Slope Stability Analysis of Rockfill Embankments Considering Stress-Dependent Spatial Variability in Friction Angle of Granular Materials

Abstract

1. Introduction

2. Approach for Slope Stability Analysis of Rockfill Embankments Considering Stress-Dependent Spatial Variability in Friction Angle

2.1. Bishop’s Simplified Method and Pseudo-Static Method for Seismic Slope Stability Analysis of Embankments

2.2. An Algorithm for Determining the Values of the Friction Angle at the Bases of the Slices

- (a)

- Assume an initial and ; in this study, and = 1.

- (b)

- Determine φf by substituting and () in Equation (7), then σ′3 is calculated using Equations (6) and (8).

- (c)

- Obtain from Equations (3)–(5).

- (d)

- Compute using Equation (1).

- (e)

- Repeat steps (b) to (d) until ≤ ε, where ε is the tolerance; in this study, ε = 0.001.

3. Illustrative Example

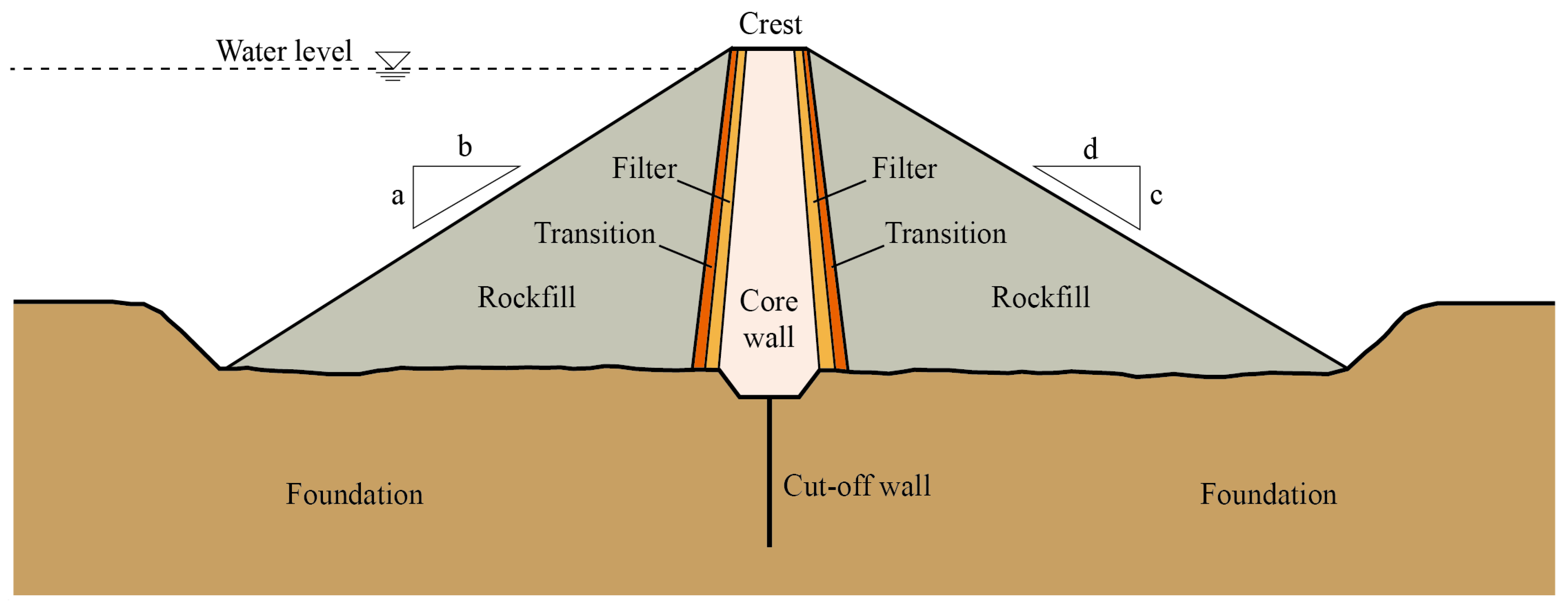

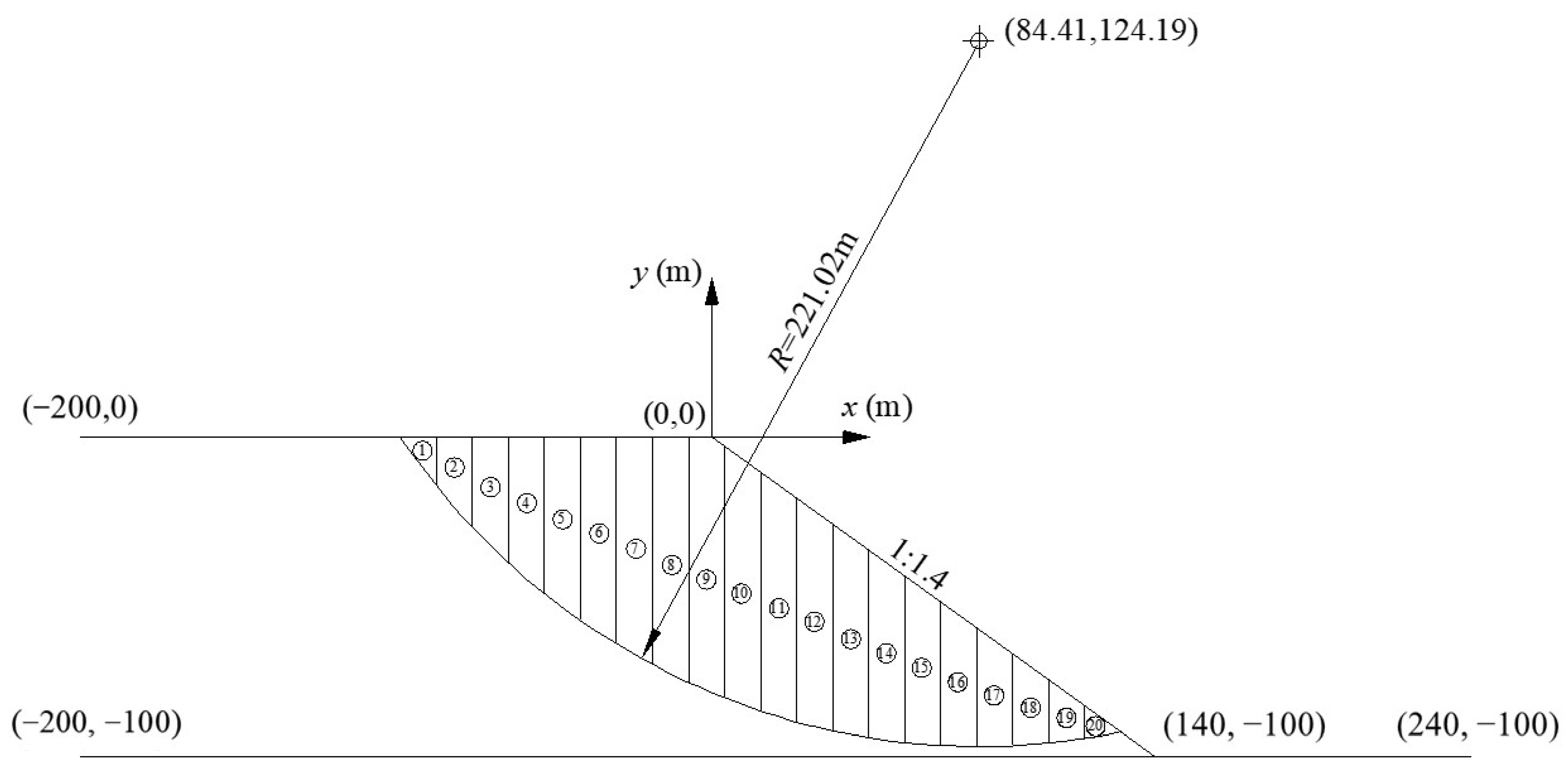

3.1. The Slope Stability Analysis of a Rockfill Embankment

3.2. Parametric Analysis of Variance Function of Friction Angle

4. Summary and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liu, S.; Sun, Y.; Shen, C.; Yin, Z. Practical nonlinear constitutive model for rockfill materials with application to rockfill dam. Comput. Geotech. 2020, 119, 103383. [Google Scholar] [CrossRef]

- Zhou, X.; Chi, S.; Wang, M.; Jia, Y. Study on wetting deformation characteristics of coarse granular materials and its simulation in core-wall rockfill dams. Int. J. Numer. Anal. Methods Geomech. 2020, 44, 851–873. [Google Scholar] [CrossRef]

