1. Introduction

Modern motor control methods are those that provide the power supply to the motor through a power converter that allows for the regulation of the supplied voltage and frequency. Induction motors can be viewed as complex nonlinear control systems, and there are mainly three control strategies: scalar control or V/F control, where the manipulated variables are the magnitude and frequency of each voltage or current supplied to the stator; the field oriented control (FOC), which allows one to regulate the electromagnetic torque generated by the motor; and modern control, which regulates all the states of the nonlinear or linear plant [

1].

Some examples of scalar control applied to induction motors include ref. [

2], where the control was implemented on the Compact RIO control board 9074, which was used along with a static frequency converter to supply the three-phase asynchronous motor with a squirrel cage rotor. Additionally, a fuzzy logic controller was developed in LabVIEW software for speed regulation, and its performance was compared to the speed control with a PI control. In ref. [

3], simulations and experimental results were provided by applying a dual-mode adaptive robust controller to control the angular shaft speed of a three-phase induction motor. A microcomputer received the rotor speed using a tachometer, and Hall effect sensors were used to measure the currents of two phases of the motor. In ref. [

4], LabVIEW software:

https://studyatncepu.ncepu.edu.cn/docs/2023-12/d52f7540704649bdb7a1929e989190bd.pdf, accessed on 8 April 2024 running on a field programmable gate array, was used to design a V/F control. A general purpose inverter controller was used to control the speed of the induction motor with a pulse width modulation technique. MATLAB/Simulink,

https://studyatncepu.ncepu.edu.cn/docs/2023-12/d52f7540704649bdb7a1929e989190bd.pdf, accessed on 8 April 2024 and LabVIEW tools were used for the simulations and experiments.

With respect to the field oriented control (FOC), in ref. [

5], an adaptive indirect FOC based on a rotor flux observer was presented. Rotor flux estimation was based on the backstepping technique using the integral of tracking errors. It was implemented in real time using a dSPACE DS1104R&D board with a TMS320F240 digital signal processor and ControlDesk software:

https://www.sciencedirect.com/science/article/abs/pii/S0888327017303801, accessed on 6 February 2024 for the control of the load torque and rotor speed of the 3 kW induction motor. In ref. [

6], motor speed control via the FOC approach was synthesized, and constant flux control of a three-phase induction motor was calculated. It was performed using the discrete linearized three input–three output model (stator angular frequency, two components of the stator space voltage vector–rotor angular speed, and two components of the stator space flux linkage). Furthermore, a robust optimal preview control was proposed. The simulation and experimental results were presented using a dSpace DS 1104 control board.

Focusing on the developed advanced modern control techniques for three-phase induction motors, in some works, including ref. [

7], a quasi-linearization approach was presented that converts the nonlinear optimal control problem of a three-phase induction motor (modeled as a third order nonlinear model) into a sequence of linear quadratic optimal control problems. The simulation results are presented. In ref. [

8], the predictive control model approach was applied to the induction motor drive system that controls its torque and current. Using the linear state-space representation (currents were state variables), the simulation results were shown. In ref. [

9], the implementation of an optimal control based on quadratic criteria was presented in a low-power electric drive with a three-phase induction motor. The dSPACE 1104 controller was used to obtain the optimal online solution of the Riccati matrix differential equation. A linear model was considered, and its state variables were the rotor speed and the angular position of the rotor field. Based on the optimal solution and the corresponding feedback signals, the optimal speed reference for the AC drive system was obtained and tracked by the Altivar 71 inverter. It was compared with the inner rotor field oriented control and the PI controller of the Altivar 71 inverter. Experimental results of speed and load torque regulation were presented. In ref. [

10], a robust adaptive speed position tracking control was presented for a mathematical model of the linear fith-order induction motor mathematical model with unknown end effects and secondary resistance.

Other works related to the synthesis of advanced control strategies considering the full state (fifth-order) nonlinear model of the induction motor have been developed. For example, in ref. [

11], a nonlinear predictive control was synthesized to regulate an induction motor in a water pumping system. This scheme was validated via simulations. Another similar work on predictive control is ref. [

12], as well as applications of motor control such as ref. [

13]. In ref. [

14], a discrete-time sliding mode control of an induction motor was designed to regulate the rotor speed and stator current. Real-time experiments were carried out using a dSpace system with the DS1104 control board based on the TMS320F240 digital signal processor. In ref. [

15], an indirect rotor flux oriented control and backstepping control of a five-phase induction motor drive were presented. The performance of both controllers was analyzed through experimental validation.

