Pattern Recognition in Dried Milk Droplets Using Lacunarity and Deep Learning

Abstract

1. Introduction

2. Experimental Details

2.1. Sample Preparation and Storage

2.2. Drop Evaporation

2.3. Image Acquisition

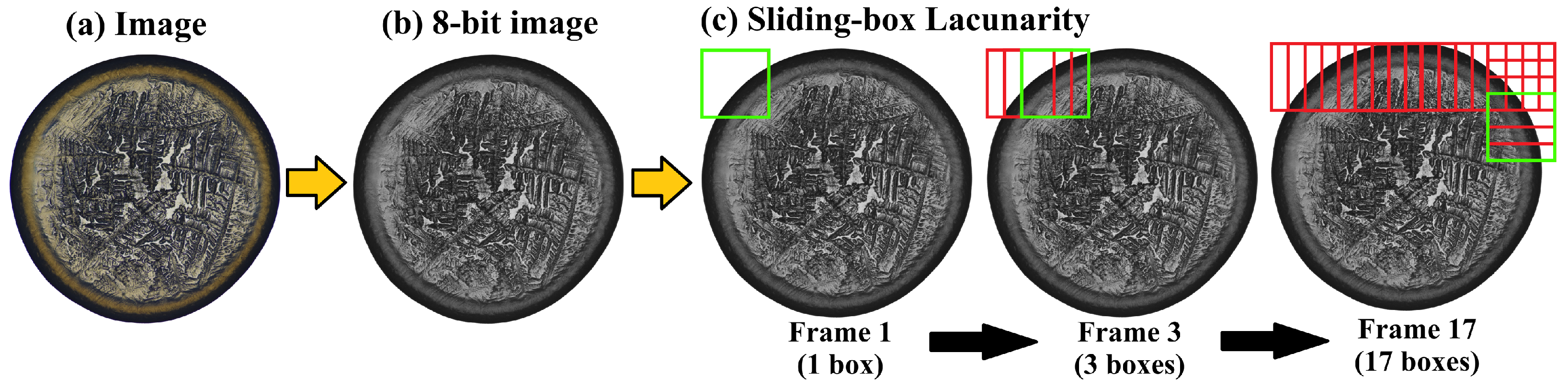

2.4. Lacunarity Analysis of Dried Droplets

2.5. The Receiver Operating Characteristic (ROC) Curve

2.6. Lacunarity Analysis and Classification Using Deep Learning

2.6.1. Image Processing and Lacunarity Calculation

2.6.2. Classification Using Deep Learning

2.6.3. Model Evaluation and Statistical Testing

3. Results

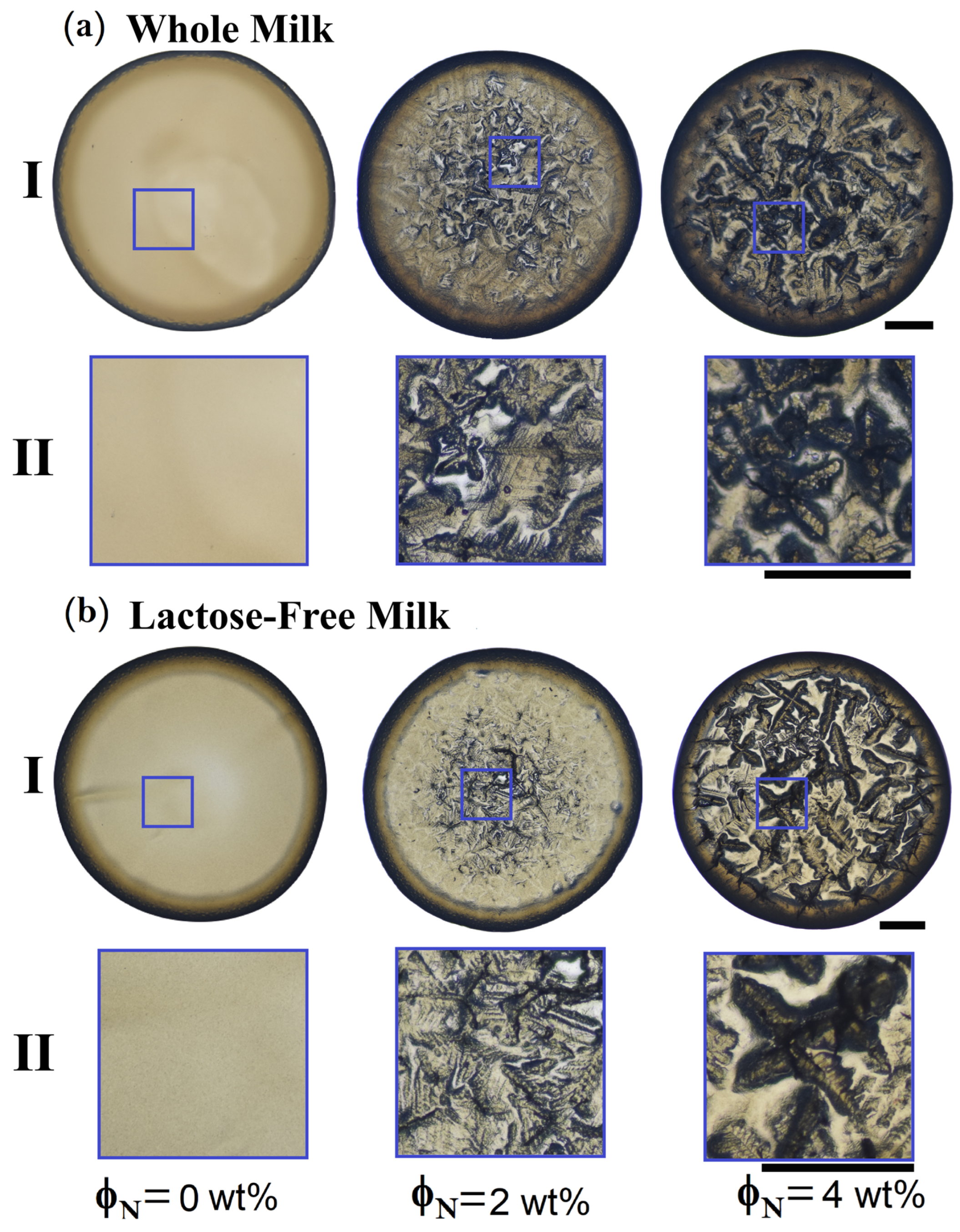

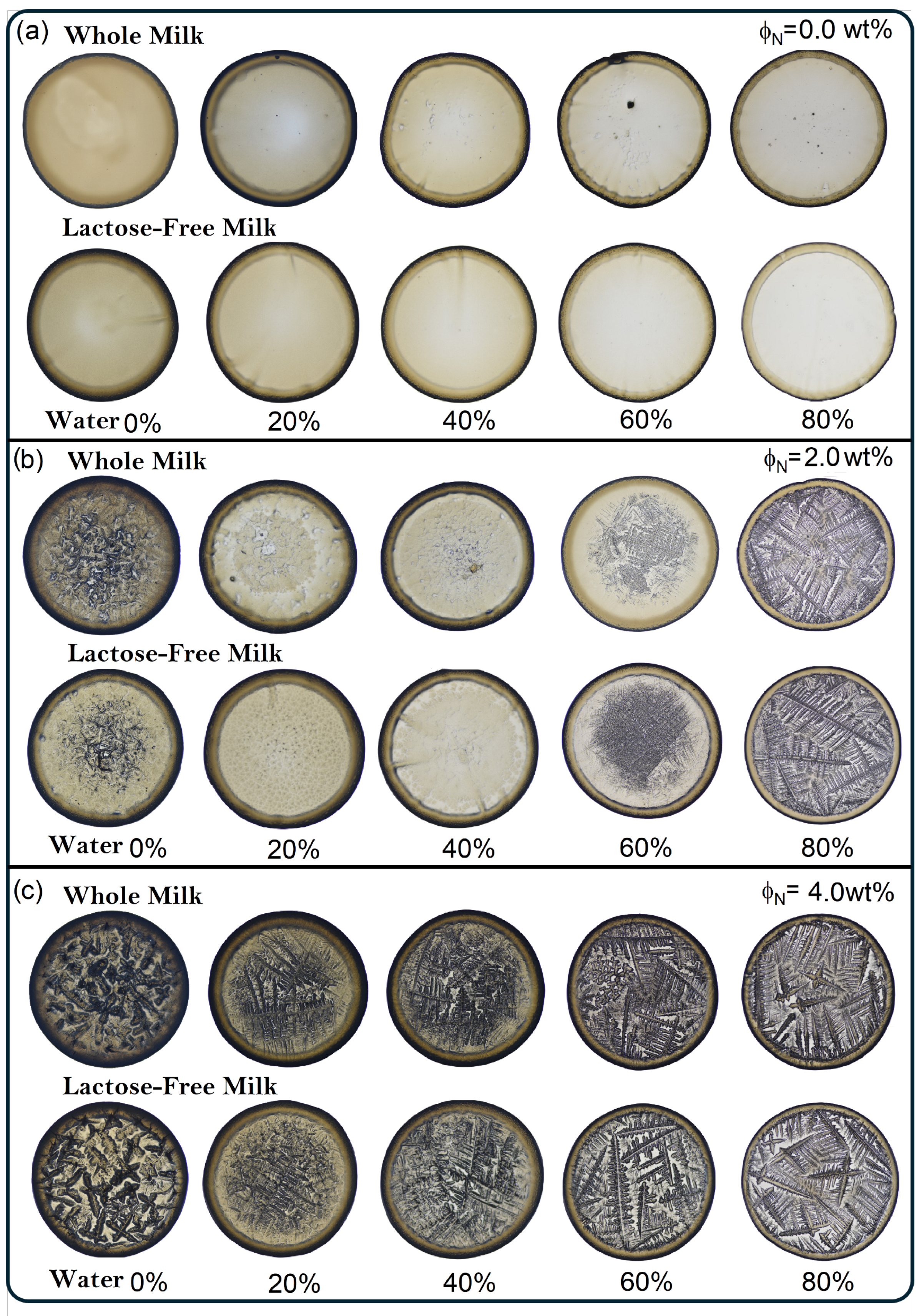

3.1. Pattern in Dried Droplets of Milk with NaCl

