Integrated Deep Ultraviolet Doublet Metalens for Projection Imaging

Abstract

1. Introduction

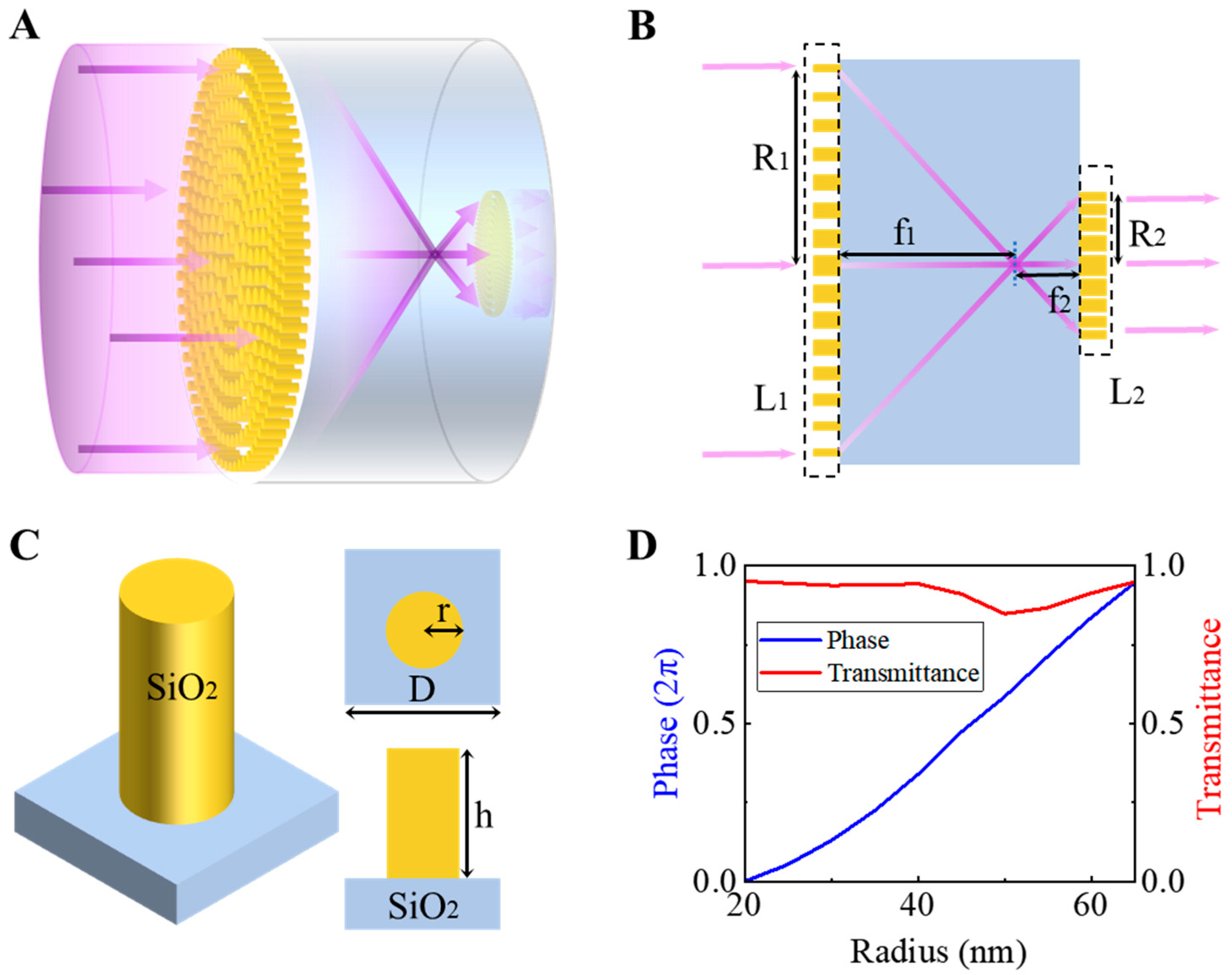

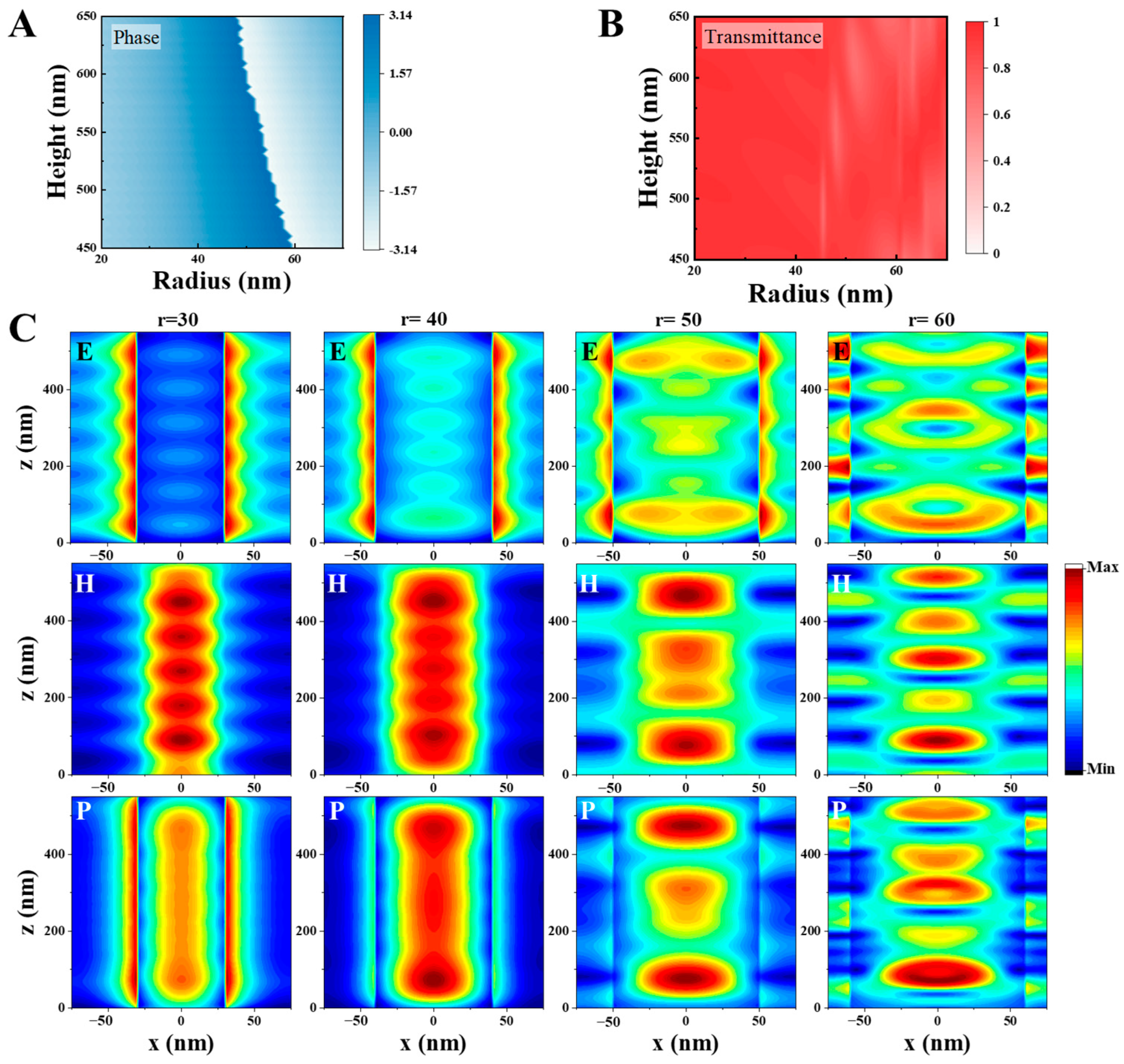

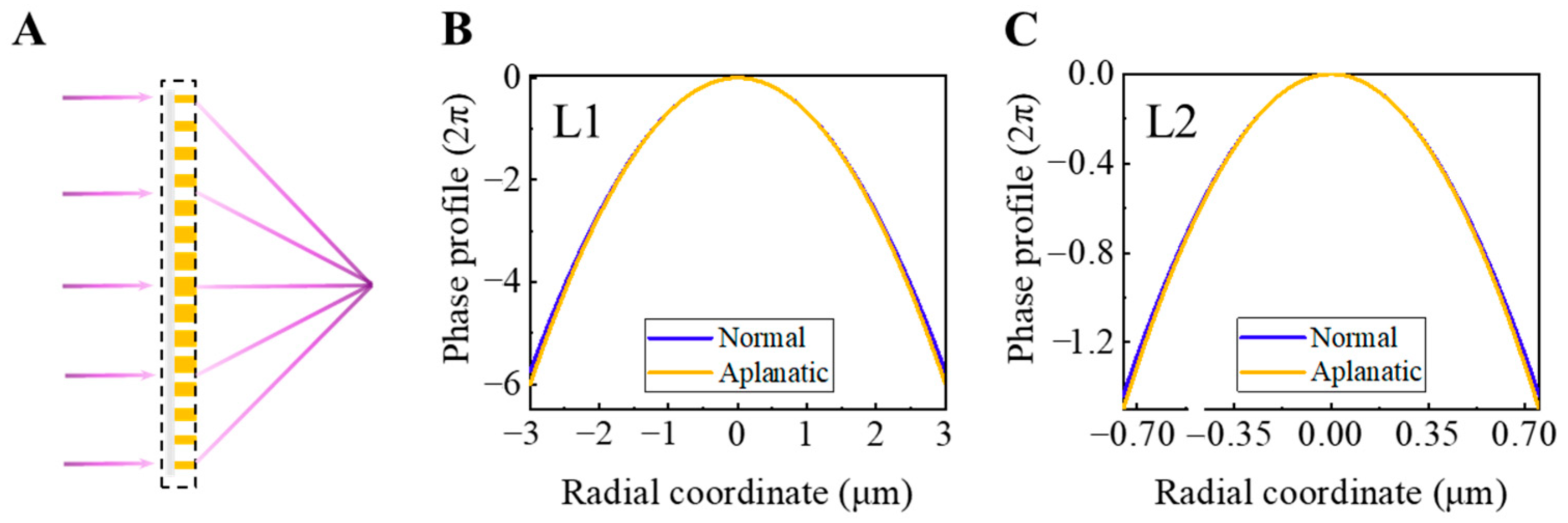

2. Materials and Methods

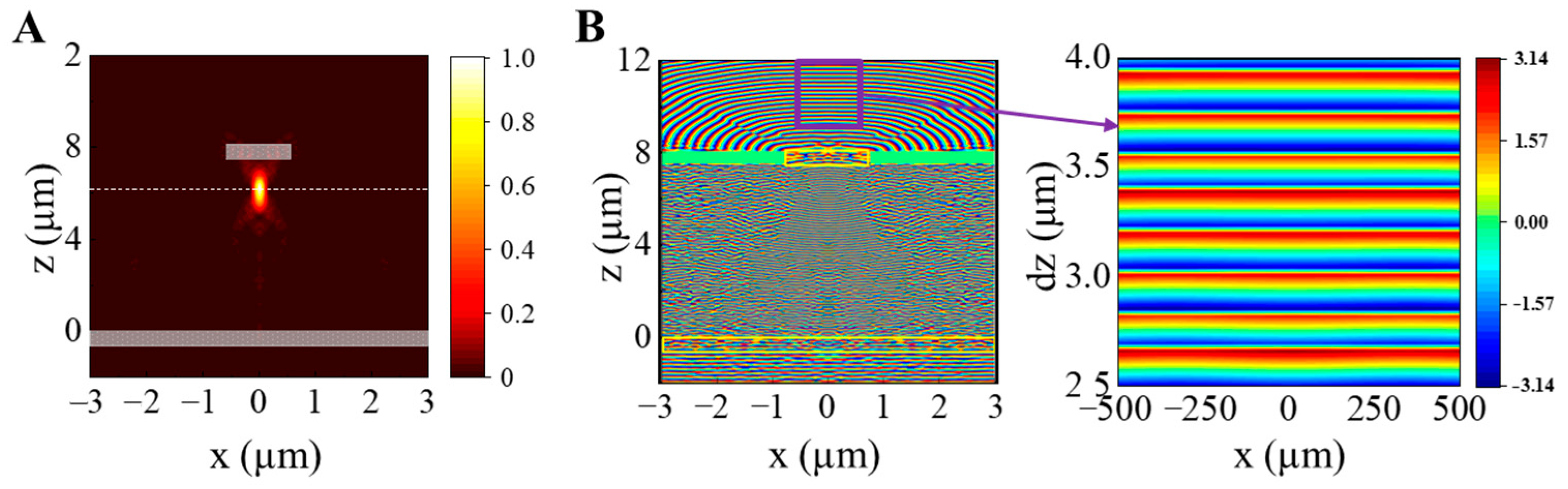

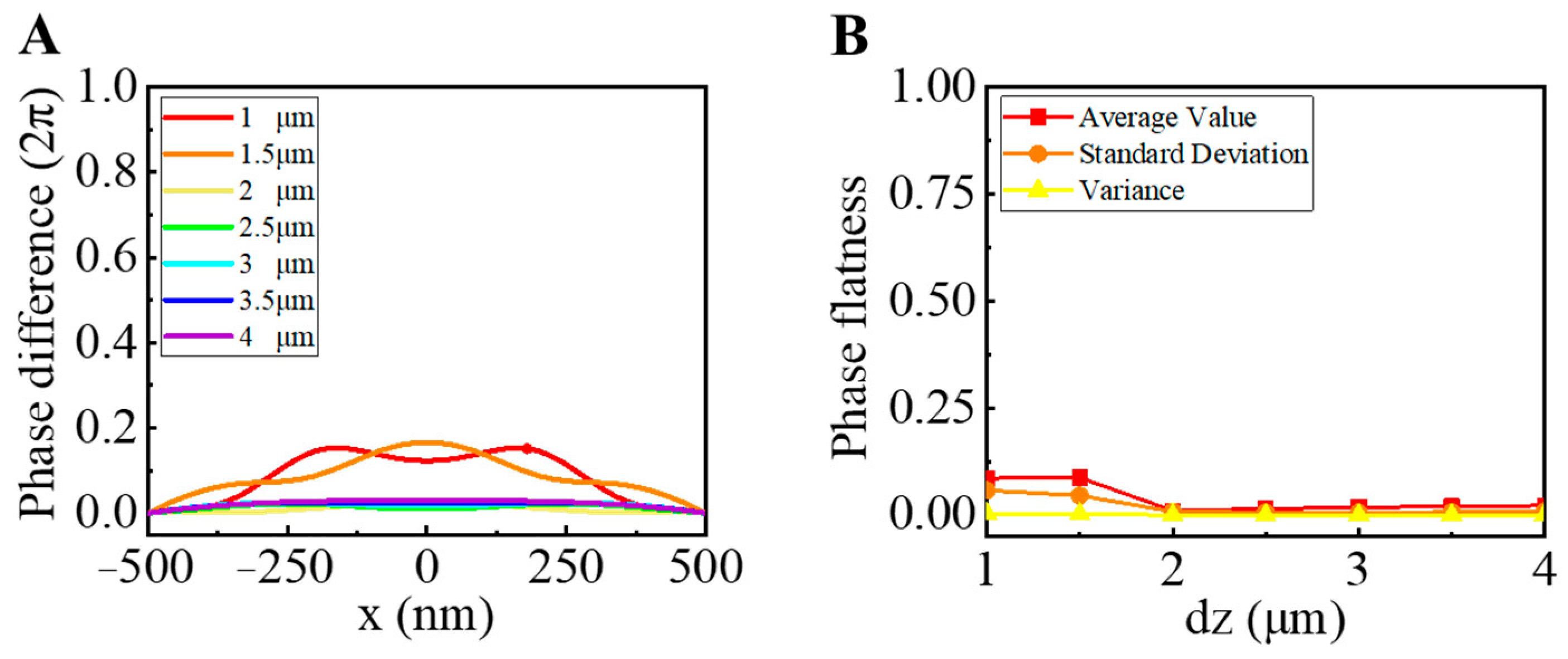