- Qu, Y.; Zou, D.; Liu, J.; Yang, Z.; Chen, K. Two-dimensional DEM-FEM coupling analysis of seismic failure and anti-seismic measures for concrete faced rockfill dam. Comput. Geotech. 2022, 151, 104950. [Google Scholar] [CrossRef]

- Liu, D.; Yang, J.; Dong, B. Discrete element analysis of the influence of compaction quality on mechanical properties of rockfill materials. Comput. Geotech. 2022, 151, 104958. [Google Scholar] [CrossRef]

- Zhang, H.; Jing, Y.; Chen, J.; Gao, Z.; Xu, Y. Characteristics and causes of crest cracking on a high core-wall rockfill dam: A case study. Eng. Geol. 2022, 297, 106488. [Google Scholar] [CrossRef]

- Zhao, X.; Zhu, J.; Wu, Y.; Jia, Y.; Colliat, J.-B.; Bian, H. A Numerical Study on the Influence of Coordination Number on the Crushing of Rockfill Materials. Rock Mech. Rock Eng. 2022, 55, 6279–6300. [Google Scholar] [CrossRef]

- Cheng, J.; Ma, G.; Zhang, G.; Chang, X.; Zhou, W. A theoretical model for evaluating the deterioration of mechanical properties of rockfill materials. Comput. Geotech. 2023, 163, 105757. [Google Scholar] [CrossRef]

- Yan, S.; Chi, S.; Shao, X.; Guo, Y. Effect of size and strain rate on particle strength and stress–strain properties of rockfill materials. Soil Dyn. Earthq. Eng. 2022, 162, 107422. [Google Scholar] [CrossRef]

- Xing, H.; Gong, X.; Zhou, X.; Fu, H. Construction of Concrete-Faced Rockfill Dams with Weak Rocks. J. Geotech. Geoenviron. Eng. 2006, 132, 778–785. [Google Scholar] [CrossRef]

- Wu, Z.; Chen, C.; Lu, X.; Pei, L.; Zhang, L. Discussion on the allowable safety factor of slope stability for high rockfill dams in China. Eng. Geol. 2020, 272, 105666. [Google Scholar] [CrossRef]

- Wu, G. Earthquake-induced deformation analyses of the upper San Fernando dam under the 1971 San Fernando earthquake. Can. Geotech. J. 2001, 38, 1–15. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, C.; Wong, H.; Jiang, T.; Dong, J. Modeling dam deformation in the early stage of internal seepage erosion-application to the Teton dam, Idaho, before the 1976 incident. J. Hydrol. 2022, 605, 127378. [Google Scholar] [CrossRef]

- Andjelkovic, V.; Pavlovic, N.; Lazarevic, Z.; Radovanovic, S. Modelling of shear strength of rockfills used for the construction of rockfill dams. Soils Found. 2018, 58, 881–893. [Google Scholar] [CrossRef]

- Wu, Z.; Li, Y.; Chen, J.; Zhang, H.; Pei, L. A reliability-based approach to evaluating the stability of high rockfill dams using a nonlinear shear strength criterion. Comput. Geotech. 2013, 51, 42–49. [Google Scholar] [CrossRef]

- Xiao, Y.; Liu, H.; Chen, Y.; Jiang, J. Strength and Deformation of Rockfill Material Based on Large-Scale Triaxial Compression Tests. I: Influences of Density and Pressure. J. Geotech. Geoenviron. Eng. 2014, 140, 04014070. [Google Scholar] [CrossRef]

- Wu, Z.; Chen, J. Pressure-dependent variability in shear strength of a blasting-quarried granite rockfill material. Soils Found. 2019, 59, 2299–2310. [Google Scholar] [CrossRef]

- Heshmati, A.; Tabibnejad, A.; Salehzadeh, H.; Tabatabaei, S.H. Effect of stress conditions on collapse deformation behavior of a rockfill material. KSCE J. Civ. Eng. 2015, 19, 1637–1646. [Google Scholar] [CrossRef]

- Xu, M.; Song, E.; Chen, J. A large triaxial investigation of the stress-path-dependent behavior of compacted rockfill. Acta Geotech. 2012, 7, 167–175. [Google Scholar] [CrossRef]

- Frossard, E.; Hu, W.; Dano, C.; Hicher, P.Y. Rockfill shear strength evaluation: A rational method based on size effects. Géotechnique 2012, 62, 415–427. [Google Scholar] [CrossRef]