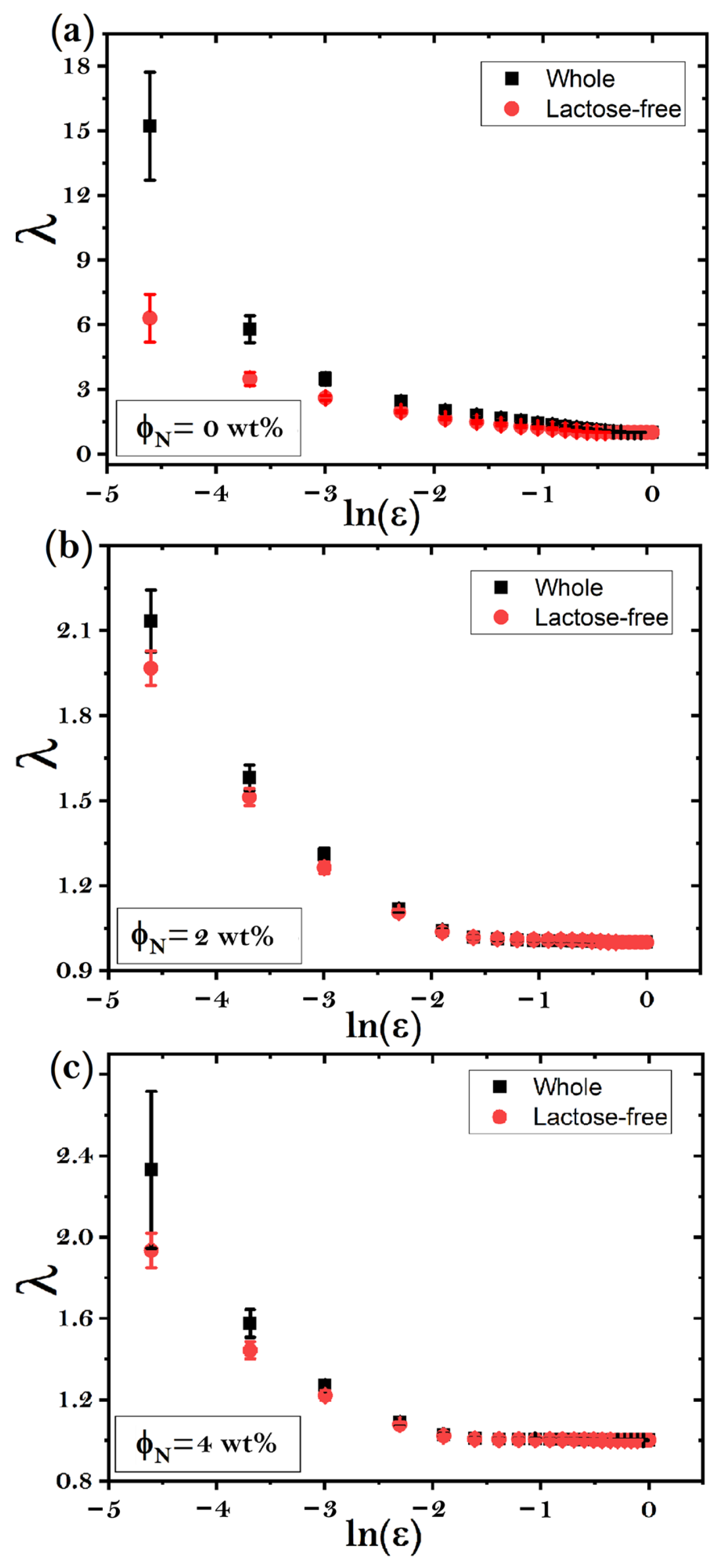

3.2. Discrimination Between Milk Types Using Lacunarity Analysis

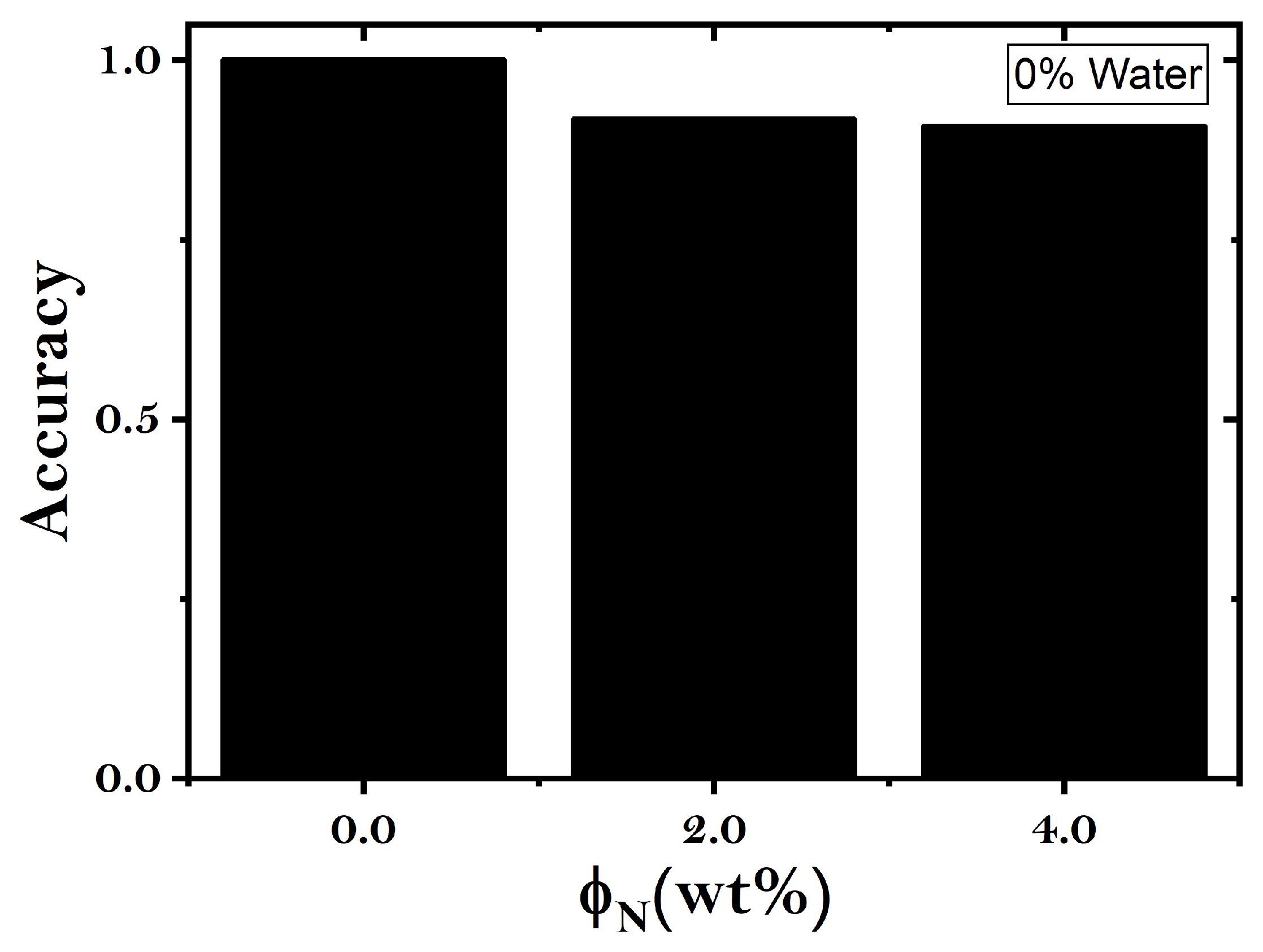

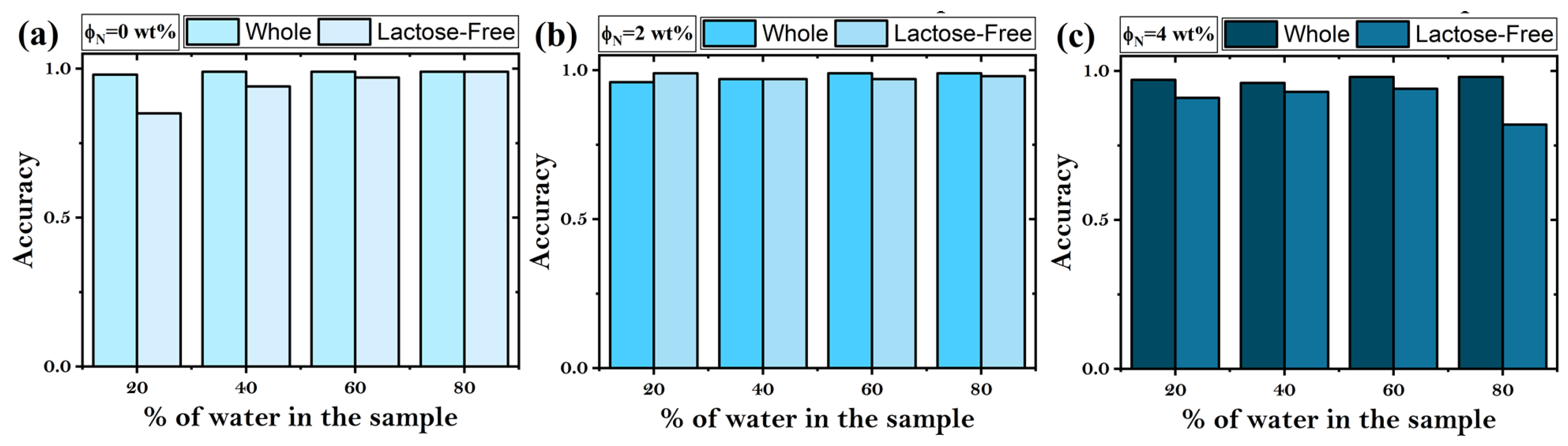

3.3. Deep Learning-Based Differentiation Between Milk Types

3.4. Pattern in Dried Droplets of Milk with NaCl and Added Water

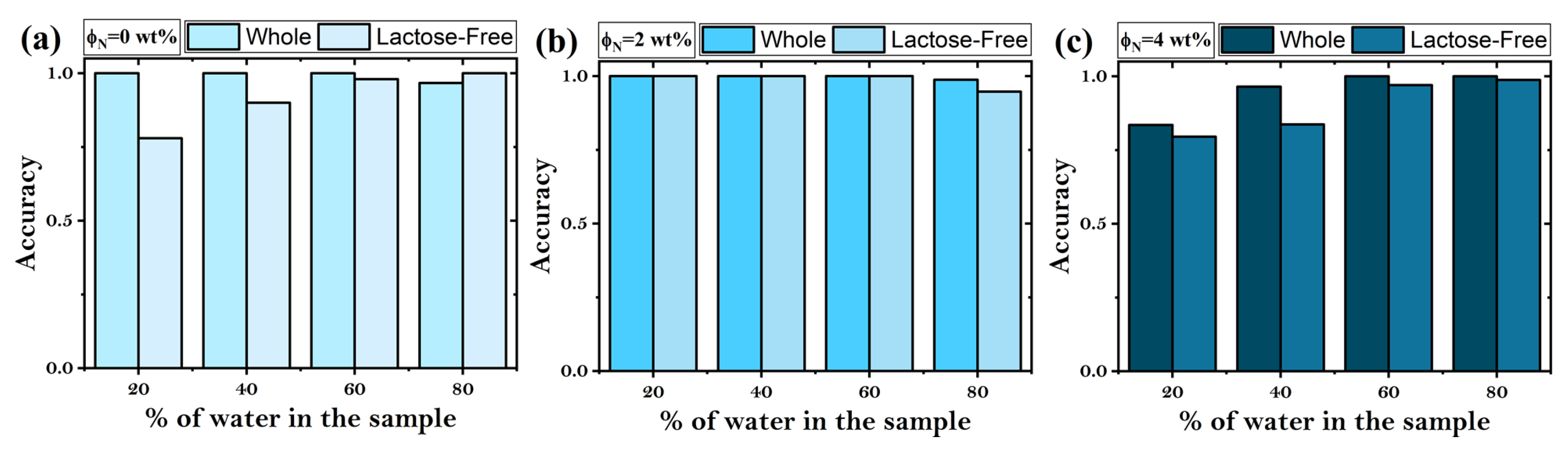

3.5. Detection of Water Adulteration Using Lacunarity Analysis

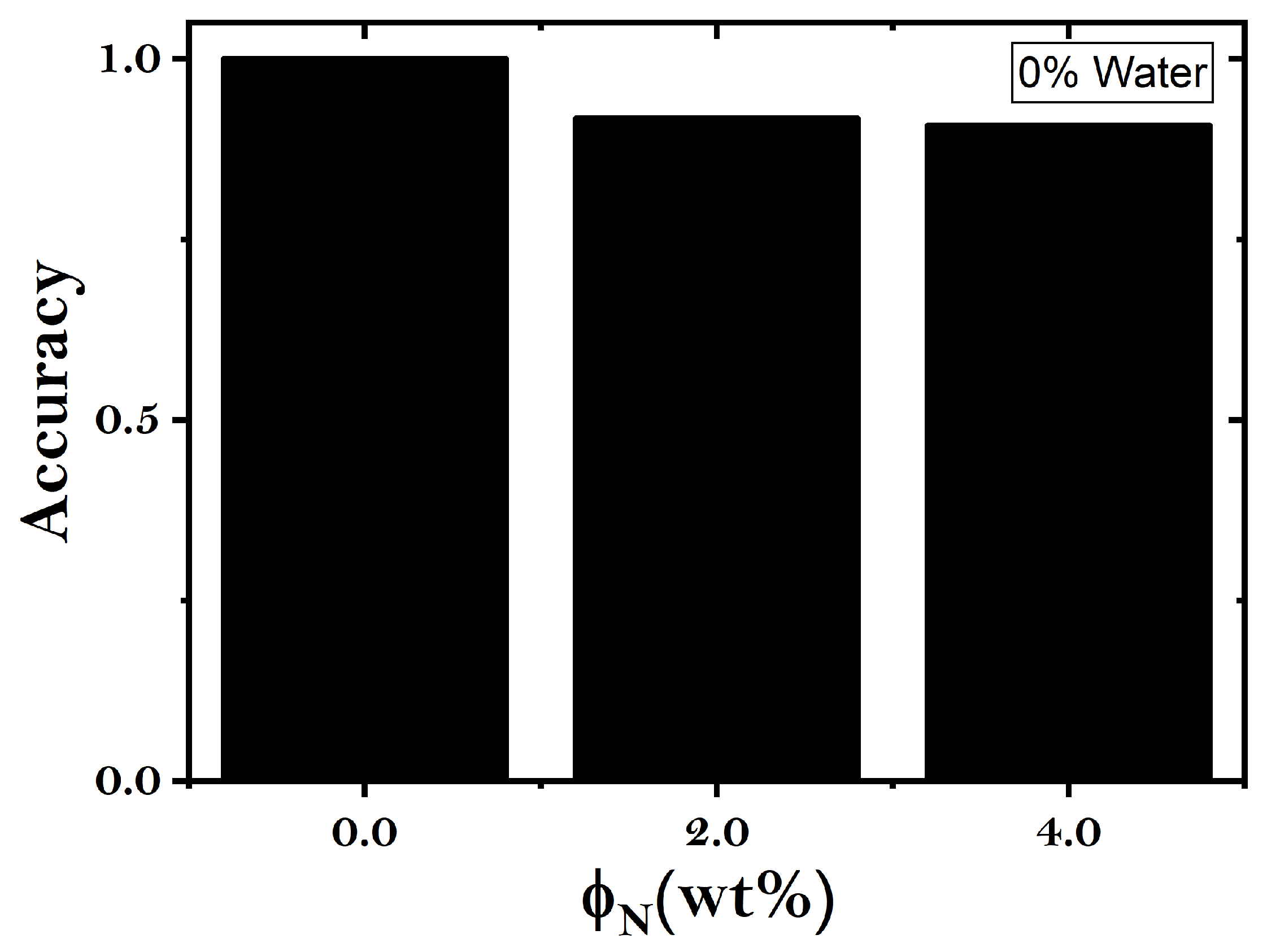

3.6. Deep Learning-Based Detection of Water Adulteration in Milk

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Azad, T.; Ahmed, S. Common milk adulteration and their detection techniques. Int. J. Food Contam. 2016, 3, 1–9. [Google Scholar] [CrossRef]

