Study of Noise Effect of Slag Storage Technology on Surrounding Environment

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Study Area Description: Metallurgical Plant

2.1.2. Integrating Sound Level Meter

2.1.3. Software: CadnaA

- creating 3D models. The possibility of creating dimensionally accurate objects, devices, machines, etc. in 3D directly in the working environment of the software;

- the possibility of defining the acoustic properties of objects, walls, partitions, devices, etc.;

- the possibility to choose from 4 calculation methods;

- calculation accuracy;

- the possibility of finding the expected value of any point on the surface;

- automatically takes into account the size of the space;

- dependence of the calculation on the acoustic performance of the devices.

- complexity of information and knowledge from the given area;

- lengthy modeling;

- higher price.

2.2. Methods

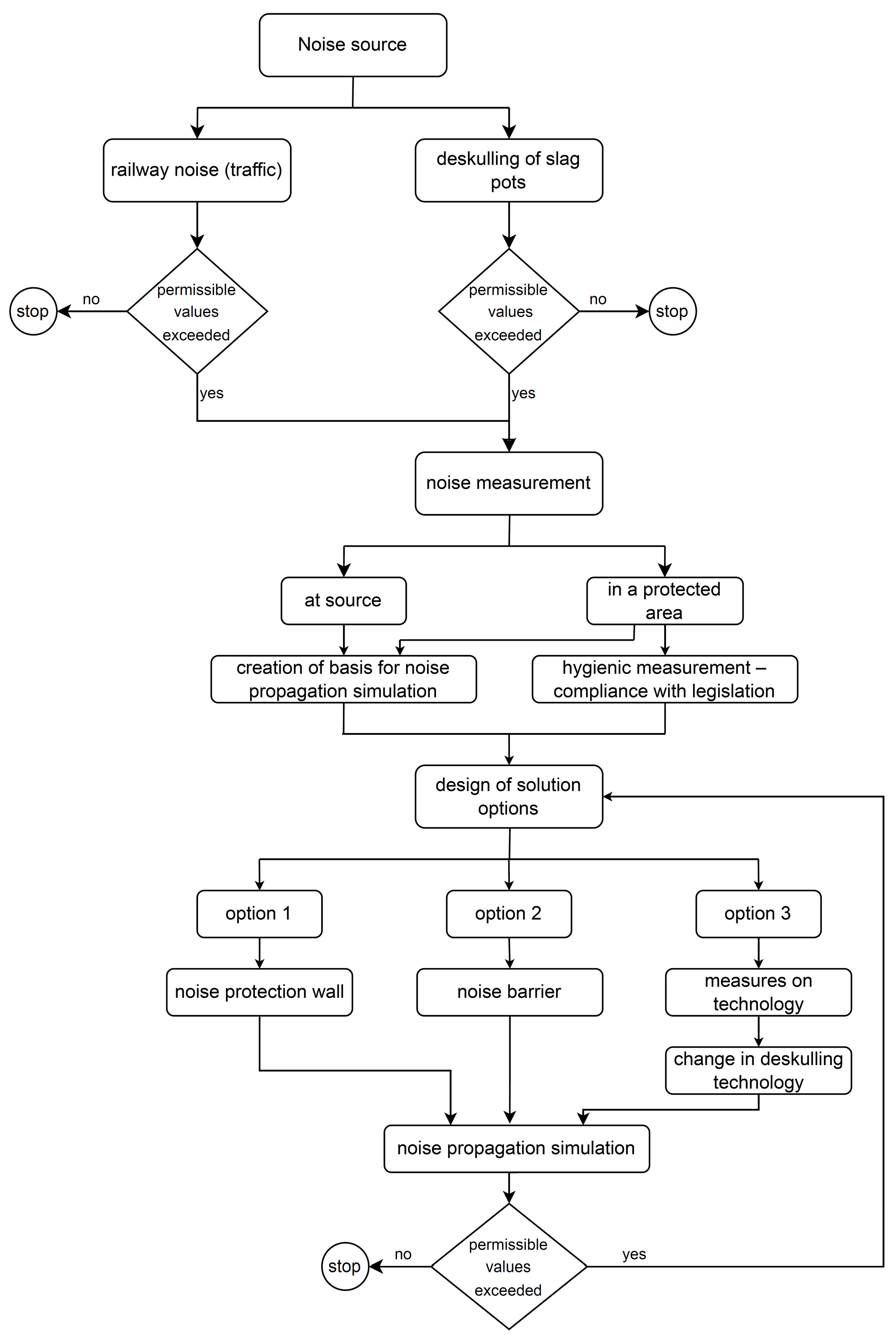

2.2.1. Design of a Methodology for Minimizing the Effects of Slag Storage Technology

2.2.2. Theoretical Basis for the Calculation and Prediction of Noise Propagation

Modeling of Industrial Noise

- source type (point, area, and line);

- frequency spectrum of acoustic power in octave bands;

- operating time composed on the basis of the annual average;

- positioning using orthogonal coordinates;

- directional characteristics of the source;

- dimensions and spatial orientation;

- a decrease in the bending conditions of sound propagation (positive vertical gradient of the effective speed of sound propagation) from the source to the receiver;

- homogeneous atmospheric conditions (zero vertical gradient of sound propagation speed) in the entire calculation area of propagation [20].

