Abstract

A new flour blend (F) composed of selected milling and leaving passages with a high content of non-starch polysaccharides underwent thermal (T), hydrothermal (H) or hybrid processing and was used along with cellulase (C) and cellulase-xylanase complex (CX) to produce bread. This modified flour can be considered a clean label product. In this study, blends of common and treated flours were tested for dough properties and rheology. The modified flours were added at 10 and 20% to the base wheat flour. A pan bread was then prepared to test their suitability for bread baking. Dough and bread properties were subsequently assessed. Accordingly, dough with added thermally, hydrothermally, and hybrid modified flours revealed differences in rheology. Addition of hybrid enzymatic-hydrothermal treated flour increased dough tenacity by 23% and baking strength by 26%, but decreased dough extensibility by 19%, whereas hybrid enzymatic-thermal modification increased water absorption by 6% and bread yield from 146.77% to 150.02% when modified flour was added at 20%. Breads with added modified flours demonstrated a 16% increase in bread volume, 8% lower baking loss, and 14% greater density, with no negative effect on color and texture. Thus, hybrid thermal-enzymatic treatment of the developed flours can be recommended as a suitable method for enhancing the utilization of waste flour fractions and increasing their value by enabling them to be considered as clean label bread improvers.

1. Introduction

Bread, as one of the most common food products in the world, is considered crucial in human nutrition due to its accessibility and nutritional value. It is a very good source of carbohydrates, protein, dietary fiber, vitamins, and minerals [1]. Progress in the milling and bakery industries has resulted in the development of technology for the production of bakery products. These products are constantly improved, which allows industry to introduce wheat-based products with special health-promoting and functional values to the food market. Current research trends are focused on nutritional and technological improvements in cereal-based products using various additives and production processes that, ideally, allow these products to be recognized as clean label products [2,3]. The outcome of such work is that the addition of alternative components to standard wheat flour (insects, legumes, fruits, vegetables, herbs, microalgae, or by-products from the agri-food industry) [4,5,6,7,8,9], as well as the use of modern grain processing technologies [10,11] has enabled improvement of bakery products, especially of whole grain flours and breads [12].

To improve the functional properties of wheat flour through physical modification, various flour treatment technologies can be used. The most popular are dry heating or hydrothermal treatment with steam [13,14,15,16,17]. Additional modifications may be supported by utilizing selected enzymes such as cellulase or xylanase [18,19]. Modern technologies that can be applied to change or improve cereals’ properties include steam explosion (SE), high-hydrostatic-pressure (HHP), high-pressure homogenization (HPH), pulsed electric field (PEF), and plasma processing. The use of these technologies has significant effects on the resulting flour’s chemical, rheological, and hydration properties, as reported by Li and Niu [20]. Introducing specific physical modifications to grains or flours could reduce the negative effects of supplementation with wholegrain flour or unmodified bran-rich fractions on bread quality, especially with regard to dough rheology and bread quality [21,22,23]. Processes for extracting selected ingredients and components with desired properties from grains, mostly based on soluble and insoluble dietary fiber or beta-glucans, vitamins, and antioxidants, are under intense development [6,24,25].

Heating, as a physical treatment, via various methods (dry heating, hydrothermal, extrusion) may effectively modify the techno-functional properties of wheat grain and flour without the introduction of undesirable chemical additives. Hence, the developed products can be considered clean label additives [7]. Even if enzymes are used in such modification processes, after drying, the enzymes are inactivated, so enzymatically assisted modification can also be considered a clean label approach in bread production [12,13]. Each of the aforementioned modifications are intended to improve the various attributes of bakery products, especially their nutritional attributes, but, unfortunately, they often also have a negative impact on the technological and production properties of dough and, consequently, bakery products, e.g., bread [2].

Mill streams richest in fiber fractions come from the outer parts of the grain. As we described in our previous studies [26], differences in the composition of individual main milling streams of wheat result directly from the origin of specific fractions from the anatomical parts of the grain and the influence of grinding processes such as the mechanical damage of starch. Fractions containing bran parts, also of various sizes, are considered undesirable as a component of standard bread flours due to lower overall quality of dough and a decrease in dough elasticity and bread volume [26,27,28,29]; as such, they are sold as bran-rich products and supplements or animal feed [30]. Such items bring in less profit to the mill owners. These underutilized fractions amount to about 10% of the total production in a milling company, so it is economically important to find technological solutions for reducing the quantity of these underutilized fractions by increasing their use in higher quality products.

Economics and growing consumer concerns about food ingredients and clean labelling have had an impact on industrial bread production, resulting in enhanced efficiency and new recipes [3]. Consumers are looking for clean label products, without E-marked additives, but also with proper quality [20]. Unfortunately, some bread improvers are perceived as being unknown and harmful chemicals that may be unhealthy to consume [3]. In contrast, thermal processing methods may have a positive impact on the final quality of bakery products while enabling these to be considered “clean label”. In this present study, we investigate the possibility of using a developed wheat flour with an increased content of non-starch polysaccharides [26], fortified with baking enzymes, and additionally treated via various physical methods for bread production. Such modifications may offset the negative effects of treatments on the final quality of flour and help in the utilization of unused flour fractions as clean label additives to commercial bread flour blends.

The aim of the study was to investigate the impact of the addition of flours subjected to enzymatic, thermal, hydrothermal, and enzyme-assisted hybrid modifications on the quality of bread dough during mixing and fermentation, and on the characteristics of bread, as compared to the use of conventional flour.

2. Materials and Methods

2.1. Materials

Common wheat flour type 750 produced in PZZ Lubella was used as the base raw material suitable for the production of wheat bread. This was characterized by a moisture content of 14.3%, a gluten content of 28.2%, an ash content of 0.77%, and a falling number of 280 s. The developed flour before modifications was characterized as having a moisture content of 13.7%, a gluten content of 31.0%, an ash content of 0.78%, and a falling number of 340 s. The functional flours were prepared by undergoing thermal and hydrothermal treatments as described in Section 2.2 and were added in amounts of 10 and 20% of the total common flour base. The quantities of the incorporated modified flours were selected based on a preliminary study and on economic profitability. In the preliminary study, at over 20% of modified flours, the tested bread showed a tendency to collapse during fermentation and baking, thus 20% was considered the upper limit in the full study (any greater amount would lower the final product quality, hence lowering the profitability of production).

Selected batches of the functional flours underwent hybrid enzyme-assisted treatments. Commercial baking enzymes were employed to fortify the flour (the amount of the enzyme was determined based on preliminary tests and on the suggestions of the enzyme manufacturer). The following baking enzymes were used in the experiment: Bakezyme® WholeGrain-cellulase from Trichoderma reesei (DSM Food Specialities B.V., Delft, The Netherlands) with declared enzyme activity 1475 EGU/g (+/−5%); VERON 292-xylanase from Aspergillus niger, (AB Enzymes GmbH, Darmstadt, Germany) with declared enzyme activity min 1701 XylH/g. The cellulase enzyme was added in the amount of 120 ppm (samples marked as C), and the complex of cellulase and xylanase enzyme was incorporated in amounts of 60 ppm and 50 ppm, respectively (samples marked CX). Salt (Ciech S.A., Warszawa, Poland) and commercial bakery yeast (Lallemand, Lublin, Poland) were also used in the recipe.

2.2. Flour Modification Procedure

Enzymatic modification of the developed wheat flour (F) [31] was performed through the addition of 120 ppm of powdered cellulase (FC) and a combined 50 + 60 ppm of cellulase-xylanase complex (FCX). Components were mixed for 5 min at room temperature using a laboratory ribbon mixer (Konstal-Zakład Mechaniczny CNC Zbigniew Własiuk, Lublin, Poland) and left for 2 h to start enzymatic action.

A prototype installation (owned by PZZ Lubella) with an efficiency of 650 kg/h was used to obtain the modified flours. This consisted of cylindrical barrels with heating jackets that incorporated screw transporting-mixing elements.

Dry thermal treatment (T) was carried out for the tested wheat flour (TF) and for the flours incorporating the enzymes (TFC and TFCX) after mixing in a continuous ribbon mixer for 2 min at 25 °C. The processed flours underwent 5 min of dry heating at 15% moisture content inside the barrel, wherein the heating jacket temperature was set to 100 °C; the product temperature was measured during the tests so as not to exceed 50 °C.

Hydrothermal modification (H) of base wheat flour (HF) and the flours incorporating the enzymes (HFC and HFCX) was performed after mixing in a continuous ribbon mixer for 2 min at 25 °C using a prototype installation equipped with an additional steam-assisted preconditioner. Herein, flour samples without/with enzymes were mixed at 30 °C for 2 min and transferred to a single-screw preconditioner with 20 L/h of water, with a set jacket temperature of 100 °C, and were subjected to steam injection for 5 min. The product temperature measured during the tests did not exceed 65 °C.

The heated or hybrid enzymatic-assisted treated samples were subsequently dried in an air dryer at 100 °C for at least 15 min to end enzyme activity. A final moisture content of below 9% was achieved.

All samples were ground and sieved using a square sifter (Toruńskie Zakłady Urządzeń Młyńskich Spomasz S.A., Toruń, Poland) to homogenize the material and remove aggregates to obtain particle sizes below 300 µm. The samples were then stored at room temperature in closed plastic bags before tests.

