Advanced Sound Insulating Materials: An Analysis of Material Types and Properties

Abstract

1. Introduction

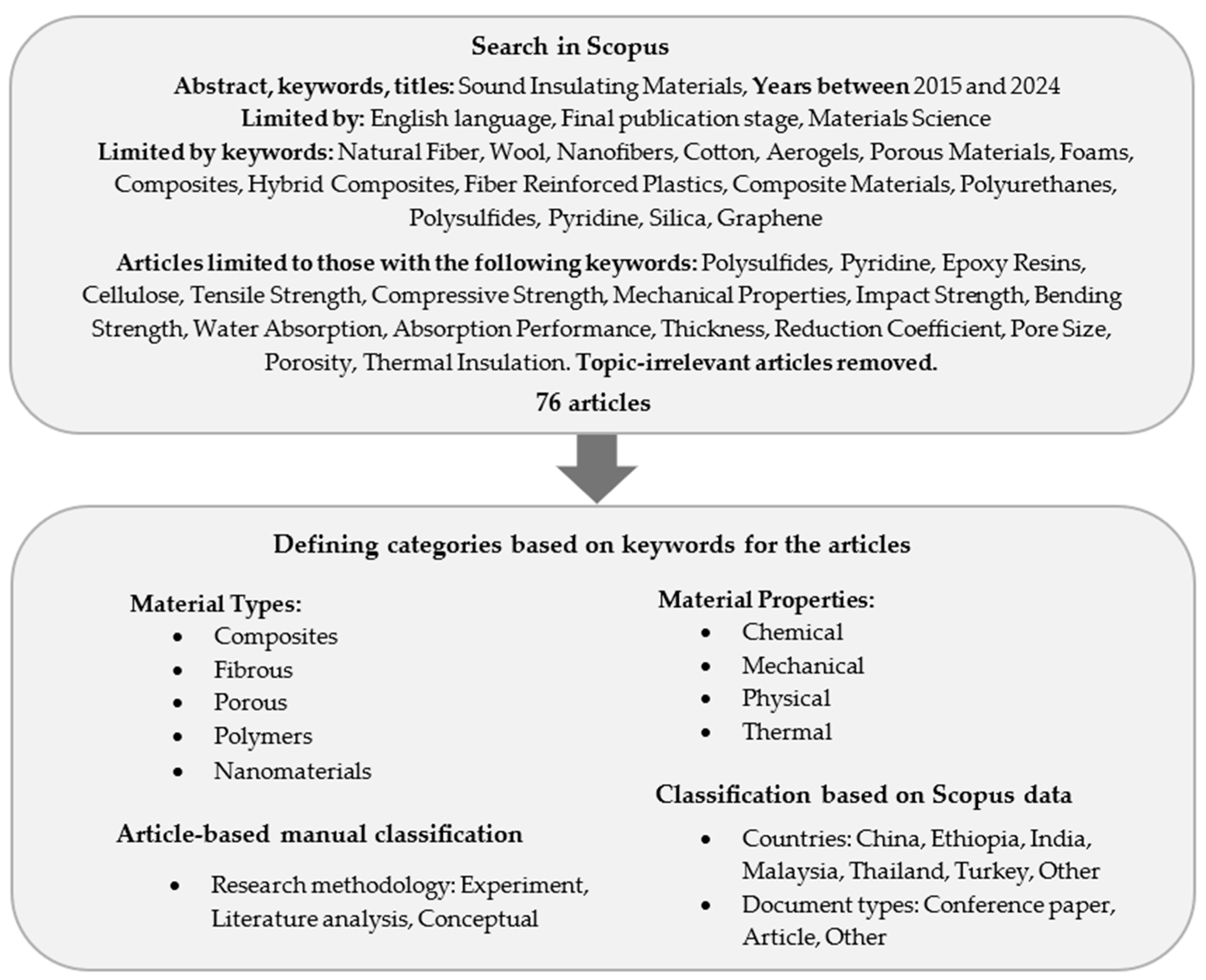

2. Materials and Methods

2.1. Data Selection

2.2. Data Analysis

- Type of materials (composites, fibrous, porous, polymers, or nanomaterials),

- Material properties investigated (chemical, mechanical, physical, or thermal),

- Country of affiliation of the authors (based on SCOPUS data)—if 2 authors are from China and 1 is from India, then both locations will appear, i.e., China, India,

- Type of document (article, conference paper, or review article),

- Research methodology—this classification was conducted based on the analysis of abstracts and the full content of the articles. Each publication was read individually and evaluated to assign it to one of three methodological categories, according to the following rules:

- a.

- Experiment—articles were classified into this category if they described empirical studies conducted by the authors, such as their own measurements of material properties.

- b.

- Literature analysis—this category included publications based on the analysis of existing literature, research reviews, or previously published studies.

- c.

- Conceptual—this group included articles in which the authors developed models (e.g., using linear regression) or presented new theoretical concepts.

3. Results

4. Discussion

5. Conclusions

- Composites—research included the effect of selected parameters (e.g., type of fiber [1,2,3,4,5,6] or resin addition [7,8]), but was conducted under different test conditions. This makes it difficult to compare the results. Thus, it is worth conducting comparative studies with standardized measurement procedures for acoustic properties, e.g., according to ISO 11654 (for the classification of sound-absorbing materials) [96]. The second area worth pointing out is the insufficient amount of research in the context of environmental specs. Only a few publications have considered recycled materials (e.g., tire granulate [24], recycled textiles [25]), and there is a lack of a broader environmental assessment of composite materials. This is particularly important when promoting biocomposites as a sustainable and environmentally friendly alternative to other materials.

- Fibrous—the category to which the most publications were assigned. The studies carried out were on different types of fibers (cotton [10,33,34,36], wool [29,30,31,32], jute [18], kapok [48], bamboo [15], luffa [18,49], biduri [46], and banana [12]). However, a comparative analysis conducted under the same conditions is lacking, making it difficult to draw conclusions about the effectiveness of different types of fibers in terms of sound absorption. As with other materials, research has focused mainly on properties under laboratory conditions. Missing, for example, are analyses of the effects of atmospheric conditions, resistance to mechanical wear, or the behavior of a given material over a long period of use. On the basis of the analysis, it was also diagnosed that some of the work focused on modern concepts, but little of it translates into concrete prototypes of products ready to be implemented in practice.

- Porous—the analyzed publications presented, among other things, results on specific material properties (e.g., [55,56,57,58]). However, there is a lack of a consistent set of standards and test methods, which makes direct comparisons and utilization in practical applications difficult. Despite the innovation and high performance of some materials (e.g., aerogels with a hierarchical cell structure [59]), there is a lack of analyses of economic viability or the availability of raw materials and energy intensity of production processes.

- Polymers—this group of materials was the least represented among the publications analyzed. Previous research has focused mainly on the acoustic properties of various forms of polyurethane foam [22,72] and its modifications [23,65,70,71]. In-depth analyses of the chemical, mechanical, and thermal properties of these materials, especially in the context of their durability or resistance, are lacking. It is worth extending the research to biodegradable polymers, especially in the context of sustainable development and environmental protection. In the context of future research, it is proposed, among other things, to compare biodegradable polymers with traditional polymers in terms of environmental impact, energy intensity, and CO₂ emissions. Further research may also aim to analyze increasing their performance without increasing costs by designing cellular and porous structures (e.g., PLA or PHA foams) for improved sound attenuation. In addition, research into the effects of various types of additives, such as natural fibers, on the acoustic properties of polymer composites is a promising direction of development.

