Featured Application

This work fits into the idea of utilizing alternative raw materials for the development of traditional meat products like Greek sausages, which will have an impact on their lipid profile as well as their physicochemical and sensory characteristics. Τhe scientific impact and novelty of the present work include the end of the dominance of the use of pork backfat as a source of fat for meat products in which its use was mandatory until recently, which makes it possible for other cultures to consume the products as well as for the products to have a better nutritional profile. Also, it provides a perspective of altering the fat and meat content of traditional meat products without sacrificing the essential ingredients of the fat.

Abstract

Applying a statistical mixture design, 10 different blending combinations of traditional Greek sausages were prepared based on different percentages of the three ingredients (buffalo meat: 40–70%; pork fat: 0–30%; buffalo fat: 0–30%). Samples were then analyzed for chemical composition, instrumental textural properties and sensory attributes, using a balanced incomplete block design (BIBD) for the sensory analysis. According to the chemical set, the fat content increased when both fat origins increased, and the protein content also increased when the proportion of buffalo meat increased in the formulations. Regarding textural properties, an instrumental analysis revealed a positive relationship between fat level increases and hardness, whereas a sensory analysis revealed a rise in hardness when the proportion of buffalo fat increased, but that was not observed for sensory juiciness. A hierarchical cluster analysis and PCA revealed a strong relationship between the elasticity, juiciness and overall acceptability of samples with high fat contents, regardless of the origin of the fat, whereas at the same time, a strong relationship was found between high buffalo meat contents (70%) in samples and both instrumental and sensory hardness, chewiness and protein content.

1. Introduction

Traditional Greek sausages are a meat product that is produced artisinally with different recipes within the Greek territory. Different recipes contain different raw ingredients, such as spices, seasonings, fruits and vegetables [1]. According to the Greek Food Legislation (2014) [2], traditional Greek sausages are non-thermally processed raw meat products, which are produced through the stuffing of comminuted meat from various origins of meat (except poultry) into natural or artificial edible casings and then exposed to a stage of short-term dehydration and ripening and/or smoking. Traditionally, ground pork meat and pork backfat were used, and their fat content should not exceed 35% of their total weight [3].

However, since it is a product that has been produced since ancient times, when people recognized the beneficial effects on meat of its introduction in natural animal casings [4], the production of country sausages is not limited to within Greek borders, which is a guarantee that the results of the present study can be applied in other regions of the world. Similar products to Greek traditional sausages are the Boerewors from the South African region [5], Salsiccia, which is a traditional Italian fresh sausage [6], or fresh Santarrosano sausage, originating from Colombia [7]. Τhe aforementioned products, together with traditional country sausages, share a common characteristic, which is the use of pork meat and fat as a raw material. Its replacement or substitution by beef or buffalo meat or fat is therefore a challenging prospect.

Among the various livestock animals that currently live in Greek territories for meat production, in recent decades, Greek Buffalo (Bubalus bubalis)—which is also an endangered–maintained species—has gained significant attention because of some distinguishing traits that characterize its meat [8]. The specific traits of the meat derived from Greek Buffalo is location-dependent to the region of north Greece and more specifically the prairies around Lake Kerkini [9]. However, apart from the great environmental importance, buffalo meat possesses important qualities and health benefits as well. For example, buffalo meat was recognized globally as the healthiest red meat, mainly due to its low cholesterol and fat contents, and more specifically, in many cases, the content of CLA (conjugated linoleic acid) and PUFA/SFA ratio are more beneficial for human health than those of cattle or pigs [10,11]. Also, when it comes to the sensory attributes of buffalo meat, a wide range of results have been observed in the literature, and most of them highlight the superior or equal organoleptic perception of buffalo meat compared to many cattle breeds that are reared for meat production globally [11,12]. All the data presented above lead to the conclusion that the use of buffalo meat and fat is very promising for manufacturing traditional meat products.

For this purpose, several applications have been developed in research and industry that have involved both the replacement or substitution of animal fat with carbohydrate fat mimetics [13,14] or changing the fatty acid profile of fat by adding vegetable oils that are rich in monounsaturated or polyunsaturated fatty acids [15,16]. These techniques have faced several obstacles based on the very important and multiple roles that the addition of fat to meat products such as sausages plays in the physicochemical and organoleptic parameters, which is why industrial applications have not been widely accepted so far [17]. Furthermore, from a nutritional point of view, by replacing animal fat in these products, a significant proportion of fat-soluble vitamins (A, D, E, K) is lost, the lack of which is an issue nowadays and is partly due to the large reduction in the consumption of animal fat. In addition, newly released clinical results are questioning the positive relationship between animal fat consumption and cardiovascular diseases (CVDs) [18,19]. Therefore, studies aimed at changing the type of fat and meat that are used in traditional meat products and include in-depth research on the physicochemical, mechanical and organoleptic parameters of these products represent an efficient approach that also has a health effect.

