Featured Application

Active ultrasonic treatment is an innovative option to speed up meat curing.

Abstract

In the meat industry, significant time is required for curing, which is determined by the rate of salt and water migration within the meat. The aim of our research was to determine the diffusion rate of salt and water during different curing processes by measuring salt and water content at different times. The diffusion coefficients were determined in three curing processes: dry salting (traditional process), wet curing (industry standard process), and wet curing combined with active ultrasound (innovative process). Three theoretical models were examined to describe the diffusion in meat. The salt diffusion coefficient of a cylindrical loin meat sample (80 mm × Ø15 mm) treated with dry salting was found to be 4.22 × 10−10 m2/s, which increased by one-third when wet curing was applied and doubled when active ultrasound with an intensity of 14.1474 W/cm2 and a frequency of 19 kHz was added. The water diffusion coefficient was found to be 2.42 × 10−9 m2/s in the case of dry salting, which decreased by 75–80% when wet curing was applied. In wet curing supplemented with ultrasound, water diffusion decreases less than in traditional wet curing. Our research has confirmed that active ultrasound can be used as a part of a combined treatment to accelerate curing.

1. Introduction

Curing, as a technological operation, has been present in food production throughout history, but the phenomena influencing the curing process are still the subject of scientific research today. The changes occurring during curing require time, which, on the one hand, determines the “turnover rate” of the product, i.e., the financial profit-making ability, and, on the other hand, as a bottleneck of the plant, limits the product volume that can be released. Therefore, during curing operations, efforts should be made to minimize the time while maintaining the quality.

The classic and simple method of curing is dry salting. Its disadvantage is that the distance between the “curing core” and the brine is typically large. Unfortunately, the diffusion factor for salt migration in the meat cannot be improved. Another problem is that the surface salt concentration is very high; so, to achieve the appropriate enjoyment value, equalization must be solved in a separate operation (e.g., through storage, washing, or soaking), which are space- and time-consuming procedures and involve microbiological risks [1]. Despite the fact that its production is less economical, it remains an important product, and its raison d’être is undeniable among customers looking for and consuming “traditional products”.

Wet curing is a widely used technology in the industry. It is similar to dry salting in many respects, but the surface salt concentration can be better controlled, the product shrinkage is less, and the yield is more favorable. The factors influencing diffusion (curing core–surface distance and diffusion coefficient) cannot be influenced either. Due to the lower surface concentration, the concentration gradient decreases, which is not favorable for the curing time [2].

The permeability of the cell membrane can be improved by using active ultrasound [3]. According to Flórik [4] “…sounds with a frequency higher than 20 kHz are ultrasound”. Yao et al. [5] define the concept of ultrasound from the human hearing threshold, 16 kHz. They also define the concept of active ultrasound, which refers to acoustic waves with an energy higher than 0.1 W/cm2 and a frequency range of 16–100 kHz (i.e., high energy but relatively low frequency). The characteristic of active ultrasound is that it causes a change in the structure or other characteristics of the treated material or product. Somogyi et al. [6] showed that, in the case of bean samples soaked in water, sonication at a frequency of 20/40 kHz significantly accelerated the diffusion processes. According to Friedrich [7], the diffusion of salt in pork loin is favorably influenced by active ultrasound treatment with an intensity between 2 and 4 W/cm2, and in this case, the following exponential relationship exists between the diffusion coefficient and the ultrasound intensity:

where I [W/cm2] is the intensity of the ultrasound. Cruz-Garibaldi et al. [8] also found that the effect of active ultrasound on a product depends not only on the intensity of the treatment but also on the geometry of the product. Research on the industrial applicability of active ultrasound is ongoing. A.D. Alarcon-Rojo et al. [9] reviewed several research results, from the 1990s onward. In their summary, they drew attention to the fact that the field of US treatments is controversial in both food preservation and product modification. The contradictory research results suggest that the application of active ultrasound in the food industry may primarily gain legitimacy as part of combined treatments, for example, chemical treatment + active ultrasound [10,11] or supplementing traditional treatment with active ultrasound [12]. So, further clarifying scientific work is needed to ensure wide-ranging industrial applicability. A notable example of combined processes is ultrasonic curing supplemented with microbubble treatment. Particularly noteworthy is the work of Visy et al. [13], who measured the diffusion coefficient of static curing and compared it with the diffusion coefficient of ultrasonic curing and ultrasonic curing supplemented with microbubble treatment. In pork loin, a diffusion coefficient of 0.18 × 10−9 m2/s was measured for dry salting, 2.0 × 10−9 m2/s for ultrasonic curing, and 2.5 × 10−9 m2/s for microbubble ultrasonic curing. The diffusion of chemical components can also be modeled using mathematical–statistical methods. Martuscelli et al. [14], Abbasi et al. [15], and Telis et al. [16] have developed models describing radial diffusion processes in cylindrical bodies. These models can be used to determine the diffusion factors.