2.3. Rheological Properties of Flours and Dough with Added Modified Flours

Rheological tests were performed with the following devices: Mixolab (Chopin Tech-nologies, Villeneuve-la-Garenne, France) according to ICC method 173, Brabender Farinograph-E apparatus (Duisburg, Germany) according to ICC method 115/1, and Alveograph (Chopin Technologies, Villeneuve-la-Garenne, France) according to ICC method 121 [32].

Rheological properties of blends prepared with additions of the modified flours were studied using a Chopin Mixolab based on the Chopin+ flour protocol with some modifications. The device was equipped with an additional attachment (the set includes a dough feeder and a special nozzle for this application) to control the quality of the prepared dough. For this purpose, 75 g of dough prepared during the bread preparation procedure described in Section 2.4 was transferred directly to the mixer and the test was begun according to the standard protocol at the following settings: dough weight—75 g, total analysis time—45 min, mixing speed—80 rpm, hydration water temperature 30 °C [33]. The Mixolab test was performed using a standard protocol: 8 min at 30 °C, heating for 15 min at a rate of 4 °C/min, holding at 90 °C for 7 min, cooling for 10 min to 50 °C at a rate of 4 °C/min, and holding at 50 °C for 5 min [14]. The following rheological features were evaluated via the Mixolab procedure: protein weakening (C2), starch gelatinization (C3), amylase activity (C4), starch retrogradation (C5) [34].

The rheological properties of the dough prepared without and with modified flours were determined using the Farinograph procedure [16] with some modification according to preparation of bread by way of the pan method. Water absorption (WA) was tested at the consistency of 400 BU, as recommended for this type of bread as prepared with pans (% of water needed to obtain a dough consistency of 400 BU or corrected at 14%).

Standard testing procedure was applied using Alveograph (Chopin Technologies, Villeneuve-la-Garenne, France) to investigate the blends with the addition of modified flours. The following features were assessed: the baking strength (W) as the surface area under the curve obtained, dough strength (P) as the maximum pressure needed to blow the dough bubble expressing dough resistance, dough extensibility (L) as the length of the curve expressing dough extensibility, elasticity index (Ie) [35], strain hardening index (SH), and P/L as configuration ratio [36]. All rheological tests were performed in triplicate.

2.4. Bread Preparation

The control bread sample (K) was prepared without the addition of modified flours. The control bread preparation was as follows: common wheat bread flour 750 type was mixed with 2% of salt and 3% of yeast, and water was added to obtain a dough consistency of 400 BU. The bread dough was prepared by way of the direct one-step method [7] with slight modifications. To prepare the tested breads, common bread wheat flour was replaced with developed flour (F), enzymatically modified flours (FC, FCX), as well as with thermal, hydrothermal, and hybrid enzymatic-assisted modified flours (TF, TFC, TFCX and HF, HFC, HFCX, respectively) in amounts of 10 and 20% (w/w). All ingredients were mixed in a laboratory mixer for 6 min (JMP12, Fimar Food Processing Equipment, Vericchio, Italy). The prepared dough was then divided into 300 g pieces and placed in loaf pans (approx. 10 × 10 × 10 cm) and fermented at 30 °C and 75% relative humidity (RH) for 50 min in a climatic chamber (MIWE US 2.0, Arnstein, Germany) controlled by an incorporated automatic temperature and humidity control system with an accuracy of 1 °C and 1% RH, respectively. After fermentation, the bread was then baked at 210/200/190/210 °C for 30 s/2 min/20 min/3.5 min—for a total of 26 min in a MIWE AERO backcombi oven (Arnstein, Germany). After loaf placement, steam was introduced for 30 s in an amount of 0.08 L. The temperature inside the baking oven was controlled by an incorporated automatic temperature control system with an accuracy of 1 °C. Post-baking, the loaves were removed from the tins and weighed. The breads were then cooled down for 1 h and weighed again, packed in polyethylene bags, and stored at 21 °C before the tests. All procedures were repeated in triplicate for each flour sample.

2.5. Proximate Composition Analysis of Bread

The chemical composition of ground dried bread samples was determined according to standard methods: AACC 46-10 method for protein (Nx6.25), AACC 30-10 method for fat, and AACC 08-01 method for ash [37]. The 991.43 method was applied to evaluate soluble (SDF) and insoluble (IDF) fractions and the content of total dietary fiber (TDF) [38]. Total carbohydrates and caloric values with Atwater energy equivalents were calculated for the tested breads [39]. All tests were performed in triplicate.

2.6. Bread Quality Tests

Specific bread volume (mL) was tested by way of the rapeseed displacement method according to AACC 10-05 standard [37] by using a known volume/mass of rapeseeds replaced by bread loaf and calculated as bread volume to bread weight [40]. Bread density (g/cm3) was calculated as the weight to volume ratio of single loaf. Baking loss (%) was evaluated as the difference of dough and loaf mass directly after baking to proper dough mass [6]. Weight loss (%) was checked as the difference between mass of the hot bread just after baking and after 24 h of storage. Bread yield (%) was calculated as the ratio of dough mass multiplied by dough yield to the mass of cold bread after baking [41]. Data were given as the averages of three independent experiments.

2.7. Water Absorption Index and Water Solubility Index Assessment

Water absorption index (WAI) and water solubility index (WSI) in breads were determined according to Soja et al. [42]. WAI was expressed as g of water absorbed by g of bread. WSI was expressed as % of components soluble in water after WAI testing. Measurements were conducted in triplicate.

2.8. Color Profile of Bread

To evaluate the color characteristics of bread crumb and crust 24 h after baking, the NH310 colorimeter was used (3NH TECHNOLOGY Co., Ltd., Guangzhou, China). Color assessment followed the CIE-Lab system, where L* describes the lightness and ranged from 0 (black) to 100 (white), the a* chromatic coordinate is determined as the balance between red (positive values) and green (negative values), and the b* chromatic coordinate is ascertained as the balance between yellow (if positive) and blue (if negative) [7]. The final values of the L*, a*, and b* coordinates of bread crumb and crust were expressed as the means of at least five measurements of each color determinant from three individual bread loaves. ΔE was calculated as the total color difference [7]. Before each measurement, the colorimeter was calibrated using a supplied white calibration plate.

2.9. Bread Crumb Texture Analysis

The textural properties of control bread and samples prepared with modified flours were determined in triplicate using a ZwickRoell BDO-FB0.5TH (Zwick GmbH and Co., Ulm, Germany) instrument, according to the TPA protocol, and testXpert®13.3 software. Bread samples were cut from the middle part of the crumb (3 × 3 × 1 cm). An Ottawa cell was employed for the testing, and had a working head speed of 100 mm/min in the double compression test to 50% of sample height and 10 s distance between cycles. TPA curves were analyzed, and textural properties were evaluated as mean values of five replications. The following features were determined: firmness as the highest peak during the first compression run, adhesion as the work needed to separate crumb and piston, springiness as the distance of the detected height during the second compression cycle divided by the original compression distance, gumminess and chewiness calculated on the base of firmness, cohesiveness, and springiness, and cohesiveness as the area of work during the second compression cycle divided by the area of work during the first compression [43].

2.10. Statistical Analysis

The obtained data were subjected to one-way analysis of variance (ANOVA) via the Statistica 13.3 software (StatSoft, Inc., Tulsa, OK, USA) application, followed by Tukey post hoc test to compare means at the 0.05 significance level. Pearson’s correlation coefficients were found to evaluate the correlations between the tested properties using Statistica 13.3 software (StatSoft, Inc., Tulsa, OK, USA) within the 95% confidence interval.

Statistica software (version 12.0, StatSoft Inc., Tulsa, OK, USA) was used for statistical analyses. Principal component analysis (PCA), analysis of variance, and determination of correlations were performed at the significance level of α = 0.05. Principal component analysis was applied to determine the relationship between conventional and hybrid thermal-enzymatic modified wheat flours and the studied parameters. The PCA data matrix for statistical analysis of the research results consisted of 40 columns (parameters) and 20 rows (Type of material). The input matrix was automatically rescaled. The optimal number of principal components obtained in the analysis for each matrix was determined based on the Cattel criterion.

3. Results

3.1. Flour and Dough Features Analysis

The developed flour was characterized as having an increased content of proteins, polysaccharides, and arabinoxylans due to it containing mostly the outer fractions of the wheat grain [14]. The composition of the NSP-rich developed wheat flour before modifications was as follows (%): protein—14.62 ± 0.06, fat—1.31 ± 0.01, ash—0.78 ± 0.02, insoluble dietary fiber—3.94 ± 0.04, soluble dietary fiber—2.86 ± 0.02, and total dietary fiber—6.80 ± 0.03. The composition of polysaccharides in the developed flour before modifications was as follows (%): total arabinoxylans—1.91 ± 0.06, which consisted of 1.31 ± 0.04 of insoluble fraction and 0.60 ± 0.02 of soluble fraction, and total non-starch polysaccharides—3.40 ± 0.00, which consisted of 2.06 ± 0.01 of insoluble fraction and 1.34 ± 0.00 of soluble fraction [31].

