Influence of Plant-Based Structuring Ingredients on Physicochemical Properties of Whey Ice Creams

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Samples

2.3. Characterization of Ice Cream Mixes

3. Results and Discussion

3.1. Chemical Composition of Ice Cream Mixes

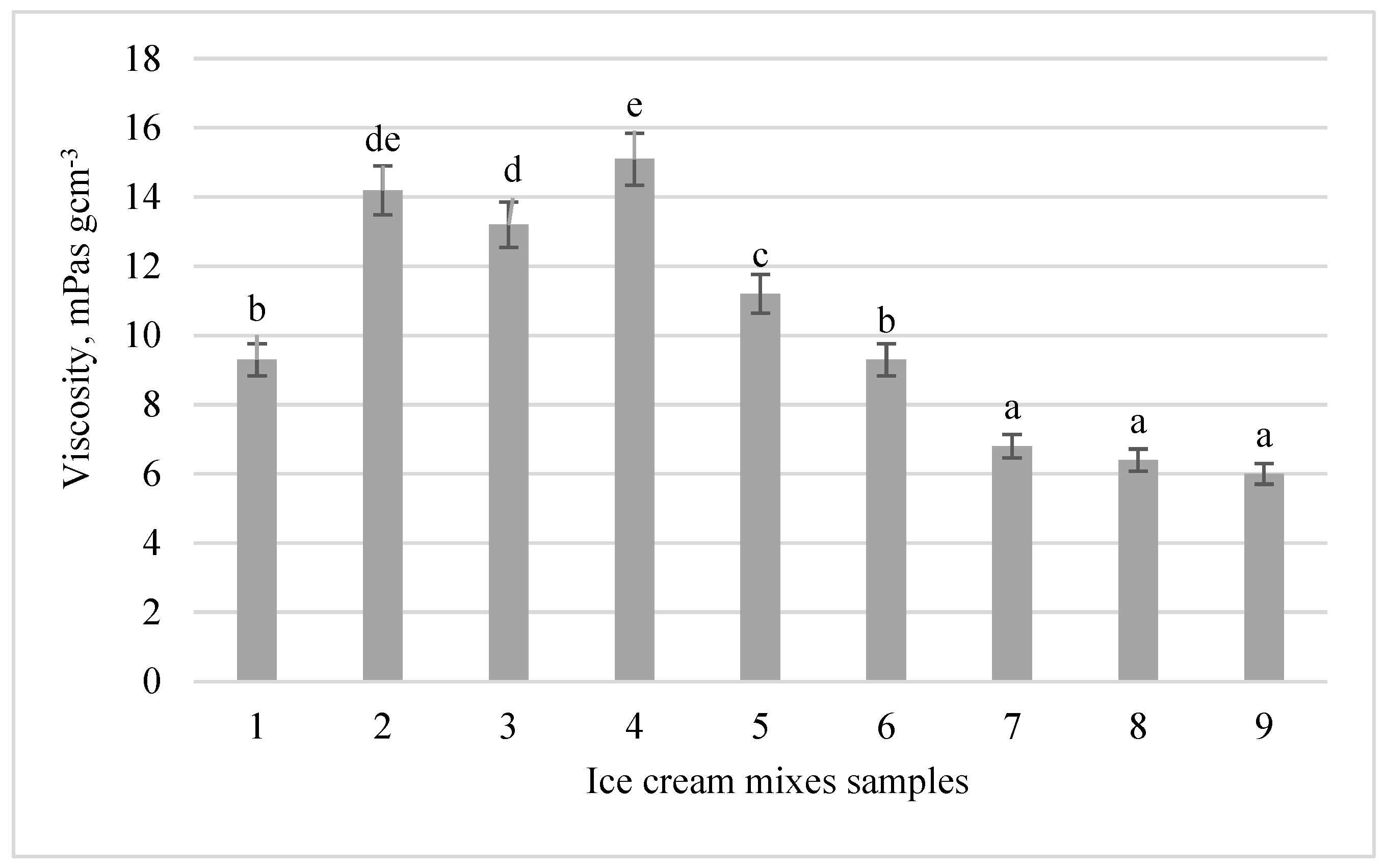

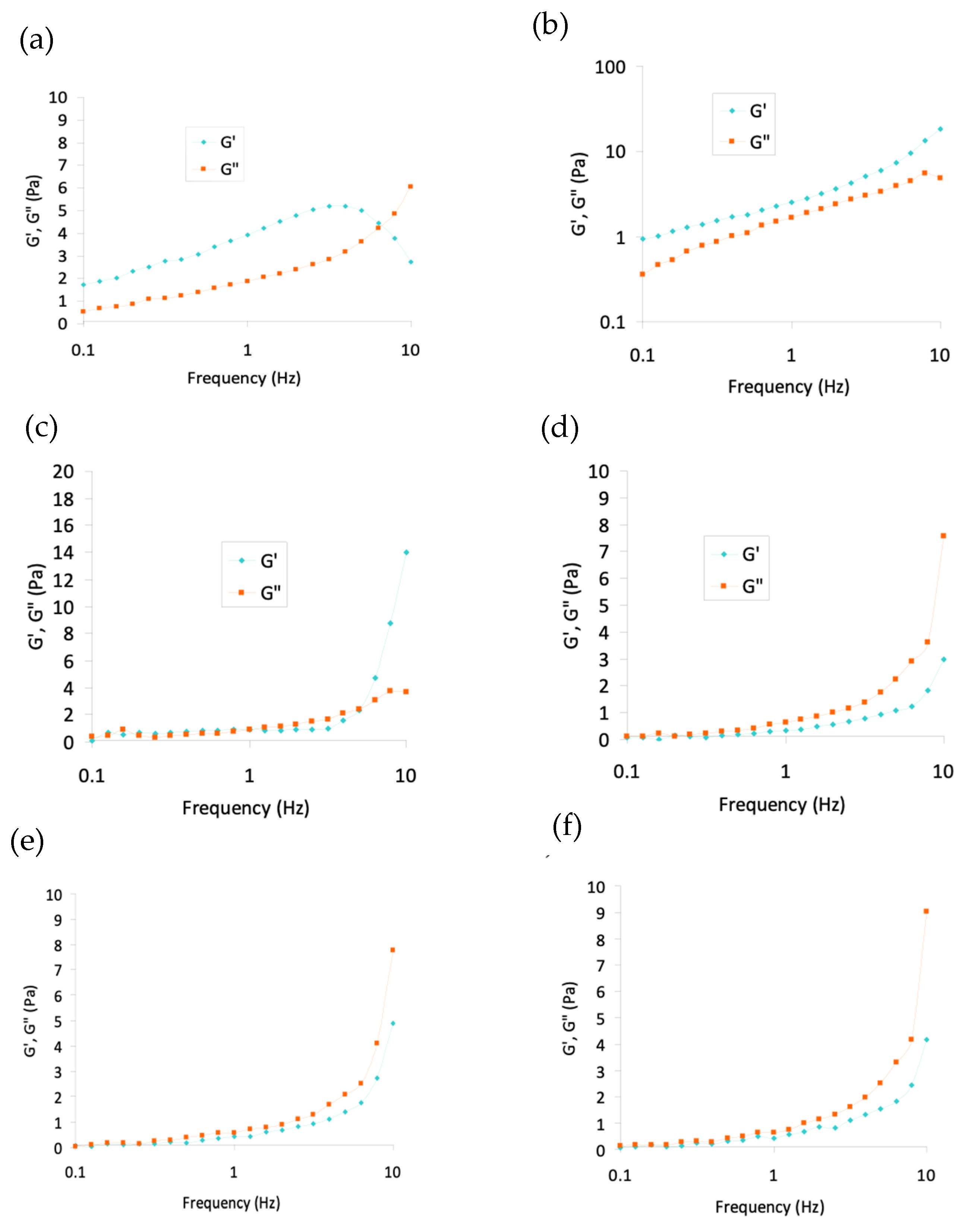

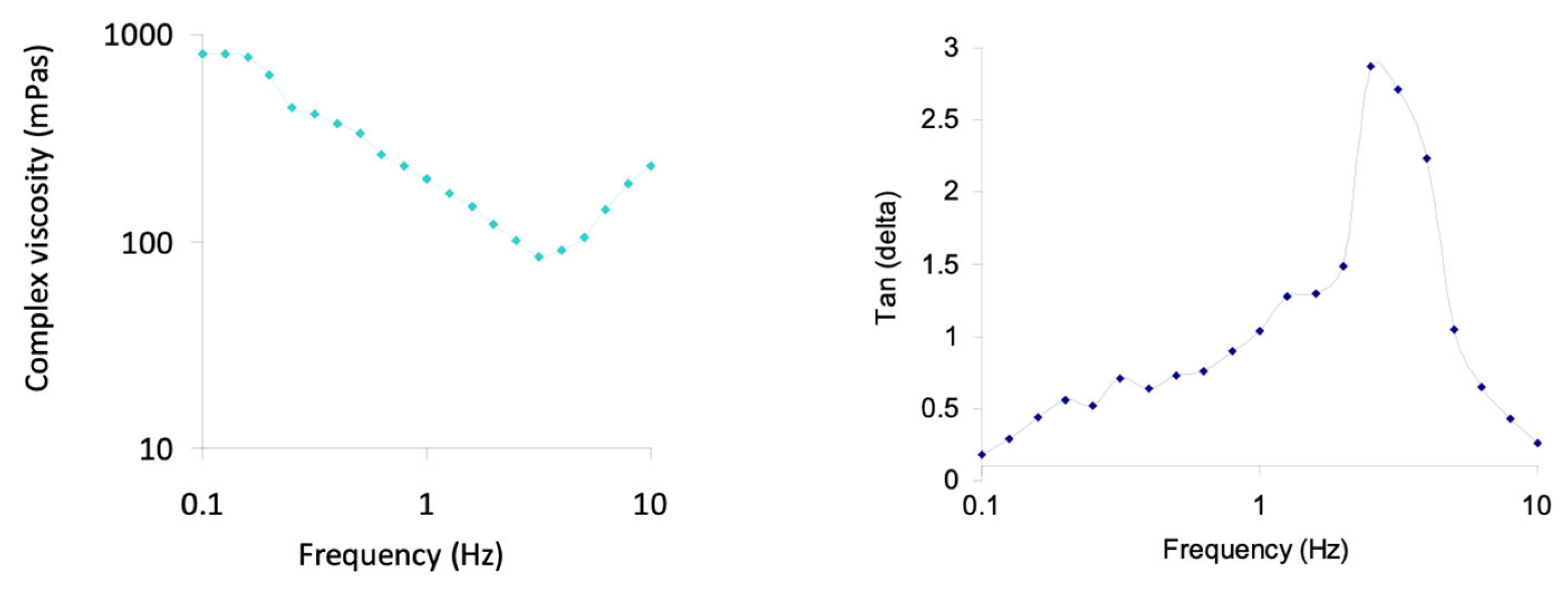

3.2. Rheological Characteristics

3.3. Whey-Based Ice Creams Aqueous Phase Analysis

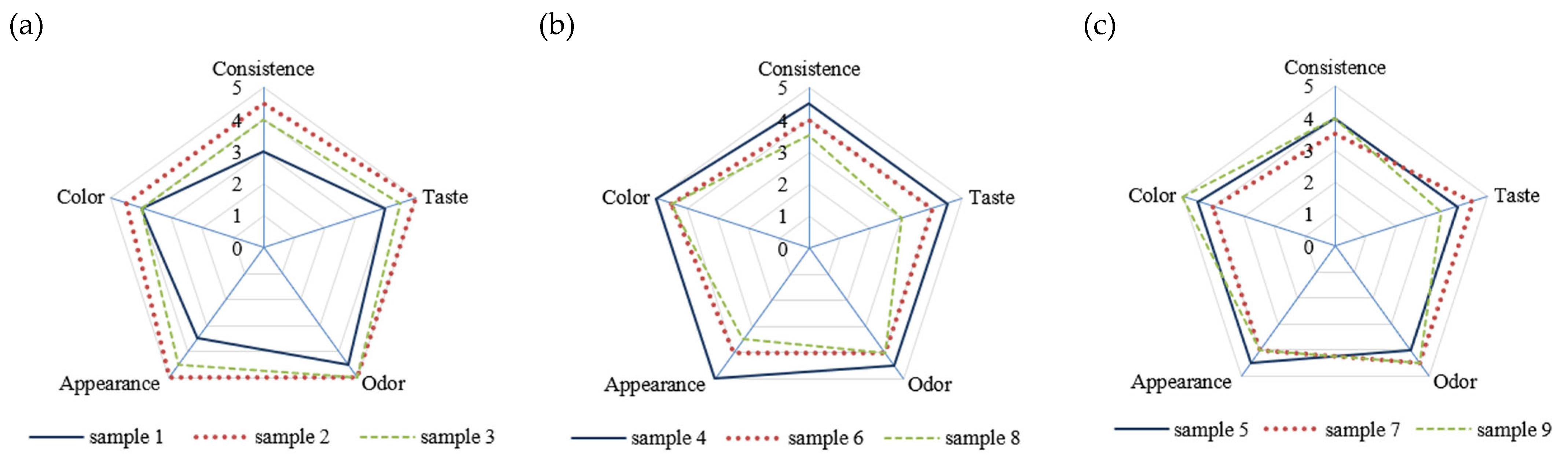

3.4. Sensory Evaluation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Abdel-Haleem, A.M.H.; Awad, R.A. Some quality attributes of low fat ice cream substituted with hulless barley flour and barley ß-glucan. J. Food Sci. Technol. 2015, 52, 6425–6434. [Google Scholar] [CrossRef] [PubMed]