D [m2/s] = 2.7 × 10−10 × e0.477×I,

The aim of our research was to determine the change in the diffusion rate of salt and water in the wet process and the wet process supplemented with active ultrasound compared to classic dry salting. Accordingly, we compared three curing processes: dry salting (traditional process), wet curing (a process common in the industry), and wet curing with high-intensity (14.1474 W/cm2) active ultrasound treatment (an innovative process). Based on previous research [7], this treatment is not yet destructive, but a significant effect can be expected from its shape reduction. Taking into account that the diffusion of salt has the greatest impact on the curing time and the diffusion of moisture has the greatest impact on the yield of the product, we determined these two diffusion constants for all three curing processes. Knowing these, the relative effect of each treatment on diffusion compared to dry salting could be determined. Based on the accuracy of the fit of the different diffusion models applied to the measurement results, we evaluated the applicability of these models to the meat curing case process.

2. Materials and Methods

2.1. Sample Preparation

The raw material of the tested sample was pre-chilled pork loin (Longissimus dorsi). A total of 69 cylinders with a length of 80 mm and a diameter of Ø15 mm were cut from the fat-free parts of the whole meat, parallel to the muscle fibers, and their initial weight was measured. Only normal-quality meat was used for the experiment. The normal meat quality was verified with a digital pH meter (testo 206 pH2) in the middle of the cylinder shell: the pH of each test sample fell within the normal range (min pH: 5.49, max pH: 5.97).

The meat samples were cured using the treatments shown in Table 1. All measurements were performed on 3 independent samples. The treated meat samples were stored under aluminum foil until measurements to prevent dehydration.

Table 1.

Number of independent samples in the experiment.

2.2. Curing Methods

During the experiments, the temperature of the samples was kept at 20 °C, but due to the energy input during wet curing supplemented with ultrasonic treatment, the temperature of the pickle increased up to 26.9 °C.

In all three processes, it was ensured that a saturated salt solution was present on the surface of the product. In dry salting, the meat/salt ratio was 1.5, so only a fraction of the salt was dissolved in a saturated concentration on the surface of the sample during the treatment. In both wet treatments, the saturated brine was prepared using 400 g/liter of salt (more than saturated). The meat/brine ratio was approximately 0.15, so the brine was saturated throughout the entire treatment.

2.2.1. Control Samples

Two types of controls were used: No treatment was performed on 3 of the control samples. The other 3 were placed in a saturated marinade solution at 20 °C until the salt content was equalized for about 2 days.

2.2.2. Dry Salting

During dry salting, the samples were placed under complete salt coverage (meat/salt rate was 1.5), for which nitrite marinade (with a 0.4–0.5 m/m% sodium nitrite, produced by Salinen Austria AG) was used. After 15/30/60/90/120/150/180 min, the samples were rinsed in clean water, the water was drained from the surface, and the pH and the weight after treatment were measured.

2.2.3. Wet Curing

The samples to be wet-cured were immersed in a saturated marinade solution (26.3% at room temperature) so that the individual pieces of meat did not come into contact with each other (placed in standing plastic grids, at least 5 cm apart). After the curing time, the samples were removed, rinsed, and weighed in the same way as for dry salting.

2.2.4. Wet Curing + Ultrasound

For wet curing supplemented with ultrasonic treatment, a generator (Power Ultrasound System, Ultrasonotech Team, Mosonmagyaróvár, Hungary) with a power of 400 W, a frequency of 19 kHz, and a cylindrical radiating head with a size of 60 mm was used. The emitted acoustic energy was accordingly 14.1474 W/cm2. During wet curing supplemented with ultrasonic treatment, the samples were parallel but not touching each other (placed in standing plastic grids, at least 5 cm apart) and perpendicular to the direction of propagation of the acoustic wave.

