Abstract

Ensuring employee safety is a top priority for every enterprise, and it is especially critical in high-risk industries like coal mining. To achieve this goal, it is essential to focus efforts on identifying existing hazards and thoroughly assessing the associated risks. Accurate identification and detailed characterization of occupational hazards play a pivotal role in the occupational risk assessment process, providing the foundation for effective safety strategies. This article presents an analysis of the process of identifying occupational hazards in hard coal mining, based on applicable legal regulations and a review of the relevant literature. The analysis reveals, on the one hand, a diversity of approaches to hazard classification, and on the other, a limited use of the characteristic features of hazards in classification processes. The findings of this review form the basis for proposing a systematic classification of occupational hazards in hard coal mining, taking into account the specific features of hazards in relation to their sources and potential consequences. The proposed classification not only categorizes hazards but also describes the specifics of hazard sources, such as environmental conditions, machinery, chemicals, and human factors, as well as the possible outcomes of these hazards, including physical injury, health impacts, and even fatalities. The aim of this article is to present a proposed classification of occupational hazards in hard coal mining and to provide a detailed characterization of these hazards based on the description of their sources and potential consequences. The proposed approach, grounded in the identification of characteristic features of hazards, facilitates the effective selection of preventive measures that can be implemented to reduce risk and improve workplace safety. Due to the presence of the full spectrum of natural hazards in Polish hard coal mining, the analysis draws on available statistical data, focusing on those hazards that contribute most significantly to fatal accidents and serious injuries. In conclusion, the article emphasizes the importance of a structured and systematic approach to identifying and assessing occupational hazards in the coal mining industry. By drawing on legal and literature-based insights, it aims to contribute to the development of more effective safety practices that protect workers and minimize the occurrence of workplace accidents and illnesses.

1. Introduction

In underground mining, the level of occupational risk is determined by the presence of numerous hazards of diverse nature—including traditional occupational hazards, machinery-related risks, exposure to workplace environmental factors, excessive physical workloads, threats arising from work organization, and individual characteristics or behaviors, as well as natural hazards. These hazards may be classified according to various criteria, such as root causes, mechanism of action, consequences, measurability, internal or external origin, and the type of preventive measures applied.

A review of existing classifications of occupational hazards in the mining industry reveals that no single, comprehensive, and universal system currently exists—one that would account for all relevant hazards stemming from technological processes and machinery, natural conditions, and human factors. This observation served as the foundation for developing the classification proposed in this study.

The existence of occupational risk leads to accidents as well as diseases and, in specific situations, may result in failures and disasters. Ensuring employee safety and developing a safety culture [1] is a priority for every enterprise. Focusing efforts on identifying existing hazards and assessing the associated risks enables the achievement of this goal.

The essence of the occupational hazard identification process lies in the detailed characterization of factors that influence the consequences and likelihood of an event occurring. The more precisely we define and examine the existing hazards, the more accurately we can assess the associated risk. In every activity, decision-makers strive to avoid the consequences of identified risks or reduce the likelihood of their occurrence. This is particularly crucial in industrial operations, where risks are an inherent part of daily activities, and the entire enterprise management process must be fundamentally based on risk management.

The risk assessment process begins with identifying its underlying causes, particularly the factors that constitute sources of occupational hazards. The more thoroughly these factors and the associated hazards are understood and characterized, the more accurately occupational health risks can be assessed. Consequently, this facilitates the implementation of preventive measures directly targeting the root causes/sources of these hazards, thereby enhancing workplace safety and minimizing the likelihood of adverse events.

The guidelines and principles for the identification and classification of occupational hazards are derived from various sources, including applicable legal regulations, standardization documents, statistical forms and registers, as well as the results of accident analyses.

The legal framework in force in Poland [2,3,4,5] introduces diverse criteria and varying levels of detail in hazard classification. The list of hazards resulting from measurable physical factors includes those that pose a threat to workers’ health, with specified maximum allowable concentrations and intensities. Hazard classifications are also included in the ‘Z-10 Workplace Conditions Report’ form [6] and are further supported by accident investigation analyses [6,7,8,9,10,11], which identify material, organizational, and human factors as primary sources of workplace incidents. Table 1 presents a comparative summary of classifications based on the three analyzed sources.

Table 1.

Classification of identified hazard sources according to the type of analyzed source.

According to data from the Poland Statistics Office (GUS) for 2023 [10], the unsafe behaviors mentioned earlier may account for 70% or more of workplace accident causes. Therefore, they are a critical and non-negligible element in the risk assessment process.

The Polish Standard PN-Z-08052:1980 [12] provides general definitions of hazard sources, as follows:

- −

- A hazardous factor is a factor whose impact on a worker leads or may lead to injury.

- −

- A harmful factor is a factor whose impact on a worker leads or may lead to an illness.

Additionally, PN-N-18001:2004, which has been replaced by PN-ISO 45001:2024 [13,14], introduced the definition of a burdensome factor as a factor whose impact on a worker may cause discomfort or excessive fatigue but does not lead to permanent deterioration of health. An essential standardization act in the field of hazard identification is the Standard ISO 12100-1:2012 [15]. This standard defines risk assessment principles related to machine safety and provides a hazard classification. It is particularly applicable to machine design and identifies the following hazard categories:

- −

- Mechanical hazards;

- −

- Electrical hazards;

- −

- Thermal hazards;

- −

- Hazards caused by noise;

- −

- Hazards caused by vibrations;

- −

- Hazards caused by radiation;

- −

- Hazards related to materials and substances (e.g., chemical and dust hazards, fire and explosion risks, biological hazards);

- −

- Hazards resulting from non-compliance with ergonomic design principles;

- −

- Hazards caused by machines (e.g., physical and mental workload, human errors);

- −

- Slips, trips, and falls;

- −

- Combination of hazards;

- −

- Hazards related to the environment in which the machine is used (e.g., temperature, wind, snow, lighting conditions).

Due to the specific nature of mining hazards, their identification must also consider natural hazards, which are defined as follows [16]:

- −

- Gas hazard—“A natural hazard in underground gas mines arising from gases accumulated in the rock mass, particularly methane and carbon dioxide, which pose a threat, especially in cases of unexpected and sudden emissions (gas and rock outbursts) or intensified gas release.”

- −

- Fire hazard—“The occurrence of open flames in mine workings or the presence of fire gases and smoke in the mine atmosphere originating from underground fires.”

- −

- Dust hazard—“A natural hazard in mines resulting from the presence of fine dust in the air, particularly stone dust, which can cause occupational lung diseases (coal workers’ pneumoconiosis and silicosis). The current classification of natural hazards [4] no longer lists this hazard as a natural one.”

- −

- Water hazard—“A natural hazard that may occur in mines due to the unexpected intrusion of water into workings from underground or surface reservoirs.”

- −

- Explosion hazard—“A natural hazard in mines related to the explosion of gases and, in coal mines, coal dust explosions, which can be triggered by faulty electrical equipment (sparking) or other factors (e.g., blasting operations).”

The characteristics of natural hazards in coal mines have been described in several studies [17], covering the following risks:

- −

- Rock bursts;

- −

- Gas hazard;

- −

- Dust hazard;

- −

- Water hazards;

- −

- Roof collapses;

- −

- Endogenous fires;

- −

- Combined hazards;

- −

- Technical hazards.

It is important to note that numerous publications [6,8,17,18,19,20,21,22,23] discuss natural mining hazards not only listed in legal requirements [23] but also other significant risks. These include endogenous fire hazards, which arise from the natural tendency of coal to spontaneous combustion [24,25]; combined hazards, resulting from the interaction between different natural hazards [17,24,25,26,27]; and gaso-geodynamic hazards, recently defined as a combination of rock burst and methane hazards [21]. The characteristics of occupational hazards in mining have been extensively discussed in various publications [17,28]. The main sources of hazards are categorized into five key factors: physical, chemical, biological, ergonomic, and psychosocial hazards. For the mining industry, the most characteristic hazard groups include traumatic hazards (with natural hazards), ergonomics-related hazards [29,30], noise exposure, and psychosocial hazards.

Natural hazards, along with those resulting from work processes, mechanization, and work organization in mining, are most commonly classified into three main groups [24]:

- −

- Natural hazards;

- −

- Technical hazards;

- −

- Human-related hazards.

The hazard identification stage is considered a critical step in the overall risk assessment process. This stage involves the use of both formal and informal techniques [31,32] to recognize potential risks, which is referred to as hazard characterization. Informal techniques include:

- −

- Workplace observations;

- −

- Interviews;

- −

- Occupational health and safety (OHS) committee meetings;

- −

- Professional experience;

- −

- Employee consultations;

- −

- Safety audit results.

Some authors [33] emphasize, however, that relying solely on employees’ knowledge and experience—an informal approach to hazard identification—does not ensure that hazards will be correctly recognized. Therefore, it is crucial to employ formal hazard identification methods [31] specifically designed for this process. Other researchers [34] have developed a catalog of 250 potential hazards for workers in gold mines and applied the multi-criteria AHP (Analytic Hierarchy Process) method in the occupational risk assessment process [34,35]. The developed catalog [34] could also be useful in hazard identification processes in hard coal mining. Furthermore, the literature [1] highlights several frequently recurring hazards, including those associated with machinery, falls from height, workplace cleanliness, material storage, movement through mine roadways, and hazardous substances—all of which should not be overlooked in the hazard identification process. In summary, in the hazard identification process in the workplace, it is essential to consider all the discussed registers, lists, catalogs, and classifications.

The main objective of the presented study is to develop a structured classification of occupational hazard factors that can support the identification, analysis, and assessment of risk, as well as the planning of preventive measures in the hard coal mining industry.

