Food Processing with UHP Waterjets

Abstract

1. Introduction

- Cutting: In this case, high-velocity waterjets, generated by pressures up to 621 MPa (90 Ksi), are used for the following:

- ○

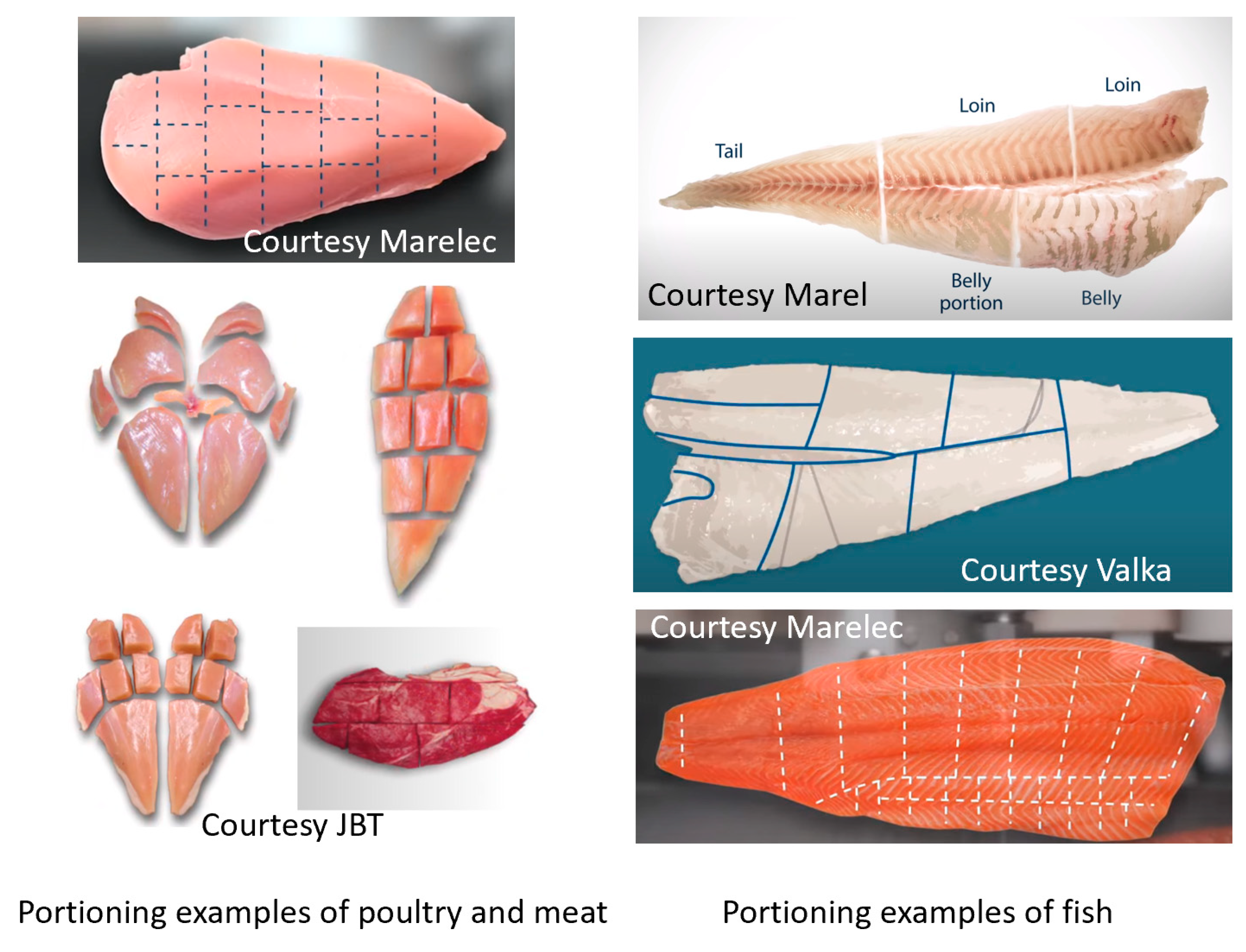

- Portioning: This is to slice through food product to produce food portions.

- ○

- Excision: This is to cut undesirable food areas such as the fat off some meat cuts.

- ○

- Trimming: This is to trim off some areas of the food such as the crowns of carrots.

- ○

- Peeling: This is to remove the skin off some fruits or vegetables.

- ○

- Stripping: This is to separate food from each other such as deboning operations.

- This can be accomplished with different types of jets, not all of which have been commercially implemented.

- ○

- Pure liquid jets: In this case, a liquid jet is used which is commonly water but sometimes an alternative liquid may be used (Ex. coconut oil is used for cutting some chocolates). This is the most commercially used waterjet tool.

- ○

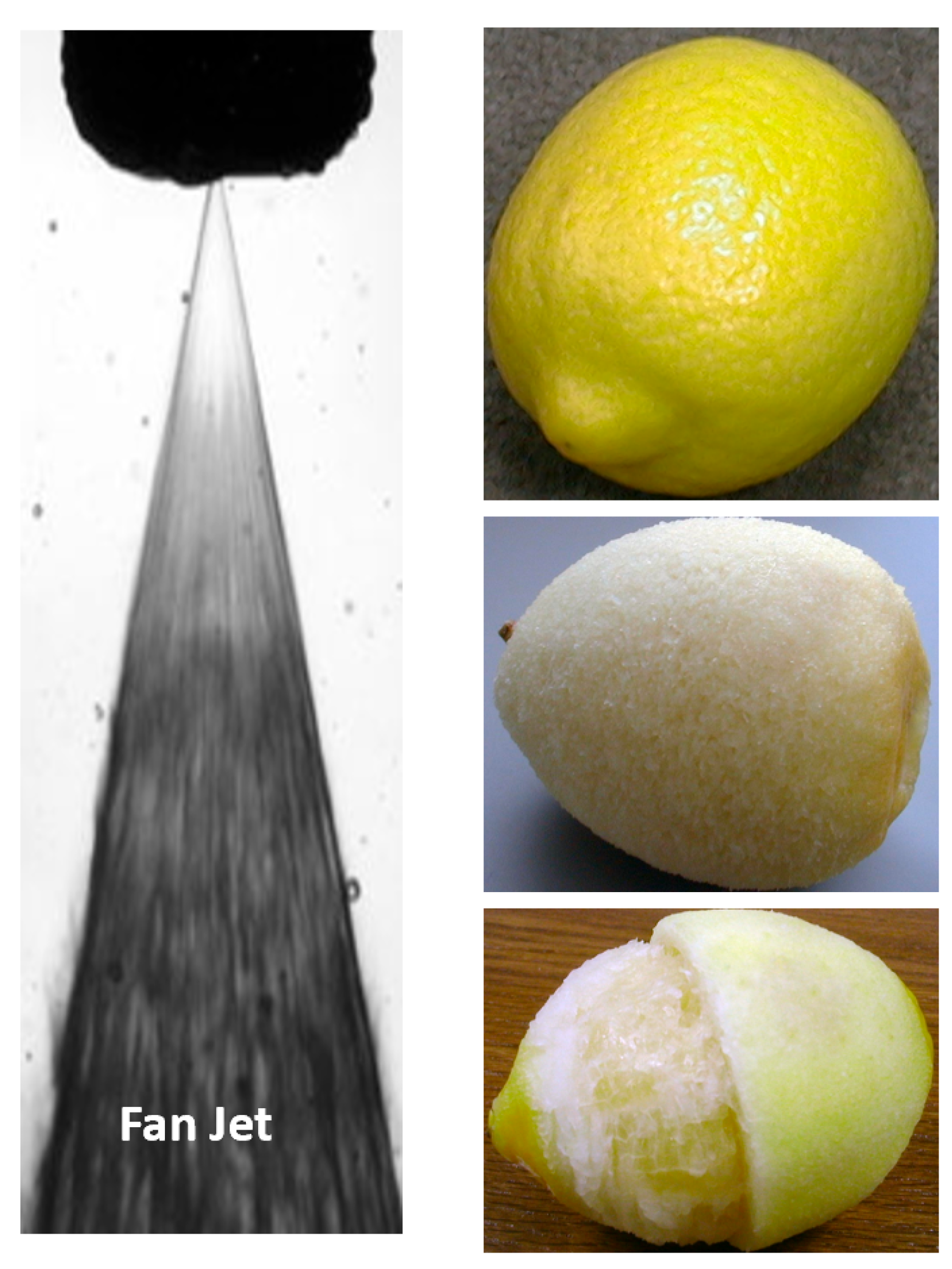

- Pure liquid fanjet: In this case, a fan jet is used either for peeling or stripping.

- ○

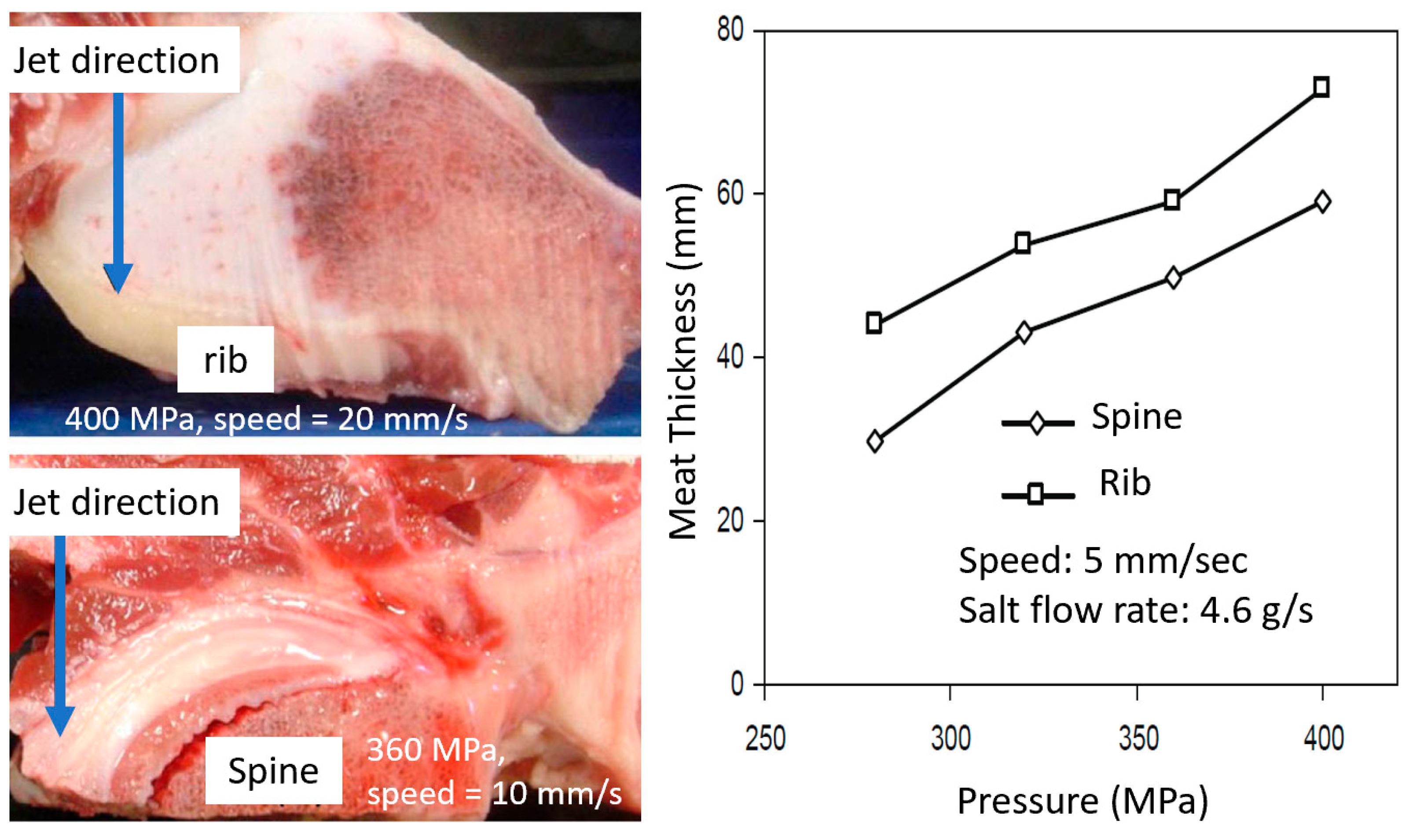

- Abrasive waterjet: In this case, solid particles are entrained into the waterjet to increase its cutting ability as may be needed to cut through bones.

