Design of Safety Evaluation and Risk Traceability System for Agricultural Product Quality

Abstract

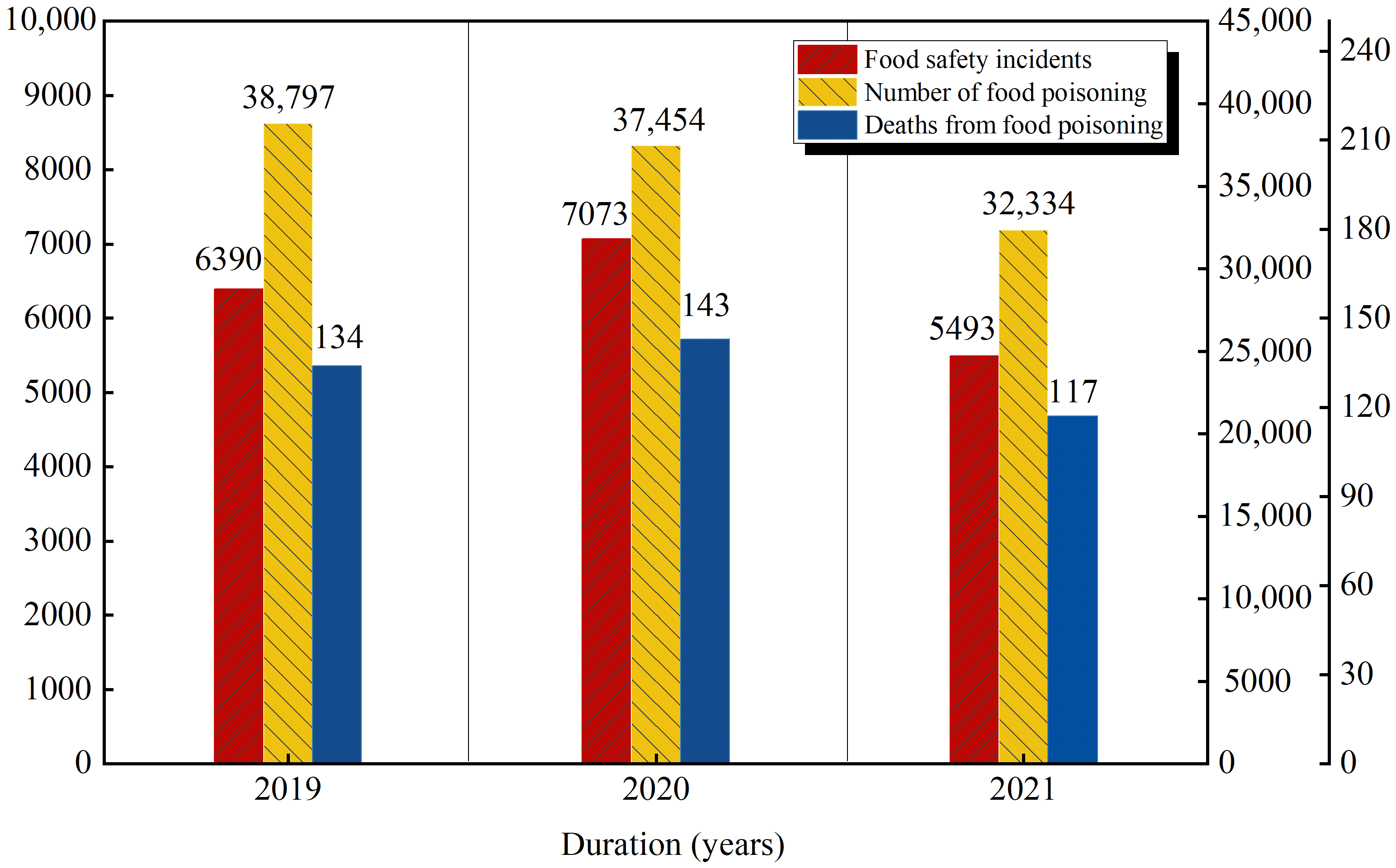

1. Introduction

2. Design of Agricultural Product Quality and Safety Evaluation System

2.1. Screening of Evaluation Indicators

2.2. Design of Evaluation System

2.3. Construction of Evaluation Model

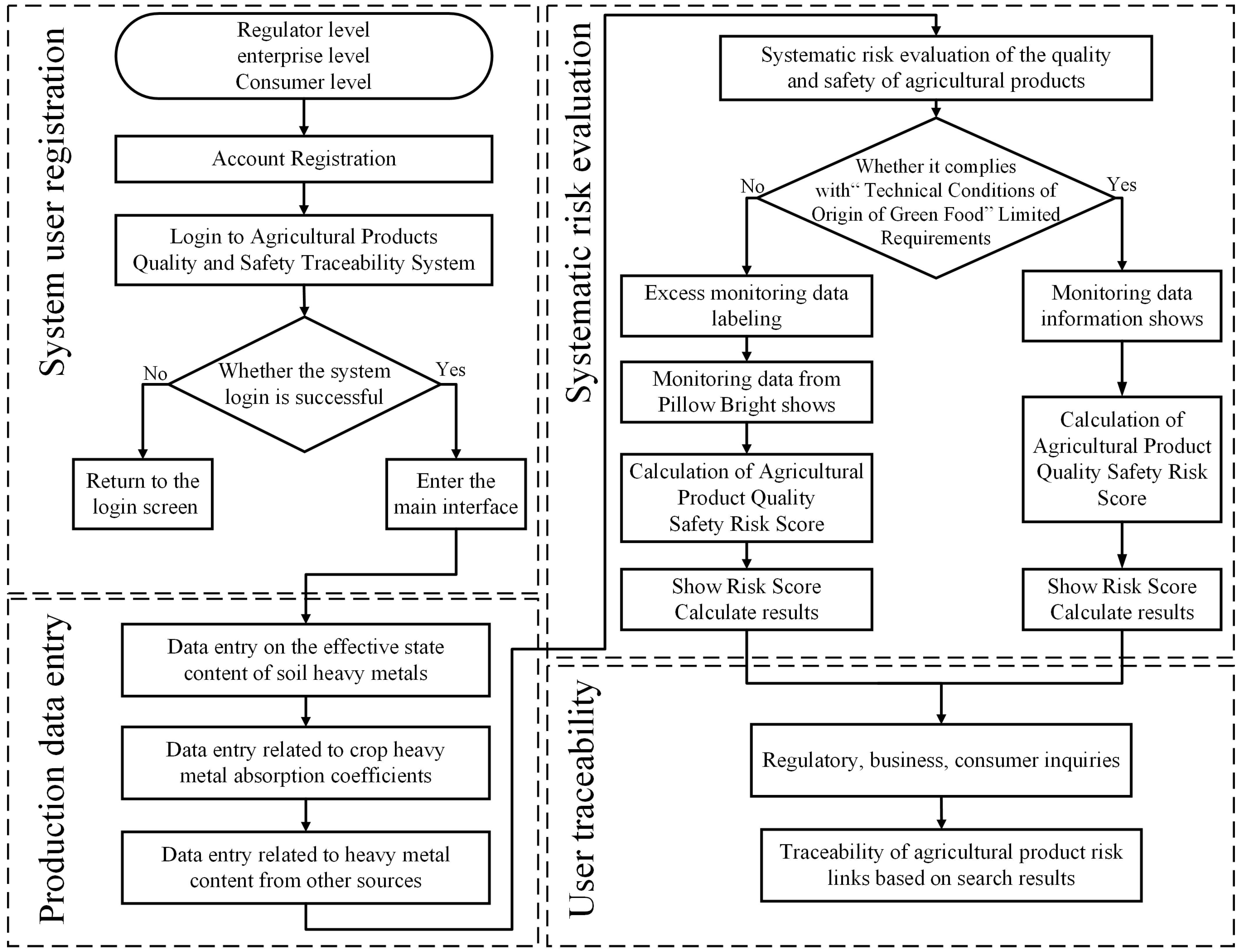

3. Construction of Risk Traceability System

3.1. Systematic Traceability Methods

3.2. Traceability System Design

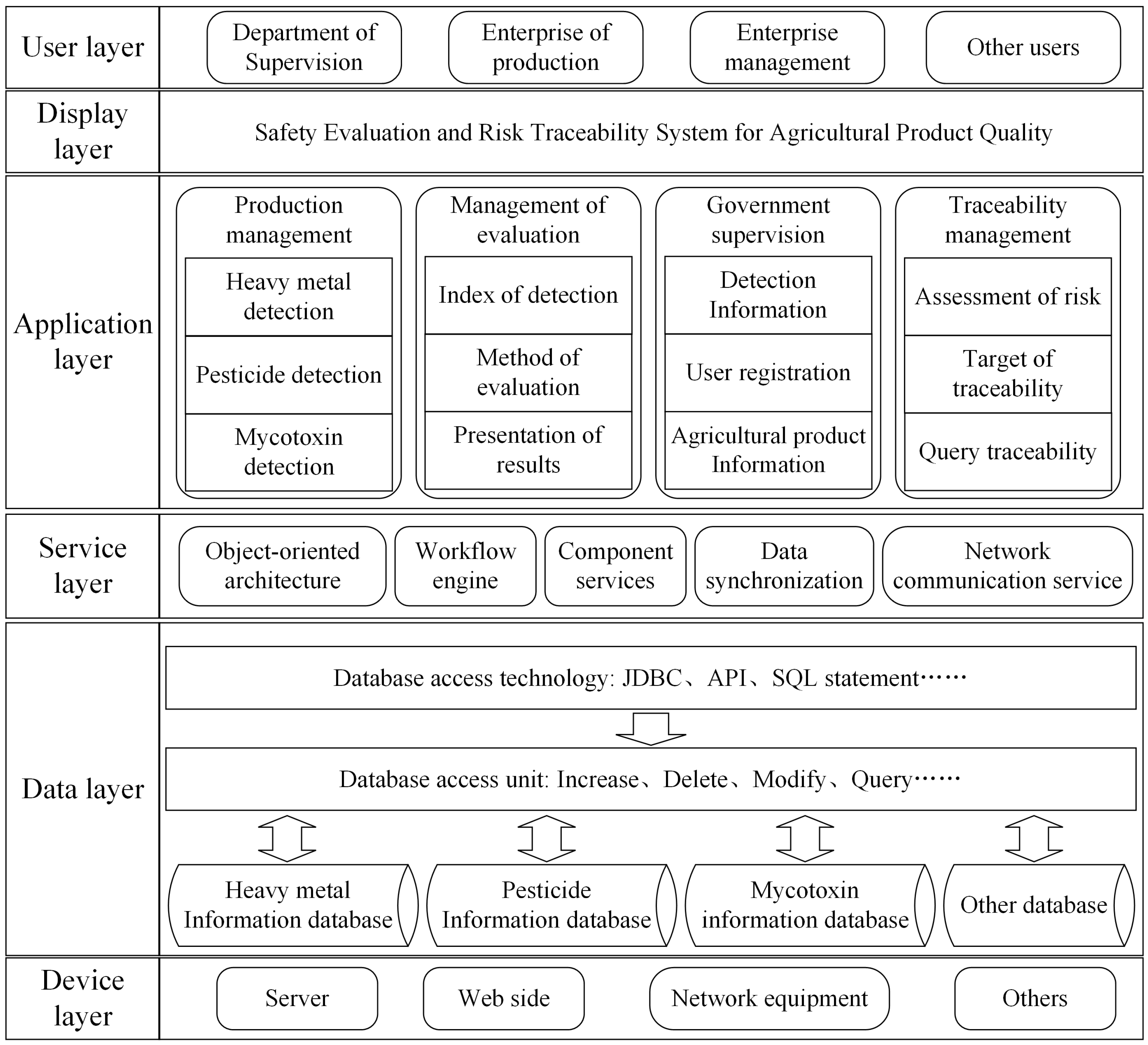

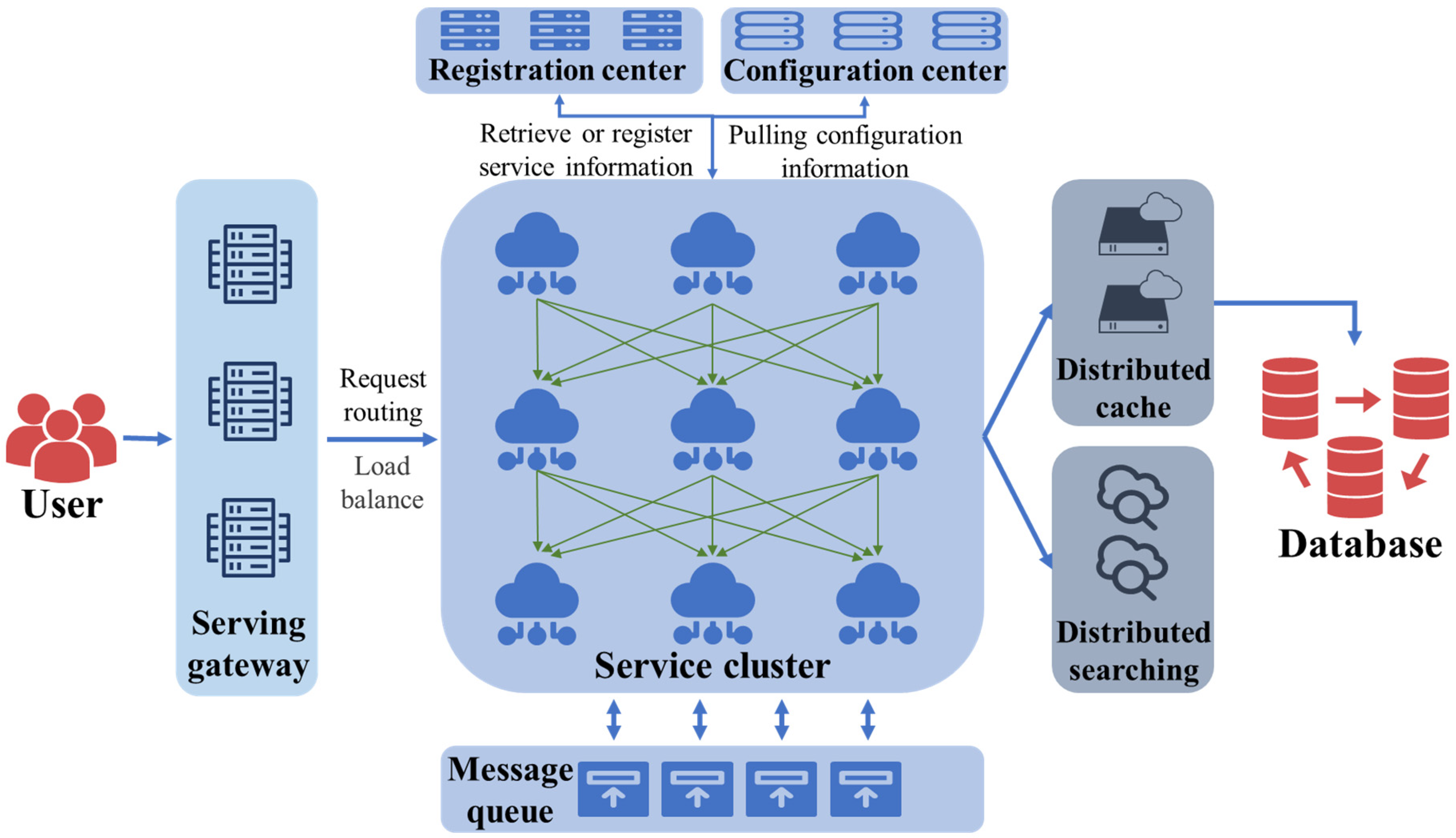

3.2.1. System Architecture Design

- (1)

- The equipment layer is the foundation for system construction and operation. The collection of monitoring data for agricultural product risk tracing and system maintenance involves various service support devices. Dividing the equipment layer separately helps to clarify equipment interfaces and improve system development efficiency. The device layer is centered around the server, including network devices and other devices. The terminal for collecting agricultural-product-related data information is connected to the system based on actual sensors to achieve data collection. The main data collection sensors involved in the system are gas sensors, pH sensors, etc.