- Asadi, R.; Disfani, M.M.; Ghahreman-Nejad, B. A New Modified Replacement Method for Discrete Element Modelling of Rockfill Material. Comput. Geotech. 2024, 168, 106168. [Google Scholar] [CrossRef]

- Gupta, A.K. Effects of particle size and confining pressure on breakage factor of rockfill materials using medium triaxial test. J. Rock Mech. Geotech. Eng. 2016, 8, 378–388. [Google Scholar] [CrossRef]

- Zhang, W.; Gu, X.; Han, L.; Wu, J.; Xiao, Z.; Liu, M.; Wang, L. A short review of probabilistic slope stability analysis considering spatial variability of geomaterial parameters. Innov. Infrastruct. Solut. 2022, 7, 249. [Google Scholar] [CrossRef]

- Wijesinghe, D.R.; Dyson, A.; You, G.; Khandelwal, M.; Ooi, E.T. Image based probabilistic slope stability analysis of soil layer interface fluctuations with Brownian bridges. Eng. Fail. Anal. 2023, 148, 107227. [Google Scholar] [CrossRef]

- Jiang, S.; Zhu, G.; Wang, Z.; Huang, Z.; Huang, J. Data augmentation for CNN-based probabilistic slope stability analysis in spatially variable soils. Comput. Geotech. 2023, 160, 105501. [Google Scholar] [CrossRef]

- Bardhan, A.; Samui, P. Probabilistic slope stability analysis of Heavy-haul freight corridor using a hybrid machine learning paradigm. Transp. Geotech. 2022, 37, 100815. [Google Scholar] [CrossRef]

- Zhang, W.; Wu, J.; Gu, X.; Han, L.; Wang, L. Probabilistic stability analysis of embankment slopes considering the spatial variability of soil properties and seismic randomness. J. Mt. Sci. 2022, 19, 1464–1474. [Google Scholar] [CrossRef]

- Li, L.; Li, C.; Wen, J.; Yu, G.; Cheng, Y.; Xu, L. Probabilistic seismic slope stability analysis using swarm response surfaces and rotational Newmark sliding model with primary sliding direction. Comput. Geotech. 2023, 163, 105754. [Google Scholar] [CrossRef]

- Zeng, X.; Khajehzadeh, M.; Iraji, A.; Keawsawasvong, S. Probabilistic Slope Stability Evaluation Using Hybrid Metaheuristic Approach. Period. Polytech. Civ. Eng. 2022, 66, 1309–1322. [Google Scholar] [CrossRef]

- Pandit, B.; Kumar, A.; Tiwari, G. Assessing the applicability of local and global sensitivity approaches and their practical utility for probabilistic analysis of rock slope stability problems: Comparisons and implications. Acta Geotech. 2023, 18, 2615–2637. [Google Scholar] [CrossRef]

- Kafle, L.; Xu, W.; Zeng, S.; Nagel, T. A numerical investigation of slope stability influenced by the combined effects of reservoir water level fluctuations and precipitation: A case study of the Bianjiazhai landslide in China. Eng. Geol. 2022, 297, 106508. [Google Scholar] [CrossRef]

- Wang, G.; Zhao, B.; Wu, B.; Zhang, C.; Liu, W. Intelligent prediction of slope stability based on visual exploratory data analysis of 77 in situ cases. Int. J. Min. Sci. Technol. 2023, 33, 47–59. [Google Scholar] [CrossRef]

- Deng, D.; Zhao, L.; Li, L. Limit equilibrium slope stability analysis using the nonlinear strength failure criterion. Can. Geotech. J. 2014, 52, 563–576. [Google Scholar] [CrossRef]

- Faramarzi, L.; Zare, M.; Azhari, A.; Tabaei, M. Assessment of rock slope stability at Cham-Shir Dam Power Plant pit using the limit equilibrium method and numerical modeling. Bull. Eng. Geol. Environ. 2017, 76, 783–794. [Google Scholar] [CrossRef]

- Deng, D.; Zhao, L.; Li, L. Limit equilibrium method for slope stability based on assumed stress on slip surface. J. Cent. South Univ. 2016, 23, 2972–2983. [Google Scholar] [CrossRef]

