. J. Mech. Sci. 2024, 268, 109053. [Google Scholar] [CrossRef]

- Aktaş, C.; Acar, E.; Güler, M.A.; Altın, M. An Investigation of the Crashworthiness Performance and Optimization of Tetra-Chiral and Reentrant Crash Boxes. Mech. Based Des. Struct. Mach. 2023, 51, 6881–6904. [Google Scholar] [CrossRef]

- Kathiresan, M.; Manisekar, K.; Rajamohan, V.; Güler, M.A. Investigations on Crush Behavior and Energy Absorption Characteristics of GFRP Composite Conical Frusta with a Cutout under Axial Compression Loading. Mech. Adv. Mater. Struct. 2022, 29, 5360–5377. [Google Scholar] [CrossRef]

- Hull, C.W. Apparatus for Production of Three Dimensional Objects by Stereolithography. U.S. Patent 4575330A, 11 March 1986. [Google Scholar]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive Manufacturing (3D Printing): A Review of Materials, Methods, Applications and Challenges. Compos. Part B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Wu, Y.; Fang, J.; Wu, C.; Li, C.; Sun, G.; Li, Q. Additively Manufactured Materials and Structures: A State-of-the-Art Review on Their Mechanical Characteristics and Energy Absorption. Int. J. Mech. Sci. 2023, 246, 108102. [Google Scholar] [CrossRef]

- Yao, R.; Pang, T.; Zhang, B.; Fang, J.; Li, Q.; Sun, G. On the Crashworthiness of Thin-Walled Multi-Cell Structures and Materials: State of the Art and Prospects. Thin-Walled Struct. 2023, 189, 110734. [Google Scholar] [CrossRef]

- Abdullah, N.A.Z.; Sani, M.S.M.; Salwani, M.S.; Husain, N.A. A Review on Crashworthiness Studies of Crash Box Structure. Thin-Walled Struct. 2020, 153, 106795. [Google Scholar] [CrossRef]

- Ha, N.S.; Lu, G. A Review of Recent Research on Bio-Inspired Structures and Materials for Energy Absorption Applications. Compos. Part B Eng. 2020, 181, 107496. [Google Scholar] [CrossRef]

- Xiang, X.M.; Lu, G.; You, Z. Energy Absorption of Origami Inspired Structures and Materials. Thin-Walled Struct. 2020, 157, 107130. [Google Scholar] [CrossRef]

- Ha, N.S.; Lu, G. Thin-Walled Corrugated Structures: A Review of Crashworthiness Designs and Energy Absorption Characteristics. Thin-Walled Struct. 2020, 157, 106995. [Google Scholar] [CrossRef]

- Langley, A.A. Description of a Hydraulic Buffer-Stop for Railways. Proc. Inst. Mech. Eng. 1886, 37, 105–120. [Google Scholar] [CrossRef]

- Thornton, P.H. Energy Absorption in Composite Structures. J. Compos. Mater. 1979, 13, 247–262. [Google Scholar] [CrossRef]

- Wierzbicki, T.; Abramowicz, W. On the Crushing Mechanics of Thin-Walled Structures. J. Appl. Mech. Trans. ASME 1983, 50, 727–734. [Google Scholar] [CrossRef]

- Abramowitch, S.; Easley, D. Introduction to Classical Mechanics. In Biomechanics of the Female Pelvic Floor; Academic Press: Cambridge, MA, USA, 2016; pp. 89–107. ISBN 9780128032299. [Google Scholar]

- Boria, S. Lightweight Design and Crash Analysis of Composites. In Lightweight Composite Structures in Transport: Design, Manufacturing, Analysis and Performance; Woodhead Publishing: Cambridge, UK, 2016; pp. 329–360. ISBN 9781782423430. [Google Scholar]

- Altin, M.; Acar, E.; Güler, M.A. Foam Filling Options for Crashworthiness Optimization of Thin-Walled Multi-Tubular Circular Columns. Thin-Walled Struct. 2018, 131, 309–323. [Google Scholar] [CrossRef]

- Saber, A.; Güler, M.A.; Altin, M.; Acar, E. Bio-Inspired Thin-Walled Energy Absorber Adapted from the Xylem Structure for Enhanced Vehicle Safety. J. Braz. Soc. Mech. Sci. Eng. 2024, 46, 613. [Google Scholar] [CrossRef]

- Jiménez, M.; Romero, L.; Domínguez, I.A.; Espinosa, M.D.M.; Domínguez, M. Additive Manufacturing Technologies: An Overview about 3D Printing Methods and Future Prospects. Complexity 2019, 2019, 9656938. [Google Scholar] [CrossRef]

- Guerrero de Mier, A.; del Espinosa Escudero, M. Progress in RepRap: Open Source 3D Printing. DYNA Eng. Ind. 2014, 89, 34–38. [Google Scholar] [CrossRef]

- Whyte, D.J.; Rajkhowa, R.; Allardyce, B.; Kouzani, A.Z. A Review on the Challenges of 3D Printing of Organic Powders. Bioprinting 2019, 16, e00057. [Google Scholar] [CrossRef]

- Zhang, B.; Kowsari, K.; Serjouei, A.; Dunn, M.L.; Ge, Q. Reprocessable Thermosets for Sustainable Three-Dimensional Printing. Nat. Commun. 2018, 9, 1831. [Google Scholar] [CrossRef]