- ○

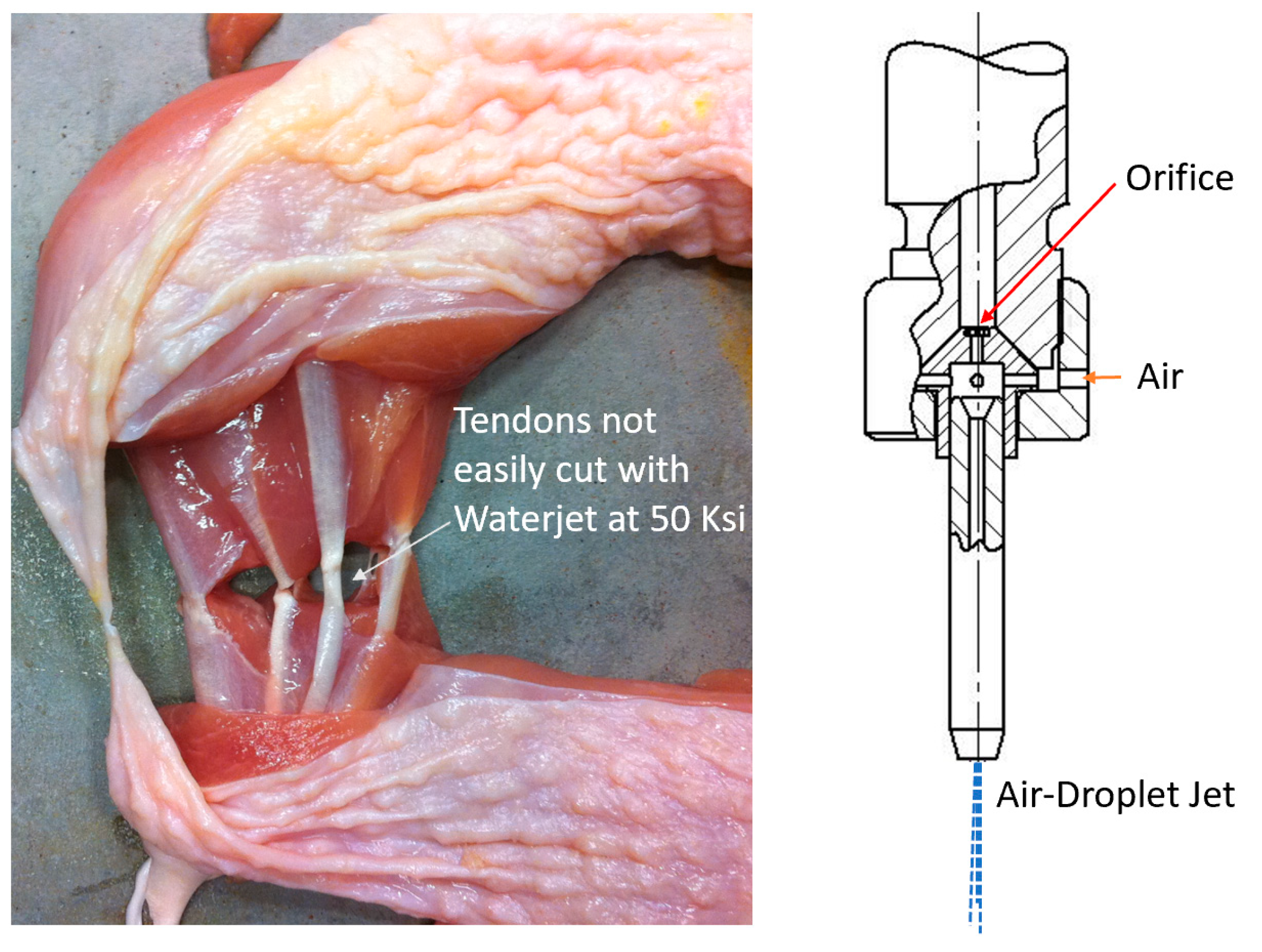

- Air–Liquid Jets. Instead of abrasives, air is entrained into the waterjet to create a highly focused droplet jet.

- Pressurization: Processing food products by static pressurization is used to sterilize the food by killing harmful microorganisms and thus extending the shelf life and safety of the food.

- Pumping: In this case, the food, mainly liquids, may be pumped through the nozzle for the purpose of homogenization or other effects where high shear rates are required.

2. Waterjet Characteristics

2.1. Advantages

- The waterjet cutting edge is renewable and thus there is no cross contamination.

- Long-life waterjets have diamond orifices and thus there is no need to clean or sharpen blades or disks.

- The waterjet is flexible for cutting a wide range of food products.

- Omnidirectional cutting capability allows for easy shape cutting.

- A waterjet allows for a higher yield of produce as kerf widths are narrow.

- No heat or chemicals are used, only pure water.

- They have the ability to cut through multiple layers of food contents such as cady with nuts.

- The waterjet tool lends itself to automation and intelligent control.

- No metal detection equipment is needed such as that used when cutting with blades.

- High productivity with multiple jets on the same machine is possible.

- They have the ability to cut very soft food products without distortion.

- They have the ability to cut small portions of any shape.

- The waterjet tool can be used inside factories and in the field for harvesting.

- It is highly capable of cutting both soft and hard food items.

- It can easily be integrated into existing production lines, replacing conventional methods.

- The waterjet is approved by regulators such as the U.S. Food and Drug Administration.

2.2. Waterjet Coherency

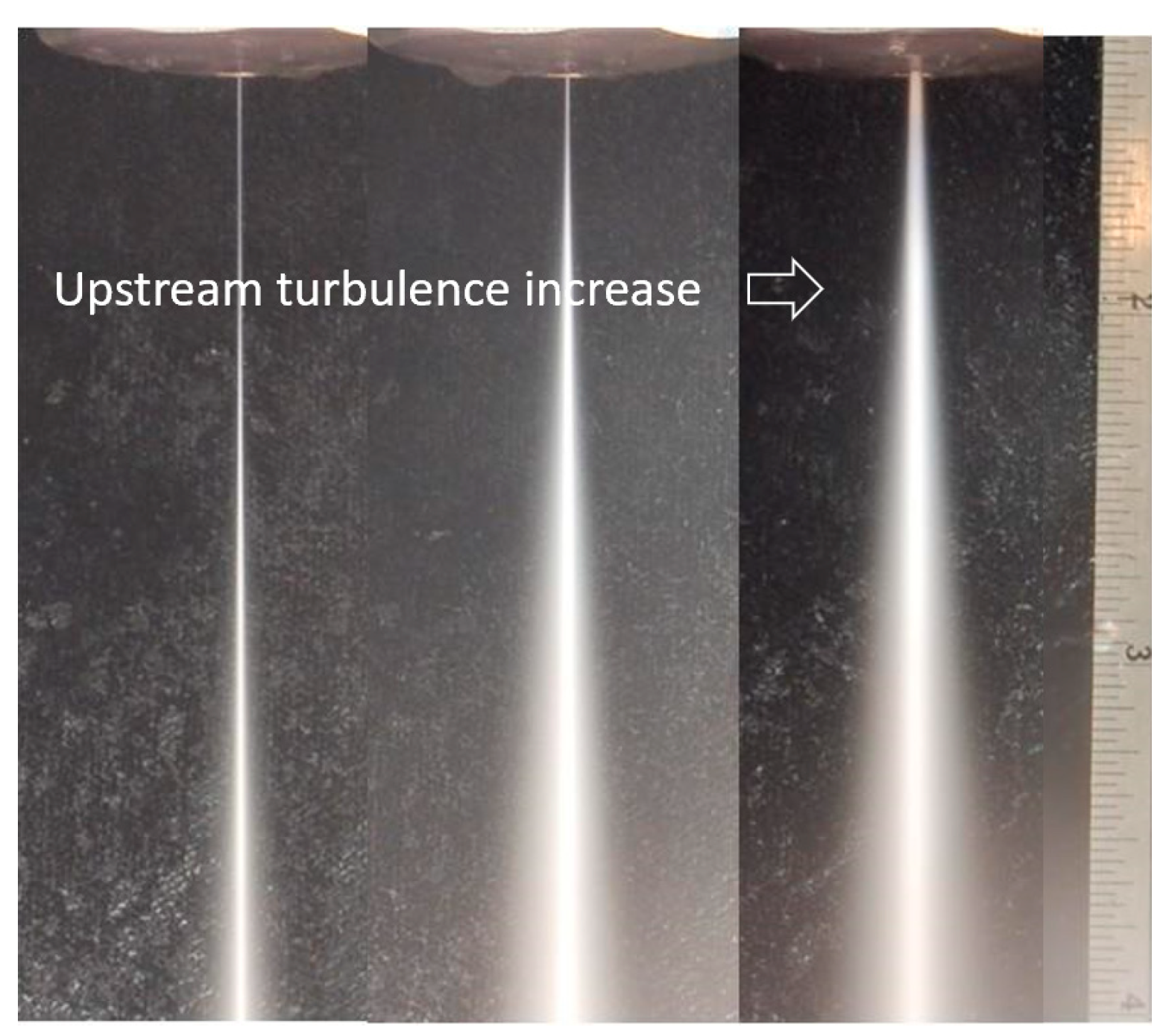

- Upstream tube diameter and length—The effects of the upstream tube diameter, d, and the level of turbulence above the orifice were studied. Results show that jet coherency improves when the tube size reaches a certain critical size so that the upstream Reynolds number is below a critical value. An upstream length of at least 20 tube diameters was found to also be important in producing coherent jets to allow for any turbulent eddies from the on/off valve passages to die out.

- Orifice edge geometry and condition—The upstream edge characteristic of an orifice is a most important factor that affects jet coherency. A sharp edge allows a vena contracta to form with maximum power density output. A fileted edge is not preferred as the water flow will attach to the edge, causing more friction and spreading. However, a minimal filet radius is needed to reduce sensitivity to small particles in the water. Water filters are typically used in upstream water pumps to increase the lifetime of the pump seals and the orifice. Sometimes inline filters are used inside the UHP water body above the orifice to catch any debris in the lines.