2. Materials and Methods

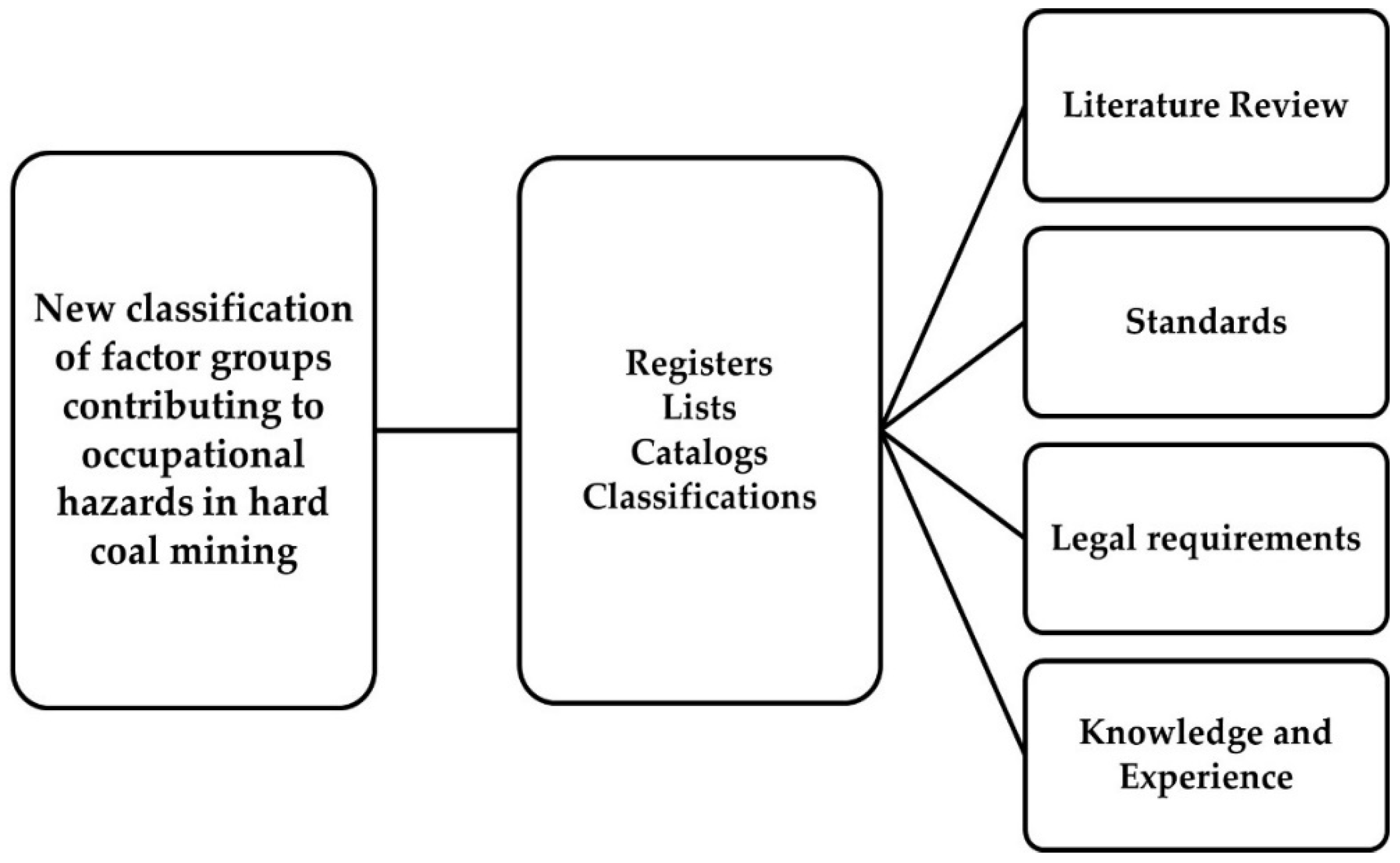

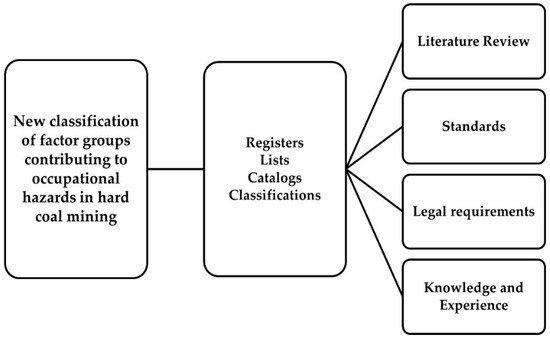

To develop an original classification of factors contributing to occupational hazards in hard coal mining, the approach was based on a comprehensive review of sources, including scientific literature, technical standards, legal requirements, as well as expert knowledge and professional experience. The methodology involved the following stages:

- −

- Review of scientific literature—identification of hazards as described in research studies, technical reports, and industry publications;

- −

- Analysis of standards and legal regulations—consideration of current regulatory requirements related to occupational health and safety in mining operations;

- −

- Incorporation of expert knowledge—consultations with practitioners and subject-matter experts, leveraging professional field experience.

The systematization of the gathered information involved compiling and comparing data from various sources (in the form of lists, inventories, and hazard catalogs), which enabled the authors to distinguish four categories of contributing factors and to develop a structured and systematic classification of mining-related hazards for the purposes of occupational risk assessment.

2.1. Groups of Occupational Hazard Factors

Based on the sources outlined in Figure 1, the following groups of factors contributing to the occurrence of occupational hazards in hard coal mining are proposed for distinction:

Figure 1.

Sources of the new classification of factor groups contributing to occupational hazards in hard coal mining.

- −

- Natural hazardous factors: These originate from the natural properties of the rock mass and geological phenomena. In coal mining, these include methane ignition and explosion, coal dust explosion, seismic tremors and rock bursts, gas and rock outbursts, water intrusion, and endogenous fires.

- −

- Technical hazardous factors: These result from the technical work environment and include machinery and tools and their usage; installations and technological processes, including mining and transportation systems; workplace conditions and access routes; and work activities related to technical operations, materials, and substances used in mining, including chemicals and other hazardous materials.

- −

- Harmful and burdensome factors: These contribute to gradual health deterioration or temporary health issues. The most common in mining include vibrations, noise, radiation (infrared, UV, electromagnetic, visible, laser), radioactive substances, lighting conditions, microclimate conditions, hazardous substances and mixtures, biological hazards, and static and dynamic workload.

- −

- Organizational and human factors: These relate to procedures, compliance, stressors, and human-related issues, often referred to as “human factors” in workplace safety. They include procedural and instructional compliance, violation of safety rules, workload imbalances (excessive or insufficient workload, qualitative or quantitative), role conflicts, physical working conditions, workplace distractions, worker fatigue, employee competence and training, communication errors, and the psychophysical state of employees.

The proposed comprehensive classification provides a structured approach to hazard identification in hard coal mining, ensuring broad and extensive identification of risk factors.

2.2. Characteristics of Occupational Hazards

According to the definition [12], “hazard identification” is not merely the process of recognizing hazards but, more importantly, determining their characteristic features. As stated in [5], “characterization” refers to the description of features that define a person or object, while a “feature” is an element that distinguishes or defines living beings, objects, their activities, conditions, or phenomena.

In the context of hazard characterization, this means establishing the defining characteristics of each identified hazard. However, in business practices, occupational risk assessments often omit this step, failing to document or analyze the key attributes of hazards.

Conducting hazard identification solely to confirm the existence of a hazard is insufficient for selecting the appropriate risk assessment method [6,11,14,32,36,37,38,39]. This limitation can lead to situations where an incorrect assessment method is applied, failing to identify the need for risk control measures.

The primary reasons for omitting hazard characterization include:

- −

- The use of a single, pre-selected risk assessment method chosen before a detailed analysis of hazard characteristics.

- −

- A lack of exploration into alternative risk assessment techniques, which reduces the credibility of the results.

Determining the characteristic features of hazards is a critical process in which a detailed hazard description is established. Without this step, risk assessments may fail to accurately reflect workplace hazards, leading to ineffective safety measures. A comprehensive approach integrating hazard characterization ensures a more reliable and effective occupational risk management process. Both literature data and standards indicate that the following aspects should be considered when determining hazard characteristics [17]:

- −

- Physicochemical data of chemical compounds and dust;

- −

- Descriptions of energy types, including their values (e.g., reactivity, concentration, voltage, current, kinetic energy, potential energy, electrical energy, etc.);

- −

- Information on work methods and organization, including duration, load, work techniques, working posture, cycle count, and task repetition;

- −

- Effects of hazards, such as injuries, illnesses, and work-related discomfort;

- −

- Statistical data for probability estimation (e.g., accident records, severity, and frequency);

- −

- Legal requirements and literature data, including safety data sheets for hazardous substances, biological agent product sheets, and technical material information sheets;

- −

- Threshold values for harmful exposure (e.g., Threshold Limit Values, TLVs).