- calculation of attenuation under favorable conditions;

- calculation of attenuation under homogeneous conditions;

- geometric divergences;

- the influence of the terrain surface and its properties;

- diffractions;

- reflections.

Source Description and Basic Equations

Corrections

- 1.

- Geometric divergence

- 2.

- Sound absorption in the atmosphere

- 3.

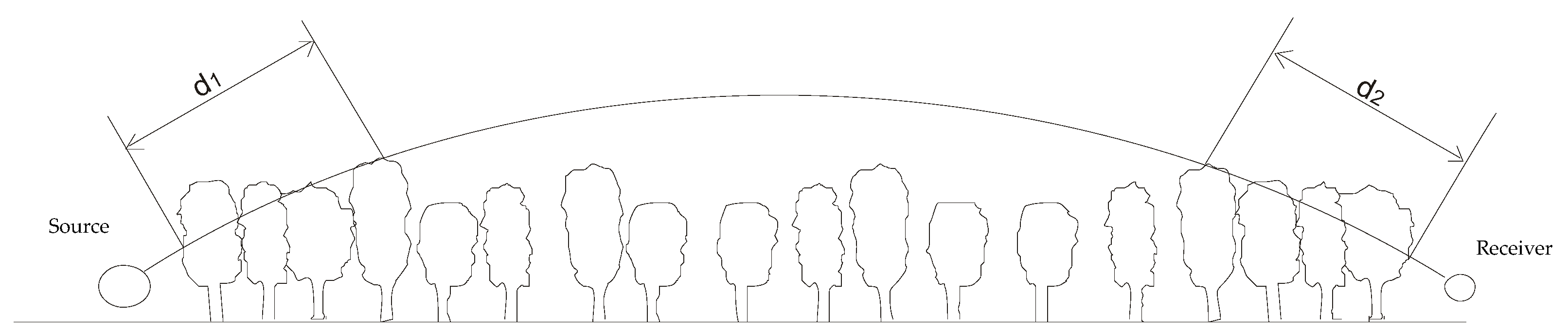

- Ground surface effect

- (a)

- the source area is in the space from the source towards the immission point at a distance of 30 hs, with a maximum distance of dp, where hs is the height of the source and dp is the projection of the distance from the source to the immission point onto the ground plane;

- (b)

- the area of the immission point is in space from the immission point towards the source at a distance of 30 hr, with a maximum distance of dp, where hr is the height of the receiver;

- (c)

- the median area is at the distance between the source area and the immission point area; if dp < (30 hs + 30 hr), the source area and the immission point area overlap and there is no median area.

- to calculate the attenuation component for the source area specified by the ground index ;

- to calculate the component for the receiver area specified by the ground surface index ;

- and to calculate the component for the median area specified by the ground surface index .

- 4.

- Attenuation due to the barrier

- 5.

- Additional attenuation

2.2.3. Methodology for Calculating Equivalent Noise Levels

- dividing the entire problem to be solved into subproblems that address a specific noise emission rate, in the form of inputting the sound power level A or sound pressure level A, from the point sources of acoustic energy used in the isophone prediction;

- for noise sources whose sound power levels A vary over the time period under consideration, an equivalent value for the time period under consideration shall be determined;

- for each of the point sources used, the direct propagation of acoustic energy in the outdoor environment, corrected for possible reflections from existing terrain and attenuation from existing objects, shall be addressed;

- the resulting noise level at the site under consideration is calculated as a superposition of the effects from the individual elementary sources and the acoustic energy;

- only the airborne noise component is considered;