- Gülcan, O.; Günaydın, K.; Tamer, A. The State of the Art of Material Jetting—A Critical Review. Polymers 2021, 13, 2829. [Google Scholar] [CrossRef]

- Elkaseer, A.; Chen, K.J.; Janhsen, J.C.; Refle, O.; Hagenmeyer, V.; Scholz, S.G. Material Jetting for Advanced Applications: A State-of-the-Art Review, Gaps and Future Directions. Addit. Manuf. 2022, 60, 103270. [Google Scholar] [CrossRef]

- Capasso, I.; Andreacola, F.R.; Brando, G. Additive Manufacturing of Metal Materials for Construction Engineering: An Overview on Technologies and Applications. Metals 2024, 14, 1033. [Google Scholar] [CrossRef]

- Álvarez-Trejo, A.; Cuan-Urquizo, E.; Bhate, D.; Roman-Flores, A. Mechanical Metamaterials with Topologies Based on Curved Elements: An Overview of Design, Additive Manufacturing and Mechanical Properties. Mater. Des. 2023, 233, 112190. [Google Scholar] [CrossRef]

- Kouka, M.A.; Abbassi, F.; Habibi, M.; Chabert, F.; Zghal, A.; Garnier, C. 4D Printing of Shape Memory Polymers, Blends, and Composites and Their Advanced Applications: A Comprehensive Literature Review. Adv. Eng. Mater. 2023, 25, 2200650. [Google Scholar] [CrossRef]

- van de Werken, N.; Tekinalp, H.; Khanbolouki, P.; Ozcan, S.; Williams, A.; Tehrani, M. Additively Manufactured Carbon Fiber-Reinforced Composites: State of the Art and Perspective. Addit. Manuf. 2020, 31, 100962. [Google Scholar] [CrossRef]

- Valino, A.D.; Dizon, J.R.C.; Espera, A.H.; Chen, Q.; Messman, J.; Advincula, R.C. Advances in 3D Printing of Thermoplastic Polymer Composites and Nanocomposites. Prog. Polym. Sci. 2019, 98, 101162. [Google Scholar] [CrossRef]

- Cheng, P.; Peng, Y.; Li, S.; Rao, Y.; Le Duigou, A.; Wang, K.; Ahzi, S. 3D Printed Continuous Fiber Reinforced Composite Lightweight Structures: A Review and Outlook. Compos. Part B Eng. 2023, 250, 110450. [Google Scholar] [CrossRef]

- Wang, K.; Lin, H.; Le Duigou, A.; Cai, R.; Huang, Y.; Cheng, P.; Zhang, H.; Peng, Y. Geometric Accuracy and Energy Absorption Characteristics of 3D Printed Continuous Ramie Fiber Reinforced Thin-Walled Composite Structures. Chin. J. Mech. Eng. 2023, 36, 150. [Google Scholar] [CrossRef]

- Wang, K.; Sun, G.; Wang, J.; Yao, S.; Baghani, M.; Peng, Y. Reversible Energy Absorbing Behaviors of Shape-Memory Thin-Walled Structures. Eng. Struct. 2023, 279, 115626. [Google Scholar] [CrossRef]

- Wang, K.; Tan, Q.; Wang, J.; Liu, Y.; Zhai, Z.; Yao, S.; Peng, Y. A Low-Cost Granular-Medium Hot Quasi-Isostatic Pressing Method for Enhancing Compressive Properties of 3D Printed Structures. J. Manuf. Process. 2024, 115, 441–451. [Google Scholar] [CrossRef]

- Wirawan, W.A.; Junipitoyo, B.; Putro, S.H.S.; Sabitah, A.; Suudy, A.H.; Ridwan, R.; Choiron, M.A. Collapse Behavior and Energy Absorption Characteristics of Design Multi-Cell Thin Wall Structure 3D-Printed Under Quasi Statistic Loads. Automot. Exp. 2024, 7, 149–160. [Google Scholar] [CrossRef]

- Bintara, R.D.; Choiron, M.A. Deformation Pattern and Energy Absorption of Polylactic Acid (PLA) Carbon Crash Box under Quasi Static Loading. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1034, 012011. [Google Scholar] [CrossRef]

- Sun, G.; Wang, J.; Wang, K.; Baghani, M.; Peng, Y.; Rao, Y. Repeatable Compressive Functionality of 3D Printed Shape-Memory Thin-Walled Corrugated Structures. Int. J. Mech. Sci. 2023, 257, 108552. [Google Scholar] [CrossRef]

- Tunay, M.; Bardakci, A. A Study of Crashworthiness Performance in Thin-Walled Multi-Cell Tubes 3D-Printed from Different Polymers. J. Appl. Polym. Sci. 2024, 141, e56287. [Google Scholar] [CrossRef]

- Wang, K.; Liu, Y.; Wang, J.; Xiang, J.; Yao, S.; Peng, Y. On Crashworthiness Behaviors of 3D Printed Multi-Cell Filled Thin-Walled Structures. Eng. Struct. 2022, 254, 113907. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, J.; Tan, Q.; Gao, H.; Wang, K.; Yao, S.; Peng, Y. On Multi-Stage Deformation and Gradual Energy Absorption of 3D Printed Multi-Cell Tubes with Varying Cross-Section. Eng. Struct. 2024, 319, 118839. [Google Scholar] [CrossRef]