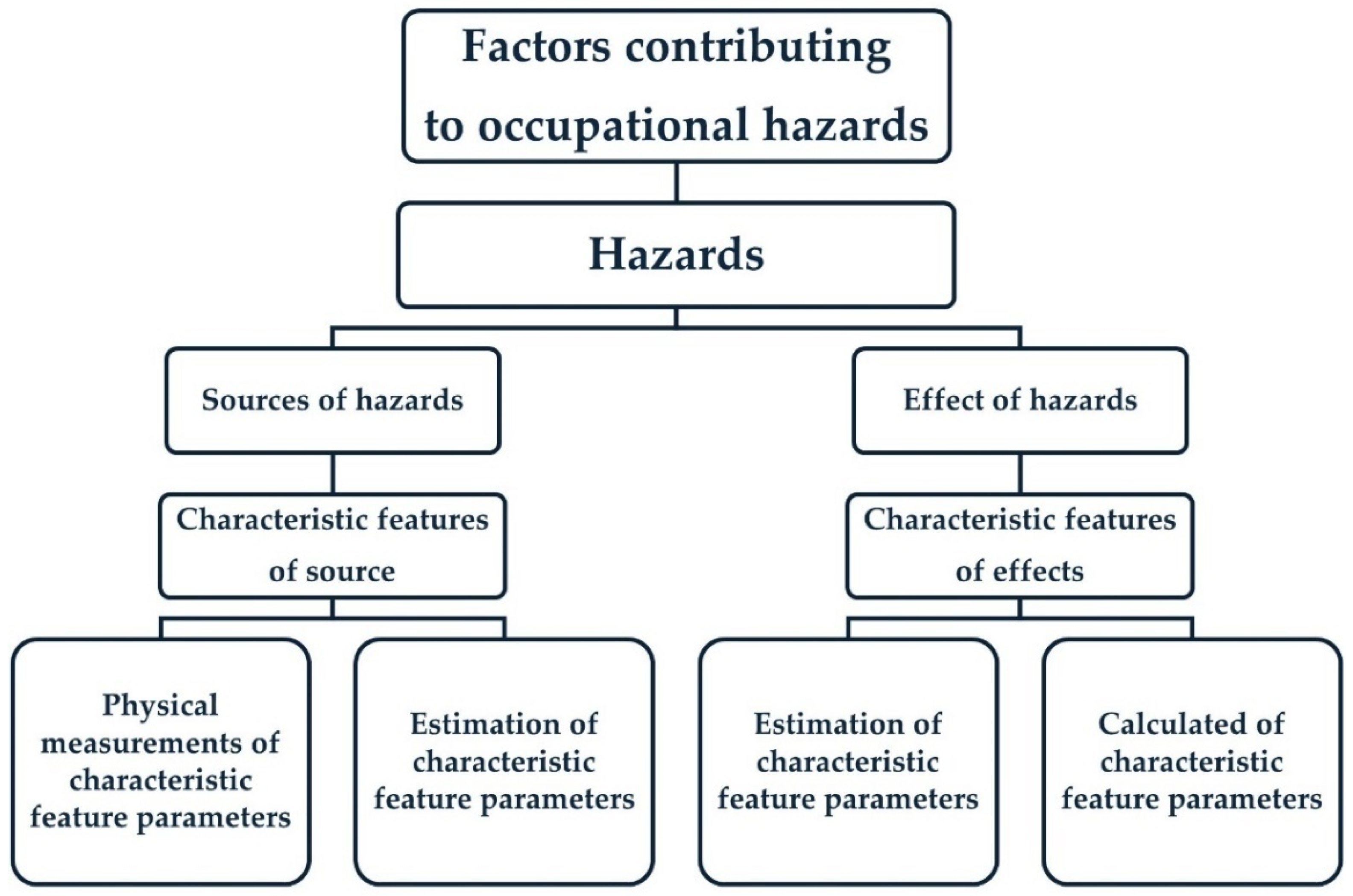

Hazard classification can be conducted based on various criteria, including causes, nature of effects, consequences, measurability, external and internal causes, and applied preventive measures [17,40]. These criteria can simultaneously serve as characteristic features of hazards.

The explanatory notes for the “Z-10 Workplace Conditions Report” form [10] provide examples of features of selected factors, which, when a person comes into contact with a hazardous factor, may lead to injuries. For instance, mechanical hazards related to particularly dangerous machines can be described using the following characteristic features: kinetic and potential energy (including pressurized fluids), shape, dimensions, surface properties, stability, and mechanical strength. Publications related to hazard identification focus on two primary aspects:

- −

- Hazard sources;

- −

- Consequences of hazards.

To enhance hazard characterization, two types of features have been established:

- −

- Characteristics of hazard sources;

- −

- Characteristics of hazard effects.

A parameter is defined as a variable considered constant within a specific context, either to highlight its distinct role in relation to other variables or to represent a characteristic value specific to a material, process, or device [5]. In the context of hazard characterization, parameters of characteristic features can be expressed as measured values of physical quantities, obtained through direct measurement or estimated values, where the parameter describing the characteristic feature can only be determined approximately.

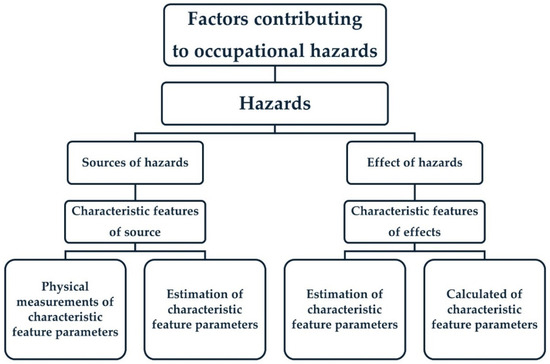

Considering the above, a hazard identification algorithm incorporating characteristic features and their parameters can be proposed (Figure 2).

Figure 2.

Algorithm for hazard identification considering characteristic features and their parameters.

Both sources of hazards and their consequences are described using their characteristic features. Characteristic features of sources describing the origin of a hazard, which can be further evaluated based on:

- −

- Physical measurements (e.g., kinetic energy, pressure, noise levels).

- −

- Estimations (e.g., qualitative assessments of hazard potential).

Characteristic features of consequences describing the impact of hazards on individuals, equipment, or processes can be further evaluated based on:

- −

- Estimations (e.g., probability of injury occurrence).

- −

- Calculated parameters (e.g., risk index values derived from mathematical models).

This approach enables a structured identification and classification of hazards, ensuring a more precise risk assessment.

3. Results

The approach utilizing characteristic features enables a structured identification and classification of hazards, ensuring a more precise risk assessment. It is proposed that the hazard identification process be carried out by developing a detailed characterization of each hazard-inducing factor, specifying both the sources of the hazard and its consequences. Therefore, to conduct a comprehensive hazard characterization, the first step should involve determining its characteristic features in accordance with the proposed algorithm (Figure 2).

These features should describe both the source and consequences of hazards with the highest possible precision, comprehensiveness, and extensiveness. Table 2, Table 3, Table 4 and Table 5 present an original compilation of characteristic features for the most common mining hazards, divided into characteristic features of hazard sources and characteristic features of hazard consequences. This classification follows the hazard categories adopted in this study: technical hazardous factors, natural hazardous factors, organizational and human factors, and harmful and burdensome factors.

Table 2.

Characteristic features of natural hazardous factors.

Table 3.

Characteristic features of technical hazardous factors.

Table 4.

Characteristic features of harmful and burdensome factors.

Table 5.

Characteristic features of organizational and human factors.

3.1. Characteristics of Natural Hazardous Factors

The first group of hazards comprises natural hazardous factors. Proposed descriptions of the sources and consequences of hazards in this group are provided in Table 2.

The table does not include characteristics of the effects of each factor. These characteristics include the number of incidents, types of injuries, number of affected persons, and incidence of injuries, and they are basically consistent across all natural factors.

3.2. Characteristics of Technical Hazardous Factors

The second group of hazards consists of technical hazardous factors. Proposals for describing the technical hazardous factor are provided in Table 3.

The table does not include the characteristics of the effects of each factor. These characteristics include the number of incidents, types of injuries, and number of affected persons for all technical factors.

3.3. Characteristic Features of Harmful and Burdensome Factors

These two categories are addressed jointly, as they typically originate from the same sources and their differentiation is based solely on the intensity or concentration levels of the respective exposure. For example, noise can illustrate this overlap: sound levels around 60 dB may impair concentration and cause discomfort during cognitively demanding tasks, thus being classified as burdensome. Only when the permissible exposure limits are exceeded can it be recognized as a harmful factor.

The table does not include characteristics of the effects of each factor. These characteristics include the number of incidents, number and type of injuries, number of errors, number of affected persons, and incidence of injuries, and they are basically consistent for all harmful and troublesome factors.

3.4. Characteristics of Organizational and Human Factors

The final group of hazards, according to the proposed classification, includes organizational and human factors. Proposed descriptions of hazard sources and their consequences for this group are presented in Table 5.

The above table does not include columns containing repetitive phrases related to the characteristic features of hazard consequences, as these are common across all listed hazards. These features include the number of illnesses and injuries and the type of illnesses and injuries.

For the four distinguished groups of factors, the effects of their impact are of a similar nature—they are primarily concentrated on the type and number of injuries or health problems they may cause. However, it should be emphasized that certain workplace environmental factors, classified as harmful factors, under specific conditions (e.g., at high intensity or concentration levels), may produce effects characteristic of another group. That group includes hazardous factors capable of causing injuries. In such cases, the critical elements are the concentration or intensity values of the source, as well as the type and severity of the resulting injury, which depend on the level of the factor’s impact on the worker’s body. An example may include extremely loud noises leading to immediate hearing damage or toxic substances, which, in large quantities, can cause severe injuries or even death.

4. Discussion

In the proposed classification of factors influencing the occurrence of occupational hazards in hard coal mining, the first group consists of natural hazardous factors. Polish hard coal mining is characterized by the presence of all natural hazards typically associated with underground operations. The manifestation of these hazards—particularly methane hazard and rock bursts—results in the highest number of fatal and serious accidents compared to other groups of factors.

4.1. Accident Rates in Hard Coal Mining in the Years 2020–2024

In 2024, hard coal extraction in Poland was carried out in 19 mines, with a total output of 43,740.3 thousand Mg and an employment figure of 112,489 workers [22].

During the period of 2020–2024, a total of 9151 accidents were recorded, including 67 fatal accidents and 28 serious accidents (Table 6) [22].

Table 6.

Accident rates in Polish hard coal mining in the years 2020–2024.