3. Results and Discussion

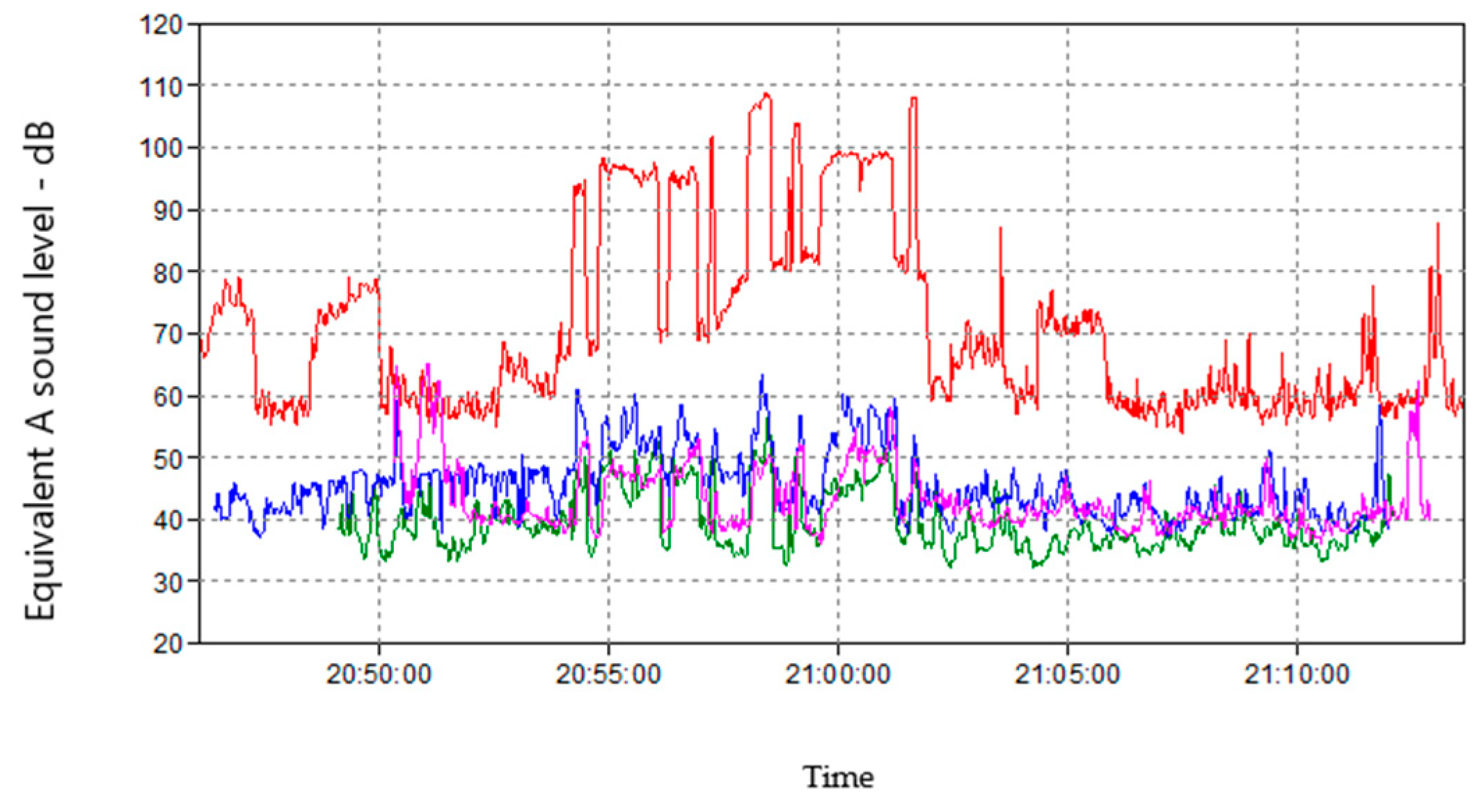

3.1. Measurement Results

- lifting the arm with a hydraulic hammer;

- handling of the ladle car—plugging into the electrical grid;

- lifting of the slag pot and the dumping of slag;

- deskulling of the slag.