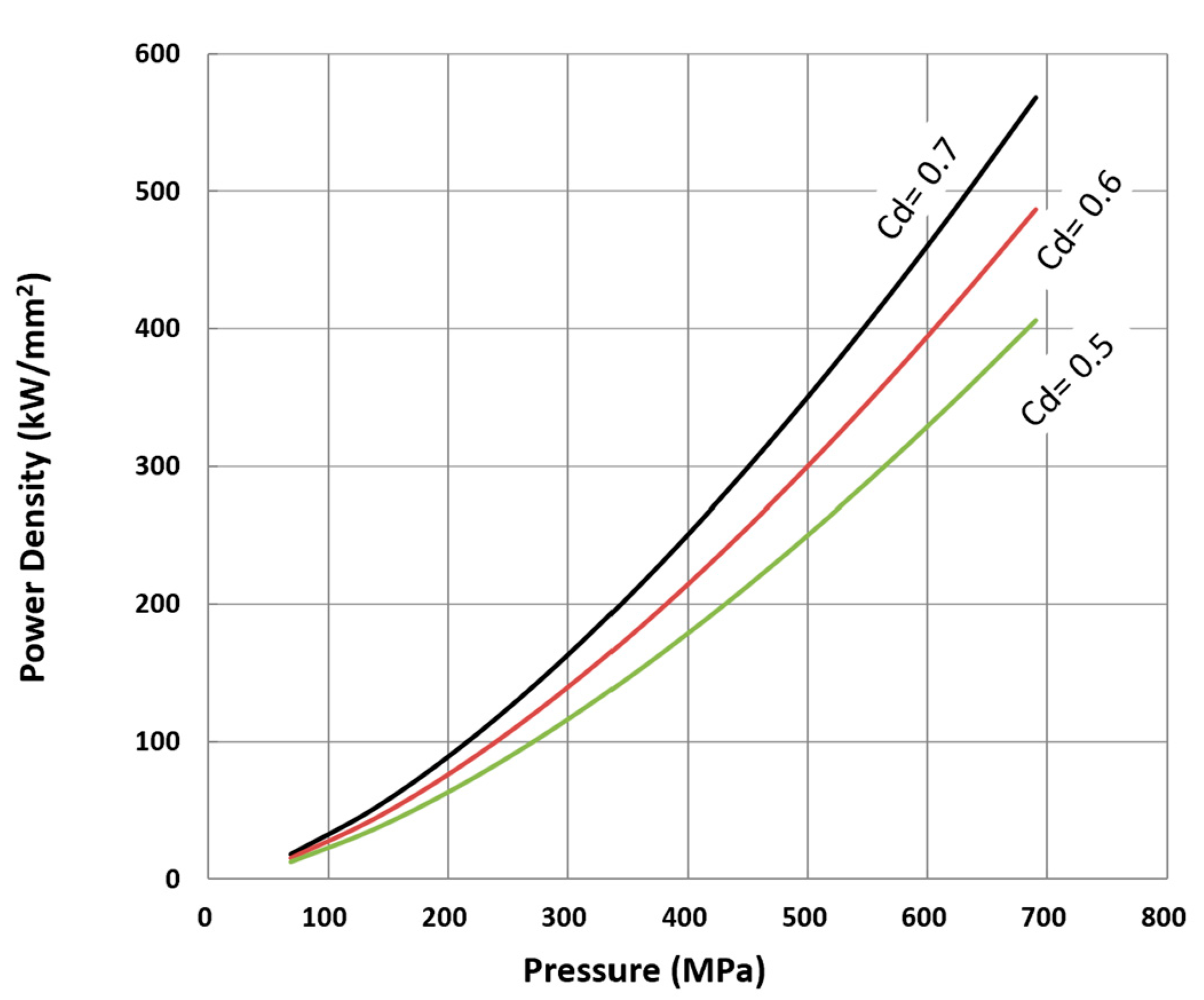

2.3. Waterjet Power Density

2.4. Waterjet Force

3. Waterjet Food Systems

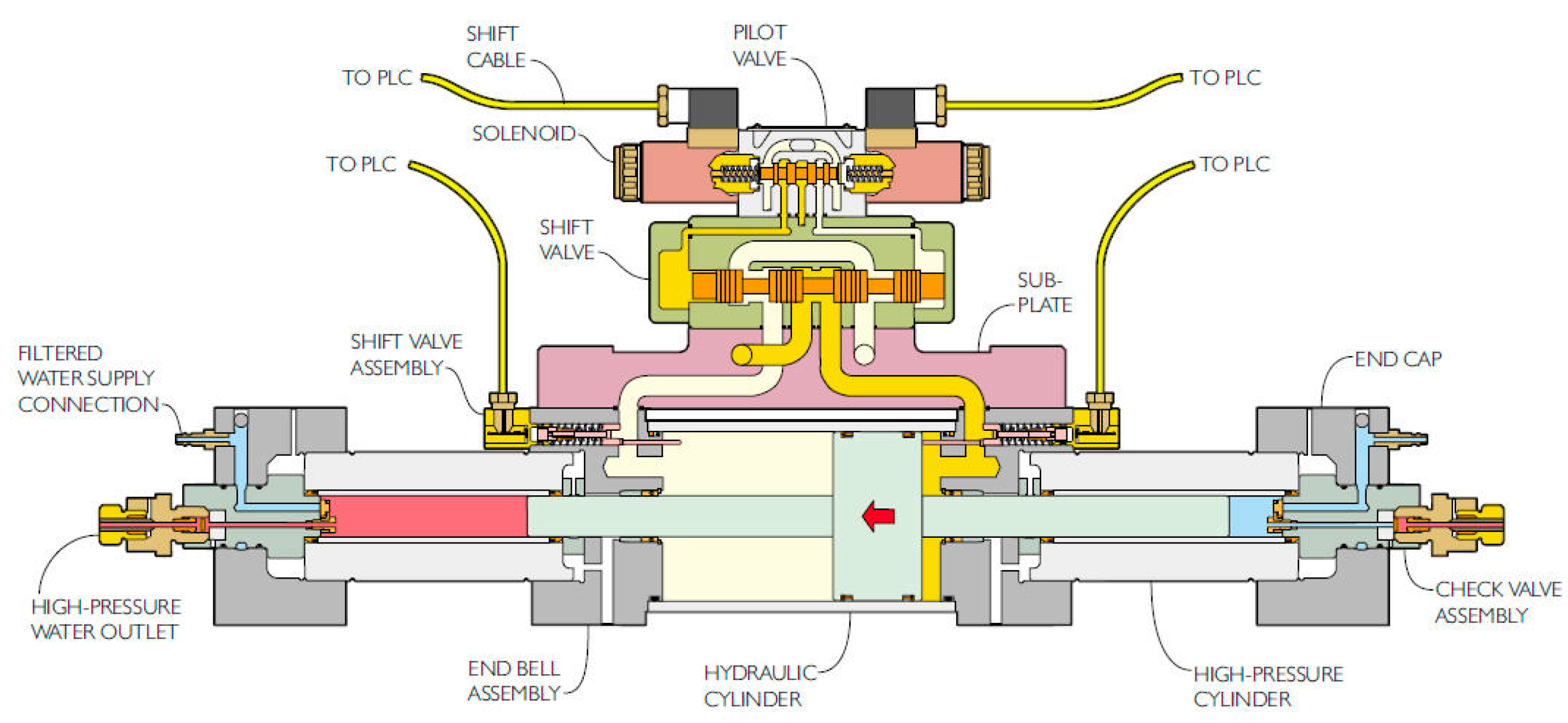

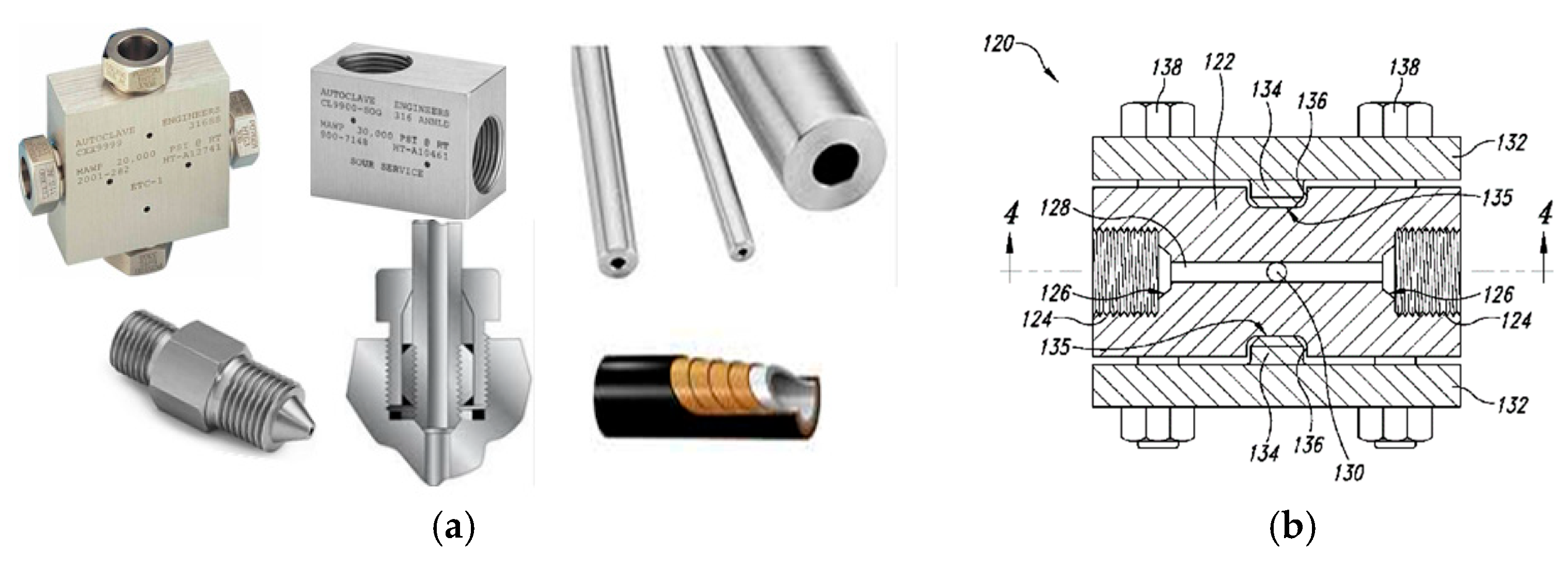

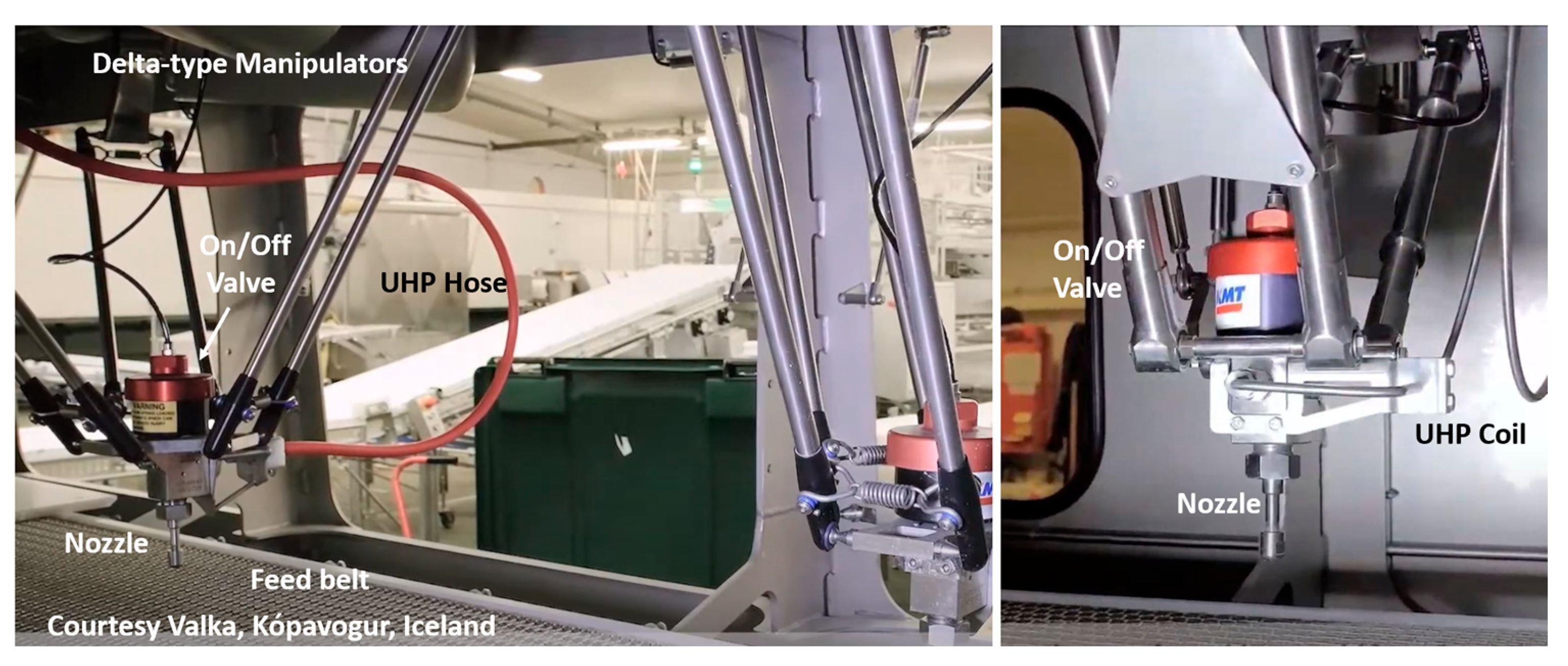

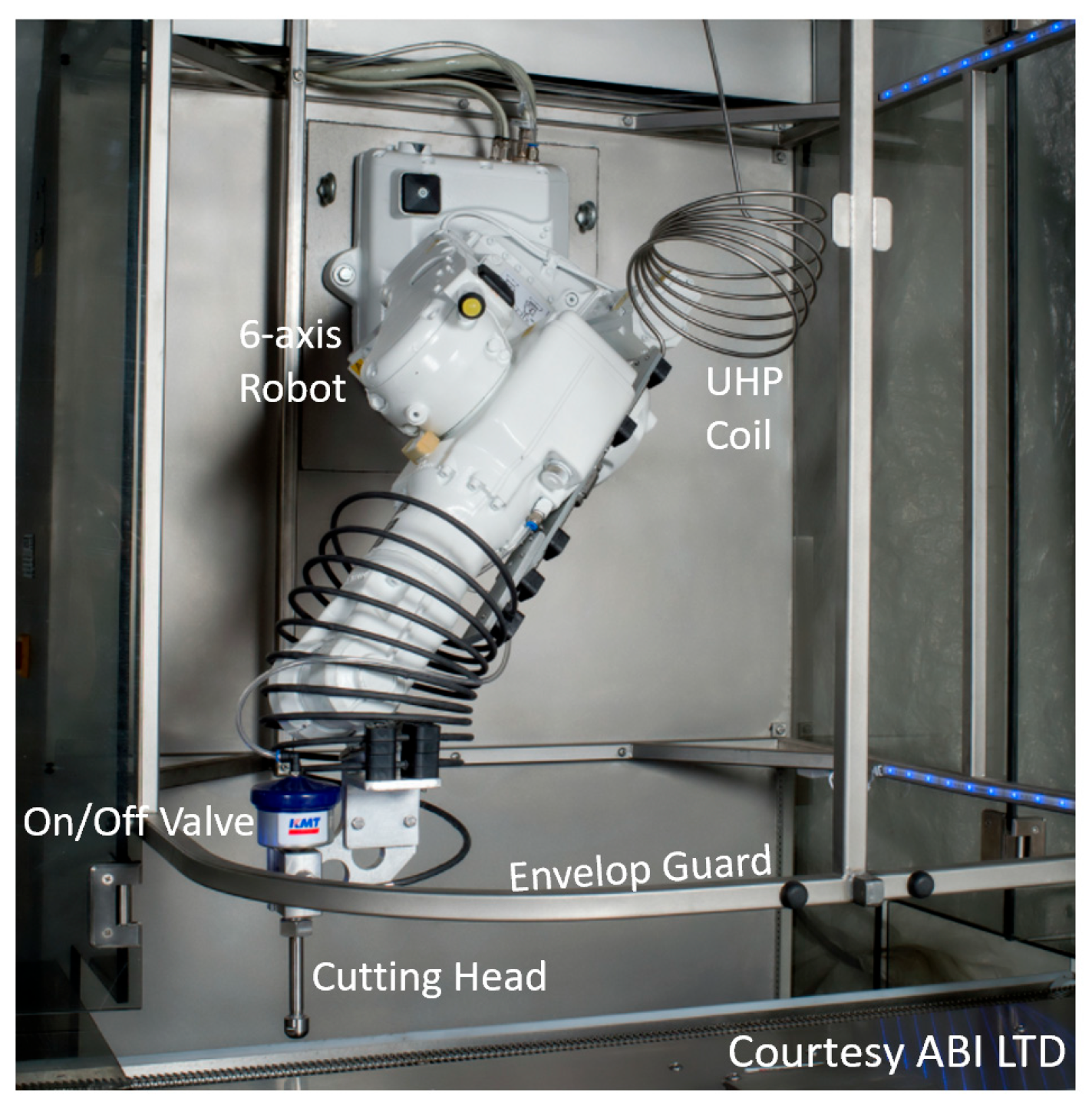

- UHP pumps and lines: This is the most upstream component in a waterjet system where the water enters the pump at ambient pressure and exits the pump into the plumbing system at a higher pressure. The UHP plumbing is used to transport