- Nanomaterials—in the reviewed publications, nanocomposites with enhanced mechanical properties [76], hardness [19], and elasticity [60], as well as compressive, flexural, and tensile strength [75], were analyzed. Most of the research was conducted under laboratory conditions [5,19,75]. There is a lack of research conducted under field or application conditions to verify the effectiveness of nanomaterials in, for example, industrial equipment or transportation infrastructure.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mondal, M.S.; Hussain, S.Z. Banana-Glass Fiber Composite for Acoustic Insulation and Prediction of Its Properties by Fuzzy Logic System. J. Nat. Fibres 2023, 20, 2212928. [Google Scholar] [CrossRef]

- Marichelvam, M.K.; Kandakodeeswaran, K.; Geetha, M. Mechanical and Acoustic Properties of Bagasse–Coconut Coir Based Hybrid Reinforced Composites. J. Nat. Fibres 2022, 19, 4105–4114. [Google Scholar] [CrossRef]

- Jawahar, V.; Gabriel, M.; Santhanam, S.; Selvaraj, S.K. Sustainable Waste Cotton and Pigeon Pea Stalk Fibers Composite Materials for Acoustics and Thermal Properties. J. Eng. Fibers Fabr. 2023, 18, 15589250231189814. [Google Scholar] [CrossRef]

- Krishnasamy, B.; Shanmugam, N.; Subramanian, A.; Selvaraj, S.K.; Sakthivel, S.; Guru, R.; Admassu, Y. Sound-Absorbing and Thermal Insulating Properties of Natural Coir/Jute Hybrid Composites for Functional Materials. J. Eng. Fibers Fabr. 2024, 19, 15589250241270522. [Google Scholar] [CrossRef]

- Mondal, M.S.; Sarkar, J.; Hasan, N.; Mehedi, H.A.; Dutta, P. Development of Recycled Natural Fiber Based Composite Material by Hand Lay-Up Process and Analysis of Its Acoustic & Physical Properties. J. Nat. Fibres 2022, 19, 14898–14908. [Google Scholar] [CrossRef]

- Prabhu, L.; Krishnaraj, V.; Gokulkumar, S.; Sathish, S.; Ramesh, M. Mechanical, Chemical and Acoustical Behavior of Sisal-Tea Waste-Glass Fiber Reinforced Epoxy Based Hybrid Polymer Composites. In Proceedings of the Materials Today: Proceedings; Palanikumar, K., Ed.; Elsevier Ltd.: Amsterdam, The Netherlands, 2019; Volume 16, pp. 653–660. [Google Scholar] [CrossRef]

- Dhandapani, N.; Megalingam, A. Mechanical and Sound Absorption Behavior of Sisal and Palm Fiber Reinforced Hybrid Composites. J. Nat. Fibres 2022, 19, 4530–4543. [Google Scholar] [CrossRef]

- Moulya, H.V.; Vasu, V.K.; Praveena, B.A.; Rajesh, M.; Ruthuparna, S.A.; Rahul, K. Study on Acoustic Properties of Polyester-Fly Ash Cenosphere\Nanographene Composites. In Proceedings of the Materials Today: Proceedings; Karinka, S., Yarlagadda, P.K.D.V., Shetty, R., Veeresha, K., Kumar, N., Eds.; Elsevier Ltd.: Amsterdam, The Netherlands, 2022; Volume 52, pp. 1272–1277. [Google Scholar] [CrossRef]

- Agirgan, M.; Agirgan, A.O.; Taskin, V. Investigation of Thermal Conductivity and Sound Absorption Properties of Rice Straw Fiber/Polylactic Acid Biocomposite Material. J. Nat. Fibres 2022, 19, 15071–15084. [Google Scholar] [CrossRef]

- Subramanian, A.; Selvaraj, S.K.; Mani, R.; Chandrasekaran, P.; Kunjuraman, S.; Guru, R.; Santhanam, S. Utilizing Waste Cotton/Pigeon Pea Stalk Fibers Composites for Enhanced Sound Absorption and Insulation in Automotive Interiors. J. Nat. Fibres 2024, 21, 2333940. [Google Scholar] [CrossRef]

- Sakthivel, S.; Senthil Kumar, S.; Solomon, E.; Getahun, G.; Admassu, Y.; Bogale, M.; Gedilu, M.; Aduna, A.; Abedom, F. Sound Absorbing and Insulating Properties of Natural Fiber Hybrid Composites Using Sugarcane Bagasse and Bamboo Charcoal. J. Eng. Fibers Fabr. 2021, 16, 15589250211044818. [Google Scholar] [CrossRef]

- Imoisili, P.E.; Jen, T.-C. Mechanical and Acoustic Performance of Plantain (Musa Paradisiacal) Fibre Reinforced Epoxy Bio-Composite. J. Nat. Fibres 2022, 19, 11658–11665. [Google Scholar] [CrossRef]

- Witthayolankowit, K.; Boonyarit, J.; Srichola, P.; Rungruangkitkrai, N.; Apipatpapha, T.; Chollakup, R. Drought Tolerant Plants’ Fiber and Recycled PET Co-Fibrous Composite as Acoustic Absorbers and Thermal Insulators. J. Nat. Fibres 2023, 20, 2277842. [Google Scholar] [CrossRef]

- Sekar, V.; Eh Noum, S.Y.; Sivanesan, S.; Putra, A.; Chin Vui Sheng, D.D.; Kassim, D.H. Effect of Thickness and Infill Density on Acoustic Performance of 3D Printed Panels Made of Natural Fiber Reinforced Composites. J. Nat. Fibres 2022, 19, 7132–7140. [Google Scholar] [CrossRef]

- Kudva, A.; Mahesha, M.; Hegde, S.; Pai, D. Influence of Chemical Treatment of Bamboo Fibers on the Vibration and Acoustic Characterization of Carbon/Bamboo Fiber Reinforced Hybrid Composites. Mater. Res. Express 2024, 11, 075304. [Google Scholar] [CrossRef]

- Thakare, P.A.; Kumar, N.; Ugale, V.B. Sound Transmission Loss and Flexural Strength Assessment of Hybrid Composite Reinforced with Natural Fibers and Kevlar. In Proceedings of the Materials Today: Proceedings; Davim, J.P., Kumar, K., Babu, S., Eds.; Elsevier Ltd.: Amsterdam, The Netherlands, 2019; Volume 19, pp. 686–690. [Google Scholar] [CrossRef]

- Senthilrajan, S.; Venkateshwaran, N.; Giri, R.; Ismail, S.O.; Nagarajan, R.; Krishnan, K.; Mohammad, F. Mechanical, Vibration Damping and Acoustics Characteristics of Hybrid Aloe Vera /Jute/Polyester Composites. J. Mater. Res. Technol. 2024, 31, 2402–2413. [Google Scholar] [CrossRef]

- Koruk, H.; Ozcan, A.C.; Genc, G.; Sanliturk, K.Y. Jute and Luffa Fiber-Reinforced Biocomposites: Effects of Sample Thickness and Fiber/Resin Ratio on Sound Absorption and Transmission Loss Performance. J. Nat. Fibres 2022, 19, 6239–6254. [Google Scholar] [CrossRef]

- Iyyadurai, J.; Arockiasamy, F.S.; Manickam, T.S.; Suyambulingam, I.; Siengchin, S.; Appadurai, M.; Raj, E.F.I. Revolutionizing Polymer Composites: Boosting Mechanical Strength, Thermal Stability, Water Resistance, and Sound Absorption of Cissus Quadrangularis Stem Fibers with Nano Silica. Silicon 2023, 15, 6407–6419. [Google Scholar] [CrossRef]

