Optimization of Mode-Switching Quality of Hybrid Tractor Equipped with HMCVT

Abstract

1. Introduction

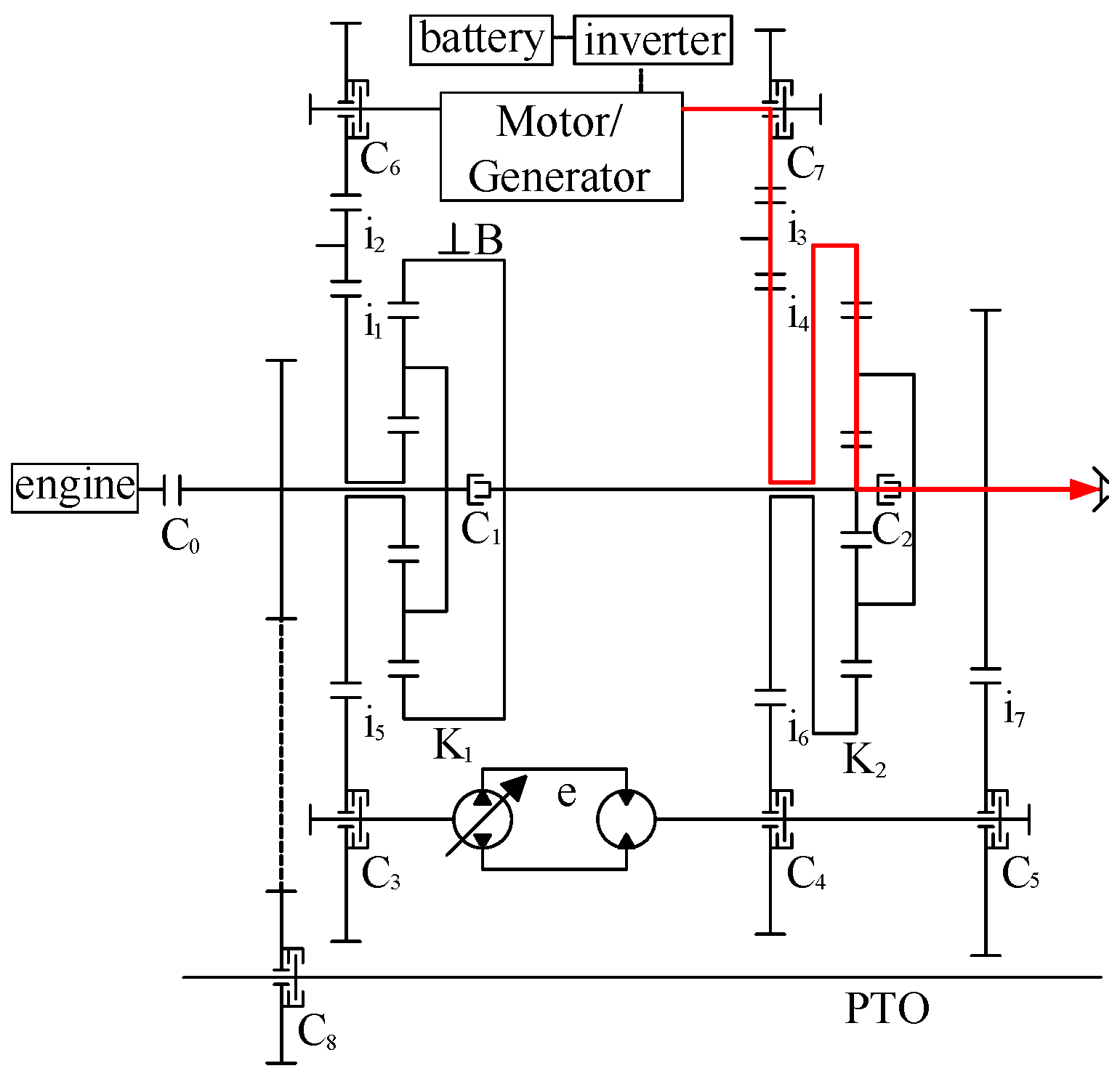

2. Transmission System of Hybrid Tractor