pressurized water to the jet-forming nozzle(s). This plumbing system may consist of tubing, hoses, fittings, swivel joints, and rotary swivels

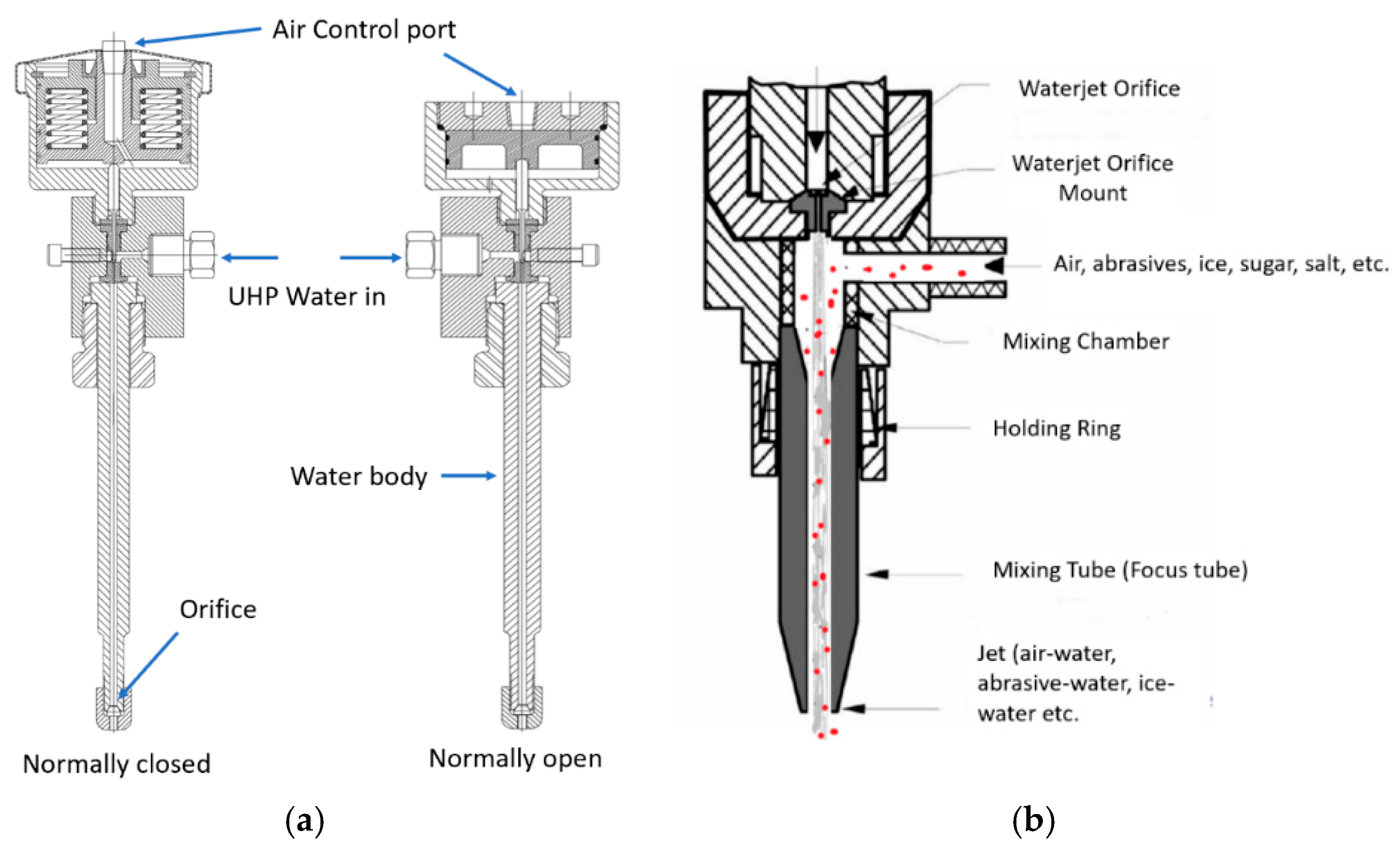

- Cutting heads: An on/off valve is used upstream from the nozzle to start and stop the UHP water flow to the jet-forming orifice. The orifice is a most critical component that transforms the pressure energy into kinetic energy. If abrasives are used, then a mixing tube is used to mix and accelerate the abrasives using the high-velocity jet.