Analysis of Flatness of Outgoing Light

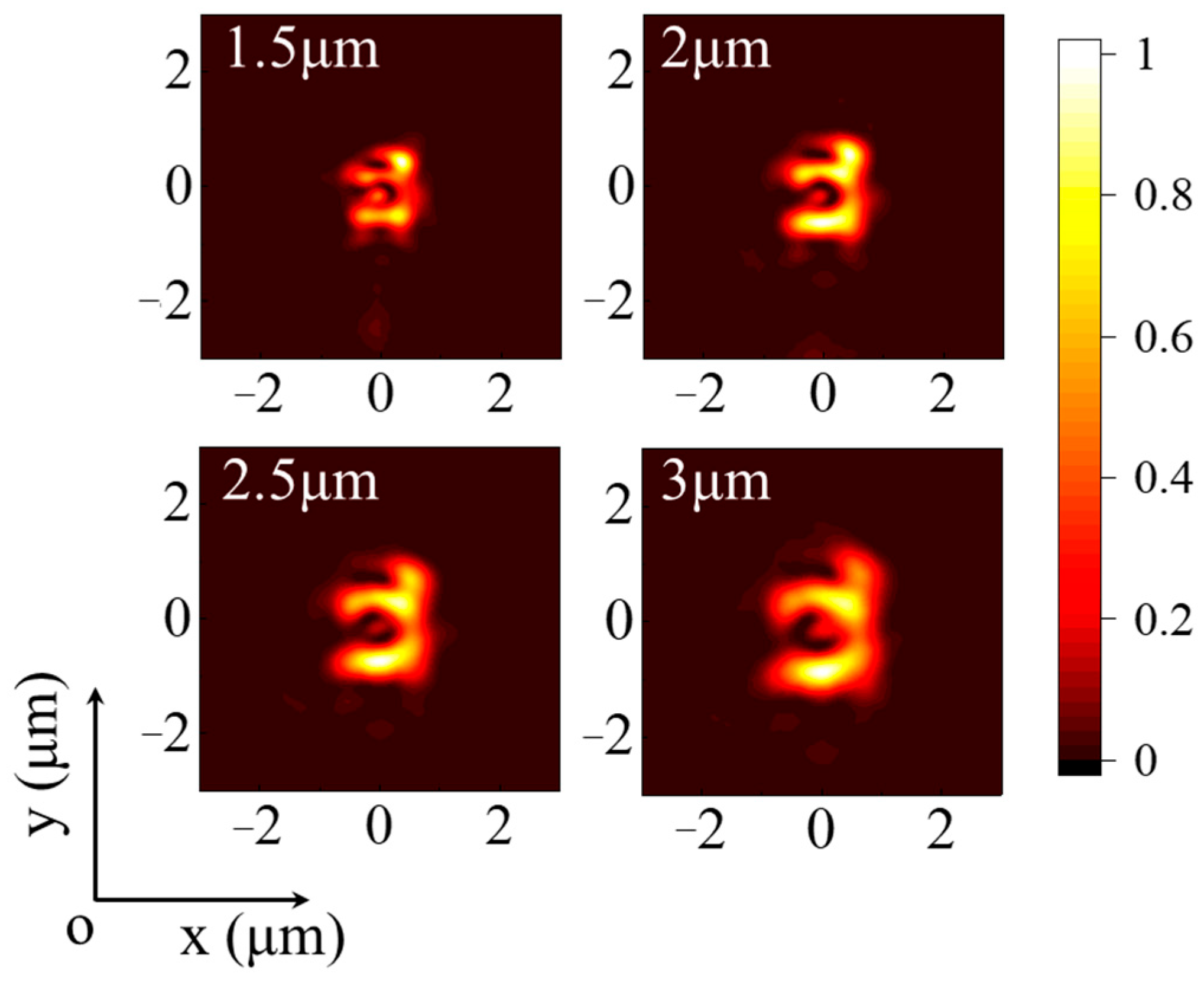

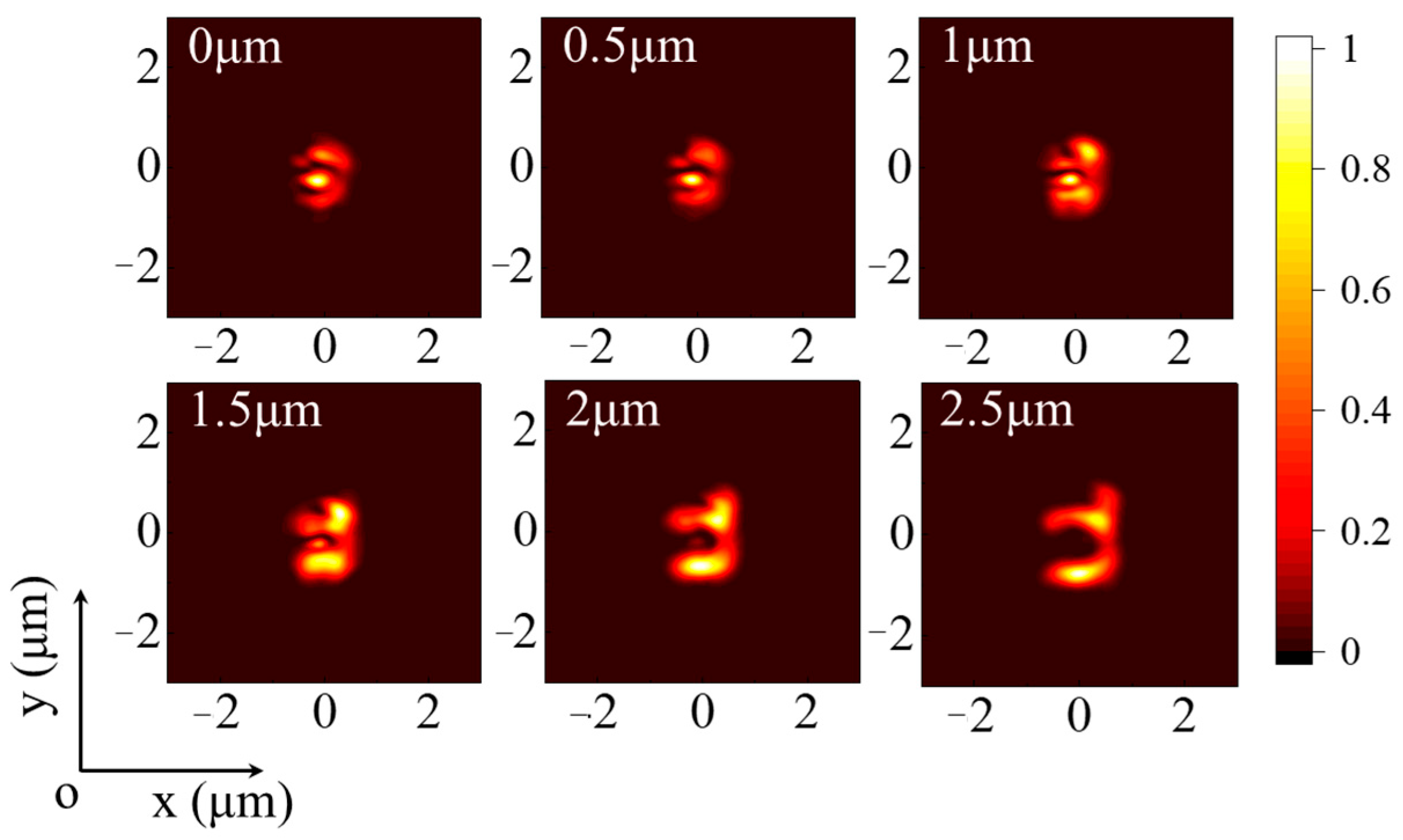

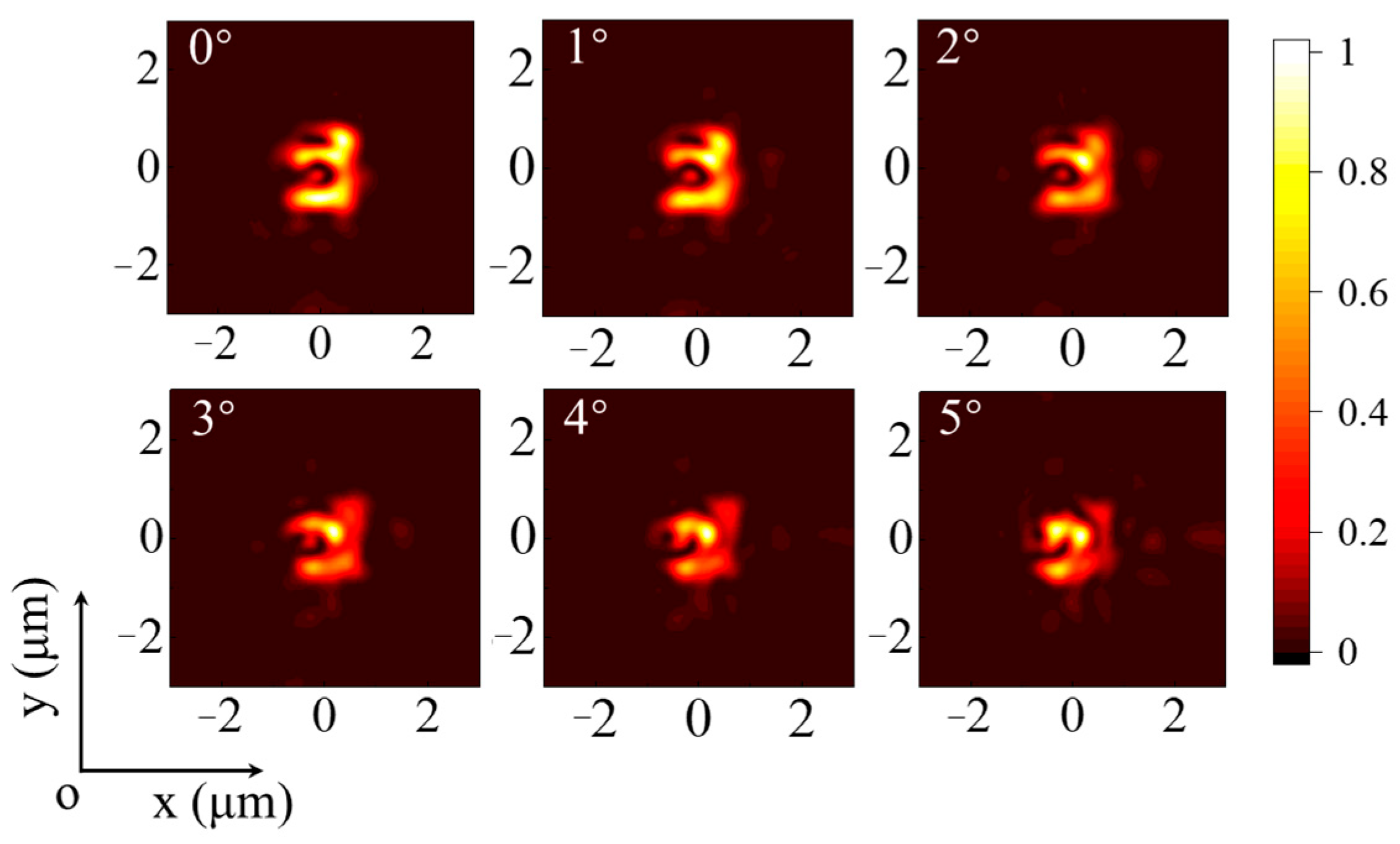

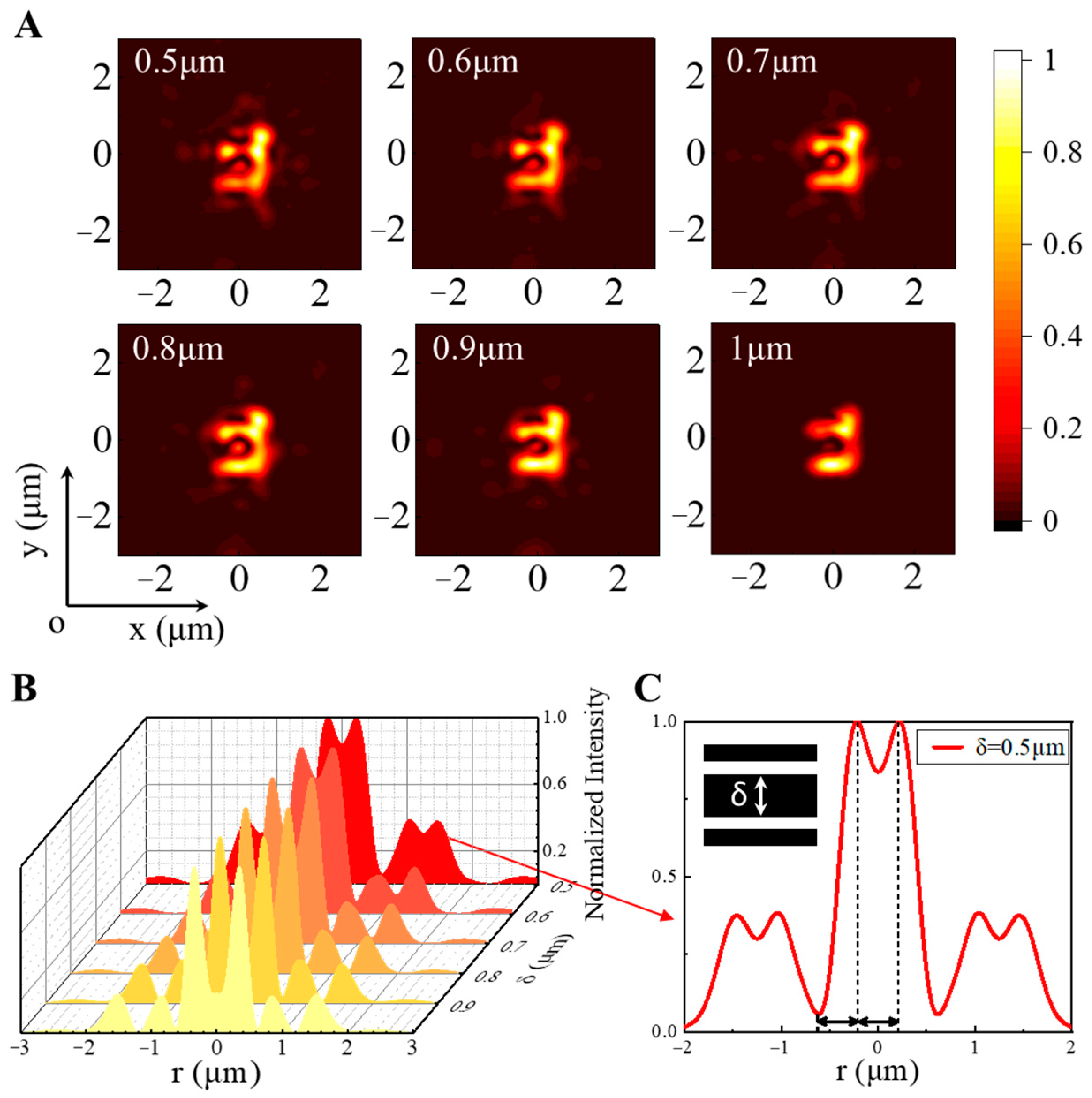

3. Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chang, C.C.; Kort-Kamp, W.J.M.; Nogan, J.; Luk, T.S.; Azad, A.