A Study on the Softening Shear Model of the Energy Pile–Soil Contact Surface

Abstract

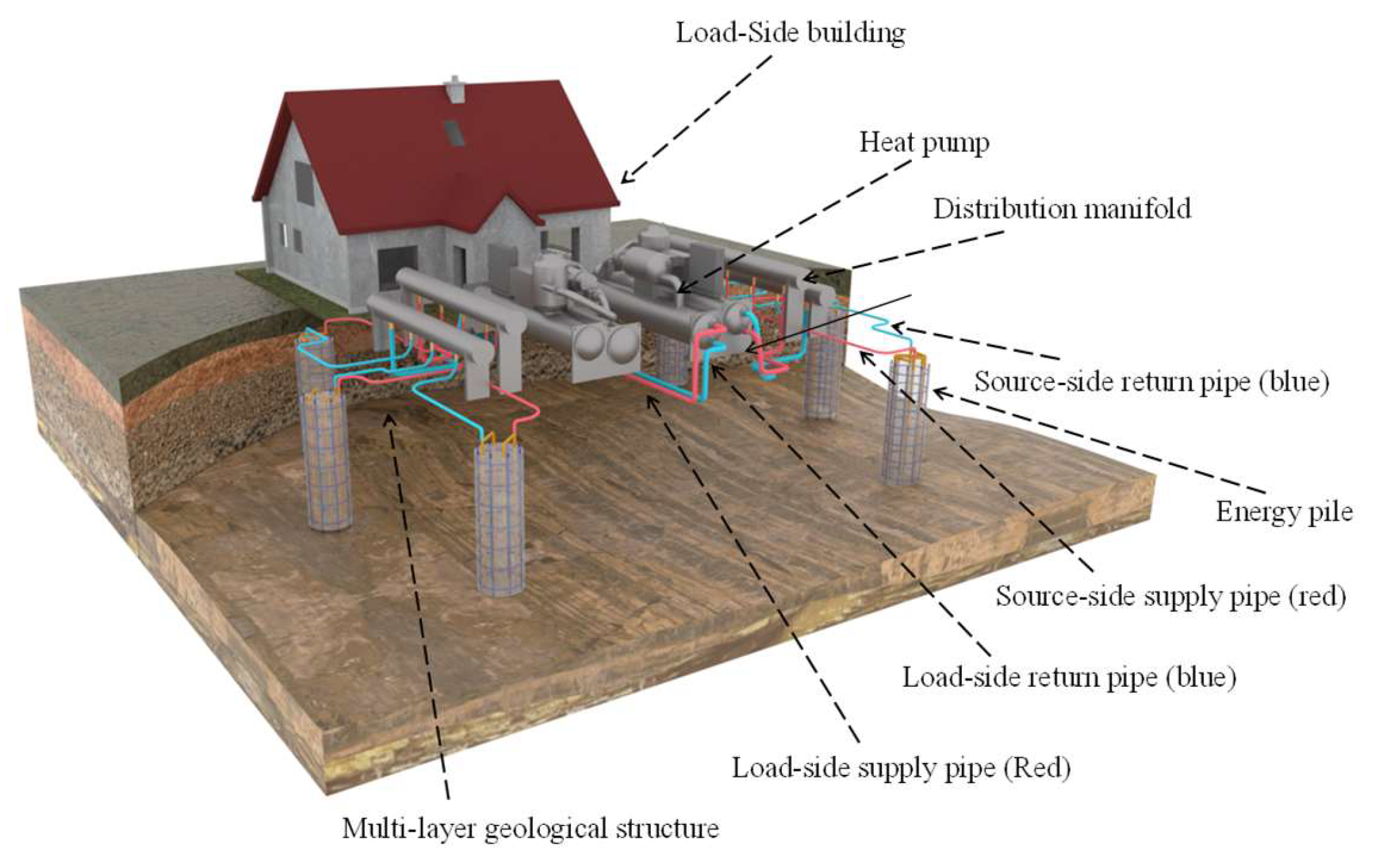

1. Introduction

2. Materials and Methods

2.1. Governing Equation

2.2. Model Assumptions

- (1)

- The physical properties of soil in heat transfer engineering are constant, and the substances within the soil do not undergo phase changes.

- (2)

- The thermal-physical parameters of the pile concrete remain unchanged during the heat transfer process, and the concrete pile transfers heat in a thermally conductive manner.

- (3)

- The effects of temperature changes in the soil along the depth direction and of air heat transfer at the surface are not considered.

- (4)

- The contact thermal resistance between the wall of the embedded pipe in the pile and the pile body, and between the pile body and the soil around the pile is not considered.

- (5)

- Seepage velocity and direction remain constant.

- (6)

- The formation in the seepage area is an isotropic saturated porous medium.

- (7)

- The deformation of the pile body is elastic and the deformation of the soil around the pile is elastic-plastic.