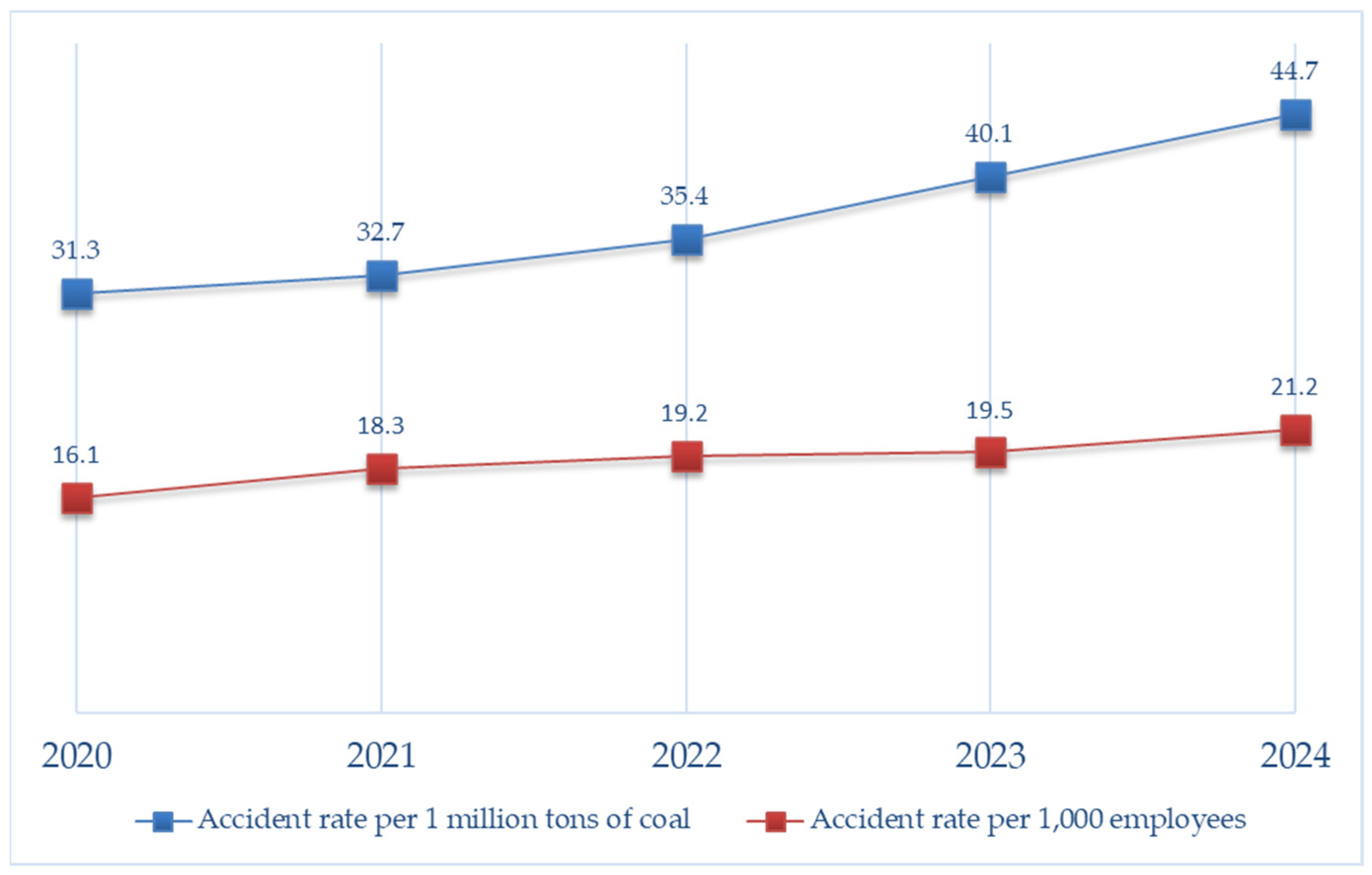

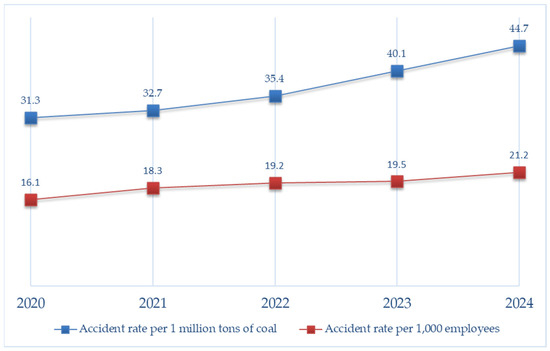

During the analyzed period, the overall accident rate per 1 million tons of extracted coal ranged from 31.3 to 44.7, while the rate per 1000 employees varied between 16.1 and 21.2 (Figure 3) [22].

Figure 3.

Overall accident rates per 1 million tons of extracted coal and per 1000 employees in the years 2020–2024 [22].

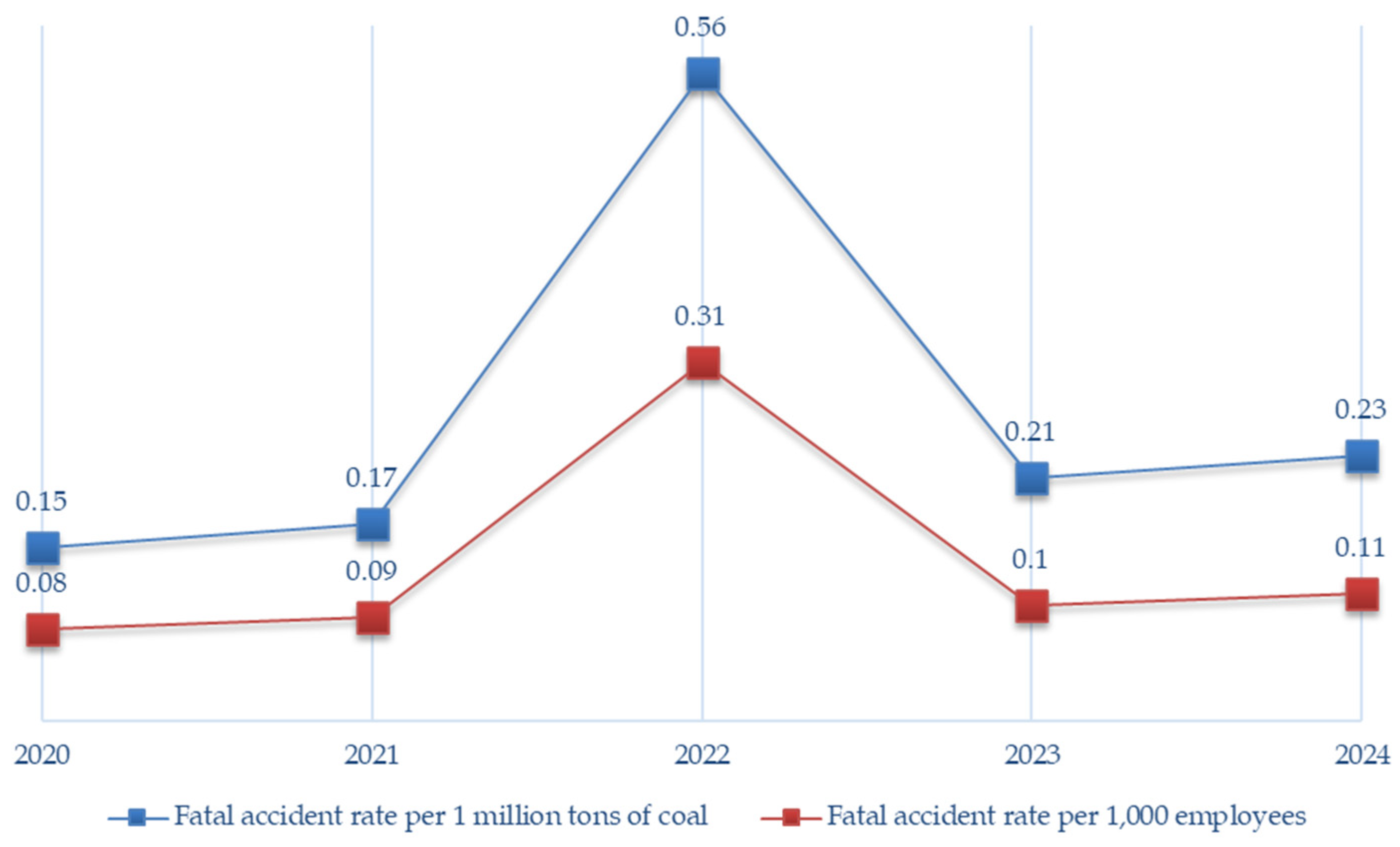

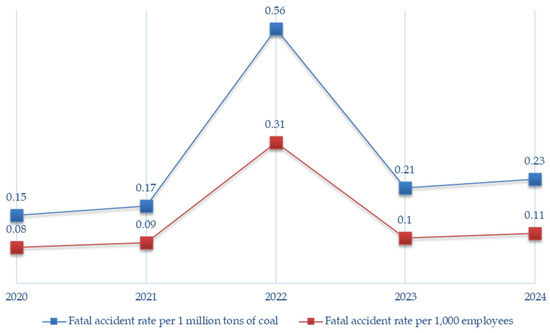

The fatal accident rate per 1 million tons of extracted coal ranged from 0.15 to 0.56, while the rate per 1000 employees ranged from 0.08 to 0.31 (Figure 4) [22].

Figure 4.

Fatal accident rates per 1 million tons of extracted coal and per 1000 employees in Polish hard coal mining in the years 2020–2024 [22].