- Yang, K.; Xu, S.; Shen, J.; Zhou, S.; Xie, Y.M. Energy Absorption of Thin-Walled Tubes with Pre-Folded Origami Patterns: Numerical Simulation and Experimental Verification. Thin-Walled Struct. 2016, 103, 33–44. [Google Scholar] [CrossRef]

- Yang, K.; Xu, S.; Zhou, S.; Shen, J.; Xie, Y.M. Design of Dimpled Tubular Structures for Energy Absorption. Thin-Walled Struct. 2017, 112, 31–40. [Google Scholar] [CrossRef]

- Yang, K.; Xu, S.; Zhou, S.; Xie, Y.M. Multi-Objective Optimization of Multi-Cell Tubes with Origami Patterns for Energy Absorption. Thin-Walled Struct. 2018, 123, 100–113. [Google Scholar] [CrossRef]

- Li, J.; Qu, M.; Jiang, Z. Multi-Objective Optimization for 3D Printed Origami Crash Box Cell Based on Artificial Neural Networks and NSGA-II. J. Mater. Process. Des. 2023, 7, 1–13. [Google Scholar] [CrossRef]

- Qiu, N.; Yu, Z.; Wang, D.; Xiao, M.; Zhang, Y.; Kim, N.H.; Fang, J. Bayesian Optimization of Origami Multi-Cell Tubes for Energy Absorption Considering Mixed Categorical-Continuous Variables. Thin-Walled Struct. 2024, 199, 111799. [Google Scholar] [CrossRef]

- Xiao, Y.; Long, H.; Wang, Y.J.; Hu, H.L.; Liu, Y.; Wu, Q. Structural Design and Analysis of Impact Energy Absorption Characteristics for Pre-Folded External Double-Layer Biomimetic Multi-Cell Thin-Walled Tubes. Mech. Adv. Mater. Struct. 2024, 31, 12469–12480. [Google Scholar] [CrossRef]

- Yin, H.; Zhang, W.; Zhu, L.; Meng, F.; Liu, J.; Wen, G. Review on Lattice Structures for Energy Absorption Properties. Compos. Struct. 2023, 304, 116397. [Google Scholar] [CrossRef]

- Yin, H.; Liu, Z.; Dai, J.; Wen, G.; Zhang, C. Crushing Behavior and Optimization of Sheet-Based 3D Periodic Cellular Structures. Compos. Part B Eng. 2020, 182, 107565. [Google Scholar] [CrossRef]

- Wang, Z.; Yao, S.; Liu, K.; Wei, K.; Gao, T.; Zhao, M. Origami Embedded Honeycomb with Three-Axial Comparable and Improved Energy Absorption Performance. Thin-Walled Struct. 2023, 193, 111295. [Google Scholar] [CrossRef]

- Najafi, M.; Ahmadi, H.; Liaghat, G. Experimental Investigation on Energy Absorption of Auxetic Structures. Mater. Today Proc. 2021, 34, 350–355. [Google Scholar] [CrossRef]

- Lin, J.; Huang, W.; Zhang, Y.; Kong, H.; Jiang, M.; Hong, Y. Novel Symmetry Corrugate Hierarchical Honeycomb for Superior Crashworthiness. Thin-Walled Struct. 2024, 204, 112354. [Google Scholar] [CrossRef]

- Li, Q.; Zhi, X.; Fan, F. Dynamic Crushing of Uniform and Functionally Graded Origami-Inspired Cellular Structure Fabricated by SLM. Eng. Struct. 2022, 262, 114327. [Google Scholar] [CrossRef]

- Zhou, J.; Liu, H.; Dear, J.P.; Falzon, B.G.; Kazancı, Z. Comparison of Different Quasi-Static Loading Conditions of Additively Manufactured Composite Hexagonal and Auxetic Cellular Structures. Int. J. Mech. Sci. 2023, 244, 108054. [Google Scholar] [CrossRef]

- Wang, H.; Tan, D.; Liu, Z.; Yin, H.; Wen, G. On Crashworthiness of Novel Porous Structure Based on Composite TPMS Structures. Eng. Struct. 2022, 252, 113640. [Google Scholar] [CrossRef]

- Yin, H.; Zhou, J.; Wen, G.; Wu, Z. Crushing Analysis and Optimization for Bio-Inspired Hierarchical 3D Cellular Structure. Compos. Struct. 2022, 286, 115333. [Google Scholar] [CrossRef]

- Liu, Y.; Tan, Q.; Lin, H.; Wang, J.; Wang, K.; Peng, Y.; Yao, S. Integrated Design and Additive Manufacturing of Lattice-Filled Multi-Cell Tubes. Compos. Sci. Technol. 2023, 243, 110252. [Google Scholar] [CrossRef]

- Alemayehu, D.B.; Todoh, M. Enhanced Energy Absorption with Bioinspired Composite Triply Periodic Minimal Surface Gyroid Lattices Fabricated via Fused Filament Fabrication (FFF). J. Manuf. Mater. Process. 2024, 8, 86. [Google Scholar] [CrossRef]

- Harish, A.; Alsaleh, N.A.; Ahmadein, M.; Elfar, A.A.; Djuansjah, J.; Hassanin, H.; El-Sayed, M.A.; Essa, K. Designing Lightweight 3D-Printable Bioinspired Structures for Enhanced Compression and Energy Absorption Properties. Polymers 2024, 16, 729. [Google Scholar] [CrossRef] [PubMed]