2.1. Transmission Mode Analysis

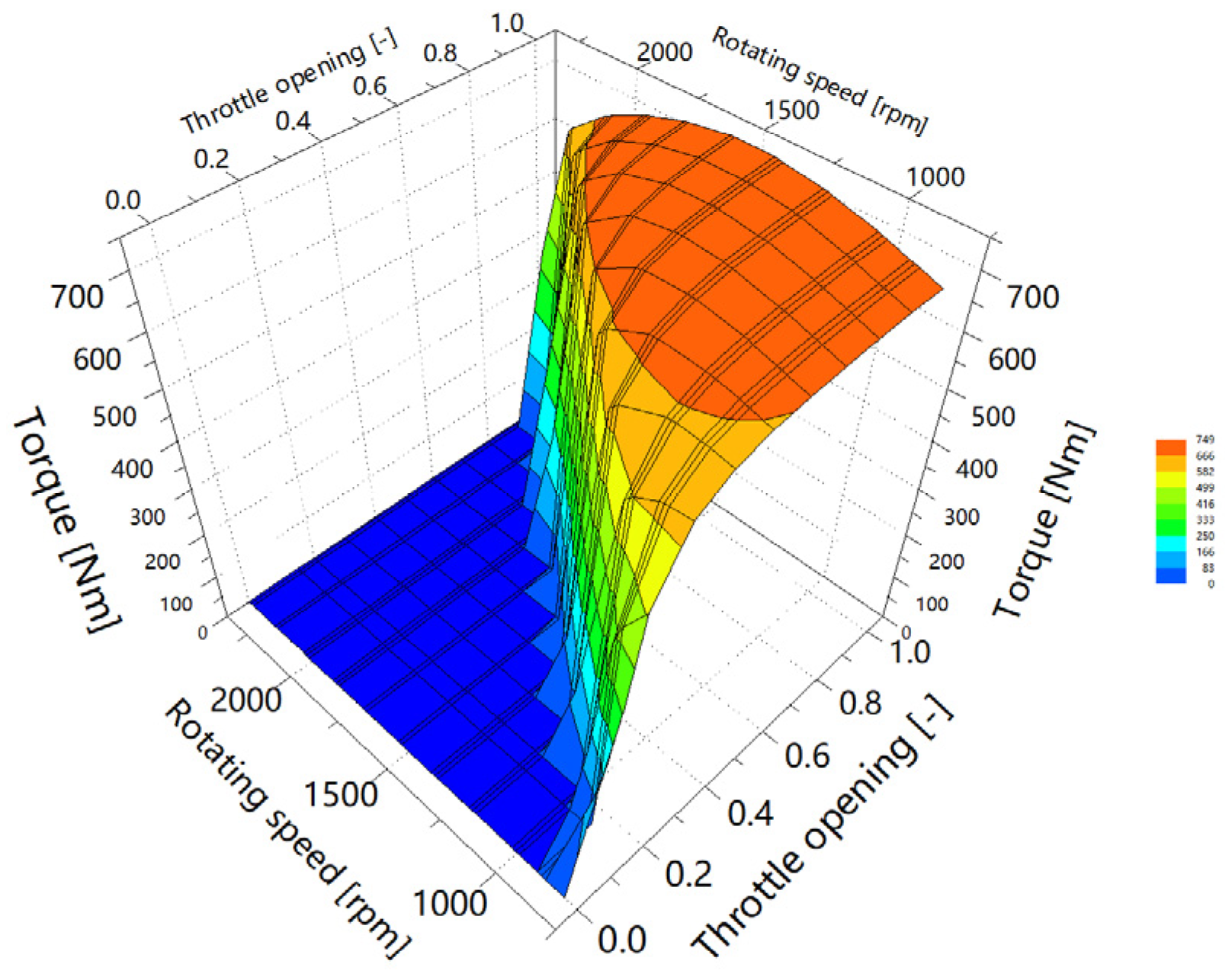

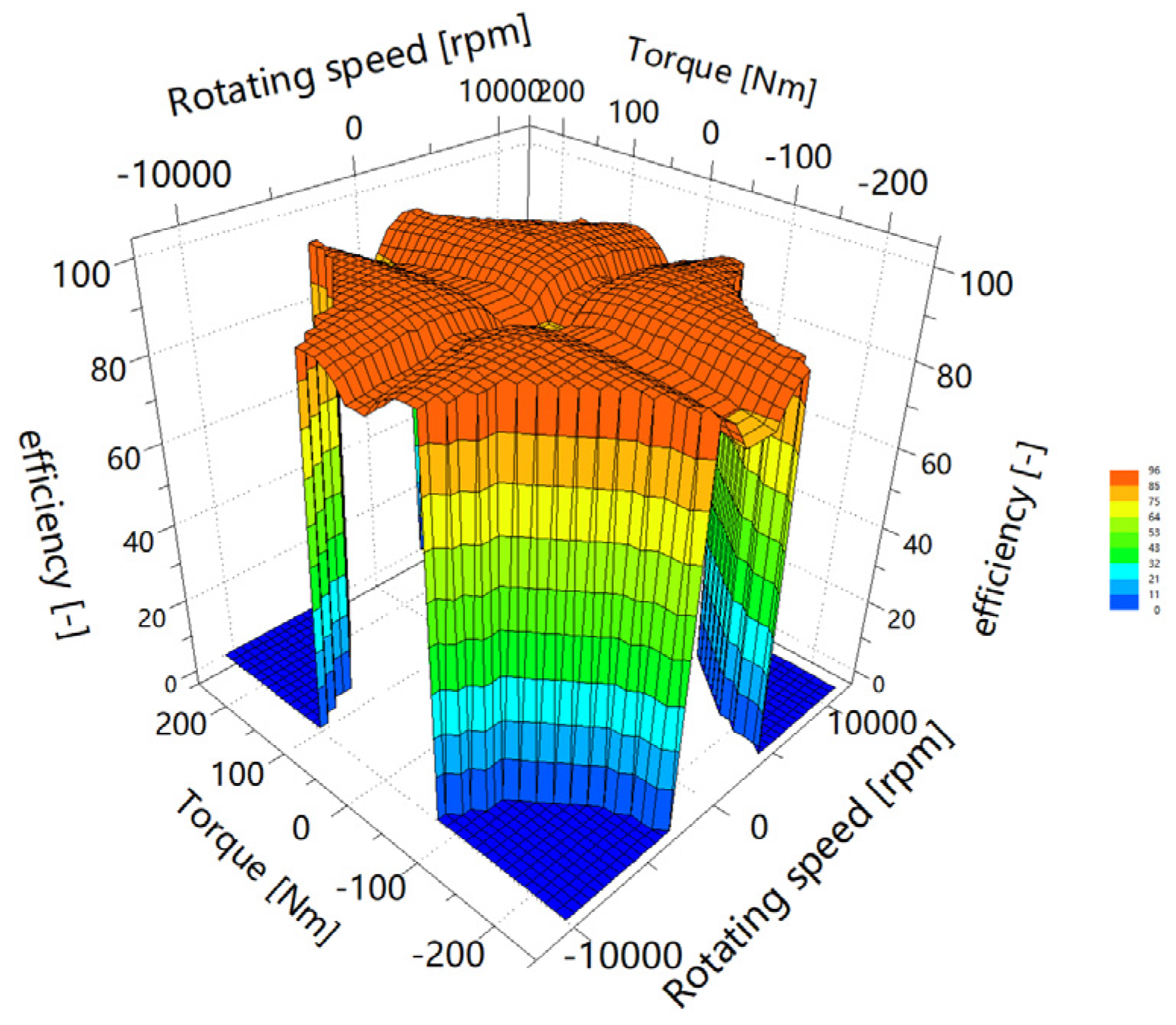