- Tiwari, S.K.; Umamaheswara Rao, A.; Reddy, N.; Sharma, H.; Pandey, J.K. Synthesis, Characterization and Finite Element Analysis of Polypropylene Composite Reinforced by Jute and Carbon Fiber. In Proceedings of the Materials Today: Proceedings; Singh, Y., Ed.; Elsevier Ltd.: Amsterdam, The Netherlands, 2021; Volume 46, pp. 10884–10891. [Google Scholar] [CrossRef]

- Wang, Y.; Zuo, X.; Kong, D.; Zhang, F.; Ran, S. Pore Structure and Compressive Property of High Porosity ZL104 Alloy/Aluminium Fiber Composite Foam. Mater. Res. Express 2019, 6, 0965b2. [Google Scholar] [CrossRef]

- Guo, C.; Sun, P.; Shao, S.; Yu, T.; Jiang, F.; Li, Y.; Cui, X.; Li, J. Investigation on the Low-Frequency Acoustic Performance of Polymer Matrix Composite With Metallic Hollow Spheres Under Different Acoustic Stack Structures. Polym. Adv. Technol. 2024, 35, e6647. [Google Scholar] [CrossRef]

- Jiang, F.; Yu, T.; Wang, C.; Cao, M.; Wang, Z.; Chang, Y.; Guo, C. Acoustic/Mechanical Properties of Polyurethane Composites with Syntactic Hollow Spheres. Polym. Adv. Technol. 2021, 32, 1363–1371. [Google Scholar] [CrossRef]

- Shah, S.N.; Beddu, S.; Yap, S.P.; Putra, A.; Othman, M.N.; Yuen, C.W.; Mo, K.H. Physical, Strength and Acoustic Properties of Lightweight Cement Composite with Preplaced Chemically-Treated Crumb Rubber. Case Stud. Constr. Mater. 2024, 20, e02821. [Google Scholar] [CrossRef]

- Kanta Mahapatra, T.; Satapathy, S.; Kumar Panda, S. Thermal and Acoustic Properties Evaluation of Waste Tire and Textile Reinforced Epoxy Composites. In Proceedings of the Materials Today: Proceedings; Elsevier Ltd.: Amsterdam, The Netherlands, 2022; Volume 62, pp. 5982–5986. [Google Scholar] [CrossRef]

- Yan, L.; Chu, F.; Tuo, W.; Zhao, X.; Wang, Y.; Zhang, P.; Gao, Y. Review of Research on Basalt Fibers and Basalt Fiber-Reinforced Composites in China (I): Physicochemical and Mechanical Properties. Polym. Polym. Compos. 2021, 29, 1612–1624. [Google Scholar] [CrossRef]

- Prabhune, S.; Munde, Y.; Shinde, A.; Siva, I. Appraising the Acoustic Performance and Related Factors of Natural Fiber: A Review. J. Nat. Fibres 2022, 19, 13475–13494. [Google Scholar] [CrossRef]

- Haridass, R.; Jaganathan, A.; Subramani, N.; Loganathan, D.; Manikandan, N. Comparative Analysis of Mechanical Behaviour of Glass Fiber and Rice Husk Reinforced Composites. In Proceedings of the Materials Today: Proceedings; Elsevier Ltd.: Amsterdam, The Netherlands, 2022; Volume 65, pp. 3927–3932. [Google Scholar] [CrossRef]

- Maleksabet, F.; Zohoori, S. Surface Modification of Wool: Superior Sound Absorption and Water Resistance. J. Nat. Fibres 2022, 19, 7878–7884. [Google Scholar] [CrossRef]

- Jing, L.; Jiang, Y.; Li, L.; Zhang, T. Influence of Alkali Treatment on Microstructure Transformation and Mechanical Properties of Palm-Fiber Cell Wall. J. Nat. Fibres 2023, 20, 2237681. [Google Scholar] [CrossRef]

- Dwivedi, S.; Bajaj, D.; Sahu, D.; Rajak, T.K. Acoustical and Heat Characterization of Recycled Fibre Reinforced Bricks. In Proceedings of the Materials Today: Proceedings; Elsevier Ltd.: Amsterdam, The Netherlands, 2023; Volume 74, pp. 1042–1051. [Google Scholar] [CrossRef]

- Beheshti, M.H.; Firoozi, A.; Jafarizaveh, M.; Tabrizi, A. Acoustical and Thermal Characterization of Insulating Materials Made from Wool and Sugarcane Bagasse. J. Nat. Fibres 2023, 20, 2237675. [Google Scholar] [CrossRef]

- Broda, J.; Bączek, M. Acoustic Properties of Multi-Layer Wool Nonwoven Structures. J. Nat. Fibres 2020, 17, 1567–1581. [Google Scholar] [CrossRef]

- Zhu, W.; Nandikolla, V.; George, B. Effect of Bulk Density on the Acoustic Performance of Thermally Bonded Nonwovens. J. Eng. Fibers Fabr. 2015, 10, 39–45. [Google Scholar] [CrossRef]

- Yang, T.; Hu, L.; Xiong, X.; Yu, D.; Petrů, M.; Yang, K.; Novák, J.; Militký, J. Sound Absorption Properties and Accuracy of Prediction Models on Natural Fiber Based Nonwoven Materials. J. Nat. Fibres 2022, 19, 10588–10600. [Google Scholar] [CrossRef]

- Sakthivel, S.; Senthil Kumar, S.; Mekonnen, S.; Solomon, E. Thermal and Sound Insulation Properties of Recycled Cotton/Polyester Chemical Bonded Nonwovens. J. Eng. Fibers Fabr. 2020, 15, 1558925020968819. [Google Scholar] [CrossRef]

- Boominathan, S.; Bhuvaneshwari, M.; Sangeetha, K.; Pachiyappan, K.M.; Devaki, E. Influence of Fiber Blending on Thermal and Acoustic Properties Nonwoven Material. J. Nat. Fibres 2022, 19, 11193–11203. [Google Scholar] [CrossRef]

- Kesharwani, A.; Bedi, R.; Kumar Bagha, A.; Bahl, S. Experimental Study to Measure the Sound Transmission Loss of Natural Fibers at Tonal Excitations. In Proceedings of the Materials Today: Proceedings; Chauhan, A., Sehgal, S., Eds.; Elsevier Ltd.: Amsterdam, The Netherlands, 2020; Volume 28, pp. 1554–1559. [Google Scholar] [CrossRef]

- Koruk, H. Assessment of the Measurement and Prediction Methods for the Acoustic Properties of Natural Fiber Samples and Evaluation of Their Properties. J. Nat. Fibres 2022, 19, 6283–6311. [Google Scholar] [CrossRef]

- Pavlović, S.S.; Stanković, S.B.; Žekić, A.; Nenadović, M.; Popović, D.M.; Milosavljević, V.; Poparić, G.B. Impact of Plasma Treatment on Acoustic Properties of Natural Cellulose Materials. Cellulose 2019, 26, 6543–6554. [Google Scholar] [CrossRef]

- Periyasamy, A.P.; Karunakaran, G.; Rwahwire, S.; Kesari, K. Nonwoven Fabrics Developed from Agriculture and Industrial Waste for Acoustic and Thermal Applications. Cellulose 2023, 30, 7329–7346. [Google Scholar] [CrossRef]

- Malawade, U.A.; Malgaonkar, V.V.; Badadhe, A.M.; Jadhav, M.G. Utilization and Study of Raw Groundnut Shell as a Source of Sound Absorbing Material. J. Nat. Fibres 2022, 19, 6335–6347. [Google Scholar] [CrossRef]