- Vu, T.D.; Pham, D.B.; Huang, S.C. A Novel Bio-Inspired Hierarchical Corrugated Tube to Enhance Crashworthiness Performance. In Proceedings of the 2023 IEEE 6th International Conference on Knowledge Innovation and Invention (ICKII), Sapporo, Japan, 11–13 August 2023; pp. 677–682. [Google Scholar] [CrossRef]

- Xia, P.; Li, N.; Fu, H.; Wang, L.; Qin, H.; Xiong, C.; Yu, X.; Wang, Q.; Wang, C.; Zhao, F. Achieving High Strength and Energy Absorption of Novel 3D Printed Helical Layered Square Honeycombs. Thin-Walled Struct. 2024, 203, 112155. [Google Scholar] [CrossRef]

- Cetin, E. Energy Absorption of Thin-Walled Multi-Cell Tubes with DNA-Inspired Helical Ribs under Quasi-Static Axial Loading. J. Braz. Soc. Mech. Sci. Eng. 2024, 46, 607. [Google Scholar] [CrossRef]

- Chen, B.C.; Zou, M.; Liu, G.M.; Song, J.F.; Wang, H.X. Experimental Study on Energy Absorption of Bionic Tubes Inspired by Bamboo Structures under Axial Crushing. Int. J. Impact Eng. 2018, 115, 48–57. [Google Scholar] [CrossRef]

- Xiang, X.; Xiao, C.; Ha, N.S.; Lu, G.; Zhang, S.; Liu, Y. The Quasi-Static Compressive Mechanical Properties of Barnacle Bioinspired Structures. Eng. Struct. 2023, 275, 115307. [Google Scholar] [CrossRef]

- Xiang, X.; Xiao, C.; Lu, G.; Xie, Y.M.; Zhu, M.; Ha, N.S. Crushing Performance of Bioinspired Hierarchical Tapered Structures. Mater. Des. 2024, 238, 112611. [Google Scholar] [CrossRef]

- Ha, N.S.; Pham, T.M.; Tran, T.T.; Hao, H.; Lu, G. Mechanical Properties and Energy Absorption of Bio-Inspired Hierarchical Circular Honeycomb. Compos. Part B Eng. 2022, 236, 109818. [Google Scholar] [CrossRef]

- Khoa, N.D.; Bohara, R.P.; Ghazlan, A.; Thai, T.; Ngo, T. Novel Hierarchical Bioinspired Cellular Structures with Enhanced Energy Absorption under Uniaxial Compression. Aerosp. Sci. Technol. 2024, 147, 108995. [Google Scholar] [CrossRef]

- Wang, X.; Jiang, M.; Zhou, Z.; Gou, J.; Hui, D. 3D Printing of Polymer Matrix Composites: A Review and Prospective. Compos. Part B Eng. 2017, 110, 442–458. [Google Scholar] [CrossRef]

- Cheng, Q.; Yin, J.; Wen, J.; Yu, D. Mechanical Properties of 3D-Printed Hierarchical Structures Based on Sierpinski Triangles. Int. J. Mech. Sci. 2023, 247, 108172. [Google Scholar] [CrossRef]

- Ji, Y.; Gao, Z.; Chen, W.; Huang, H.; Li, M.; Li, X. Study on the Deformation Mode and Energy Absorption Characteristics of a Corner-Enhanced Biomimetic Spider Web Hierarchical Structure. Thin-Walled Struct. 2024, 199, 111810. [Google Scholar] [CrossRef]

- Vălean, C.; Marșavina, L.; Linul, E. Compressive Behavior of Additively Manufactured Lightweight Structures: Infill Density Optimization Based on Energy Absorption Diagrams. J. Mater. Res. Technol. 2024, 33, 4952–4967. [Google Scholar] [CrossRef]

- Zuo, X.; Guo, C.; Chen, W.; Wang, Y.; Zhao, J.; Lv, H. Influence of Loading Rate and Temperature on the Energy Absorption of 3D-Printed Polymeric Origami Tubes under Quasi-Static Loading. Polymers 2022, 14, 3859. [Google Scholar] [CrossRef]

- Hidayat, D.; Istiyanto, J.; Sumarsono, D.A.; Kurniawan, F.; Ardiansyah, R.; Wandono, F.A.; Nugroho, A. Investigation on the Crashworthiness Performance of Thin-Walled Multi-Cell PLA 3D-Printed Tubes: A Multi-Parameter Analysis. Designs 2023, 7, 108. [Google Scholar] [CrossRef]

- Isaac, C.W.; Sokołowski, A.; Duddeck, F.; Adamiak, M.; Pakieła, W.; Aremu, A. Mechanical Characterisation and Crashworthiness Performance of Additively Manufactured Polymer-Based Honeycomb Structures under in-Plane Quasi-Static Loading. Virtual Phys. Prototyp. 2023, 18, e2273296. [Google Scholar] [CrossRef]

- Zhang, D.; Li, M.; Qiu, N.; Yang, J.; Wu, C.; Steven, G.; Li, Q.; Fang, J. 4D-Printed Reusable Metamaterial via Shape Memory Effect for Energy Dissipation. Int. J. Mech. Sci. 2024, 275, 109309. [Google Scholar] [CrossRef]