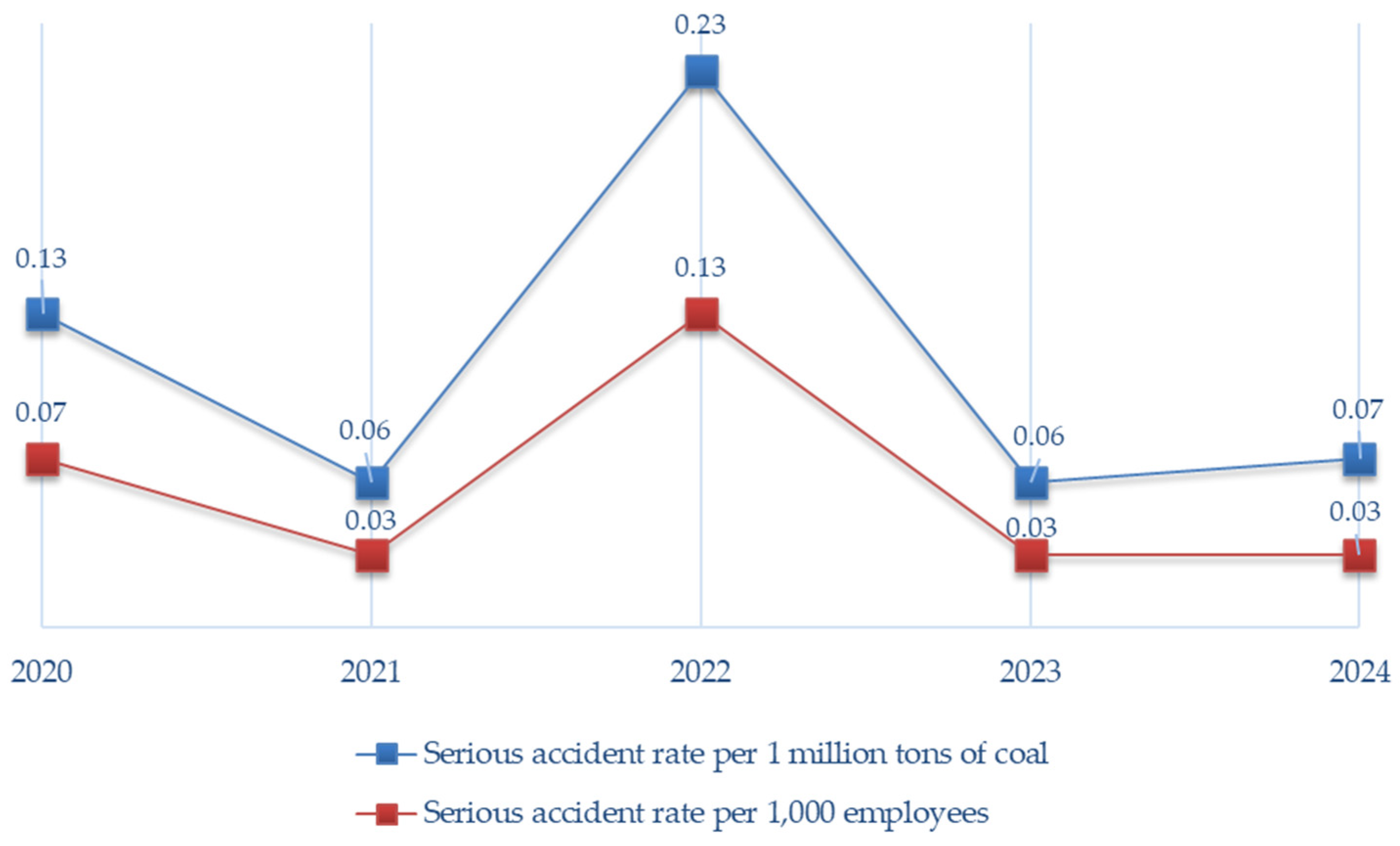

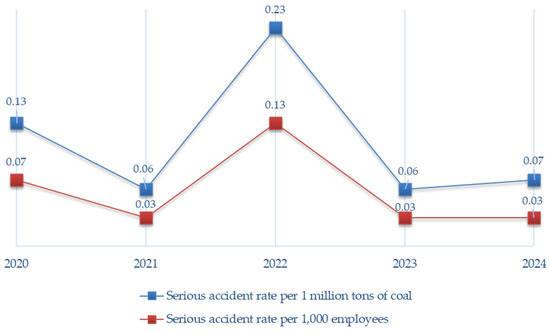

The serious accident rate per 1 million tons of extracted coal ranged from 0.03 to 0.23, while the rate per 1000 employees ranged from 0.06 to 0.13 (Figure 5) [22].

Figure 5.

Serious accident rates in hard coal mines per 1 million tons of extracted coal and per 1000 employees in the years 2020–2024 [22].

The highest values of fatal and serious accident rates in 2022 were caused by the occurrence of methane hazards and rock bursts, while the elevated fatal accident rates in 2023 and 2024 resulted from rock burst hazards.

The main causes of accidents in the years 2020–2024 were [22]:

- −

- Tripping, slipping, or falling of individuals;

- −

- Falling, sliding, or collapsing of rock masses and blocks, roof falls, and sidewall displacements;

- −

- Being struck by work tools or other objects;

- −

- Falling, sliding, or shifting of objects/materials;

- −

- Atmosphere unsuitable for breathing;

- −

- Shock wave from a methane explosion and high temperatures.

4.2. Accident Rates in Hard Coal Mining Due to Natural Hazards

In the years 2020–2024, hazardous events and accidents in Polish hard coal mines occurred as a result of the manifestation of methane-related hazards, rock bursts, and endogenous fires. For other natural hazards (coal dust explosions, gas and rock outbursts, and water hazards), no incidents or accidents were recorded during the analyzed period.

4.2.1. Methane Hazard

Methane hazard is present in 16 hard coal mines in Poland, with 11 mines operating in seams classified under the highest, fourth category of methane hazard.

In 2024, a total of 722.1 million cubic meters of methane was emitted during mining operations, with a methane emission rate of 16.5 m3 per ton of extracted coal [22].

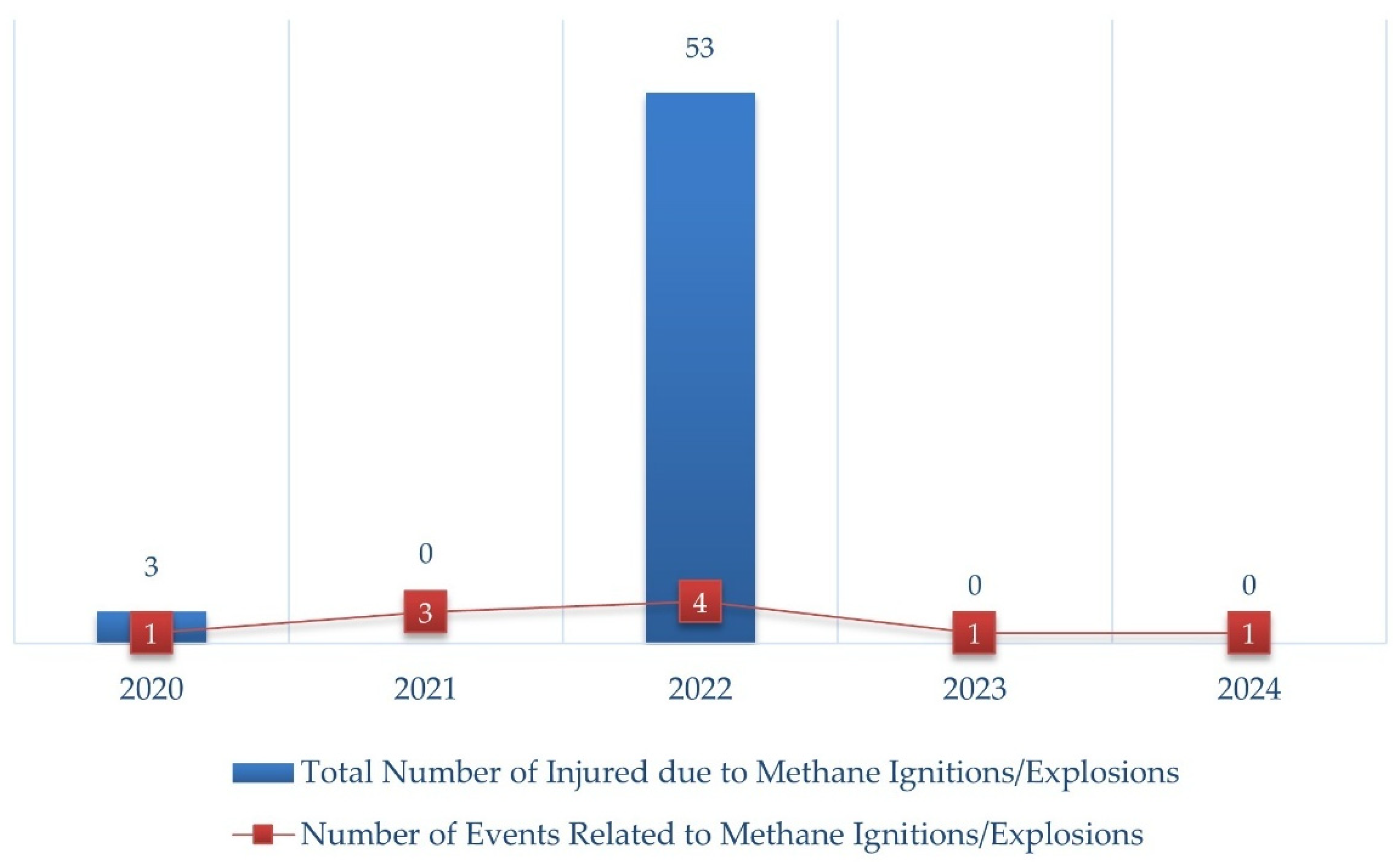

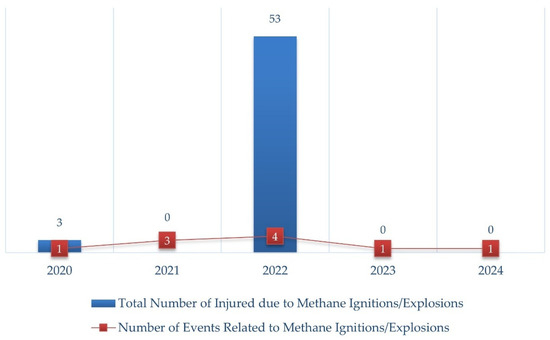

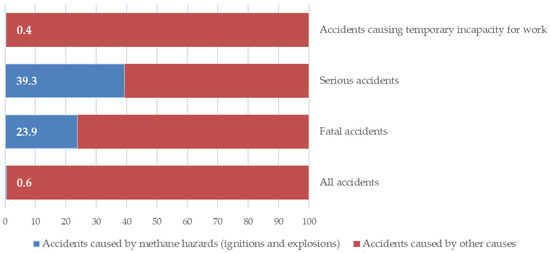

During the period of 2020–2024, there were nine instances of methane ignition and one methane explosion. These incidents resulted in 16 fatal accidents, 7 serious accidents, and 33 accidents causing temporary incapacity for work (Figure 6) [22].

Figure 6.

Number of methane ignitions, explosions, and related accidents in the years 2020–2024 [22].

In 2022, a methane explosion occurred at the “Pniówek” mine, resulting in 16 fatal accidents, 7 serious accidents, and 25 accidents causing temporary incapacity for work. The causes of these accidents were the effects of the explosion on the workers, namely the shock wave, high temperatures, and fire gases.

4.2.2. Rock Burst Hazard

Rock burst hazards are present in 15 hard coal mines in Poland, with 10 mines operating in seams classified under the second highest degree of rock burst hazard. In 2024, a total of 2112 high-energy seismic events (with energy ≥ 1 × 105 J) were recorded, with a cumulative energy release of 2.90 GJ.