Most of the synthesized control strategies in the specialized literature were validated via simulation results [

7,

11] or by experiments using a test bench [

2,

3,

4,

5,

6,

10,

14,

15] without the use of an industrial inverter. In fact, there are few projects that use industrial VFDs that incorporate advanced control techniques [

9], possibly because industrial VFDs generally have a closed architecture. For instance, in ref. [

16], a remote control system for an induction motor was presented using a PLC OMRON CJ1M- CPU11-ETN21 (Kyoto, Japan) and LabVIEW software. A VFD OMRON SYSDRIVE 3G3MV-A2007 was used to change the speed control. The whole system was in an open loop since there was no practical data measurement from the actual output of the motor. In ref. [

17], the VFD Altivar 71 was preconfigured to accept speed reference via the Modbus communication protocol from a Raspberry Pi board; however, there was no closed-loop system, and neither control strategy was mentioned. In ref. [

18], an induction motor (three-phase, 380 V, 50 Hz, four-pole, low-voltage squirrel cage) drove a conveyor belt for a bottle filling plant. The open loop control of motor speed and direction control was performed using data sent through a PLC (Schneider Electric Modicon TM241CEC24R (Rueil-Malmaison, France)) connected for serial communication (RS485 port) to the VFD (ATV12H075M2), whose parameters (speed, direction, acceleration, and deceleration) were changed and monitored using the Modbus protocol to communicate with a SCADA server.