- (2)

- The data layer is the actual inspection data related to the quality and safety of agricultural products. A large number of circulation data will be generated during the circulation of agricultural products. Data processing is also the key to the design and development of an agricultural product risk traceability system. Dividing the data layer can refine the data processing function design, improve the efficiency of data storage and access, and then improve the speed and accuracy of traceability. The data layer roughly divides the processing data into four directions: heavy-metal-related detection data, pesticide-related monitoring data, mycotoxin-related detection data, and other data. The relevant regulatory authorities provide support for the monitoring data of agricultural product quality and safety required for the system’s research and judgment; that is, they provide the detection data required by the data layer.

- (3)

- The service layer is the basic service support layer of the traceability system, which is used to connect the database and the application layer. The business functions and data transmission required by the risk traceability system involve intermediate links such as data synchronization and component implementation. Separate design and development can improve the understanding of functions during development and the reusability of functional components in the service layer. The service layer of the agricultural product risk traceability system is supported by the data provided by the data layer. It provides data synchronization to the application layer, and the back-end framework provides data management, quality and safety risk assessment calculation, user registration, and other business functions to the front end.

- (4)

- The application layer is the business function layer of the risk traceability system. During system development, the application functions are designed and developed according to the traceability function division, the actual agricultural product business scenario, and business logic. The application layer improves the coordination efficiency of the development team. Developers can focus on the development and maintenance of a single function, and coordinate the deployment of different development function modules in the application layer to ultimately realize the system functions. The application layer receives the request information from the front-end users and transmits the request information to the back-end service layer for response and processing. For example, for the detection data of agricultural product inputs by the front-end users, the application layer transmits the data to the back end after receiving it, and the back end calculates the score of the received actual detection data according to the set risk evaluation model algorithm to obtain the risk score. Further mining is conducted according to the obtained scores, and production suggestions and traceability risk objectives are put forward.

- (5)

- The display layer is the human–computer interaction interface designed by the user. The display interface of the risk traceability system uses HTML, JavaScript, and other development technologies to achieve interactive functions. The display layer unifies the development of interaction classes and improves the development specification of the system display interface. The risk traceability system uses web technology to provide users with operation functions. Different users can enter the system through different terminal devices. The applicability of web technology is better, and the designed system has better popularization significance.

- (6)

- The user layer refers to all users who have clear requirements for the agricultural product risk traceability system. It defines the definition of permissions and the differences in the operation functions of different users. The division of the user layer is conducive to developers to clarify the responsibilities and boundaries between different user roles, including supervision department personnel, production enterprise personnel, enterprise management personnel, etc.

