Thermal and Exergetic Performance Assessment of an ORC Coupled with Thermal Energy Storage Using Thermal Oils for Low-Grade Heat Recovery

Abstract

1. Introduction

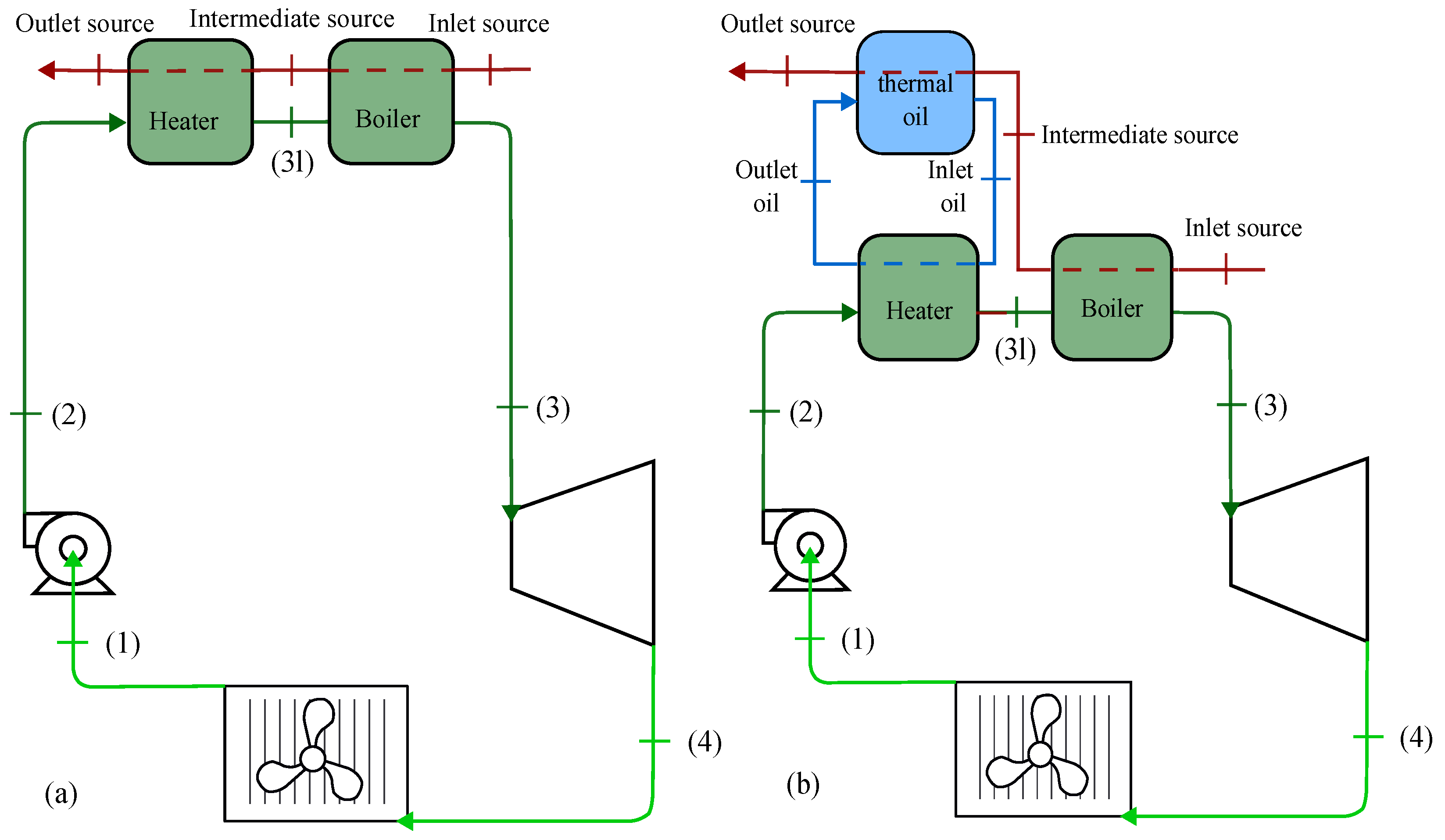

2. Thermodynamic Theory and Modeling

2.1. Thermodynamic Model

2.2. Heat Exchanger Sizing Model

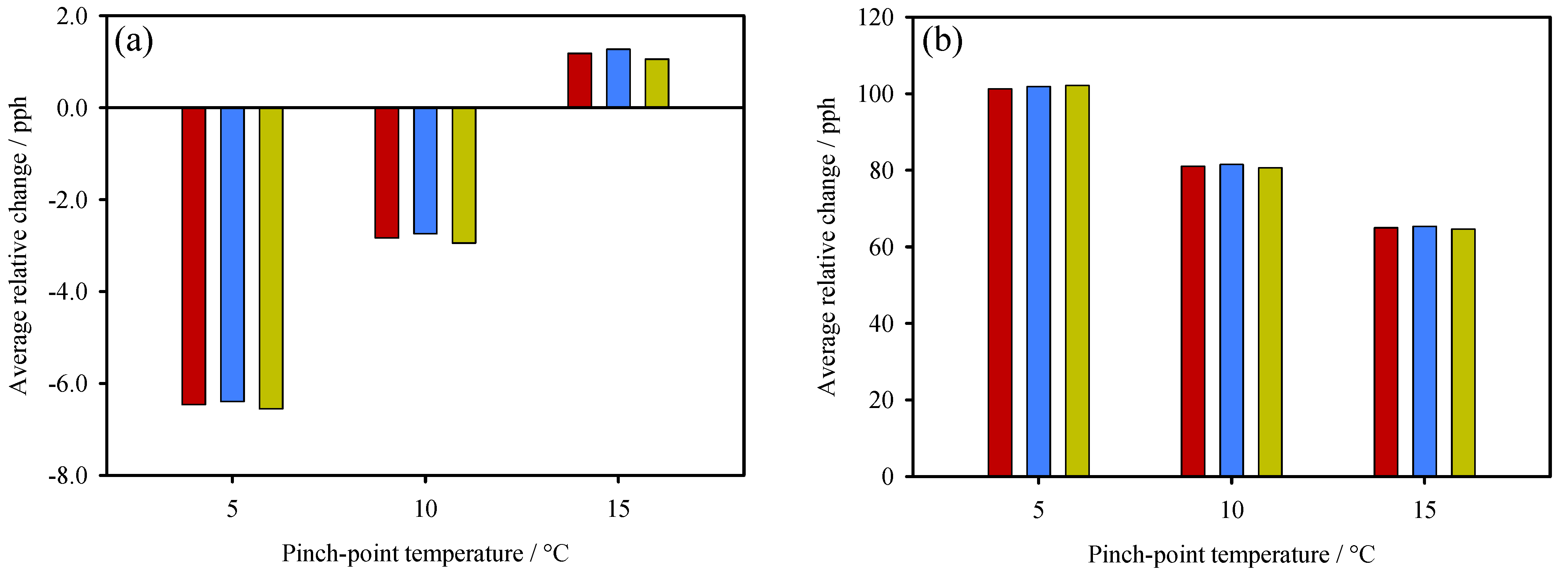