- Lyu, L.; Li, C.; Wang, Y.; Lu, J.; Guo, J. Sound Absorption, Thermal, and Flame Retardant Properties of Nonwoven Wall Cloth with Waste Fibers. J. Eng. Fibers Fabr. 2020, 15, 1558925020934124. [Google Scholar] [CrossRef]

- Beheshti, M.H.; Khavanin, A.; Safari Varyani, A.; Yahya, M.N.B.; Alami, A.; Khajenasiri, F.; Talebitooti, R. Improving the Sound Absorption of Natural Waste Material-Based Sound Absorbers Using Micro-Perforated Plates. J. Nat. Fibres 2022, 19, 5199–5210. [Google Scholar] [CrossRef]

- Zhuang, J.; Lv, J.; Jin, W.; Yu, Q.; Yu, J.; He, L.; Tang, X.; Ran, W.; Cai, G.; Cheng, D.; et al. Multifunctional Carboxymethyl Cellulose Nanofiber/Liquid Metal Aerogels for Sound Absorption and Heat Insulation. Cellulose 2024, 31, 9253–9263. [Google Scholar] [CrossRef]

- Judawisastra, H.; Sukmawati, A.; Zaidi, S.Z.J.; Harito, C. Sustainable Sound Absorber from Nonwoven Fabric of Natural Biduri Fibers (Calotropis Gigantea) with Polyester Binder. J. Nat. Fibres 2022, 19, 12791–12804. [Google Scholar] [CrossRef]

- Lee, H.P.; Ng, B.M.P.; Rammohan, A.V.; Tran, L.Q.N. An Investigation of the Sound Absorption Properties of Flax/Epoxy Composites Compared with Glass/Epoxy Composites. J. Nat. Fibres 2017, 14, 71–77. [Google Scholar] [CrossRef]

- Velayutham, T.; Kumar, M.R.; Sundararajan, P.; Chung, I.-M.; Prabakaran, M. A Study on the Effect of Natural Regenerated and Synthetic Non-Woven Fabric Properties on Acoustic Applications. J. Nat. Fibres 2022, 19, 6553–6563. [Google Scholar] [CrossRef]

- Singh, P.P.; Nath, G. Fabrication and Analysis of Luffa Natural Fiber Based Acoustic Shielding Material for Noise Reduction. J. Nat. Fibres 2022, 19, 11218–11234. [Google Scholar] [CrossRef]

- Shao, X.; Yan, X. Sound Absorption Properties and Mechanism of Multi-Layer Micro-Perforated Nanofiber Membrane. Polym. Adv. Technol. 2024, 35, e6583. [Google Scholar] [CrossRef]

- Yang, M.; Ding, Y.; Chen, Z.; Wu, Q.; Liu, L.; Liu, T.; Li, M.; Xu, K.; Le, L.; Yang, L. Layered ZrO2/SiO2 Aerogel Composite Fibrous Flexibility Membrane for Thermal Insulation and Sound Absorption. J. Am. Ceram. Soc. 2024, 107, 4307–4320. [Google Scholar] [CrossRef]

- Ding, B. Electrospun Nanofiber-Assembled Cellular Aerogels with Superelasticity and Multifunctionality. In Proceedings of the Fiber Society’s Spring 2015 Conference, in conjunction with the 2015 International Conference on Advanced Fibers and Polymer Materials: Functional Fibers and Textiles-Program, Shanghai, China, 24–27 May 2015; Fiber Society. Available online: https://thefibersociety.org/Portals/0/Past%20Conferences/2015_Spring_Abstracts.pdf (accessed on 26 May 2025).

- Eyupoglu, S.; Merdan, N. Investigation of the Characteristic and Sound Absorption Properties of a New Cellulose-Based Fiber from Alcea rose L. Plant. J. Nat. Fibres 2022, 19, 10082–10093. [Google Scholar] [CrossRef]

- Sun, H.; Yang, B.; Zhang, M. Functional–Structural Integrated Aramid Nanofiber-Based Honeycomb Materials with Ultrahigh Strength and Multi-Functionalities. Adv. Fiber Mater. 2024, 6, 1122–1137. [Google Scholar] [CrossRef]

- Cao, L.; Si, Y.; Wu, Y.; Wang, X.; Yu, J.; Ding, B. Ultralight, Superelastic and Bendable Lashing-Structured Nanofibrous Aerogels for Effective Sound Absorption. Nanoscale 2019, 11, 2289–2298. [Google Scholar] [CrossRef]

- Altay, P. The Effect of Silica Aerogel on Thermal and Sound Absorption Insulation Properties of Epoxy Plate and Glass Fiber Fabric Epoxy Composite. J. Elastomers Plast. 2023, 55, 316–330. [Google Scholar] [CrossRef]

- Zhao, X.; Hu, Y.; Xu, X.; Li, M.; Han, Y.; Huang, S. Sound Absorption Polyimide Composite Aerogels for Ancient Architectures’ Protection. Adv. Compos. Hybrid. Mater. 2023, 6, 137. [Google Scholar] [CrossRef]

- Zang, K.; Wang, X.; Liu, L.; Peng, H.-K.; Ren, H.-T.; Zhang, L.; Lin, J.-H.; Lou, C.-W.; Li, T.-T. Thermal Insulation and Antibacterial Honeycomb Aerogel Derived from Carboxymethyl Chitosan for Integrated Sound Absorption. Cellulose 2024, 31, 3573–3588. [Google Scholar] [CrossRef]

- Zhao, X.; Ruan, K.; Qiu, H.; Zhong, X.; Gu, J. Fatigue-Resistant Polyimide Aerogels with Hierarchical Cellular Structure for Broadband Frequency Sound Absorption and Thermal Insulation. Adv. Compos. Hybrid. Mater. 2023, 6, 171. [Google Scholar] [CrossRef]

- Rapisarda, M.; Meo, M. Multifunctional Thermal, Acoustic, and Piezoresistive Properties of In Situ-Modified Composite Aerogels with Graphene Oxide as the Main Phase. ACS Appl. Mater. Interfaces 2022, 14, 43646–43655. [Google Scholar] [CrossRef] [PubMed]

- Yuksek, I.O.; Ucar, N. Improvement of Sound Absorption Coefficient of Glass Fiber Fabric Epoxy Composite Inherently without Deterioration of Main Mechanical Properties. Polym. Polym. Compos. 2022, 30, 09673911221086711. [Google Scholar] [CrossRef]

- Xue, W.; Feng, Y.; Wang, J.; Fang, Z.; Shen, J.; Ma, Y.; Wang, Y.; Liu, H.; Li, L. Preparation of Polymer Hollow Microsphere Filled Epoxy Resin-Based Syntactic Foam Material and Its Performance Analysis. Front. Mater. 2024, 11, 1500015. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, J.; Cheng, Z. Application of Response Surface Methodology to Optimize the Preparation of Rubber Foam Composite as Sound-Absorbing Material Using Scrap Rubber Powder. J. Wuhan Univ. Technol. Mater Sci. Ed. 2019, 34, 1376–1383. [Google Scholar] [CrossRef]

- Chen, W.; Guo, Z.; Feng, H.; Hu, S.; Lu, L.; Chen, C.; Wu, X.; Cao, H. Optimization of Sound Absorption and Insulation Performances of a Dual-Cavity Resonant Micro-Perforated Plate. Fluid Dyn. Mater. Process. 2022, 18, 481–496. [Google Scholar] [CrossRef]

