1. Introduction

Currently, the demand for sustainable and resilient infrastructure are paramount. This paper analyses the case of unpaved forest roads, particularly focusing on considering the incorporation of pine needles as an alternative and sustainable solution, to promote a reduction of the need for maintenance works.

Traditional solutions for unpaved roads make use of natural resources, namely good-quality aggregates. Typically, unpaved roads are formed of a base layer overlaying the natural subgrade. The base layer is unbound and often is formed of good-quality aggregates. The quantity of natural aggregates needed in such traditional solutions impose large impacts on the environment. As an alternative to these materials, residues and byproducts should be considered [

1]. The incorporation of these residues in new solutions can be beneficial, as it promotes circularity and sustainability. The advantages of such solutions include lower costs and reduced environmental impacts, as residues are reassessed to be utilised as building materials. For the case of unpaved forest roads, it is important to evaluate how alternative solutions respond to loads associated with logging operations [

2]. To ensure forest roads exhibit an adequate and resilient response, when considering new solutions, it is essential to assess the road resistance to prevent (or at least minimise) deterioration problems [

3].

Alternative solutions have been studied. For example, Pinho-Lopes [

1] and Magalhães et al. [

3] considered the use of industrial byproducts, assessing the soil behaviour, studying the performance of the solution, and conducting triaxial and California Bearing Ratio (CBR) tests, respectively.

Byproducts from the paper industry can also be incorporated into road solutions. Nienov et al. [

4] created a mixture between clay soil, waste, and agglomerant in different conditions and assessed the compressive strength in relation to the proportions of this mixture. Cepriá et al. [

5] considered the use of fly ash as an alternative hydraulic binder replacing the cement in road projects.

Most design methods available in the literature refer to paved roads. These are usually based on mechanical-empirical approaches. However, the procedure of this type of design method does not focus on granular layers, but on bound materials. To optimize the performance of granular layers, how they behave when subjected to cyclic traffic loads must be considered [

6]. Given that, in most unpaved roads, the materials are unbound, this is a crucial aspect in design [

7].

Developing a straightforward laboratory test that can provide relevant mechanical characteristics of granular materials is important. However, some of the test equipment is expensive, so it is valuable to find a more affordable test equipment and method that provides these mechanical characteristics of the materials [

7]. A possible solution for a simple laboratory test that can provide relevant information is the repeated load CBR test (RL-CBR). One of the most often utilised parameters in road design, for both paved [

8,

9] and unpaved roads [

10], is the CBR value, measured through CBR tests. The conventional CBR test is a penetration test, where a plunger moves at a constant axial displacement rate into a cylindrical soil specimen, formed of layers of compacted soil placed in a steel mould. There are different test standards for the CBR test; the most common is ASTM D 1883-07 [

11]. While the conventional CBR test is only carried out with one load cycle (monotonic), the RL-CBR test is based on a standard CBR test with an increased number of load cycles [

12]. There is no standardised procedure for the RL-CBR test; however, a number of studies including this type of test are available in the literature [

6].

Table 1 summarises information from the literature on RL-CBR and the test conditions adopted, namely the base standard used (for the standard CBR test), mould dimensions (diameter; height), plunger diameter, the number of load cycles carried out, the axial displacement rate applied, the inclusion or not of a soaking phase of the specimens before testing, the penetration depth, the number of load stages, and the minimum stress reached in the unloading phase. The maximum load corresponds to the load required to achieve the penetration depth that represents the criterion for terminating the standard CBR test phase.

Mechanical properties, such as the resilient modulus (M

r) and the equivalent modulus (E

equ), can be obtained through cyclic triaxial and RL-CBR tests, respectively [

2,

7,

12]. The resilient modulus (M

r), which is another quantity frequently utilised in road design, is the ratio between the axial deviatoric stress (σ

d) and resilient axial strain (ε

a) (Equation (1)), and it is typically quantified using cyclic triaxial tests [

7]. The equivalent modulus (E

equ) represents an average response of the material in the mould, macroscopically, and is obtained by measuring the load and deformation during the loading and unloading cycle time of RL-CBR [

12]. Araya et al. [

12] proposed Equation (2) to estimate the equivalent modulus from RL-CBR. This equivalent elastic modulus (E

equ) depends on the following: Poisson’s ratio of the soil, υ; change in the stress applied through the plunger in a loading cycle (difference between the maximum and minimum applied load), Δσ

p (MPa); radius of plunger, r (mm); change in elastic displacement in a loading cycle, Δu (mm). Instead of referring to the resilient modulus of the material, the equivalent modulus is used to represent the stiffness of the unbound material [