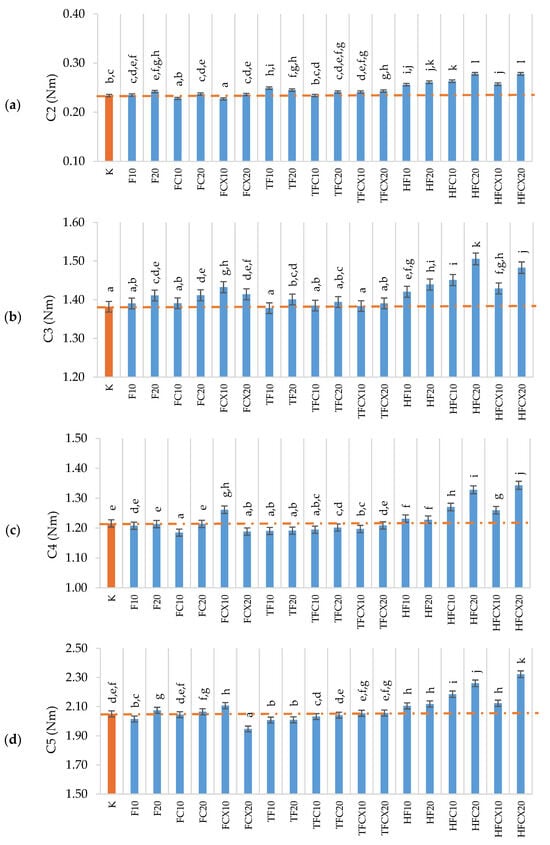

The following rheological features were evaluated through the Mixolab procedure: protein weakening (C2), starch gelatinization (C3), amylase activity (C4), and starch retrogradation (C5) [34]. In order to qualitatively assess individual samples, using the Mixolab device, an analysis of the dough taken from the mixer was carried out just before forming the dough in pans. This allowed us to check whether the dough had proper consistency and the flour was properly hydrated. This is made evident by reading the dough resistance at point C1 of the graph [5]. The properties of the finished dough, prepared for shaping, were tested at specific analysis points in accordance with the adopted methodology for the Chopin + protocol, i.e., C2, C3, C4, C5. Additional analysis allowed for effective control of the dough consistency, as the calculated average consistency for all dough samples at point C1 was 0.763 Nm ± 0.01 Nm. Figure 1 presents the rheological properties of the tested doughs with added modified flours in amounts of 10 and 20%.

Figure 1.

Rheological features of raw materials composition with added modified flours as compared to control common bread flour: (a) protein weakening (C2); (b) starch gelatinization (C3); (c) amylase activity (C4); (d) starch retrogradation (C5); K—control; F—flour; T—dry thermal treatment; H—hydrothermal treatment; C—cellulase enzyme; CX—cellulase-xylanase enzyme complex; 10 and 20—% of modified flour in bread recipe; dash line—level for control sample; a–l—means indicated with similar letters in columns do not differ significantly at α = 0.05.

The results of the analyses confirmed that the addition of flours modified by the addition of FC and FCX enzymes did not significantly affect the tested features, such as the level of C2 protein weakening, C3 starch gelatinization, C4 amylase activity, or the level of C5 starch retrogradation (Figure 1).

In tests with the addition of flour modified by thermal treatment, a slight increase in the C2 point value was observed for flours without the use of enzymes TF10 and TF20, indicating greater stiffness of the dough (Figure 1a). Incorporating hybrid enzymatic-thermal modified flours TFC10-TFCX20 resulted in a reduction of the C2 parameter values to the level of the control flour K. Mixtures with the addition of TF, TFC, and TFCX flours after thermal treatment were characterized by a reduction in C4 amylase activity without a significant effect of enzyme activity (Figure 1c), and the level of retrogradation of C5 starch was similar to the value for the control flour (Figure 1d).

The greatest differences in the values indicated via the Mixolab procedure were observed for mixtures with the addition of the hydrothermally processed flours–HF, HFC, and HFCX–where the values of all tested parameters–C2, C3, C4, C5–increased, as compared to the control flour, which indicates the large impact of flours modified with this method on the dough’s protein and starch complexes. These flours were characterized by a higher level of protein weakening, starch gelatinization, reduced activity of amylolytic enzymes, and a higher level of starch retrogradation than the control flour K. High-temperature treatment with steam and water had a negative effect on the protein-starch complex of the tested HF, HFC, and HFCX flours. Partial denaturation of gluten proteins occurred, thus bringing about difficulties in creating a gluten network matrix (unpublished data) and affecting an increase in the C2 parameter of protein weakening. The hydrothermal process induced initial starch gelatinization, hence, generating, through inactivation of amylolytic enzymes, a significant increase in starch gelatinization (C3), amylase activity (C4), and starch retrogradation (C5). These observations are supported by the PCA analysis presented in Section 3.5, which showed a commonality of effect in all the hydrothermally treated flours.

The addition of developed flour treated with enzymes in the hybrid processing increased this effect. Of note, the parameters from this analysis were well correlated with the parameters obtained in the alveographic analysis of bread composition mixtures consistency features. We found significant correlations between C2, C3, C4, C5 and dough tenacity (P) values with coefficients of 0.842, 0.825, 0.773, and 0.785, respectively, as well as dough configuration index (P/L) with r values of 0.845, 0.850, 0.812, and 0.794, respectively. Slightly lower but still significant negative correlations were noted between C2–C5 and dough extensibility L (range of r coefficients form −0.601 to −0.687). Starch gelatinization (C3), amylase activity (C4), and starch retrogradation (C5) were also significantly negatively correlated with water absorption (WA), with values of r ranging from −0.706 to −0.723.

Jurkaninová et al. [7] tested unfermented bread dough using the Mixolab procedure and they reported a negligible effect of herb extract addition on dough rheological characteristics, whereas their C2–C5 results were higher than that of our tested bread dough. Mahmoud et al. [8] assessed bread products with the addition of microalgae, and the results of their Mixolab rheological tests were similar, the C2 range being 0.23–0.44 Nm and the C3 being 2.12–2.74 Nm, while the C4 varied from 2.00 to 2.41 Nm, and, finally, C5 ranged between 3.06–4.27 Nm.

Upon analyzing the tested flour mixtures via farinographic analysis (Table 1), we observed that the improved tendency to absorb water seen in the modified developed flours had the greatest impact on the increase in water absorption (WA) within the bread mixtures. This was especially noticeable in the doughs created from flours incorporating thermally treated flours at both 10 and 20% values. Thus, for TFCX10 flour, WA increased by 3.5%, for TFCX20 by 5.4% and for TFC20 by 5.7%, as compared to the control K recipe. An increase in water absorption of the analyzed flour blends was also found for samples incorporating hydrothermally processed flours, but without significant differences when baking enzymes were used during this treatment. The results allowed the selection of the appropriate amount of water to prepare pan method bread dough with a constant consistency of 400 BU, enabling comparison of the impact of the addition of modified flours on the quality and bread yield.

Table 1.

Consistency characteristics of tested bread dough compositions with 10 and 20% w/w added modified flours treated through various methods.

Cacak-Pietrzak et al. [44] tested the addition of dried crushed roots of Taraxacum officinale to wheat flour and observed decreased WA from 57.5% (control sample) to 55.5% (sample with 6% TO), but significant differences were found even if 1% TO rich in inulin content was applied. Inulin, as a dietary fiber fraction rich in soluble components (such as inulin-type fructans), has a limited ability to absorb water [45]. In our samples, the increased level of non-starch polysaccharides in the developed flour rich in arabinoxylans (especially the insoluble fractions that came mostly from the final fractions of the reduction and sorting passages, as well as from filtration stream flours) was positively correlated with the water absorption [26]. Hence, the increased water absorption ability in blends with 10 and 20% of developed modified flour content may be connected with the presence of non-starch polysaccharides that were slightly modified by thermal or hydrothermal and hybrid treatments.

Tayefe et al. [11] reported increased WA in dough with the addition of hydrothermally treated bran. Their explanation for this outcome is that hydrothermal treatment causes interaction between water molecules and structural fibers through hydrogen bonding and thus increases the WA. Moreover, this hydrothermal processing may convert the starch present in developed flour to pregelatinized starch, which is characterized by improved retention of water molecules. They also reported an increase in dough development time and a decrease in dough stability when 6 and 9% of HT treated bran were added to the component bread flour. Similarly, when extruded at 50, 60, and 70 °C, wheat starch added to bread flour caused increased water absorption, as tested with Farinograph by Tao et al. [46].

The results of dough property testing utilizing an Alveograph are presented in Table 1 for control common bread flour and for blends with enzymatic, thermally, hydrothermally, and hybrid enzyme-assisted modified methods. The tested base common bread flour (K) was characterized by appropriate parameters for baking bread, wherein the baking force W was 212 J 10−4, with the dough elasticity and extensibility coefficient P/L being 1.26. After the addition of flour with increased content of non-starch polysaccharides (F), in amounts of both 10 and 20%, a slight increase in dough extensibility (L) was observed, and thus an improvement in baking value (W). However, with the addition of enzymatically modified flours, the flours had these values at a level similar to the control flour. When modified heat-treated raw materials (TF) were employed as additions to the control flour, a deterioration in the baking value (W) was found, mainly due to a decrease in dough elasticity (P). Here, the dough elasticity parameters (Ie) and (SH) also deteriorated. Of note, when thermally modified flours with enzymatic fortification were used as an additive, the elasticity parameters (P) increased to those observed for the control flour.