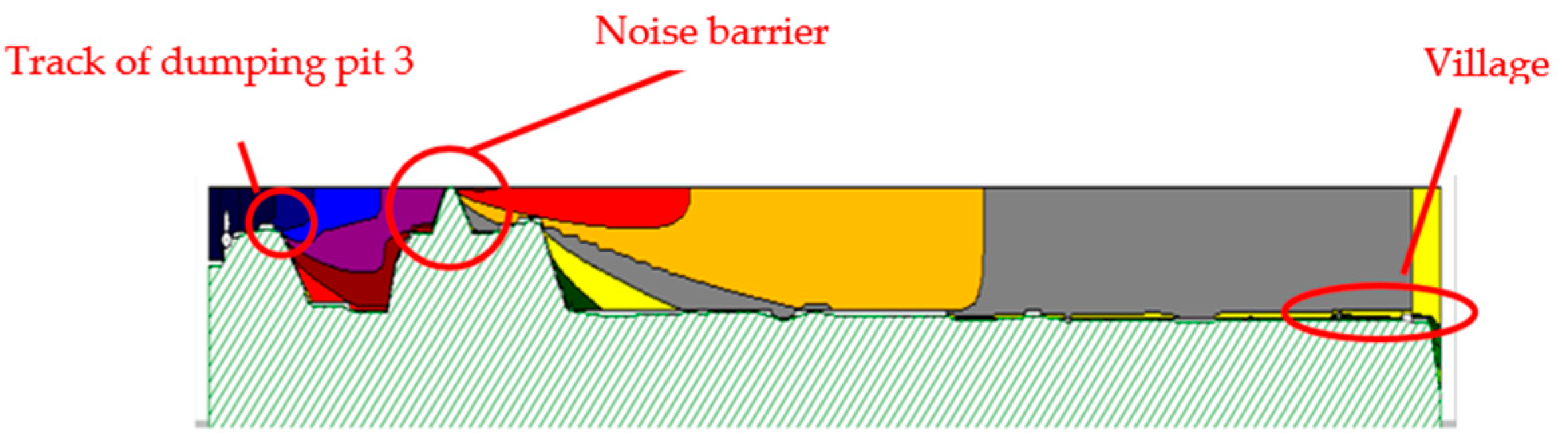

- Measurement point M1 was located on the slag dump at a distance of 14 m from the track axis, on which a train with ten slag pots was at a height of 1.5 m above the ground level.

- Measurement point M2 was located on the road next to the slag landfill 25 m from the road axis at the time of measurement without vegetation at a height of 1.5 m above ground level at a distance of 940 m from the source. The measurement point was in the acoustic shadow of the landfill.

- Measurement point M3 was located in the village on the boundary of the land adjacent to the family house at a distance of 1710 m from the source at a height of 1.5 m above ground level.

- Measurement point M4 was situated on the road on the boundary of the land adjacent to the family house at a distance of 1980 m from the source at a height of 1.5 m above ground level.

- average values for September—the month in which the most slag pots were deskulled; the intensity of slag pot deskulling was taken from the data provided by the metallurgical plant (1655 slag pots during the reference time interval day, 661 slag pots during the reference time interval evening, and 1109 slag pots during the reference time interval night); see Table 1.

- the day during which the most slag pots were deskulled; see Table 2:

- reference time interval day—84 slag pots;

- reference time interval evening—38 slag pots;

- reference time interval night—60 slag pots.