2.3. Measurement of the Salt and Water Content

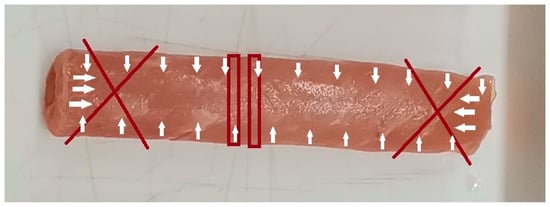

Since all diffusion models require a “sufficiently long” cylindrical matrix for the salt and moisture concentration measurements, a disk-shaped sample (approx. 5 g) was cut out from the inside cross-section of the sample cylinders so that the measurement model would not be affected by diffusion from the end plates (see Figure 1). The dry matter content of the samples was determined in a drying oven at 105 °C until a constant mass (2 days). Knowing the dry matter, the water content [m/m%] was determined. The salt content was determined using the Mohr method.

Figure 1.

Test sample, of which only the middle part was sampled, where only diffusion from the cylinder wall side prevails. X: not used parts, arrow: direction of salt diffusion.

2.4. Diffusion Modeling

Since the average salt and moisture contents of the tested samples were determined during the physical measurements, diffusion models following the corresponding logic were sought:

where the left side of the equation was known since these values were measured. The control samples provided us with the c0 (initial) and c∞ (equilibrium) values, and the ct concentration was determined for several time points (15/30/60/90/120/150 min). The right side of the equation was given by a model that describes the phenomenon under study well. In our case, we used the models of Martuscelli et al. [15], Abbasi et al. [16], and Telis et al. [14]. The parameter D—the diffusion coefficient of the models—was determined by fitting the models.

2.4.1. Model of Martuscelli

Martuscelli et al. [15] examined the evolution of salt content in dry-aged pork ham. The model of Martuscelli follows the Weibull distribution with parameter β:

where in our case, R = 0.0075 m (radius of the sample cylinder), β = 0.72 (determined by Marabi et al. [17] for cylindrical shapes), t = 900/1800/3600/5400/7200/9000/10,800 s, corresponding to the curing times, and Dcalc is the calculated diffusion coefficient. The model modifies the actual diffusion coefficient with the (dimensionless) factor Rg expressing the shape of the sample, which in the case of a long cylindrical body is Rg = 9.5 (also determined by Marabi):

2.4.2. Model of Abbasi

Abbasi et al. [16] also modeled the diffusion of salt and moisture in cylindrical food. Although they studied plant material rather than meat, their mathematical model is worth examining because it does not include product-specific variables. Their model with Bessel function roots is

where in our case, we use an N = 50 approximation, μn is the nth root of the Bessel function, R = 0.0075 m (radius of the sample cylinder), t = 900/1800/3600/5400/7200/9000/10,800 s, corresponding to the curing times, and D is the calculated diffusion coefficient.

2.4.3. Model of Telis

Telis et al. [14] studied osmotic drying and defined their mathematical model for salt and moisture diffusion, which also does not contain material-specific parameters. Kang et al. [18] also used the Telis model to model salt diffusion in beef. Their model solves the diffusion calculation with the following approximation:

where we also use the N = 50 approximation, R = 0.0075 m (radius of the sample cylinder), t = 900/1800/3600/5400/7200/9000/10,800 s, corresponding to the curing times, and D is the calculated diffusion coefficient. In this model, the 50-term approximation is sufficiently accurate, but at the same time does not make the calculation too complicated.

2.4.4. Model Fitting

For each method, the left side of the equation was calculated by arranging it in an Excel table. The right sides of the equations were also arranged in a table, and the diffusion constants were determined using the SOLVER tool of the spreadsheet program so that the difference between the two sides of the equation was minimal. To achieve this, we minimized the root mean sum of squares (RMSE) of the measured–modeled results during the SOLVER run.

2.5. Statistical Analysis

2.5.1. Selection of Statistical Method

During the statistical evaluation of the measurement data, the dependent variables (salt content [m/m%] and water content [m/m%]) are explained by two factors: one factor is the type of process (process, 3 levels: dry salting, wet curing, and wet curing + ultrasound), and the other factor is the duration of the treatment (time [min], 7 levels: 15/30/60/90/120/150/180 min). Pearson’s correlation between the development of the salt content and water content was slightly significant (F(63) = −0.487; p < 0.001); so, we used multivariate analysis of variance (MANOVA) as a statistical method.

2.5.2. Assumption Tests

The normality of the error terms was confirmed based on the Shapiro–Wilk test for both the salt content (W(63) = 0.965; p = 0.069) and water content (W(63) = 0.982; p = 0.491).

The homogeneity of variance was confirmed based on Levene’s test for salt content (F(20;42) = 1.746; p = 0.064). For water content, the homogeneity of variance can be accepted, as the variance coefficient F < 6, and the sample numbers within groups were equal.