- Johari, A.; Mousavi, S. An analytical probabilistic analysis of slopes based on limit equilibrium methods. Bull. Eng. Geol. Environ. 2019, 78, 4333–4347. [Google Scholar] [CrossRef]

- Hu, S.; Zhao, L.; Li, L.; Zuo, S.; Xie, Z.; Qiao, N. Nonlinear analysis of slope stability considering geomaterial dilatancy. Int. J. Geomech. 2024, 24, 04024029. [Google Scholar] [CrossRef]

- Bishop, A.W. The use of the Slip Circle in the Stability Analysis of Slopes. Géotechnique 1955, 5, 7–17. [Google Scholar] [CrossRef]

- Morgenstern, N.R.; Price, V.E. The Analysis of the Stability of General Slip Surfaces. Géotechnique 1965, 15, 79–93. [Google Scholar] [CrossRef]

- National Development and Reform Commission (NDRC). Design Specification for Rolled Earth-Rock Fill Dams (DL/T 5395-2007); China Electric Power Press: Beijing, China, 2007. [Google Scholar]

- National Development and Reform Commission, PRC. Chinese Specifications for Seismic Design of Hydraulic Structures (Industry Standard No. DL 5073-1997); China Electric Power Press: Beijing, China, 1997. [Google Scholar]

- Chen, Z. Slope stability analysis using nonlinear strength parameters. Water Power 1990, 9, 9–13. (In Chinese) [Google Scholar]

- Sali, S.; Noori, K. Assessment of the upstream slope stability of darbandikhan rockfill dam during drawdown. Aro-Sci. J. Koya Univ. 2021, 9, 8–15. [Google Scholar]

- Smesnik, M.; Krstic, S.; Verdianz, M. Determination of rockfill shear parameters for dam stability analysis of an embankment dam. In Proceedings of the XVII ECSMGE-2019, Reykjavík, Iceland, 1–6 September 2019. [Google Scholar]

- Oggeri, C.; Ronco, C.; Vinai, R. Validation of numerical D.E.M. modelling of geogrid reinforced embankments for rockfall protection. Geam-Geoing. Ambient. Mineraria-Geam-Geoengin. Environ. Min. 2021, 163, 36–45. [Google Scholar]

- Honkanadavar, N.; Sharma, K. Testing and modeling the behavior of riverbed and blasted quarried rockfill materials. Int. J. Geomech. 2014, 14, 04014028. [Google Scholar] [CrossRef]

| Slice No. | Not Considering the Variability in the Friction Angle of the Rockfills | Considering the Stress-Dependent Spatial Variability in the Friction Angle of the Rockfills | ||||||

|---|---|---|---|---|---|---|---|---|

| σ′3 (kPa) | M(φp) (°) | Var(φp) (°) | Design Value of φp (°) | σ′3 (kPa) | M(φp) (°) | Var(φp) (°) | Design Value of φp (°) | |