Improvement in dough elasticity (L), baking value (W), and elasticity index (Ie) was also observed; the improvement in these properties was more visible in the tests with the addition of the enzyme complex (TFCX). Buscella et al. [15] analyzed wheat cakes and bread flours that differed in quality and baking value and were subjected to heat treatment without water and to hydrothermal treatment. They conducted analyses of both the suspension and the dough matrix and observed that heat treatment improved the stability of the dough, albeit more intensively for the flour with weaker baking value, and that the viscosity properties of bread flour also changed [15]. The sedimentation value indicating the quality of gluten protein of bread flour subjected to dry heat treatment also showed a significant decrease compared to untreated bread flour [15]. This outcome was attributed to changes in the gluten structure due to the rearrangement of disulfide bonds [15]. We also observed that the addition of bread flour subjected only to dry heating worsened the quality parameters determined by alveographic analysis. The use of the hybrid modification method through the participation of bakery enzymes in the mixture, especially TFCX with the cellulase-xylanase complex, allowed us to obtain a level of quality that improved the overall quality of gluten proteins, evident in the improvement of dough elasticity, as well as in the notable improvement of the hydration properties of the flour (increased water absorption) (Table 1). In the case of the addition of flours modified by hydrothermal treatment, a decrease in dough extensibility and a significant increase in its elasticity were found in all tested blends. This resulted in a significant change in the configuration of the P/L chart, the value of which increased by 26% compared to the control flour and for dough with the addition of 10% of hydrothermally processed (HF10) flour, and to 49% if 20% of hybrid enzymatic-hydrothermal flour (HFCX20) was added to the blend.

Hydrothermal treatment carried out in the developed flour also brought about significant changes in the conformation of gluten proteins by reducing their elasticity. We did not observe significant differences between the addition of hydrothermally treated flours or those treated with enzyme assisted modification. Although both the baking value W and the SH coefficient increased to a higher level than in the control flour (K), this was due to increased dough stiffness and not due to improvement in flour blend quality, as we did not observe an increase in flour water absorption. Similar results were obtained in the work of Martinez et al. [22], who used extruded flours as additives to bread. Here, the addition of extruded flours significantly increased the elasticity of the dough and reduced its extensibility [22].

3.2. Bread Proximate Composition

Table 2 summarizes the main chemical components present in bread made with a common bread flour and when 10 and 20% w/w was replaced by modified flours without or with enzymatic assistance. The level of protein in common bread flour was 13.22% and all breads with added modified flours were higher in protein content than the control bread. This is the effect of the composition of the developed flour (F), which was characterized by higher protein content (14.62%) due to selection of appropriate milling passages, as well as to the contribution of selected fractions [31]. The bread formed from the developed flour, whether modified enzymatically, thermally, or hydrothermally without or with enzyme assistance, when replacing common flour at 10 and 20%, had increased total protein content, with higher values when 20% was added to the basic bread recipe.

Table 2.

Proximate composition of bread obtained with addition of modified flours.

Moreover, fat content in the developed flour was 1.31 ± 0.01%, and, after thermal modification or enzymatic modifications, was similarly ranged—at 1.30–1.38. Bucsella et al. [47], when testing aleurone-rich flour, found a different composition (20% protein, 15% dietary fiber) to that of commercial fiber-rich wheat fractions (9–13% protein, 9% dietary fiber). They noted that the presence of a higher content of inner layers of the seed coat than seen in white or wholegrain flour also resulted in a high fat content (4%). In our work, we saw that the fortified bread was lower in fat if modified flours were added, especially following HFC and HFCX application at 20%. Accordingly, significantly lowered fat content was found to be extractable during bread analysis. This limitation may be the effect of the formation complexes with amylose that usually come about during hydrothermal or extrusion treatment at increased temperatures [48]. The final temperature of these flours was around 65 °C, hence the temperature effect was more intense than that which occurs under dry thermal treatment (TF). Additionally, during baking temperatures, formation of fat-induced complexes may take place.

Our work saw that ash content in common bread was 1.02%, but that in the developed flour, ash content was lower (0.78%) [31]. Thus, the substitution of common flour with 10 and 20% of the developed F flour decreased ash content in the prepared bread. The ash content in treated flours varied from 1.00 to 1.15%, with a slight decreasing effect of C and CX enzymes addition on ash content in the produced bread (Table 2). In our work, dietary fiber and its fractions were tested in bread composed according to control (K) and modified recipes. The content of fibrous fractions in the developed flour showed IDF 3.94%, SDF 2.86%, and TDF 6.80% [31]. In contrast, the TDF in control bread was 8.21% and demonstrated a predominance of insoluble fraction IDF. In breads fortified with untreated developer flour (F10, F20), the content of TDF was significantly higher due to the incorporation of passages rich in non-starch polysaccharides derived from the outer layer of the original wheat grains [26].

As mentioned previously, increased content of fibrous fractions, especially insoluble, may have an effect on dough properties through an increase in water binding ability [49]. We also found high correlation between insoluble fractions and the TDF content (r = 0.933 at p < 0.05). In all breads with added hydrothermally treated flour at 20% content, both without and with enzymes, a lower level of TDF was noted than that for 10% of the additive, in addition to significantly lower amounts of insoluble fiber fractions. This may be the effect of enhanced enzymes activity being improved upon by temperature and steam action, because cellulases and xylanases act mostly on fibrous fractions of polysaccharides, causing partial hydrolysis of pentosanes [19,48,49]. In contrast, replacement of 20% of bread composition by modified flours resulted in higher content of TDF in bread than if 10% was applied—no matter the treatment or supplementation. In all cases, the effect of the addition of enzymes was ambiguous or similar in all dietary fiber fractions analysis. Analysis of carbohydrates content showed a slight decrease if modified flours were added to the bread mixture, and thus some slight changes in caloric values were noted (Table 2).

3.3. Bread Quality and Appearance

Bread quality and appearance are important factors for both producers and consumers [1,3,4,5,6,7,8,9]. Breads made from whole grain flour or supplemented with unmodified bran addition, due to the reduced ability of the dough to retain gases, are characterized by having smaller loaf volume and, hence, deteriorated baking quality [27,28]. Producers prefer a high yield of bread with high loaf volume and increased water absorption ability during bread dough making, but consumers prefer a regular crust structure and homogenous pores distribution in the bread crumb. Adding more water to dough recipes is a common approach to increasing bread production. However, increasing the amount of water in the dough can result in a deterioration of the dough’s kneading ability, as it becomes too wet and sticky, and this affects the final volume and texture of the bread [21]. Additionally, a higher water content in the dough can reduce the shelf life of the bread due to microbiological hazards. The addition of physically modified flours rich in fibrous fractions have been demonstrated to bring about changes in the bread quality [20]. The results of selected quality characteristics of baked bread prepared with the addition of modified flours are presented in Table 3.

Table 3.

Selected quality characteristics of baked bread prepared with the addition of modified flours.

In analyzing the quality and performance characteristics of the baked bread obtained from recipes with the addition of modified flours, it can be noticed that the addition of enzymatically and process-modified flours had a significant impact on the volume of the tested bread. This effect was also evident in the specific loaf volume values. Bread volume increased significantly when treated flours were added to the bread composition, in most cases, when 20% of modified flours were added.

Very good results in increasing the loaf volume were obtained when only flours subjected to enzymatic fortification (FC10, FC20, and FCX20) were used as additives. Hilhorst et al. [50] reported that the addition of xylanases may enhance the handling properties of wheat dough, the ovenspring, and the bread volume. The addition of process-modified flours or flours treated using hybrid enzyme-assisted methods to the bread mixtures also improved the bread volume, but without significant differences among the applied processing methods. Significant increase in bread volume was also demonstrated if thermally and hydrothermally treated TFC10 and HF20 flours were added to the bread recipe.