It is very important, when differentiations are made in the production of traditional meat products, to evaluate the impact on many factors such as physicochemical, textural or sensory attributes. Also, the formulated products should not deviate much from the original ones to maximize consumer acceptability [20]. As mentioned above, the most famous strategies when attempting to modify traditional meat products like sausages to improve their characteristics are, among others, the reduction or total substitution of fat content or alteration of the lipid profile, which is very important for the specific meat products because of their high fat content, which exceeds 30% in most cases [21,22,23]. Another very promising methodology is the formulating of the classic recipes of traditional meat products like sausages, with the use of alternative raw materials from other origins in different ratios, to improve their textural, physicochemical, sensory and maybe nutritional characteristics. Considerable research has been conducted in this field, and for example, Bhattacharyya et al. (2007) [24] and Lorenzo et al. (2011) [25] investigated the use of duck meat in sausages, which presented high nutritional value, on their textural and sensory characteristics. Another example is the modification of fat origin, which traditionally originates from pork backfat, and more specifically Peña-Saldarriaga et al. (2020) [26] investigated the use of chicken skin as a fat source in sausages and evaluated its impact on various quality properties, including sensory attributes.

A challenge which many researchers faced when they tried to modify the traditional meat products by altering the meat or fat origin was the correlation of physicochemical, objective textural and sensory attributes and measurements. The difficulty grew significantly considering that in order to establish a robust and clear opinion about the efficiency of a new product, one should include many levels or points of analysis [27,28]. Thus, a suitable experimental design is crucial for this target, and the use of mixture design (extreme vertices design) enables the development of mathematical modeling, which gives the response prediction and the best desirable performance at the same time [29]. Also, presenting data for combining sensory with physicochemical and textural properties can be challenging; thus, the use of sophisticated statistical experimentation becomes necessary [30].

The aim of the present study is to evaluate for the first time the use of buffalo meat and fat as alternative raw materials for the production of traditional Greek sausages and their impact on physicochemical, textural and sensory characteristics and investigate the efficiency of a mixture design combined with a balanced incomplete block design (BIBD) and multivariate techniques (cluster and principal component analysis) to combine the different origin of variables and evaluate the best combinations of the raw materials.

2. Materials and Methods

2.1. Sausage Samples Preparation

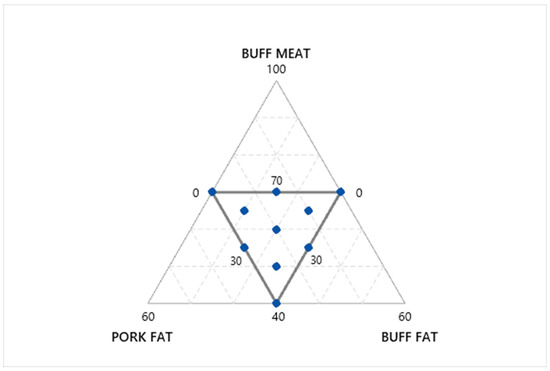

Greek Buffalo meat (thigh), buffalo fat and pork backfat as well as the natural cases of porcine small intestine were provided by Kerkini market, north Greece and stored at 4 °C. The sausage preparation was based on the work of Petridis et al. (2015) [9] with modifications. Briefly, the raw materials and more specifically the buffalo meat, buffalo fat and pork backfat were cut into small pieces and then minced with a Seydelmann minced meat machine with internal mesh of 8 mm and external mesh of 5 mm. Directly after that, the porcine small intestines 30–32 mm were used as natural casings, and the batter was stuffed using a Talsa H26PA filler machine. After the drying process, which lasted for 72 h at 4 °C, the samples were stored for further analyses. Sausages were prepared following the prescriptions derived from a mixture design of the three ingredients (Figure 1) which were generated using initial ranges as follows: buffalo meat: 40–70%, pork fat: 0–30%, buffalo fat: 0–30%. The specific ranges of the buffalo meat, pork fat and buffalo fat occurred based on preliminary experiments and results from our previous work [9]. This design produced 10 blending combinations presented in detail in Table 1.

Figure 1.

Mixture-amounts components with extreme vertices design composing a triangular operating area.

Table 1.

Formulation of sausages using different percentages of ingredients.

2.2. Proximate Analysis

The proximate composition of the sausages prepared in the present study was evaluated using the official AOAC methods. The moisture content of the sausages was determined using the method of weight loss after drying at 105 °C for 12 h in a drying oven [31]. Protein was determined using the Kjeldahl method equipped with an automatic Kjeldahl nitrogen analyzer. The fat content of sausages was determined using the Soxhlet extraction method in a programmed heating mantle using diethyl ether as a solvent [32]. For the determination of the ash content of sausages, we used the mineralization at 550 °C according to the standard AOAC method (AOAC, 2002b) [33].

2.3. Textural Profile Analysis (TPA)

Textural properties and more specifically hardness, adhesiveness and chewiness were determined using a textural analyzer (Model XT2i, Stable Micro Systems, Godalming, UK) based on the method described by Guine (2022) [34]. The analyzer was equipped with a 50 mm diameter aluminum cylinder, operating with a compression rate of 5 mm/s. Samples, 20 mm in length, were cut using a dedicated template ring and axially compressed to 40% of their original height. The capacity of the load cell used was 30 kg. The calculation of TPA parameter values was facilitated through the graphing of curves at force–time plots.