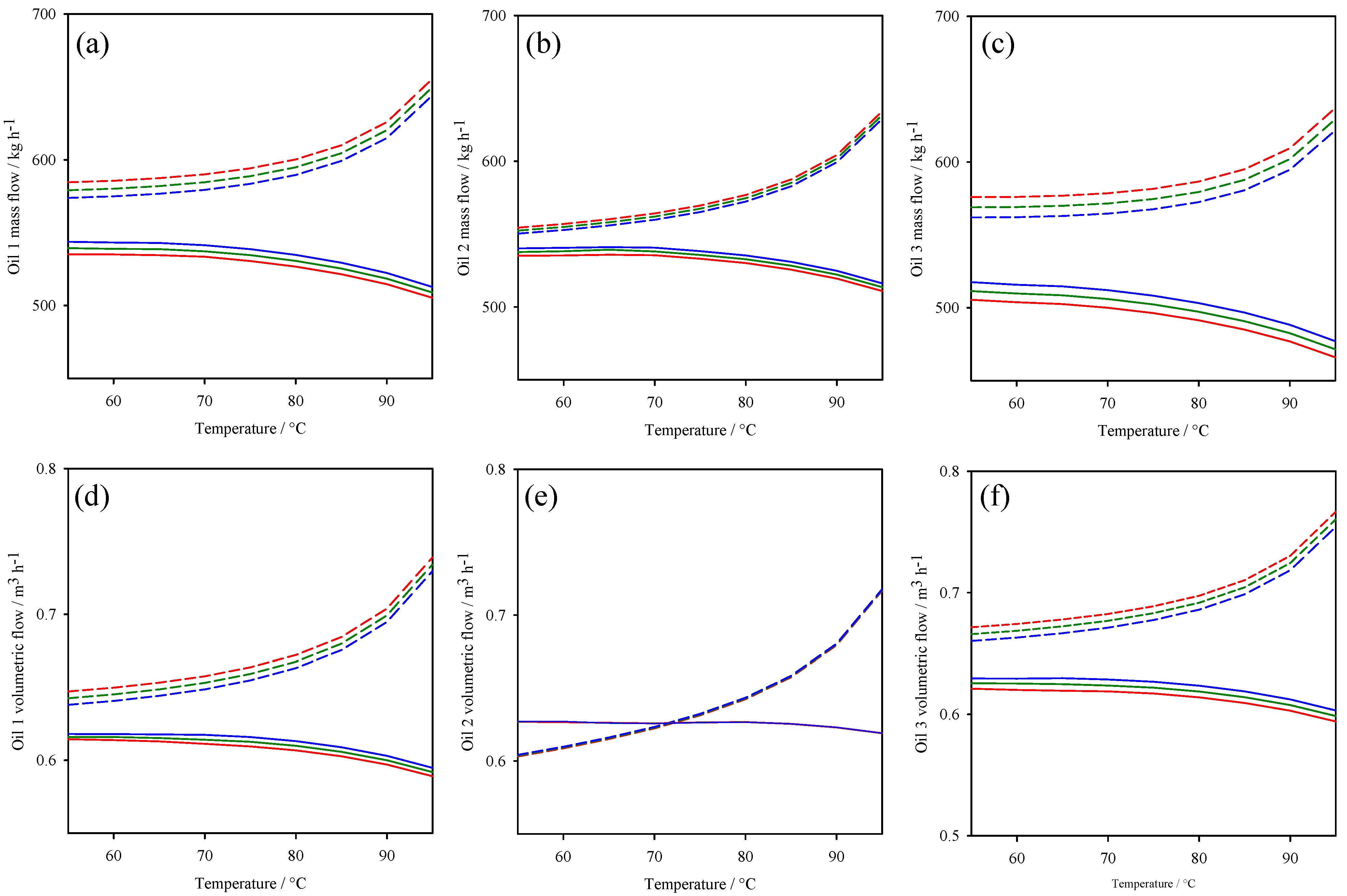

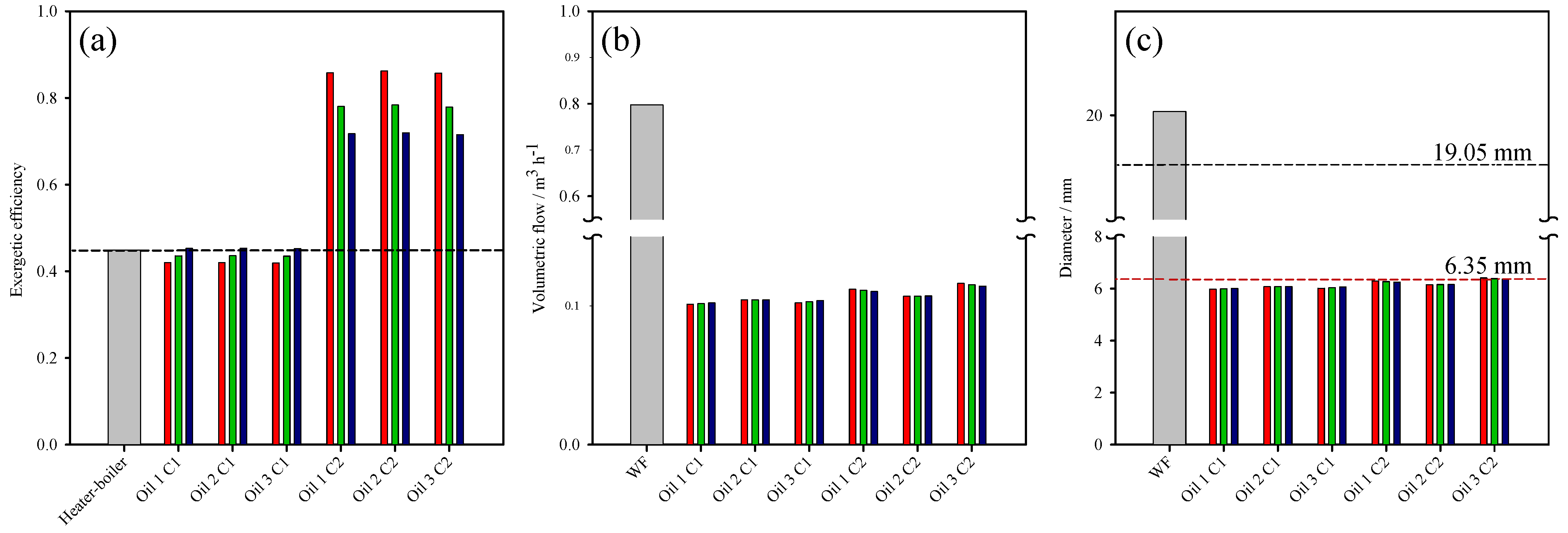

3. Thermodynamic Behavior of the ORC-TER System

4. Concluding Remarks

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| C1 | Configuration 1 |

| C2 | Configuration 2 |

| GHG | Greenhouse gases |

| GWP | Global Warming Potential |

| HTF | Heat Transfer Fluid |

| PTC | Parabolic Trough Collector |

| ORC | Organic Rankine cycle |

| TES | Thermal Energy Storage |

| WF | Working Fluid |

References

- Sorrell, S. Reducing energy demand: A review of issues, challenges and approaches. Renew. Sustain. Energy Rev. 2015, 47, 74–82. [Google Scholar] [CrossRef]