- Li, T.-T.; Zhang, X.; Wang, H.; Dai, W.; Huang, S.-Y.; Shiu, B.-C.; Lou, C.-W.; Lin, J.-H. Sound Absorption and Compressive Property of PU Foam-Filled Composite Sandwiches: Effects of Needle-Punched Fabric Structure, Porous Structure, and Fabric-Foam Interface. Polym. Adv. Technol. 2020, 31, 451–460. [Google Scholar] [CrossRef]

- Qiao, J.; Qiao, W.; Gao, H.; Yang, J.; Li, Z.; Wang, P.; Cao, C.; Zhang, J.; Tang, C.; Xue, Y. Highly Multifunctional Performances of Boron Nitride Nanosheets/Polydimethylsiloxane Composite Foams. ACS Appl. Mater. Interfaces 2023, 15, 5760–5773. [Google Scholar] [CrossRef]

- Simón-Herrero, C.; Chen, X.-Y.; Ortiz, M.L.; Romero, A.; Valverde, J.L.; Sánchez-Silva, L. Linear and Crosslinked Polyimide Aerogels: Synthesis and Characterization. J. Mater. Res. Technol. 2019, 8, 2638–2648. [Google Scholar] [CrossRef]

- Dong, K.; Wang, X.; Yang, J. Predicting Model of Sound Absorbing Properties of Cellulose-Based Porous Materials Prepared by Foam Forming. J. Nat. Fibres 2022, 19, 9614–9623. [Google Scholar] [CrossRef]

- Lou, C.-W.; Tian, F.; Zhou, X.; Zhang, L.; Li, S.; Lin, J.-H.; Li, T.-T. Dual-Network PVA Fiber-Doped Cellulose Aerogel with Labyrinth Structure for Low and Medium Frequency Acoustic and Flame Retardant Applications. Cellulose 2024, 31, 5795–5807. [Google Scholar] [CrossRef]

- Ji, Y.; Chen, S. Preparation and Acoustic Properties of a Tung Oleic Acid-Based Polyurethane Foam and Its Stratified Structure. Polym. Adv. Technol. 2020, 31, 3020–3031. [Google Scholar] [CrossRef]

- Lin, J.-H.; Chuang, Y.-C.; Li, T.-T.; Huang, C.-H.; Huang, C.-L.; Chen, Y.-S.; Lou, C.-W. Effects of Perforation on Rigid PU Foam Plates: Acoustic and Mechanical Properties. Materials 2016, 9, 1000. [Google Scholar] [CrossRef] [PubMed]

- Sukhawipat, N.; Yingshataporn-A-Nan, T.; Minanandana, T.; Puksuwan, K.; Saengdee, L.; Nakaramontri, Y.; Sosa, N.; Saetung, N. Effects of Water Hyacinth Fiber Size on Sound Absorption Properties of Advanced Recycled Palm Oil-Based Polyurethane Foam Composite. In Proceedings of the Materials Today: Proceedings; Chadra-ambhorn, S., Phalakornkule, C., Jamsawang, P., Harnnarongchai, W., Eds.; Elsevier Ltd.: Amsterdam, The Netherlands, 2021; Volume 52, pp. 2409–2413. [Google Scholar] [CrossRef]

- Du, Z.; Yao, D.; Xia, Y.; Zuo, K.; Yin, J.; Liang, H.; Zeng, Y.-P. The Sound Absorption Performance of the Highly Porous Silica Ceramics Prepared Using Freeze Casting Method. J. Am. Ceram. Soc. 2020, 103, 5990–5998. [Google Scholar] [CrossRef]

- He, C.; Du, B.; Ma, J.; Xiong, H.; Qian, J.; Cai, M.; Shui, A. Enhanced Sound Absorption Properties of Porous Ceramics Modified by Graphene Oxide Films. J. Am. Ceram. Soc. 2022, 105, 3177–3188. [Google Scholar] [CrossRef]

- Algaifi, H.A.; Syamsir, A.; Baharom, S.; Alrshoudi, F.; Qaid, A.; Al-Fakih, A.M.; Mhaya, A.M.; Salah, H.A. Assessment of Acoustic and Mechanical Properties in Modified Rubberized Concrete. Case Stud. Constr. Mater. 2024, 20, e03063. [Google Scholar] [CrossRef]

- Li, Y.; Xu, F.; Lin, Z.; Sun, X.; Peng, Q.; Yuan, Y.; Wang, S.; Yang, Z.; He, X.; Li, Y. Electrically and Thermally Conductive Underwater Acoustically Absorptive Graphene/Rubber Nanocomposites for Multifunctional Applications. Nanoscale 2017, 9, 14476–14485. [Google Scholar] [CrossRef]

- Wilk-Jakubowski, J.L.; Loboichenko, V.; Wilk-Jakubowski, G.; Yılmaz-Atay, H.; Harabin, R.; Ciosmak, J.; Ivanov, S.; Stankov, S. Acoustic Firefighting Method on the Basis of European Research: A Review: Acoustic Firefighting Method. Akustika 2023, 46, 31–45. [Google Scholar] [CrossRef]

- Loboichenko, V.; Wilk-Jakubowski, J.; Wilk-Jakubowski, G.; Harabin, R.; Shevchenko, R.; Strelets, V.; Levterov, A.; Soshinskiy, A.; Tregub, N.; Antoshkin, O. The Use of Acoustic Effects for the Prevention and Elimination of Fires as an Element of Modern Environmental Technologies. Environ. Clim. Technol. 2022, 26, 319–330. [Google Scholar] [CrossRef]

- Shi, X.; Tian, Z.; Lu, Y.; Ye, Q. Research Status and Progress of Acoustic Fire Extinguishing Technology. Fire 2025, 8, 129. [Google Scholar] [CrossRef]

- Choudhary, S.; Gupta, A.; Sukhwal, S. A study on sound wave fire extinguisher with cooling rate. Int. J. Adv. Eng. Res. Sci. 2020, 7, 505–510. [Google Scholar] [CrossRef]

- Huang, Y.; Wang, M.; Yang, K.; Xu, C.; Wu, K. Role of Acoustic Wave on Extinguishing Flames Coupling with Water Mist. Case Stud. Therm. Eng. 2022, 38, 102367. [Google Scholar] [CrossRef]

- Wilk-Jakubowski, J. Experimental Investigation of Amplitude-Modulated Waves for Flame Extinguishing: A Case of Acoustic Environmentally Friendly Technology. Environ. Clim. Technol. 2023, 27, 627–638. [Google Scholar] [CrossRef]

- Fegade, R.; Rai, K.; Dalvi, S. Extinguishing Fire Using Low Frequency Sound from Subwoofer. Gradiva Rev. J. 2022, 8, 708–713. [Google Scholar]

- Xiong, C.; Wang, Z.; Huang, X. Acoustic Flame Extinction by the Sound Wave or Speaker-Induced Wind? Fire Saf. J. 2021, 126, 103479. [Google Scholar] [CrossRef]

- Loboichenko, V.; Wilk-Jakubowski, G.; Wilk-Jakubowski, J.L.; Ciosmak, J. Application of Low-Frequency Acoustic Waves to Extinguish Flames on the Basis of Selected Experimental Attempts. Appl. Sci. 2024, 14, 8872. [Google Scholar] [CrossRef]

- Wilk-Jakubowski, J.; Wilk-Jakubowski, G.; Loboichenko, V. Experimental Attempts of Using Modulated and Unmodulated Waves in Low-Frequency Acoustic Wave Flame Extinguishing Technology: A Review of Selected Cases. Stroj. Vestn.-J. Mech. Eng. 2024, 70, 270–281. [Google Scholar] [CrossRef]