12]. However, presently, the equivalent modulus cannot be used directly in pavement design, since the loads and stresses applied in the test are higher than typical traffic loads. Therefore, it is necessary to correlate the results of a triaxial test (under the same test conditions) to estimate the corresponding resilient modulus [

12]. Given that developing countries tend to have unpaved roads carrying a large number of vehicles [

6], it is critical to define a test procedure to estimate relevant mechanical properties of unbound materials using less expensive equipment and test protocols that are simple to implement and of simple interpretation. In this context, the RL-CBR test is more adequate, affordable, and accessible than the triaxial test [

7].

In this paper, an alternative solution for unpaved forest roads is analysed to promote sustainable, resilient solutions within a context of circularity. The solution consists of using natural fibres available in the forest, pine needles, as fibre reinforcement for a local soil. The mechanical properties of the developed solution were characterised using RL-CBR tests; different percentages of natural fibres were considered. To assess the response to repeated loading of the soil and soil–needles composite material, a stiffness modulus was estimated. The RL-CBR tests carried out included different load stages in order to analyse the influence of those stages on the elastic response observed.

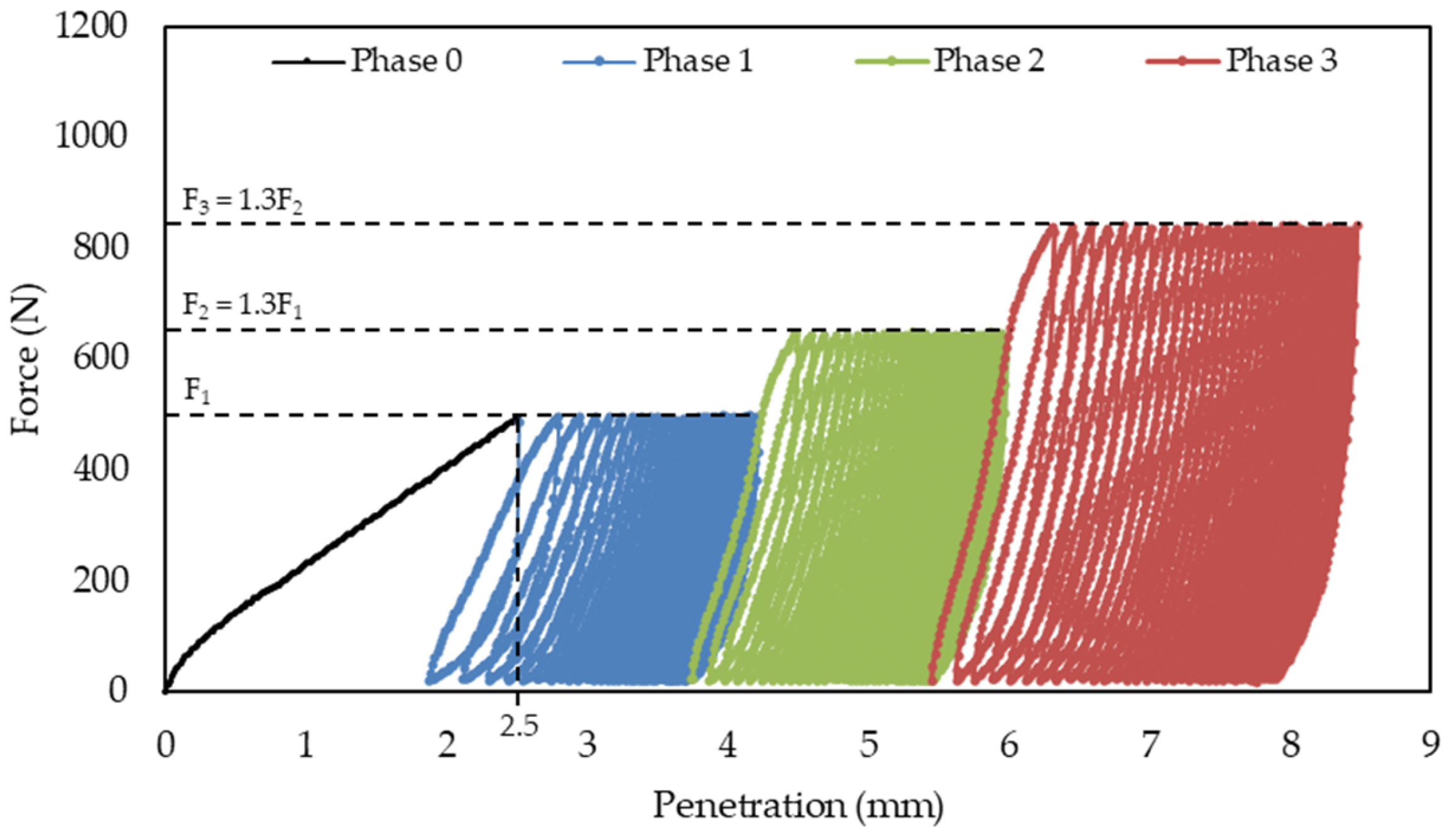

3. Results and Discussion

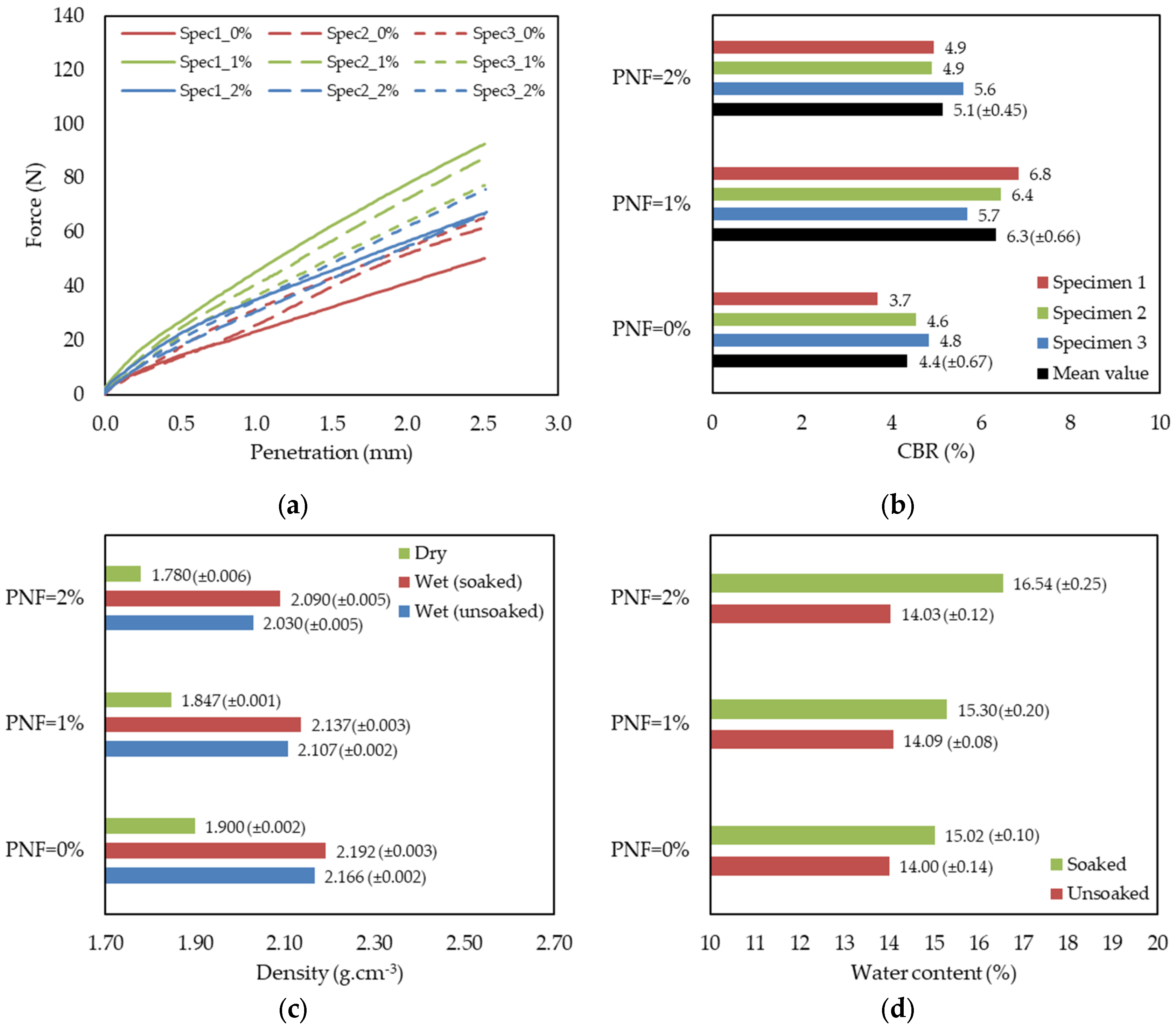

3.1. CBR Test—Phase 0, Monotonic Loading

Figure 5 summarises the main results of the initial phase of the RL-CBR tests performed (phase 0, with monotonic loading). As mentioned before, this phase corresponds to the CBR standard test. For this reason, the force–penetration response (