- Chen, W.; Guo, C.; Zuo, X.; Zhao, J.; Peng, Y.; Wang, Y. Experimental and Numerical Investigation of 3D Printing PLA Origami Tubes under Quasi-Static Uniaxial Compression. Polymers 2022, 14, 4135. [Google Scholar] [CrossRef]

- Hidayat, D.; Istiyanto, J.; Sumarsono, D.A.; Kurniawan, F.; Abdurohman, K. Crashworthiness Characteristics of Thin-Walled Multi-Cell Structures via the Application of Annealing Process: An Experimental Investigation. Evergreen 2024, 11, 1892–1900. [Google Scholar] [CrossRef]

- Aqeel, M.; Nasir, M.A.; Rehman, Z.U.; Nauman, S.; Wakeel, A.; Hanna, E.G. Development of AgNPs-PVP/TPU Based Flexible Strain Sensors for Structural Health Monitoring of Composite Structures. Results Eng. 2024, 23, 102526. [Google Scholar] [CrossRef]

- Huffman, B.; Singh, A.; Koohbor, B.; Youssef, G. Vat Photopolymerization 3D Printing of Glass Microballoon-Reinforced TPMS Meta-Structures. Compos. Part B Eng. 2024, 287, 111799. [Google Scholar] [CrossRef]

- Xing, S.; Jiang, Z.; Zhao, J.; Sun, X.; Wang, Y. Failure Mechanism and Crashworthiness Optimization of Variable Stiffness Nested Origami Crash Box. Eng. Fail. Anal. 2025, 167, 108953. [Google Scholar] [CrossRef]

- Saber, A.; Güler, M.A.; ElSayed, O.S.; Aldallal, H.; Alsadi, A.; Aldousari, Y. Crash Performance of Additively Manufactured Tapered Tube Crash Boxes: Influence of Material and Geometric Parameters. Preprints 2025, 2025051266. [Google Scholar] [CrossRef]

- Wang, J.; Liu, Y.; Wang, K.; Yao, S.; Peng, Y.; Rao, Y.; Ahzi, S. Progressive Collapse Behaviors and Mechanisms of 3D Printed Thin-Walled Composite Structures under Multi-Conditional Loading. Thin-Walled Struct. 2022, 171, 108810. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, J.; Cai, R.; Xiang, J.; Wang, K.; Yao, S.; Peng, Y. Effects of Loading Rate and Temperature on Crushing Behaviors of 3D Printed Multi-Cell Composite Tubes. Thin-Walled Struct. 2023, 182, 110311. [Google Scholar] [CrossRef]

- Li, Q.; Zhi, X.; Fan, F. Quasi-Static Compressive Behaviour of 3D-Printed Origami-Inspired Cellular Structure: Experimental, Numerical and Theoretical Studies. Virtual Phys. Prototyp. 2022, 17, 69–91. [Google Scholar] [CrossRef]

- Liu, B.; Xu, X. Experimental and Numerical Study on Crashworthiness of Bionic Hedgehog Spine Thin-Walled Structures. Thin-Walled Struct. 2023, 189, 110892. [Google Scholar] [CrossRef]

- Tao, C.; Wang, Z.; Liu, Z.; Wang, Y.; Zhou, X.; Liang, X.; Li, H. Crashworthiness of Additively Manufactured Lattice Reinforced Thin-Walled Tube Hybrid Structures. Aerospace 2023, 10, 524. [Google Scholar] [CrossRef]

- Niu, X.; Qin, R.; Lu, Y.; Chen, B. Energy Absorption Behaviors of Laser Additive Manufactured Aluminium Alloy Thin-Walled Tube Tailored by Heat Treatment. Mater. Trans. 2021, 62, 278–283. [Google Scholar] [CrossRef]

- Mohamed, A.S.; Laban, O.; Tarlochan, F.; Al Khatib, S.E.; Matar, M.S.; Mahdi, E. Experimental Analysis of Additively Manufactured Thin-Walled Heat-Treated Circular Tubes with Slits Using AlSi10Mg Alloy by Quasi-Static Axial Crushing Test. Thin-Walled Struct. 2019, 138, 404–414. [Google Scholar] [CrossRef]

- Zorzetto, L.; Ruffoni, D. Wood-Inspired 3D-Printed Helical Composites with Tunable and Enhanced Mechanical Performance. Adv. Funct. Mater. 2019, 29, 1805888. [Google Scholar] [CrossRef]

- Johnston, R.; Kazancı, Z. Analysis of Additively Manufactured (3D Printed) Dual-Material Auxetic Structures under Compression. Addit. Manuf. 2021, 38, 101783. [Google Scholar] [CrossRef]

- Li, Q.; Wang, W.; Tan, H.; Long, X.; Wang, F.; Hu, L. Energy Absorption Characteristics of Modular Assembly Structures under Quasi-Static Compression Load. Compos. Struct. 2024, 342, 118260. [Google Scholar] [CrossRef]

- Wang, Y.J.; Zhang, Z.J.; Xue, X.W.; Zhou, J.; Song, Z.X. Axial and Lateral Crushing Performance of Plate-Lattice Filled Square Sandwich Tubes. Compos. Struct. 2021, 274, 114404. [Google Scholar] [CrossRef]