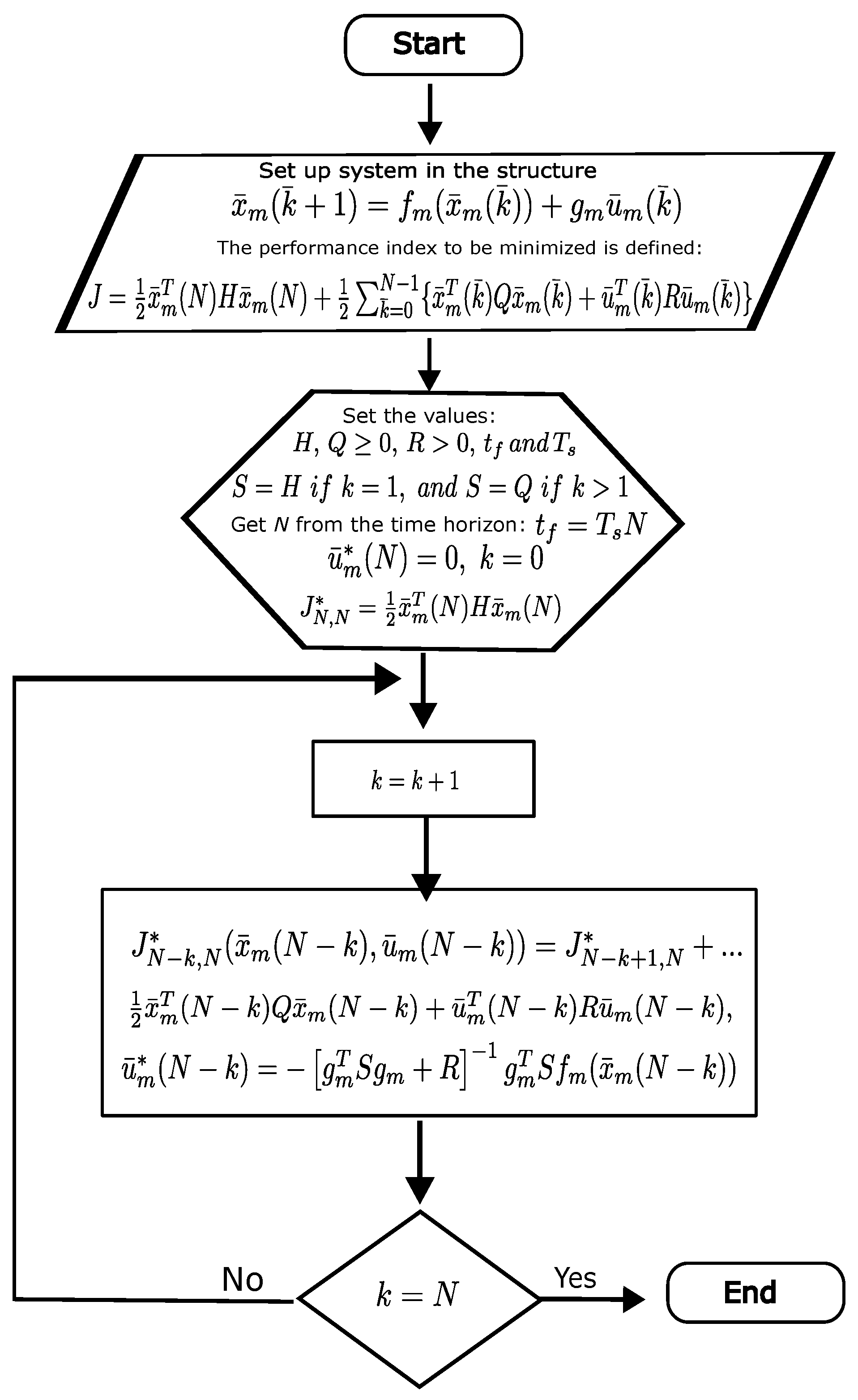

The dynamic programming approach was used as a base to develop the nonlinear control for the Baldor IDNM3534 induction motor, which was modeled using the Clarke transformation from three phases into two phases [

1], leading to an equivalent representation given by an affine nonlinear fifth-order model. The main ideas of the dynamic programming approach exposed here were originally proposed in ref. [

19]. This approach was applied to the unmanned aerial vehicle (UAV) in ref. [

20], an autonomous soaring UAV in ref. [

21], to a hybrid exoskeleton in ref. [

22], and a tomato dehydrator modeled as discrete affine nonlinear systems with delayed input [

23].

Since the rotor flux is not usually measurable, in some cases, it is obtained via an observer. However, in this proposal, the real-time reconstruction of the fluxes is carried out according to ref. [