K.; Taylor, A.J.; Dalvit, D.A.R.; Sykora, M.; Chen, H.T. High-Temperature Refractory Metasurfaces for Solar Thermophotovoltaic Energy Harvesting. Nano Lett. 2018, 18, 7665–7673. [Google Scholar] [CrossRef]

- Decker, M.; Chen, W.T.; Nobis, T.; Zhu, A.Y.; Khorasaninejad, M.; Bharwani, Z.; Capasso, F.; Petschulat, J. Imaging Performance of Polarization-Insensitive Metalenses. ACS Photonics 2019, 6, 1493–1499. [Google Scholar] [CrossRef]

- Mohtashami, Y.; DeCrescent, R.A.; Heki, L.K.; Iyer, P.P.; Butakov, N.A.; Wong, M.S.; Alhassan, A.; Mitchell, W.J.; Nakamura, S.; DenBaars, S.P.; et al. Light-emitting metalenses and meta-axicons for focusing and beaming of spontaneous emission. Nat. Commun. 2021, 12, 3591. [Google Scholar] [CrossRef] [PubMed]

- Guo, Y.; Pu, M.; Ma, X.; Li, X.; Shi, R.; Luo, X. Experimental demonstration of a continuous varifocal metalens with large zoom range and high imaging resolution. Appl. Phys. Lett. 2019, 115, 163103. [Google Scholar] [CrossRef]