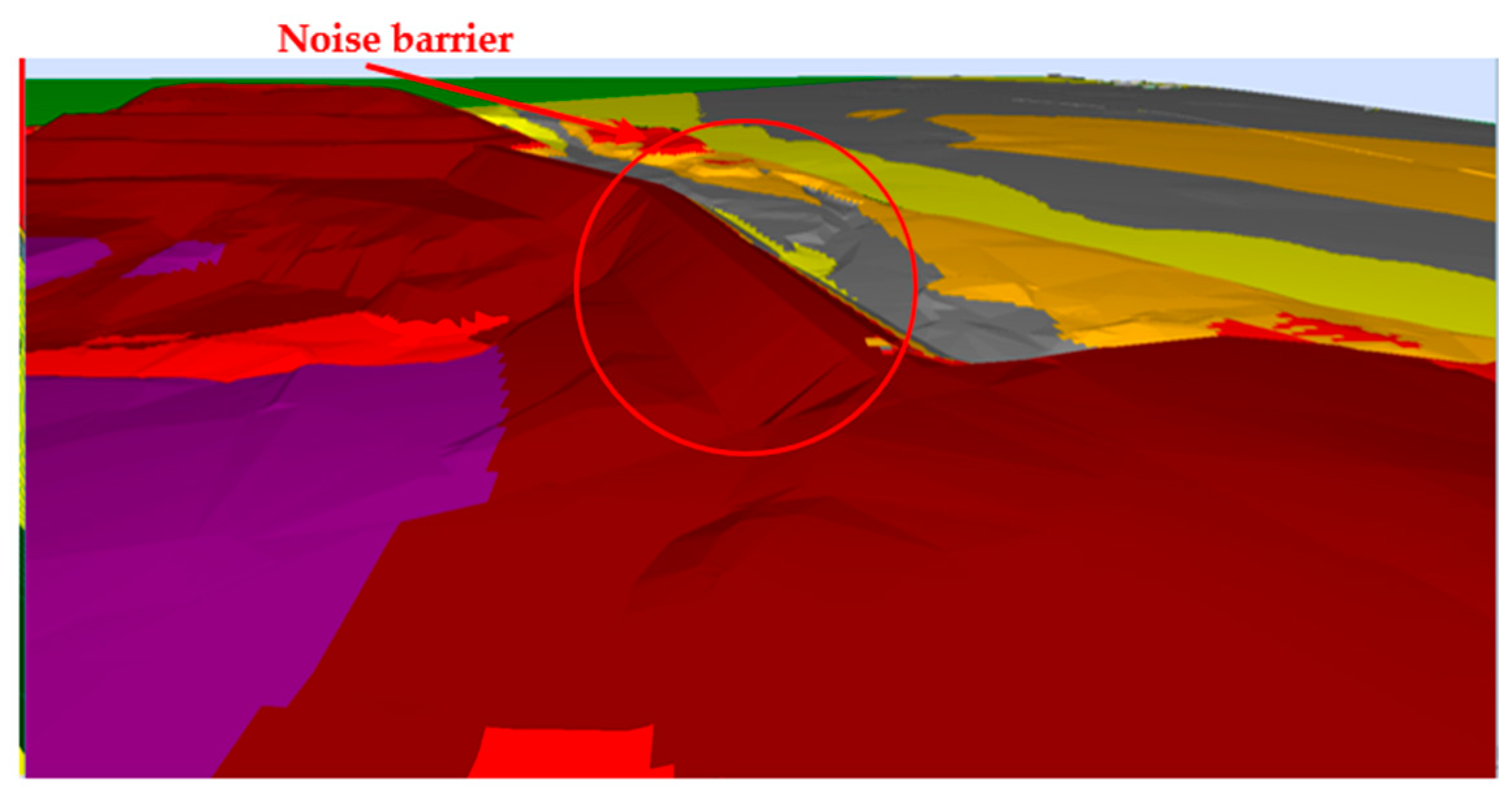

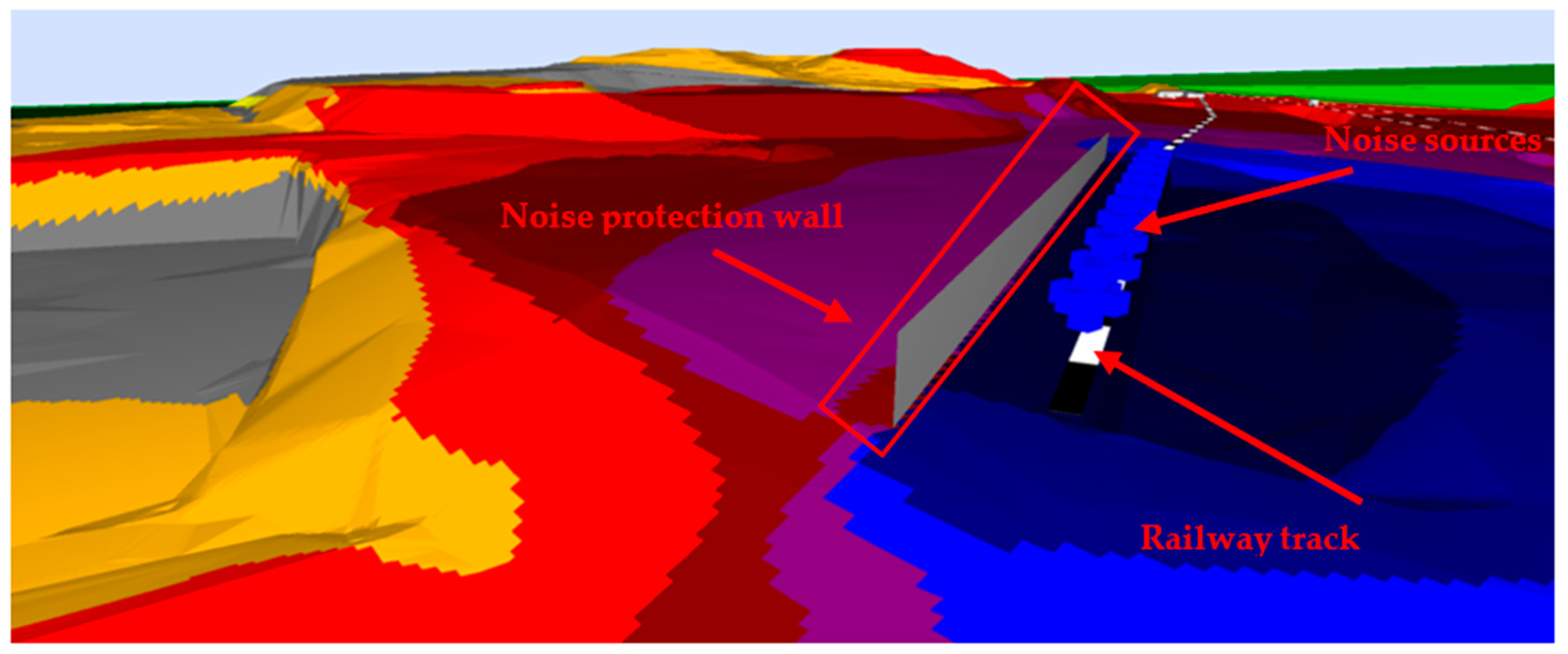

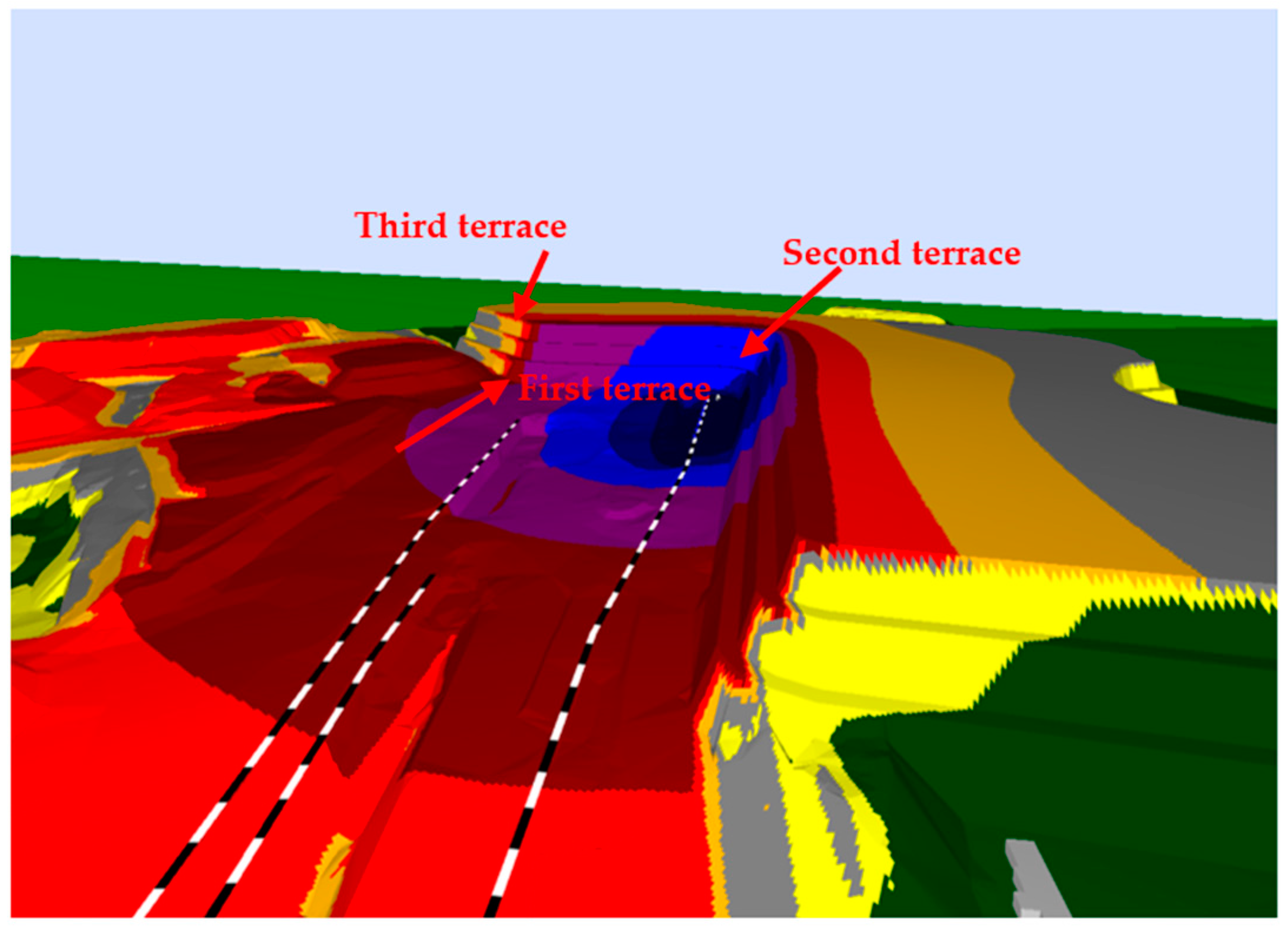

3.2. Proposal of Measures and Discussion

- first terrace, height 2 m;

- first terrace, height 5 m;

- first terrace, height 10 m;

- first terrace, height 13 m;

- second terrace, height 11 m;

- third terrace, height 11 m.

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Levi, E.; Sgarbi, S.; Piana, E.A. Acoustic Characterization of Some Steel Industry Waste Materials. Appl. Sci. 2021, 11, 5924. [Google Scholar] [CrossRef]

- Schwietz, J.; Panic, B. Utilisation of noise level emitted by the electric arc furnace (eaf) for optimisation of the feeding process of slag foaming materials. Metalurgia 2022, 61, 753–756. [Google Scholar]

- Butorina, I.; Butorina, M.; Kulkin, D.; Shashurin, A. Innovative Approaches to Noise Reduction in Metallurgy. Bull. Tabbin Inst. Metall. Stud. 2022, 110, 68–80. [Google Scholar] [CrossRef]