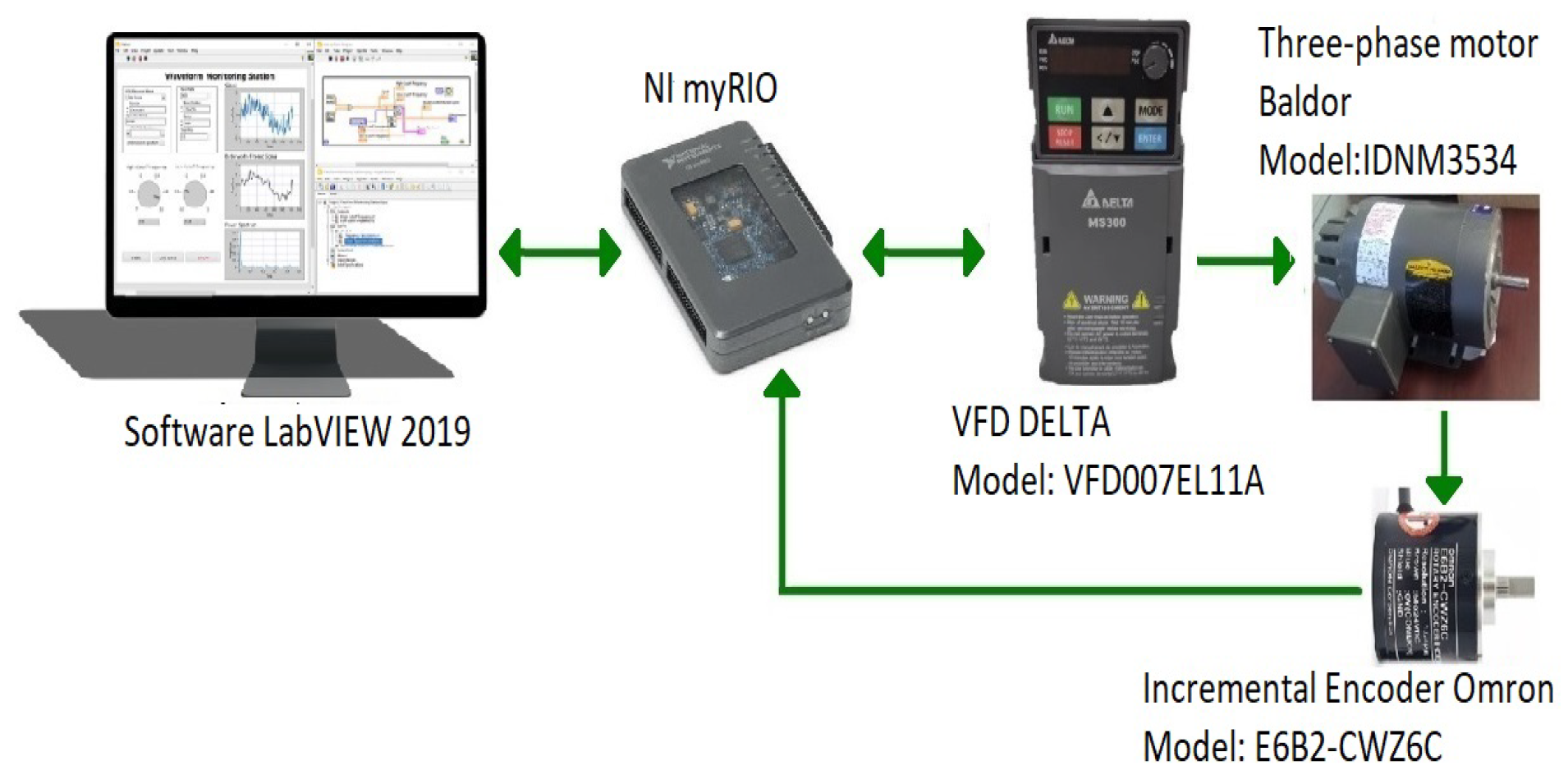

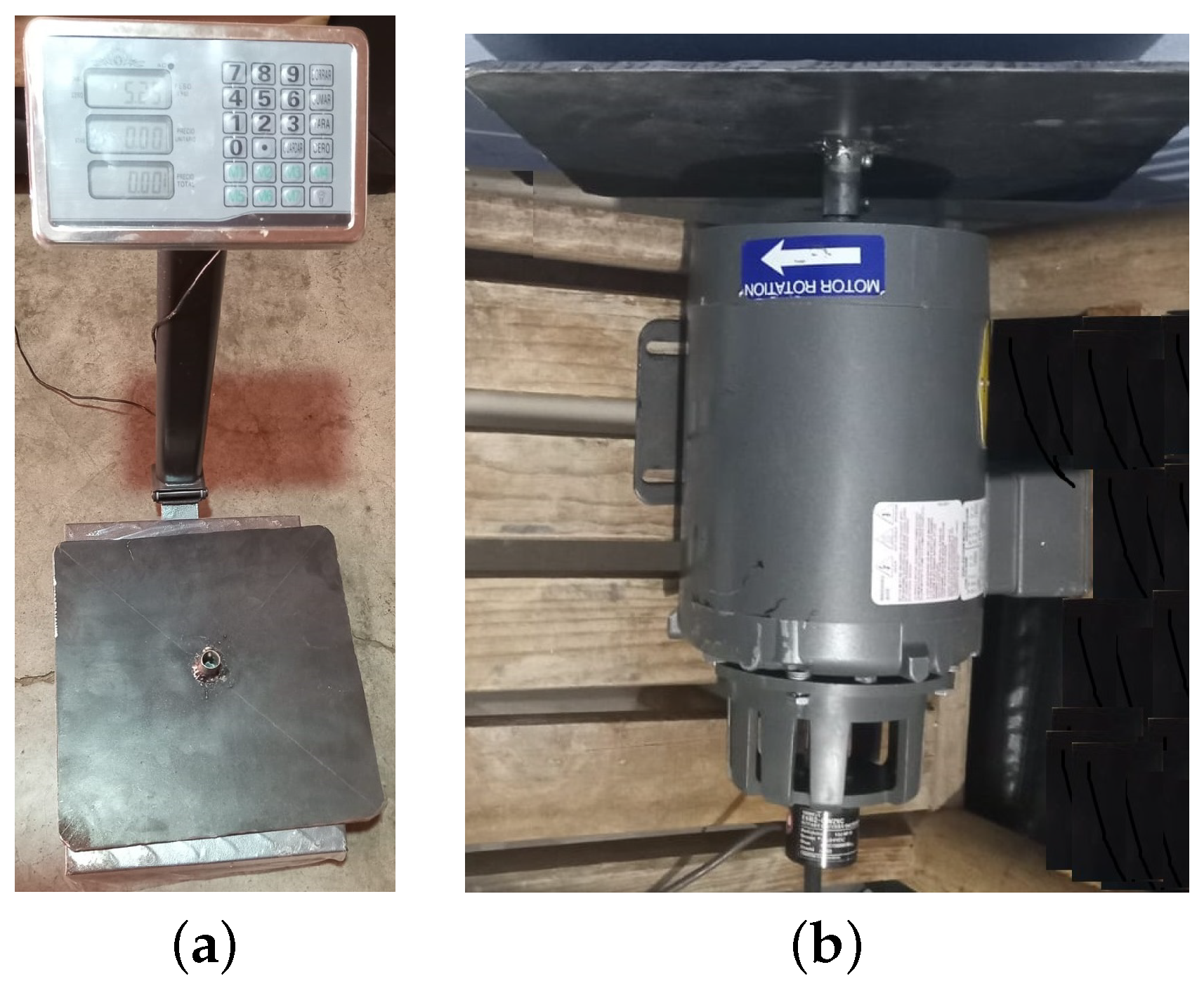

24]; that is, using measured variables and the mathematical model. These flux estimations, the stator currents (obtained from an industrial VFD Delta VFD007EL11A), and the rotor speed (measured from an encoder) are used for the computation of the proposed nonlinear discrete suboptimal control, which uses the plant model. The real-time experiments are made using a data acquisition NI MyRIO card, an industrial VFD, and LabVIEW software, in which a command interface is developed to set the setpoints (experimentally obtained), the penalty matrices for computation of the discrete suboptimal controller, and the nonlinear control strategy. The inner PID control of an industrial VFD, usually used to regulate the velocity of the rotor of the motor, is tuned (the proportional part is the unity, the integral and derivative parts are disabled) to allow the external control signal from the MyRIO card and the PC with LabVIEW software. The setpoint of the inner PID of the VFD is set to zero using the potentiometer available from the VFD. The internal PID control of the VFD is configured with positive feedback (the part of the process variable is positive and configured as an analog input of the VFD). In this analog input, the suboptimal nonlinear control signal, given by the MyRIO card (a root mean square voltage that is proportional to frequency, which guarantees the relation of V/F of the VFD) is introduced to the industrial VFD instead of the encoder signal. The encoder signal is read through the MyRIO card and processed using LabVIEW software. A comparison with an optimal PI controller using the VI LabVIEW PID of the Control toolkit is made.

The main contributions of the paper are summarized as follows:

The experimental application of the discrete suboptimal controller for the nonlinear induction motor model is developed with a relatively low cost to regulate the five state variables of the biphasic system.

An industrial VFD is used as interface between the nonlinear control and the AC motor by using a MyRIO card and LabVIEW software. The experiments were conducted with different sampling times.

The real-time reconstruction of the rotor fluxes is obtained directly from the nonlinear model and is used to calculate the suboptimal nonlinear discrete control.

Good tracking performance and robustness to unknown parameters is obtained when the set point is varying (without and with load on the motor shaft). The proposed suboptimal nonlinear discrete controller improves the operation of the V/F scalar control (currents and fluxes tracking) of the industrial VFD when compared with an optimal PI. It gives experimental evidence that the mathematical model used is a good approximation of the real behavior of the AC motor.

This paper is organized as follows.

Section 2 is devoted to useful results for the implementation of the proposed scheme. In

Section 3, the suboptimal sequence to regulate a transformed biphasic system is synthesized. The experimental results are presented in

Section 4, and finally, in

Section 5, concluding comments are presented.