- McKinney, D.J.; Dunn-Rankin, D. Acoustically driven extinction in a droplet stream flame. Combust. Sci. Technol. 2007, 161, 27–48. [Google Scholar] [CrossRef]

- Friedman, A.N.; Stoliarov, S.I. Acoustic extinction of laminar line-flames. Fire Saf. J. 2017, 93, 102–113. [Google Scholar] [CrossRef]

- Wilk-Jakubowski, J.L.; Loboichenko, V.; Divizinyuk, M.; Wilk-Jakubowski, G.; Shevchenko, R.; Ivanov, S.; Strelets, V. Acoustic Waves and Their Application in Modern Fire Detection Using Artificial Vision Systems: A Review. Sensors 2025, 25, 935. [Google Scholar] [CrossRef]

- Daoud, Z.; Ben Hamida, A.; Ben Amar, C. A one stream three-dimensional convolutional neural network for fire recognition based on Spatio-temporal fire analysis. Evol. Syst. 2024, 15, 2355–2381. [Google Scholar] [CrossRef]

- Koklu, M.; Taspinar, Y.S. Determining the extinguishing status of fuel flames with sound wave by machine learning methods. IEEE Access 2021, 9, 207–216. [Google Scholar] [CrossRef]

- Loboichenko, V.; Wilk-Jakubowski, J.L.; Levterov, A.; Wilk-Jakubowski, G.; Statyvka, Y.; Shevchenko, O. Using the burning of polymer compounds to determine the applicability of the acoustic method in fire extinguishing. Polymers 2024, 16, 3413. [Google Scholar] [CrossRef] [PubMed]

- Yılmaz-Atay, H.; Wilk-Jakubowski, J.L. A Review of Environmentally Friendly Approaches in Fire Extinguishing: From Chemical Sciences to Innovations in Electrical Engineering. Polymers 2022, 14, 1224. [Google Scholar] [CrossRef] [PubMed]

- Beisner, E.; Wiggins, N.D.; Yue, K.B.; Rosales, M.; Penny, J.; Lockridge, J.; Page, R.; Smith, A.; Guerrero, L. Acoustic flame suppression mechanics in a microgravity environment. Microgravity Sci. Technol. 2015, 27, 141–144. [Google Scholar] [CrossRef]

- Yang, Y.; Jiang, G.; Liu, L. Research progress and prospects on the influence of sound waves on the combustion characteristics of coal powder. J. China Coal Soc. 2023, 48, 3895–3911. [Google Scholar]

- International Standard. Available online: https://cdn.standards.iteh.ai/samples/19583/f05ae41625eb4cb0b95611feccf6fda6/ISO-11654-1997.pdf (accessed on 26 May 2025).