- Bolteho, C.T.; Lopes Paz, A.P.M.; Goncalves, A.M.; Frota, S. Comparative study of audiometrics tests on metallurgical workers exposed to noise only as well as noise associated to the handling of chemical products. Braz. J. Otorhinolaryngol. 2009, 75, 51–57. [Google Scholar]

- Kim, Y.I.; Kim, W.J. Development of noise mapping system to manage the interior room noise of power plants. J. Acoust. Soc. Korea 2021, 40, 92–98. [Google Scholar]

- Bockstael, A.; De Bruyne, L.; Vinck, B.; Botteldooren, D. Hearing protection in industry: Companies’ policy and workers’ perception. Int. J. Ind. Ergon. 2013, 43, 512–517. [Google Scholar] [CrossRef]

- Meegahapola, P.A.; Prabodanie, R.A.R. Impact of environmental conditions on workers’ productivity and health. Int. J. Workplace Health Manag. 2018, 11, 74–84. [Google Scholar] [CrossRef]

- Mohammed, M.I.; Rabeea, M.A. Effects of Noise Pollution from Electric Backup Generators on the Operators’ Health. Pertanika J. Sci. Technol. 2021, 29, 2675–2687. [Google Scholar] [CrossRef]

- Manwar, V.D.; Mandal, B.B.; Pal, A.K. Environmental propagation of noise in mines and nearby villages: A study through noise mapping. Noise Health 2016, 18, 185–193. [Google Scholar]

- Casas, W.J.P.; Cordeiro, E.P.; Mello, T.C.; Zannin, P.H.T. Noise mapping as a tool for controlling industrial noise pollution. J. Sci. Ind. Res. 2014, 73, 262–266. [Google Scholar]

- Lokhande, S.; Gautam, R.; Dhawale, S.; Jain, M.; Bodhe, G. Evaluation of practical framework for industrial noise mapping: A case study. Noise Health 2019, 21, 194–199. [Google Scholar]

- Del Amor, M.M.D.; Caracena, A.B.; Llorens, M.; Esquembre, F. Tools for evaluation and prediction of industrial noise sources. Application to a wastewater treatment plant. J. Environ. Manag. 2022, 319, 115725. [Google Scholar] [CrossRef]

- Lumnitzer, E.; Andrejiova, M.; Yehorova, A. Analysis of the Dependence of the Apparent Sound Reduction Index on Excitation Noise Parameters. Appl. Sci. 2022, 10, 8557. [Google Scholar] [CrossRef]

- da Silva, V.A.R.; Kruchewsch, M.M.; Lavinsky, J.; Pauna, H.F.; Guimaraes, A.C.; Castilho, A.M.; Duarte, A.S.M.; Crespo, A.N. Progressive Asymmetry in Occupational Noise-Induced Hearing Loss: A Large Population-Based Cohort Study with a 15-Year Follow-Up. J. Int. Adv. Otol. 2021, 17, 520–525. [Google Scholar]

- Bagherian, E.R. Improvement of productivity in kuwait steel using ergonomics parameters by controlling the noise and temperature. In Proceedings of the 29th International Conference on Metallurgy and Materials (METAL 2020), Brno, Czech Republic, 20–22 May 2020; pp. 74–79. [Google Scholar]

- Panneerselvam, T.; Kandavel, T.K.; Sreenivas, S.A.; Karthik, S.; Andru, M.M. Effects of Working Parameters on Performance Characteristics of Cutting Tools Processed through Powder Metallurgy under Turning Operation. J. Mater. Eng. Perform. 2021, 30, 2890–2898. [Google Scholar] [CrossRef]

- Gökalp, I.; Emre Uz, V.; Saltan, M.; Tutumluer, E. Technical and environmental evaluation of metallurgical slags as aggregate for sustainable pavement layer applications. Transp. Geotech. 2018, 14, 61–69. [Google Scholar] [CrossRef]

- WHO. Environmental Noise Guidelines for the European Region; Regional Office for Europe, World Health Organization: Geneva, Switzerland, 2018; Available online: https://www.who.int/europe/health-topics/environmental-health#tab=tab_1 (accessed on 20 December 2023).

- Wosniacki, G.G.; Zannin, P.H.T. Framework to manage railway noise exposure in Brazil based on field measurements and strategic noise mapping at the local level. Sci. Total Environ. 2021, 757, 14372. [Google Scholar] [CrossRef] [PubMed]

- Yang, W.; He, J.; He, C.; Cai, M. Evaluation of urban traffic noise pollution based on noise maps. Transp. Research. Transp. Environ. 2020, 87, 102516. [Google Scholar] [CrossRef]

- ISO 1996-2:2007; Description, Measurement And Assessment Of Environmental Noise, Part 2: Determination Of Environmental Noise Levels. Available online: https://www.iso.org/standard/41860.html (accessed on 1 December 2023).