2.4. Sensory Analysis

Sensory analysis methodology was based on the study of Petridis et al. (2015) [9] with minor modifications. More specifically for the sensory analysis, a balanced incomplete block design was used. Fifteen panelists were selected from the academic staff and research students of the department, well trained previously in consecutive sensory trials with varying meat formulations, and asked to evaluate the intensity of each property in specially designed booths by ticking their assessment on an unstructured scaled line 15 cm long whose left anchor (0 cm) was noted as not at all intense and the right anchor (15 cm) as very intense (e.g., very hard). The samples were grilled for 20 min and then presented to panelists after cooling at approximately 30 °C. The sensory attributes were particularly itemized:

Brown color;

Elasticity;

Hardness;

Cohesiveness;

Juiciness;

Overall acceptability.

2.5. Statistical Analysis

The product profile was based on the assessment of the chemical (moisture, ash, fat, protein), textural (hardness, adhesiveness, chewiness, springiness) and sensory objective properties (hardness, cohesiveness, elasticity, juiciness, brown color), using triplicate samples for the first two sets and a particular balanced incomplete block design for the latter set including the sensory parameters: t = number of treatments (10 points from the mixture design), k = 4 restricted number of treatments presented to each panelist (4 servings), b = 15 panelists, r = 6 replicates per treatment and λ = 2 similar pairs of treatments in the design (plan 11.16 from Cochran and Cox, 1957) [35]. The sensory experiment was conducted twice; thus, two adjusted variable means per treatment were calculated. Individual values were dot-plotted to detect and remove the potential outliers between each treatment and panelist combination.

For each variable Y, the special cubic mixture equation was performed, which includes the main three components and their first and second order interactions:

where Ŷ = the fitted variable response under question, X1 = buffalo meat, X2 = pork fat, and X3 = buffalo fat.

Ŷ = b1X1 + b2X2 + b3X3 + b12X1X2 + b13X1X3 + b23X2X3 + b123X1X2X3

The statistical significance of each term in the polynomial equation was tested applying the forward selection of variables (p-entrance ≤ 0.05), so selecting only the parsimonious model. The main components were always forced to retain in the final equation, no matter the statistical significance, paying also attention to the desirable non-significant effect of the lack-of-fit test for detecting curvature. The results were expressed as tables with regression coefficients plus the determined and predicted R2 coefficients of fit reliability and predictability. Trace plots were also constructed to detect particular trends of the variable responses as affected by the blending components. In these plots, the interest is focused on how each variable responds when one ingredient increases in proportion (right part of graph) and the other two always decrease. On the three sets of attributes, a two-way cluster analysis was conducted using the Euclidean distance for samples similarity and the Ward technique for samples linkage along with the clustering of attributes. The forthcoming groups are expected each to include samples with common effects on specific variables from different sets. Finally, to detect potential relationships among the three variable sets with reference on samples, a principal component analysis (PCA) was performed—a method which is known to extract as much information as possible from the whole set of variables into the two first major components. When samples and variables of different sets are found in a proximate position in the PCA graph, they signal unique information.

The statistical information on the regression equations and the trace plots were obtained using the MINITAB 19.0 (Minitab LLC, State College, PA, USA) software, and the cluster and PCA analysis was performed via the JMP 17.0 statistical software (Statistical Discovery LLC, Cary, NC, USA).