| Name | 2015–2019 | 2020–2024 | All Years | Share [%] | Chi-Square |

|---|---|---|---|---|---|

| Total | 12 | 64 | 76 | 100.0 | χ2 |

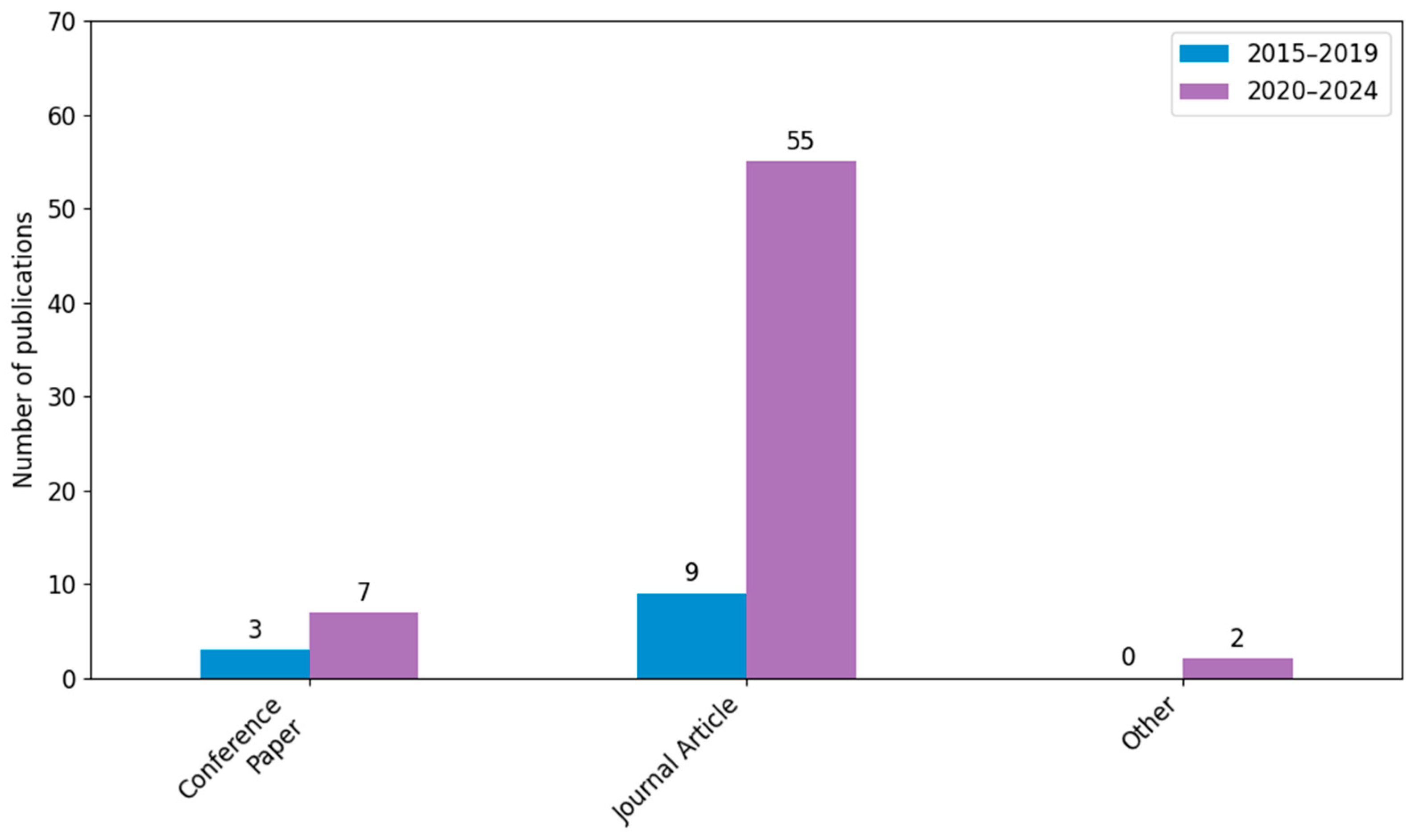

| Document type | |||||

| Conference paper | 3 | 7 | 10 | 13.16 | χ2 = 2.04 (df = 2, p = 0.36) |

| Journal article | 9 | 55 | 64 | 84.21 | |

| Other | 0 | 2 | 2 | 2.63 | |

| Material type | |||||

| Composites | 3 | 25 | 28 | 36.84 | χ2 = 1.77 (df = 4, p = 0.78) |

| Fibrous | 6 | 35 | 41 | 53.95 | |

| Polymers | 1 | 5 | 6 | 7.89 | |

| Porous | 5 | 17 | 22 | 28.95 | |

| Nanomaterials | 1 | 10 | 11 | 14.47 | |

| Material properties | |||||

| Chemical | 3 | 7 | 10 | 13.16 | χ2 = 1.68 (df = 3, p = 0.64) |

| Mechanical | 4 | 23 | 27 | 35.53 | |

| Physical | 5 | 30 | 35 | 46.05 | |

| Thermal | 4 | 25 | 29 | 38.16 | |

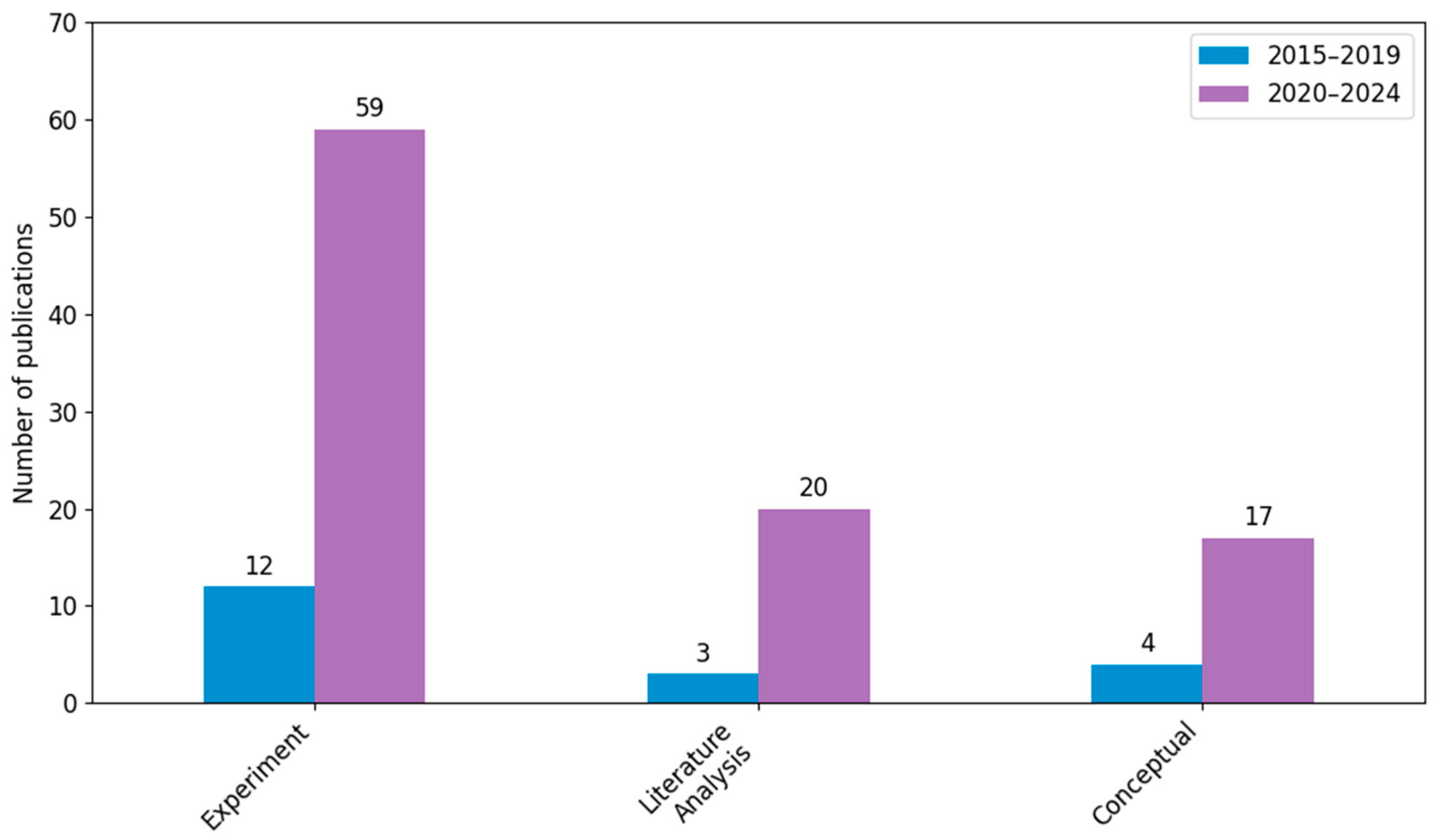

| Research methodology | |||||

| Experiment | 12 | 59 | 71 | 93.42 | χ2 = 0.31 (df = 2, p = 0.86) |

| Literature analysis | 3 | 20 | 23 | 30.26 | |

| Conceptual | 4 | 17 | 21 | 27.63 |

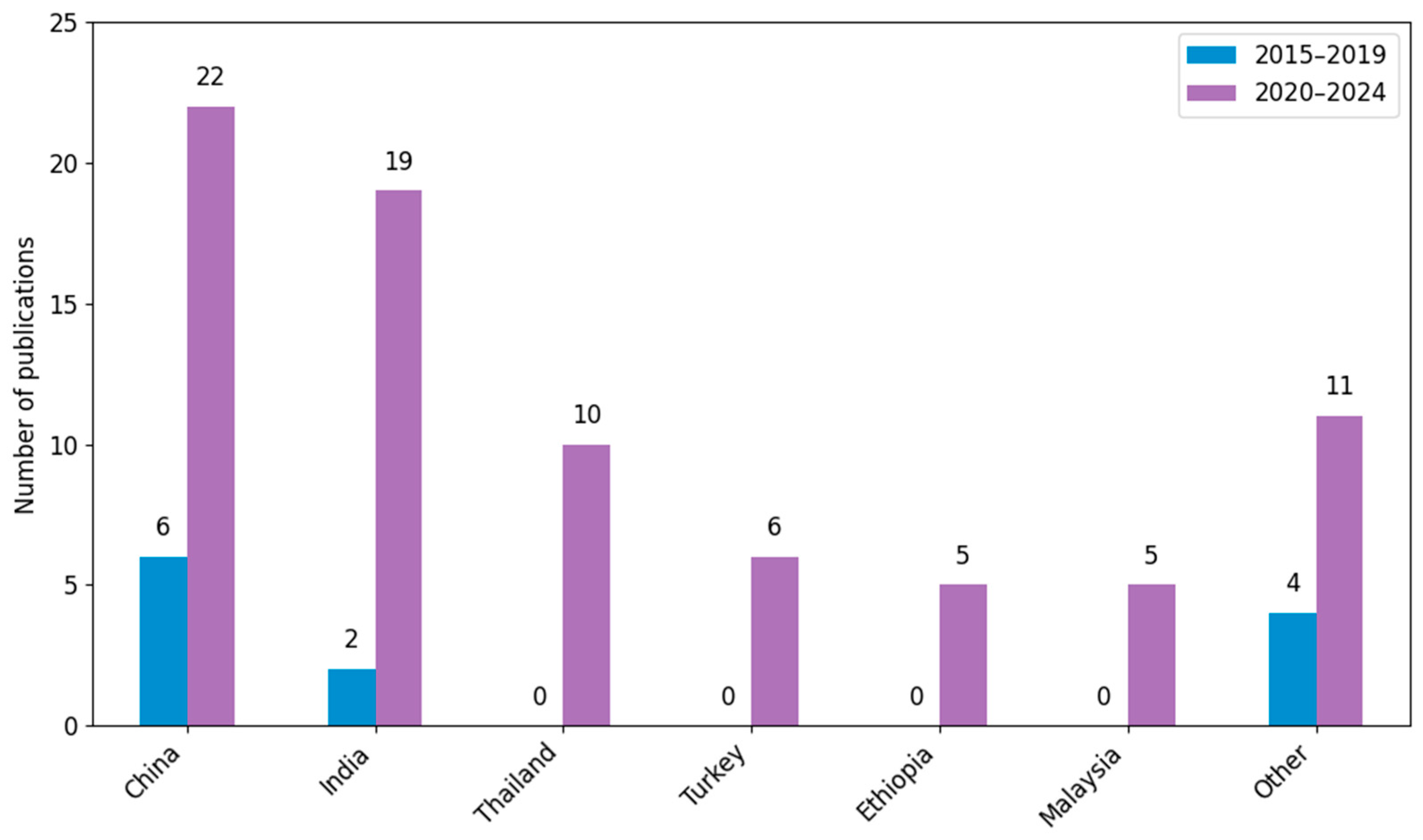

| Country | 2015–2019 | 2020–2024 | All Years | Share [%] | Chi-Square |

|---|---|---|---|---|---|

| All countries | 12 | 64 | 76 | 100.0 | χ2 = 8.16 (df = 6, p = 0.23) |

| China | 6 | 22 | 28 | 36.84 | |

| India | 2 | 19 | 21 | 27.63 | |

| Thailand | 0 | 10 | 10 | 13.16 | |

| Turkey | 0 | 6 | 6 | 7.89 | |

| Ethiopia | 0 | 5 | 5 | 6.58 | |

| Malaysia | 0 | 5 | 5 | 6.58 | |

| Other | 4 | 11 | 15 | 19.74 |

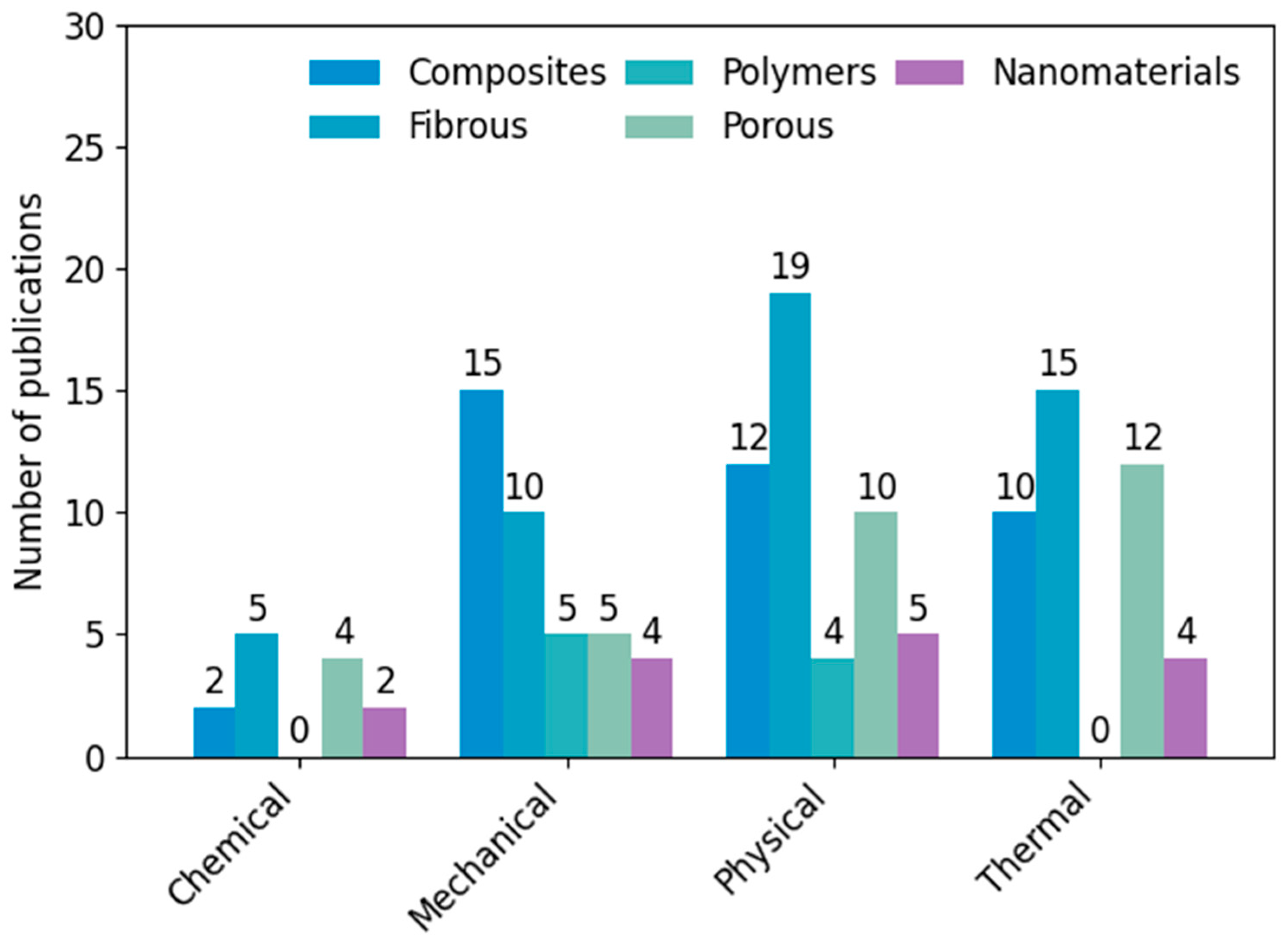

