The Fate of Yersinia pseudotuberculosis in Raw Fermented Meat Products

Abstract

1. Introduction

2. Materials and Methods

2.1. Preparation of Inoculum

2.2. Preparation of Spreadable Fermented Sausage (Teewurst)

2.3. Preparation of Dry Fermented Sausage

2.4. Physicochemical, Microbiological, and Statistical Analyses

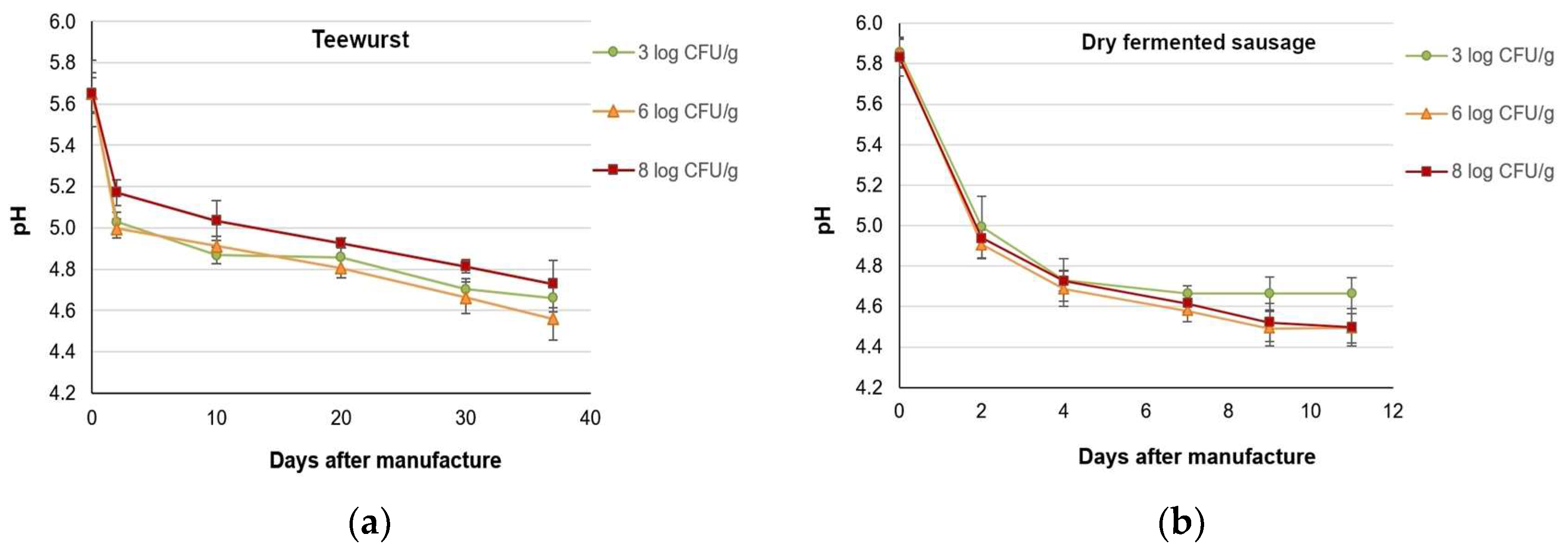

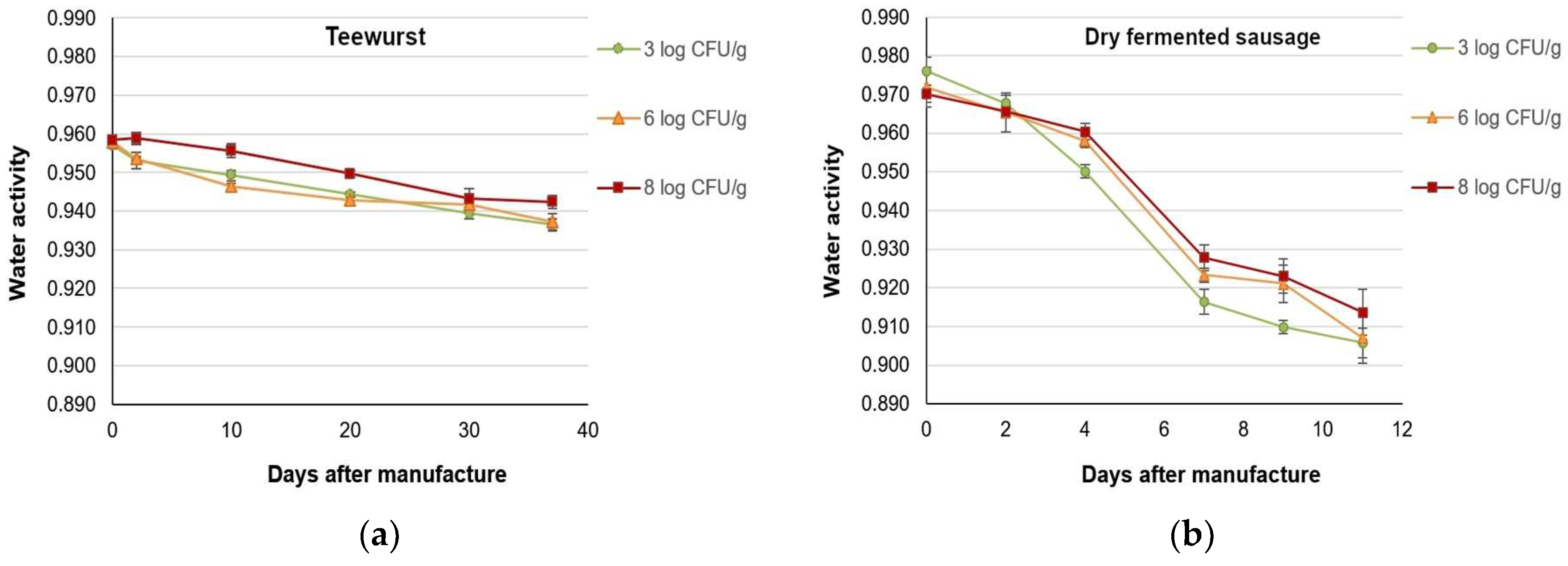

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Fàbrega, A.; Vila, J. Yersinia enterocolitica: Pathogenesis, virulence and antimicrobial resistance. Enferm. Infecc. Microbiol. Clin. 2012, 30, 24–32. [Google Scholar] [CrossRef]

- Marggraf, M.; Barac, A.; Hammerl, J.A.; Hertwig, S. Improvement of the EN ISO 10273:2017 method for the cultural detection of Yersinia enterocolitica in meat. Food Microbiol. 2024, 117, 104384. [Google Scholar] [CrossRef] [PubMed]

- Hammerl, J.A.; vom Ort, N.; Barac, A.; Jäckel, C.; Grund, L.; Dreyer, S.; Heydel, C.; Kuczka, A.; Peters, H.; Hertwig, S. Analysis of Yersinia pseudotuberculosis Isolates Recovered from Deceased Mammals of a German Zoo Animal Collection. Clin. Vet. Microbiol. 2021, 59, e03125-20. [Google Scholar] [CrossRef] [PubMed]

- Le Guern, A.S.; Martin, L.; Savin, C.; Carniel, E. Yersiniosis in France: Overview and potential sources of infection. Int. J. Infect. Dis. 2016, 46, 1–7. [Google Scholar] [CrossRef]