Figure 5a) and the CBR values (

Figure 5b) for three specimens per condition are defined. Herein, the CBR values are obtained as the ratio of the force measured during the test for a value of penetration of 2.5 mm to the corresponding force for a standard material, typically a well-graded crushed stone (1355 kgf or 13.29 kN, defined in LNEC E198 [

23]); the mean values of CBR are also included in

Figure 5b.

The force–penetration response and the CBR value are improved by the incorporation of the natural fibres in the soil. The inclusion of the pine needles led to a stiffer response for all reinforced specimens. The CBR value increased by 45% for PNF = 1% and 18% for PNF = 2%, compared to unreinforced soil. The specimens with 1.0% of pine needles (PNF = 1%) showed the best force–penetration response and the highest CBR values, indicating that this is the ideal PNF to improve the behaviour of this soil.

The redistribution of stresses and strains within the soil, induced by the inclusion of fibres, is the main cause of the improved soil response. This process occurs when the fibres transfer tensile forces to the soil through interaction mechanisms. However, this process is limited because the inclusion of fibres changes other relevant parameters, such as density and water content of the mix, which greatly influence its behaviour. The bearing capacity of fine soils is greatly influenced by their water content and density.

Figure 5c illustrates the density of the specimens, dry, wet before soaking (as prepared), and wet after soaking. The density of the reinforced specimens decreases, particularly for PNF = 2%. The reduced density can be attributed to several factors: (1) the fibres tend to restrict the packing of soil grains; (2) the excessive length of the fibres makes it difficult to mix them into the soil, resulting in heterogeneous orientation and spatial distribution of the fibres in the specimen; (3) part of the specimen is occupied by fibres that are less dense than the soil; (4) the compaction process is made more difficult due to the elastic behaviour of the fibres and the voids created next to the fibres, which absorb the impact forces generated by the rammer.

In contrast, the water content of the reinforced specimens is higher than in the unreinforced soil. This change is more pronounced for PNF = 2% (see

Figure 5d). Possible reasons for the increase in water content include the following: (1) during the soaking process, water is absorbed by both the soil and fibres; (2) the needles, being hydrophilic with high absorbent capacity, expand more than the soil, creating preferential paths for water to flow through; (3) the increase in voids near the fibres also contribute to an increase in water flow into the specimens.

Higher PNF may have also reduced the mobilisation and transfer of stresses between the fibres and the soil, thereby decreasing the soil response. For instance, the agglomeration of fibres (overlapping in certain areas of a specimen) and the bending and breaking of some fibres contribute to decreasing the effectiveness of the mobilisation of the fibres. Furthermore, the water absorbed by the specimens during the soaking process reduces the effectiveness of the interaction mechanisms at the materials interface. The presence of water in the voids reduces effective stresses in the soil, decreasing frictional shear stresses and increasing sliding and ruptures at the interface. The combined effect of these parameters (and maybe others) may have led to the limited improvement observed for PNF = 2.0%.