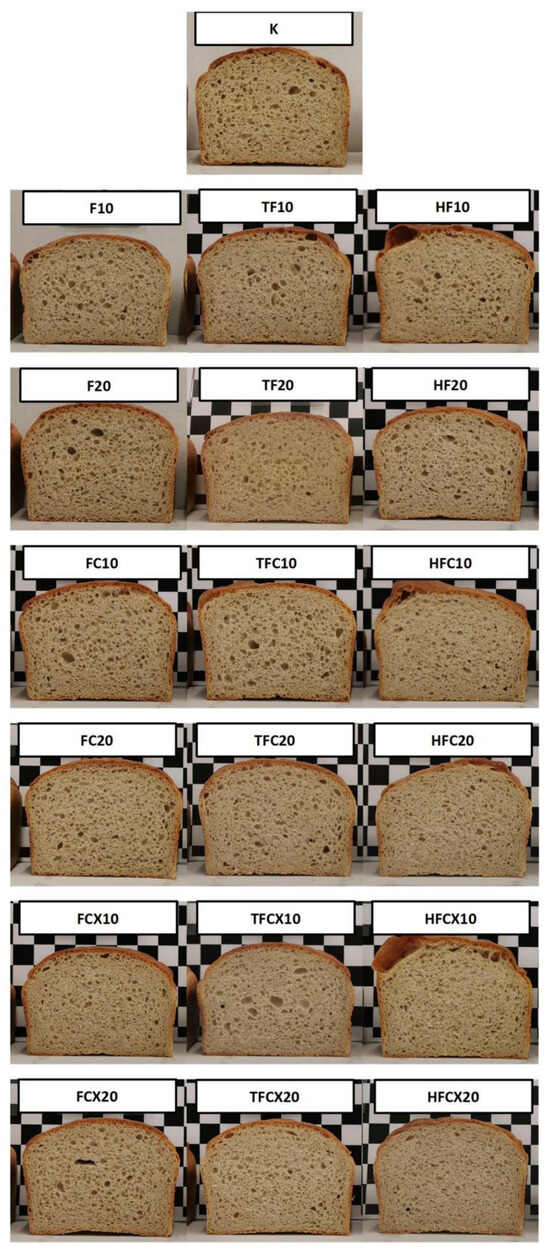

It should be noted that the higher loaf volume of breads prepared with the addition of hydrothermally treated flour with enzymes was also the result of uneven distribution of gas bubbles, which were located in large numbers under the bread crust, causing it to stand aside and bringing about the collapse of the loaf in the final stage of baking, as visible in the obtained bread pictures presented in Figure 2. This suggests that the consistency of the dough may have been too loose, and that the amount of water added to the recipes should be reduced when adding hydrothermally modified flours [47].

Figure 2.

Bread samples with the addition of modified flours: K—control; F—flour; T—dry thermal treatment; H—hydrothermal treatment; C—cellulase enzyme; CX—cellulase-xylanase enzyme complex; 10 and 20—% of modified flour in bread recipe.

When flours modified hydrothermally were used as an additive for baking, a negative impact on the final quality of the produced bread was evident. The problems with gas retention in bread were probably due to flours modified in this way losing their gluten network formation properties. According to Hong et al. [51], modification of wheat flour via superheated steam treatment causes protein denaturation and brings about the initial gelatinization of its contained starch granules, thus reducing the access of water to the protein phase due to its greater absorption. The resulting problem with the formation of a continuous network by starch is that it results in a weakening of the gluten quality and a reduction in its elasticity. This effect was noted in the alveographic analyses. The presence of HF, HFC, and HFCX flour components in the bread dough induced a lowering of dough strength and a problem with gas bubble containment in the dough matrix. Despite the use of bakery enzymes for processing, which increased the soluble fiber fraction, this did not eliminate the negative impact of the process on gluten protein quality.

In our work, specific bread volume increased significantly with the addition of thermal, hydrothermal, and hybrid treated developed flour, or if FC10 and FC20 was incorporated within the bread recipe (Table 3). A significant decrease in bread density (0.30–0.33 g/cm3) was also observed in these samples, as compared to control (0.35 g/cm3), due to the larger number of pores in the crumb than in the control bread.

We also found that bread volume and specific volume were highly negatively correlated with bread density (r = −0.997 and 0.987, respectively, at p < 0.05). Accordingly, Tao et al. [46] reported increased specific bread volume (from 1.63 to 2.15 cm3/g) when low temperature extrusion was applied to process wheat starch added to a bread recipe. Moreover, in our work, the addition of modified flours did not cause an increase in baking loss compared to the control bread, while an increase in weight loss after 24 h was observed. The increase in baking loss after 24 h was, however, slightly greater, albeit statistically insignificant, when modified and control flour recipes were compared. The greatest baking loss was observed in the control breads. The loss during baking of bread incorporating modified flours was lower, which indicates a heightened ability to retain water during baking; however, after 24 h, the weight loss was slightly higher, which may be the effect of retrogradation of starch treated via T and H methods after baking and cooling. The WAI values were also lower in the control bread and higher in that made with the modified additives. The addition of dry thermal heating reduced the retrogradation of the dough, as illustrated by the results of the C5 measurement, while the addition of hydrothermally treated flour increased the retrogradation, which is confirmed by the C5 results. Here, after cooling, the internal consistency was less springy, as confirmed by texture measurements.

In related work, Kurek et al. [52] found that values of a specific volume of wheat bread depend on the flour type used, with the lowest specific volume observed in wholegrain bread (0.82 cm3/g) and the highest in control white bread samples (1.60 cm3/g). Ma et al. [13] investigated the effect of superheated steam treatment on enhancing the physicochemical properties of flour for baked products. They noted that steam treatment could improve certain dough quality characteristics, such as volume and crumb quality. In their research, they found that the superheated steam treatment increased the starch gelatinization level and weakened the gluten strength due to denaturation, and that changes in these physicochemical properties of flour showed an effect on dough quality [13,16]. In our research, treatment with enzymes eliminated the negative aspects of the physical processes. In contrast, Hydrothermal treatment, despite the use of an enzyme complex, negatively affected the quality of the modified flour, the addition of which caused problems with bread dough gas bubble retention during rising and baking.

From an economic and quality point of view, the most desired outcome of flour/recipe modification is generating the highest specific volume. Alamri et al. [53] reported a specific volume between 2.55 and 3.14 cm3/g for bread with addition of 1 and 2% of plant gums, with the lowest value obtained for common wheat flour control bread. Wholegrain or fiber enriched dough generally has more phytic acid, which reduces alpha-amylase activity, which, in turn, causes a decrease in bread specific volume. A much higher specific bread volume was obtained by Zhan et al. [5] for whole wheat bread (3.82 cm3/g), and replacement of wheat flour by pulses decreased the specific volume of supplemented bread because of the lower water absorption of pulse flour.

In our study, change in the yield of the obtained bread was calculated for individual baked loaves. A significant increase was observed in breads made with recipes containing the addition of HFC20, HFCX20, HFCX10, TFCX 20, and TFC20 flours; however, as mentioned earlier, breads baked with the addition of HF flours were characterized by a lower ability to retain gases during fermentation, especially when 10% HFC and HFCX flours were added, and the bubbles moved under the crust, causing it to stand apart after baking (Figure 2). Such changes were not observed when dry heat-treated flour was used as an additive.

As shown in Figure 2, breads with TF, TFC, and TFCX additions were characterized by an increased or similar number of pores as in the control bread K; these were located evenly in the crumb, increasing the overall volume of the loaves. Ambrosewicz-Walacik et al. [41], in a related work, tested bread yield of yeast or sourdough fermented bread based on various compositions of doughs. They reported that bread yield varied from 131.1% if yeast were used in white wheat bread to 134.8% in wholemeal wheat bread, whereas bread yield ranged from 152.8% to 162.4%, respectively, when natural sourdough was applied. A much higher bread yield was obtained if rye flour was used, especially wholegrain (188.3%), with natural sourdough being used for bread preparation.

3.4. Bread Physical Properties

The color profile of bread crumb and crust are quality parameters mostly associated with the attractiveness of bakery products to the consumer. Development of non-enzymatic browning, as the effect of sugars caramelization or the Maillard reaction, on the surface of baked goods is important because of the formation of a marketable beige-brown color and specific flavor [7]. Table 4 presents the results of color profile evaluation of bread crumb and crust depending on the addition of the developed flour (F) as modified via the researched methods.

Table 4.

Color profile evaluation of bread crumb and crust.

In our work, the control bread crumb and crust had L* values 65.26 and 45.60, respectively. Breads with the addition of TH20 and HF20 were lighter than other samples with added modified flours, and the color profile was similar to the control. The use of modified flours with enzymes significantly decreased bread crumb lightness, and breads with the addition of FC10, FCX10, and FCX20 and HFC10 and HFC20 showed L* values ranging between 61.92 and 62.77. Other results were comparable with negligible effects of processing methods and enzymes used.

Bread crust color profiles were similar in lightness and a* values; however, a wider range of results were noted if the crust yellowness b* was evaluated (19.93–24.14). The more intensive redness or yellowness and darker crust color seen in some resulting breads may be the effect of nonenzymatic browning reactions or surface caramelization occurring under high temperature baking, especially when an increased content of reducing sugars is present in the bread composition [21]. In our work, ∆E was calculated separately for bread crumb and crust, and the results were, in almost all tested breads, below a value of 5, which is an easily recognized color difference.

Some differences were found between the tested breads and control sample if CX enzyme complex was added to the developed flour modifications. Especially in FCX10 and TFCX20, bread crust total color change values notably differed from the control. This could have come about due to the action of the enzyme complex upon the contained polysaccharides (which were hydrolyzed into simple sugars). This effect was not observed in the hydrothermally treated samples, probably due to the intensiveness of the treatment, which resulted in the complete deactivation of the enzymes. In the tested breads, however, no clear trend was observed, and the obtained breads were visually very similar. This confirms the appropriate quality of the resulting breads and that the additives did not have a deteriorating effect.