3. Results and Discussion

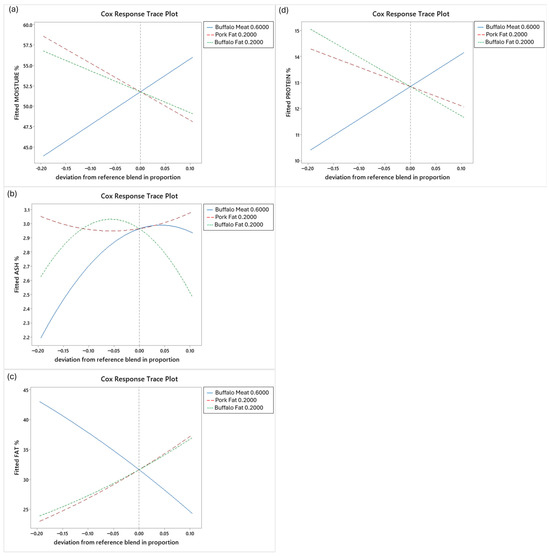

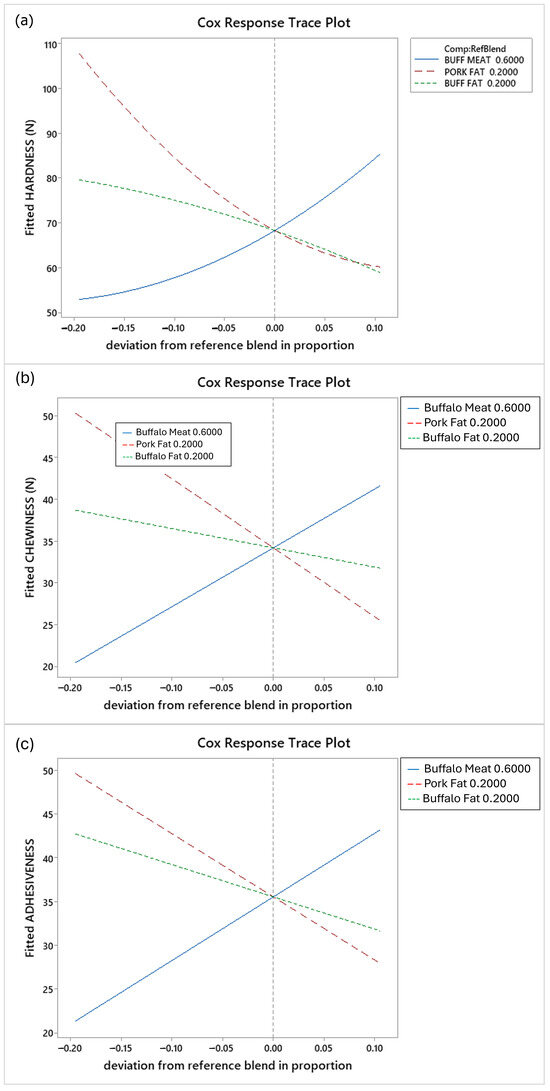

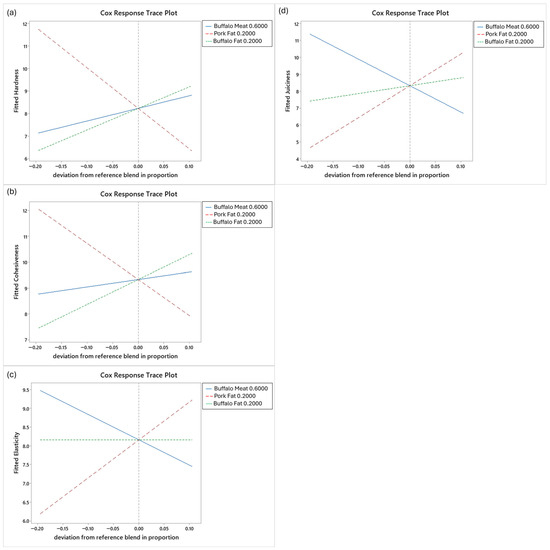

Most of the product attributes followed a linear trend in the mixture equations, highlighting good equation fits and produced regression coefficients whose higher values correspond to greater effects (Table 2), positive or negative, explicitly illustrated in Figure 2, Figure 3 and Figure 4.

Table 2.

Regression coefficients (in amounts) of the statistically significant variables as affected by the mixture of components.

Figure 2.

Trace plots of chemical variable responses across the proportion increase in mixture components from the reference blend point: (a) moisture, (b) ash, (c) fat, (d) protein.

Figure 3.

Trace plots of textural variable responses across the proportion increase in mixture components from the reference blend point: (a) hardness, (b) adhesiveness, (c) chewiness.

Figure 4.

Trace plots of sensory variable responses across the proportion increase in mixture components from the reference blend point: (a) hardness, (b) cohesiveness, (c) elasticity, (d) juiciness.

Regarding the chemical set (Figure 2), moisture and protein followed a similar trend of response, i.e., an increase in buffalo meat and decrease in both fat ingredients as their proportions increased individually from the reference blend point (centroid of the mixture design), which consisted of 60% buffalo meat, 20% pork fat and 20% buffalo fat. Inversely, an increasing pattern for the fat concentration of sausages occurred as the proportion of both fat ingredients increased with the model indicating no significant difference between the effects of pork and buffalo fat on total fat content. The increasing trend of protein and moisture content as the fat level of sausages decreased was also observed in the studies of Lorenzo et al. (2011) [25] and Chin et al. (2004) [36]. Unique curvilinear responses of the ash concentration of sausages were formed and depicted in the trace plot, in which the most striking effect was the rapid decline when only the buffalo meat increases in the blend.

The textural adhesiveness and chewiness showed a similar pattern of responses (Figure 3): they both increase (in equal rates of change) in higher buffalo meat proportions and decrease in increasing proportions of both fat ingredients with a more reductive effect of the pork fat. The hardness is also enhanced in higher proportions of buffalo meat and is reduced equally when the fat increases indiscriminately in the mixture. The fat is known to play a major role in the final textural quality of sausages and meat emulsion-type products; thus, decreasing the animal fat content and especially pork backfat is correlated with higher textural hardness and chewiness [37,38].

Two different patterns of responses are formed regarding the sensory attributes (Figure 4). Firstly, the hardness and cohesiveness increased slightly when both buffalo meat and fat increased. The second pattern refers to the steep decline of the hardness and cohesiveness in higher amounts of pork fat. To better understand this fact, one should consider both the higher polyunsaturated to saturated lipid ratio (P/S) of pork backfat compared to the buffalo and beef fat and the effect of fatty acid composition on the meat’s and meat products’ firmness, since the melting point lowers as unsaturation increases [39]. The fact that unsaturated lipids are softer in storage temperatures could lead to sausages that have a higher content of unsaturated fat and are also softer and juicier and thus could result in the perception of better textural traits by consumers [40]. Another important reason for this observation is the higher percentage of connective tissue in the beef or buffalo fat (tallow) especially from the external positions compared to the pork backfat, which is known to increase the hardness of the meat products [41]. On the other hand, the elasticity and juiciness increased upon increasing the proportions of the pork fat and decreasing the proportions of the buffalo meat. Plus, the buffalo fat exerts a neutral effect on both sensory attributes. This fact agrees with the literature, since the sausages with higher fat content were correlated with higher juiciness and lower hardness, as shown in the study of Olivares et al. (2010) [42].