- Akalın, A.S.; Karagözlü, C.; Ünal, G. Rheological properties of reduced-fat and low-fat ice cream containing whey protein isolate and inulin. Eur. Food Res. Technol. 2008, 227, 889–895. [Google Scholar] [CrossRef]

- Aljewicz, M.; Florczuk, A.; Dąbrowska, A. Influence of β-Glucan Structures and Contents on the Functional Properties of Low-Fat Ice Cream During Storage. Pol. J. Food Nutr. Sci. 2020, 70, 233–240. [Google Scholar] [CrossRef]

- Kurek, M.A.; Moczkowska, M.; Karp, S.; Horbańczuk, O.K.; Rodak, E. Application of rich in β-glucan flours and preparations in bread baked from frozen dough. Food Sci. Technol. Int. 2020, 26, 53–64. [Google Scholar] [CrossRef]

- Parsons, J.G.; Dybing, S.T.; Coder, D.S.; Spurgeon, K.R.; Seas, S.W. Acceptability of ice cream made with processed wheys and sodium caseinate. J. Dairy Sci. 1985, 68, 2880–2885. [Google Scholar] [CrossRef]

- Amamou, A.H.; Benkhelifa, H.; Alvarez, G.; Flick, D. Study of crystal size evolution by focused-beam reflectance measurement during the freezing of sucrose/water solutions in a scraped-surface heat exchanger. Process Biochem. 2010, 45, 1821–1825. [Google Scholar] [CrossRef][Green Version]

- Nasrollahzadeh, M.; Nezafat, Z.; Shafiei, N. Proteins in food industry. Biopolym.-Based Met. Nanopart. Chem. Sustain. Appl. 2021, 2, 97–136. [Google Scholar] [CrossRef]

- Nooshkam, M.; Varidi, M.; Alkobeisi, F. Bioactive food foams stabilized by licorice extract/whey protein isolate/sodium alginate ternary complexes. Food Hydrocoll. 2022, 126, 107488. [Google Scholar] [CrossRef]

- Polishchuk, G.; Breus, N.; Shevchenko, I.; Gnitsevych, V.; Yudina, T.; Nozhechkina-Yeroshenko, G.; Semko, T. Determining the effect of casein on the quality indicators of ice cream with different fat content. East.-Eur. J. Enterp. Technol. 2020, 4, 24–30. [Google Scholar] [CrossRef]

- Atik, I.; Tekin Cakmak, Z.H.; Avcı, E.; Karasu, S. The Effect of Cold Press Chia Seed Oil By-Products on the Rheological, Microstructural, Thermal, and Sensory Properties of Low-Fat Ice Cream. Foods 2021, 10, 2302. [Google Scholar] [CrossRef]

- Whey Protein Market Size, Share & Growth Report 2022–2029. Available online: https://www.fortunebusinessinsights.com/whey-protein-market-106555 (accessed on 2 February 2023).