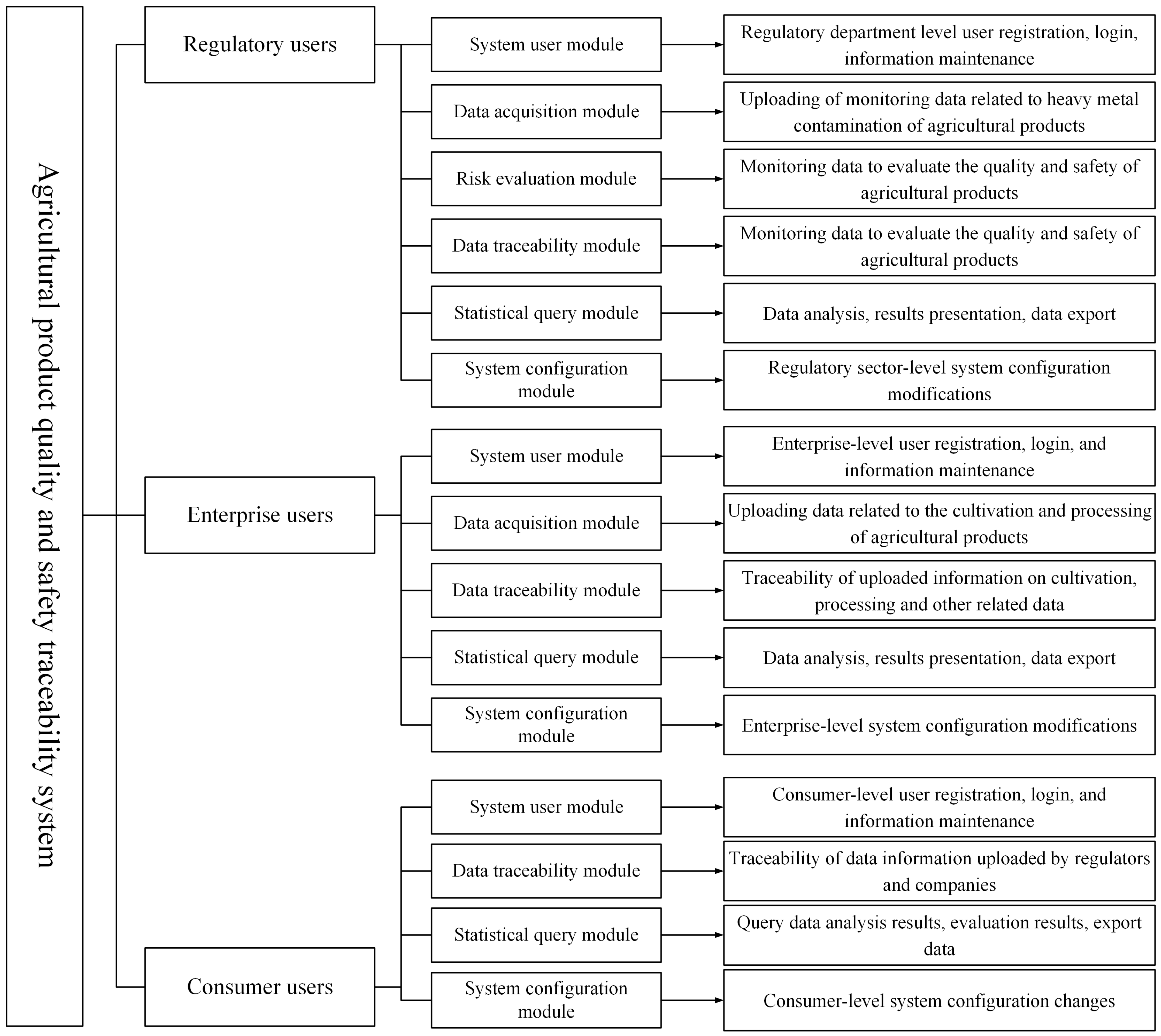

3.2.2. System Function Module Design

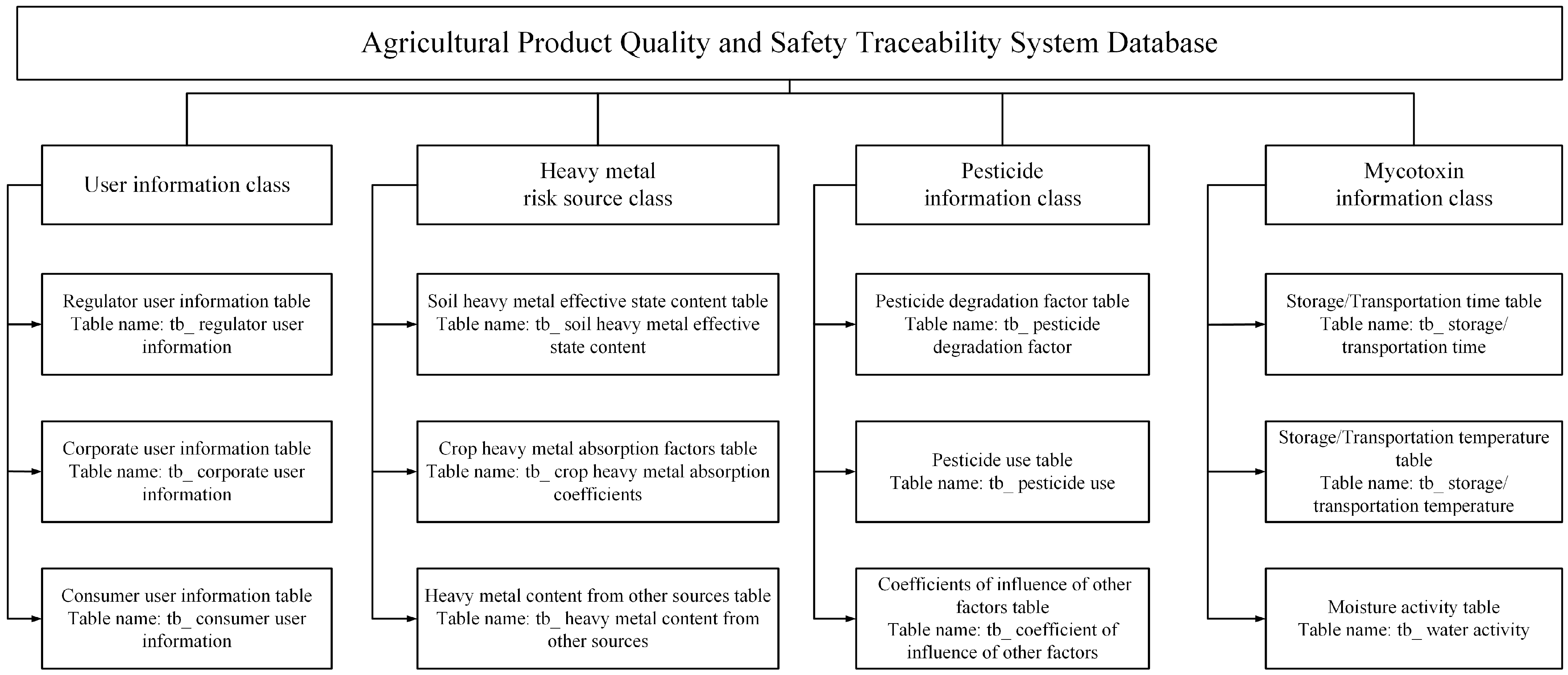

3.2.3. System Database Design

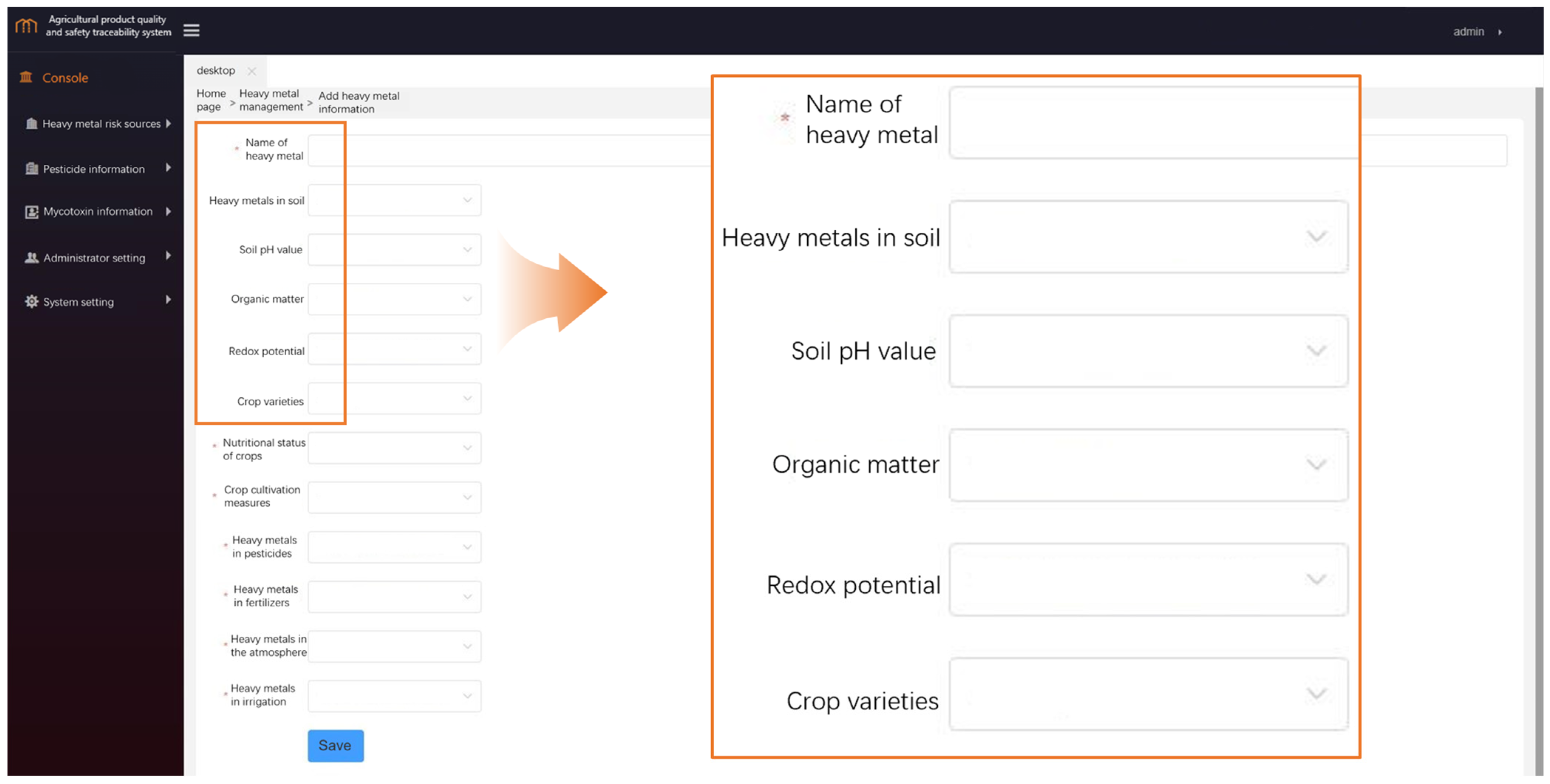

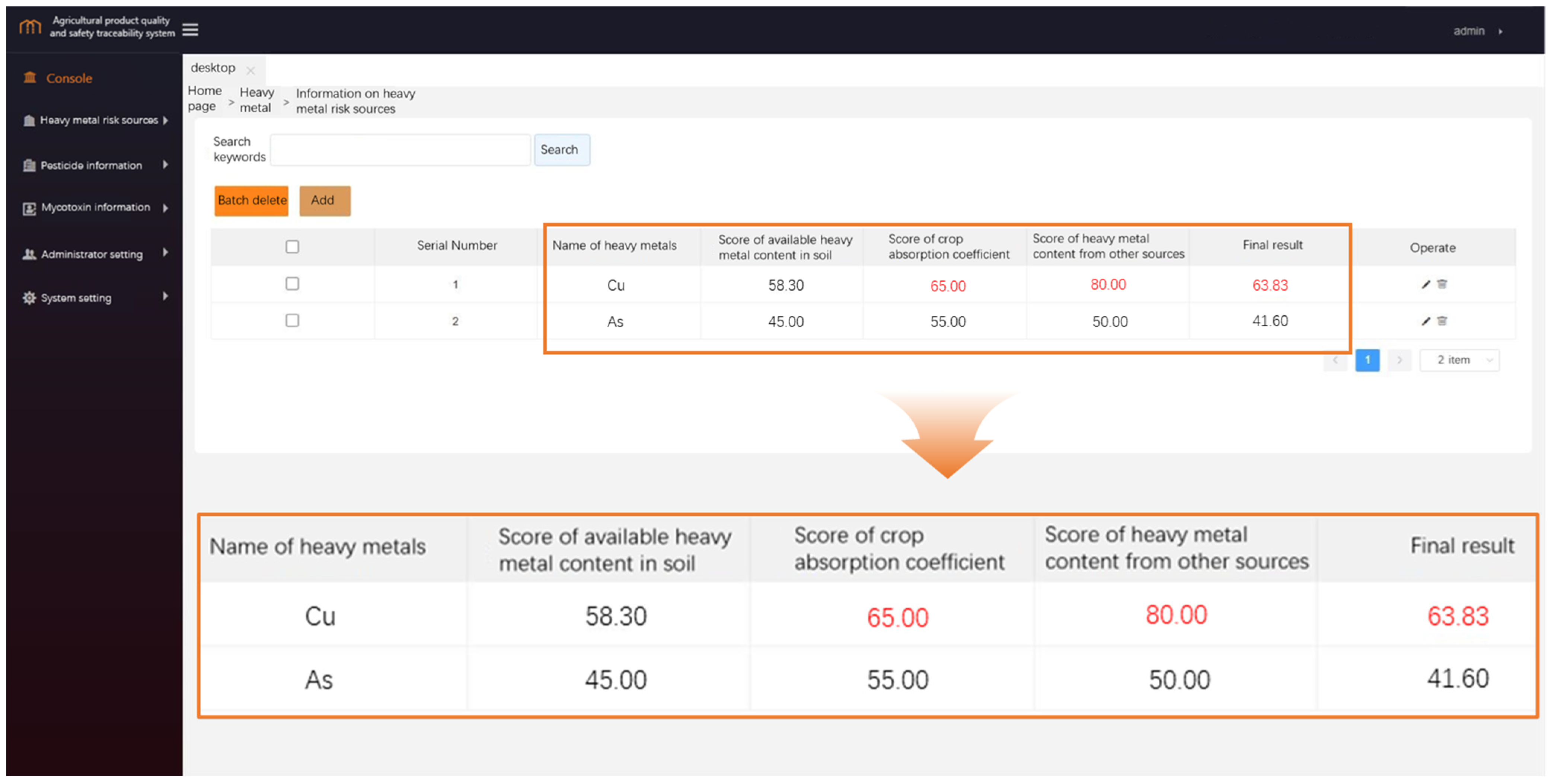

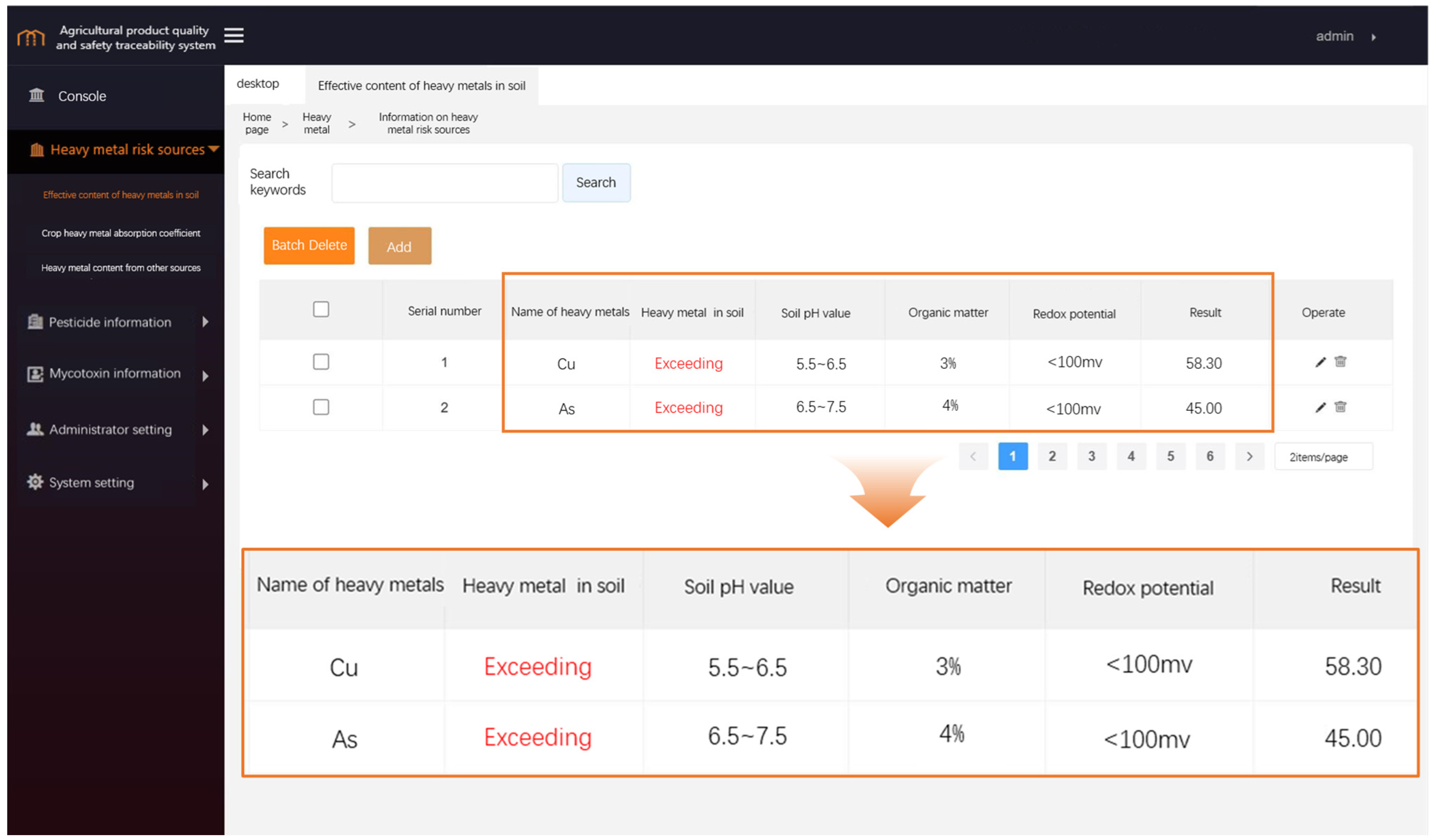

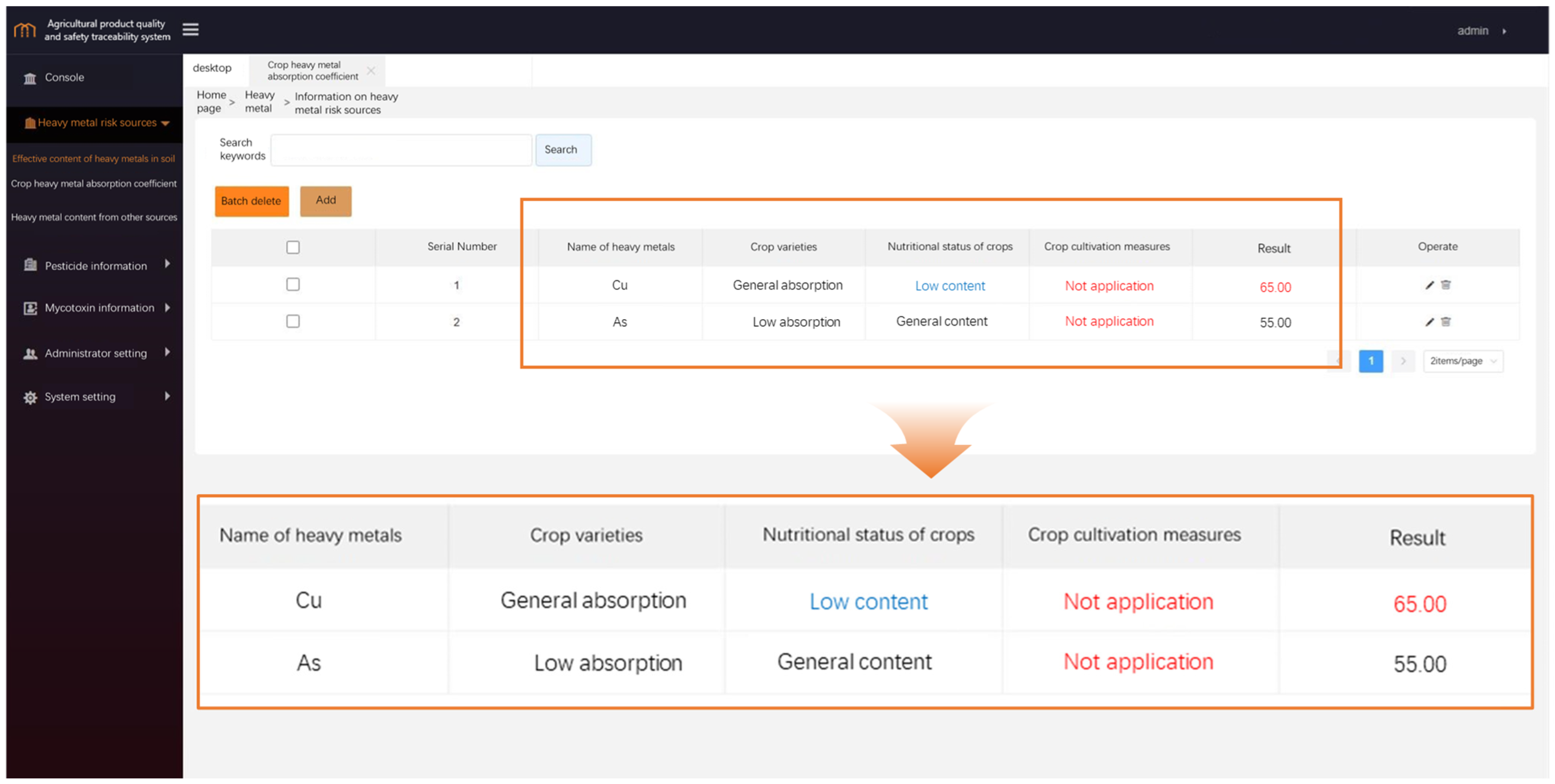

4. Realization of Results

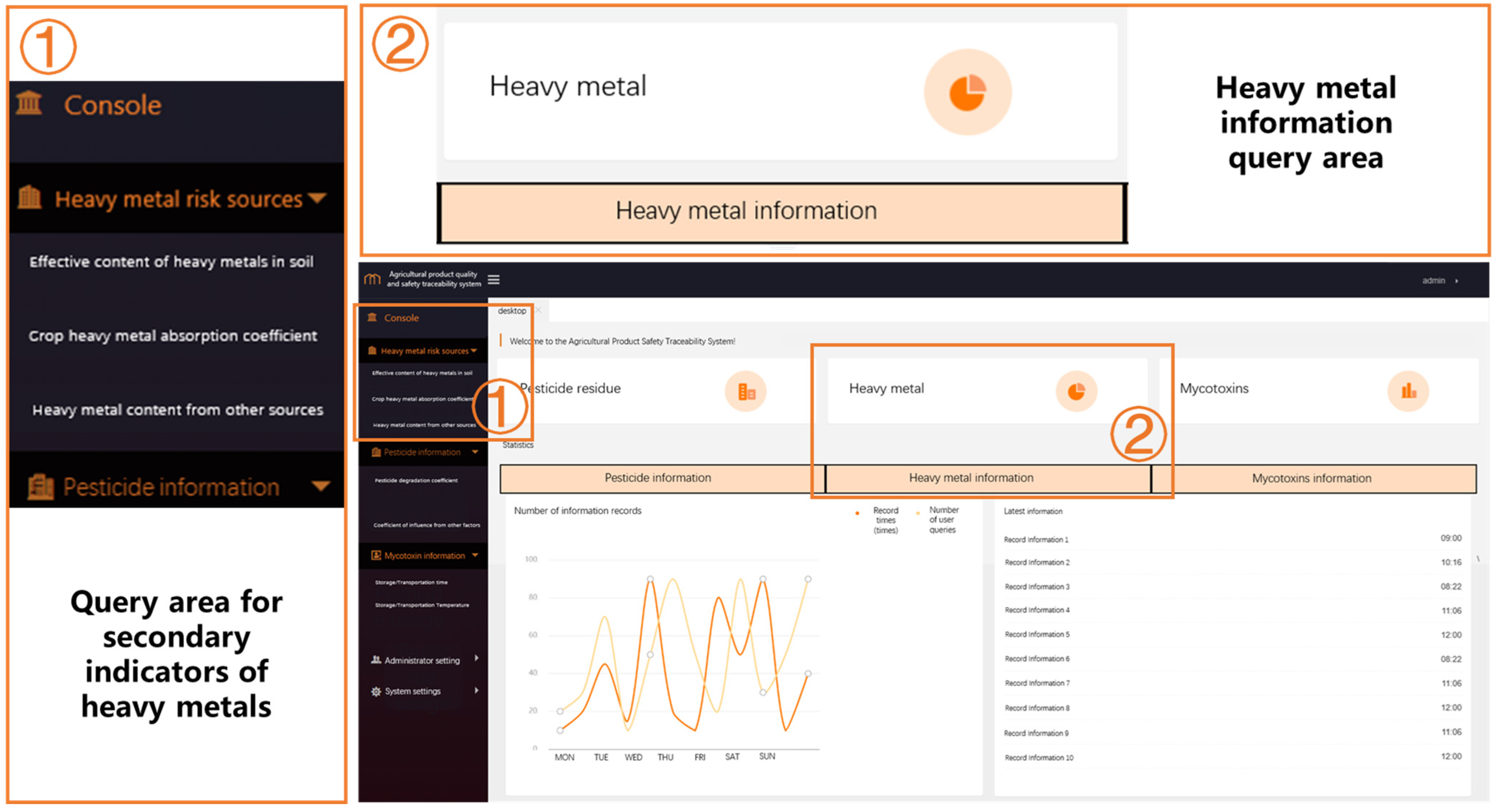

4.1. System Implementation

4.2. System Test

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yang, L.; Zhu, J.; Huang, Z.; Geng, J. A Systematic Review of China’s Food Safety Management since Reform and Opening Up. Emerg. Mark. Financ. Trade 2019, 55, 3472–3489. [Google Scholar] [CrossRef]

- Jaa, B.; Rmt, C.; Mdk, D.; Aeh, A.; Atn, A. Evaluating food safety management systems in Singapore: A controlled interrupted time-series analysis of foodborne disease outbreak reports—ScienceDirect. Food Control 2020, 117, 107324. [Google Scholar]

- Wales, C.; Harvey, M.; Warde, A. Recuperating from BSE: The shifting UK institutional basis for trust in food. Appetite 2006, 47, 187–195. [Google Scholar] [CrossRef] [PubMed]