- Jiménez-García, J.C.; Ruiz, A.; Pacheco-Reyes, A.; Rivera, W. A comprehensive review of organic rankine cycles. Processes 2023, 11, 1982. [Google Scholar] [CrossRef]

- Forman, C.; Muritala, I.K.; Pardemann, R.; Meyer, B. Estimating the global waste heat potential. Renew. Sustain. Energy Rev. 2016, 57, 1568–1579. [Google Scholar] [CrossRef]

- Intergovernmental Panel on Climate Change. Climate Change 2007: Synthesis Report; IPCC: Geneva, Switzerland, 2007. [Google Scholar]

- Goyal, A.; Sherwani, A.F.; Tiwari, D. Optimization of cyclic parameters for ORC system using response surface methodology (RSM). Energy Sources Part Recover. Util. Environ. Eff. 2021, 43, 993–1006. [Google Scholar] [CrossRef]

- González, J.; Garrido, J.M.; Quinteros-Lama, H. Analysis of the Maximum Efficiency and the Maximum Net Power as Objective Functions for Organic Rankine Cycles Optimization. Entropy 2023, 25, 882. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, Y.; Wang, J. New classification of dry and isentropic working fluids and a method used to determine their optimal or worst condensation temperature used in Organic Rankine Cycle. Energy 2020, 201, 117722. [Google Scholar] [CrossRef]

- Yadav, K.; Sircar, A. Selection of working fluid for low enthalpy heat source Organic Rankine Cycle in Dholera, Gujarat, India. Case Stud. Therm. Eng. 2019, 16, 100553. [Google Scholar] [CrossRef]

- González, J.; Llovell, F.; Garrido, J.M.; Quinteros-Lama, H. Selection of a suitable working fluid for a combined organic Rankine cycle coupled with compression refrigeration using molecular approaches. Fluid Phase Equilibria 2023, 572, 113847. [Google Scholar] [CrossRef]

- Bronicki, L.Y. Technologies and Applications. In Organic Rankine Cycle Power Systems; Elsevier: Amsterdam, The Netherlands, 2017; pp. 25–66. [Google Scholar]

- Liu, B.T.; Chien, K.H.; Wang, C.C. Effect of working fluids on organic Rankine cycle for waste heat recovery. Energy 2004, 29, 1207–1217. [Google Scholar] [CrossRef]

- European Parliament and Council. Amendment to the Montreal Protocol on Substances that Deplete the Ozone Layer; Cambridge University Press: Cambridge, UK, 2016. [Google Scholar]

- Loni, R.; Ja’fari, M.; Khan, M.I.; Al-Ghamdi, S.G.; Jaworski, A.J.; Asfand, F. Waste heat recovery with ORCs: Challenges and future outlook. J. Clean. Prod. 2021, 287, 146925. [Google Scholar] [CrossRef]

- González, J.; Llovell, F.; Garrido, J.M.; Quinteros-Lama, H. A rigorous approach for characterising the limiting optimal efficiency of working fluids in organic Rankine cycles. Energy 2022, 124191, 254. [Google Scholar] [CrossRef]

- Daniarta, S.; Nemś, M.; Kolasiński, P.; Pomorski, M. Sizing the Thermal Energy Storage Device Utilizing Phase Change Material (PCM) for Low-Temperature Organic Rankine Cycle Systems Employing Selected Hydrocarbons. Energies 2022, 15, 956. [Google Scholar] [CrossRef]

- Zahedi, R.; Ahmadi, A. Case Studies in Thermal Engineering Thermodynamic and thermoeconomic analysis of solar derived ORC with storage system utilizing PCM. Case Stud. Therm. Eng. 2025, 68, 105942. [Google Scholar] [CrossRef]

- Guerron, G.; Nicolalde, J.F.; Martínez-Gómez, J.; Dávila, P.; Velásquez, C. Experimental analysis of a pilot plant in Organic Rankine Cycle configuration with regenerator and thermal energy storage (TES-RORC). Energy 2024, 308, 132964. [Google Scholar] [CrossRef]

- Dragomir-Stanciu, D.; Luca, C. Solar power generation system with low temperature heat storage. Procedia Technol. 2016, 22, 848–853. [Google Scholar] [CrossRef]

- Ezgi, C.; Kepekci, H. Thermodynamic Analysis of Marine Diesel Engine Exhaust Heat-Driven Organic and Inorganic Rankine Cycle Onboard Ships. Appl. Sci. 2024, 14, 7300. [Google Scholar] [CrossRef]