- Panghal, A.; Patidar, R.; Jaglan, S.; Chhikara, N.; Khatkar, S.K.; Gat, Y.; Sindhu, N. Whey valorization: Current options and future scenario—A critical review. Nutr. Food Sci. 2018, 48, 520–535. [Google Scholar] [CrossRef]

- Ryan, M.P.; Walsh, G. The biotechnological potential of whey. Rev. Environ. Sci. Biotechnol. 2016, 15, 479–498. [Google Scholar] [CrossRef]

- Ravash, N.; Peighambardoust, S.H.; Soltanzadeh, M.; Pateiro, M.; Lorenzo, J.M. Impact of high-pressure treatment on casein micelles, whey proteins, fat globules and enzymes activity in dairy products: A review. Crit. Rev. Food Sci. Nutr. 2022, 62, 2888–2908. [Google Scholar] [CrossRef] [PubMed]

- Ukrainets, A.; Kochubei-Lytvynenko, O.; Bilyk, O.; Zakharevych, V.; Vasylchenko, T. A study of the effect of enriched whey powder on the quality of a special-purpose bread. East.-Eur. J. Enterp. Technol. 2016, 2, 32–41. [Google Scholar] [CrossRef][Green Version]

- Królczyk, J.B.; Dawidziuk, T.; Janiszewska-Turak, E.; Solowiej, B. Use of whey and whey preparations in the food industry—A review. Pol. J. Food Nutr. Sci. 2016, 66, 157. [Google Scholar] [CrossRef]

- Bozhko, N.; Tischenko, V.; Pasichnyi, V.; Moroz, O. Research of nutritional and biological value of semismoked meat-containing sausage. Food Sci. Technol. 2019, 13, 96–103. [Google Scholar] [CrossRef]

- Lukin, A. Applicability of demineralized milk whey powder in cooked sausage production. Songklanakarin J. Sci. Technol. 2020, 42, 255–262. [Google Scholar]

- Foegeding, E.A.; Davis, J.P.; Doucet, D.; McGuffey, M.K. Advances in modifying and understanding whey protein functionally. Trends Food Sci. Technol. 2002, 13, 151–159. [Google Scholar] [CrossRef]

- Mykhalevych, A.; Polishchuk, G.; Buniowska-Olejnik, M.; Tomczyńska-Mleko, M.; Mleko, S. Functional and technological properties of protein ingredients in whey ice cream. Ukr. Food J. 2022, 10, 125–135. [Google Scholar] [CrossRef]

- Pandiyan, C.; Kumaresan, G.; Annal, V.R.; Rajarajan, G. Incorporation of whey protein concentrates in ice cream. Int. J. Chem. Sci. 2010, 8, s563–s567. [Google Scholar]

- Cavender, G.A.; Kerr, W.L. Microfluidization of full-fat ice cream mixes: Effects on rheology and microstructure. J. Food Process Eng. 2020, 43, e13350. [Google Scholar] [CrossRef]

- Pertsevoy, F.; Gurskyi, P.; Ladyk, V.; Ianchik, M.; Krapivnytska, I.; Omelchenko, S.; Bredykhin, V.; Kis, V.; Marenkova, T.; Garncarek, Z. Food Technology Using Structurants; Dissa+: Kharkiv, Ukraine, 2021; p. 252. [Google Scholar]

- Seo, C.W.; Yoo, B. Effect of Milk Protein Isolate/κ-Carrageenan Conjugates on Rheological and Physical Properties of Whipping Cream: A Comparative Study of Maillard Conjugates and Electrostatic Complexes. Food Sci. Anim. Resour. 2022, 42, 889–902. [Google Scholar] [CrossRef]

- Syed, Q.A.; Anwar, S.; Shukat, R.; Zahoor, T. Effects of different ingredients on texture of ice cream. J. Nutr. Health Food Eng. 2018, 8, 422–435. [Google Scholar] [CrossRef]

- Yan, C.; Kim, S.R.; Ruiz, D.R.; Farmer, J.R. Microencapsulation for Food Applications: A Review. ACS Appl. Bio Mater. 2022, 5, 5497–5512. [Google Scholar] [CrossRef]

- Şengül, M.; Seda, U.F.U.K. Therapeutic and Functional Properties of Beta-Glucan, and Its Effects on Health. Eurasian J. Eng. Sci. Technol. 2022, 6, 29–41. [Google Scholar]

- Fan, R.; Ma, P.; Zhou, D.; Yuan, F.; Cao, X. The properties and formation mechanism of oat β-glucan mixed gels with different molecular weight composition induced by high-pressure processing. PLoS ONE 2019, 14, e0225208. [Google Scholar] [CrossRef]