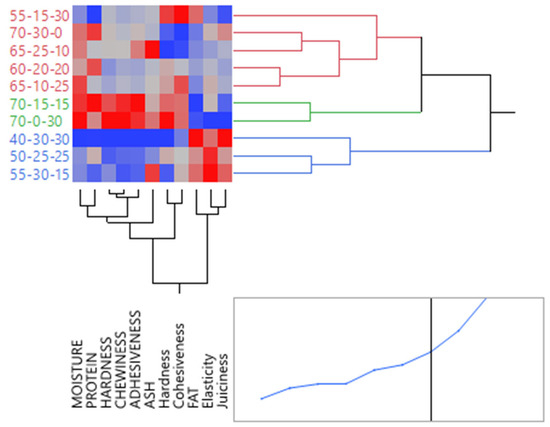

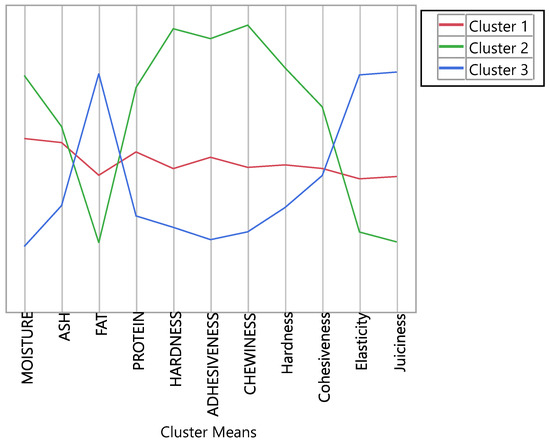

Three groups of the samples in accordance with three groups of the variables are depicted in the two-way cluster diagram of Figure 5 below. Fat, sensory elasticity and juiciness are found in high values in cluster 3 (see Figure 5), which are indicative of the low percentage of buffalo meat (40–55%), whereas in the same cluster, the moisture and protein together with the textural hardness, chewiness and adhesiveness are observed in lower values (blue and gray color) (Table 3, Figure 6). In contrast, the same attributes together with sensory hardness and cohesiveness reach high values in cluster 2 (see Figure 5), which are indicative of the highest abundance of buffalo meat (70%). Cluster 1 shows an intermediate range of attribute responses combined also with moderate buffalo fat content. These figures (Figure 5 and Figure 6), along with Table 3, could also imply that textural and sensory methods of evaluating the firmness of the sausages with different meat and fat content and origin gave similar results. The agreement between sensory and objective textural analysis is very important when it comes to food products, because only then is food control in accordance with consumer acceptability [43].

Figure 5.

Arrangement of samples and variables groups according to a two-way cluster analysis. Clusters are colored and numbered as red (1), green (2) and blue (3). Red squares show the highest response values and blue squares the lowest values. Capital letters show textural and chemical variables and lowercase the sensory ones. Samples are notated accordingly as percentage buffalo meat-pork fat–buffalo fat.

Table 3.

Cross-tabulation of variable means per cluster.

Figure 6.

Graphical distribution of variable means per cluster.

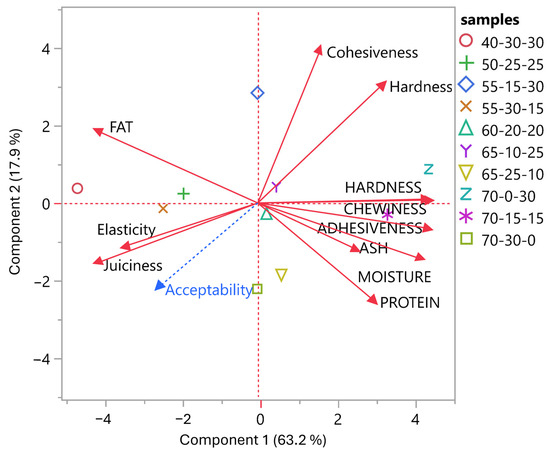

The information from cluster analysis is eloquently manifested in the PCA results (Table 4, Figure 7). Both PCA axes explain 81.1% of the total variation, indicating a reliable information of the results. The major component 1 correlates strongly and positively (r > 0.900) with the chewiness, adhesiveness, textural hardness and moisture and in a lesser intensity with the sensory hardness and protein (Table 4). All the above variables form a bundle in which the buffalo meat becomes very abundant, since the two samples with the maximum meat values (70%) are closely positioned (Figure 6). On the contrary, the fat, elasticity and juiciness correlate strongly and negatively with component 1, occupying the left part of the biplot in which the sample with the lowest content of buffalo meat (40%) and the highest content of total fat content (60%) predominates. The positive relationship between the meat products of higher fat content and higher juiciness was also shown in the work of Arildsen Jakobsen et al. (2014) [44] and Araujo et al. (2019) [45]. Component 2 is best described by the sensory cohesiveness (r = 0.850) and the blend 55–15–30. It is worth stressing that the sensory hardness correlates positively with textural hardness and the blend 70–0–30, which happens only in the presence of both buffalo meat and fat. Also, the overall acceptability of the products, which was entered passively as a supplementary variable in the PCA biplot, is strongly and positively correlated with the elasticity and juiciness, which agrees with the literature results [46,47]. The latter two attributes correlate strongly and negatively with the cohesiveness and sensory hardness. Similarly, the total fat content showed a strong negative correlation with the group of variables (hardness, chewiness, etc.) associated with high buffalo meat content.