2.3. Modeling Process

2.4. Model Verification

2.4.1. Comparative Analysis of Supply and Return Temperatures

2.4.2. Comparative Analysis of Supply and Return Temperatures

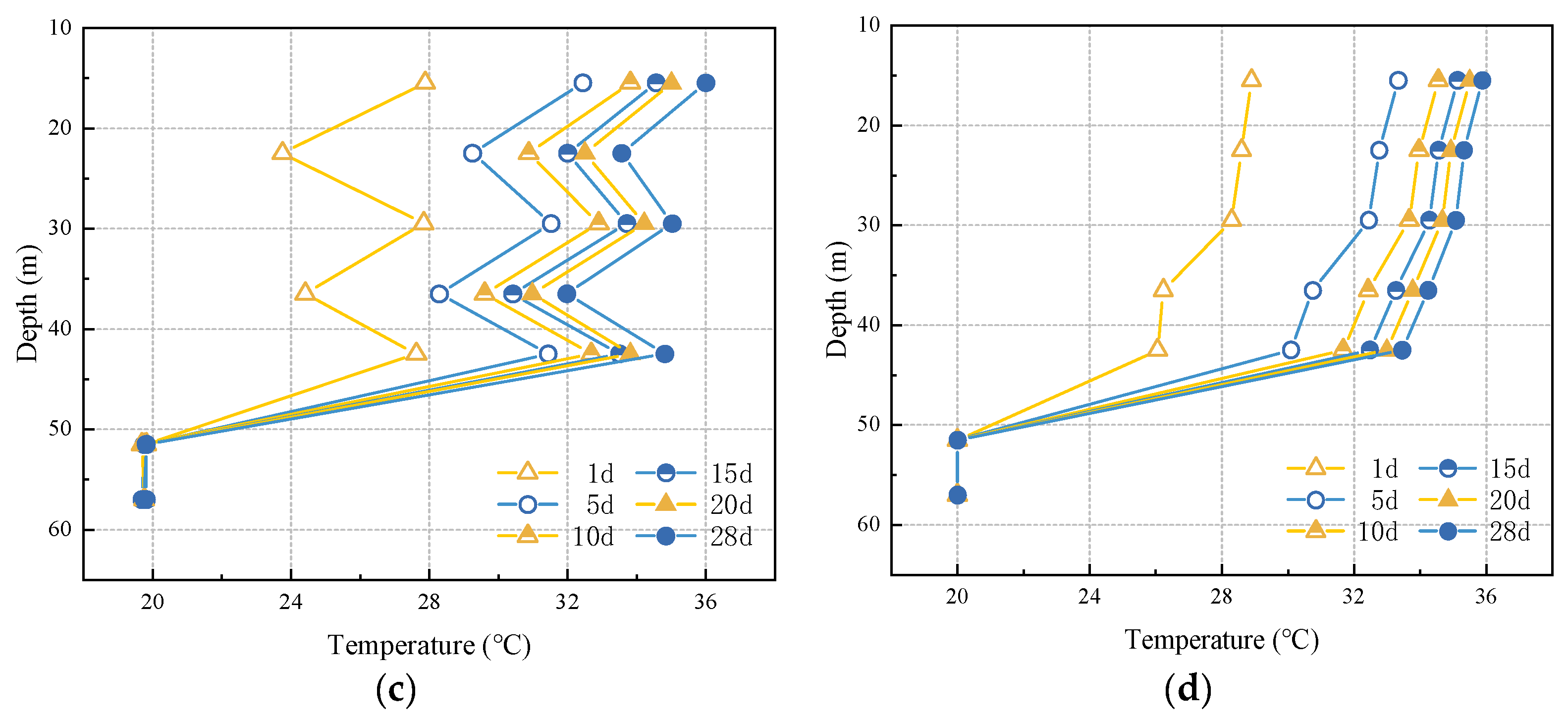

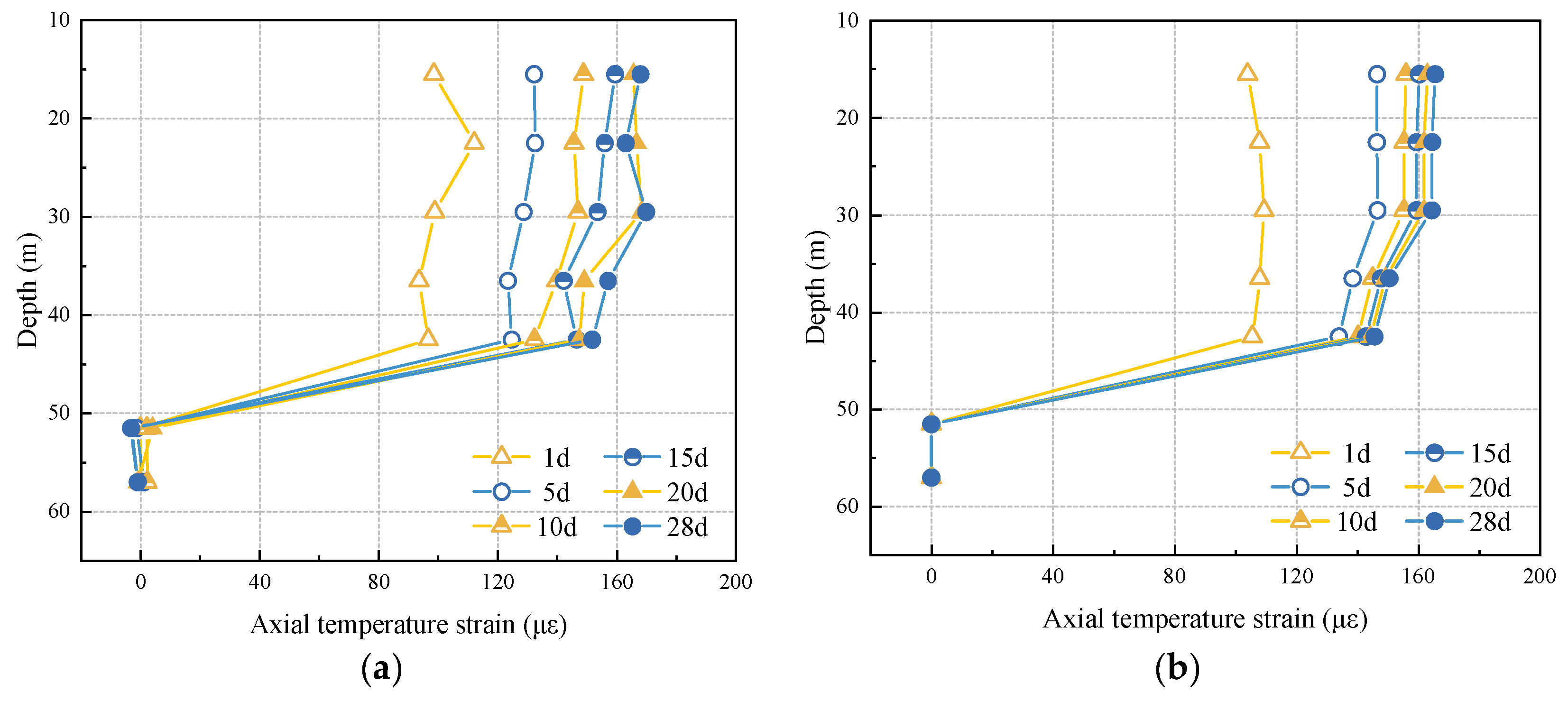

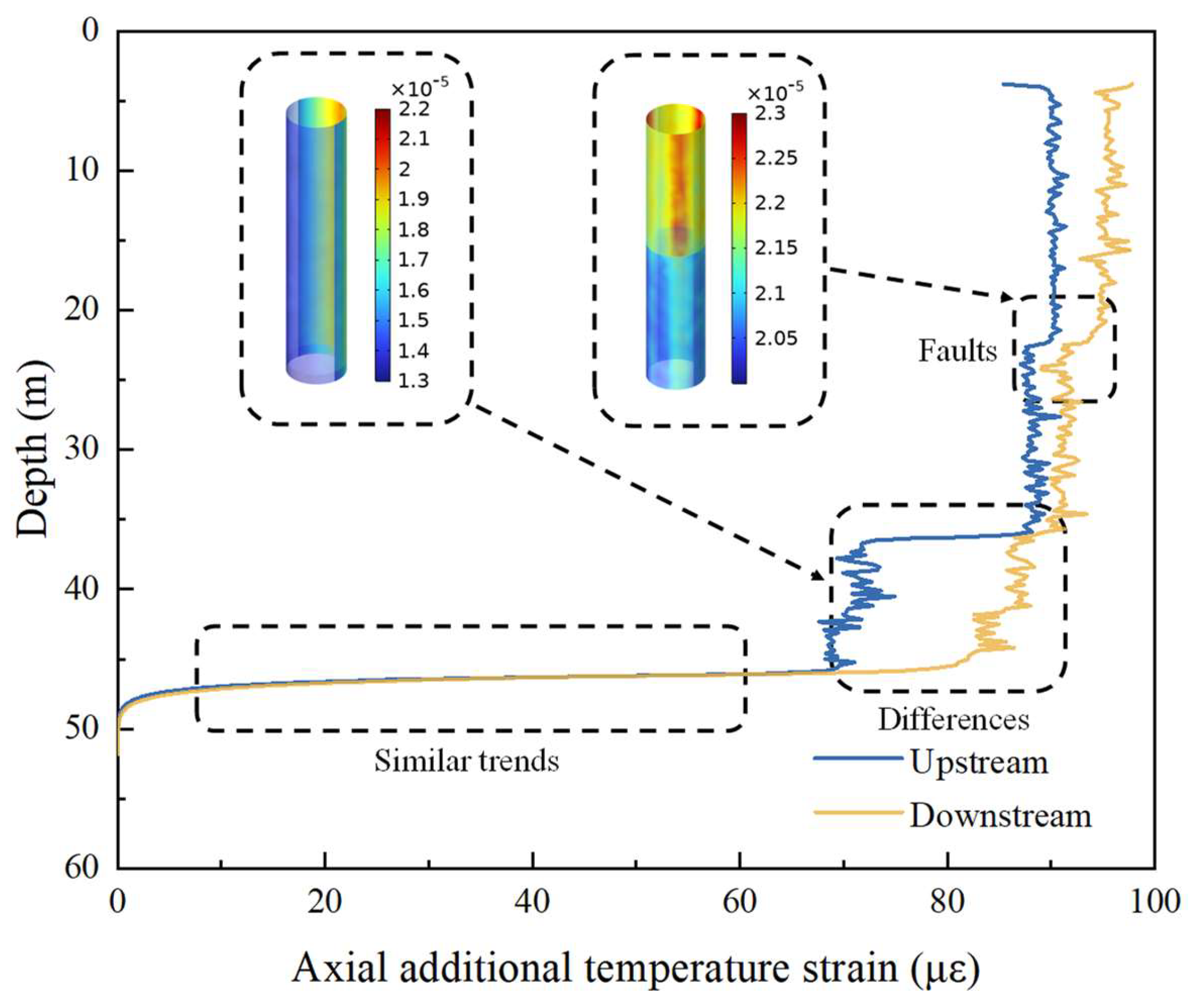

2.4.3. Comparative Analysis of Axial Temperature Strain

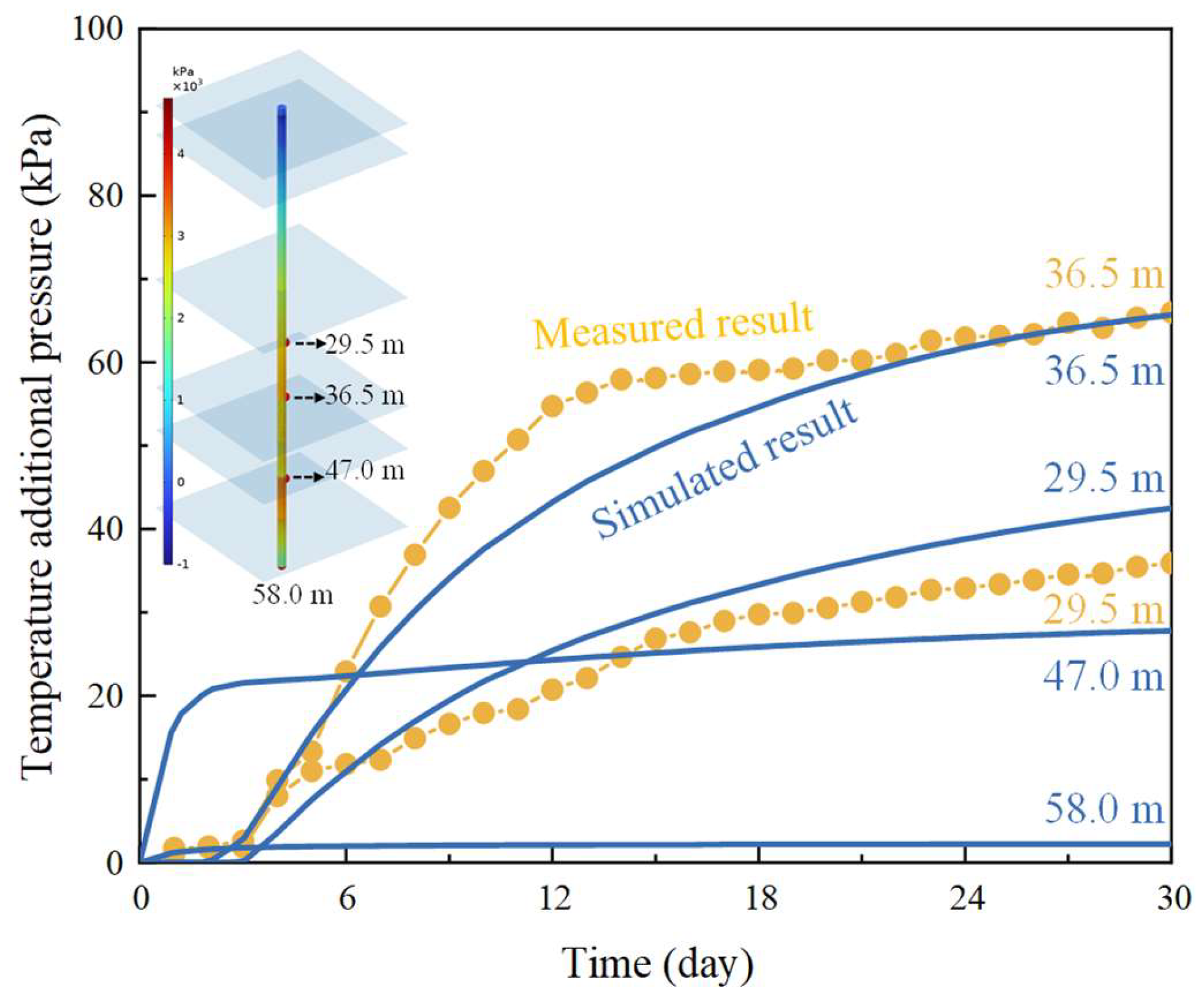

2.4.4. Comparative Analysis of Temperature Additional Pressure on Pile Side

3. Results

3.1. The Evolution of Supply and Return Water Temperatures

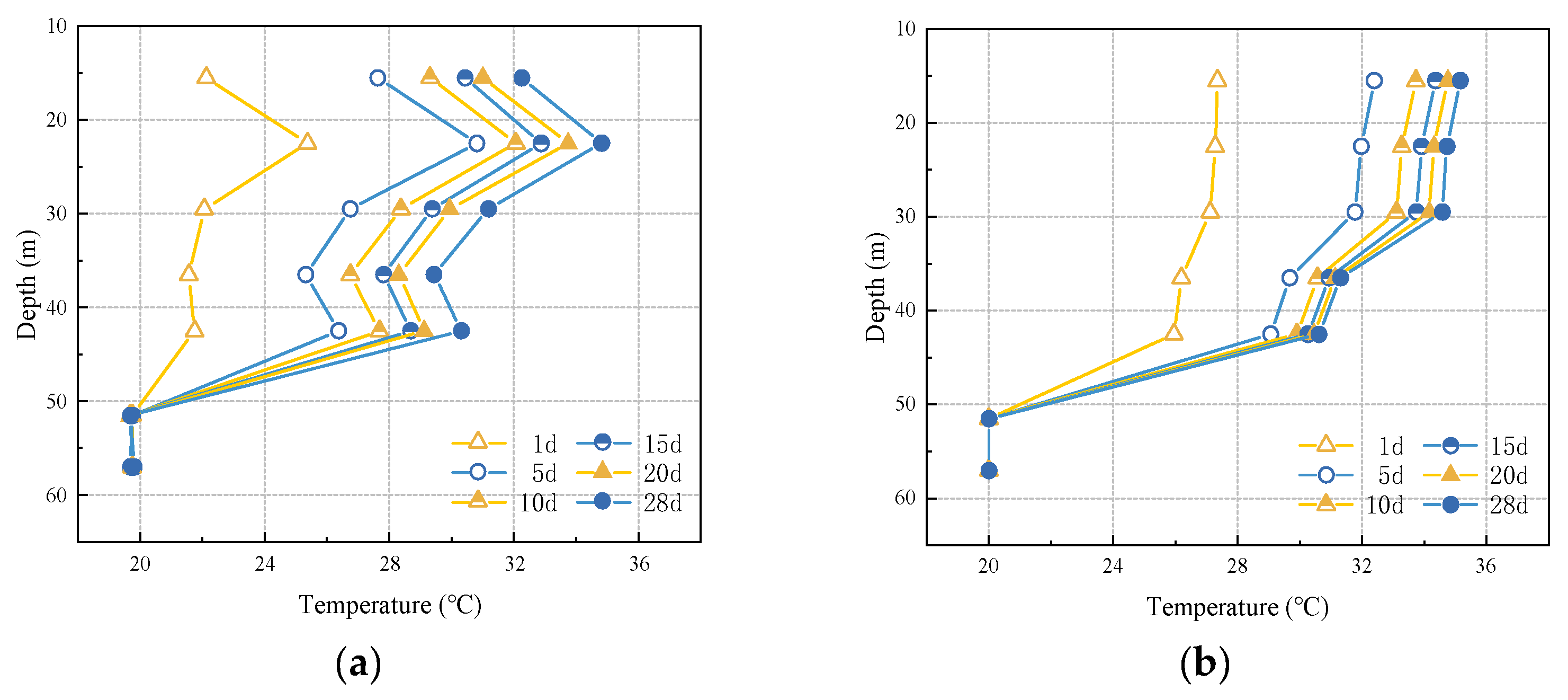

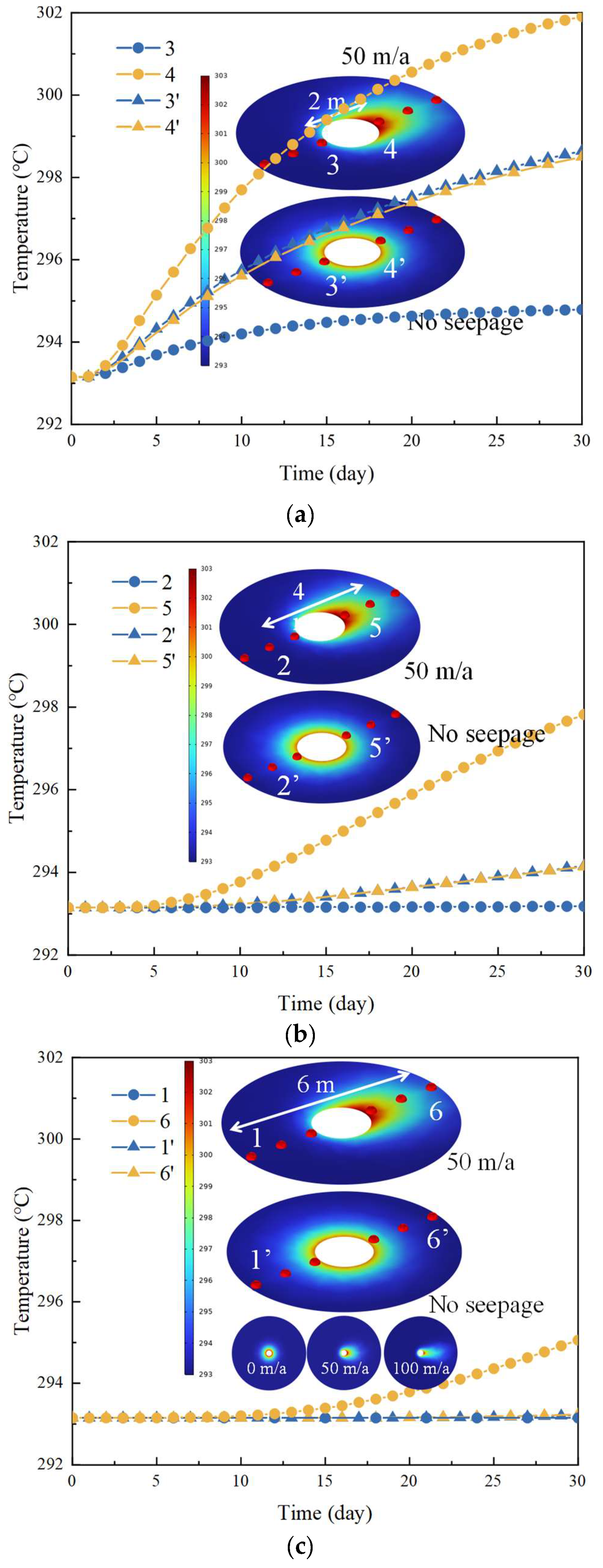

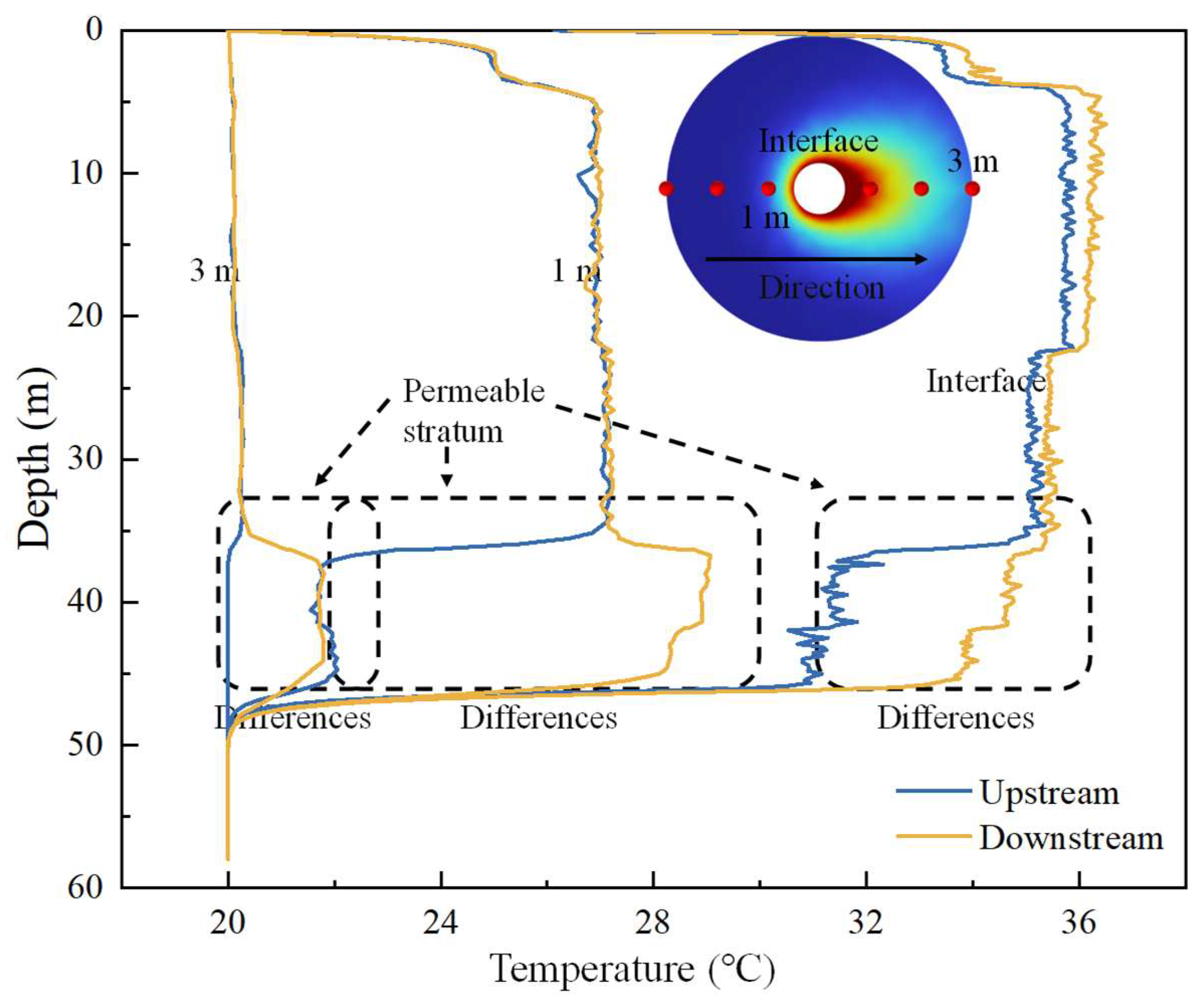

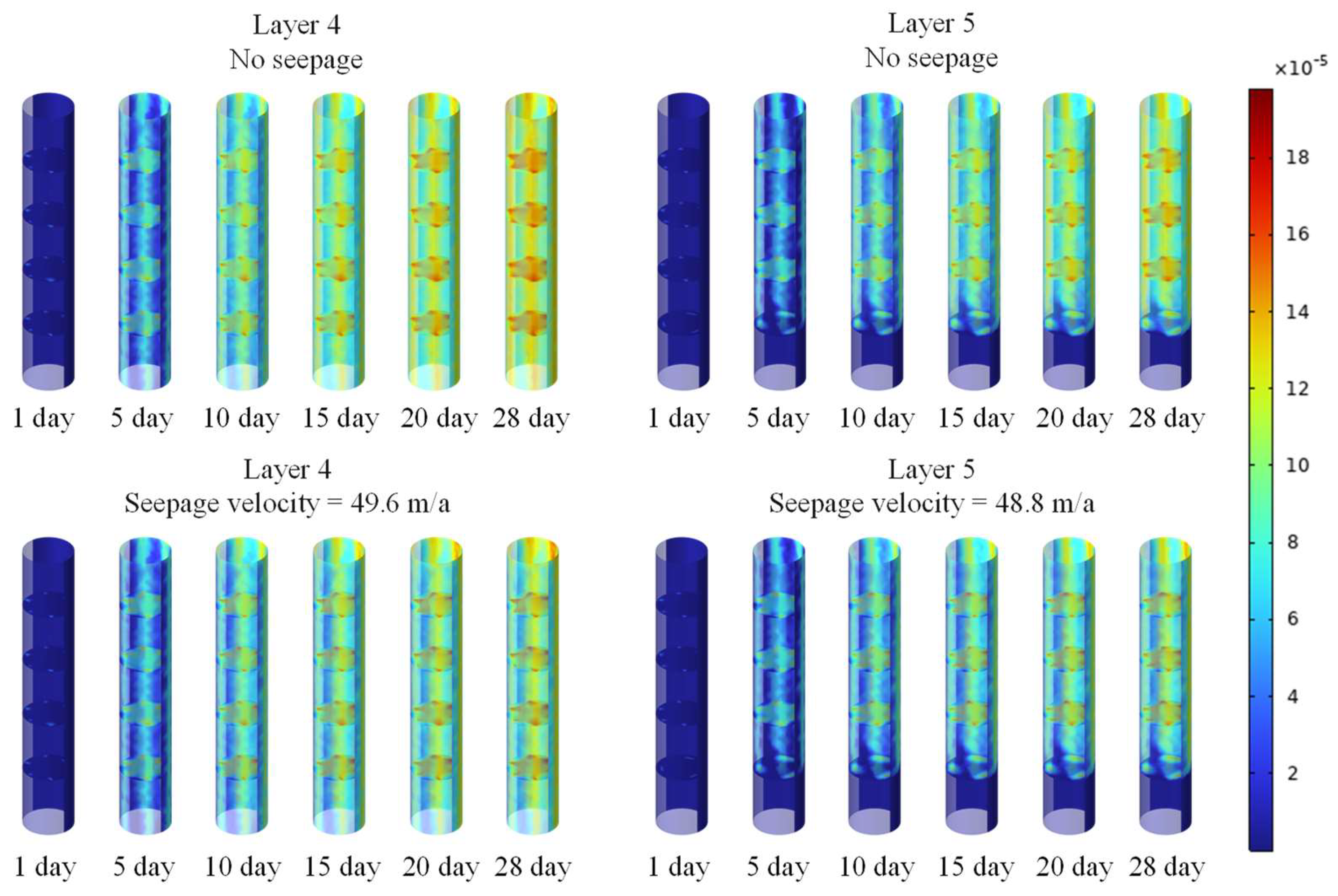

3.2. The Evolution of Temperature in Pile and Surrounding Soil

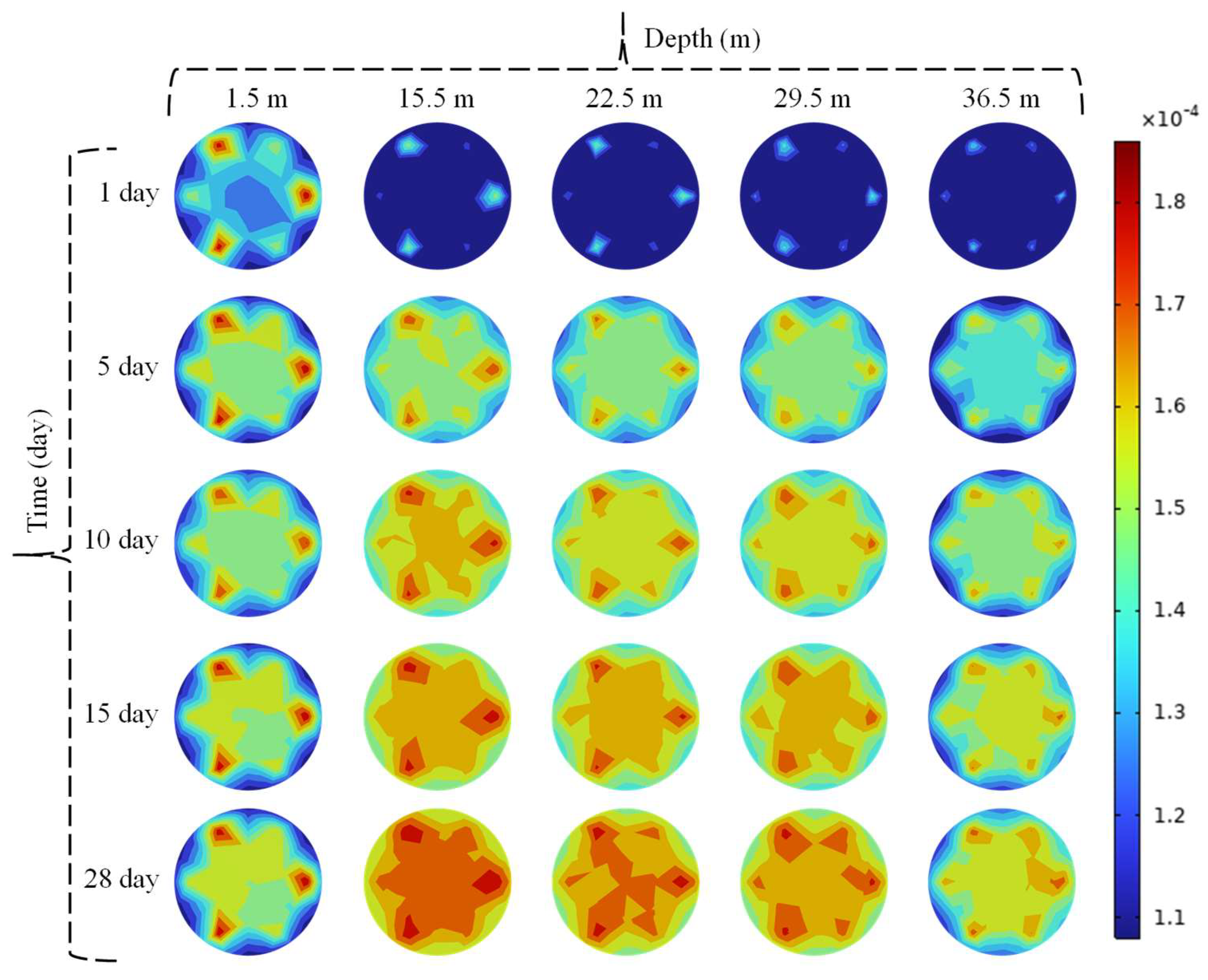