- Henrion, M.; Francey, C.; Lê, K.A.; Lamothe, L. Cereal B-Glucans: The Impact of Processing and How It Affects Physiological Responses. Nutrients 2019, 11, 1729. [Google Scholar] [CrossRef] [PubMed]

- Mykhalevych, A.; Polishchuk, G.; Nassar, K.; Osmak, T.; Buniowska-Olejnik, M. β-Glucan as a Techno-Functional Ingredient in Dairy and Milk-Based Products—A Review. Molecules 2022, 27, 6313. [Google Scholar] [CrossRef]

- El Khoury, D.; Cuda, C.; Luhovyy, B.L.; Anderson, G.H. Beta glucan: Health benefits in obesity and metabolic syndrome. J. Nutr. Metab. 2012, 2012, 851362. [Google Scholar] [CrossRef]

- Jahan, K.; Qadri, O.S.; Younis, K. Dietary fiber as a functional food. In Functional Food Products and Sustainable Health; Springer: Berlin/Heidelberg, Germany, 2020; pp. 155–167. [Google Scholar] [CrossRef]

- Buniowska-Olejnik, M.; Mykhalevych, A.; Polishchuk, G.; Sapiga, V.; Znamirowska-Piotrowska, A.; Kot, A.; Kamińska-Dwórznicka, A. Study of Water Freezing in Low-Fat Milky Ice Cream with Oat β-Glucan and Its Influence on Quality Indicators. Molecules 2023, 28, 2924. [Google Scholar] [CrossRef]

- Mykhalevych, A.; Sapiga, V.; Polischuk, G.; Osmak, T. Functional and technological properties of oat beta-glucan in acidophilic-whey ice cream. Food Environ. Saf. J. 2022, 21, 116–128. [Google Scholar] [CrossRef]

- Burkus, Z.; Temelli, F. Stabilization of emulsions and foams using barley β-glucan. Food Res. Int. 2000, 33, 27–33. [Google Scholar] [CrossRef]

- Rezaei, R.; Khomeiri, M.; Kashaninejad, M.; Mazaheri-Tehrani, M.; Aalami, M. Potential of β-d-glucan to enhance physicochemical quality of frozen soy yogurt at different aging conditions. Iran. Food Sci. Technol. Res. J. 2019, 15, 1–12. [Google Scholar] [CrossRef]

- ISO 19662 I IDF 238: 2018; Milk—Fat Content Determination, Gerber Method (NP Standard No. 469 in Portuguese). Instituto Português da Qualidade: Monte de Caparica, Portugal, 2002.

- AOAC. Official Method 960.52. Microchemical determination of nitrogen. Micro-Kjeldahl method. In Official Methods of Analysis of Association of Official Analytical Chemists, 15th ed.; AOAC International: Arlington, TX, USA, 1995. [Google Scholar]

- Tomczyńska-Mleko, M.; Gustaw, W.; Piersiak, T.; Terpiłowski, K.; Sołowiej, B.; Wesołowska-Trojanowska, M.; Mleko, S. Whey protein aerated gels as a new product obtained using ambient temperature magnesium and iron (II) induced gelation. Acta Aliment. 2014, 43, 465–472. [Google Scholar] [CrossRef]

- Nastaj, M.; Sołowiej, B.G.; Terpiłowski, K.; Mleko, S. Effect of erythritol on physicochemical properties of reformulated high protein meringues obtained from whey protein isolate. Int. Dairy J. 2020, 105, 104672. [Google Scholar] [CrossRef]

- ISO 22935-3:2009/IDF 99-3:2009; Milk and Milk Products—Sensory Analysis. Part 3: Guidance on a Method for Evaluation of Compliance with Product Specifications for Sensory Properties by Scoring. BSI: London, UK, 2009.