| Name | Composites | Fibrous | Polymers | Porous | Nanomaterials | Total | Chi-square |

|---|---|---|---|---|---|---|---|

| Total | 28 | 41 | 6 | 22 | 11 | 76 | χ2 |

| Material properties | |||||||

| Chemical | 2 | 5 | 0 | 4 | 2 | 10 | χ2 = 13.63 (df = 12, p = 0.33) |

| Mechanical | 15 | 10 | 5 | 5 | 4 | 27 | |

| Physical | 12 | 19 | 4 | 10 | 5 | 35 | |

| Thermal | 10 | 15 | 0 | 12 | 4 | 29 | |

| Research methodology | |||||||

| Experiment | 25 | 38 | 6 | 21 | 11 | 71 | χ2 = 13.14 (df = 8, p = 0.11) |

| Literature analysis | 12 | 16 | 0 | 3 | 2 | 23 | |

| Conceptual | 5 | 12 | 0 | 11 | 4 | 21 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wilk-Jakubowski, J.L.; Kuchcinski, A.; Pawlik, L.; Wilk-Jakubowski, G. Advanced Sound Insulating Materials: An Analysis of Material Types and Properties. Appl. Sci. 2025, 15, 6156. https://doi.org/10.3390/app15116156

Wilk-Jakubowski JL, Kuchcinski A, Pawlik L, Wilk-Jakubowski G. Advanced Sound Insulating Materials: An Analysis of Material Types and Properties. Applied Sciences. 2025; 15(11):6156. https://doi.org/10.3390/app15116156

Chicago/Turabian StyleWilk-Jakubowski, Jacek Lukasz, Artur Kuchcinski, Lukasz Pawlik, and Grzegorz Wilk-Jakubowski. 2025. "Advanced Sound Insulating Materials: An Analysis of Material Types and Properties" Applied Sciences 15, no. 11: 6156. https://doi.org/10.3390/app15116156

APA StyleWilk-Jakubowski, J. L., Kuchcinski, A., Pawlik, L., & Wilk-Jakubowski, G. (2025). Advanced Sound Insulating Materials: An Analysis of Material Types and Properties. Applied Sciences, 15(11), 6156. https://doi.org/10.3390/app15116156