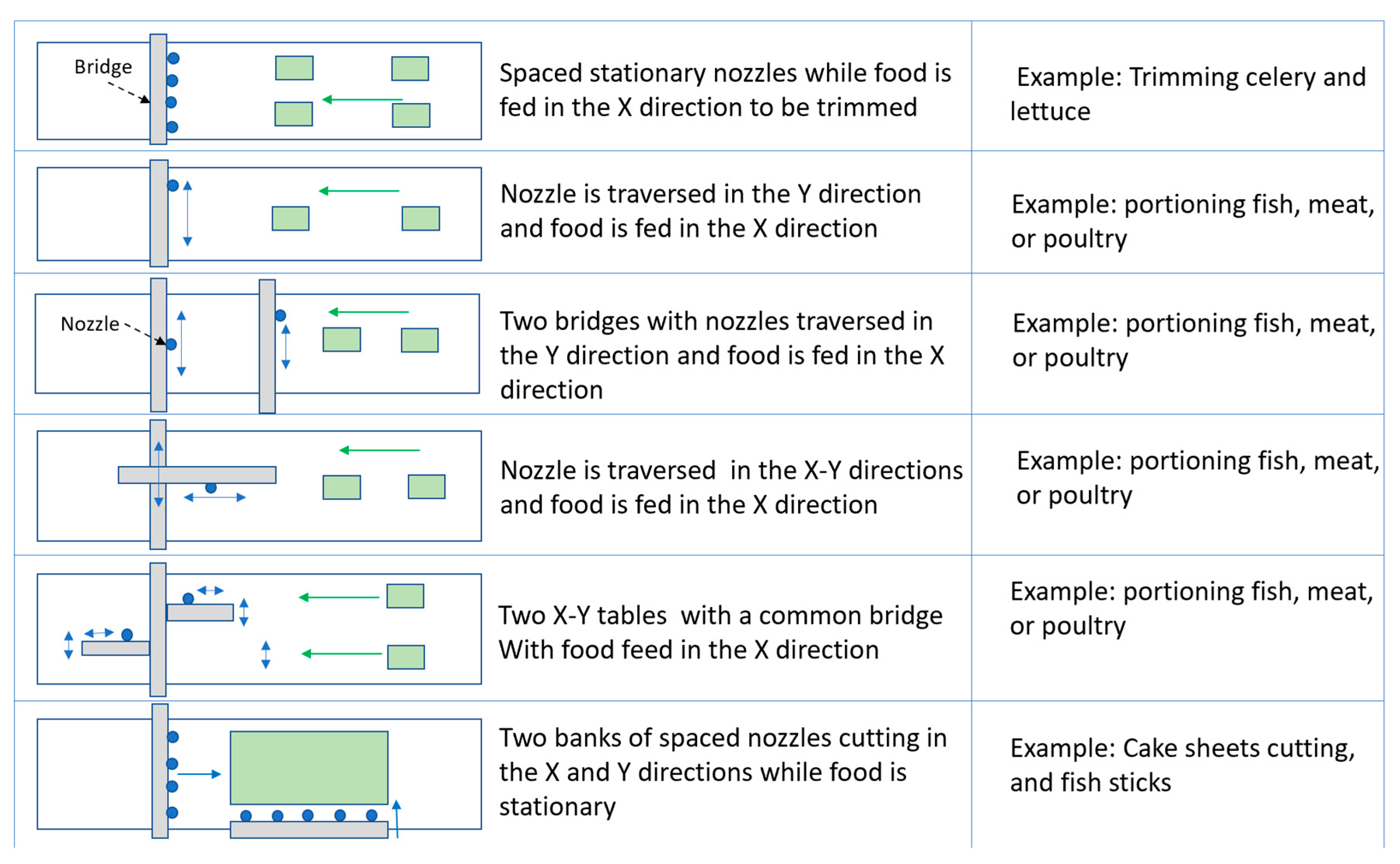

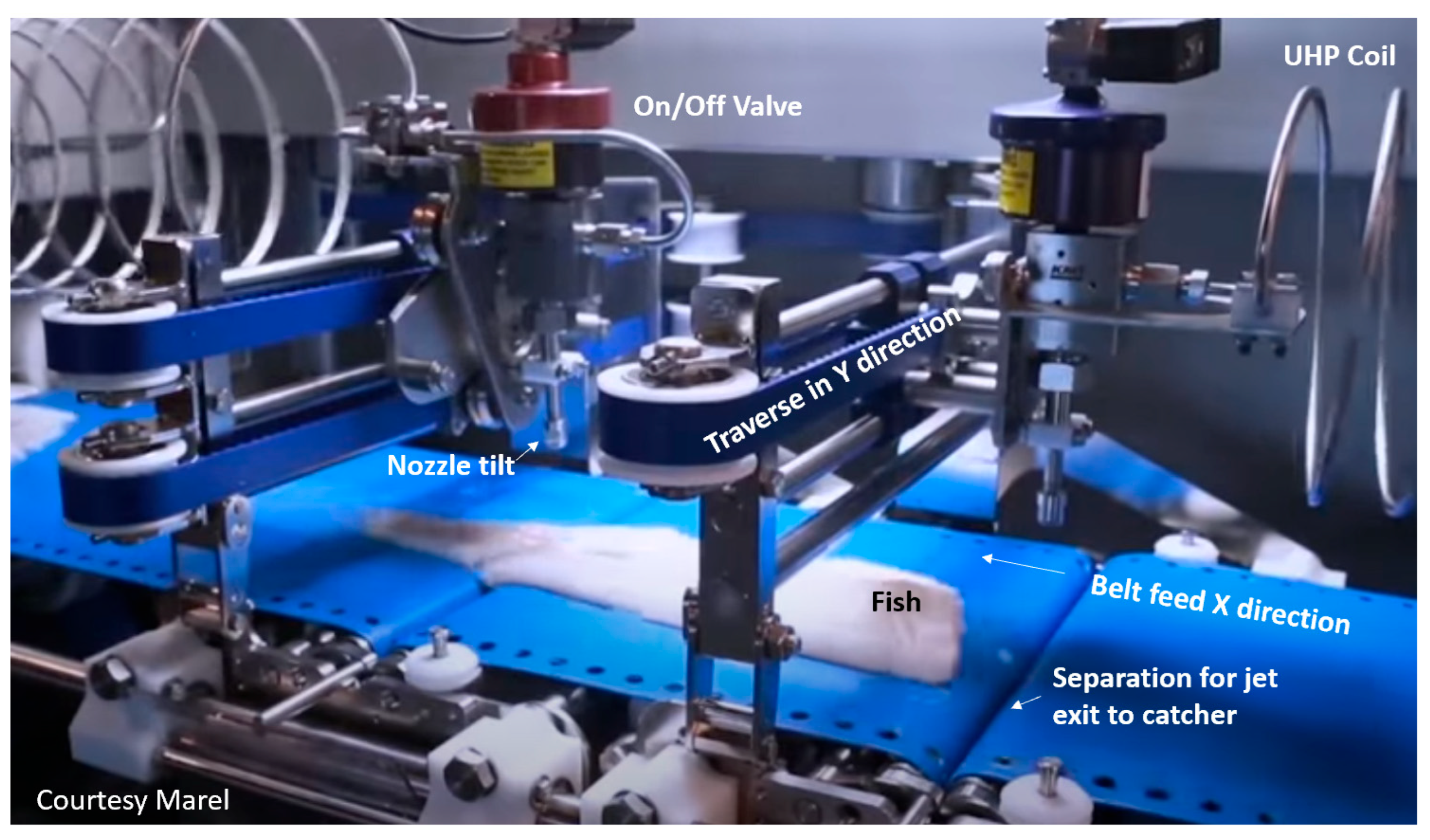

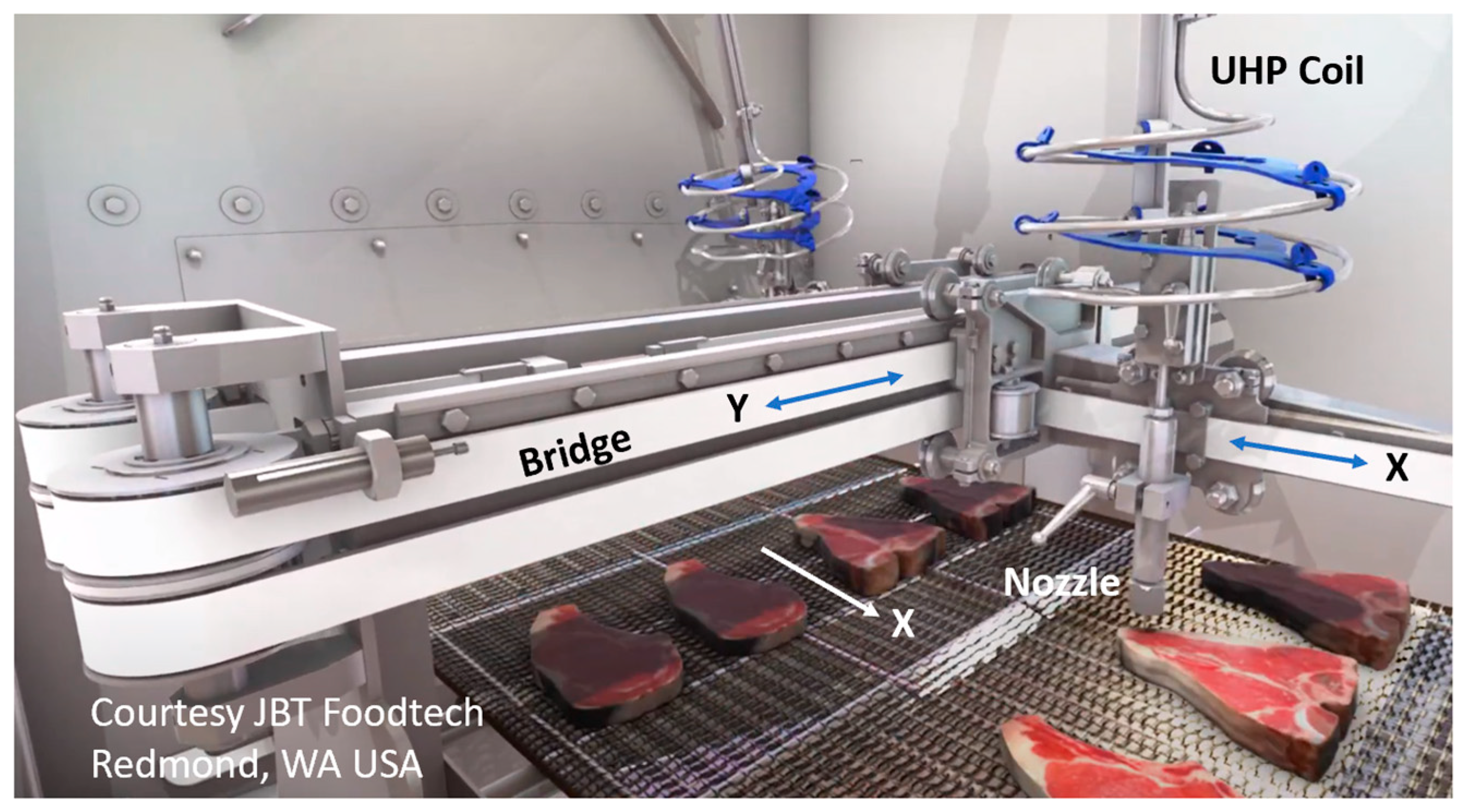

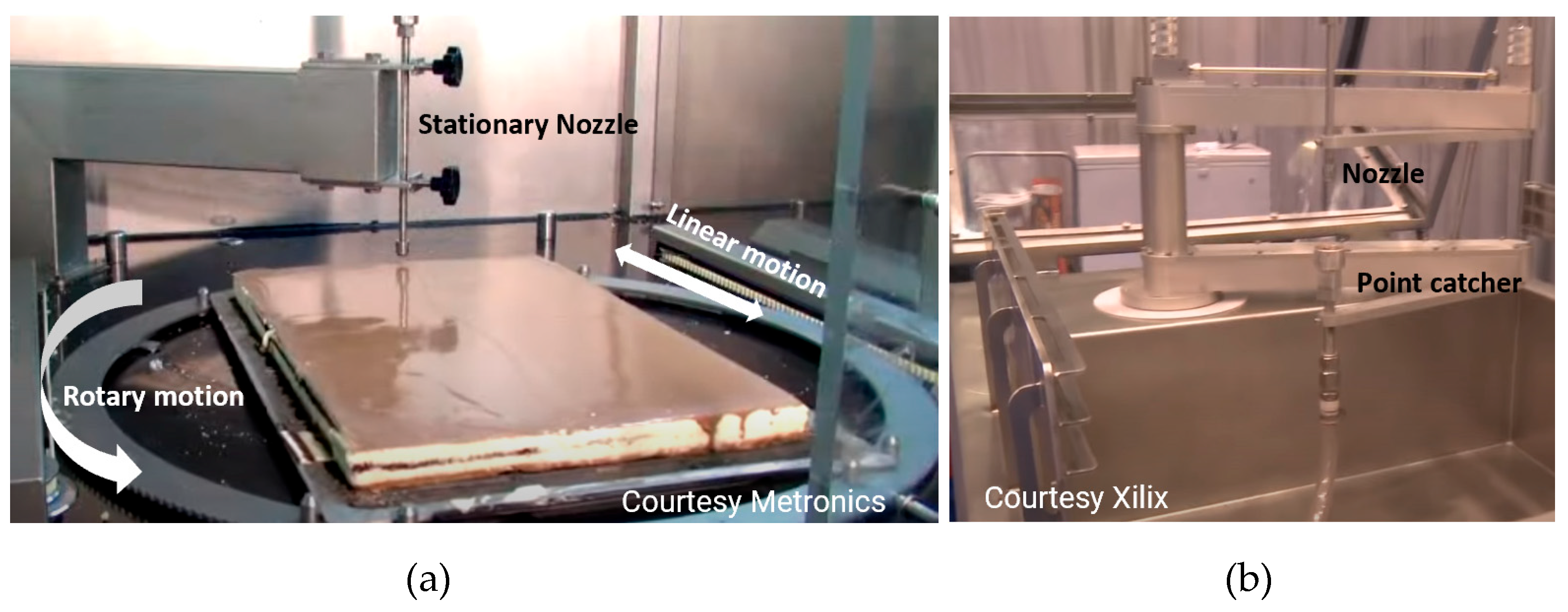

- Motion System: The motion system in a food system depends on the food product to be cut. General examples are the following:

- ○

- Cross cutting table: In this example, the waterjet(s) are traversed in one direction (X direction) and the food product is traversed on a feed screen in the Y direction.

- ○

- Robotic arm: A robotic arm is used to manipulate the jet over a traveling or indexed screen carrying the food product, mainly meat such as chicken beef, fish, and pork.