- Peyrovedin, H.; Haghbakhsh, R.; Duarte, A.R.C.; Shariati, A. Deep eutectic solvents as phase change materials in solar thermal power plants: Energy and exergy analyses. Molecules 2022, 27, 1427. [Google Scholar] [CrossRef]

- Kolahi, M.; Yari, M.; Mahmoudi, S.M.; Mohammadkhani, F. Thermodynamic and economic performance improvement of ORCs through using zeotropic mixtures: Case of waste heat recovery in an offshore platform. Case Stud. Therm. Eng. 2016, 8, 51–70. [Google Scholar] [CrossRef]

- Paramita, P.D.P.; Daniarta, S.; Imre, A.R.; Kolasiński, P. Techno-Economic Analysis of Waste Heat Recovery in Automotive Manufacturing Plants. Appl. Sci. 2025, 15, 569. [Google Scholar] [CrossRef]

- Ramalingam, R.D.; Esakkimuthu, G.S.; Natarajan, S.K.; Athikesavan, M.M. Energy and exergy studies on the receiver models with materials and heat transfer fluids. Environ. Sci. Pollut. Res. Int. 2024, 31, 4764–4778. [Google Scholar] [CrossRef]

- Kannaiyan, S.; Bokde, N.D. Performance of Parabolic Trough Collector with Different Heat Transfer Fluids and Control Operation. Energies 2022, 15, 7572. [Google Scholar] [CrossRef]

- Assareh, E.; Hoseinzadeh, S.; Agarwal, N.; Delpisheh, M.; Dezhdar, A.; Feyzi, M.; Wang, Q.; Garcia, D.A.; Gholamian, E.; Hosseinzadeh, M.; et al. A transient simulation for a novel solar-geothermal cogeneration system with a selection of heat transfer fluids using thermodynamics analysis and ANN intelligent (AI) modeling. Appl. Therm. Eng. 2023, 231, 120698. [Google Scholar] [CrossRef]

- Vikraman, H.; Hari Suthan, V.; Rajan, K.S.; Suganthi, K.S. ZnO nanostructures modulate the thermo-physical properties of Therminol 55 favorably for heat transfer applications. J. Nanopart. Res. 2024, 26, 42. [Google Scholar] [CrossRef]

- Ravikumar, R.; Biju, R.; Surendran, V.S.; Binish, B.; Raghavan, J.R.; Krishnakumar, T.S.; Indulal, C.R. Thermal transmission application of mixed metal oxide nanocomposite in Therminol-based nanofluid. J. Braz. Soc. Mech. Sci. Eng. 2022, 44, 541. [Google Scholar] [CrossRef]

- Kadirgama, G.; Ramasamy, D.; Kadirgama, K.; Samylingam, L.; Aslfattahi, N.; Chalak Qazani, M.R.; Kok, C.K.; Yusaf, T.; Schmirler, M. Characterization and machine learning analysis of hybrid alumina-copper oxide nanoparticles in therminol 55 for medium temperature heat transfer fluid. Sci. Rep. 2025, 15, 8383. [Google Scholar] [CrossRef]

- Siddiqui, M.U.; Owes, A.; Al-Amri, F.G.; Saeed, F. Recent developments in the search for alternative low-global-warming-potential refrigerants: A review. Int. J.-Air-Cond. Refrig. 2020, 28, 2030004. [Google Scholar] [CrossRef]

- Shaik, S.V.; Babu, T.P. Theoretical Performance Investigation of Vapour Compression Refrigeration System Using HFC and HC Refrigerant Mixtures as Alternatives to Replace R22. Energy Procedia 2017, 109, 235–242. [Google Scholar] [CrossRef]

- Tillner Roth, R.; Baehr, H.D. An International Standard Formulation for the Thermodynamic Properties of 1,1,1,2-Tetrafluoroethane (HFC-134a) for Temperatures from 170 K to 455 K and Pressures up to 70 MPa. J. Phys. Chem. Ref. Data 1994, 23, 657–729. [Google Scholar] [CrossRef]

- Wolfram Research, Inc. Wolfram Mathematica, Version 12.0.0.0, Wolfram Research, Inc.: Champaign, IL, USA, 2019. Available online: https://www.wolfram.com/mathematica/ (accessed on 26 May 2025).

- Yekoladio, P.J.; Bello-Ochende, T.; Meyer, J.P. Thermodynamic analysis and performance optimization of organic rankine cycles for the conversion of low-to-moderate grade geothermal heat. Int. J. Energy Res. 2015, 39, 1256–1271. [Google Scholar] [CrossRef]

- Pirobloc SA. Pirobloc HTF-FDA HT1 NSF. 2024. Available online: https://www.fluidotermico.com/es/aceites-medicinales/12-pirobloc-htf-fda-ht1-nsf.html (accessed on 19 May 2025).