In a related work, Zhang et al. [5] tested the color of bread crumb prepared with whole what and supplemented with various pulse flours up to 25%. Here, the addition of pulse flour limited L* and b* coordinates, but, similarly, no significant trend was observed. Jurkaninová et al. [7] observed L* values from 59.0 to 69.8 for bread crust of breads fortified with herb extracts, which is within the standard range of lightness. They determined that a* ranged from 8.79 to 15.70 and b* from 32.98 to 38.33, which, while indicating a red–yellow area of crust color that is favorable for baked goods, demonstrated that the color profile of the crumb was much less intensive in redness and more yellow. Mahmoud et al. [8], in turn, tested the addition of microalgae to bread and they reported twice as much a decrease of crust and crumb lightness and a more intensive green and more yellow tint of crumb when various algaes were added. In our bread with the developed treated flour, the lightness and yellowness of crust and crumb were lower, but redness was more intensive than in the control.

Testing of WAI and WSI is helpful in identifying the integration of components in products that undergo variable heat-related treatments, for example, thermal treatment, baking, or extrusion [17,42]. In all the tested breads fortified with the modified developed flours, an increased WAI was obtained as compared to control bread K (Table 5). This confirms the ability of the dough to absorb more water when the developed modified flour was added to breads. When starch granules are partly gelatinized, they have tendency to absorb and hold water, but after exceeding the gelatinization point temperature, the starch granules become broken, and they do not have the ability to absorb water [54]. Of additional interest, thermal and hydrothermal treatment may be responsible for increasing swelling capacity; in our work, the addition of treated flours showed the tendency to increase WAI. During the steam process, wheat flour components are restructured and may present different affinities with water, because strong water binding capacity can be related to interactions between water and the carbohydrates and proteins present inside the flour. Delatte et al. [17] noted some differences in the WAI and WSI of untreated and modified flours when steam treated. They reported WAI of 0.929 to 2.089 g/g in the former, and up to 4.169 to 7.450 g/g in the latter, depending on the amount of steam added during treatment. In our study, increased WAI was noted if thermally, hydrothermally, and enzyme-assisted modified flours were incorporated into the basic bread recipe, as compared to control common wheat bread (Table 5), but differences were not strictly dependent on treatment method. WAI varied from 2.668 g/g in control bread K to 3.754 g/g in the TFC10 fortified bread.

Table 5.

WAI and WSI of breads.

WSI, as an indicator of degradation of molecular components, is usually employed to measure the degree of starch conversion during baking and may be an indicator of the amount of soluble polysaccharide released from the starch component after processing [55]. The decrease in WSI may be because of the reduction of carbohydrates, especially starch, in the recipe as replaced by the developed modified flour (Table 2), and thus limited gelatinization is one of the important effects of utilized baking procedure. Since WSI indicates the water solubility of non-bounded food components into water after WAI measurements, a tendency towards WSI increase with lowering of WAI was observed for most of the obtained results. Soluble components evaluated after bread testing indicated enhanced solubility if F developed flour was added to bread at 10 and 20%; here, the increase was associated with higher TDF in bread (Table 2) produced from fibrous fractions of selected passages in this new flour [26]. The highest WSI results were noted in bread with the addition of FC20 (Table 5). This outcome confirms the cellulase enzyme action on polysaccharides fractions in enzyme modified flour. Quite low WSI values were noted in breads with added enzyme-hydrothermal hybrid treated flour, both with cellulase and cellulase-xylanase complex application. All WSI values were below 8%. This confirms that the breads have both an appropriate internal structure and combination of most components within the protein-starch matrix of the bread dough after baking.

Texture measurements of the bread crumb showed some differences in the main textural properties of the tested breads, with the results from double-compression tests being presented in Table 6. Accordingly, control bread firmness was 15.47 N, springiness was 0.81, chewiness was 5.00 N, and cohesiveness was 0.40. Substitution of bread wheat flour with thermal, hydrothermal, or enzyme-assisted hybrid treated developed flour induced slight changes in the textural properties of the bread crumb. Most of the tested breads showed higher firmness values when thermal and hydrothermal modification of the added flour was applied. Moreover, the addition of untreated F flours increased bread hardness. Furthermore, lower compression forces were noted if enzymes were added to the developed flour. This outcome may be the effect of enzyme action on the fibrous flour fractions and subsequently on loosening the internal structure of bread crumb fortified with FC and FCX flours. Adhesion, as the work needed to separate the measuring element from the crumb surface, was very low in all the tested breads and differences were insignificant. Similarly, low values and insignificant differences were found for bread springiness.

Table 6.

Texture of bread with the addition of modified flours.

Chewiness of breads supplemented with F10 and F20, and those which contained unchanged fibrous fractions in the developed flour, was slightly higher than that of the control bread K. For other bread samples, the results did not differ significantly, except for the addition of TFC20. This increased bread chewiness. All baked breads were similar in cohesiveness, which confirms the visual observations of bread crumb presence of a compact internal structure (Figure 2). In general, the addition of modified flours did not significantly deteriorate the texture of the bread, while bread yield, bread volume, and specific volume of prepared breads with the modified developed flour were improved significantly. Zhang et al. [5] found that increasing the substitution level of pulse flours significantly enhanced the starch retrogradation value and resulted in a harder bread texture, as both polysaccharides and protein in the pulse flours have an effect on bread hardness. Tao et al. [46], in turn, found that the hardness of the bread crumb is limited if extruded flour was added; this is because bread containing extruded starch had a softer texture and a more porous crumb structure. The addition of plant gums to bread recipes also significantly reduces the firmness of bread via a clear effect of crumb-softening, as reported by Alamri et al. [53].

3.5. PCA Analysis

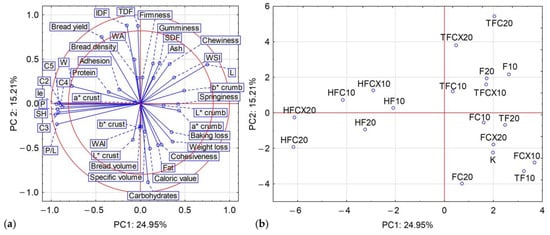

From the PCA analysis performed to determine the parameters that have the greatest influence on the variability of the system, eighteen new variables were obtained, of which the first three principal components explain more than 50% of the variability of the system. Indeed, the first two principal components explain 40.16% of the variability of the system (PC1 in 24.95% and PC2 in 15.21%), and the parameters that are contained between the two circles have the greatest influence on the variability of the system. As a result of this procedure, fourteen parameters were determined from the forty parameters examined: C2, C3, C4, C5, L, IDF, TDF, bread yield, W, le, SH, P, P/L, and carbohydrates (Figure 3a). The remaining parameters have a weak influence on the variability of the system. Moreover, C2, C3, C4, C5, W, le, SH, P, and P/L are strongly and positively correlated. The same relationship was observed for IDF, TDF, and bread yield. A strong but negative correlation occurs between parameters C2, C3, C4, C5, W, Ie, SH, P, P/L, and L, while a strong and negative correlation was also determined for IDF, TDF, bread yield, and carbohydrates. There is no correlation between C2, C3, C4, C5, W, Ie, SH, P, P/L, and IDF, TDF, bread yield, and carbohydrates. There is also no correlation between L and IDF, TDF and bread yield, and between L and carbohydrates.

Figure 3.

PCA analysis: (a) projection of variables all parameters on the PC1 and PC2 loadings plot; (b) projection of modified wheat flours on the PC1 and PC2 scores plot.

The PCA analysis also shows (Figure 3a,b) that HF, HFC, and HFCX are strongly and positively correlated with C2, C3, C4, C5, W, Ie, SH, P, and P/L, and strongly and negatively with L. In turn, F10, F20, TFC, and TFCX are strongly and positively correlated with L. In turn, K, FC, TF, and FCX are strongly and positively correlated with carbohydrates. The PCA analysis shows that the first principal component PC1 distinguishes hybrid thermal-enzymatic flour from control flour and thermal-enzymatic flour by 24.95% (Figure 3b). Positive values of the principal component PC1 describe the results of F and T and the control, and negative values of the principal component PC1 describe the results for H. The second principal component PC2 characterizes F, TF, and TFCX (positive values of PC2) and K, FC, and FCX (negative values of PC2) to 15.21%.

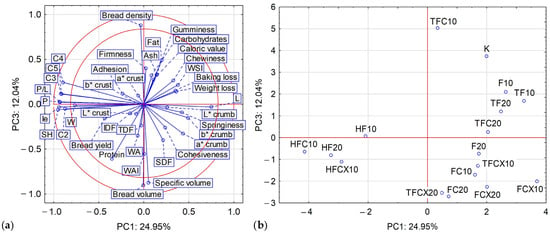

The first and third principal components explain 36.99% of the variability of the system (PC1 to 24.95% and PC2 to 15.21%). The parameters that are contained between the two circles have the greatest influence on the variability of the system. As a result of the analysis, twelve parameters were determined from the forty parameters studied: C2, C3, C4, C5, bread yield, W, Ie, SH, P, P/L, specific volume, and bread volume (Figure 4a). The remaining parameters have a weak influence on the variability of the system. C2, C3, C4, C5, W, Ie, SH, P, and P/L are strongly and positively correlated. The same relationship was observed for specific volume and bread volume. A strong but negative correlation occurs between the parameters: specific volume, bread volume, and bread yield. There is no correlation between C2, C3, C4, C5, W, Ie, SH, P, P/L, and bread yield, specific volume, and bread volume.

Figure 4.