- ISO 9613 1:1993; Attenuation of Sound during Propagation Outdoors, Part 1: Calculation Of The Absorption Of Sound By The Atmosphere. Available online: https://www.iso.org/standard/17426.html (accessed on 1 December 2023).

- ISO 9613 2:1996; Attenuation of Sound during Propagation Outdoors, Part 2: General Method of Calculation. Available online: https://www.iso.org/standard/20649.html (accessed on 1 December 2023).

- Sukaj, S.; Iannace, G.; Ciaburro, G.; Iannace, F. Wind Turbines Noise: Predictions and Measurements. Rom. J. Acoust. Vib. 2021, 18, 69–75. [Google Scholar]

- Lan, Z.Q.; He, C.M.; Cai, M. Urban road traffic noise spatiotemporal distribution mapping using multisource data. Transp. Res. 2020, 82, 102323. [Google Scholar] [CrossRef]

- Smol, M. Towards Zero Waste in Steel Industry: Polish Case Study. J. Steel Struct. Constr. 2015, 1, 102. [Google Scholar] [CrossRef]

- Rondi, L.; Bregoli, G.; Sorlini, S.; Cominoli, L.; Collivignarelli, C.; Plizzari, G. Concrete with EAF steel slag as aggregate: A comprehensive technical and environmental characterization. Compos. Part B Eng. 2016, 90, 195–202. [Google Scholar] [CrossRef]

- Ilutiu-Varvara, D.A.; Aciu, C. Metallurgical Wastes as Resources for Sustainability of the Steel Industry. Sustainability 2022, 14, 5488. [Google Scholar] [CrossRef]

- Chamling, P.K.; Haldar, S.; Patra, S. Physico-Chemical and Mechanical Characterization of Steel Slag as Railway Ballast. Indian Geotech. J. 2020, 50, 267–275. [Google Scholar] [CrossRef]

- Friedrich, B. Sustainable Utilization of Metals-Processing, Recovery and Recycling. Metals 2019, 9, 769. [Google Scholar] [CrossRef]

- Izydorczyk, G.; Mikula, K.; Skrzypczak, D.; Moustakas, K.; Witek-Krowiak, A.; Chojnacka, K. Potential environmental pollution from copper metallurgy and methods of management. Environ. Res. 2021, 197, 111050. [Google Scholar] [CrossRef] [PubMed]

- Bevilacqua, A.; Iannace, G.; Lombardi, I.; Trematerra, A. 2D Sonic Acoustic Barrier Composed of Multiple-Row Cylindrical Scatterers: Analysis with 1:10 Scaled Wooden Models. Appl. Sci. 2022, 12, 6302. [Google Scholar] [CrossRef]

- Ekici, I.; Bougdah, H. A Review of Research on Environmental Noise Barriers. Build. Acoust. 2003, 10, 289–323. [Google Scholar] [CrossRef]

| Measurement Point | Reference Time Interval Tref | Assessed Value of the Equivalent Sound Pressure Level A for the Reference Time Interval LAeq,Tref dB | Permissible Values dB | Exceedance dB |

|---|---|---|---|---|

| M3 | day | 49.0 | 50 | - |

| evening | 49.8 | 50 | - | |

| night | 49.0 | 45 | 4.0 | |

| M4 | day | 42.7 | 50 | - |

| evening | 43.5 | 50 | - | |

| night | 42.7 | 45 | - |

| Measurement Point | Reference Time Interval Tref | Assessed Value of the Equivalent Sound Pressure Level A for the Reference Time Interval LAeq,Tref dB | Permissible Values dB | Exceedance dB |

|---|---|---|---|---|

| M3 | day | 51.0 | 50 | 1.0 |

| evening | 52.3 | 50 | 2.3 | |

| night | 51.3 | 45 | 6.3 | |

| M4 | day | 44.7 | 50 | - |

| evening | 46.0 | 50 | - | |

| night | 45.0 | 45 | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yehorova, A.; Lumnitzer, E. Study of Noise Effect of Slag Storage Technology on Surrounding Environment. Appl. Sci. 2024, 14, 1678. https://doi.org/10.3390/app14041678

Yehorova A, Lumnitzer E. Study of Noise Effect of Slag Storage Technology on Surrounding Environment. Applied Sciences. 2024; 14(4):1678. https://doi.org/10.3390/app14041678

Chicago/Turabian StyleYehorova, Anna, and Ervin Lumnitzer. 2024. "Study of Noise Effect of Slag Storage Technology on Surrounding Environment" Applied Sciences 14, no. 4: 1678. https://doi.org/10.3390/app14041678

APA StyleYehorova, A., & Lumnitzer, E. (2024). Study of Noise Effect of Slag Storage Technology on Surrounding Environment. Applied Sciences, 14(4), 1678. https://doi.org/10.3390/app14041678