- Seabaugh, J.A.; Anderson, D.M. Pathogenicity and virulence of Yersinia. Virulence 2024, 15, 2316439. [Google Scholar] [CrossRef] [PubMed]

- Hordofa, D.L. Review on yersiniosis and its public health importance. Int. J. Vet. Sci. Anim. Husb. 2021, 6, 37–41. [Google Scholar] [CrossRef]

- Rivas, L.; Strydom, H.; Paine, S.; Wang, J.; Wright, J. Yersiniosis in New Zealand. Pathogens 2021, 10, 191. [Google Scholar] [CrossRef]

- Wielkoszynski, T.; Moghaddam, A.; Bäckman, A.; Broden, J.; Piotrowski, R.; Mond-Paszek, R.; Kozarenko, A.; Ny, T.; Wilczynska, M. Novel diagnostic ELISA test for discrimination between infections with Yersinia enterocolitica and Yersinia pseudotuberculosis. Eur. J. Clin. Microbiol. Infect. Dis. 2018, 37, 2301–2306. [Google Scholar] [CrossRef]

- Gounadaki, A.; Skandamis, P.N.; Nychas, G.-J. Fermented meats. In Microbiology Handbook: Meat Products, 1st ed.; Fernandes, R., Ed.; Royal Society of Chemistry: Cambridge, UK, 2009; pp. 129–155. [Google Scholar]

- Hulankova, R. Higher Resistance of Yersinia enterocolitica in Comparison to Yersinia pseudotuberculosis to Antibiotics and Cinnamon, Oregano and Thyme Essential Oils. Pathogens 2022, 11, 1456. [Google Scholar] [CrossRef]

- Decree No. 69/2016 on Requirements for Meat, Meat Products, Fishery and Aquaculture Products and Products Thereof, Eggs and Products Thereof; Czech Collection of Laws; FAOLEX No. LEX-FAOC174728; FAO: Rome, Italy, 2016.