PCA analysis: (a) projection of variables parameters on the PC1 and PC3 loadings plot; (b) projection of modified wheat flours on the PC1 and PC3 scores plot.

The PCA analysis also shows (Figure 4a,b) that HF, HFC, and HFCX are strongly and positively correlated with C2, C3, C4, C5, W, Ie, SH, P, and P/L. In turn, F10, F20, TFC, and TFCX are strongly and positively correlated with specific volume and bread volume. In turn, K, FC, TF, and FCX are strongly and positively correlated with bread yield.

The PCA analysis shows that the first principal component PC1 distinguishes hybrid thermal-enzymatic flour from flour and thermal-enzymatic flour to 24.95% (Figure 4b). Positive values of the PC1 principal component describe the results of F and T and the control, and negative values of the PC1 principal component describe the results for H. The third principal component PC3 characterizes F20, FC, FCX, and TFCX (negative PC2 values) and K F, TF, and TFC (positive PC2 values) to 12.04%.

4. Conclusions

The presented research has both scientific and practical impact due to it providing the possibility to find technological solutions for reducing the amount of underutilized wheat flour fractions (10% of production in a milling company) by incorporating it into blends that may be applicable for bread making with appropriate properties. Moreover, new knowledge acquired about the characteristics of developed flour modified with thermal, hydrothermal, and enzyme-assisted hybrid treatment and its application in bread is valuable for the baking industry and in providing food for a fast-growing population.

The presented research results confirmed the possibility of substituting standard wheat flours with flours treated via thermal, hydrothermal, or enzyme-assisted hybrid methods in bread recipes for the purpose of improving bread yield in a clean label manner. The investigated modification processes brought about some significant changes in dough rheology when 10 or 20% of modified flours replaced common wheat flour in bread composition. According to our research results, bread dough properties varied depending on modification process and level of added modified flour. Treatment with enzymes allowed us to eliminate the negative aspects of the physical processes. The hydrothermal treatment, despite the use of an enzyme complex, negatively affected the quality of modified flour, the addition of which caused problems with gas bubble retention in the bread dough during rising and baking. When modified flours were introduced, the protein weakening values increased by 19%. This indicates that the resulting bread product showed enhanced bread dough stiffness. However, dry thermal heated flours without or with enzymes showed significantly decreased amylase activity and starch retrogradation results by 2–11% and 2–13%, respectively, as compared to the control sample or to the hydrothermally modified flours. This indicates that thermal treatment deteriorated the flour parameters, but the addition of enzymes resulted in a dough quality similar to control, with increased bread efficiency related to the higher water absorption of the flour.

Bread properties, in terms of chemical composition, quality features, texture, and color, were slightly different if modified flours were added. Application of thermal treated modified flours to a common wheat bread recipe gave the highest bread yield of 150.02% and increased water absorption of the dough by 6%, especially when the enzyme-assisted method was applied to the developed flour; this was achieved without a negative impact on the texture or color of the obtained breads. It should be noted that the developed flours modified via hydrothermal method or hybrid enzyme-assisted method, when added to bread composition, did not produce a desired dough structure, and the addition resulted in a deteriorated bread crust formation, despite the increasing of bread volume and yield, as compared to control common wheat flour bread. However, all types of additives lowered baking loss and weight loss of the produced bread by 8% as compared to control sample. The resulting doughs with added thermally modified flour may be suitable for processing, mixing, and fermentation without deterioration of the quality of the bread and with improved bread volume (16%).

The presented results can be readily implemented in practice by milling companies as a solution for reducing the amount of underutilized fractions. Moreover, the composition of the new flour blends with the added developed modified flour (with its specific properties) may be offered as a ready-to-use bakery blend with a clean label as a bread improver. As a limitation in the use of the obtained modified flours, it should be noted that the addition of more than 20% of the total blend would not be profitable for bread producers as such amounts lower the final product quality. Future research, however, will be focused on production optimization, as well as exploring the possibilities of incorporating other flours into bread-making and evaluating the effects of the aforementioned additions on dough and bread quality. Moreover, additional tests will be carried out using other baking enzymes (e.g., bacterial xylanase) that could modify the processed flours more effectively.

Author Contributions

Conceptualization, P.L. and A.W.; methodology, P.L., A.W. and M.G.; software, P.L., A.W. and M.G.; validation, P.L. and A.W.; formal analysis, P.L. and M.G.; investigation, P.L.; resources, P.L.; data curation, P.L. and A.W.; writing—original draft preparation, P.L. and A.W.; writing—review and editing, P.L., A.W. and M.G.; visualization, P.L. and M.G.; supervision, A.W.; project administration, A.W.; funding acquisition, P.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research was financially supported from the founds of the Polish Ministry of Education and Science as a part of Implementation doctorate project (agreement number DWD/4/84/2020).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data presented in this study are available on request from the corresponding author.

Acknowledgments

Particular acknowledgements to Marek Goldsztejn from PZZ Lubella GMW Sp. z o.o., for his kind support during the research.

Conflicts of Interest

The authors declare no conflicts of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

References

- Cauvain, S.P. (Ed.) Breadmaking: Improving Quality; Series: Food Science, Technology and Nutrition; Woodhead Publishing: Cambridge, UK, 2012; Available online: https://www.sciencedirect.com/book/9780857090607/breadmaking (accessed on 3 June 2024).

- Cappelli, A.; Bettaccini, L.; Cini, E. The kneading process: A systematic review of the effects on dough rheology and resulting bread characteristics, including improvement strategies. Trends Food Sci. Technol. 2020, 104, 91–101. [Google Scholar] [CrossRef]

- Vargas, M.C.A.; Simsek, S. Clean label in bread. Foods 2021, 10, 2054. [Google Scholar] [CrossRef]

- Campbell, L.; Euston, S.R.; Ahmed, M.A. Effect of addition of thermally modified cowpea protein on sensory acceptability and textural properties of wheat bread and sponge cake. Food Chem. 2016, 194, 1230–1237. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Hu, R.; Tilley, M.; Siliveru, K.; Li, Y. Effect of pulse type and substitution level on dough rheology and bread quality of whole wheat-based composite flours. Processes 2021, 9, 1687. [Google Scholar] [CrossRef]

- Wójcik, M.; Bieńczak, A.; Woźniak, P.; Różyło, R. Impact of watermelon seed flour on the physical, chemical, and sensory properties of low-carbohydrate, high-protein bread. Processes 2023, 11, 3282. [Google Scholar] [CrossRef]

- Jurkaninová, L.; Švec, I.; Kučerová, I.; Havrlentová, M.; Božik, M.; Klouček, P.; Leuner, O. The use of thyme and lemongrass essential oils in cereal technology — Effect on wheat dough behavior and bread properties. Appl. Sci. 2024, 14, 4831. [Google Scholar] [CrossRef]

- Mahmoud, N.; Ferreira, J.; Raymundo, A.; Nunes, M.C. Enhancing the protein, mineral content, and bioactivity of wheat bread through the utilisation of microalgal biomass: A comparative study of Chlorella vulgaris, Phaeodactylum tricornutum, and Tetraselmis chuii. Appl. Sci. 2024, 14, 2483. [Google Scholar] [CrossRef]

- Zarzycki, P.; Wirkijowska, A.; Teterycz, D.; Łysakowska, P. Innovations in wheat bread: Using food industry by-products for better quality and nutrition. Appl. Sci. 2024, 14, 3976. [Google Scholar] [CrossRef]

- Lee, Y.Y.; Ma, F.; Byars, J.A.; Felker, F.C.; Liu, S.; Mosier, N.S.; Lee, J.H.; Kenar, J.A.; Baik, B.K. Influences of hydrothermal and pressure treatments on compositional and hydration properties of wheat bran and dough mixing properties of whole wheat meal. Cereal Chem. 2021, 98, 673–682. [Google Scholar] [CrossRef]

- Tayefe, M.; Shahidi, S.A.; Milani, J.M.; Sadeghi, S.M. Development, optimization, and critical quality characteristics of new wheat four dough formulations fortified with hydrothermally treated rice bran. J. Food Meas. Charact. 2020, 14, 2878–2888. [Google Scholar] [CrossRef]

- Tebben, L.; Shen, Y.; Li, Y. Improvers and functional ingredients in whole wheat bread: A review of their effects on dough properties and bread quality. Trends Food Sci. Tech. 2018, 81, 10–24. [Google Scholar] [CrossRef]

- Ma, F.; Lee, Y.Y.; Park, E.; Luo, Y.; Delwiche, S.; Baik, B.-K. Influences of hydrothermal and pressure treatments of wheat bran on the quality and sensory attributes of whole wheat Chinese steamed bread and pancakes. J. Cereal Sci. 2021, 102, 103356. [Google Scholar] [CrossRef]

- Keppler, S.; Bakalis, S.; Leadley, C.E.; Sahi, S.S.; Fryer, P.J. Evaluation of dry heat treatment of soft wheat flour for the production of high ratio cakes. Food Res. Int. 2018, 107, 360–370. [Google Scholar] [CrossRef] [PubMed]

- Bucsella, B.; Takács, Á.; Vizer, V.; Schwendener, U.; Tömösközi, S. Comparison of the effects of different heat treatment processes on rheological properties of cake and bread wheat flours. Food Chem. 2016, 190, 990–996. [Google Scholar] [CrossRef]