- Qian, G.; Guo, X.; Guo, J.; Wu, J. China’s dairy crisis: Impacts, causes and policy implications for a sustainable dairy industry. Int. J. Sustain. Dev. World Ecol. 2011, 18, 434–441. [Google Scholar] [CrossRef]

- Banach, J.K.; Żywica, R.; Szpendowski, J.; Kiełczewska, K. Possibilities of using electrical parameters of milk for assessing its adulteration with water. Int. J. Food Prop. 2012, 15, 274–280. [Google Scholar] [CrossRef]

- Schumacher, O.; Ates, C.; Börnhorst, M.; Koch, R.; Stephan, P. Deposit formation from evaporating urea-water droplets on substrates of different wettability. J. Colloid Interface Sci. 2023, 634, 1–13. [Google Scholar] [CrossRef]

- Weon, B.M.; Je, J.H. Fingering inside the coffee ring. Phys. Rev. E 2013, 87, 013003. [Google Scholar] [CrossRef]

- Kolegov, K.; Barash, L.Y. Joint effect of advection, diffusion, and capillary attraction on the spatial structure of particle depositions from evaporating droplets. Phys. Rev. E 2019, 100, 033304. [Google Scholar] [CrossRef] [PubMed]

- Mampallil, D.; Eral, H.B. A review on suppression and utilization of the coffee-ring effect. Adv. Colloid Interface Sci. 2018, 252, 38–54. [Google Scholar] [CrossRef]

- Kim, H.; Boulogne, F.; Um, E.; Jacobi, I.; Button, E.; Stone, H.A. Controlled uniform coating from the interplay of Marangoni flows and surface-adsorbed macromolecules. Phys. Rev. Lett. 2016, 116, 124501. [Google Scholar] [CrossRef]