- Keto-Timonen, R.; Pöntinen, A.; Aalto-Araneda, M.; Korkeala, H. Growth of Yersinia pseudotuberculosis Strains at Different Temperatures, pH Values, and NaCl and Ethanol Concentrations. J. Food Prot. 2018, 81, 142–149. [Google Scholar] [CrossRef]

- Bhaduri, S.; Phillips, J.G. Growth model of a plasmid-bearing virulent strain of Yersinia pseudotuberculosis in raw ground beef. Zoonoses Public Health 2011, 58, 77–84. [Google Scholar] [CrossRef] [PubMed]

- Iliev, M.; Najdenski, H. Monitoring of plasmid dissociation and pathogenic potential among Yersinia enterocolotica and Yersinia pseudotuberculosis during storage of refrigerated pork meat. Ann. Microbiol. 2008, 58, 623–632. [Google Scholar] [CrossRef]

- Asplund, K.; Nurmi, E.; Hirn, J.; Hirvi, T.; Hill, P. Survival of Yersinia enterocolitica in Fermented Sausages Manufactured With Different Levels of Nitrite and Different Starter Cultures. J. Food Prot. 1993, 56, 710–712. [Google Scholar] [CrossRef] [PubMed]

- Ren, H.; Deng, Y.; Wang, X. Effect of a compound starter cultures inoculation on bacterial profile and biogenic amine accumulation in Chinese Sichuan sausages. Food Sci. Hum. Wellness 2022, 11, 341–348. [Google Scholar] [CrossRef]

- Ceylan, E.; Fung, D. Destruction of Yersinia enterocolitica by Lactobacillus sake and Pediococcus acidilactici During Low-temperature Fermentation of Turkish Dry Sausage (sucuk). J. Food Sci. 2000, 655, 876–879. [Google Scholar] [CrossRef]

- Lindqvist, R.; Lindblad, M. Inactivation of Escherichia coli, Listeria monocytogenes and Yersinia enterocolitica in fermented sausages during maturation/storage. Int. J. Food Microbiol. 2009, 129, 59–67. [Google Scholar] [CrossRef] [PubMed]

- Ivanovic, J.; Mitrovic, R.; Janjic, J.; Boskovic, M.; Djordjevic, V.; Djordjevic, J.; Baltic, T.; Baltic, M. Inactivation of Yersinia enterocolitica in Fermented Sausages during Fermentation. J. Agri. Sci. Technol. 2015, 5, 626–634. [Google Scholar]

- Siddi, G.; Piras, F.; Meloni, M.P.; Spanu, V.; Carta, N.; Cuccu, M.; Spanu, C.; Di Salvo, R.; Piga, C.; De Santis, E.P.L.; et al. Sardinian fermented sausage traditional production process: A preliminary survey in eight establishments. Ital. J. Food Saf. 2024, 13, 12203. [Google Scholar] [CrossRef]

- Sperandii, A.F.; Neri, D.; Romantini, R.; Santarelli, G.A.; Prencipe, V. Definition of a Standard Protocol to Determine the Growth Potential of Listeria monocytogenes and Yersinia enterocolitica in Pork Sausage Produced in Abruzzo Region, Italy. Ital. J. Food Saf. 2014, 4, 204–208. [Google Scholar] [CrossRef]

- Anonymous. Health risk from sausage and cold cuts. BfR2GO—The Science Magazine of the German Federal Institute for Risk Assessment. 2018, 2, 27. Available online: https://www.bfr.bund.de/cm/364/bfr-2-go-issue-2-2018.pdf (accessed on 6 August 2024).