3.3. The Evolution of Axial Strain in Pile

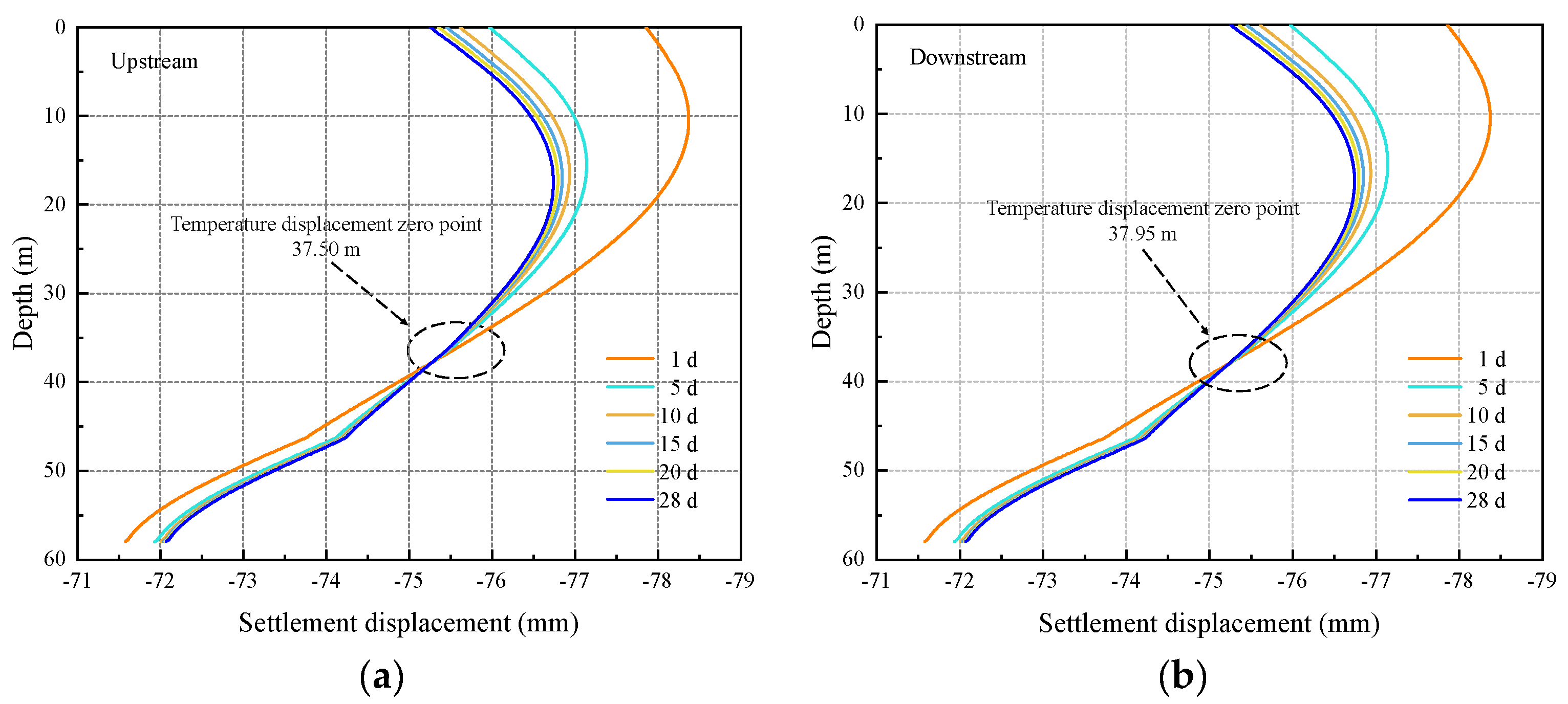

3.4. The Evolution of Pile Settlement

3.5. Softening Shear Model of Pile–Soil Contact Surface under Large Shear Displacement Conditions

3.5.1. Constitutive Equation

3.5.2. Model Parameters and Physical Meaning

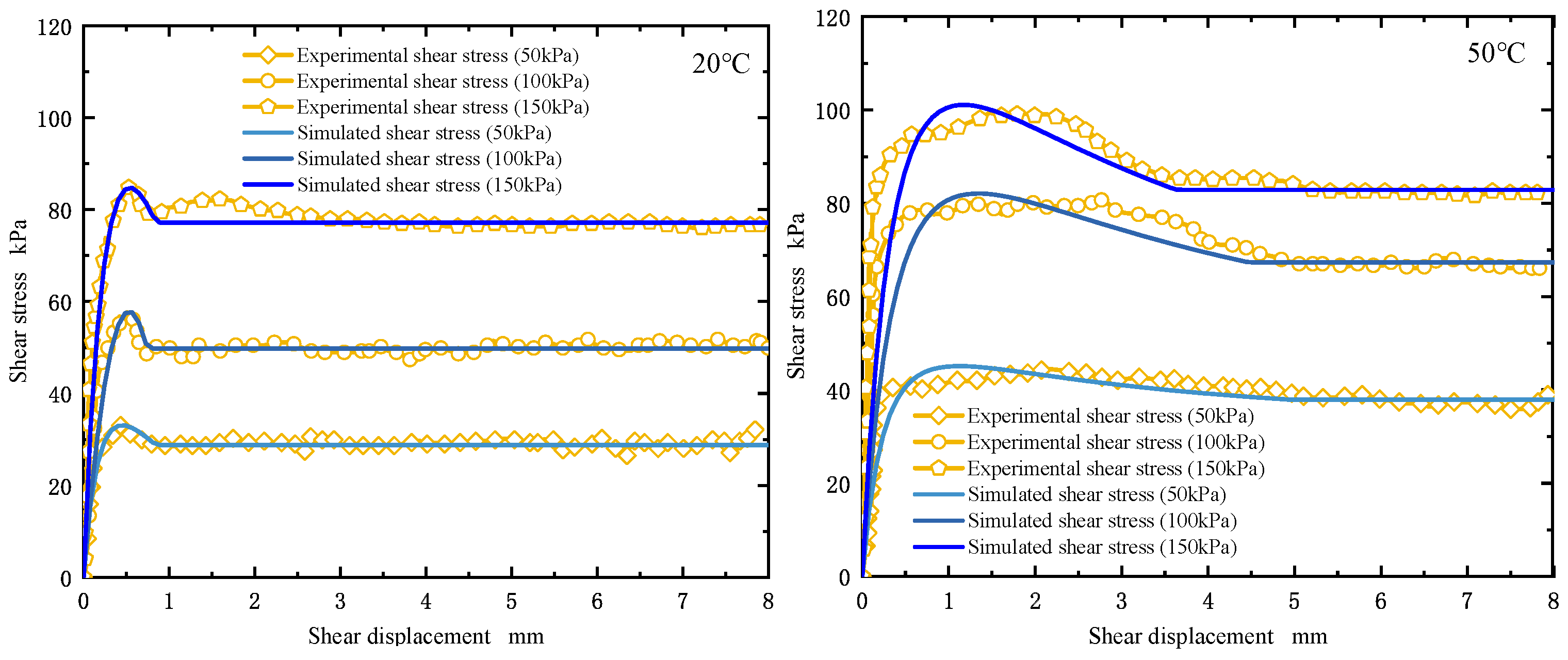

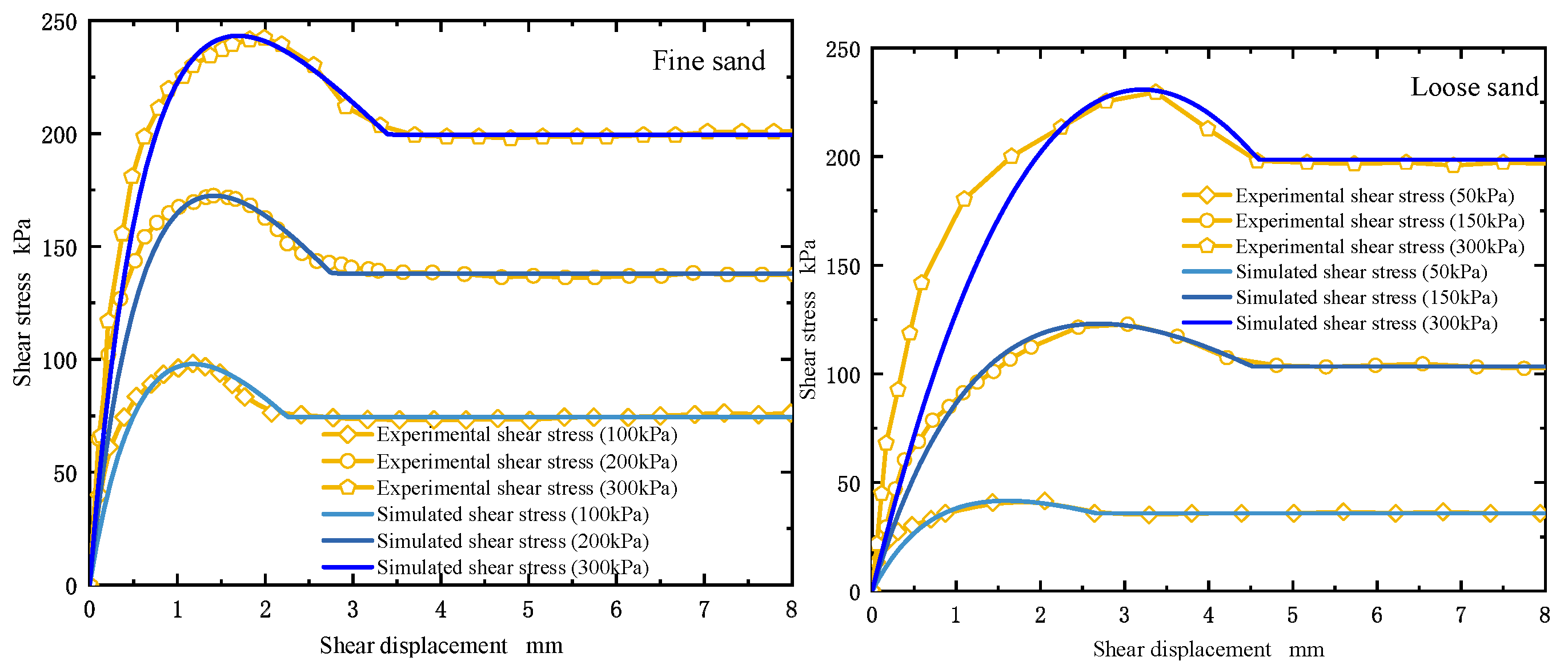

3.5.3. Validation of Pile–Soil Interface Model Simulation Capability

4. Conclusions

- (1)

- Groundwater seepage enhances convective heat transfer within the soil, increasing the heat transfer temperature difference between the heat transfer tubes and thus increasing the amount of heat transferred. The seepage dissipates heat from the upstream soil zone, effectively minimizing heat buildup in the upstream soil.