- Carreón, Y.J.; Gómez-López, M.L.; Díaz-Hernández, O.; Vazquez-Vergara, P.; Moctezuma, R.E.; Saniger, J.M.; González-Gutiérrez, J. Patterns in dried droplets to detect unfolded BSA. Sensors 2022, 22, 1156. [Google Scholar] [CrossRef]

- Jeihanipour, A.; Lahann, J. Deep-Learning-Assisted Stratification of Amyloid Beta Mutants Using Drying Droplet Patterns. Adv. Mater. 2022, 34, 2110404. [Google Scholar] [CrossRef]

- Ancheyta-Palacios, M.; Velasco-Terán, I.G.; Carreón, Y.J.; González-Gutiérrez, J. Dried Droplets of Diluted Blood to Detect a High Concentration of Lipids. Processes 2023, 11, 2047. [Google Scholar] [CrossRef]

- Pal, A.; Gope, A.; Sengupta, A. Drying of bio-colloidal sessile droplets: Advances, applications, and perspectives. Adv. Colloid Interface Sci. 2023, 102870. [Google Scholar] [CrossRef]

- González-Gutiérrez, J.; Pérez-Isidoro, R.; Ruiz-Suárez, J. A technique based on droplet evaporation to recognize alcoholic drinks. Rev. Sci. Instrum. 2017, 88, 074101. [Google Scholar] [CrossRef]

- Beigtan, M.; Hwang, Y.; Weon, B.M. Inhibiting Cracks in Latte Droplets. Langmuir 2023, 39, 5275–5283. [Google Scholar] [CrossRef]

- Carreón, Y.J.; Díaz-Hernández, O.; Escalera Santos, G.J.; Cipriano-Urbano, I.; Solorio-Ordaz, F.J.; González-Gutiérrez, J.; Zenit, R. Texture Analysis of Dried Droplets for the Quality Control of Medicines. Sensors 2021, 21, 4048. [Google Scholar] [CrossRef] [PubMed]