By checking the outliers, it can be determined that they were probably correct and realistic data, therefore they were used unchanged in further analysis.

2.5.3. POST HOC Test

The effect of the factors on the salt content was determined using the Tukey test. The time evolution of the difference between dry and wet processes was modeled by fitting a saturation function.

The software used is the following: IBM SPSS 29.0.2.0 [19].

3. Results and Discussion

3.1. Statistical Condition Test

During our studies, we determined the salt content and water content for all three treatments and for all of the treatment times. During the MANOVA analysis performed on the data, using the Wilks’ Lambda test, we determined that both the effect of the type of procedure (F(4;82) = 0.262; p < 0.001) and the effect of time [minutes] (F(12;82) = 0.065; p < 0.001) were significant, but the interaction of the two factors (F(24;82) = 0.818; p = 0.997) was not. The interaction effect was therefore excluded from further analyses, and a pairwise UNIANOVA test with Bonferroni correction was performed between the significant factors and the dependent variables.

3.2. Salt Content

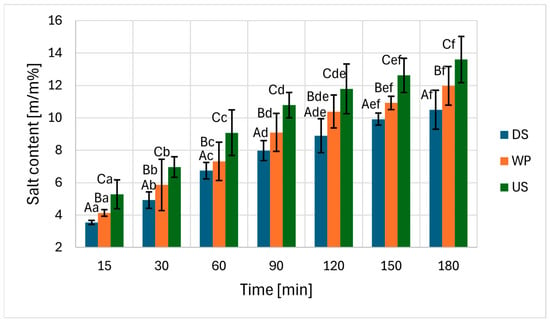

The effect of both factors on salt content was confirmed (for the curing method F(2;42) = 34.252; p < 0.001 and for the curing duration F(6;42) = 72.368; p < 0.001), and then the separability of the groups was examined with post hoc Tukey tests. The average salt content values and standard deviations of the concentrations from independent measurements supplemented with the results of the Tukey test are shown in Figure 2.

Figure 2.

Average salt content and its standard deviation during curing with the results of the Tukey test. Treatments: DS: dry salting, WP: wet curing, US: wet curing + ultrasound. A, B, C: separable processes. a, b, c, d, e, f: separable treatment times. Significance: for treatment F(2;42) = 34.252; p < 0.001, for time: F(6;42) = 72.368; p < 0.001.

It can be seen that the average salt concentration measured in the meat samples increases most slowly during dry salting and most quickly during wet curing supplemented with active ultrasound treatment. Given that a saturated salt solution was used for wet curing, it can be assumed that it approaches saturation on the surface of the meat in both processes. However, there is a significant difference between the two processes, the explanation for which is that, during dry salting, the salt is present in crystalline form and thus is unable to diffuse until water diffusing from the inside of the meat to the outside appears in its environment and dissolves it. The diffusion of salt towards the inside of the meat is therefore limited by the diffusion of water from the outside of the meat.

There is also a striking difference between wet curing and wet curing supplemented with active ultrasound treatment. Ultrasonic treatment loosens the tissue structure due to cavitation phenomena acting on the surface of the meat, and the “sponge effect” inside the meat helps the flow of the salt introduced into the solution. Our study therefore confirms the previous research results [5], and it can be clearly stated that the change in salt concentration corresponds to the following order: DRY SALTING < WET PICKLING < WET PICKLING + US.

3.3. Determination of Water Content

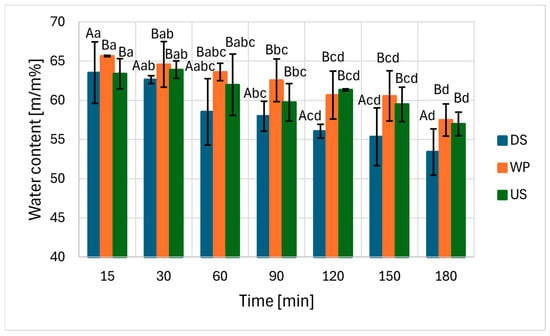

The water content results are shown in Figure 3.

Figure 3.

Average water content and its standard deviation during curing with the results of the Tukey test. Treatments: DS: dry salting, WP: wet curing, US: wet curing + ultrasound. A, B: separable processes. a, b, c, d: separable treatment times. Significance: for treatment F(2;42) = 13.451; p < 0.001, for time F(6;42) = 11.957; p < 0.001.