- Lin, P.; Zhang, Z.; Chen, Y.; Hu, D. Investigation of Structural Energy Absorption Performance in 3D-Printed Polymer (Tough 1500 Resin) Materials with Novel Multilayer Thin-Walled Sandwich Structures Inspired by Peano Space-Filling Curves. Polymers 2023, 15, 4068. [Google Scholar] [CrossRef]

- Liu, L.; Li, L.; Guo, C.; Ge, Y.; Zhang, L. A Study of the Mechanical Properties of Naturally-Inspired Tubular Structures Designed for Lightweight Applications. Appl. Sci. 2023, 13, 6519. [Google Scholar] [CrossRef]

- Liu, L.; Li, L.; Guo, C.; Ge, Y.; Chen, Y.; Zhang, L. The Design of a Biomimetic Hierarchical Thin-Walled Structure Inspired by a Lotus Leaf and Its Mechanical Performance Analysis. Materials 2023, 16, 4116. [Google Scholar] [CrossRef]

- Tao, Y.; Li, W.; Wei, K.; Duan, S.; Wen, W.; Chen, L.; Pei, Y.; Fang, D. Mechanical Properties and Energy Absorption of 3D Printed Square Hierarchical Honeycombs under In-Plane Axial Compression. Compos. Part B Eng. 2019, 176, 107219. [Google Scholar] [CrossRef]

- Zhang, X.; Xie, J.; Chen, J.; Okabe, Y.; Pan, L.; Xu, M. The Beetle Elytron Plate: A Lightweight, High-Strength and Buffering Functional-Structural Bionic Material. Sci. Rep. 2017, 7, 4440. [Google Scholar] [CrossRef]

- Xu, W.; Wang, C.; Liu, B.; Jia, S. Crushing Responses and Energy Absorption of Bionic Inspired Corrugated Honeycombs. Int. J. Impact Eng. 2023, 179, 104641. [Google Scholar] [CrossRef]

- Yang, K.; Li, Z.; Ge, D. Quasi-Static and Dynamic out-of-Plane Crashworthiness of 3D Curved-Walled Mixed-Phase Honeycombs. Thin-Walled Struct. 2023, 182, 110305. [Google Scholar] [CrossRef]

- Alkhatib, S.E.; Matar, M.S.; Tarlochan, F.; Laban, O.; Mohamed, A.S.; Alqwasmi, N. Deformation Modes and Crashworthiness Energy Absorption of Sinusoidally Corrugated Tubes Manufactured by Direct Metal Laser Sintering. Eng. Struct. 2019, 201, 109838. [Google Scholar] [CrossRef]

- Niu, X.; Xu, F.; Zou, Z.; Zhu, Y. Impact Resistance of Horsetail Bio-Honeycombs. Int. J. Mech. Sci. 2024, 266, 108988. [Google Scholar] [CrossRef]

- Stanczak, M.; Fras, T.; Blanc, L.; Pawlowski, P.; Rusinek, A. Numerical and Experimental Study on Mechanical Behaviour of the AlSi10Mg Aluminium Structures Manufactured Additively and Subjected to a Blast Wave. EPJ Web Conf. 2021, 250, 02017. [Google Scholar] [CrossRef]

- Tang, Y.; Li, Q.; Miao, X.; Chen, B.; Yin, L.; Liu, X.; Gu, C. Design Novel Origami Structures for Energy Absorption under Compressive Load. Acta Mech. Sin. Xuebao 2024, 40, 423271. [Google Scholar] [CrossRef]

- Zeng, Y.; Du, X.; Yao, H.; Li, P.; Dong, P.; Chen, J. An Nylon Lattice Structure with Improved Mechanical Property and Energy Absorption Capability. Compos. Part C Open Access 2022, 8, 100285. [Google Scholar] [CrossRef]

- Peng, X.; Liu, G.; Li, J.; Wu, H.; Jia, W.; Jiang, S. Compression Property and Energy Absorption Capacity of 4D-Printed Deformable Honeycomb Structure. Compos. Struct. 2023, 325, 117591. [Google Scholar] [CrossRef]

- Raj, R.; Jiyalal Prajapati, M.; Tsai, J.T.; Kumar, A.; Jeng, J.Y. Design and Additive Manufacturing of Novel Hybrid Lattice Metamaterial for Enhanced Energy Absorption and Structural Stability. Mater. Des. 2024, 245, 113268. [Google Scholar] [CrossRef]

- Shen, W.; Zhang, Z.; Okudan Kremer, G.E.; Qin, H. Origami-Inspired Infill Pattern for Additive Manufacturing. Manuf. Lett. 2022, 33, 516–520. [Google Scholar] [CrossRef]

- Awd Allah, M.M.; Abdel-Aziem, W.; Abd El-baky, M.A. Collapse Behavior and Energy Absorbing Characteristics of 3D-Printed Tubes with Different Infill Pattern Structures: An Experimental Study. Fibers Polym. 2023, 24, 2609–2622. [Google Scholar] [CrossRef]

- Hashemi, S.; Galehdari, S.A. Numerical and Experimental Study of Energy Absorption of PLA Calibrated Honeycomb Structures under Quasi-Static Loading. J. Braz. Soc. Mech. Sci. Eng. 2023, 46, 26. [Google Scholar] [CrossRef]

- Niutta, C.B.; Ciardiello, R.; Tridello, A. Experimental and Numerical Investigation of a Lattice Structure for Energy Absorption: Application to the Design of an Automotive Crash Absorber. Polymers 2022, 14, 1116. [Google Scholar] [CrossRef]