- Wilkinson, J.; Tam, C.; Askounis, A.; Qi, S. Suppression of the coffee-ring effect by tailoring the viscosity of pharmaceutical sessile drops. Colloids Surf. Physicochem. Eng. Asp. 2021, 614, 126144. [Google Scholar] [CrossRef]

- Kumar, V.; Dash, S. Evaporation-based low-cost method for the detection of adulterant in milk. ACS Omega 2021, 6, 27200–27207. [Google Scholar] [CrossRef]

- Ishwarya S, P.; Dugyala, V.R.; Pradhan, S.; Basavaraj, M.G. Sessile drop evaporation approach to detect starch adulteration in milk. Food Control 2023, 143, 109272. [Google Scholar] [CrossRef]

- Harindran, A.; Hashmi, S.; Madhurima, V. Pattern formation of dried droplets of milk during different processes and classifying them using artificial neural networks. J. Dispers. Sci. Technol. 2022, 43, 1838–1847. [Google Scholar] [CrossRef]

- Liang, Y.; Wang, S. Evaporation-Induced Crystal Nucleation and Morphology of Dried Poly (Vinylidene Fluoride) Droplets. Crystals 2021, 11, 1442. [Google Scholar] [CrossRef]

- Kuznetsov, G.; Feoktistov, D.; Orlova, E.; Misyura, S.; Morozov, V.; Islamova, A. Evaporation modes of LiBr, CaCl2, LiCl, NaCl aqueous salt solution droplets on aluminum surface. Int. J. Heat Mass Transf. 2018, 126, 161–168. [Google Scholar] [CrossRef]

- Soulié, V.; Karpitschka, S.; Lequien, F.; Prené, P.; Zemb, T.; Moehwald, H.; Riegler, H. The evaporation behavior of sessile droplets from aqueous saline solutions. Phys. Chem. Chem. Phys. 2015, 17, 22296–22303. [Google Scholar] [CrossRef]

- Perrin, L.; Akanno, A.; Guzman, E.; Ortega, F.; Rubio, R.G. Pattern formation upon evaporation of sessile droplets of polyelectrolyte/surfactant mixtures on silicon wafers. Int. J. Mol. Sci. 2021, 22, 7953. [Google Scholar] [CrossRef] [PubMed]

- Linnow, K.; Steiger, M.; Lemster, C.; De Clercq, H.; Jovanović, M. In situ Raman observation of the crystallization in NaNO 3–Na 2 SO 4–H 2 O solution droplets. Environ. Earth Sci. 2013, 69, 1609–1620. [Google Scholar] [CrossRef]

- Shahidzadeh, N.; Schut, M.F.; Desarnaud, J.; Prat, M.; Bonn, D. Salt stains from evaporating droplets. Sci. Rep. 2015, 5, 10335. [Google Scholar] [CrossRef] [PubMed]

- Qazi, M.; Salim, H.; Doorman, C.; Jambon-Puillet, E.; Shahidzadeh, N. Salt creeping as a self-amplifying crystallization process. Sci. Adv. 2019, 5, eaax1853. [Google Scholar] [CrossRef]

- Misyura, S. The crystallization behavior of the aqueous solution of CaCl2 salt in a drop and a layer. Sci. Rep. 2020, 10, 256. [Google Scholar] [CrossRef]

- Mandelbrot, B.B.; Mandelbrot, B.B. The Fractal Geometry of Nature; WH Freeman: New York, NY, USA, 1982; Volume 1. [Google Scholar]

- Plotnick, R.E.; Gardner, R.H.; Hargrove, W.W.; Prestegaard, K.; Perlmutter, M. Lacunarity analysis: A general technique for the analysis of spatial patterns. Phys. Rev. E 1996, 53, 5461. [Google Scholar] [CrossRef]

- Guidolin, D.; Nico, B.; Mazzocchi, G.; Vacca, A.; Nussdorfer, G.; Ribatti, D. Order and disorder in the vascular network. Leukemia 2004, 18, 1745–1750. [Google Scholar] [CrossRef]

- Won, S.Y.; Lee, J.H.; Lee, N.; Park, Y.W.; Ahn, S.S.; Kim, J.; Chang, J.H.; Kim, S.H.; Lee, S.K. Three-dimensional fractal dimension and lacunarity features may noninvasively predict TERT promoter mutation status in grade 2 meningiomas. PLoS ONE 2022, 17, e0276342. [Google Scholar] [CrossRef]

- Zaia, A.; Rossi, R.; Galeazzi, R.; Sallei, M.; Maponi, P.; Scendoni, P. Fractal lacunarity of trabecular bone in vertebral MRI to predict osteoporotic fracture risk in over-fifties women. The LOTO study. BMC Musculoskelet. Disord. 2021, 22, 1–13. [Google Scholar] [CrossRef] [PubMed]

- Ríos-Ramírez, M.; Reyes-Figueroa, A.; Ruiz-Suárez, J.; González-Gutiérrez, J. Pattern formation of stains from dried drops to identify spermatozoa motility. Colloids Surf. B 2018, 169, 486–493. [Google Scholar] [CrossRef]