Table 4.

Correlation coefficients between axis 1 and 2 and the variables of the study.

Figure 7.

Correlation biplot of variables with the major two components and arrangement of samples in the graph space. Variables forming low acute angles correlate strongly and positively and those with very obtuse angles correlate strongly and negatively. Samples positioned close to particular variables indicate a positive relationship.

4. Conclusions

Cluster analysis revealed that the use of the highest percentages of the buffalo meat is linked to increased hardness and cohesiveness, while at the same time, increased buffalo fat content is linked with higher juiciness and decreased hardness in the sausages. It is very important when altering the fat origin to consider the lipid profile of the specific fat. More specifically, in the present study, the higher unsaturated lipid profile of the pork backfat led to decreased hardness and increased juiciness in the final products when compared to the samples containing buffalo fat. Also, a strong agreement between objective and sensory attributes was established, which must be stressed when modifying traditional products to increase consumer acceptability and shelf-life.

Author Contributions

Conceptualization, D.P., E.D. and E.T.; methodology, D.P. and T.F.; software, T.F. and D.P.; validation, T.F., D.P., E.D. and E.T.; formal analysis, D.P., E.D. and E.T.; investigation, T.F. and D.P.; resources, D.P.; data curation, T.F., D.P., E.D. and E.T.; writing—original draft preparation, T.F. and D.P.; writing—review and editing, T.F. and D.P.; visualization, T.F., D.P., E.D. and E.T.; supervision, D.P.; project administration, D.P.; funding acquisition, T.F. and D.P. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in the study are included in the article; further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Papadima, S.N.; Bloukas, J.G. Effect of fat level and storage conditions on quality characteristics of traditional Greek sausages. Meat Sci. 1999, 51, 103–113. [Google Scholar] [CrossRef] [PubMed]

- Greek Food Legislation (2014); Article 91; Government of Greece: Athens, Greece, 2014.

- Ambrosiadis, J.; Soultos, N.; Abrahim, A.; Bloukas, J.G. Physicochemical, microbiological and sensory attributes for the characterisation of Greek traditional sausages. Meat Sci. 2004, 66, 279–287. [Google Scholar] [CrossRef] [PubMed]

- Rivas, F.P.; Cayré, M.E.; Campos, C.A.; Castro, M.P. Natural and artificial casings as bacteriocin carriers for the biopreservation of meats products. J. Food Saf. 2018, 38, 12419. [Google Scholar] [CrossRef]

- Freitag, A.; Cluff, M.; Pretorius, W.; Bothma, C.; Hugo, A.; Hugo, C. Chemical, Microbial, and Sensory Effects of Natural Preservatives as Sulfur Dioxide Replacers in Boerewors. J. Food Process. 2024, 11, 4336909. [Google Scholar] [CrossRef]

- Pedonese, F.; Torracca, B.; Mancini, S.; Pisano, S.; Turchi, B.; Cerri, D.; Nuvoloni, R. Effect of a Lactobacillus sakei and Staphylococcus xylosus protective culture on Listeria monocytogenes growth and quality traits of Italian fresh sausage (salsiccia) stored at abusive temperature. Ital. J. Anim. Sci. 2020, 19, 1363–1374. [Google Scholar] [CrossRef]

- Jaramillo-Bedoya, E.; Flórez-Elvira, L.J.; Ocampo-Ibáñez, I.D. High Prevalence of Salmonella spp. in Ready-to-Eat Artisanal Pork Sausages Sold at Food Outlets in Quindío, Colombia. Pathogens 2025, 14, 31. [Google Scholar] [CrossRef]

- Food and Agriculture Organization of the United Nations (FAO). Determining the conservation value of a breed. In In Vivo Conservation of Animal Genetic Resources, 1st ed.; Food and Agriculture Organization of the United Nations (FAO): Rome, Italy, 2013; pp. 58–86. Available online: https://www.fao.org/4/i3327e/i3327e.pdf (accessed on 1 January 2022).