- Efstathiadis, A.; Symeonidou, I.; Tsongas, K.; Tzimtzimis, E.K.; Tzetzis, D. 3D Printed Voronoi Structures Inspired by Paracentrotus Lividus Shells. Designs 2023, 7, 113. [Google Scholar] [CrossRef]

- Dávila, J.L.; Neto, P.I.; Noritomi, P.Y.; Coelho, R.T.; da Silva, J.V.L. Hybrid Manufacturing: A Review of the Synergy between Directed Energy Deposition and Subtractive Processes. Int. J. Adv. Manuf. Technol. 2020, 110, 3377–3390. [Google Scholar] [CrossRef]

- He, Y.; He, Y.; Sun, J.; Li, X.; Lu, M.H.; Chen, Y.F. Breaking Mechanical Performance Trade-off in 3D-Printed Complex Lattice-Inspired Multi-Cell Tubes under Axial Compression. Compos. Sci. Technol. 2024, 258, 110920. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, Y.; Liang, X.; Yu, W. Crashworthiness Study of Functional Gradient Lattice-Reinforced Thin-Walled Tubes under Impact Loading. Materials 2024, 17, 2264. [Google Scholar] [CrossRef]

- Tan, H.; He, Z.; Li, E.; Cheng, A.; Chen, T.; Tan, X.; Li, Q.; Xu, B. Crashworthiness Design and Multi-Objective Optimization of a Novel Auxetic Hierarchical Honeycomb Crash Box. Struct. Multidiscip. Optim. 2021, 64, 2009–2024. [Google Scholar] [CrossRef]

- Savaş, C.; Altın, M.; Güler, M.A.; Acar, E. Crushing Performance of an Additively Manufactured Bio-Inspired Hybrid Energy Absorption Profile. Mater. Test. 2024, 66, 1751–1765. [Google Scholar] [CrossRef]

- Astuti, F.A.F.; Choiron, M.A.; Purnowidodo, A.; Irawan, Y.S. Energy Absorption and Deformation Pattern of Honeycomb Hybrid Crash Box under Frontal Load. AIP Conf. Proc. 2024, 3132, 010001. [Google Scholar]

- Hidayat, D.; Istiyanto, J.; Nabilah, J.D.; Ardiansyah, R.; Saptari, S.A.; Kurniawan, F.; Sumarsono, D.A. Experimental Investigation on Axial Quasi-Static Crushing of Al/PLA Hybrid Tubes. J. Phys. Conf. Ser. 2023, 2551, 012008. [Google Scholar] [CrossRef]

- Fu, X.; Zhang, X.; Huang, Z. Axial Crushing of Nylon and Al/Nylon Hybrid Tubes by FDM 3D Printing. Compos. Struct. 2021, 256, 113055. [Google Scholar] [CrossRef]

- Kocabas, G.B.; Yalcinkaya, S.; Cetin, E.; Sahin, Y. Energy Absorption of a Novel Lattice Structure-Filled Multicell Thin-Walled Tubes Under Axial and Oblique Loadings. Adv. Eng. Mater. 2024, 26, 2400483. [Google Scholar] [CrossRef]

- Tao, C.; Zhou, X.; Liu, Z.; Liang, X.; Zhou, W.; Li, H. Crashworthiness Study of 3D Printed Lattice Reinforced Thin-Walled Tube Hybrid Structures. Materials 2023, 16, 1871. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Zhang, M.; Pei, W.; Yu, F.; Jiang, Y. Energy-Absorbing Mechanism and Crashworthiness Performance of Thin-Walled Tubes Diagonally Filled with Rib-Reinforced Foam Blocks under Axial Crushing. Compos. Struct. 2022, 299, 116149. [Google Scholar] [CrossRef]

- Sadeghzade, M.; Gharehbaghi, H.; Toozandehjani, H.; Farrokhabadi, A. Experimental Study of Energy Absorption Capability in the Lattice Structures Based on the Octagonal Bipyramid Unit Cell. J. Braz. Soc. Mech. Sci. Eng. 2023, 45, 460. [Google Scholar] [CrossRef]

- Luo, G.; Liu, J.; Li, L.; Xue, P.; Zhao, J.; Chen, Y. Crashworthiness Analysis and Multi-Objective Optimization Design for Foam-Filled Spiral Tube. Int. J. Mech. Sci. 2024, 282, 109588. [Google Scholar] [CrossRef]

| Methods | Category | Materials Used | Advantages | Disadvantages |

|---|---|---|---|---|

| SLA | Liquid-based | Photoresin liquids | High resolution |

|

| MJT | Liquid-based | Photoresin liquids |

|

|

| SLM | Powder-based | Metal alloys |

|

|

| FDM | Solid-based |

|

|

|

| AM Technique | Material | Geometry | Reference |

|---|---|---|---|

| SLA | Tough 1500 Resin | Lattice | [102] |

| R4600 Resin | Bio-Inspired Multi-Cell Tube | [103] | |

| R4600 Resin | Bio-Inspired Multi-Cell Tube | [104] | |

| MJT | VeroWhitePlus/ TangoPlus Polymers | Bio-Inspired Tube | [98] |

| VeroWhitePlus | Hierarchical Lattice | [105] | |

| DSM Somos 14120 Resin | Bio-Inspired Hierarchical Lattice | [106] | |

| SLM | Stainless Steel 316L | Multi-Cell Origami Tube | [55] |

| Stainless Steel 316L | Bio-Inspired Multi-Cell Origami Tube | [56] | |

| Stainless Steel 316L | Hierarchical Lattice | [61] | |

| Stainless Steel 304L | Origami Graded Lattice | [62] | |

| Stainless Steel 316L | Triply Periodic Minimal Surface Lattice | [64] | |

| Stainless Steel 316L | Hierarchical Triply Periodic Minimal Surface Lattice | [65] | |