| 1 | 64.729 | 54.1 | 0 | 54.1 | 69.757 | 53.8 | 3.6 | 48.1 |

| 2 | 216.197 | 49.4 | 0 | 49.4 | 226.633 | 49.2 | 2.8 | 44.2 |

| 3 | 364.245 | 47.4 | 0 | 47.4 | 374.652 | 47.2 | 2.0 | 43.0 |

| 4 | 504.128 | 46.1 | 0 | 46.1 | 511.388 | 46.0 | 1.4 | 42.5 |

| 5 | 634.679 | 45.2 | 0 | 45.2 | 637.585 | 45.2 | 1.0 | 42.2 |

| 6 | 755.676 | 44.5 | 0 | 44.5 | 754.219 | 44.5 | 0.7 | 42.0 |

| 7 | 867.219 | 44.0 | 0 | 44.0 | 862.001 | 44.0 | 0.6 | 41.7 |

| 8 | 969.515 | 43.5 | 0 | 43.5 | 961.358 | 43.6 | 0.5 | 41.5 |

| 9 | 1055.782 | 43.2 | 0 | 43.2 | 1045.674 | 43.2 | 0.4 | 41.3 |

| 10 | 1048.436 | 43.2 | 0 | 43.2 | 1038.993 | 43.3 | 0.4 | 41.3 |

| 11 | 1004.613 | 43.4 | 0 | 43.4 | 996.688 | 43.4 | 0.5 | 41.4 |

| 12 | 948.799 | 43.6 | 0 | 43.6 | 942.618 | 43.7 | 0.5 | 41.5 |

| 13 | 881.248 | 43.9 | 0 | 43.9 | 877.012 | 43.9 | 0.6 | 41.7 |

| 14 | 802.096 | 44.3 | 0 | 44.3 | 799.948 | 44.3 | 0.7 | 41.8 |

| 15 | 711.366 | 44.7 | 0 | 44.7 | 711.333 | 44.7 | 0.8 | 42.0 |

| 16 | 608.971 | 45.4 | 0 | 45.4 | 610.882 | 45.3 | 1.1 | 42.2 |

| 17 | 494.717 | 46.2 | 0 | 46.2 | 498.097 | 46.1 | 1.5 | 42.5 |

| 18 | 368.314 | 47.3 | 0 | 47.3 | 372.297 | 47.3 | 2.0 | 43.0 |

| 19 | 229.422 | 49.2 | 0 | 49.1 | 232.760 | 49.1 | 2.8 | 44.1 |

| 20 | 77.993 | 53.4 | 0 | 53.4 | 79.308 | 53.3 | 3.6 | 47.6 |

| Slice No. | Not Considering the Variability in the Friction Angle of the Rockfills | Considering the Stress-Dependent Spatial Variability in the Friction Angle of the Rockfills | ||||||

|---|---|---|---|---|---|---|---|---|

| σ′3 (kPa) | M(φp) (°) | Var(φp) (°) | Design Value of φp (°) | σ′3 (kPa) | M(φp) (°) | Var(φp) (°) | Design Value of φp (°) | |

| 1 | 52.552 | 54.9 | 0 | 54.9 | 56.937 | 54.6 | 3.7 | 48.9 |

| 2 | 179.975 | 50.1 | 0 | 50.1 | 189.809 | 49.9 | 3.0 | 44.7 |

| 3 | 307.703 | 48.0 | 0 | 48.0 | 318.338 | 47.9 | 2.3 | 43.4 |

| 4 | 430.573 | 46.7 | 0 | 46.7 | 438.844 | 46.6 | 1.7 | 42.7 |

| 5 | 546.939 | 45.8 | 0 | 45.8 | 551.225 | 45.7 | 1.3 | 42.4 |

| 6 | 656.188 | 45.1 | 0 | 45.1 | 656.002 | 45.1 | 1.0 | 42.1 |

| 7 | 758.113 | 44.5 | 0 | 44.5 | 753.681 | 44.5 | 0.7 | 41.9 |

| 8 | 852.681 | 44.0 | 0 | 44.0 | 844.608 | 44.1 | 0.6 | 41.8 |

| 9 | 933.684 | 43.7 | 0 | 43.7 | 922.951 | 43.7 | 0.5 | 41.6 |

| 10 | 931.488 | 43.7 | 0 | 43.7 | 921.364 | 43.7 | 0.5 | 41.6 |

| 11 | 896.394 | 43.8 | 0 | 43.8 | 887.966 | 43.9 | 0.5 | 41.7 |

| 12 | 850.146 | 44.1 | 0 | 44.1 | 843.665 | 44.1 | 0.6 | 41.8 |

| 13 | 792.894 | 44.3 | 0 | 44.3 | 788.544 | 44.3 | 0.7 | 41.9 |

| 14 | 724.676 | 44.7 | 0 | 44.7 | 722.546 | 44.7 | 0.8 | 42.0 |

| 15 | 645.417 | 45.1 | 0 | 45.1 | 645.449 | 45.1 | 1.0 | 42.2 |

| 16 | 554.929 | 45.7 | 0 | 45.7 | 556.848 | 45.7 | 1.2 | 42.4 |

| 17 | 452.900 | 46.5 | 0 | 46.5 | 456.142 | 46.5 | 1.6 | 42.7 |

| 18 | 338.892 | 47.6 | 0 | 47.6 | 342.557 | 47.6 | 2.2 | 43.2 |

| 19 | 212.355 | 49.5 | 0 | 49.5 | 215.264 | 49.4 | 2.9 | 44.3 |

| 20 | 72.857 | 53.6 | 0 | 53.6 | 73.868 | 53.6 | 3.6 | 47.9 |

| Slice No. | Not Considering the Variability in the Friction Angle of the Rockfills | Considering the Stress-Dependent Spatial Variability in the Friction Angle of the Rockfills | ||||||