- Pirobloc SA. Pirobloc HTF-HIGH FP. 2024. Available online: https://www.fluidotermico.com/es/aceites-sinteticos/19-pirobloc-htf-high-flash-point.html (accessed on 19 May 2025).

- Pirobloc SA. Pirobloc HTF-Plus. 2024. Available online: https://www.fluidotermico.com/es/aceites-sinteticos/22-pirobloc-htf-plus.html (accessed on 19 May 2025).

- Eastman Therminol. Therminol 66. 2024. Available online: https://www.therminol.com/sites/therminol/files/documents/TF-8695_Therminol-66_Technical_Bulletin.pdf (accessed on 19 May 2025).

- Eastman Therminol. Therminol VP1. 2024. Available online: https://www.therminol.com/sites/therminol/files/documents/TF09A_Therminol_VP1.pdf (accessed on 19 May 2025).

- Eastman Therminol. Therminol 75. 2024. Available online: https://www.eastman.com/Literature_Center/T/TF9035.pdf (accessed on 19 May 2025).

- Eastman Therminol. Therminol VP-3. 2024. Available online: https://www.therminol.com/sites/therminol/files/documents/TF22A_Therminol_VP3.pdf (accessed on 19 May 2025).

- Eastman Therminol. Therminol 72. 2024. Available online: https://www.therminol.com/sites/therminol/files/documents/TF-13A_Therminol_72.pdf (accessed on 19 May 2025).

- Eastman Therminol. Therminol 59. 2024. Available online: https://www.therminol.com/sites/therminol/files/documents/TF-9029_Therminol_59_Product_Bulletin.pdf (accessed on 19 May 2025).

- Eastman Therminol. Therminol 54. 2024. Available online: https://www.eastman.com/Literature_Center/T/TF5353.pdf?_gl=1*bfxs5q*_gcl_au*NTMzMzYxNDAzLjE3NDc1Mzc3NDQ.#_ga=2.49828260.385272232.1747537744-820170329.1747537744 (accessed on 19 May 2025).

- Eastman Therminol. Therminol XP. 2024. Available online: https://www.therminol.com/sites/therminol/files/documents/TF-8694_Therminol_XP_Technical_Bulletin.pdf (accessed on 19 May 2025).

- Eastman Therminol. Therminol LT. 2024. Available online: https://www.therminol.com/sites/therminol/files/documents/TF-8726_Therminol_LT.pdf (accessed on 19 May 2025).

- Eastman Therminol. Therminol VLT. 2024. Available online: https://www.therminol.com/sites/therminol/files/documents/TF-21_Therminol_VLT.pdf (accessed on 19 May 2025).

- Eastman Therminol. Therminol D-12. 2024. Available online: https://www.eastman.com/Literature_Center/T/TF15.pdf#_ga=2.73962710.513219384.1718204584-689746566.1717960125 (accessed on 19 May 2025).

- Shell plc. Shell Heat Transfer Oil S2. 2024. Available online: https://www.southernlubricants.co.uk/wp-content/uploads/2018/01/heat-transfer-oil.pdf (accessed on 19 May 2025).

- Shell plc. Shell Heat Transfer Oil S4X. 2024. Available online: https://www.shell-livedocs.com/data/published/en/830dad29-7100-42ab-b4ef-9322a512d4d7.pdf (accessed on 19 May 2025).

- Chevron Corporation. Heat Transfer Oil 22/46. 2024. Available online: https://cglapps.chevron.com/msdspds/PDSDetailPage.aspx?docDataId=77160&docFormat (accessed on 19 May 2025).

- Paratherm Corporation. Paratherm HR. 2024. Available online: https://www.paratherm.com/wp-content/uploads/2022/11/2022-HR-ID.pdf (accessed on 19 May 2025).

- Paratherm Corporation. Paratherm NF. 2024. Available online: https://www.paratherm.com/heat-transfer-fluids/paratherm-nf-htf/ (accessed on 19 May 2025).

- Paratherm Corporation. Paratherm GLT. 2024. Available online: https://www.paratherm.com/wp-content/uploads/2023/11/2023-GLT-ID-1.pdf (accessed on 19 May 2025).

- Paratherm Corporation. Paratherm HE. 2024. Available online: https://www.paratherm.com/heat-transfer-fluids/paratherm-he-htf/ (accessed on 19 May 2025).

- Paratherm Corporation. Paratherm OR. 2024. Available online: https://www.paratherm.com/heat-transfer-fluids/paratherm-or-htf/ (accessed on 19 May 2025).