For the water content, the effect of both factors was also confirmed (for curing method F(2;42) = 13.451; p < 0.001, for curing duration F(6;42) = 11.957; p < 0.001), and then the separability of the groups was examined with post hoc Tukey tests. The Tukey test could only separate dry salting from the other two procedures. According to the Tukey test, there was no significant difference between wet curing with or without ultrasound treatment ((W(41) = 0.616; p = 0.296)), see Table 2. According to the present study, the water content of the samples treated with ultrasound was higher than that of the samples without ultrasound, but this difference was not significant. However, others (Inguglia et al., 2018) [20] managed to demonstrate a significantly favorable effect of ultrasound on yield.

Table 2.

Results of post hoc Tukey test for water content.

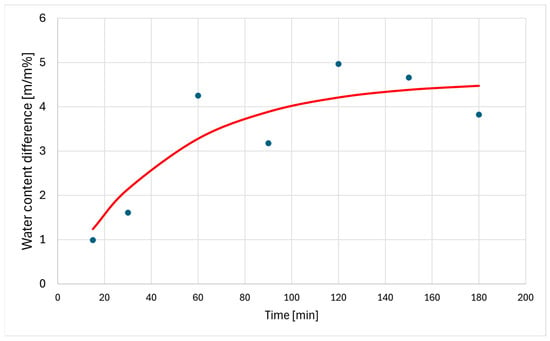

Therefore, the expected value of the moisture content was different in the case of dry and wet curing, but the significance of the ultrasonic treatment could not be confirmed on the sample size examined. The change in the moisture content was examined over time using regression. The linear regression was not significant (F(1;5) = 6.541; p = 0.51); so, we fitted a saturation curve (water difference~A × (1 − EXP(−B × Time))) (see Figure 4). The equation of the saturation function is

Figure 4.

Average water content differences between dry salting and wet curing methods (wet curing + wet curing with ultrasound) and the regression curve (4.579 × (1 − e(−0.021×Time)), R2 = 0.796).

During the application of both wet curing methods, the excess moisture content of the cylindrical long loin meat sample with a length of 80 mm and a diameter of Ø15 mm approached +4.58 m/m% along the saturation curve.

The ANOVA model of the regression was significant (F(2;5) = 78.706; p < 0.001; R2 = 0.796; RMSE = 0.5977) Among the parameters of the model, A = 4.579; p < 0.001 was significant, but B = 0.021; p = 0.066 was not. The saturation model is therefore suitable for estimating the excess moisture achieved during wet processes, but it cannot adequately predict the rate of change. When calculating the economic efficiency of curing processes, it is therefore worth considering that, in the case of wet curing, with the same curing times, an approximately 4.58% yield increase can be achieved than in the case of dry curing. This is disadvantageous for cured-dried hams since this extra water must also be evaporated later. However, in the case of heat-treated products, it can increase the yield of the finished product.

3.4. Diffusion Constants

3.4.1. Diffusion Constant for Salt

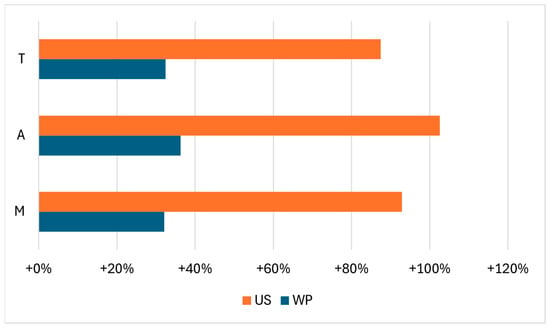

The values of the diffusion coefficients estimated by the diffusion models for salt are given in Table 3. It is clear that, of the three models examined, the model of Abbasi et al. (2011) [16] best approximated the measured salt content values, regardless of the curing method. According to this model, the diffusion coefficient of a cylindrical long loin meat sample treated with dry salting at 20 °C, with a length of 80 mm and a diameter of Ø15 mm was 4.22 × 10−10 m2/s, which can be improved by 36.3% (5.75 × 10−10 m2/s) using wet curing and by 102.6% (8.55 × 10−10 m2/s) using wet curing assisted by active ultrasound (14.1474 W/cm2 and a frequency of 19 kHz). We can also state that, despite the fact that the other two modeling methods gave different numerical results, they determined the relationship between the individual curing methods in the same way (see Figure 5). Based on the smallest RMSE values, Abbasi’s model is recommended for determining the diffusion of salt in meat.

Table 3.

Estimation of the diffusion constant of the salt content based on the fitted literature models.