- Dong, X.W.; Qi, Q.; Fang, S.S. The Optimization and Countermeasures Research of Agricultural Products Quality and Safety Supervision Mode. Adv. Mater. Res. 2014, 1061–1062, 1271–1274. [Google Scholar]

- Zhang, X.; Guo, Q.; Shen, X.; Yu, S.; Qiu, G. Water quality, agriculture and food safety in China:Current situation, trends, interdependencies, and management. J. Integr. Agric. 2015, 11, 2365–2379. [Google Scholar] [CrossRef]

- Wang, J.; Yue, H.; Zhou, Z. An Improved Traceability System for Food Quality Assurance and Evaluation Based on Fuzzy Classification and Neural Network. Food Control 2017, 79, 363–370. [Google Scholar] [CrossRef]

- Demestichas, K.; Peppes, N.; Alexakis, T.; Alexakis, T.; Adamopoulou, E. Blockchain in Agriculture Traceability Systems: A Review. Appl. Sci. 2020, 10, 4113. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, J.; Liu, F.; Fu, Z.; Mu, W. Strengths and limitations on the operating mechanisms of traceability system in agro food, China. Food Control 2010, 21, 825–829. [Google Scholar] [CrossRef]

- Ping, H.; Wang, J.; Ma, Z.; Du, Y. Mini-review of application of IoT technology in monitoring agricultural products quality and safety. Int. J. Agric. Biol. Eng. 2018, 11, 35–45. [Google Scholar] [CrossRef]

- Hu, J.; Zhang, X.; Moga, L.; Neculita, M. Modeling and implementation of the vegetable supply chain traceability system. Food Control 2013, 30, 341–353. [Google Scholar] [CrossRef]

- Zhou, Z.; Zhou, Z. Application of Internet of things in agriculture products supply chain management. In Proceedings of the 2012 International Conference on Control Engineering and Communication Technology, Shenyang, China, 7–9 December2012. [Google Scholar]

- Song, Y.; Lv, C.; Liu, J. Quality and safety traceability system of agricultural products based on Multi-agent. J. Intell. Fuzzy Syst. 2018, 35, 2731–2740. [Google Scholar]

- Schwägele, F. Traceability from a European perspective. Meat Sci. 2005, 71, 164–173. [Google Scholar] [CrossRef] [PubMed]

- Peets, S.; Gasparin, C.P.; Blackburn, D.; Godwin, R.J. RFID tags for identifying and verifying agrochemicals in food traceability systems. Precis. Agric. 2009, 10, 382–394. [Google Scholar] [CrossRef]

- Alfian, G.; Syafrudin, M.; Farooq, U.; Ma’Arif, M.R.; Syaekhoni, M.A.; Fitriyani, N.L.; Lee, J.; Rhee, J. Improving efficiency of RFID-based traceability system for perishable food by utilizing IoT sensors and machine learning model. Food Control 2020, 110, 107016. [Google Scholar] [CrossRef]

- Velepucha, V.; Flores, P. A Survey on Microservices Architecture: Principles, Patterns and Migration Challenges. IEEE Access 2023, 11, 88339–88358. [Google Scholar] [CrossRef]

- Söylemez, M.; Tekinerdogan, B.; Tarhan, A.K. Challenges and Solution Directions of Microservice Architectures: A Systematic Literature Review. Appl. Sci. 2022, 12, 5507. [Google Scholar] [CrossRef]

- Namiot, D.; Sneps-Sneppe, M. On Micro-services Architecture. Int. J. Open Inf. Technol. 2014, 2, 24–27. [Google Scholar]

- Raj, V.; Sadam, R. Patterns for Migration of SOA Based Applications to Microservices Architecture. J. Web Eng. 2021, 20, 1229–1245. [Google Scholar]

- Krishnan, A.R.; Kasim, M.M.; Hamid, R.; Ghazali, M.F. A Modified CRITIC Method to Estimate the Objective Weights of Decision Criteria. Symmetry 2021, 13, 973. [Google Scholar] [CrossRef]

- Keshavarz-Ghorabaee, M.; Amiri, M.; Zavadskas, E.K.; Turskis, Z.; Antucheviciene, J. Determination of Objective Weights Using a New Method Based on the Removal Effects of Criteria (MEREC). Symmetry 2021, 13, 525. [Google Scholar] [CrossRef]

- Shivanagowda, G.P.; Chitimalla, R.; Karabasanavar, N.; Sen, A.R. A Database for Buffalo Meat Traceability in India. Buffalo Bull. 2023, 42, 437–447. [Google Scholar] [CrossRef]

- Govindan; Kannan. Sustainable consumption and production in the food supply chain: A conceptual framework. Int. J. Prod. Econ. 2018, 195, 419–431. [Google Scholar] [CrossRef]

- Wong, D.R.; Bhattacharya, S.; Butte, A.J. Prototype of running clinical trials in an untrustworthy environment using blockchain. Nat. Commun. 2019, 10, 10–18. [Google Scholar] [CrossRef] [PubMed]

- Cocco, L.; Mannaro, K.; Tonelli, R.; Mariani, L.; Lodi, M.B.; Melis, A.; Simone, M.; Fanti, A. A Blockchain-Based Traceability System in Agri-Food SME: Case Study of a Traditional Bakery. IEEE Access 2021, 9, 62899–62915. [Google Scholar] [CrossRef]

- Surjandari, I.; Yusuf, H.; Laoh, E.; Maulida, R. Designing a Permissioned Blockchain Network for the Halal Industry using Hyperledger Fabric with multiple channels and the raft consensus mechanism. J. Big Data 2021, 8, 10. [Google Scholar] [CrossRef]

| Primary Indicators | Secondary Indicators | Unit of Measurement |

|---|---|---|

| Available content of heavy metals in soil (Acs) | Total content of heavy metals in soil (a) | mg/kg |

| Soil pH (b) | / | |

| Organic matter (c) | g/kg | |

| Redox potential (d) | mV | |

| Absorption coefficient of heavy metals in crops (Ac) | Crop varieties (e) | / |

| Nutritional status (f) | / | |

| Cultivation measures (g) | / | |

| Heavy metal content from other sources (Os) | Heavy metal content in pesticides (h) | mg/kg |

| Heavy metal content in fertilizers (i) | mg/kg | |

| Heavy metal content in the atmosphere (j) | mg/kg | |

| Heavy metal content in irrigation water (k) | mg/kg |

| Risk Level Evaluation Index | Scoring Criteria | Score (Point) |

|---|---|---|

| Total content of heavy metals in soil (a) | Exceeding the standard | 1 |

| Not exceeding the standard | 0 | |

| Risk level of soil pH (b) | pH value < 4.5, Extremely acid | 6 |

| 4.5 ≤ pH value < 5.5, Strong acid | 5 | |

| 5.5 ≤ pH value < 6.5, acid | 4 | |

| 6.5 ≤ pH value < 7.5, neutral | 3 | |

| 7.5 ≤ pH value < 8.5, alkalinity | 2 | |

| 8.5 ≤ pH value < 9.5, Strong alkalinity | 1 | |

| 9.5 ≤ pH value, Extreme alkalinity | 0 | |

| Risk level of soil organic matter (c) | Soil organic matter content 0% | 6 |

| Soil organic matter content < 1% | 5 | |

| Soil organic matter content < 2% | 4 | |

| Soil organic matter content < 3% | 3 | |

| Soil organic matter content < 4% | 2 | |

| Soil organic matter content < 5% | 1 | |

| Soil organic matter content > 5% | 0 | |

| Risk level of soil redox potential (d) | Soil redox potential ≤ −200 mv | 6 |

| −200 mv ≤ Soil redox potential < −100 mv | 5 | |

| −100 mv ≤ Soil redox potential < 0 mv | 4 | |

| 0 mv ≤ Soil redox potential < 100 mv | 3 | |

| 100 mv ≤ Soil redox potential < 200 mv | 2 | |

| 200 mv ≤ Soil redox potential | 1 | |

| Risk level of crop varieties (e) | Extremely easy to absorb heavy metals | 5 |

| Easy to absorb heavy metals | 4 | |

| General to absorb heavy metals | 3 | |

| Low to absorb heavy metals | 2 | |

| Extremely low to absorb heavy metals | 1 | |

| Risk level of crop nutritional status (f) | High content of nutrient elements that can resist the absorption of heavy metals | 1 |

| General content of nutrient elements that can resist the absorption of heavy metals | 2 | |

| Low content of nutrient elements that can resist the absorption of heavy metals | 3 | |

| Risk level of crop Cultivation measures (g) | Application of related substances inhibiting the absorption and transport of heavy metals | 1 |

| Not application of related substances inhibiting the absorption and transport of heavy metals | 2 | |