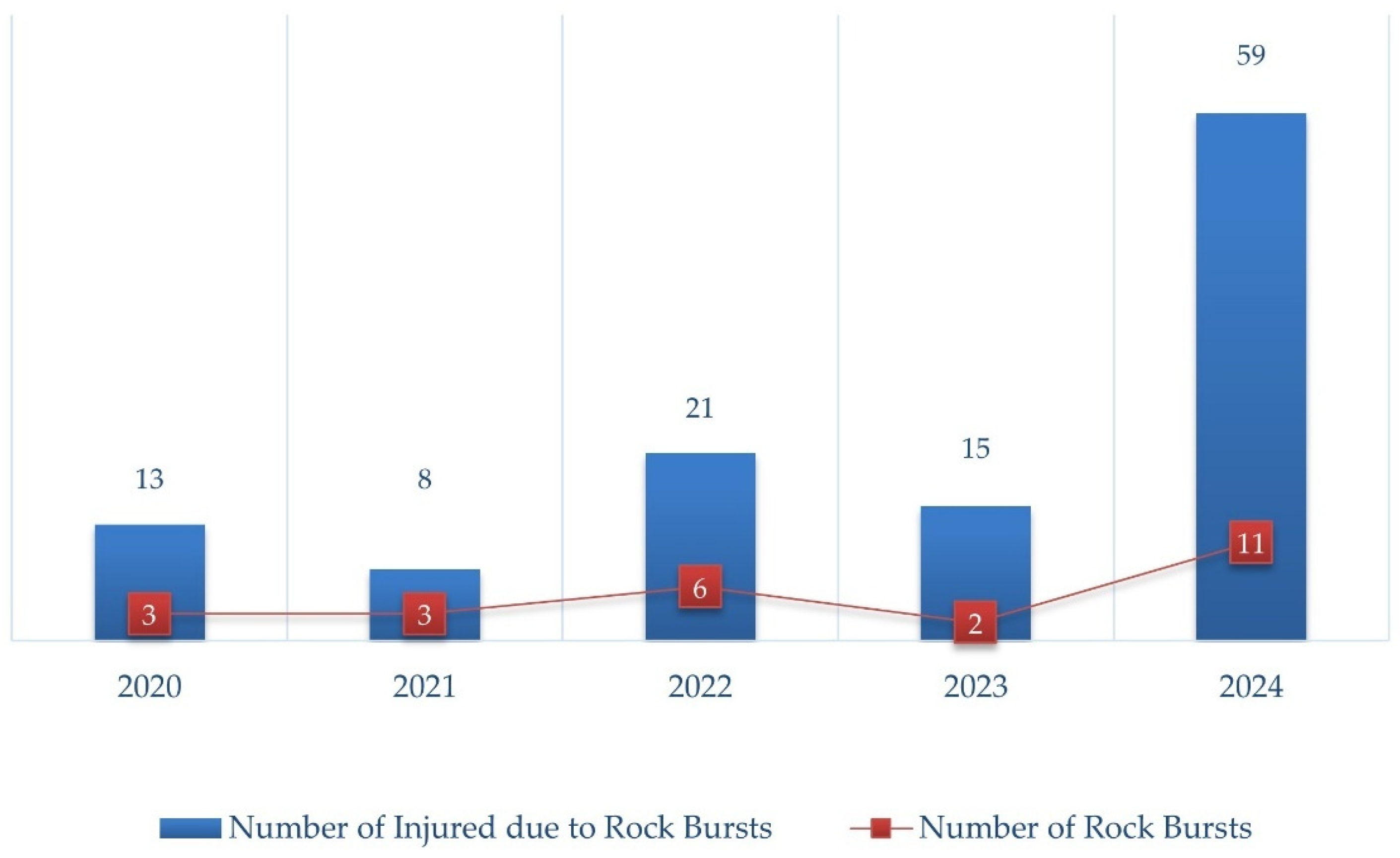

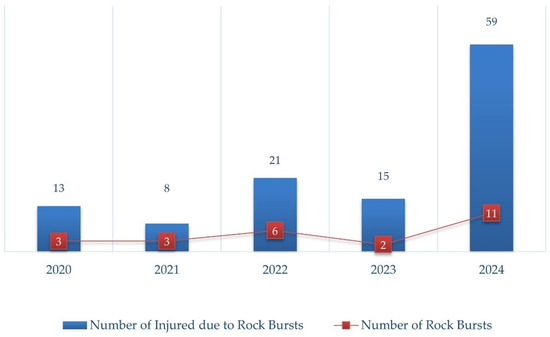

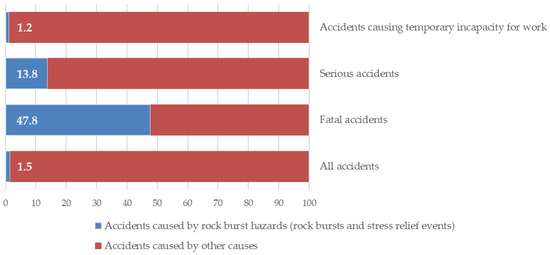

Eleven of these seismic events caused three rock bursts and eight stress relief events (incidents with lesser impacts within the workings), resulting in 7 fatal accidents and 61 accidents causing temporary incapacity for work [22]. During the period of 2020–2024, there were 10 rock bursts and 15 stress relief events, leading to 32 fatal accidents, 4 serious accidents, and 104 accidents causing temporary incapacity for work (Figure 7) [22].

Figure 7.

Number of rock bursts, stress relief events, and related accidents in the years 2020–2024 [22].

In 2022, a rock burst occurred at the “Borynia-Zofiówka” mine, resulting in fatal accidents involving 10 workers. Apart from causing significant damage to the mine workings, the rock burst led to a sudden release of methane and an increase in its concentration to 100%; a total of 124,522 cubic meters of methane was released. The causes of the accidents were the release of methane creating an atmosphere unsuitable for breathing and the dynamic effects of the rock burst on the victims. In the case of other rock bursts and stress relief events, the accidents were caused by the dynamic impact of these phenomena on the workers.

4.2.3. Endogenous Fire Hazard

Endogenous fire hazards are present in all hard coal mines in Poland. In the years 2020–2024, there were 13 endogenous fires reported, none of which resulted in any accidents. The early detection of fire symptoms allowed for the safe evacuation of personnel from the endangered areas.

4.3. Accident Rates Due to Natural Hazards Compared to Overall Accident Rates

In the years 2020–2024, a total of 48 hazardous events associated with the manifestation of methane hazards, rock bursts, and endogenous fires occurred. These events included methane ignitions and explosions, rock bursts, and stress relief events, as well as endogenous fires (Table 7):

Table 7.

Hazardous events resulting from natural hazards in the years 2020–2024.

In cases in which methane and rock burst hazards manifested, these events resulted in accidents (Table 8).

Table 8.

Accident rates resulting from natural hazards in the years 2020–2024.