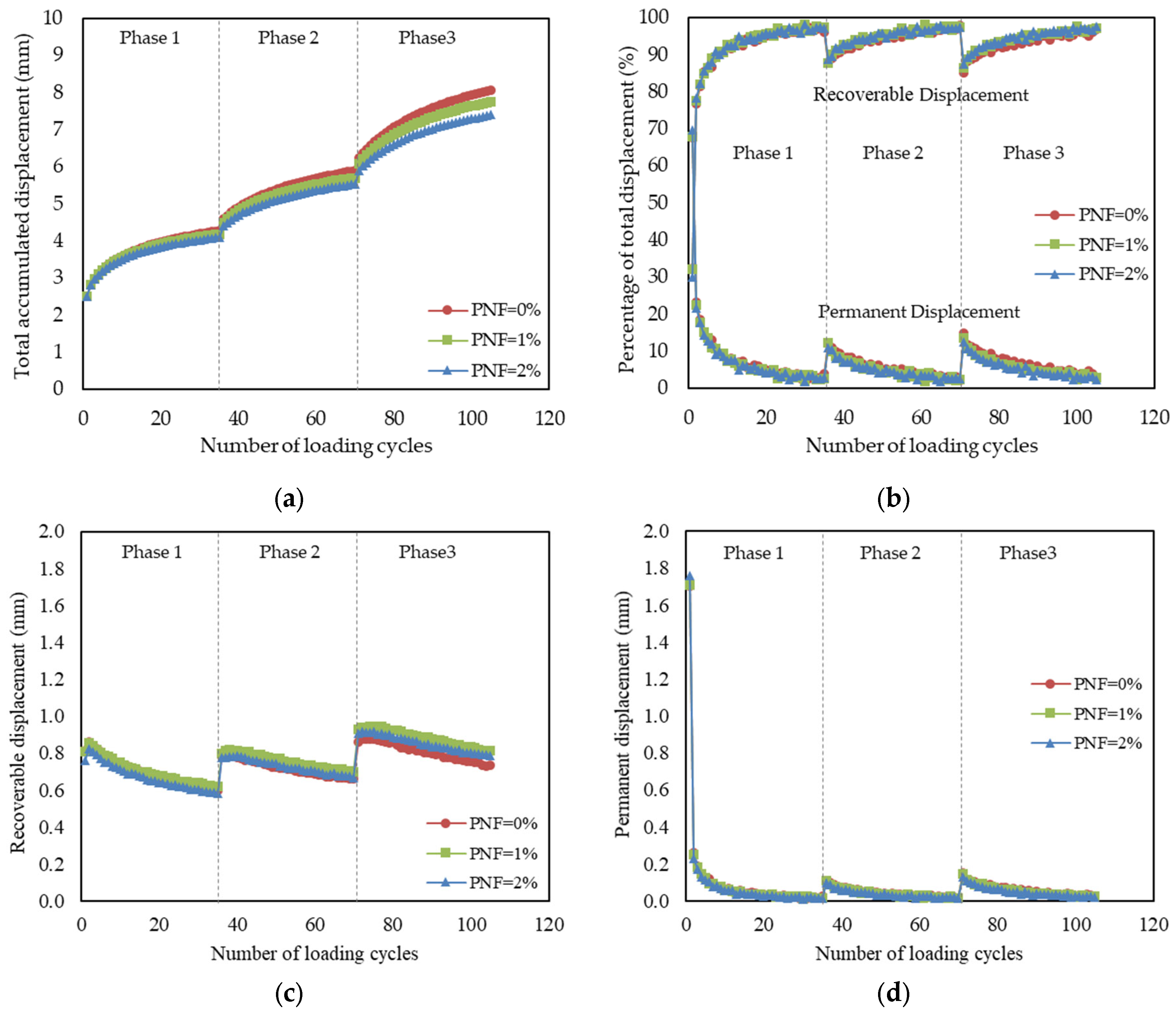

3.2. CBR Test—Phases 1 to 3, Repeated Loading

The results of phases 1 to 3 of the RL-CBR tests allowed the assessment of the evolution of the permanent and recoverable displacements suffered by the specimens until a resilient response is reached, i.e., when the application of a load only causes elastic deformations in the material.

Figure 6 illustrates the total displacement, as well as the recoverable (elastic) and permanent (plastic) components of the penetration displacement observed during each loading cycle (average for three specimens per condition).

The largest component of the displacement is the recoverable portion, except for the first cycle (phase 0) in which most of the permanent displacement takes place. Both the recoverable and permanent displacement decreased as the number of cycles increased. In theory, the permanent displacement will tend to decrease towards zero while the recoverable displacement will also decrease until it reaches a constant minimum value as the number of loading cycles increases. Although the permanent displacement at the last cycle of phase 1 was very small (~0.02 mm), the corresponding recoverable displacement had not yet stabilised (after 35 loading cycles). This shows that the criterion used to define the number of cycles may need to be adjusted to achieve a constant elastic displacement, i.e., a resilient response. The total displacement of the unreinforced soil (PNF = 0%) was the largest and decreased with the inclusion of the natural reinforcement (pine needles). The lowest total displacement was observed for PNF = 2%. The presence of pine needles (PNF = 1% or PNF = 2%) did not change the proportion of recoverable and permanent displacement per cycle observed for the unreinforced solution (PNF = 0%).