- Marshall, R.T.; Goff, H.D.; Hartel, R.W. Ice Cream; Springer: New York, NY, USA, 2003; 371p. [Google Scholar]

- Bolliger, S.; Goff, H.D.; Tharp, B.W. Correlation between colloidal properties of ice cream mix and ice cream. Int. Dairy J. 2000, 10, 303–309. [Google Scholar] [CrossRef]

- Brummer, Y.; Defelice, C.; Wu, Y.; Kwong, M.; Wood, P.J.; Tosh, S.M. Textural and rheological properties of oat beta-glucan gels with varying molecular weight composition. J. Agric. Food Chem. 2014, 62, 3160–3167. [Google Scholar] [CrossRef]

- Mudarisova, R.K.; Sagitova, A.F.; Kukovinets, O.S.; Kolesov, S.V. Metal Complexes of Pharmacophore-Containing Pectin with d-Elements Ions (Cu2+, Co2+, and Mn2+). Russ. J. Gen. Chem. 2020, 90, 660–666. [Google Scholar] [CrossRef]

- Sapiga, V.; Polischuk, G.; Breus, N.; Osmak, T. Enzymatic destruction of protopectin in vegetable raw materials to increase its structuring ability in ice cream. Ukr. Food J. 2021, 10, 321–332. [Google Scholar] [CrossRef]

- Petravić-Tominac, V.; Zechner-Krpan, V.; Grba, S.; Srečec, S.; Panjkota-Krbavčić, I.; Vidović, L. Biological effects of yeast β-glucans. Agric. Conspec. Sci. 2010, 75, 149–158. [Google Scholar]

- Vyrova, D.V.; Selezneva, I.S. Isolation of beta-glucan from yeast and its use as a dietary supplement for low-fat yoghurt manufacturing. AIP Conf. Proc. 2019, 2174, 020266. [Google Scholar] [CrossRef]

- Xu, X.; Pu, Q.; He, L.; Na, Y.; Wu, F.; Jin, Z. Rheological and SEM studies on the interaction between spent brewer’s yeast β-glucans and κ-carrageenan. J. Texture Stud. 2009, 40, 482–496. [Google Scholar] [CrossRef]

- Du, Q.; Zhou, L.; Lyu, F.; Liu, J.; Ding, Y. The complex of whey protein and pectin: Interactions, functional properties and applications in food colloidal systems—A review. Colloids Surf. B Biointerfaces 2022, 210, 112253. [Google Scholar] [CrossRef] [PubMed]

- Siew, C.K.; Williams, P.A.; Young, N.W. New insights into the mechanism of gelation of alginate and pectin: Charge annihilation and reversal mechanism. Biomacromolecules 2005, 6, 963–969. [Google Scholar] [CrossRef] [PubMed]

- Caballero, B.; Trugo, L.; Finglas, P. Encyclopedia of Food Sciences and Nutrition, 2nd ed.; Elsevier Science BV: Amsterdam, The Netherlands, 2003; pp. 1–10. [Google Scholar]

- Raikos, V.; Grant, S.B.; Hayes, H.; Ranawana, V. Use of β-glucan from spent brewer’s yeast as a thickener in skimmed yogurt: Physicochemical, textural, and structural properties related to sensory perception. J. Dairy Sci. 2018, 101, 5821–5831. [Google Scholar] [CrossRef] [PubMed]

- Gardiner, T.; Carter, G. β-glucan biological activities: A review. Glycosci. Nutr. 2000, 1, 1–6. [Google Scholar]

- Thammakiti, S.; Suphantharika, M.; Phaesuwan, T.; Verduyn, C. Preparation of spent brewer’s yeast β-glucans for potential applications in the food industry. Int. J. Food Sci. Technol. 2004, 39, 21–29. [Google Scholar] [CrossRef]

- Ren, S.; Jiménez-Flores, R.; Giusti, M.M. The interactions between anthocyanin and whey protein: A review. Compr. Rev. Food Sci. Food Saf. 2021, 20, 5992–6011. [Google Scholar] [CrossRef]

| Ingredient | Content (%) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| S.1 | S.2 | S.3 | S.4 | S.5 | S.6 | S.7 | S.8 | S.9 | |