- Petro-Canada. CALFLO Synthetic. 2024. Available online: https://petrocanadalubricants.com/es-cl/brand/calflo-synthetic (accessed on 19 May 2025).

- Petro-Canada. CALFLO AF. 2024. Available online: https://petrocanadalubricants.com/es-cl/brand/calflo-af (accessed on 19 May 2025).

- Petro-Canada. CALFLO HTF. 2024. Available online: https://petrocanadalubricants.com/es-cl/brand/calflo-htf (accessed on 19 May 2025).

- Petro-Canada. CALFLO LT. 2024. Available online: https://www.ewprocess.com/wp-content/uploads/LT-TD_IM-7874E.pdf (accessed on 19 May 2025).

- Petro-Canada. CALFLO XR. 2024. Available online: https://petrocanadalubricants.com/es-cl/brand/calflo-xr (accessed on 19 May 2025).

- Bhatia, S. Advanced Renewable Energy Systems, (Part 1 and 2); Woodhead Publishing India in Energy, WPI India: Delhi, India, 2014. [Google Scholar]

- Keenan, J.; Chao, J.; Kaye, J. Gas Tables: Thermodynamic Properties of Air Products of Combustion and Component Gases, Compressible Flow Functions; Wiley: Hoboken, NJ, USA, 1980. [Google Scholar]

- González, L.; Romero, J.; Saavedra, N.; Garrido, J.M.; Quinteros-lama, H.; González, J. Heat pump performance mapping for the energy recovery from an industrial building. Processes 2024, 12, 1955. [Google Scholar] [CrossRef]

- Moshinsky, M. Chapter 5: Evaporador. In Manual de Refrigeración; Reverté: Barcelona, Spain, 2012. [Google Scholar]

- Pasupuleti, R.K.; Bedhapudi, M.; Jonnala, S.R.; Kandimalla, A.R. Computational Analysis of Conventional and Helical Finned Shell and Tube Heat Exchanger Using ANSYS-CFD. Int. J. Heat Technol. 2021, 39, 1755–1762. [Google Scholar] [CrossRef]

- Patel, M.M. Shell & tube heat exchangers: Thermal design and optimization. In Mihir’s Handbook of Chemical Process Engineering; Heat Exchanger World Publisher: Rotterdam, The Netherlands, 2023. [Google Scholar]

- Menon, E.S. Chapter 1: Water Systems Piping. In Piping Calculations Manual; McGraw-Hill Calculations: New York, NY, USA, 2005. [Google Scholar]

- González, J.; Llovell, F.; Garrido, J.M.; Quinteros-Lama, H. A study of the optimal conditions for organic Rankine cycles coupled with vapour compression refrigeration using a rigorous approach based on the Helmholtz energy function. Energy 2023, 285, 129554. [Google Scholar] [CrossRef]

- Marzouk, S.; Almehmadi, F.A.; Aljabr, A.; Sharaf, M.A.; Alam, T.; Dobrotă, D. Study of effects of constructed fins on melting of PCM in helical coil heat exchanger. Case Stud. Therm. Eng. 2025, 68, 105896. [Google Scholar] [CrossRef]

| Commercial Name | Heat | Low. | High | Density | Viscosity | Criteria | Ref. | |