A similar behaviour was observed for the following repeated load stages considered (phases 2 and 3). However, the total displacement due to phase 1 is substantially greater than that caused by phases 2 and 3 (

Figure 6). This is because the plastic displacement at the beginning of the test (phase 0, monotonic loading) is extremely high and around 68 to 70% of the total displacement (depending on the PNF considered). A densification of the specimen below the plunger is observed, which influences the behaviour of the material and leads to a stiffer response. In the following cycles, the reduction in total displacement is substantial because much of the plastic displacement has already occurred. The total displacements caused by phases 2 and 3 are smaller because, as mentioned before, most of the plastic displacement has already occurred (the plastic displacement caused by the first cycle of phase 2 and of phase 3 was 12 to 14% of the total displacement (varied with PNF)).

To assess the soil response to repeated loading, an equivalent elastic modulus (Eequ) was estimated (Equation (2)). This parameter was calculated for all loading cycles of phases 0 to 3, although the most representative value refers to the last cycle of each phase (E

equ for the resilient response of the material).

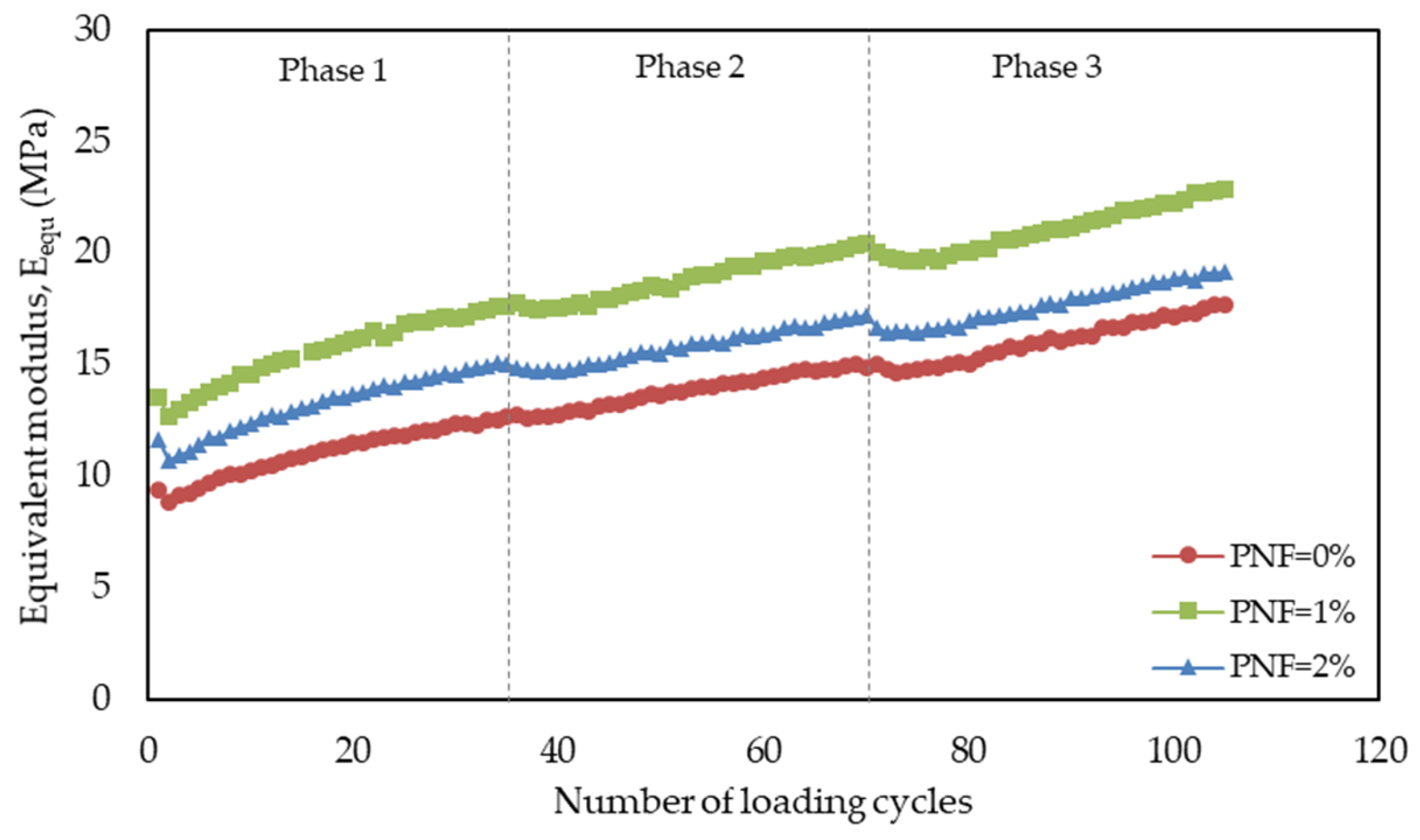

Figure 7 shows the evolution of E

equ with the number of loading cycles for the different conditions studied (PNF of 0%, 1%, and 2%).