- Mamgain, A.; Kumar, V.; Dash, S. Image-based detection of adulterants in milk using convolutional neural network. ACS Omega 2024, 9, 27158–27168. [Google Scholar] [CrossRef]

- Yasar, F.; Akgunlu, F. Fractal dimension and lacunarity analysis of dental radiographs. Dentomaxillofacial Radiol. 2005, 34, 261–267. [Google Scholar] [CrossRef] [PubMed]

- Fawcett, T. An introduction to ROC analysis. Pattern Recognit. Lett. 2006, 27, 861–874. [Google Scholar] [CrossRef]

- Munir, K.; Elahi, H.; Ayub, A.; Frezza, F.; Rizzi, A. Cancer diagnosis using deep learning: A bibliographic review. Cancers 2019, 11, 1235. [Google Scholar] [CrossRef]

- D’Amico, A.V.; Whittington, R.; Malkowicz, S.B.; Schultz, D.; Schnall, M.; Tomaszewski, J.E.; Wein, A. A multivariate analysis of clinical and pathological factors that predict for prostate specific antigen failure after radical prostatectomy for prostate cancer. J. Urol. 1995, 154, 131–138. [Google Scholar] [CrossRef]

- Tharwat, A. Classification assessment methods. Appl. Comput. Inform. 2020, 17, 168–192. [Google Scholar] [CrossRef]

| Nutritional Information of 100 mL | Whole Milk | Lactose-Free Milk | |

|---|---|---|---|

| Energy content (kcal) | 61 | 48 | |

| Energy content (kJ) | 256 | 201 | |

| Proteins, g | 3.1 | 3.1 | |

| Total fat, g | 3.3 | 1.8 | |

| Saturate fat, g | 2 | 1.1 | |

| Trans fat, mg | 0 | 0 | |

| Available carbohydrates, g | 4.8 | 4.8 | |

| Sugars, g | 4.8 | 4.8 | |

| Added sugars, g | 0 | 0 | |

| Dietary fiber, g | 0 | 0 | |

| Sodium, mg | 46 | 46 | |

| Calcium, mg | 116 | 116 | |

| Vitamin A, µg | 66.4 | 66.4 | |

| Vitamin D, µg | 0.5 | 0.5 |

| (wt%) | Water (%) | Number of Images | Number of ROIs |

|---|---|---|---|

| 0 | 0 | 120 | 7268 |

| 20 | 120 | 5209 | |

| 40 | 120 | 6341 | |

| 60 | 120 | 8003 | |

| 80 | 120 | 5209 | |

| 2 | 0 | 136 | 14,393 |

| 20 | 128 | 8535 | |

| 40 | 136 | 8058 | |

| 60 | 108 | 5782 | |

| 80 | 128 | 8269 | |

| 4 | 0 | 148 | 18,028 |

| 20 | 148 | 16,038 | |

| 40 | 112 | 16,388 | |

| 60 | 136 | 19,510 | |

| 80 | 108 | 15,406 |

| (wt%) | Water (%) | Number of Images | Number of ROIs |

|---|---|---|---|

| 0 | 0 | 124 | 10,025 |

| 20 | 100 | 6416 | |

| 40 | 124 | 7137 | |

| 60 | 84 | 4955 | |

| 80 | 100 | 5403 | |

| 2 | 0 | 132 | 9825 |

| 20 | 80 | 6839 | |

| 40 | 132 | 9924 | |

| 60 | 120 | 7912 | |

| 80 | 120 | 13,592 | |

| 4 | 0 | 140 | 16,647 |

| 20 | 84 | 10,238 | |

| 40 | 100 | 10,194 | |

| 60 | 140 | 18,054 | |

| 80 | 120 | 16,021 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Molina-Courtois, J.N.; Aguilar Morales, Y.J.; Escalante-Zarate, L.; Castelán, M.; Carreón, Y.J.P.; González-Gutiérrez, J. Pattern Recognition in Dried Milk Droplets Using Lacunarity and Deep Learning. Appl. Sci. 2025, 15, 5676. https://doi.org/10.3390/app15105676

Molina-Courtois JN, Aguilar Morales YJ, Escalante-Zarate L, Castelán M, Carreón YJP, González-Gutiérrez J. Pattern Recognition in Dried Milk Droplets Using Lacunarity and Deep Learning. Applied Sciences. 2025; 15(10):5676. https://doi.org/10.3390/app15105676

Chicago/Turabian StyleMolina-Courtois, Josías N., Yaquelin Josefa Aguilar Morales, Luis Escalante-Zarate, Mario Castelán, Yojana J. P. Carreón, and Jorge González-Gutiérrez. 2025. "Pattern Recognition in Dried Milk Droplets Using Lacunarity and Deep Learning" Applied Sciences 15, no. 10: 5676. https://doi.org/10.3390/app15105676

APA StyleMolina-Courtois, J. N., Aguilar Morales, Y. J., Escalante-Zarate, L., Castelán, M., Carreón, Y. J. P., & González-Gutiérrez, J. (2025). Pattern Recognition in Dried Milk Droplets Using Lacunarity and Deep Learning. Applied Sciences, 15(10), 5676. https://doi.org/10.3390/app15105676