Figure 5.

Effect of wet and ultrasonically assisted wet curing processes on improving the salt diffusion coefficient compared to dry salting (x-axis: Variation in diffusion coefficient in percent of dry salting). WP: wet curing, US: wet curing + ultrasound. Fitted models: M: Martuscelli, A: Abbasi, T: Telis.

Telis et al. (2003) [21] performed similar studies on caiman meat. With a 25% (nearly saturated) brine concentration, at 20 °C, and a meat/brine ratio of 0.2, the salt diffusion coefficient was 8.42 × 10−10 m2/s. The approximately 46% faster diffusion is likely due to the different animal species.

The effect of ultrasound intensity on the diffusion coefficient of salt was demonstrated by Siró et al. (2009) [22]. However, it is important that the energy investment required for higher intensity is consistent with the degree of diffusion acceleration. Compared to the experiments of Visy et al. [13], which were conducted under similar conditions to those in this study, our results showed that the application of ultrasound improved the diffusion of salt to a greater extent (Visy et al.: ×1.25, own data: ×1.48). However, since the applied acoustic intensity was increased from 5.09 W/cm2 to 14.15 W/cm2 (i.e., approximately 2.8 times), it can be stated that the improvement in the diffusion coefficient of salt is not proportional to the additional energy investment required.

3.4.2. Diffusion Constant for Water

The values of the diffusion coefficients estimated by the diffusion models for water content are given in Table 4. In this case, the model of Telis et al. (2004) [14] had the smallest error (the smallest RMSE in the case of dry salting and wet curing + ultrasound and the middle RMSE in the case of simple wet curing). According to this model, the diffusion coefficient of a cylindrical long loin meat sample treated with dry salting at 20 °C, with a length of 80 mm and a diameter of Ø15 mm, was 2.42 × 10−9 m2/s.

Table 4.

Estimation of the diffusion constant of water based on the fitted literature models.

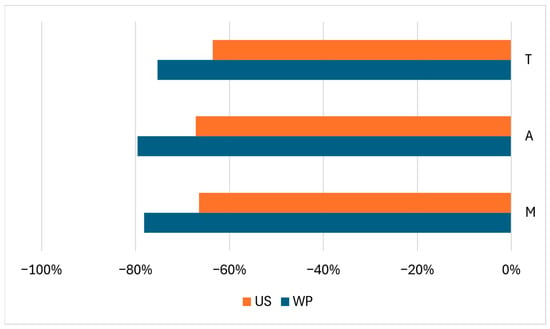

According to all three mathematical models, the diffusion constant of water decreases by an order of magnitude (75–80%) in the case of wet processes. Due to this, the use of wet curing results in a more favorable yield than traditional dry curing. It is interesting to observe that the addition of ultrasound to wet curing does not improve the favorable effect on the yield, since in this case, the diffusion coefficient only shows a decrease of about 65%.

Furthermore, it can be said that all three models proved to be much more inaccurate than with the salt content. The reasons for this may be the following:

- The movement of water is not characterized by pure diffusion as salt is, but as described above, it is a two-way process, the result of which provides the driving force for the movement of water.

- The binding of water does not only occur based on the principle of diffusion but surface binding must also be taken into account. We were prepared for this phenomenon during the measurement, which is why the removal of moisture from the surface of the cured samples was an important step. However, the removal of surface moisture cannot be carried out perfectly. On the one hand, this is because water molecules can bind more strongly to molecular chains with polar groups on the surface of the meat than to the material of the blotting paper. On the other hand, the surface of the meat cut in the direction of the grain contains a ribbed surface and grooves, due to which, some of the surface water does not even come into contact with the blotting paper during the soaking.

Despite the inaccuracy of the individual models, similarly to the diffusion of salt, the weakening effect of wet curing processes on water diffusion compared to dry salting can be clearly seen (Figure 6).

Figure 6.

The effect of wet and ultrasound-assisted wet curing processes on modifying the water diffusion coefficient compared to dry salting (x-axis: Variation in diffusion coefficient in percent of dry salting). WP: wet curing, US: wet curing + ultrasound. Fitted models: M: Martuscelli, A: Abbasi, T: Telis.

4. Conclusions

When using our results in further industrial applications, it should be taken into account that we performed experiments on relatively small geometric sample elements. When curing products of an order of magnitude larger size, the ratio between the product size and the microstructure forming the product structure also changes. We recommend conducting further research under the same conditions but using meat parts of larger geometric size with anatomical rather than regular shapes. During the application of wet curing, the excess moisture content of the cylindrical long loin meat sample with a length of 80 mm and a diameter of Ø15 mm approaches +4.58 m/m% along the saturation curve. Under the parameters of the present experiment, the effect of ultrasound on water content was not significant, therefore we do not recommend the use of ultrasound to improve yield.