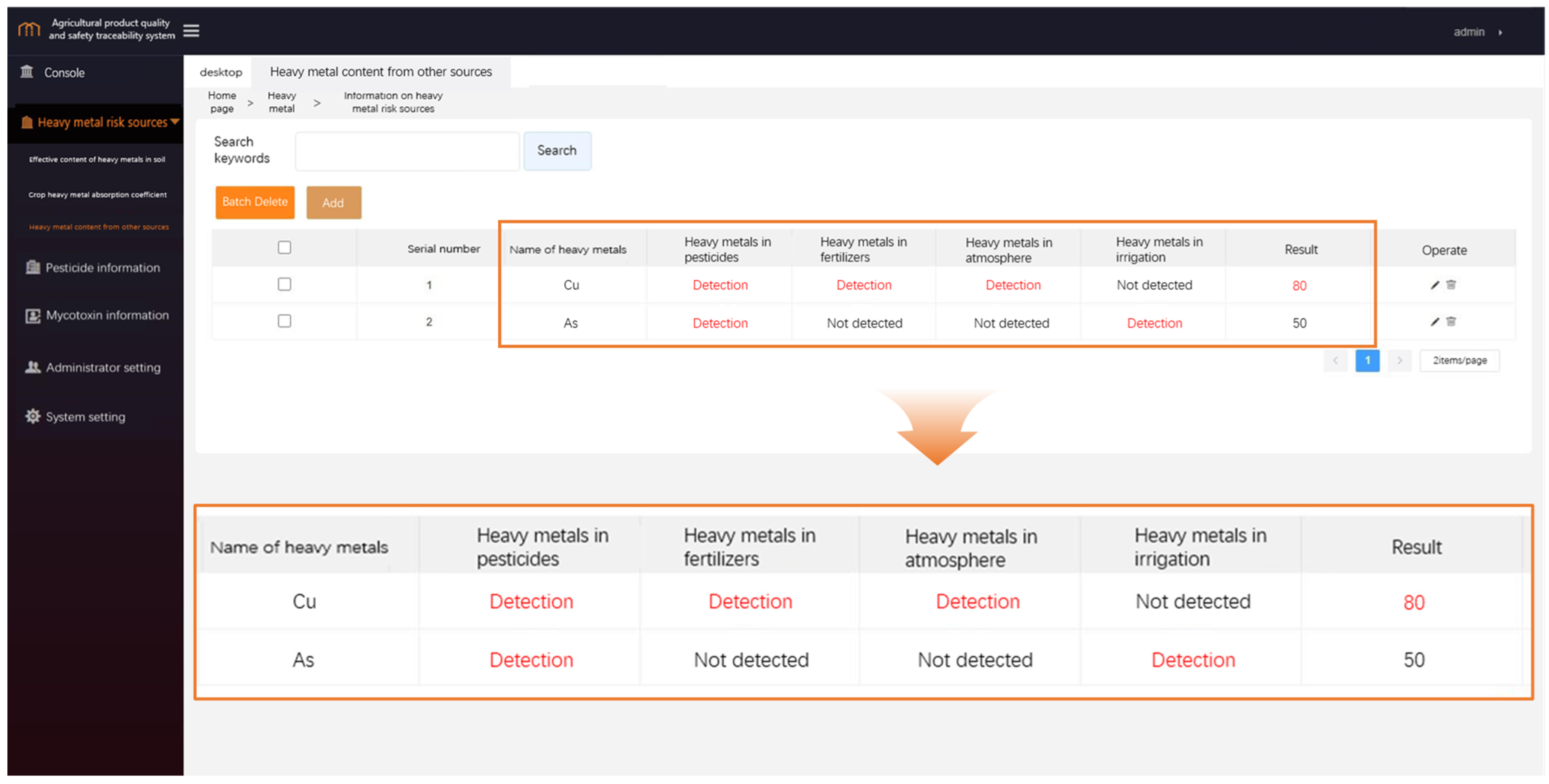

| Content of heavy metals in pesticides (h) | Detection | 1 |

| Not detected | 0 | |

| Heavy metal content in fertilizer (i) | Detection | 1 |

| Not detected | 0 | |

| Heavy metal content in the atmosphere (j) | Detection | 1 |

| Not detected | 0 | |

| Heavy metal content in irrigation water (k) | Detection | 1 |

| Not detected | 0 |

| Item (Unit) | Sample Size | Average Value | Standard Deviation |

|---|---|---|---|

| Soil pH | 200 | 4.46 | 0.432 |

| Soil organic matter content (g/kg) | 200 | 33.76 | 0.493 |

| Soil cation exchange capacity (cmol/kg) | 200 | 14.67 | 0.539 |

| Cadmium content (mg/kg) | 200 | 0.05 | 0.398 |

| Mercury content (mg/kg) | 200 | 0.12 | 0.425 |

| Arsenic content (mg/kg) | 200 | 4.45 | 0.512 |

| Lead content (mg/kg) | 200 | 37.62 | 0.563 |

| Category | Heavy Metal Content (mg/kg) | |||||||

|---|---|---|---|---|---|---|---|---|

| Cu | Pb | Cr | Cd | As | Hg | Ni | Zn | |

| Soil | 395.1 | 97.2 | 53.5 | 2.76 | 13.5 | 0.143 | 8.18 | 49.3 |

| Fertilizer | 75.46 | 29.6 | 42.4 | 1.5 | \ | 0.551 | \ | \ |

| Atmosphere | 48.2 | 84.4 | 82.7 | 2.25 | \ | 0.213 | 20.06 | 176.7 |

| Irrigation | \ | 0 | 0.57 | 0 | 1.46 | 0 | 0 | 0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, C.; Lu, Y.; Bian, Y.; Tian, J.; Yuan, M. Design of Safety Evaluation and Risk Traceability System for Agricultural Product Quality. Appl. Sci. 2024, 14, 2980. https://doi.org/10.3390/app14072980

Li C, Lu Y, Bian Y, Tian J, Yuan M. Design of Safety Evaluation and Risk Traceability System for Agricultural Product Quality. Applied Sciences. 2024; 14(7):2980. https://doi.org/10.3390/app14072980

Chicago/Turabian StyleLi, Chen, Yinxu Lu, Yong Bian, Jie Tian, and Mu Yuan. 2024. "Design of Safety Evaluation and Risk Traceability System for Agricultural Product Quality" Applied Sciences 14, no. 7: 2980. https://doi.org/10.3390/app14072980

APA StyleLi, C., Lu, Y., Bian, Y., Tian, J., & Yuan, M. (2024). Design of Safety Evaluation and Risk Traceability System for Agricultural Product Quality. Applied Sciences, 14(7), 2980. https://doi.org/10.3390/app14072980