The results obtained for phase 1 show that the equivalent modulus tends to increase with the number of load cycles. This parameter is influenced by the recoverable displacement and should reach a maximum constant value when this portion of the displacement is constant, i.e., when the material reaches its resilient response. As mentioned in relation to the recoverable displacement, regardless of the PNF considered, the equivalent modulus had also not yet stabilised at the end of phase 1 (i.e., after 35 load cycles), showing once again that the criterion used to define the number of cycles may need to be adjusted. For the unreinforced soil (PNF = 0%), at the end of phase 1, E

equ was 12.65 (±2.12)MPa (95% confidence interval in brackets), which is within the range of the Young’s modulus values reported by Bardet [

24] for silts (2 to 20 MPa). The equivalent modulus at the end of phase 1 of the reinforced soil for both PNF of 1% and 2% increased relative to that of the unreinforced soil, which confirms the beneficial effect of the natural fibre reinforcement. This parameter also indicates that the inclusion of pine needles led to a stiffer response for all reinforced specimens. The higher equivalent modulus was observed for soil reinforced with PNF = 1%. After 35 cycles, i.e., at the end of phase 1, and relative to the unreinforced soil (PNF = 0%), the equivalent modulus increased by 58% for PNF = 1% and 22% for PNF = 2%.

The immediate effect of changing the magnitude of the load (phases 2 and 3) was to increase the displacement (both permanent and recoverable) suffered by the specimens. This effect is small but sufficient to reduce the equivalent modulus during the first 2–3 cycles of each phase. After that, the equivalent modulus rises again with a growth rate similar to that of the previous phase. Increasing the load does not seem to significantly modify the evolution of the equivalent modulus. However, it is not possible to guarantee that the resilient response of the material was achieved after 35 load cycles of phase.