|---|---|---|---|---|---|---|---|---|

| Capacity | Tem. | Tem. | Point | 40 °C | ||||

| J g−1 °C−1 | °C | °C | kg m−3 | cSt | ||||

| 1 | HTF-FDA HT1 NSF | 2.10 | −10 | 325 | 873 | 37.1 | B | [34] |

| 2 | HTF-HIGH FP | 2.10 | −6 | 275 | 903 | 490.0 | B, D | [35] |

| 3 | HTF-PLUS | 2.00 | −40 | 280 | 864 | 20.5 | B, D | [36] |

| 4 | Therminol 66 | 1.84 | −3 | 345 | 995 | 29.6 | B, C | [37] |

| 5 | Therminol VP-1 | 1.78 | 12 | 400 | 1064 | 2.5 | A, C, D | [38] |

| 6 | Therminol 75 | 1.77 | 80 | 385 | 1041 | 4.1 | A, C, D | [39] |

| 7 | Therminol VP-3 | 1.96 | 2 | 330 | 935 | 2.0 | C, D | [40] |

| 8 | Therminol 72 | 1.77 | −14 | 380 | 1079 | 5.7 | A, C | [41] |

| 9 | Therminol 59 | 1.94 | −49 | 315 | 977 | 4.0 | C | [42] |

| 10 | Therminol 54 | 2.19 | −28 | 280 | 858 | 19.0 | D | [43] |

| 11 | Therminol XP | 2.18 | −20 | 315 | 879 | 23.7 | B | [44] |

| 12 | Therminol LT | 2.09 | −75 | 315 | 867 | 0.8 | - | [45] |

| 13 | Therminol VLT | 2.29 | −115 | 175 | 749 | 0.7 | D | [46] |

| 14 | Therminol D-12 | 2.41 | −94 | 230 | 763 | 1.2 | D | [47] |

| 15 | Shell HT Oil S2 | 2.40 | −12 | 320 | 857 | 25.0 | B | [48] |

| 16 | Shell HT Oil S4X | 2.23 | −30 | 300 | 823 | 34.3 | B | [49] |

| 17 | Chevron HT OIL 22 | 2.32 | −13 | 343 | 853 | 23.1 | B | [50] |

| 18 | Chevron HT OIL 46 | 2.32 | −15 | 316 | 859 | 41.1 | B | [50] |

| 19 | Paratherm HR | 2.10 | −13 | 357 | 961 | 11.0 | - | [51] |

| 20 | Paratherm NF | 2.20 | −4 | 332 | 884 | 20.0 | - | [52] |

| 21 | Paratherm GLT | 2.20 | −11 | 302 | 877 | 41.0 | B | [53] |

| 22 | Paratherm HE | 2.20 | 3 | 332 | 863 | 41.5 | B, D | [54] |

| 23 | Paratherm OR | 2.31 | 4 | 260 | 881 | 40.1 | B, D | [55] |

| 24 | CALFLO Synthetic | 2.40 | −48 | 226 | 799 | 5.2 | D | [56] |

| 25 | CALFLO AF | 2.20 | −42 | 316 | 870 | 55.0 | B | [57] |

| 26 | CALFLO HTF | 2.20 | −18 | 343 | 877 | 35.9 | B | [58] |

| 27 | CALFLO LT | 2.30 | −57 | 225 | 906 | 7.5 | D | [59] |

| 28 | CALFLO XR | 2.22 | −27 | 288 | 840 | 15.0 | D | [60] |

| Commercial Name | Ref. | ||||

|---|---|---|---|---|---|

| K−1 | K−2 | ||||

| Oil 1 | Therminol LT | 12.8067 | 5.5078 | 2.4950 | [45] |

| Oil 2 | Paratherm HR | 43.8256 | 2.8091 | 46.8136 | [51] |

| Oil 3 | Paratherm NF | 7.7397 | 23.0976 | −15.0726 | [52] |

| kg m−3 | kg m−3K−1 | kg m−3K−2 | |||

| Oil 1 | Therminol LT | 1027.42 | −0.3530 | −6.8775 | [45] |

| Oil 2 | Paratherm HR | 1188.77 | −0.7852 | 0.1843 | [51] |

| Oil 3 | Paratherm NF | 1081.53 | −0.6787 | 0.1990 | [52] |

| Value | Range | |

|---|---|---|

| ORC | ||

| Turbine displaced volume | 120.00 cm3 | - |

| Turbine revolutions per minute | 2900.00 rpm | - |

| Boiler saturation temperature | - | 330.15 to 368.15 K |

| Condenser temperature | 303.15 K | - |

| Expander isentropic efficiency | 1.0 | - |

| Pump isentropic efficiency | 1.0 | - |

| Energy source and TES | ||

| Exhaust gases temperature | - | 493.15 K to 373.15 K |

| Pinch point temperature | - | 5, 10, and 15 K |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Birriel, A.; Romero, J.; Saavedra, N.; Quinteros-Lama, H.; González, J. Thermal and Exergetic Performance Assessment of an ORC Coupled with Thermal Energy Storage Using Thermal Oils for Low-Grade Heat Recovery. Appl. Sci. 2025, 15, 6153. https://doi.org/10.3390/app15116153

Birriel A, Romero J, Saavedra N, Quinteros-Lama H, González J. Thermal and Exergetic Performance Assessment of an ORC Coupled with Thermal Energy Storage Using Thermal Oils for Low-Grade Heat Recovery. Applied Sciences. 2025; 15(11):6153. https://doi.org/10.3390/app15116153

Chicago/Turabian StyleBirriel, Andrés, Jerson Romero, Nicolás Saavedra, Héctor Quinteros-Lama, and Johan González. 2025. "Thermal and Exergetic Performance Assessment of an ORC Coupled with Thermal Energy Storage Using Thermal Oils for Low-Grade Heat Recovery" Applied Sciences 15, no. 11: 6153. https://doi.org/10.3390/app15116153

APA StyleBirriel, A., Romero, J., Saavedra, N., Quinteros-Lama, H., & González, J. (2025). Thermal and Exergetic Performance Assessment of an ORC Coupled with Thermal Energy Storage Using Thermal Oils for Low-Grade Heat Recovery. Applied Sciences, 15(11), 6153. https://doi.org/10.3390/app15116153