| Stainless Steel 316L | Bio-Inspired Multi-Cell Tube | [72] | |

| Stainless Steel 316L | Bio-Inspired Tapered Tube | [73] | |

| Stainless Steel 316L | Bio-Inspired Hierarchical Multi-Cell Tube | [74] | |

| Stainless Steel 316L | Bio-Inspired Lattice | [110] | |

| Aluminum AlSi10Mg | Tube | [96] | |

| Aluminum AlSi10Mg | Tube | [97] | |

| Aluminum AlSi10Mg | Corrugated Tube | [109] | |

| Aluminum AlSi10Mg | Auxetic Lattice Non-Auxetic Lattice | [111] | |

| SLS | PA11 | Origami Tube | [112] |

| PA2200 | Lattice | [113] | |

| FDM | PLA Carbon Fiber | Tube | [46] |

| PLA/TPU Blend | Corrugated Tube | [47] | |

| PLA+ ABS | Multi-Cell Tube | [48] | |

| PA Carbon Fiber | Multi-Cell Tube | [49] | |

| PA Carbon Fiber | Multi-Cell Stepwise Graded Tube Multi-Cell Continuous Graded Tube | [50] | |

| PA Carbon Fiber | Origami Tube | [54] | |

| PA PA Carbon Fiber | Auxetic Lattice | [63] | |

| PA Carbon Fiber | Lattice-Filled Multi-Cell Tube | [66] | |

| PLA | Bio-Inspired Multi-Cell Tube | [71] | |

| PA | Bio-Inspired Hierarchical Lattice | [75] | |

| PA | Bio-Inspired Hierarchical Lattice | [76] | |

| PLA+ PLA-LW PLA-ST | Multi-Cell Tube | [82] | |

| PLA PETG ABS ASA PA Carbon Fiber | Lattice | [83] | |

| PLA PETG | Lattice | [84] | |

| PLA | Origami Tube | [85] | |

| PLA | Multi-Cell Tube | [86] | |

| PA PA Carbon Fiber PA Glass Fiber | Tube | [91] | |

| PA Carbon Fiber | Multi-Cell Tube | [92] | |

| PLA PLA/TPU PLA/PA | Auxetic Lattice Non-Auxetic Lattice | [99] | |

| PLA/Ramie Yarn Fiber | Tube | [42] | |

| PLA | Tube | [117] | |

| PLA | Lattice | [118] | |

| PA Carbon Fiber | Lattice | [119] | |

| PLA | Bio-Inspired Lattice | [120] | |

| Hybrid Manufacturing Technique | Aluminum/PLA Carbon Fiber | Multi-Cell Tube | [126] |

| Aluminum/PLA | Multi-Cell Tube | [127] | |

| Aluminum/PA | Multi-Cell Tube | [128] | |

| Aluminum Al1060/ Aluminum AlSi10Mg | Tube/Gradient Lattice | [130] | |

| Aluminum Al6063–T5 /Aluminum AlSi10Mg | Multi-Cell Tube/Lattice | [129] | |

| Aluminum/Foam Aluminum/PLA Aluminum/Foam/PLA | Multi-Cell Tube/Foam | [131] | |

| PA/Foam PLA/Foam | Lattice/Foam | [132] | |

| Stainless Steel 316L/PLA | Spiral Tube/Foam | [133] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Saber, A.; Amer, A.M.; Shehata, A.I.; El-Gamal, H.A.; Abd_Elsalam, A. Recent Developments in Additively Manufactured Crash Boxes: Geometric Design Innovations, Material Behavior, and Manufacturing Techniques. Appl. Sci. 2025, 15, 7080. https://doi.org/10.3390/app15137080

Saber A, Amer AM, Shehata AI, El-Gamal HA, Abd_Elsalam A. Recent Developments in Additively Manufactured Crash Boxes: Geometric Design Innovations, Material Behavior, and Manufacturing Techniques. Applied Sciences. 2025; 15(13):7080. https://doi.org/10.3390/app15137080

Chicago/Turabian StyleSaber, Ahmed, A. M. Amer, A. I. Shehata, H. A. El-Gamal, and A. Abd_Elsalam. 2025. "Recent Developments in Additively Manufactured Crash Boxes: Geometric Design Innovations, Material Behavior, and Manufacturing Techniques" Applied Sciences 15, no. 13: 7080. https://doi.org/10.3390/app15137080

APA StyleSaber, A., Amer, A. M., Shehata, A. I., El-Gamal, H. A., & Abd_Elsalam, A. (2025). Recent Developments in Additively Manufactured Crash Boxes: Geometric Design Innovations, Material Behavior, and Manufacturing Techniques. Applied Sciences, 15(13), 7080. https://doi.org/10.3390/app15137080