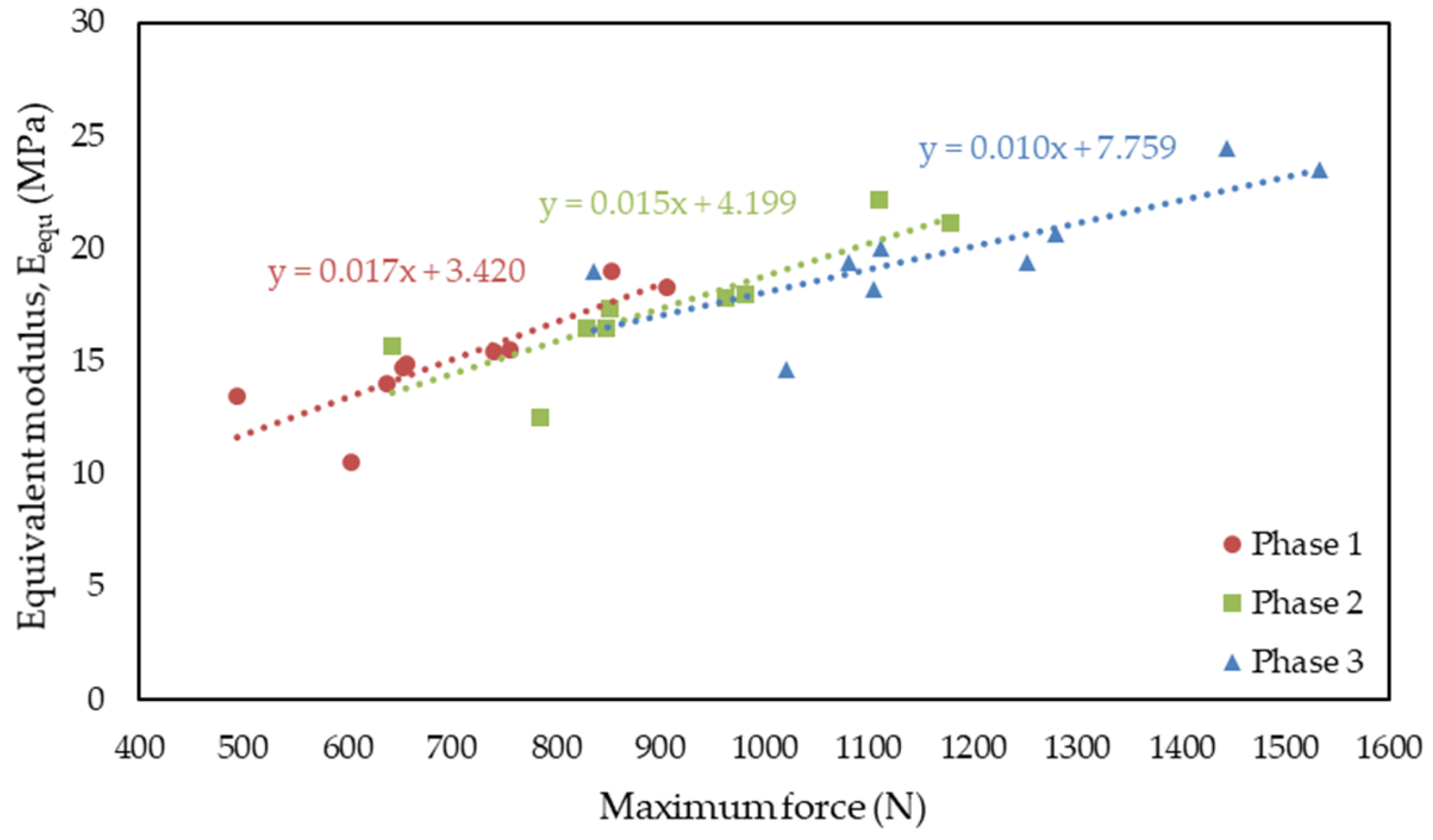

Haghighi et al. [

2] mentioned that the slope of the equivalent modulus–plunger stress relation can be used as an indication to investigate the failure of the material. According to the authors, if the slope decreases, the soil is approaching its maximum strength. The relation between E

equ and maximum force for each of the phases 1 to 3 is presented and analysed in

Figure 8 (for all PNF). The slope of the trendline for each phase is reduced: 0.017 for phase 1, 0.015 for phase 2, and 0.010 for phase 3. This reduction indicates that the soil matrix is reaching its maximum strength, regardless of the fibre reinforcement.

4. Conclusions

The main goal of this paper was to study the resilient response of a fine soil reinforced with natural fibres from the forest value chain (pine needles) and to evaluate their potential use on unpaved forest roads. Repeated load CBR tests (RL-CBR) were carried out on soil and soil–pine needles composite material (with 1 and 2% of needles incorporated). The force–penetration response, CBR value, recoverable and permanent displacements, and equivalent modulus were estimated. The effect of different load stages on the elastic response of both unreinforced and reinforced soil was also evaluated.

The results of the initial phase (phase 0) of the tests, which is equivalent to the standard CBR tests, allowed us to conclude the following:

The force–penetration response and CBR value of the soil improved with the inclusion of pine needles.

The best response was obtained for specimens with 1% of needles since the use of a higher percentage of incorporation did not result in further improvement. Several causes for this are outlined in the document.

The three phases of repeated loading carried out in RL-CBR tests showed the following:

For each repeated load phase (1 to 3), as the number of cycles increased, the permanent displacement decreased, approaching a resilient response.

The total displacement of the unreinforced soil was the largest and decreased with the inclusion of the natural reinforcement. The total displacements caused by phases 2 and 3 (i.e., with the increment of load applied to the specimen) were smaller because most of the plastic displacement had already occurred during the initial phase of the test (phase 0).

The equivalent modulus quantified for the unreinforced soil was within the range of the Young’s modulus values reported in literature for the same type of soil (2 to 20 MPa for silts).

The equivalent modulus of the soil reinforced with 1% or 2% of pine needles increased relative to that of the unreinforced soil, confirming the beneficial effect of the natural fibre reinforcement. This parameter also indicates that the reinforced specimens exhibited a stiffer response.

The criterion used to define the number of cycles per repeated load phase may need to be adjusted to achieve a constant elastic displacement, i.e., a resilient response.

The experiments conducted in this work showed that for unpaved forest roads, where the investment in soil characterization is often very limited (and often unused), RL-CBR tests can be a promising (simple, quick, and affordable) approach to obtain current design parameters. However, there are some open questions that need to be further investigated. The effect of reinforcement geometry, soaking process, specimens dimensions, and of applying other types of repeated loads should be included in future studies. In addition, the test procedure should be revised regarding the number of cycles per repeated load phase to ensure that the resilient response can be properly assessed. It should also be noted that aspects related to the durability (effect of mechanical, physical, chemical, environmental agents, etc.) of the natural fibres considered in this study were not evaluated (as they were beyond the scope of the work).