- A CNC controller is typically used to control the interpolating motion of the machine. A robotic arm system may also be used as a manipulator.

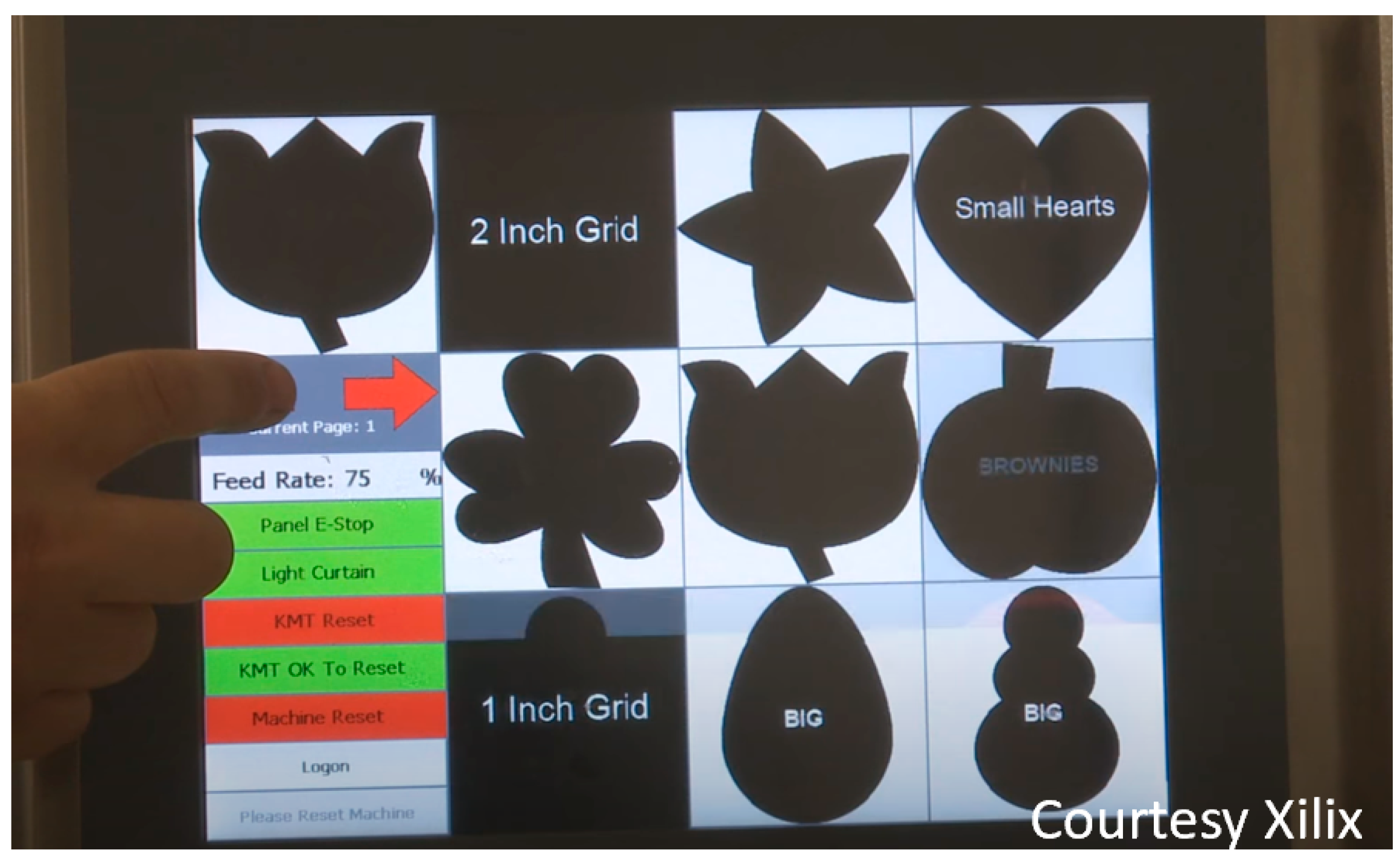

- Controls, Software, and Sensors: A CNC controller is typically used to control the interpolating motion of the machine. The software is used to enable operators to interface with the machine controller and is specifically tailored for the application. Sensors are used to guide the motion based on certain portioning criteria.

- Other: There are other subsystems for food processing such as sorting, packaging, and labeling but these are outside the scope of this paper.