- Lorencova, A.; Babak, V.; Kralova, A.; Borilova, G. Survival of Mycobacterium avium subsp. paratuberculosis in raw fermented sausages during production and storage. Meat Sci. 2019, 155, 20–26. [Google Scholar]

- Böhnlein, C.; Kabisch, J.; Müller-Herbst, S.; Fiedler, G.; Franz, C.M.A.P.; Pichner, R. Persistence and reduction of Shiga toxin-producing Escherichia coli serotype O26:H11 in different types of raw fermented sausages. Int. J. Food Microbiol. 2017, 261, 82–88. [Google Scholar] [CrossRef] [PubMed]

- Lücke, F.K.; Zangerl, P. Food safety challenges associated with traditional foods in German-speaking regions. Food Control. 2014, 43, 217–230. [Google Scholar] [CrossRef]

- Heir, E.; Holck, A.L.; Omer, M.K.; Alvseike, O.; Høy, M.; Måge, I.; Axelsson, L. Reduction of verotoxigenic Escherichia coli by process and recipe optimisation in dry-fermented sausages. Int. J. Food Microbiol. 2010, 141, 195–202. [Google Scholar] [CrossRef] [PubMed]

- Feiner, G. Spreadable raw fermented sausage. In Meat Products Handbook, 1st ed.; Woodhead Publishing Limited: Cambridge, UK, 2006; pp. 400–413. [Google Scholar]

- Dourou, D.; Porto-Fett, A.C.S.; Shoyer, B.; Call, J.E.; Nychas, G.-J.E.; Illg, E.K.; Luchansky, J.B. Behavior of Escherichia coli O157:H7, Listeria monocytogenes, and Salmonella Typhimurium in teewurst, a raw spreadable sausage. Int. J. Food Microbiol. 2009, 130, 245–250. [Google Scholar] [CrossRef]

- Werber, D.; Behnke, S.C.; Fruth, A.; Merle, R.; Menzler, S.; Glaser, S.; Kreienbrock, L.; Prager, R.; Tschäpe, H.; Roggentin, P.; et al. Shiga toxin-producing Escherichia coli infection in Germany: Different risk factors for different age groups. Am. J. Epidemiol. 2007, 165, 425–434. [Google Scholar] [CrossRef]

- Rosner, B.M.; Stark, K.; Höhle, M.; Werber, D. Risk factors for sporadic Yersinia enterocolitica infections, Germany 2009–2010. Epidemiol. Infect. 2012, 140, 1738–1747. [Google Scholar] [CrossRef]

- Fredriksson-Ahomaa, M.; Murros-Kontiainen, A.; Säde, E.; Puolanne, E.; Björkroth, J. High number of Yersinia enterocolitica 4/O:3 in cold-stored modified atmosphere-packed pig cheek meat. Int. J. Food Microbiol. 2012, 155, 69–72. [Google Scholar] [CrossRef]

- Messelhäusser, U.; Kämpf, P.; Colditz, J.; Bauer, H.; Schreiner, H.; Höller, C.; Busch, U. Qualitative and quantitative detection of human pathogenic Yersinia enterocolitica in different food matrices at retail level in Bavaria. Foodborne Pathog. Dis. 2011, 8, 39–44. [Google Scholar] [CrossRef]

- Pärn, T.; Hallanvuo, S.; Salmenlinna, S.; Pihlajasaari, A.; Heikkinen, S.; Telkki-Nykänen, H.; Hakkinen, M.; Ollgren, J.; Huusko, S.; Rimhanen-Finne, R. Outbreak of Yersinia pseudotuberculosis O: 1 infection associated with raw milk consumption, Finland, spring 2014. Euro Surveil. 2015, 20, 30033. [Google Scholar] [CrossRef]

- Jalava, K.; Hakkinen, M.; Valkonen, M.; Nakari, U.M.; Palo, T.; Hallanvuo, S.; Ollgren, J.; Siitonen, A.; Nuorti, J.P. An outbreak of gastrointestinal illness and erythema nodosum from grated carrots contaminated with Yersinia pseudotuberculosis. J. Infect. Dis. 2006, 194, 1209–1216. [Google Scholar] [CrossRef] [PubMed]

- Hudson, J.A.; King, N.J.; Cornelius, A.J.; Bigwood, T.; Thom, K.; Monson, S. Detection, isolation and enumeration of Yersinia enterocolitica from raw pork. Int. J. Food Microbiol. 2008, 123, 25–31. [Google Scholar] [CrossRef] [PubMed]