- Luo, Y.; Chu, C.H.; Vyas, S.; Kuo, H.Y.; Chia, Y.H.; Chen, M.K.; Shi, X.; Tanaka, T.; Misawa, H.; Huang, Y.Y.; et al. Varifocal Metalens for Optical Sectioning Fluorescence Microscopy. Nano Lett. 2021, 21, 5133–5142. [Google Scholar] [CrossRef] [PubMed]

- Wei, Y.; Wang, Y.; Feng, X.; Xiao, S.; Wang, Z.; Hu, T.; Hu, M.; Song, J.; Wegener, M.; Zhao, M.; et al. Compact Optical Polarization-Insensitive Zoom Metalens Doublet. Adv. Opt. Mater. 2020, 8, 2000142. [Google Scholar] [CrossRef]

- Hua, J.; Hua, E.; Zhou, F.; Shi, J.; Wang, C.; Duan, H.; Hu, Y.; Qiao, W.; Chen, L. Foveated glasses-free 3D display with ultrawide field of view via a large-scale 2D-metagrating complex. Light-Sci. Appl. 2021, 10, 213. [Google Scholar] [CrossRef] [PubMed]

- Spagele, C.; Tamagnone, M.; Kazakov, D.; Ossiander, M.; Piccardo, M.; Capasso, F. Multifunctional wide-angle optics and lasing based on supercell metasurfaces. Nat. Commun. 2021, 12, 3787. [Google Scholar] [CrossRef]

- Wang, L.; Kruk, S.; Tang, H.; Li, T.; Kravchenko, I.; Neshev, D.N.; Kivshar, Y.S. Grayscale transparent metasurface holograms. Optica 2016, 3, 194. [Google Scholar] [CrossRef]

- Dixon, K.; Montazeri, A.O.; Shayegannia, M.; Barnard, E.S.; Cabrini, S.; Matsuura, N.; Holman, H.Y.; Kherani, N.P. Tunable rainbow light trapping in ultrathin resonator arrays. Light-Sci. Appl. 2020, 9, 194. [Google Scholar] [CrossRef]

- Holsteen Aaron, L.; Cihan Ahmet, F.; Brongersma Mark, L. Temporal color mixing and dynamic beam shaping with silicon metasurfaces. Science 2019, 365, 257–260. [Google Scholar] [CrossRef]

- Zhang, X.; Li, Q.; Liu, F.; Qiu, M.; Sun, S.; He, Q.; Zhou, L. Controlling angular dispersions in optical metasurfaces. Light-Sci. Appl. 2020, 9, 76. [Google Scholar] [CrossRef] [PubMed]

- Grant, J.; Kenney, M.; Shah, Y.D.; Escorcia-Carranza, I.; Cumming, D.R.S. CMOS compatible metamaterial absorbers for hyperspectral medium wave infrared imaging and sensing applications. Opt. Express 2018, 26, 10408–10420. [Google Scholar] [CrossRef] [PubMed]

- Lochbaum, A.; Fedoryshyn, Y.; Dorodnyy, A.; Koch, U.; Hafner, C.; Leuthold, J. On-Chip Narrowband Thermal Emitter for Mid-IR Optical Gas Sensing. ACS Photonics 2017, 4, 1371–1380. [Google Scholar] [CrossRef]

- Chen, S.; Xie, Z.; Ye, H.; Wang, X.; Guo, Z.; He, Y.; Li, Y.; Yuan, X.; Fan, D. Cylindrical vector beam multiplexer/demultiplexer using off-axis polarization control. Light-Sci. Appl. 2021, 10, 222. [Google Scholar] [CrossRef]

- Dorrah, A.H.; Rubin, N.A.; Tamagnone, M.; Zaidi, A.; Capasso, F. Structuring total angular momentum of light along the propagation direction with polarization-controlled meta-optics. Nat. Commun. 2021, 12, 6249. [Google Scholar] [CrossRef] [PubMed]

- Dorrah, A.H.; Rubin, N.A.; Zaidi, A.; Tamagnone, M.; Capasso, F. Metasurface optics for on-demand polarization transformations along the optical path. Nat. Photonics 2021, 15, 287–296. [Google Scholar] [CrossRef]

- Aydin, K.; Ferry, V.E.; Briggs, R.M.; Atwater, H.A. Broadband polarization-independent resonant light absorption using ultrathin plasmonic super absorbers. Nat. Commun. 2011, 2, 517. [Google Scholar] [CrossRef]

- Contractor, R.; D’Aguanno, G.; Menyuk, C. Ultra-broadband, polarization-independent, wide-angle absorption in impedance-matched metamaterials with anti-reflective moth-eye surfaces. Opt. Express 2018, 26, 24031–24043. [Google Scholar] [CrossRef]

- Du, C.; Zhou, D.; Guo, H.H.; Pang, Y.Q.; Shi, H.Y.; Liu, W.F.; Su, J.Z.; Singh, C.; Trukhanov, S.; Trukhanov, A.; et al. An ultra-broadband terahertz metamaterial coherent absorber using multilayer electric ring resonator structures based on anti-reflection coating. Nanoscale 2020, 12, 9769–9775. [Google Scholar] [CrossRef]

- Fan, K.; Suen, J.Y.; Liu, X.; Padilla, W.J. All-dielectric metasurface absorbers for uncooled terahertz imaging. Optica 2017, 4, 601–604. [Google Scholar] [CrossRef]

- Hoa, N.T.Q.; Lam, P.H.; Tung, P.D.; Tuan, T.S.; Nguyen, H. Numerical Study of a Wide-Angle and Polarization-Insensitive Ultrabroadband Metamaterial Absorber in Visible and Near-Infrared Region. IEEE Photonics J. 2019, 11, 4600208. [Google Scholar] [CrossRef]

- Yesilkoy, F.; Arvelo, E.R.; Jahani, Y.; Liu, M.; Tittl, A.; Cevher, V.; Kivshar, Y.; Altug, H. Ultrasensitive hyperspectral imaging and biodetection enabled by dielectric metasurfaces. Nat. Photonics 2019, 13, 390–396. [Google Scholar] [CrossRef]

- Dolia, V.; Balch, H.; Dagli, S.; Abdollahramezani, S.; Delgado, H.; Moradifar, P.; Chang, K.; Stiber, A.; Safir, F.; Lawrence, M.; et al. Very-Large-Scale Integrated High-Q Nanoantenna Pixels (VINPix). arXiv 2023, arXiv:2310.08065. [Google Scholar]

- Zhao, M.; Chen, M.K.; Zhuang, Z.P.; Zhang, Y.; Chen, A.; Chen, Q.; Liu, W.; Wang, J.; Chen, Z.M.; Wang, B.; et al. Phase characterisation of metalenses. Light-Sci. Appl. 2021, 10, 52. [Google Scholar] [CrossRef] [PubMed]