3.1. UHP Pumps and Plumbing

3.2. Cutting Heads

3.3. System Manipulators, Support Tables, Sensors, and Software

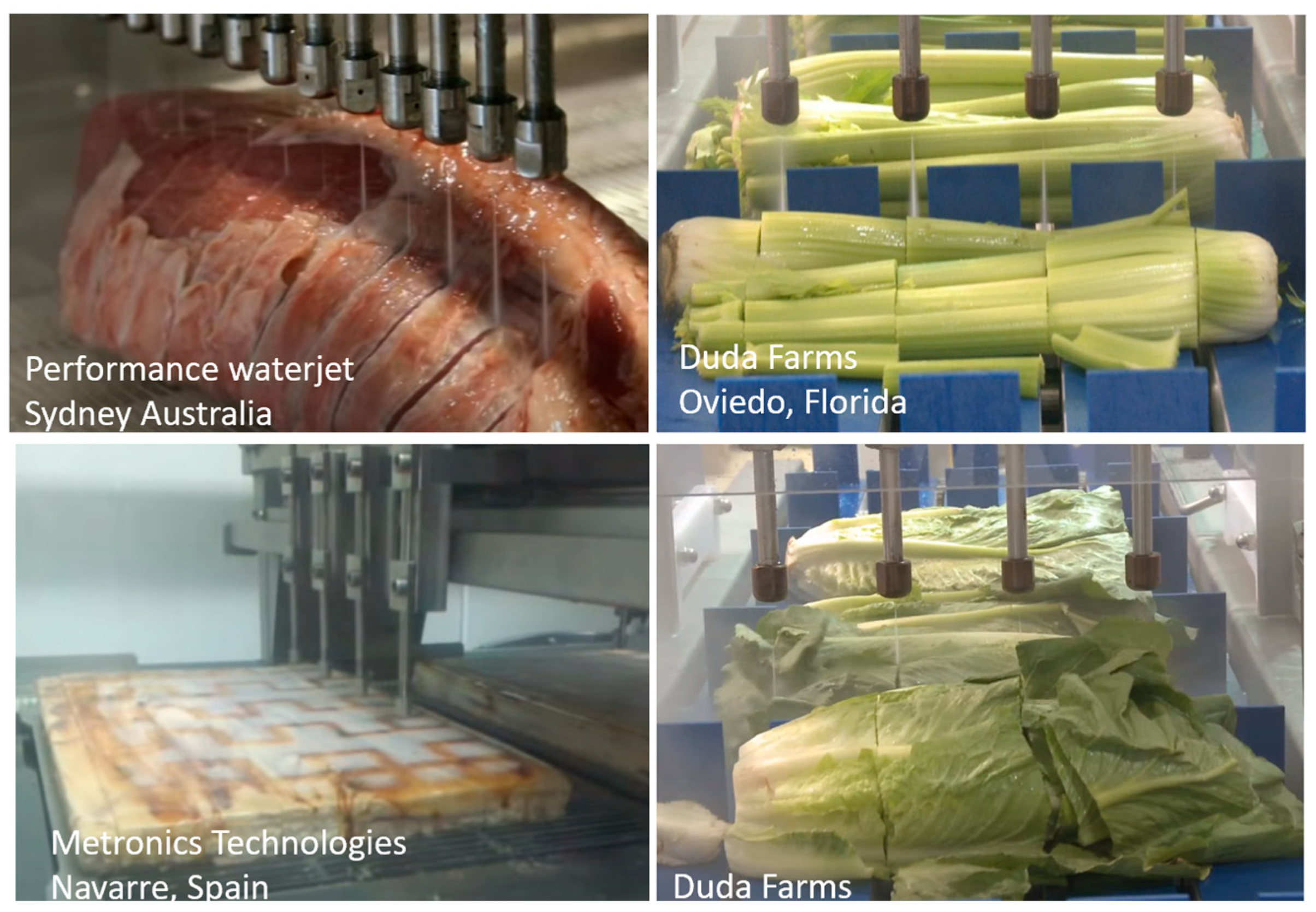

4. Selected Cutting Applications

4.1. Beef, Pork, and Lamb

4.1.1. Abrasive Waterjet

4.1.2. Ice-Waterjet

4.2. Fish

4.3. Poultry

Air-Waterjet

4.4. Vegetables

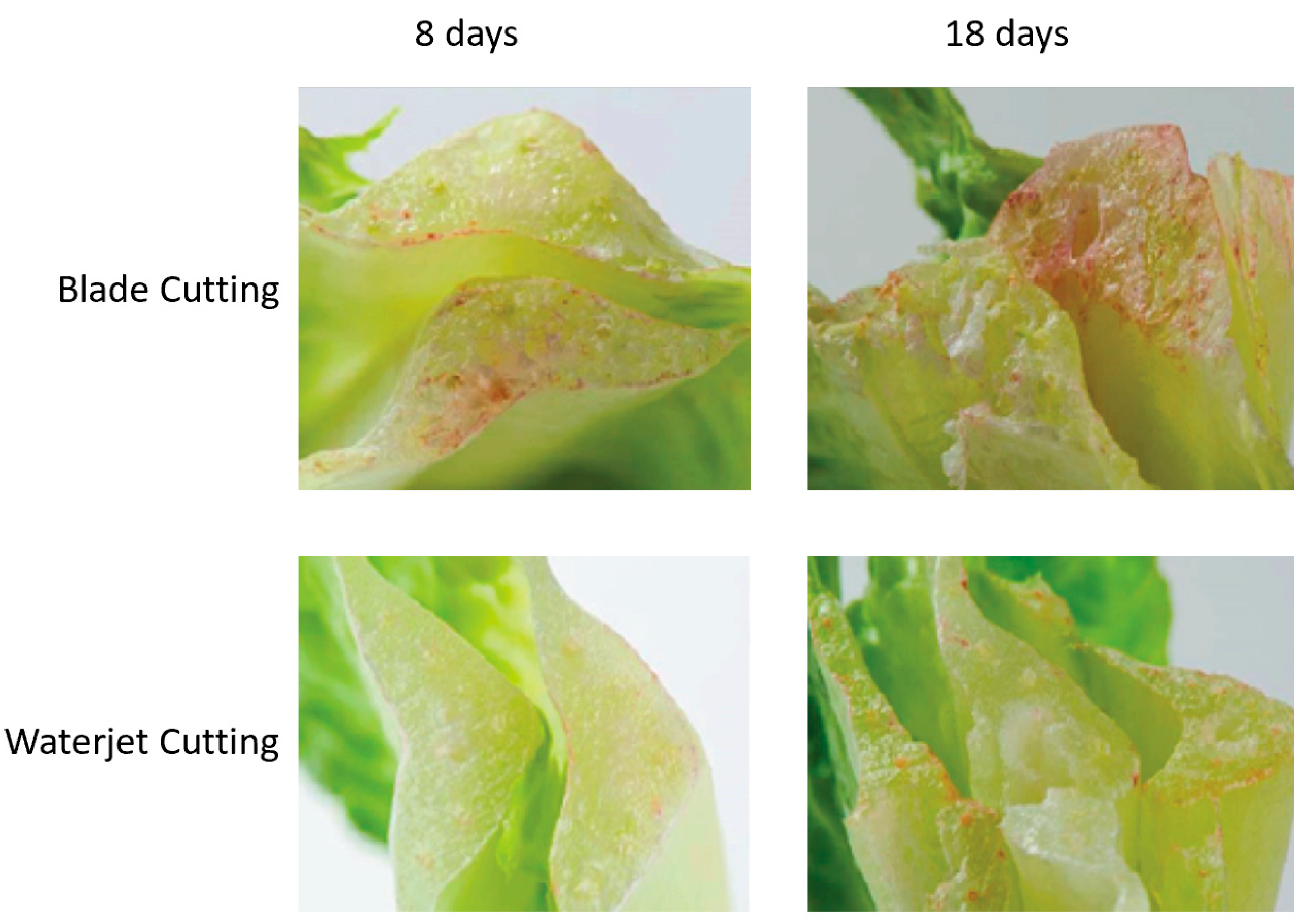

4.4.1. Lettuce and Celery Harvesting and Trimming

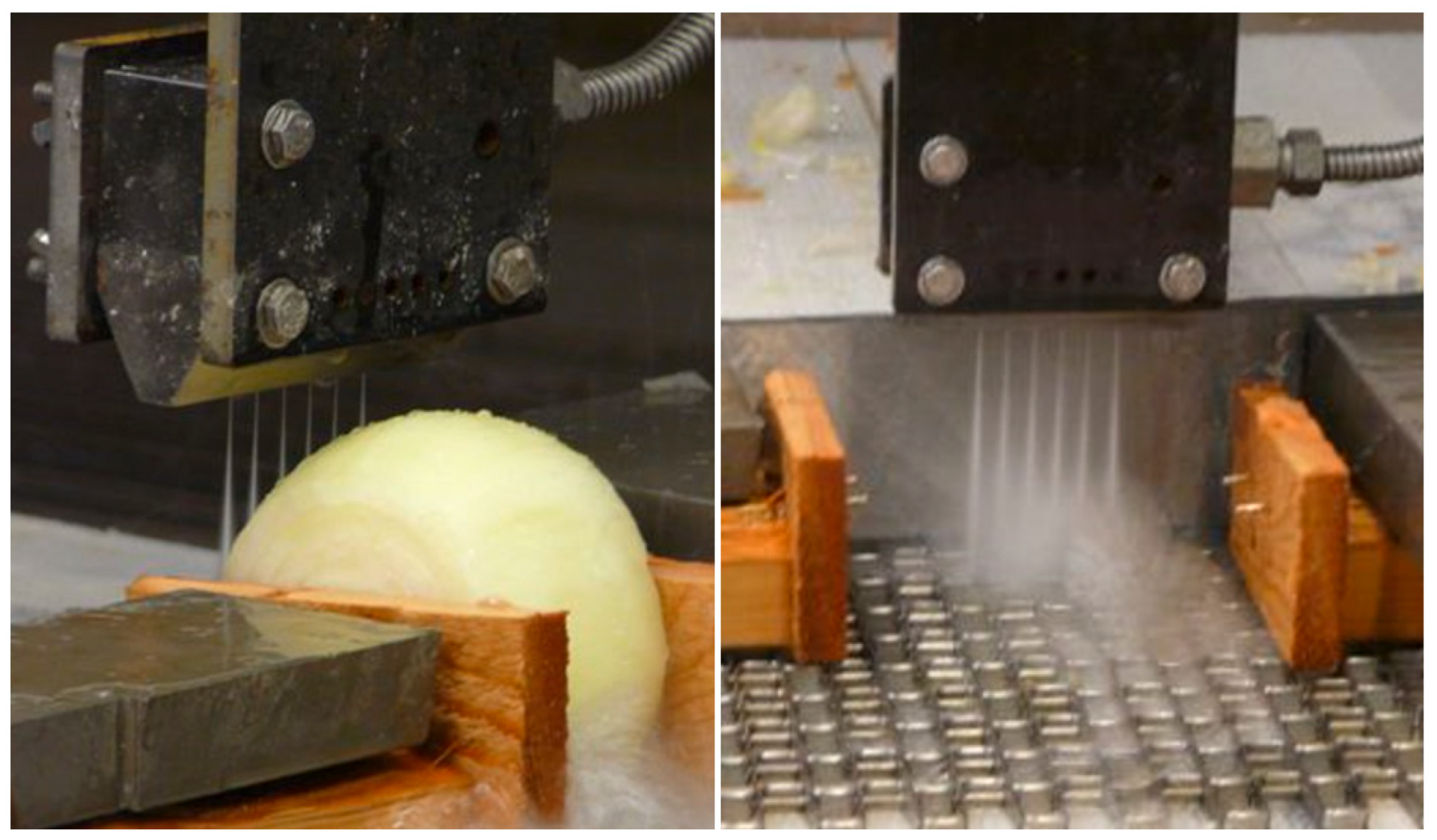

4.4.2. Potatoes, Onions, Carrots, and Sugarcane

4.5. Candy, Backed Food, and Sandwiches

5. Non-Through Cutting Applications

5.1. Deboning

5.2. Peeling and Skinning

6. Conclusions and Recommendations

6.1. Conclusions

- The demands placed on UHP waterjet systems in food processing are well within the capabilities of the current state-of-the-art technology. These systems exhibit high reliability, robustness, and adaptability for both plant-based and field operations.

- Waterjet cutting imparts minimal mechanical force while delivering high power density, allowing for the precise processing of delicate food products without deformation, crushing, or structural damage. This is particularly advantageous for products with soft or heterogeneous textures.

- Compared to conventional mechanical cutting tools such as blades, disks, and wire saws, UHP waterjets offer superior sanitary performance. The absence of contact surfaces eliminates the risk of cross-contamination, as each cut is executed with a clean, renewable cutting medium. Furthermore, waterjets require no tool sharpening or replacement, thereby reducing downtime and maintenance.

- The trimming of vegetables such as celery, lettuce, and green onions using waterjets has been shown to extend shelf life by minimizing cellular damage and reducing microbial contamination at the cut surface. This advantage directly translates to improved product quality and reduced waste in the supply chain.

- A wide range of waterjet cutting system configurations have been successfully deployed, including stationary jet arrays, single- and dual-axis platforms, delta robots, SCARA arms, and six-axis articulated robotic systems. This architectural versatility allows systems to be tailored to diverse food products, geometries, and throughput requirements.

- The integration of software and control technologies, including computer numerical control (CNC), graphical user interfaces (GUIs), and vision-guided sensing systems, plays a critical role in modern waterjet food processing. These systems enable real-time adaptive cutting and portioning, particularly in fish, poultry, and meat applications, and are increasingly integrated into higher-level manufacturing execution systems (MESs) and enterprise resource planning (ERP) platforms.

- Automated field harvesting using waterjets—most notably in lettuce processing—has been successfully implemented and has resulted in significant improvements in operational efficiency, workplace ergonomics, and produce quality. These outcomes validate the feasibility of UHP waterjets beyond in-plant applications.

- Although the waterjet technique has demonstrated promise for non-through-cutting applications such as peeling, skinning, and deboning, there are currently no commercially reported systems operating at scale in these domains. Further technological development, including the refinement of jet types (e.g., fan jets, air–liquid jets, and food-grade abrasive jets), is needed to unlock these applications.

6.2. Recommendation

- Development of High-Cycle On/Off Valves: Although current UHP on/off valve performance is acceptable, future advancements should focus on developing faster-response valves with an extended service life. This is particularly important for high-throughput food applications that require rapid actuation cycles, especially at elevated pressures.

- Utilization of Higher Pressures (Up to 621 MPa): While current systems often operate below 400 MPa, the application of higher pressures up to 621 MPa (90 Ksi) remains largely unexplored in food cutting. Leveraging these higher pressures may enable greater power density, narrower kerf widths, and reduced water consumption—all of which could enhance productivity and process efficiency.

- Exploration of Alternative Jet Modalities: Additional research is warranted to investigate non-traditional waterjet configurations, including the following:

- ○

- Air–liquid jets: These can produce focused droplet streams that may be advantageous in cutting fibrous or layered food products.

- ○

- Food-grade abrasive waterjets: The development of safe, consumable abrasive media (e.g., salt, sugar, starch) could expand waterjet applications to bone-in meats, frozen foods, and tough-skinned produce.