- Hu, J.; Wang, L.; Zhu, H.; Li, Z. Superheated steam treatment improved flour qualities of wheat in suitable conditions. J. Food. Process. Pres. 2017, 41, 13238. [Google Scholar] [CrossRef]

- Delatte, S.; Doran, L.; Blecker, C.; Mol, G.; Roiseux, O.; Gofflot, S.; Malumba, P. Effect of pilot-scale steam treatment and endogenous alpha-amylase activity on wheat flour functional properties. J. Cereal Sci. 2019, 88, 38–46. [Google Scholar] [CrossRef]

- de Souza, T.; Kawaguti, H.Y. Cellulases, hemicellulases, and pectinases: Applications in the food and beverage industry. Food Bioprocess Technol. 2021, 14, 1446–1477. [Google Scholar] [CrossRef]

- Melim Miguel, A.S.; Souza, T.; da Costa Figueiredo, E.V.; Paulo Lobo, B.W.; Maria, G. Enzymes in Bakery: Current and Future Trends. In Food Industry; Muzzalupo, I., Ed.; IntechOpen: London, UK, 2013. [Google Scholar] [CrossRef][Green Version]

- Li, M.; Niu, M. New technologies in cereal processing and their impact on the physical properties of cereal foods. Foods 2023, 12, 4008. [Google Scholar] [CrossRef]

- Gómez, M.; Jiménez, S.; Ruiz, E.; Oliete, B. Effect of extruded wheat bran on dough rheology and bread quality. LWT-Food Sci. Technol. 2011, 44, 2231–2237. [Google Scholar] [CrossRef]

- Martinez, M.; Oliete, B.; Gómez, M. Effect of the addition of extruded wheat flours on dough rheology and bread quality. J. Cereal Sci. 2013, 57, 424–429. [Google Scholar] [CrossRef]

- Jiang, X.; Wang, X.; Zhou, S. Effect of flaxseed marc flour on high-yield wheat bread production: Comparison in baking, staling, antioxidant and digestion properties. LWT-Food Sci. Technol. 2022, 169, 113979. [Google Scholar] [CrossRef]

- Cingöz, A.; Akpinar, O.; Sayaslan, A. Rheological properties of dough by addition of wheat bran hydrolysates obtained at different temperatures. J. Cereal Sci. 2023, 109, 103612. [Google Scholar] [CrossRef]

- Li, X.; Wang, L.; Jiang, P.; Zhu, Y.; Zhang, W.; Li, R.; Tan, B. The effect of wheat bran dietary fibre and raw wheat bran on the flour and dough properties: A comparative study. LWT-Food Sci. Technol. 2023, 173, 114304. [Google Scholar] [CrossRef]

- Lewko, P.; Wójtowicz, A.; Gancarz, M. Distribution of arabinoxylans and their relationship with physiochemical and rheological properties in wheat flour mill streams as an effective way to predict flour functionality. Appl. Sci. 2023, 13, 5458. [Google Scholar] [CrossRef]

- Schmiele, M.; Jaekel, L.; Patricio, S.; Chang, Y.; Steel, C. Rheological properties of wheat flour and quality characteristics of pan bread as modified by partial additions of wheat bran or whole grain wheat flour. Int. J. Food Sci. Tech. 2012, 47, 2141–2150. [Google Scholar] [CrossRef]

- Bucsella, B.; Molnár, D.; Harasztos, A.; Tömösközi, S. Comparison of the rheological and end-product properties of an industrial aleurone-rich wheat flour, whole grain wheat and rye flour. J. Cereal Sci. 2016, 69, 40–48. [Google Scholar] [CrossRef]

- Noort, M.; Haaster, D.; Hemery, Y.; Schols, H.A.; Hamer, R. The effect of particle size of wheat bran fractions on bread quality – Evidence for fibre–protein interactions. J. Cereal Sci. 2010, 52, 59–64. [Google Scholar] [CrossRef]

- Kaur, A.; Yadav, M.; Singh, B.; Bhinder, S.; Simon, S.; Singh, N. Isolation and characterization of arabinoxylans from wheat bran and study of their contribution to wheat flour dough rheology. Carbohyd. Polym. 2019, 221, 166–173. [Google Scholar] [CrossRef]

- Lewko, P.; Wójtowicz, A.; Różańska-Boczula, M. Effect of extruder configuration and extrusion cooking processing parameters on selected characteristics of non-starch polysaccharide-rich wheat flour as hybrid treatment with xylanase addition. Processes 2024, 12, 1159. [Google Scholar] [CrossRef]

- ICC Standard Methods, online version; International Association for Cereal Science and Technology: Vienna, Austria, 2018.

- Dubat, A.; Boinot, N. MIXOLAB Applications Handbook; Chopin Technologies: Villeneuve-la-Garenne, France, 2012; p. 148. [Google Scholar] [CrossRef]

- Dubat, A. A New AACC International Approved Method to measure rheological properties of a dough sample. Cereal Foods World 2010, 55, 150–153. [Google Scholar] [CrossRef]

- Codină, G.G.; Mironeasa, S.; Bordei, D.; Leahu, A. Mixolab versus Alveograph and falling number. Czech J. Food Sci. 2010, 28, 185–191. [Google Scholar] [CrossRef]

- Jødal, A.S.; Larsen, K.L. Investigation of the relationships between the alveograph parameters. Sci. Rep. 2021, 11, 5349. [Google Scholar] [CrossRef]

- Approved Method of the AACC, 9th ed.; American Association of Cereal Chemists: St. Paul, MN, USA, 2009; Available online: https://www.scirp.org/(S(czeh2tfqyw2orz553k1w0r45))/reference/ReferencesPapers.aspx?ReferenceID=1316335 (accessed on 2 August 2023).

- McCleary, B.; DeVries, J.; Rader, J.; Cohen, G.; Prosky, L.; Mugford, D.C.; Champ, M.; Okuma, K. Determination of insoluble, soluble, and total dietary fiber (CODEX Definition) by enzymatic-gravimetric method and liquid chromatography: Collaborative study. J. AOAC Int. 2012, 95, 824–844. [Google Scholar] [CrossRef] [PubMed]

- Charrondiere, U.R.; Chevassus-Agnes, S.; Marroni, S.; Burlingame, B. Impact of different macronutrient definitions and energy conversion factors on energy supply estimations. J. Food Compos. Anal. 2004, 17, 339–360. [Google Scholar] [CrossRef]

- Cingöz, A.; Akpinar, Ö.; Sayaslan, A. Effect of addition of wheat bran hydrolysate on bread properties. J. Food Sci. 2024, 89, 2567–2580. [Google Scholar] [CrossRef]

- Ambrosewicz-Walacik, M.; Tańska, M.; Rotkiewicz, D.; Piętak, A. Effect of various sodium chloride mass fractions on wheat and rye bread using different dough preparation techniques. Food Technol. Biotechnol. 2016, 54, 172–179. [Google Scholar] [CrossRef] [PubMed]

- Soja, J.; Combrzyński, M.; Oniszczuk, T.; Biernacka, B.; Wójtowicz, A.; Kupryaniuk, K.; Wojtunik-Kulesza, K.; Bąkowski, M.; Gancarz, M.; Mołdoch, J.; et al. The effect of fresh kale (Brassica oleracea var. sabellica) addition and processing conditions on selected biological, physical and chemical properties of extruded snack pellets. Molecules 2023, 28, 1835. [Google Scholar] [CrossRef]

- Nishinari, K.; Fang, Y. Perception and measurement of food texture: Solid foods. J. Texture Stud. 2018, 49, 160–201. [Google Scholar] [CrossRef]

- Cacak-Pietrzak, G.; Dziki, D.; Gawlik-Dziki, U.; Sułek, A.; Kalisz, S.; Sujka, K. Effect of the addition of dried dandelion roots (Taraxacum officinale F. H. Wigg.) on wheat dough and bread properties. Molecules 2021, 26, 7564. [Google Scholar] [CrossRef]

- Peressini, D.; Sensidoni, A. Effect of soluble dietary fibre addition on rheological and breadmaking properties of wheat doughs. J. Cereal Sci. 2009, 49, 190–201. [Google Scholar] [CrossRef]

- Tao, H.; Zhu, X.-F.; Nan, B.-X.; Jiang, R.-Z.; Wang, H.-L. Effect of extruded starch on the structure, farinograph characteristics and baking behavior of wheat dough. Food Chem. 2021, 348, 129017. [Google Scholar] [CrossRef]

- Bucsella, B.; Takács, Á.; von Reding, W.; Schwendener, U.; Kálmán, F.; Tömösközi, S. Rheological and stability aspects of dry and hydrothermally heat treated aleurone-rich wheat milling fraction. Food Chem. 2017, 220, 9–17. [Google Scholar] [CrossRef] [PubMed]

- Alam, M.S.; Kaur, J.; Khaira, H.; Gupta, K. Extrusion and extruded products: Changes in quality attributes as affected by extrusion process parameters: A review. Crit. Rev. Food. Sci. Nutr. 2016, 56, 445–475. [Google Scholar] [CrossRef] [PubMed]