|---|---|---|---|---|---|---|---|---|

| σ′3 (kPa) | M(φp) (°) | Var(φp) (°) | Design Value of φp (°) | σ′3 (kPa) | M(φp) (°) | Var(φp) (°) | Design Value of φp (°) | |

| 1 | 56.813 | 54.6 | 0 | 54.6 | 61.709 | 54.3 | 3.6 | 48.6 |

| 2 | 194.218 | 49.8 | 0 | 49.8 | 205.067 | 49.6 | 2.9 | 44.5 |

| 3 | 331.739 | 47.7 | 0 | 47.7 | 343.222 | 47.6 | 2.1 | 43.2 |

| 4 | 463.884 | 46.4 | 0 | 46.4 | 472.536 | 46.3 | 1.6 | 42.6 |

| 5 | 588.921 | 45.5 | 0 | 45.5 | 593.110 | 45.5 | 1.1 | 42.3 |

| 6 | 706.218 | 44.8 | 0 | 44.8 | 705.602 | 44.8 | 0.8 | 42.0 |

| 7 | 815.570 | 44.2 | 0 | 44.2 | 810.567 | 44.2 | 0.6 | 41.8 |

| 8 | 916.954 | 43.8 | 0 | 43.8 | 908.342 | 43.8 | 0.5 | 41.6 |

| 9 | 1003.711 | 43.4 | 0 | 43.4 | 992.575 | 43.4 | 0.5 | 41.4 |

| 10 | 1001.049 | 43.4 | 0 | 43.4 | 990.549 | 43.5 | 0.5 | 41.4 |

| 11 | 963.062 | 43.6 | 0 | 43.6 | 954.238 | 43.6 | 0.5 | 41.5 |

| 12 | 913.121 | 43.8 | 0 | 43.8 | 906.234 | 43.8 | 0.5 | 41.6 |

| 13 | 851.393 | 44.0 | 0 | 44.0 | 846.658 | 44.1 | 0.6 | 41.7 |

| 14 | 777.926 | 44.4 | 0 | 44.4 | 775.478 | 44.4 | 0.7 | 41.9 |

| 15 | 692.646 | 44.9 | 0 | 44.9 | 692.483 | 44.9 | 0.9 | 42.1 |

| 16 | 595.360 | 45.4 | 0 | 45.4 | 597.257 | 45.4 | 1.1 | 42.3 |

| 17 | 485.744 | 46.2 | 0 | 46.2 | 489.152 | 46.2 | 1.5 | 42.6 |

| 18 | 363.341 | 47.4 | 0 | 47.4 | 367.313 | 47.3 | 2.0 | 43.1 |

| 19 | 227.581 | 49.2 | 0 | 49.2 | 230.806 | 49.1 | 2.8 | 44.2 |

| 20 | 78.030 | 53.4 | 0 | 53.4 | 79.175 | 53.3 | 3.6 | 47.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ran, C.; Zhou, Z.; Lu, X.; Gong, B.; Jiang, Y.; Wu, Z. Slope Stability Analysis of Rockfill Embankments Considering Stress-Dependent Spatial Variability in Friction Angle of Granular Materials. Appl. Sci. 2024, 14, 6354. https://doi.org/10.3390/app14146354

Ran C, Zhou Z, Lu X, Gong B, Jiang Y, Wu Z. Slope Stability Analysis of Rockfill Embankments Considering Stress-Dependent Spatial Variability in Friction Angle of Granular Materials. Applied Sciences. 2024; 14(14):6354. https://doi.org/10.3390/app14146354

Chicago/Turabian StyleRan, Congyong, Zhengjun Zhou, Xiang Lu, Binfeng Gong, Yuanyuan Jiang, and Zhenyu Wu. 2024. "Slope Stability Analysis of Rockfill Embankments Considering Stress-Dependent Spatial Variability in Friction Angle of Granular Materials" Applied Sciences 14, no. 14: 6354. https://doi.org/10.3390/app14146354

APA StyleRan, C., Zhou, Z., Lu, X., Gong, B., Jiang, Y., & Wu, Z. (2024). Slope Stability Analysis of Rockfill Embankments Considering Stress-Dependent Spatial Variability in Friction Angle of Granular Materials. Applied Sciences, 14(14), 6354. https://doi.org/10.3390/app14146354