- ○

- Fan-type jets: These may be particularly suitable for surface treatments such as peeling and deboning, offering broader coverage at controlled impact forces.

- Commercialization of Non-Through-Cutting Applications: While laboratory studies and pilot-scale demonstrations have shown the potential of waterjets for peeling, skinning, and deboning, these applications have not yet been widely commercialized. Industry and academia should collaborate to bridge this gap by conducting targeted R&D, optimizing system configurations, and validating hygiene and quality metrics.

- Integration with Advanced Vision and AI Systems: Future systems should integrate high-resolution vision technologies and AI-driven decision-making to enhance automation, especially for variable-shape and multi-component food items. This will be critical in advancing smart manufacturing and real-time quality control.

- Sustainability and Water Efficiency: Research into closed-loop water systems and reduced-flow nozzle designs is recommended to support environmental sustainability, especially in regions where water use is regulated or limited.

- These recommendations aim to guide future innovations in waterjet food processing technologies and support broader industrial adoption across new food categories and production settings.

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| An | Cross-sectional area of orifice |

| Cd | Coefficient of discharge |

| Ew | Waterjet power |

| Ewd | WJ power density |

| F | Waterjet Force |

| mw | Water flow rate |

| P | Pressure |

| Qw | Water flow rate |

| Vw | Waterjet velocity |

References

- Dunsky, C.M.; Hashish, M. Feasibility Study of Machining with High-Pressure Liquefied CO2 Jets. In Proceedings of the 12th International WaterJet Cutting Technology Conference, Rouen, France, 25–27 October 1994; BHR group: Cranfield, UK, 1994; pp. 683–690. [Google Scholar]

- Water ‘Laser’ Cuts Food Products without Dust, Noise or Maintenance. Food Eng. 1982, 54, 99.

- Hashish, M. Kinetic Power Density in Waterjet Cutting. In Proceedings of the 22nd International Conference on Water Jetting, Haarlem, The Netherlands, 3–5 September 2014; BHR Group publication: Cranfield, UK, 2014; pp. 27–44. [Google Scholar]

- Schuldt, S.; Schneider, Y.; Rohm, H. High-speed Cutting of Foods: Cutting Behavior and Initial Cutting Forces. J. Food Eng. 2018, 230, 55–62. [Google Scholar] [CrossRef]

- Raghavan, C.; Hashish, M.; Tremoulet, S.; Callahan, S.; Schuman, B. High Fatigue life Fitting for High Pressure Fluid Systems. U.S. Patent 8,430,430 B2, 30 April 2013. [Google Scholar]

- Hashish, M. Zero-Torque Orifice Mount Assembly. U.S. Patent 7,862,405 B2, 4 January 2011. [Google Scholar]

- Hashish, M.; Monserud, D.; Bondurant, P.; Coleman, W.; Hake, J.; Craigen, S.; White, G. A New Abrasive-Waterjet Nozzle for Automated and Intelligent Machining. In Proceedings of the 7th American Water Jet Conference, Seattle, WA, USA, 28–31 August 1993; pp. 829–843. [Google Scholar]

- Malone, D.E.; Werner, E.F.; Natalie, R.S.; Patrick, P.K.L. Knowledge-Based Control in the Processing of Highly Varying Products. In Proceedings of the 1994 IEEE International Conference on Robotics and Automation, San Diego, CA, USA, 8–13 May 1994; PT 4. pp. 2903–2908. [Google Scholar]

- Waterjet Cutting of Fish under X-Ray. Food Trade Review Magazine, 1 July 2012.

- Alitavoli, M.; McGeough, J. An Expert Process Planning System for Meat Cutting by High Pressure Waterjet. J. Mater. Process. Technol. 1998, 84, 130–135. [Google Scholar] [CrossRef]

- McGeough, J.A. Cutting of Food Products by Ice-particles in a Waterjet. Procedia CIRP 2016, 42, 863–865. [Google Scholar] [CrossRef]

- Heiland, W.K.; Konstance, R.P.; Craig, J.C. Robotic High-Pressure Waterjet Cutting of Chuck Slices. J. Food Process Eng. 1990, 12, 131–136. [Google Scholar] [CrossRef]

- Wang, J.; Shanmugam, D. Cutting Meat with Bone using an Ultrahigh Pressure Abrasive waterjet. Meat Sci. 2009, 81, 671–677. [Google Scholar] [CrossRef]

- Franklínsdóttir, H. Application of Waterjet Cutting in Processing of Cod and Salmon Fillets. Master’s Thesis, University of Iceland, Reykjavík, Iceland, 2014. [Google Scholar]

- Kasperowicz, M.B.; Chomka, G.P.; Bil, T. Determination of Supply Pressure During Cutting Fish Using High-Pressure Water Stream Taking into Account the Cutting Place and Diameter of the Water Nozzle. Int. J. Food Eng. 2020, 16, 20180395. [Google Scholar] [CrossRef]

- Lobash, F.; Lyons, J.T.; Morrison, C.H.; Rustad, S.C. Apparatus and method Utilizing a Water Jet for Cutting Frozen Fish Slabs into a Plurality of Individual Portions. U.S. Patent No. 5031496, 16 July 1991. [Google Scholar]

- Morris, C.E. Vision-Controlled Waterjet Cuts 3300 lbs. of Chicken per Hour. Food Eng. 1992, 65, 64–68. [Google Scholar]

- Bansal, R.K.; Walker, J.T. A Study of High-Pressure Waterjets for Cutting Chicken Breasts. J. Food Process Eng. 1999, 22, 307–318. [Google Scholar] [CrossRef]

- Schield, M. Harvesting Lettuce by Severing with a Waterjet. Master’s Thesis, The University of Arizona, Tucson, AZ, USA, 1972. [Google Scholar]

- Schield, M.; Harriott, B. Cutting Lettuce Stems with a Waterjet. Trans. ASAE 1973, 16, 440–442. [Google Scholar] [CrossRef]

- Cantwell, M.I.; Mole, A.A.M.; Hong, G.; Klose, S. Quality of Waterjet- and Blade-Cut Romaine Salad. In Proceedings of the Third Conference on Fresh-Cut Produce: Maintaining Quality and Safety, Davis, CA, USA, 13–18 September 2015; pp. 153–158. [Google Scholar]

- Béguin, G.; Clays, G.; Delavet, C. Procédé et Dispositif de Découpe de Légumes Etde Fruits. French Patent number 95 04674, 1995. [Google Scholar]

- Maconachy, F.J.; Offerdahl, D. Waterjet Cutting Harvesting Apparatus and Method Therefore. U.S. Patent 7,281,364 B2, 17 October 2007. [Google Scholar]

- Orr, A.; Spingler, J.C. Prolonging the Shelf Life of Pre-Cut Fresh Celery. U.S. Patent 4711789, 8 December 1987. [Google Scholar]

- Orr, A.; Spingler, J.C. Method for Slicing Fruits and Vegetables. U.S. Patent 4751094, 14 June 1988. [Google Scholar]

- Becker, R.; Gray, G.M. Evaluation of Waterjet Cutting System for Slicing Potatoes. J. Food Sci. 1992, 57, 132–137. [Google Scholar] [CrossRef]

- Tatsumi, Y.; Watada, A.; Ling, P. Sodium Chloride Treatment or Waterjet Slicing Effects on White Tissue Development of Carrot Sticks. J. Food Sci. 1993, 58, 1390–1392. [Google Scholar] [CrossRef]

- Posselius, J.H.; Conklin, G.T. Crowning Carrots with a High-Pressure Waterjet. In Proceedings of the 1986 Winter Meeting ASAE, Chicago, IL, USA, 17–20 December 1968; p. #86-6550. [Google Scholar]

- Valco, T.D.; Coble, C.G.; Ruff, J.H. High Pressure Waterjet Cutting of Sugarcane. In Proceedings of the 1979 Winter Meeting ASAE, New Orleans, LA, USA, 11–14 December; 1979; p. #79-1569. [Google Scholar]

- Thanomputra, S.; Kiatiwat, T. Simulation Study of Cutting Sugarcane using Fine Sand Abrasive Waterjet. Agric. Nat. Resour. 2016, 50, 146–153. [Google Scholar] [CrossRef]

- Trieb, F. Pure Waterjets for Sandwiches—The Second Step. In Proceedings of the 2003 WJTA American Waterjet Conference, Houston, TX, USA, 17–19 August 2003; Waterjet Technology Association: St. Louis, MO USA, 2003. Paper 2F. [Google Scholar]

- Merle, M.; Bouix, M.; Sionneau, M.; Vasseur, J. Performance of HP Fluid Jet to Cut Food Products. In Proceedings of the 7th American Water Jet Conference, Seattle, WA, USA, 28–31 August 1993; Waterjet Technology Association: St. Louis, MO USA, 1993. [Google Scholar]

- Boyle, R. Industrial Food Machine of the Day: Slicing Our Breakfast Pastry with a Waterjet. Popular Science, 12 June 2012. [Google Scholar]

- Lambooij, E.; Schatzmann, U. The use of a high pressure waterjet combined with electro immobilization for the stunning of slaughter pigs: Some aspects of meat quality. Meat Sci. 1994, 37, 381–389. [Google Scholar] [CrossRef] [PubMed]

- Onions Without Tears. Food Manuf. 1982, 57, 43.

- Machine Tops, Tails, and Skins Onions. Food Eng. Int. 1982, 7, 81.

- Kluz, K.; Geskin, E. Application of Ice Powder in Biomedical and Food Industries. In Proceedings of the 2005 WJTA American Waterjet Conference, Huston, TX, USA, 21–23 August 2005. [Google Scholar]

- Singh, R.P.; Brown, D.E. Squid Processing Machine. U.S. Patent 4285099, 25 August 1981. [Google Scholar]

| Slice Thickness | Cutting Speed | Kerf Loss | Remarks |

|---|---|---|---|

| mm | m/min | ||

| 12.5 | 25 | <2% | clean cut through full thickness |

| 25 | 5 | <2% | clean cut through full thickness |

| 50 | 1 | >5% | Lower half is rough |

| 100 | 0.2 | >10% | Lower half extremely ragged |

| Cutting Method | Microflora Count | Days of Acceptable Sensory Quality (2) |

|---|---|---|

| CFU/g (1) | 10 °C | |

| Kitchen paring knife | 2 × 1011 | 12 |

| Commercial rotary blade cutter | 4 × 1011 | 13 |

| Single Edge razor blade | 1 × 109 | 24 |

| Sharp thin blade knife sawing motion | 5 × 106 | 25–40 |

| Waterjet | 5 × 104 | 25–40 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hashish, M. Food Processing with UHP Waterjets. Appl. Sci. 2025, 15, 6246. https://doi.org/10.3390/app15116246

Hashish M. Food Processing with UHP Waterjets. Applied Sciences. 2025; 15(11):6246. https://doi.org/10.3390/app15116246

Chicago/Turabian StyleHashish, Mohamed. 2025. "Food Processing with UHP Waterjets" Applied Sciences 15, no. 11: 6246. https://doi.org/10.3390/app15116246

APA StyleHashish, M. (2025). Food Processing with UHP Waterjets. Applied Sciences, 15(11), 6246. https://doi.org/10.3390/app15116246