Compared with the results of others, we found that diffusion is also influenced by the animal species; therefore, not only are food handling methods suitable for accelerating pickling but the targeted breeding of species with more favorable diffusion factors should also be taken into account. We recommend further research in this direction.

It can also be stated that in industrial applications, it is not advisable to increase the intensity of ultrasonic treatment too much. The exponential effect of intensity on diffusion established by other authors [7] breaks down and further increase in intensity becomes uneconomical. Further research is recommended to establish the economic threshold.

Our results therefore confirm the previous scientific findings, according to which active ultrasound can become importance significant in the meat industry not primarily by itself, when used but when used at low intensity as part of a combined process. [9] The applicability and optimization of ultrasound-assisted curing for time-efficient meat processing have been supported by these findings.

Furthermore, since a small temperature increase also occurred during ultrasonic curing, the results cannot be interpreted purely as the effect of ultrasound. In the future, it is recommended to perform experiments with more effective temperature control.

The interaction between temperature increases and ultrasound treatment could be beneficial for further research. If this interaction synergistically improved the diffusion and adequately inhibited the growth of spoilage microorganisms, this combined process would provide another opportunity to safely accelerate the pickling rate.

Author Contributions

Conceptualization, S.F. and G.J.; Data curation, S.F.; Funding acquisition, L.F.; Investigation, S.F.; Methodology, G.J. and L.F.; Project administration, S.F. and G.J.; Resources, L.F.; Software, S.F.; Supervision, G.J., J.F., Z.K. and L.F.; Validation, J.F., Z.K. and L.F.; Visualization, S.F.; Writing—original draft, S.F., G.J. and J.F.; Writing—review and editing, S.F., G.J., J.F., Z.K. and L.F. All authors have read and agreed to the published version of the manuscript.

Funding

Supported by the eköp-24 new national excellence program of the ministry for culture and innovation from the source of the national research, development, and innovation fund.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Dataset available on request from the authors.

Acknowledgments

We would like to thank SPAR Hungary Ltd. for providing us with the meat samples necessary for the experiments.

Conflicts of Interest

The authors declare no conflicts of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

Abbreviations

The following abbreviations are used in this manuscript:

| DS | Dry salting |

| WP | Wet curing |

| US | Wet curing + ultrasound |

References

- Baska, F.; Zukál, E. A hús ipari feldolgozása. A hús ipari feldolgozása. In Húsipari Kézikönyv; Lőrincz, F., Lencsepeti, J., Eds.; Mezőgazda Kiadó: Budapest, Hungary, 1973; pp. 583–584. [Google Scholar]

- Sabadini, E.; Carvalho, B.C., Jr.; Sobral, P.J.; Hubinger, M.D. Mass transfer and diffusion coefficient determination in salted and dried meat. Dry. Technol. 1998, 16, 2095–2115. [Google Scholar] [CrossRef]

- Firouz, M.S.; Sardari, H.; Chamgordani, P.A.; Behjati, M. Power ultrasound in the meat industry (freezing, cooking and fermentation): Mechanisms, advances and challenges. Ultrason. Sonochem. 2022, 86, 106027. [Google Scholar] [CrossRef] [PubMed]

- Flórik, G.I. Mechanika. In Fizika, 2nd ed.; Holics, L., Ed.; Műszaki Könyvkiadó: Budapest, Hungary, 1992; Volume 1, p. 401. [Google Scholar]

- Yao, Y.; Pan, Y.; Liu, S. Power ultrasound and its applications: A state-of-the-art review. Ultrason. Sonochem. 2020, 62, 104722. [Google Scholar] [CrossRef] [PubMed]

- Somogyi, T.; Madácsi, C.; Lovas-Bíró, B.; Zsom, T.; Zsom-Muha, V. Investigation of soaking water produced by ultrasound-assisted chickpea soaking process. Prog. Agric. Eng. Sci. 2023, 19, 123–130. [Google Scholar] [CrossRef]

- Friedrich, L. Ultrahang Alkalmazása Húskészítmények Minősítésében és Gyártástechnológiájában. Ph.D. Dissertation, Budapesti Corvinus Egyetem, Budapest, Hungary, 2008. [Google Scholar]