- Petridis, D.; Zotos, A.; Skapetas, B.; Bampidis, V.A. The Effect of Buffalo Meat on Composition, Instrumental and Sensory Characteristics of Traditional Greek Sausages. J. Food Res. 2015, 4, 26. [Google Scholar] [CrossRef]

- Calabrò, S.; Cutrignelli, M.I.; Gonzalez, O.; Chiofalo, B.; Grossi, M.; Tudisco, R.; Panetta, C.; Infascelli, F. Meat quality of buffalo young bulls fed faba bean as protein source. Meat Sci. 2014, 96, 591–596. [Google Scholar] [CrossRef]

- Di Stasio, L.; Brugiapaglia, A. Current Knowledge on River Buffalo Meat: A Critical Analysis. Animals 2021, 11, 2111. [Google Scholar] [CrossRef]

- Canozzi, M.E.A.; Sphor, L.Á.; Pimentel, C.M.M.; Barcellos, J.O.J.; Poli, C.H.E.C.; Bergmann, G.P.; Kindlein, L. Sensory evaluation of beef and buffalo extensively reared and its relationship to sociodemographic characteristics of consumers. Semin. Ciências Agrárias 2016, 37, 1617–1627. [Google Scholar] [CrossRef]

- Egea, M.; Álvarez, D.; Peñaranda, I.; Panella-Riera, N.; Linares, M.B.; Garrido, M.D. Fat Replacement by Vegetal Fibres to Improve the Quality of Sausages Elaborated with Non-Castrated Male Pork. Animals 2020, 10, 1872. [Google Scholar] [CrossRef] [PubMed]

- Paglarini, C.; Vidal, V.A.S.; Ozaki, M.M. Inulin gelled emulsion as a fat replacer and fiber carrier in healthier Bologna sausage. Food Sci. Technol. Int. 2021, 28, 3–14. [Google Scholar] [CrossRef]

- Hernández-Jiménez, M.; Martínez-Martín, I.; Vivar-Quintana, A.M.; Revilla, I. Effects of the Replacement of Pork Backfat with High Oleic Sunflower Oil on the Quality of the “Chorizo Zamorano” Dry Fermented Sausage. Foods 2022, 11, 2313. [Google Scholar] [CrossRef]

- De Carvalho, F.A.L.; Munekata, P.E.; Pateiro, M.; Campagnol, P.C.; Domínguez, R.; Trindade, M.A.; Lorenzo, J.M. Effect of replacing backfat with vegetable oils during the shelf-life of cooked lamb sausages. LWT 2020, 122, 109052. [Google Scholar] [CrossRef]

- Glisic, M.; Boskovic, M.; Baltic, M.Z.; Trbovic, D.; Suvajdzic, B.; Vasilev, D. Fat replacement and PUFA enrichment challenges in fermented sausage production. IOP Conf. Ser. Earth Environ. Sci. 2020, 333, 012061. [Google Scholar] [CrossRef]

- Meksawan, K.; Pendergast, D.R.; Leddy, J.J.; Mason, M.; Horvath, P.J.; Awad, A.B. Effect of low and high fat diets on nutrient intakes and selected cardiovascular risk factors in sedentary men and women. J. Am. Coll. Nutr. 2004, 23, 131–140. [Google Scholar] [CrossRef]

- Wang, B.; Tian, G.; Zhang, Q. Vegetable oil or animal fat oil, which is more conducive to cardiovascular health among the elderly in China? Curr. Probl. Cardiol. 2023, 48, 101485. [Google Scholar] [CrossRef]

- Schreuders, F.K.; Schlangen, M.; Kyriakopoulou, K.; Boom, R.M.; van der Goot, A.J. Texture methods for evaluating meat and meat analogue structures: A review. Food Control. 2021, 127, 108103. [Google Scholar] [CrossRef]

- Frangopoulos, T. Incorporation of Trigonella Foenum-Graecum seed powder in meat emulsion systems with olive oil: Effects on physicochemical, texture, and color characteristics. J. Food Sci. Technol. 2022, 59, 2060–2070. [Google Scholar] [CrossRef]

- Muguerza, E.; Fista, G.; Ansorena, D.; Astiasaran, I.; Bloukas, J.G. Effect of Fat Level and Partial Replacement of Pork Backfatwith Olive Oil on Processing and Quality Characteristics of Fermented Sausages. Meat Sci. 2002, 61, 397–404. [Google Scholar] [CrossRef]

- Pérez, L.; Pincay, R.; Salazar, D.; Flores, N.; Escolastico, C. Evaluation of the Quality and Lipid Content of Artisan Sausages Produced in Tungurahua, Ecuador. Foods 2023, 12, 4288. [Google Scholar] [CrossRef] [PubMed]

- Bhattacharyya, D.; SInhamahapatra, M.; Biswas, S. Preparation of sausage from spent duck–an acceptability study. Int. J. Food Sci. Technol. 2007, 42, 24–29. [Google Scholar] [CrossRef]

- Lorenzo, J.M.; Temperán, S.; Bermúdez, R.; Purriños, L.; Franco, D. Effect of fat level on physicochemical and sensory properties of dry-cured duck sausages. Poult. Sci. 2011, 90, 1334–1339. [Google Scholar] [CrossRef]

- Peña-Saldarriaga, L.M.; Pérez-Alvarez, J.A.; Fernández-López, J. Quality Properties of Chicken Emulsion-Type Sausages Formulated with Chicken Fatty Byproducts. Foods 2020, 9, 507. [Google Scholar] [CrossRef]

- Müller, C.H. Robustness Measures: Bias and Breakdown Points. In Robust Planning and Analysis of Experiments; Lecture Notes in Statistics; Springer: New York, NY, USA, 1997; Volume 124. [Google Scholar] [CrossRef]