| Whey powder | 7.0 | 7.0 | 7.0 | 7.0 | 7.0 | 7.0 | 7.0 | 7.0 | 7.0 |

| White sugar | 17.0 | 17.0 | 17.0 | 17.0 | 17.0 | 17.0 | 17.0 | 17.0 | 17.0 |

| Stabilization system | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 |

| Oat β-glucan | – | 0.75 | – | – | – | – | – | – | – |

| Yeast β-glucan | – | – | 0.5 | – | – | – | – | – | – |

| Protein complex | – | – | – | 3.0 | 4.5 | 3.0 | 4.5 | 3.0 | 4.5 |

| Beet | – | – | – | 10.0 | 10.0 | – | – | – | – |

| Broccoli | – | – | – | – | – | 10.0 | 10.0 | – | – |

| Zuchinni | – | – | – | – | – | – | – | 10.0 | 10.0 |

| Water | 75.60 | 74.85 | 75.10 | 62.60 | 61.10 | 62.60 | 61.10 | 62.60 | 61.10 |

| Sample No. | Total Solid (%) | Protein (%) | Fat (%) |

|---|---|---|---|

| 1. | 24.05 ± 0.53 a | 0.75 ± 0.01 a | 0.51 ± 0.01 a |

| 2. | 24.81 ± 0.28 a | 0.79 ± 0.01 a | 0.52 ± 0.01 a |

| 3. | 24.57 ± 0.55 a | 0.76 ± 0.02 a | 0.51 ± 0.01 a |

| 4. | 29.53 ± 0.40 a | 2.41 ± 0.09 b | 0.55 ± 0.02 a |

| 5. | 31.02 ± 0.51 c | 3.23 ± 0.12 a | 0.55 ± 0.01 a |

| 6. | 29.38 ± 0.46 a | 2.39 ± 0.05 b | 0.59 ± 0.02 a |

| 7. | 31.16 ± 0.11 c | 3.18 ± 0.13 c | 0.54 ± 0.02 a |

| 8. | 29.32 ± 0.59 a | 2.30 ± 0.07 a | 0.58 ± 0.01 a |

| 9. | 30.95 ± 0.52 b | 3.28 ± 0.04 c | 0.61 ± 0.01 a |

| Sample No. | Surface Tension mN/m | Water Activity aw |

|---|---|---|

| 1. | 46.422 ± 0.748 ab | 0.969 ± 0.008 bc |

| 2. | 35.801 ± 0.472 d | 0.963 ± 0.007 bc |

| 3. | 36.448 ± 0.305 d | 0.962 ± 0.004 c |

| 4. | 39.590 ± 0.451 c | 0.960 ± 0.005 c |

| 5. | 40.484 ± 0.815 c | 0.963 ± 0.006 bc |

| 6. | 46.609 ± 0.541 ab | 0.969 ± 0.005 ab |

| 7. | 46.085 ± 0.885 ab | 0.968 ± 0.007 b |

| 8. | 47.228 ± 0.992 ab | 0.987 ± 0.003 a |

| 9. | 46.998 ± 1.087 ab | 0.985 ± 0.007 a |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tomczyńska-Mleko, M.; Mykhalevych, A.; Sapiga, V.; Polishchuk, G.; Terpiłowski, K.; Mleko, S.; Sołowiej, B.G.; Pérez-Huertas, S. Influence of Plant-Based Structuring Ingredients on Physicochemical Properties of Whey Ice Creams. Appl. Sci. 2024, 14, 2465. https://doi.org/10.3390/app14062465

Tomczyńska-Mleko M, Mykhalevych A, Sapiga V, Polishchuk G, Terpiłowski K, Mleko S, Sołowiej BG, Pérez-Huertas S. Influence of Plant-Based Structuring Ingredients on Physicochemical Properties of Whey Ice Creams. Applied Sciences. 2024; 14(6):2465. https://doi.org/10.3390/app14062465

Chicago/Turabian StyleTomczyńska-Mleko, Marta, Artur Mykhalevych, Victoria Sapiga, Galyna Polishchuk, Konrad Terpiłowski, Stanisław Mleko, Bartosz G. Sołowiej, and Salvador Pérez-Huertas. 2024. "Influence of Plant-Based Structuring Ingredients on Physicochemical Properties of Whey Ice Creams" Applied Sciences 14, no. 6: 2465. https://doi.org/10.3390/app14062465

APA StyleTomczyńska-Mleko, M., Mykhalevych, A., Sapiga, V., Polishchuk, G., Terpiłowski, K., Mleko, S., Sołowiej, B. G., & Pérez-Huertas, S. (2024). Influence of Plant-Based Structuring Ingredients on Physicochemical Properties of Whey Ice Creams. Applied Sciences, 14(6), 2465. https://doi.org/10.3390/app14062465