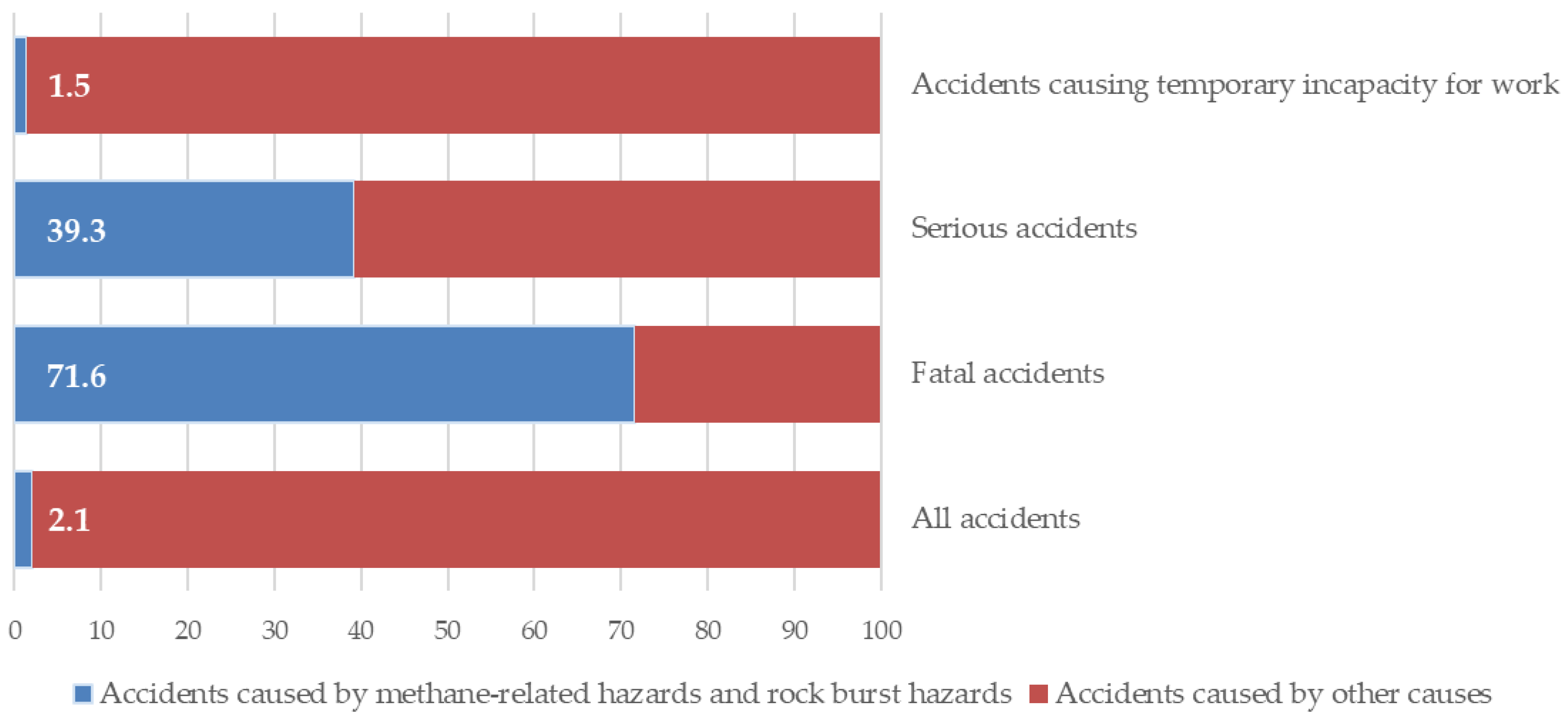

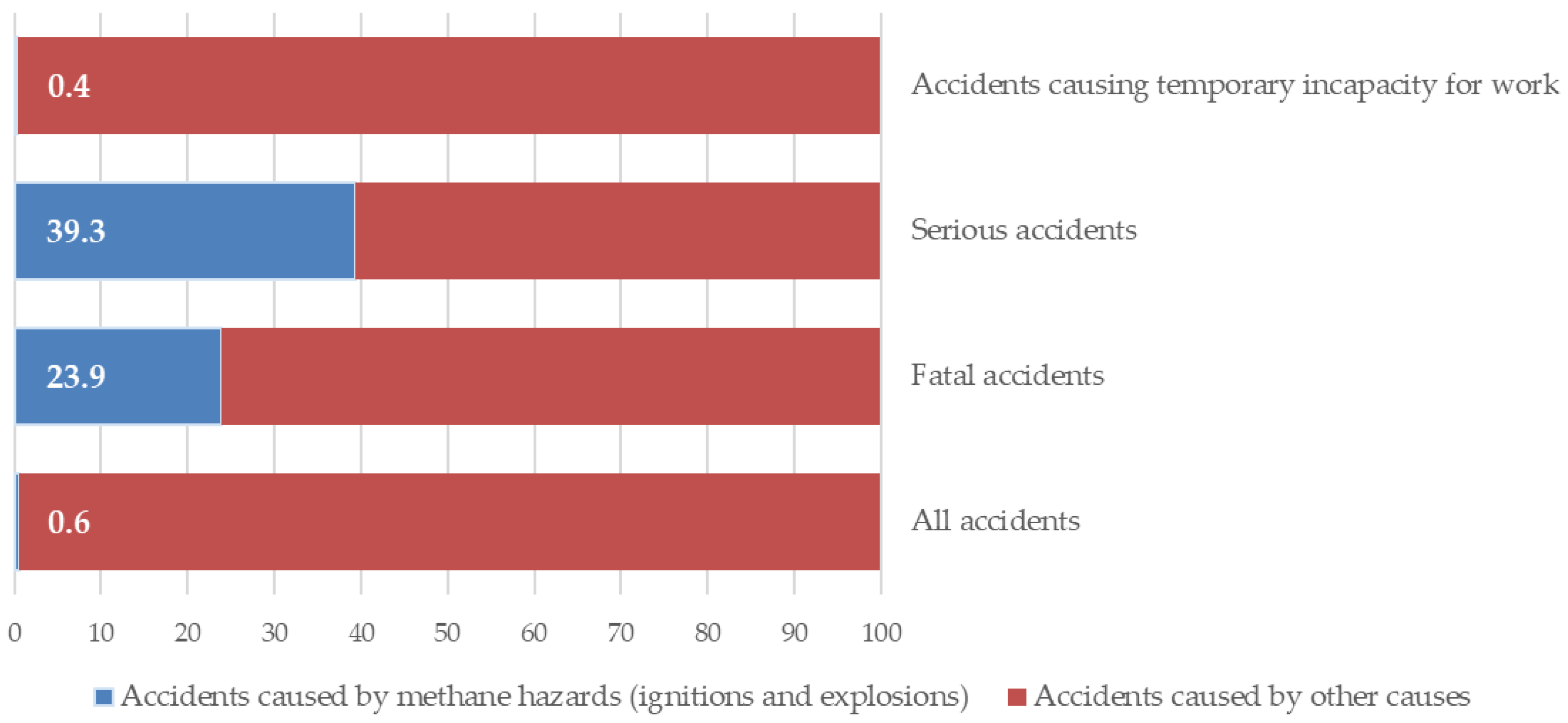

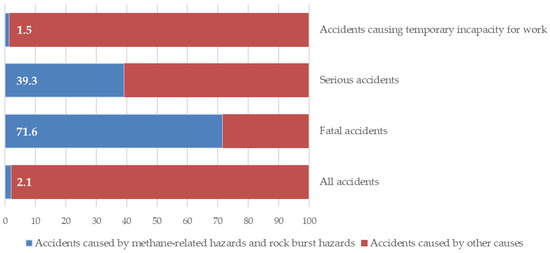

Against the background of overall accident rates in the years 2020–2024, the share of accidents resulting from hazardous events caused by the manifestation of natural hazards (methane-related hazards and rock bursts) is illustrated in Figure 8.

Figure 8.

Accident rates resulting from natural hazards compared to overall accident rates (in %).

With regard to methane hazards, the share of accidents resulting from methane ignitions and explosions compared to overall accident rates is presented in Figure 9.

Figure 9.

Accident rates resulting from methane hazards compared to overall accident rates (in %).

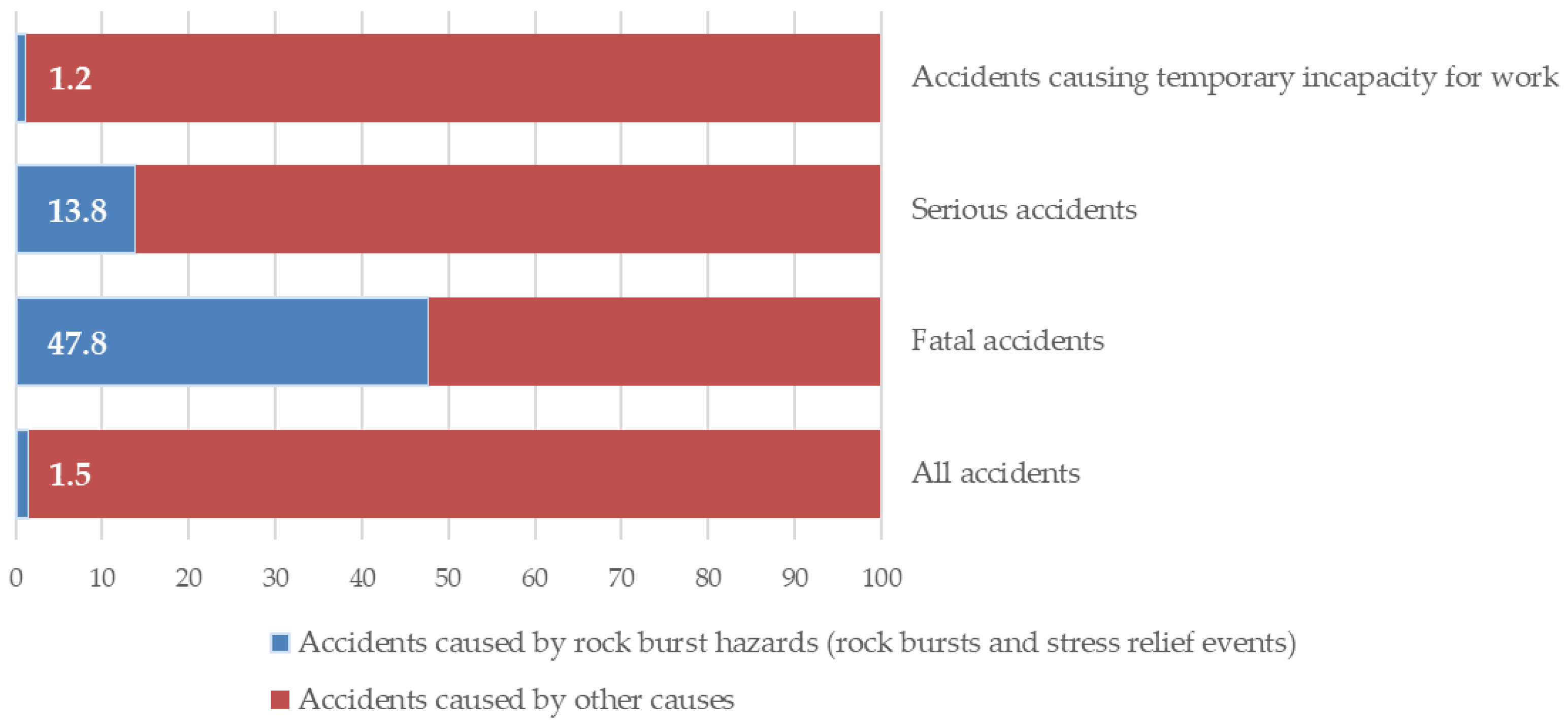

With regard to rock burst hazards, the share of accidents resulting from rock bursts and stress relief events compared to overall accident rates is presented in Figure 10.

Figure 10.

Accident rates resulting from rock burst hazards compared to overall accident rates (%).

In summary, the manifestation of natural hazards (methane-related hazards and rock bursts) in Polish hard coal mines during the years 2020–2024 was responsible for the majority (62%) of all fatal and serious accidents. The occurrence of hazardous events resulting from these natural hazards can not only cause accidents but may also lead to the limitation, temporary suspension, or even cessation of mining operations, thereby reducing coal production. The exclusion of parts of deposits affected by natural hazard events from mining activities may further decrease production capacities and, in some cases, lead to the premature closure of mining operations.

5. Conclusions

The proposed sets of factor–hazard–characteristic features occurring in coal mining systematically organize the approach and define the scope of data that should be taken into account during hazard information collection. The industry and specific type of industrial process for which hazard identification is conducted will determine both the types of characteristic features and the parameter values.

Introducing characteristic features along with parameters describing them into the hazard identification process necessitates a detailed analysis of each hazard. This ensures thorough hazard identification, taking into account the specificity of underground mining processes. If adopting an approach with clearly defined characteristics and associated parameters, it is essential to emphasize the importance of precise data collection on hazards.

In subsequent stages of occupational risk assessment, the identification of these characteristic features and the determination of how to measure or estimate their parameter values become critical. This process significantly enhances the effectiveness and reliability of risk assessments, allowing for tailored prevention and mitigation measures and fully acknowledging the unique conditions found in underground coal mining operations.

In the proposed classification of factors influencing the occurrence of occupational hazards, the most significant group is that of natural hazardous factors.

Polish hard coal mining involves the full spectrum of natural hazards commonly found in underground environments. The most accident-prone natural hazards are rock burst hazards and methane hazards. Methane ignitions, explosions, as well as rock bursts and stress relief events that occurred during the years 2020–2024 were responsible for the majority of fatal and serious accidents in the Polish mining industry. In the practice of occupational risk assessment in mining, evaluations are generally based on the estimation of parameters describing the characteristic effects of hazards (such as the probability, type, and severity of injury).

However, by basing the risk assessment on the characteristic features of the sources of hazards themselves, it is possible to estimate occupational risks more precisely and to more precisely and to identify the necessary preventive measures more effectively.

The new classification of hazards in hard coal mining, together with the detailed characterization of their defining features, can be particularly useful in the hazard identification process at workplaces where underground mining operations are carried out—especially in longwall mining, covering the stages of panel commissioning, steady-state extraction, and face recovery.