- Ahmad, M.; Qureshi, S.; Akbar, M.H.; Siddiqui, S.A.; Gani, A.; Mushtaq, M.; Hassan, I.; Dhull, S.B. Plant-Based Meat Alternatives: Compositional Analysis, Current Development and Challenges. Appl. Food Res. 2022, 2, 100154. [Google Scholar] [CrossRef]

- Akinwande, A.A.; Moskovskikh, D.; Romanovskaia, E.; Balogun, O.A.; Kumar, J.P.; Romanovski, V. Applicability of Extreme Vertices Design in the Compositional Optimization of 3D-Printed Lightweight High-Entropy-Alloy/B4C/ZrO2/Titanium Trihybrid Aero-Composite. Math. Comput. Appl. 2023, 28, 54. [Google Scholar] [CrossRef]

- Foegeding, E.A.; Vinyard, C.J.; Essick, G.; Guest, S.; Campbell, C. Food Structure Breakdown and Texture. J. Texture Stud. 2015, 46, 152–170. [Google Scholar] [CrossRef]

- Association of Official Analytical Chemists. Official Methods of Analysis (AOAC), 19th ed.; Association of Official Analytical Chemists: Gaithersburg, MD, USA, 2012. [Google Scholar]

- Association of Official Analytical Chemists. Official Methods of Analysis of AOAC International. 33.3.10, Method 920.109; Association of Official Analytical Chemists: Gaithersburg, MD, USA, 2002. [Google Scholar]

- Association of Official Analytical Chemists. Ash of Seafood’s, Method 938.08; Association of Official Analytical Chemists: Gaithersburg, MD, USA, 2002. [Google Scholar]

- Guiné, R.P.F. Textural Properties of Bakery Products: A Review of Instrumental and Sensory Evaluation Studies. Appl. Sci. 2022, 12, 8628. [Google Scholar] [CrossRef]

- Cochran, W.G.; Cox, G.M. Experimental Design, 2nd ed.; John Wiley and Sons: New York, NY, USA, 1957; p. 615. [Google Scholar]

- Chin, K.B.; Lee, H.L.; Chun, S.S. Product characteristics of comminuted sausages as affected by various fat and moisture combinations. Asian-Australas. J. Anim. Sci. 2004, 17, 538–542. [Google Scholar] [CrossRef]

- Saldaña, E.; Siche, R.; da Silva Pinto, J.S.; de Almeida, M.A.; Selani, M.M.; Rios-Mera, J.; Contreras-Castillo, C.J. Optimization of lipid profile and hardness of low-fat mortadella following a sequential strategy of experimental design. J. Food Sci. Technol. 2018, 55, 811–820. [Google Scholar] [CrossRef]

- Mouta-Afif, F.; Kırkyol, M.; Akköse, A. Effects of Animal Fat Replacement with Argan Oil on the Quality Properties of Bologna-type Chicken Sausages. ACS Food Sci. Technol. 2025, 5, 234–240. [Google Scholar] [CrossRef]

- Wood, J.D.; Richardson, R.I.; Nute, G.R.; Fisher, A.V.; Campo, M.M.; Kasapidou, E.; Sheard, P.R.; Enser, M. Effects of fatty acids on meat quality: A review. Meat Sci. 2003, 66, 21–32. [Google Scholar] [CrossRef]

- Baek, K.H.; Utama, D.T.; Lee, S.G.; An, B.K.; Lee, S.K. Effects of Replacing Pork Back Fat with Canola and Flaxseed Oils on Physicochemical Properties of Emulsion Sausages from Spent Layer Meat. Asian-Australas. J. Anim. Sci. 2016, 29, 865–871. [Google Scholar] [CrossRef]

- FAO. Guidelines for slaughtering, meat cutting and further processing. In FAO Animal Production and Health Paper; FAO: Rome, Italy, 1991; p. 91. [Google Scholar]

- Navarro, J.L.; Salvador, A.; Flores, M. Sensory Acceptability of Slow Fermented Sausages Based on Fat Content and Ripening Time. Meat Sci. 2010, 86, 251–257. [Google Scholar] [CrossRef]

- Singham, P.; Birwal, P.; Yadav, B.K. Importance of Objective and Subjective Measurement of Food Quality and their Interrelationship. J. Food Process Technol. 2015, 6, 488. [Google Scholar] [CrossRef]

- Arildsen Jakobsen, L.M.; Vuholm, S.; Aaslyng, M.D.; Kristensen, M.; Sørensen, K.V.; Raben, A.; Kehlet, U. Sensory characteristics and consumer liking of sausages with 10% fat and added rye or wheat bran. Food Sci. Nutr. 2014, 2, 534–546. [Google Scholar] [CrossRef]

- Araujo, I.B.S.; Lima, D.A.S.; Pereira, S.F.; Madruga, M.S. Quality of low-fat chicken sausages with added chicken feet collagen. Poult. Sci. 2019, 98, 1064–1074. [Google Scholar] [CrossRef]

- Garmyn, A. Consumer Preferences and Acceptance of Meat Products. Foods 2020, 9, 708. [Google Scholar] [CrossRef]

- Tang, W.; Pan, Q.; He, J.; Liu, J. Plant-based meat: The influence on texture by protein-polysaccharide interactions and processing techniques. Food Res. Int. 2025, 202, 115673. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).