- Gao, S.; Park, C.S.; Zhou, C.; Lee, S.S.; Choi, D.Y. Twofold Polarization-Selective All-Dielectric Trifoci Metalens for Linearly Polarized Visible Light. Adv. Opt. Mater. 2019, 7, 1900883. [Google Scholar] [CrossRef]

- Engelberg, J.; Zhou, C.; Mazurski, N.; Bar-David, J.; Kristensen, A.; Levy, U. Near-IR wide-field-of-view Huygens metalens for outdoor imaging applications. Nanophotonics 2020, 9, 361–370. [Google Scholar] [CrossRef]

- Liang, H.; Lin, Q.; Xie, X.; Sun, Q.; Wang, Y.; Zhou, L.; Liu, L.; Yu, X.; Zhou, J.; Krauss, T.F.; et al. Ultrahigh Numerical Aperture Metalens at Visible Wavelengths. Nano Lett. 2018, 18, 4460–4466. [Google Scholar] [CrossRef] [PubMed]

- Paniagua-Dominguez, R.; Yu, Y.F.; Khaidarov, E.; Choi, S.; Leong, V.; Bakker, R.M.; Liang, X.; Fu, Y.H.; Valuckas, V.; Krivitsky, L.A.; et al. A Metalens with a Near-Unity Numerical Aperture. Nano Lett. 2018, 18, 2124–2132. [Google Scholar] [CrossRef]

- Hu, M.; Wei, Y.; Cai, H.; Cai, Y. Polarization-insensitive and achromatic metalens at ultraviolet wavelengths. J. Nanophotonics 2019, 13, 036015. [Google Scholar] [CrossRef]

- Balli, F.; Sultan, M.A.; Ozdemir, A.; Hastings, J.T. An ultrabroadband 3D achromatic metalens. Nanophotonics 2021, 10, 1259–1264. [Google Scholar] [CrossRef]

- Chen, W.T.; Zhu, A.Y.; Sisler, J.; Bharwani, Z.; Capasso, F. A broadband achromatic polarization-insensitive metalens consisting of anisotropic nanostructures. Nat. Commun. 2019, 10, 355. [Google Scholar] [CrossRef] [PubMed]

- Cheng, K.; Wei, Z.; Fan, Y.; Zhang, X.; Wu, C.; Li, H. Realizing Broadband Transparency via Manipulating the Hybrid Coupling Modes in Metasurfaces for High-Efficiency Metalens. Adv. Opt. Mater. 2019, 7, 1900016. [Google Scholar] [CrossRef]

- Deng, Y.; Wang, X.; Gong, Z.; Dong, K.; Lou, S.; Pegard, N.; Tom, K.B.; Yang, F.; You, Z.; Waller, L.; et al. All-Silicon Broadband Ultraviolet Metasurfaces. Adv. Mater. 2018, 30, e1802632. [Google Scholar] [CrossRef] [PubMed]

- Hu, T.; Feng, X.; Yang, Z.; Zhao, M. Design of scalable metalens array for optical addressing. Front. Optoelectron. 2022, 15, 32. [Google Scholar] [CrossRef] [PubMed]

- Ossiander, M.; Meretska, M.L.; Hampel, H.K.; Lim, S.W.D.; Knefz, N.; Jauk, T.; Capasso, F.; Schultze, M. Extreme ultraviolet metalens by vacuum guiding. Science 2023, 380, 59–63. [Google Scholar] [CrossRef] [PubMed]

- Hemmatyar, O.; Abdollahramezani, S.; Kiarashinejad, Y.; Zandehshahvar, M.; Adibi, A. Full color generation with Fano-type resonant HfO2 nanopillars designed by a deep-learning approach. Nanoscale 2019, 11, 21266–21274. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.; Kim, W.; Oh, D.K.; Kang, H.; Kim, H.; Badloe, T.; Kim, S.; Park, C.; Choi, H.; Lee, H.; et al. One-step printable platform for high-efficiency metasurfaces down to the deep-ultraviolet region. Light Sci. Appl. 2023, 12, 68. [Google Scholar] [CrossRef]

- Zhou, Y.; Kravchenko, I.I.; Wang, H.; Zheng, H.; Gu, G.; Valentine, J. Multifunctional metaoptics based on bilayer metasurfaces. Light Sci. Appl. 2019, 8, 80. [Google Scholar] [CrossRef]

- Mansouree, M.; Kwon, H.; Arbabi, E.; McClung, A.; Faraon, A.; Arbabi, A.J.O. Multifunctional 25D metastructures enabled by adjoint optimization. Optica 2020, 7, 77–84. [Google Scholar] [CrossRef]

- Baksh Peter, D.; Ostrčil, M.; Miszczak, M.; Pooley, C.; Chapman Richard, T.; Wyatt Adam, S.; Springate, E.; Chad John, E.; Deinhardt, K.; Frey Jeremy, G.; et al. Quantitative and correlative extreme ultraviolet coherent imaging of mouse hippocampal neurons at high resolution. Sci. Adv. 2020, 6, eaaz3025. [Google Scholar] [CrossRef] [PubMed]

- Riedel, R.; Al-Shemmary, A.; Gensch, M.; Golz, T.; Harmand, M.; Medvedev, N.; Prandolini, M.J.; Sokolowski-Tinten, K.; Toleikis, S.; Wegner, U.; et al. Single-shot pulse duration monitor for extreme ultraviolet and X-ray free-electron lasers. Nat. Commun. 2013, 4, 1731. [Google Scholar] [CrossRef] [PubMed]

- Zheng, X.; Jia, Y.; Chen, A. Azobenzene-containing liquid crystalline composites for robust ultraviolet detectors based on conversion of illuminance-mechanical stress-electric signals. Nat. Commun. 2021, 12, 4875. [Google Scholar] [CrossRef] [PubMed]

- Cai, Q.; You, H.; Guo, H.; Wang, J.; Liu, B.; Xie, Z.; Chen, D.; Lu, H.; Zheng, Y.; Zhang, R. Progress on AlGaN-based solar-blind ultraviolet photodetectors and focal plane arrays. Light-Sci. Appl. 2021, 10, 94. [Google Scholar] [CrossRef] [PubMed]

- Xu, T.; Agrawal, A.; Abashin, M.; Chau, K.J.; Lezec, H.J. All-angle negative refraction and active flat lensing of ultraviolet light. Nature 2013, 497, 470–474. [Google Scholar] [CrossRef] [PubMed]