- (2)

- The temperature values at the pile–soil interface increase rapidly and then decrease in segments as the burial depth increases. In addition, the temperature at the junction location of different strata will cause an obvious fault to appear. The fluctuation of temperature along the burial depth at the pile–soil interface is significantly larger than the temperature change along the burial depth inside the soil body.

- (3)

- The rate of change of the axial additional temperature strain of the pile body is gradually increases with the increase in burial depth. The temperature stress induced by different strata is not the same, and the magnitude of temperature stress is not only related to the deformation modulus of the surrounding rocks, but also related to the axial constraint, which mainly comes from the constraints of the superstructure at the end of the pile and the holding layer at the bottom of the pile.

- (4)

- According to the mechanical characteristics of energy piles, this paper proposes a segmented softening function, which can consider the unloading process of energy piles in the upper part of the pile in the heat dissipation process and in the lower part of the pile in the heat extraction process; simulate the relationship between the contact surface shear stress and shear displacement in different conditions; and calculate the softening characteristics of the contact surface in a relatively accurate and quantitative manner.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Loveridge, F.A.; McCartney, J.S.; Narsilio, G.A.; Sánchez, M. Energy geostructures: A review of analysis approaches, in situ testing and model scale experiments. Geomech. Energy Environ. 2020, 22, 100173. [Google Scholar] [CrossRef]

- Mohamad, Z.; Fardoun, F.; Meftah, F. A review on energy piles design, evaluation, and optimization. J. Clean. Prod. 2021, 292, 125802. [Google Scholar] [CrossRef]

- Gao, J.; Zhang, X.; Liu, J.; Li, K.; Yang, J. Numerical and experimental assessment of thermal performance of vertical energy piles: An application. Appl. Energy 2008, 85, 901–910. [Google Scholar] [CrossRef]

- Liu, H.; Song, E.; Ling, H.I. Constitutive modeling of soil-structure interface through the concept of critical state soil mechanics. Mech. Res. Commun. 2006, 33, 515–531. [Google Scholar] [CrossRef]

- Feligha, M.; Hammoud, F.; Belachia, M.; Nouaouria, M.S. Experimental Investigation of Frictional Behavior Between Cohesive Soils and Solid Materials Using Direct Shear Apparatus. Geotech. Geol. Eng. 2016, 34, 567–578. [Google Scholar] [CrossRef]

- Pincus, H.J.; Tabucanon, J.; Airey, D.W.; Poulos, H.G. Pile Skin Friction in Sands from Constant Normal Stiffness Tests. Geotech. Test. J. 1995, 18, 350–364. [Google Scholar] [CrossRef]

- Bian, X.; Gao, Z.; Zhao, P.; Li, X. Quantitative analysis of low carbon effect of urban underground space in Xinjiekou district of Nanjing city, China. Tunn. Undergr. Space Technol. 2024, 143, 105502. [Google Scholar] [CrossRef]

- Conte, E.; Pugliese, L.; Troncone, A.; Vena, M. A Simple Approach for Evaluating the Bearing Capacity of Piles Subjected to Inclined Loads. Int. J. Geomech. 2021, 21, 04021224. [Google Scholar] [CrossRef]