- Cruz-Garibaldi, B.Y.; Alarcon-Rojo, A.D.; Huerta-Jimenez, M.; Garcia-Galicia, I.A.; Carrillo-Lopez, L.M. Efficacy of ultrasonic-assisted curing is dependent on muscle size and ultrasonication system. Processes 2020, 8, 1015. [Google Scholar] [CrossRef]

- Alarcon-Rojo, A.D.; Carrillo-Lopez, L.M.; Reyes-Villagrana, R.; Huerta-Jiménez, M.; Garcia-Galicia, I.A. Ultrasound and meat quality: A review. Ultrason. Sonochem. 2019, 55, 369–382. [Google Scholar] [CrossRef] [PubMed]

- Gu, S.; Zhu, Q.; Zhou, Y.; Wan, J.; Liu, L.; Zhou, Y.; Chen, D.; Huang, Y.; Chen, L.; Zhong, X. Effect of Ultrasound Combined with Glycerol-Mediated Low-Sodium Curing on the Quality and Protein Structure of Pork Tenderloin. Foods 2022, 11, 3798. [Google Scholar] [CrossRef] [PubMed]

- Latoch, A.; Stasiak, D.M.; Junkuszew, A. Combined Effect of Acid Whey Addition and Ultrasonic Treatment on the Chemical and Microbiological Stability of Lamb Stuffing. Foods 2023, 12, 1379. [Google Scholar] [CrossRef] [PubMed]

- Shu, Z.W.; Wang, S.M.; Xu, W.W.; Wang, N.; Pan, Z.Q.; Xu, Y.D.; Wu, N.N. Research progress of ultrasound technology and its combined application in fruit and vegetable storage. Acta Aliment. 2024, 53, 513–536. [Google Scholar] [CrossRef]

- Visy, A.; Jónás, G.; Szakos, D.; Horváth-Mezőfi, Z.; Hidas, K.I.; Barkó, A.; Friedrich, L. Evaluation of ultrasound and microbubbles effect on pork meat during brining process. Ultrason. Sonochem. 2021, 75, 105589. [Google Scholar] [CrossRef] [PubMed]

- Telis, V.R.N.; Murari, R.C.B.D.L.; Yamashita, F. Diffusion coefficients during osmotic dehydration of tomatoes in ternary solutions. J. Food Eng. 2004, 61, 253–259. [Google Scholar] [CrossRef]

- Martuscelli, M.; Lupieri, L.; Sacchetti, G.; Mastrocola, D.; Pittia, P. Prediction of the salt content from water activity analysis in dry-cured ham. J. Food Eng. 2017, 200, 29–39. [Google Scholar] [CrossRef]

- Abbasi Souraki, B.; Ghaffari, A.; Bayat, Y. Mathematical modeling of moisture and solute diffusion in the cylindrical green bean during osmotic dehydration in salt solution. Food Bioprod. Process. 2012, 90, 64–71. [Google Scholar] [CrossRef]

- Marabi, A.; Livings, S.; Jacobson, M.; Saguy, I.S. Normalized Weibull distribution for modeling rehydration of food particulates. Eur. Food Res. Technol. 2003, 217, 311–318. [Google Scholar] [CrossRef]

- Kang, D.; Wang, A.; Zhou, G.; Zhang, W.; Xu, S.; Guo, G. Power ultrasonic on mass transport of beef: Effects of ultrasound intensity and NaCl concentration. Innov. Food Sci. Emerg. Technol. 2016, 35, 36–44. [Google Scholar] [CrossRef]

- IBM SPSS Statistics for Windows 29.0.2.0; IBM Corp.: Armonk, NY, USA, 2023.

- Inguglia, E.S.; Zhang, Z.; Burgess, C.; Kerry, J.P.; Tiwari, B.K. Influence of extrinsic operational parameters on salt diffusion during ultrasound assisted meat curing. Ultrasonics 2018, 83, 164–170. [Google Scholar] [CrossRef] [PubMed]

- Telis, V.R.N.; Romanelli, P.F.; Gabas, A.L.; Telis-Romero, J. Salting kinetics and salt diffusivities in farmed Pantanal caiman muscle. Food Technol. 2003, 38, 529–535. [Google Scholar] [CrossRef]

- Siró, I.; Vén, C.; Balla, C.; Jónás, G.; Zeke, I.; Friedrich, L. Application of an ultrasonic assisted curing technique for improving the diffusion of sodium chloride in porcine meat. J. Food Eng. 2009, 91, 353–362. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).