- Laukkanen-Ninios, R.; Fredriksson-Ahomaa, M.; Maijala, R.; Korkeala, H. High prevalence of pathogenic Yersinia enterocolitica in pig cheeks. Food Microbiol. 2014, 43, 50–52. [Google Scholar] [CrossRef]

- Van Damme, I.; Berkvens, D.; Vanantwerpen, G.; Baré, J.; Houf, K.; Wauters, G.; De Zutter, L. Contamination of freshly slaughtered pig carcasses with enteropathogenic Yersinia spp.: Distribution, quantification and identification of risk factors. Int. J. Food Microbiol. 2015, 204, 33–40. [Google Scholar] [CrossRef] [PubMed]

| Ingredient | Teewurst | Dry Fermented Sausage |

|---|---|---|

| Pork shoulder | 1.6 kg | 1.6 kg |

| Beef neck | - | 1.2 kg |

| Pork backfat | 2.4 kg | 1.4 kg |

| Nitrite curing salt | 88 g | 88 g |

| Seasoning mix | 32 g | 32 g |

| Starter culture | 2 g | 2 g |

| Total | 4.122 kg | 4.322 |

| Inoculum | Production Process | Storage | ||||

|---|---|---|---|---|---|---|

| Day 0 | Day 2 | Day 10 | Day 20 | Day 30 | Day 37 | |

| 3 log CFU/g | 2.89 ± 0.10 a 6/6 * | 1.43 ± 0.20 b 6/6 | ≤1.00 ± 0.00 b 3/6 | ≤1.00 ± 0.00 b 1/6 | ≤1.00 ± 0.00 b 0/6 | ≤1.00 ± 0.00 b 0/6 |

| 6 log CFU/g | 5.51 ± 0.11 c 6/6 | 2.43 ± 0.08 d 6/6 | 1.11 ± 0.11 b 6/6 | ≤1.00 ± 0.00 b 2/6 | ≤1.00 ± 0.00 b 0/6 | ≤1.00 ± 0.00 b 0/6 |

| 8 log CFU/g | 7.61 ± 0.11 e 6/6 | 6.30 ± 0.08 f 6/6 | 5.52 ± 0.07 c 6/6 | 5.03 ± 0.10 g 6/6 | 4.77 ± 0.03 g 6/6 | 2.90 ± 0.17 a 6/6 |

| Inoculum | Production Process | Storage | ||||

|---|---|---|---|---|---|---|

| Day 0 | Day 2 | Day 4 | Day 7 | Day 9 | Day 11 | |

| 3 log CFU/g | 2.84 ± 0.06 a 6/6 * | ≤1.00 ± 0.00 b 0/6 | ≤1.00 ± 0.00 b 0/6 | ≤1.00 ± 0.00 b 0/6 | ≤1.00 ± 0.00 b 0/6 | ≤1.00 ± 0.00 b 0/6 |

| 6 log CFU/g | 5.78 ± 0.07 c 6/6 | ≤1.00 ± 0.00 b 0/6 | ≤1.00 ± 0.00 b 0/6 | ≤1.00 ± 0.00 b 1/6 | ≤1.00 ± 0.00 b 0/6 | ≤1.00 ± 0.00 b 0/6 |

| 8 log CFU/g | 7.96 ± 0.07 d 6/6 | 2.41 ± 0.15 e 6/6 | ≤1.00 ± 0.00 b 0/6 | ≤1.00 ± 0.00 b 0/6 | ≤1.00 ± 0.00 b 0/6 | ≤1.00 ± 0.00 b 0/6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hulánková, R.; Svobodová, I. The Fate of Yersinia pseudotuberculosis in Raw Fermented Meat Products. Appl. Sci. 2025, 15, 5324. https://doi.org/10.3390/app15105324

Hulánková R, Svobodová I. The Fate of Yersinia pseudotuberculosis in Raw Fermented Meat Products. Applied Sciences. 2025; 15(10):5324. https://doi.org/10.3390/app15105324

Chicago/Turabian StyleHulánková, Radka, and Irena Svobodová. 2025. "The Fate of Yersinia pseudotuberculosis in Raw Fermented Meat Products" Applied Sciences 15, no. 10: 5324. https://doi.org/10.3390/app15105324

APA StyleHulánková, R., & Svobodová, I. (2025). The Fate of Yersinia pseudotuberculosis in Raw Fermented Meat Products. Applied Sciences, 15(10), 5324. https://doi.org/10.3390/app15105324