The systematization of hazards—through proper classification—ensures that each hazard is identified and appropriately assessed during the risk assessment process. A thorough analysis of the characteristic features of hazards and the classification of factors present at mining workplaces determine the selection of suitable occupational risk assessment methods and facilitate the implementation of preventive measures.

The developed classification can also be adapted to other types of mining, offering tangible benefits from its application and contributing to its wider acceptance and universal applicability.

Author Contributions

Z.B., D.N.-S. and P.S.—conceptualization, methodology, formal analysis, investigation, resources, draft text editing. visualization. Z.B.—supervision. All authors have read and agreed to the published version of the manuscript.

Funding

The article was funded by AGH University of Krakow, subsidy no. 16.16.100.215.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

Author Paweł Szczepański was employed by the company QES Consulting sp. z o.o. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Khanzode, V.V.; Maiti, J.; Ray, P.K. A methodology for evaluation and monitoring of recurring hazards in underground coal mining. Saf. Sci. 2011, 49, 1172–1179. [Google Scholar] [CrossRef]

- Regulation of the Minister of Health of February 2, 2011, on the examination and measurement of harmful factors in the work environment. J. Laws 2011, 33, 166. (In Polish)

- Regulation of the Minister of Labor and Social Policy of June 6, 2014, on the maximum permissible concentrations and intensities of harmful factors in the work environment. J. Laws 2014, 817. Available online: https://natlex.ilo.org/dyn/natlex2/r/natlex/fe/details?p3_isn=99664 (accessed on 29 April 2025). (In Polish).

- Announcement of the Minister of Climate and Environment of July 28, 2021, on the publication of the uniform text of the Regulation of the Minister of the Environment on natural hazards in mining facilities. J. Laws 2013, item 1617. Available online: https://isap.sejm.gov.pl/isap.nsf/DocDetails.xsp?id=WDU20210001617 (accessed on 29 April 2025). (In Polish).

- Collective Work. Polish Language Dictionary; PWN Publishing House: Warszawa, Poland, 2005; ISBN 83-01-14392-8. (In Polish) [Google Scholar]

- Tian, S.; Wang, Y.; Hongxia, L.I. Analysis of the causes and safety countermeasures of coal mine accidents: A case study of coal mine accidents in China from 2018 to 2022. Process Saf. Environ. Prot. 2024, 187, 864–875. [Google Scholar] [CrossRef]

- Du, G.; Chen, A. Coal mine accident risk analysis with large language models and bayesian networks. Sustainability 2025, 17, 1896. [Google Scholar] [CrossRef]

- Nyoni, W.; Pillay, M.; Rubin, M.; Jeeries, M. Organizational factors and risk management in the mining industry: An updated systematic literature review. Int. J. Occup. Environ. Saf. 2018, 3, 53–69. [Google Scholar] [CrossRef]

- Pinto, A.; Carvalho, C.; Mónico, L.S.; Moio, I.; Alves, J.; Lima, T.M. Assessing Psychosocial Work Conditions: Preliminary Validation of the Portuguese Short Version of the Copenhagen Psychosocial Questionnaire III. Sustainability 2024, 16, 7479. [Google Scholar] [CrossRef]

- Statistic Poland. Available online: https://stat.gov.pl (accessed on 14 April 2025). (In Polish)

- Zeqiri, K.; Mijalkovski, S.; Ibishi, G.; Mojsiu, L.L. Comprehensive analysis of the mining accident forecasting and risk assessment methodologies: Case study–Stanterg Mine. Min. Miner. Depos. 2024, 18, 11–17. [Google Scholar] [CrossRef]

- PN-Z-08052:1980; Hazardous and Harmful Factors Occurring in the Work Process. Polish Committee for Standardization: Warszawa, Poland, 1980.

- PN-ISO 45001:2024-02; Occupational Health and Safety Management Systems–Requirements and Guidance for Use. (English Version); Polish Committee for Standardization: Warszawa, Poland, 2024.

- PN-N-18001:2004; Occupational Health and Safety Management Systems–Requirements. (Standard Withdrawn and Replaced by PN-ISO 45001:2024); Polish Committee for Standardization: Warszawa, Poland, 2004.

- PN-EN ISO 12100:2012; Safety of Machinery–General Principles for Design–Risk Assessment and Risk Reduction. Polish Committee for Standardization: Warszawa, Poland, 2012.

- Mining Lexicon; Wydawnictwo Śląsk: Katowice, Poland, 1989; ISBN 83-216-0690-3.

- Krause, M. Principles for selecting occupational risk assessment methods in the context of the diverse impact of hazardous and harmful workplace factors in coal mines. In Zarządzanie Bezpieczeństwem Pracy w Górnictwie Węgla Kamiennego; Wydawnictwo Politechniki Śląskiej: Gliwice, Poland, 2012; pp. 99–140. ISBN 978-83-7880-064-4. (In Polish) [Google Scholar]

- Hu, J.; Huang, R.; Xu, F. Data mining in coal-mine gas explosion accidents based on evidence-based safety: A case study in China. Sustainability 2022, 14, 16346. [Google Scholar] [CrossRef]

- Konopko, W. (Red) collective work. In Work Safety in Coal Mines. Volume 2: Natural Hazards; GIG: Katowice, Poland, 2013; pp. 9–382. ISBN 9788361126614. (In Polish) [Google Scholar]

- Prusek, S.; Rajwa, S.; Wrana, A.; Krzemień, A. Assessment of roof fall risk in longwall coal mines. Int. J. Min. Reclam. Environ. 2016, 31, 558–574. [Google Scholar] [CrossRef]

- Act of June 9, 2011–Geological and Mining Law. J. Laws 2011, 981, as amended. (In Polish). Available online: https://www.google.com.hk/url?sa=t&source=web&rct=j&opi=89978449&url=https://www.gov.pl/attachment/9043b183-a5c6-4461-8b24-71b50c0e240d&ved=2ahUKEwian7fi-oiOAxUAiK8BHfSiClQQFnoECBUQAQ&usg=AOvVaw3_gHvTcWj6E8uLQ_ZulDcJ (accessed on 29 April 2025).

- Higher Mining Authority. In Assessment of Work Safety, Mine Rescue, and Public Safety in Relation to Mining and Geological Activities in 2024; Higher Mining Authority: Katowice, Poland, 2025. (In Polish)

- Wang, D.; Sui, W.; Ranville, J.F. Hazard identification and risk assessment of groundwater inrush from a coal mine: A review. Bull. Eng. Geol. Environ. 2022, 81, 421. [Google Scholar] [CrossRef]

- Burtan, Z.; Chlebowski, D. Natural hazard conditions resulting in major accidents in the coal-mining sector in Poland. In Proceedings of the 25th World Mining Congress, Astana, Kazakhstan, 19–22 June 2018; pp. 62–71. [Google Scholar]

- Kabiesz, J. Normative occupational risk assessment of rockburst hazards and associated (coexisting) threats. Work Saf. Environ. Prot. Min. 2001, 4, 27–33. (In Polish) [Google Scholar]

- Burtan, Z. The significance of associated natural hazards in the mines of the Upper Silesian Coal Basin. Przegląd Górniczy 2016, 72, 21–29. (In Polish) [Google Scholar]

- Kabiesz, P.; Tutak, M. Developing a culture of safety for sustainable development and public health in manufacturing companies-A case study. Sustainability 2024, 16, 7557. [Google Scholar] [CrossRef]

- Korzeniowski, W.; Nowak-Senderowska, D. Multi-criteria analysis of ergonomic hazards with quantitative risk assessment for the operator of drilling and bolting truck. Przegląd Górniczy 2021, 10–12, 54–59. (In Polish) [Google Scholar]

- Donovan, S.-L.; Salmon, P.M.; Lenné, M.G.; Horberry, T. Safety leadership and systems thinking: Application and evaluation of a risk management framework in the mining industry. Ergonomics 2017, 60, 1336–1350. [Google Scholar] [CrossRef]

- Emanuele, C.F. Big data analytics as a tool for reducing ergonomics risk. J. Ergon. 2017, 7, 1000. [Google Scholar] [CrossRef]

- PN-EN 31010:2018-01; Risk Management–Risk Assessment Techniques. Polish Committee for Standardization: Warszawa, Poland, 2018.

- Verma, S.; Chaudhari, S. Highlights from the literature on risk assessment techniques adopted in the mining industry: A review of past contributions, recent developments and future scope. Int. J. Min. Sci. Technol. 2016, 26, 691–702. [Google Scholar] [CrossRef]

- Bahn, S. Workplace hazard identification and management: The case of an underground mining operation. Saf. Sci. 2013, 57, 129–137. [Google Scholar] [CrossRef]

- Badri, A.; Nadeau, S.; Gbodossou, A. A new practical approach to risk management for underground mining project in Quebec. J. Loss Prev. Process. Ind. 2013, 26, 1145–1158. [Google Scholar] [CrossRef]

- Korzeniowski, W.; Nowak-Senderowska, D. Efficiency of AHP method during determination of the impact of particular hazards on occupational risk level. Przegląd Górniczy 2012, 12, 145–151. (In Polish) [Google Scholar]

- PN-N-18002:2011; Occupational Health and Safety Management Systems–General Guidelines for Occupational Risk Assessment. Polish Committee for Standardization: Warszawa, Poland, 2011.

- Tripathy, D.P.; Parida, S.; Khandu, L. Safety risk assessment and risk prediction in underground coal mines using machine learning techniques. J. Inst. Eng. Ser. D 2021, 102, 495–504. [Google Scholar] [CrossRef]

- Tubis, A.; Werbińska-Wojciechowska, S.; Wroblewski, A. Risk assessment methods in mining industry-A systematic review. Appl. Sci. 2020, 10, 5172. [Google Scholar] [CrossRef]

- Wróblewski, D. (Ed.) Collective work. In Risk Management. Overview of Selected Methodologies; CNBOP-PIB: Warszawa, Poland, 2018; ISBN 978-83-61520-18-4. (In Polish) [Google Scholar]

- Gul, M.A. Review of occupational health and safety risk assessment approaches based on multi-criteria decision-making methods and their fuzzy versions. Hum. Ecol. Risk Assess. 2018, 24, 1723–1760. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).