- Hamidou, H.; Koichi, I.; Satoru, O. End bearing capacity of a single incompletely end-supported pile based on the rigid plastic finite element method with non-linear strength property against confining stress. Soils Found. 2022, 62, 101182. [Google Scholar] [CrossRef]

- Laloui, L.; Nuth, M.; Vulliet, L. Experimental and Numerical Investigations of the Behavior of a Heat Exchanger Pile. In Ground Improvement Case Histories; Indraratna, B., Chu, J., Eds.; Butterworth-Heinemann: Oxford, UK, 2015; pp. 515–535. [Google Scholar] [CrossRef]

- Yazdani, S.; Helwany, S.; Olgun, C.G. Influence of temperature on soil–pile interface shear strength. Geomech. Energy Environ. 2019, 18, 69–78. [Google Scholar] [CrossRef]

- Xiao, S.; Suleiman, M.T.; Al-Khawaja, M. Investigation of effects of temperature cycles on soil-concrete interface behavior using direct shear tests. Soils Found. 2019, 59, 1213–1227. [Google Scholar] [CrossRef]

- Yin, K.; Vasilescu, R. Effect of thermal cycles on volumetric and shear behavior of sand-concrete interface. Geomech. Energy Environ. 2023, 36, 100503. [Google Scholar] [CrossRef]

- Suryatriyastuti, M.E.; Mroueh, H.; Burlon, S. A load transfer approach for studying the cyclic behavior of thermo-active piles. Comput. Geotech. 2014, 55, 378–391. [Google Scholar] [CrossRef]

- Pasten, C.; Carlos Santamarina, J. Thermally Induced Long-Term Displacement of Thermoactive Piles. J. Geotech. Geoenviron. Eng. 2014, 140, 06014003. [Google Scholar] [CrossRef]

- Troncone, A.; Pugliese, L.; Parise, A.; Conte, E. A simple method to reduce mesh dependency in modelling landslides involving brittle soils. Géotechnique Lett. 2022, 12, 167–173. [Google Scholar] [CrossRef]

- Baek, J.; Schlinkman, R.; Beckwith, F. A deformation-dependent coupled Lagrangian/semi-Lagrangian meshfree hydromechanical formulation for landslide modeling. Adv. Model. Simul. Eng. Sci. 2022, 9, 20. [Google Scholar] [CrossRef]

- Loria, A.F.; Vadrot, A.; Laloui, L. Effect of non-linear soil deformation on the interaction among energy piles. Comput. Geotech. 2017, 86, 9–20. [Google Scholar] [CrossRef]

- Loria, A.F.; Laloui, L. Displacement interaction among energy piles bearing on stiff soil strata. Comput. Geotech. 2017, 90, 144–154. [Google Scholar] [CrossRef]

- Nghiem, H.M.; Chang, N.Y. Pile under torque in nonlinear soils and soil-pile interfaces. Soils Found. 2019, 59, 1845–1859. [Google Scholar] [CrossRef]

- Knellwolf, C.; Péron, H.; Laloui, L. Geotechnical Analysis of Heat Exchanger Piles. J. Geotech. Geoenviron. Eng. 2011, 137, 890–902. [Google Scholar] [CrossRef]

- Yavari, N.; Tang, A.M.; Pereira, J.; Hassen, G. Effect of temperature on the shear strength of soils and the soil–structure interface. Can. Geotech. J. 2016, 53, 1186–1194. [Google Scholar] [CrossRef]

- Jie, L.; Ken-neng, Z. Analysis of pile load-transfer under pile-side softening. J. Cent. South Univ. Technol. 2003, 10, 231–236. [Google Scholar] [CrossRef]

- Zhao, M.; Yang, M.; Zou, X. Vertical bearing capacity of pile based on load transfer model. J. Cent. South Univ. Technol. 2005, 12, 488–493. [Google Scholar] [CrossRef]

- Xia, Z.; Zou, J. Simplified Approach for Settlement Analysis of Vertically Loaded Pile. J. Eng. Mech. 2017, 143, 04017124. [Google Scholar] [CrossRef]

- Ni, P.; Song, L.; Mei, G.; Zhao, Y. Generalized Nonlinear Softening Load-Transfer Model for Axially Loaded Piles. Int. J. Geomech. 2017, 17, 04017019. [Google Scholar] [CrossRef]

- Donna, A.D.; Ferrari, A.; Laloui, L. Experimental investigations of the soil-concrete interface: Physical mechanisms, cyclic mobilisation and behaviour at different temperatures. Can. Geotech. J. 2016, 53, 659–672. [Google Scholar] [CrossRef]

- Jiang, J.; Chen, Q.; Ou, X.; Chen, H.; Chen, C. Analysis of thermal response of energy piles considering softening of pile-side soil. Chin. J. Rock Mech. Eng. 2023, 42, 2295–2305. [Google Scholar]

- Ghionna, V.N.; Mortara, G. An elastoplastic model for sand–structure interface behaviour. Geotechnique 2002, 52, 41–50. [Google Scholar] [CrossRef]

- Donna, A.D. Thermo-Mechanical Aspects of Energy Piles; EPFL: Lausanne, Switzerland, 2014. [Google Scholar] [CrossRef]

| Soil Layer | Name | Thickness (m) | Density (kg/m3) | Condition |

|---|---|---|---|---|

| ① | Miscellaneous fill | 3.8 | 1750 | Loose |

| ② | Silty soft clay | 18.7 | 1770 | Flow plasticity |

| ③ | Silty clay | 13.8 | 1790 | Local flow plasticity |

| ④ | Silty fine sand | 5.5 | 1920 | Sand |

| ⑤ | Silty fine sand | 10.0 | 1930 | Sand |

| ⑥ | Coarse sand mixed gravel | 17.2 | 1917 | Gravel |

| Materials | Density (kg/m3) | Thermal Conductivity (W/(m∙K)) | Specific Heat J/(kg∙K) |

|---|---|---|---|

| HDPE | 1100 | 0.42 | 1465 |

| Concrete | 2750 | 1.80 | 800 |

| Type | Rn | Dr (%) | σn (kPa) | Temperature (°C) |

|---|---|---|---|---|

| Clay-Concrete | 30 | 50, 100, 150 | 20 °C, 50 °C | |

| Sand-Concrete | 0.12 | 50, 100, 150 | 20 °C, 60 °C | |

| Sand-Aluminum Plate | 0.250 | 85 | 100, 200, 300 | Indoor temperature |

| 0.125 | 35 | 50, 150, 300 | Indoor temperature |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, H.; Zhao, P.; Li, X.; Wang, X.; Bian, X. A Study on the Softening Shear Model of the Energy Pile–Soil Contact Surface. Appl. Sci. 2024, 14, 1072. https://doi.org/10.3390/app14031072

Wang H, Zhao P, Li X, Wang X, Bian X. A Study on the Softening Shear Model of the Energy Pile–Soil Contact Surface. Applied Sciences. 2024; 14(3):1072. https://doi.org/10.3390/app14031072

Chicago/Turabian StyleWang, Huiyuan, Peng Zhao, Xiaozhao Li, Xue Wang, and Xia Bian. 2024. "A Study on the Softening Shear Model of the Energy Pile–Soil Contact Surface" Applied Sciences 14, no. 3: 1072. https://doi.org/10.3390/app14031072

APA StyleWang, H., Zhao, P., Li, X., Wang, X., & Bian, X. (2024). A Study on the Softening Shear Model of the Energy Pile–Soil Contact Surface. Applied Sciences, 14(3), 1072. https://doi.org/10.3390/app14031072