- Kuai, Y.; Chen, J.; Tang, X.; Xiang, Y.; Lu, F.; Kuang, C.; Xu, L.; Shen, W.; Cheng, J.; Gui, H.; et al. Label-free surface-sensitive photonic microscopy with high spatial resolution using azimuthal rotation illumination. Sci. Adv. 2019, 5, eaav5335. [Google Scholar] [CrossRef] [PubMed]

- Shi, J.; Wong, T.T.W.; He, Y.; Li, L.; Zhang, R.; Yung, C.S.; Hwang, J.; Maslov, K.; Wang, L.V. High-resolution, high-contrast mid-infrared imaging of fresh biological samples with ultraviolet-localized photoacoustic microscopy. Nat. Photonics 2019, 13, 609–615. [Google Scholar] [CrossRef]

- Zhao, Y.; Sun, F.; Tong, C.; Shu, S.; Hou, G.; Lu, H.; Zhang, X.; Wang, L.; Tian, S.; Wang, L. Going beyond the beam quality limit of spectral beam combining of diode lasers in a V-shaped external cavity. Opt. Express 2018, 26, 14058–14065. [Google Scholar] [CrossRef]

- Sun, F.; Shu, S.; Zhao, Y.; Hou, G.; Lu, H.; Zhang, X.; Wang, L.; Tian, S.; Tong, C.; Wang, L. High-brightness diode lasers obtained via off-axis spectral beam combining with selective feedback. Opt. Express 2018, 26, 21813–21818. [Google Scholar] [CrossRef]

- Nikolov, D.K.; Bauer, A.; Cheng, F.; Kato, H.; Vamivakas, A.N.; Rolland, J.P. Metaform optics: Bridging nanophotonics and freeform optics. Sci. Adv. 2021, 7, eabe5112. [Google Scholar] [CrossRef]

- Palik, E.D. Handbook of Optical Constants of Solids; Academic Press: Cambridge, MA, USA, 1985. [Google Scholar]

- Lin, R.J.; Su, V.C.; Wang, S.; Chen, M.K.; Chung, T.L.; Chen, Y.H.; Kuo, H.Y.; Chen, J.W.; Chen, J.; Huang, Y.T.; et al. Achromatic metalens array for full-colour light-field imaging. Nat. Nanotechnol. 2019, 14, 227–231. [Google Scholar] [CrossRef] [PubMed]

- Li, S.; Zhou, C.; Ban, G.; Wang, H.; Lu, H.; Wang, Y. Active all-dielectric bifocal metalens assisted by germanium antimony telluride. J. Phys. D Appl. Phys. 2019, 52, 095106. [Google Scholar] [CrossRef]

- Chantakit, T.; Schlickriede, C.; Sain, B.; Meyer, F.; Weiss, T.; Chattham, N.; Zentgraf, T. All-dielectric silicon metalens for two-dimensional particle manipulation in optical tweezers. Photon. Res. 2020, 8, 1435–1440. [Google Scholar] [CrossRef]

- Pu, M.; Ma, X.; Wang, C.; Luo, X.; Li, X.; Hong, M.; Wang, M.; Wu, X. Characteristics of a mid-wavelength infrared metalenses integrated imaging system. In Proceedings of the 9th International Symposium on Advanced Optical Manufacturing and Testing Technologies: Meta-Surface-Wave and Planar Optics, Chengdu, China, 26–29 June 2018. [Google Scholar]

- Guo, L.; Hu, Z.; Wan, R.; Long, L.; Li, T.; Yan, J.; Lin, Y.; Zhang, L.; Zhu, W.; Wang, L. Design of aluminum nitride metalens for broadband ultraviolet incidence routing. Nanophotonics 2018, 8, 171–180. [Google Scholar] [CrossRef]

- Guo, H.; Yue, S.; Wang, R.; Hou, Y.; Li, M.; Zhang, K.; Zhang, Z. Design of Polarization-Independent Reflective Metalens in the Ultraviolet-Visible Wavelength Region. Nanomaterials 2021, 11, 1243. [Google Scholar] [CrossRef] [PubMed]

- Kanwal, S.; Wen, J.; Yu, B.; Kumar, D.; Chen, X.; Kang, Y.; Bai, C.; Zhang, D. High-Efficiency, Broadband, Near Diffraction-Limited, Dielectric Metalens in Ultraviolet Spectrum. Nanomaterials 2020, 10, 490. [Google Scholar] [CrossRef] [PubMed]

- Ali, F.; Aksu, S. A hybrid broadband metalens operating at ultraviolet frequencies. Sci. Rep. 2021, 11, 2303. [Google Scholar] [CrossRef]

- Chen, C.; Song, W.; Chen, J.W.; Wang, J.H.; Chen, Y.H.; Xu, B.; Chen, M.K.; Li, H.; Fang, B.; Chen, J.; et al. Spectral tomographic imaging with aplanatic metalens. Light-Sci. Appl. 2019, 8, 99. [Google Scholar] [CrossRef]

- Kim, C.; Kim, S.J.; Lee, B. Doublet metalens design for high numerical aperture and simultaneous correction of chromatic and monochromatic aberrations. Opt. Express 2020, 28, 18059–18076. [Google Scholar] [CrossRef]

- Groever, B.; Chen, W.T.; Capasso, F. Meta-Lens Doublet in the Visible Region. Nano Lett. 2017, 17, 4902–4907. [Google Scholar] [CrossRef]

| dx (μm) | 1 | 1.5 | 2 | 2.5 | 3 | 3.5 | 4 |

|---|---|---|---|---|---|---|---|

| AV (2π) | 0.08588 | 0.0872 | 0.00995 | 0.01426 | 0.01818 | 0.01991 | 0.02225 |

| PV (2π) | 0.15311 | 0.16616 | 0.02268 | 0.02145 | 0.02411 | 0.02465 | 0.03073 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, X.; Yang, F.; Hou, E.; Liang, Z. Integrated Deep Ultraviolet Doublet Metalens for Projection Imaging. Appl. Sci. 2024, 14, 1316. https://doi.org/10.3390/app14031316

Shi X, Yang F, Hou E, Liang Z. Integrated Deep Ultraviolet Doublet Metalens for Projection Imaging. Applied Sciences. 2024; 14(3):1316. https://doi.org/10.3390/app14031316

Chicago/Turabian StyleShi, Xiaoyan, Fuming Yang, Enzhu Hou, and Zhongzhu Liang. 2024. "Integrated Deep Ultraviolet Doublet Metalens for Projection Imaging" Applied Sciences 14, no. 3: 1316. https://doi.org/10.3390/app14031316

APA StyleShi, X., Yang, F., Hou, E., & Liang, Z. (2024). Integrated Deep Ultraviolet Doublet Metalens for Projection Imaging. Applied Sciences, 14(3), 1316. https://doi.org/10.3390/app14031316