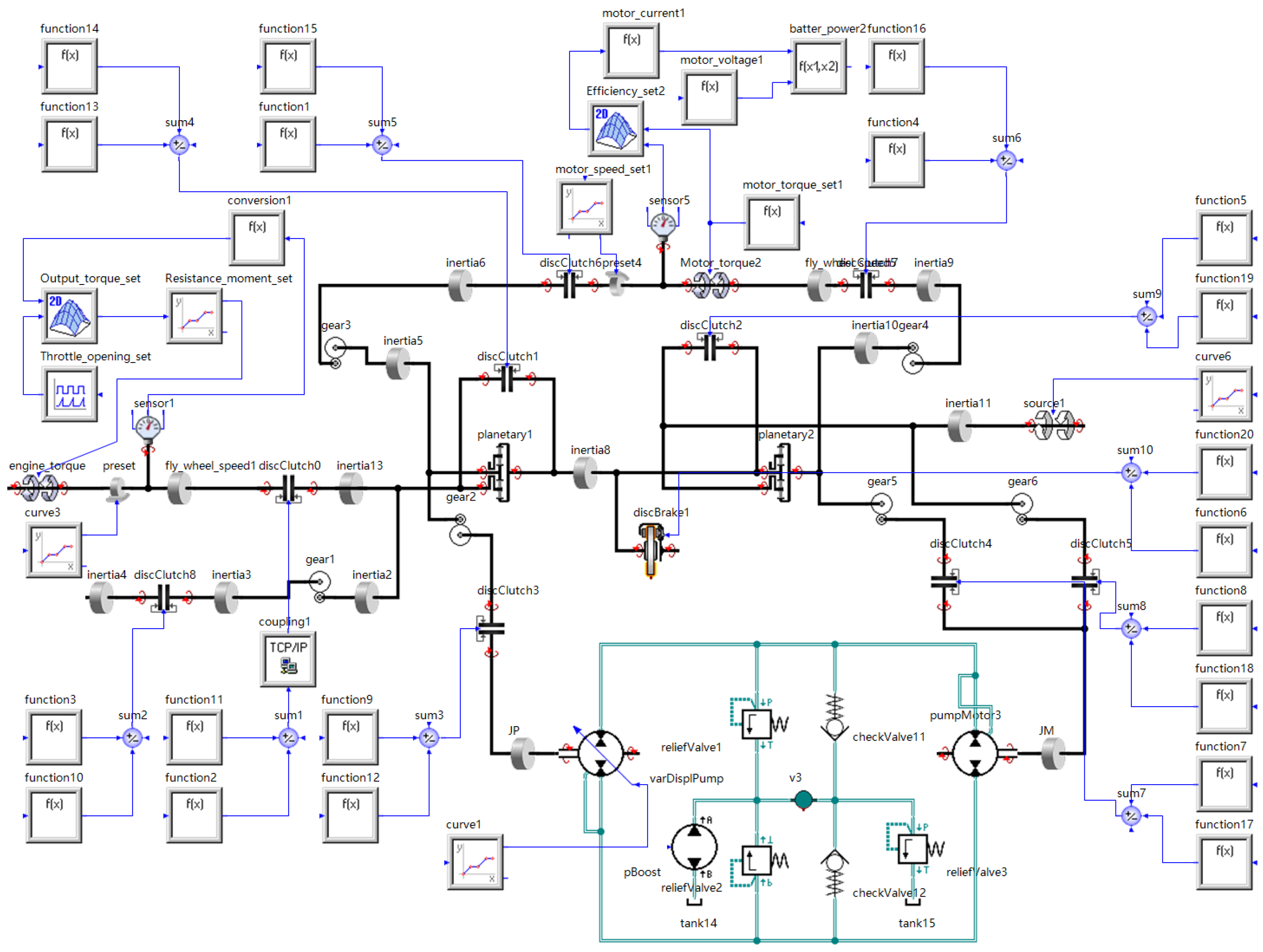

2.2. Power Transmission System Modeling

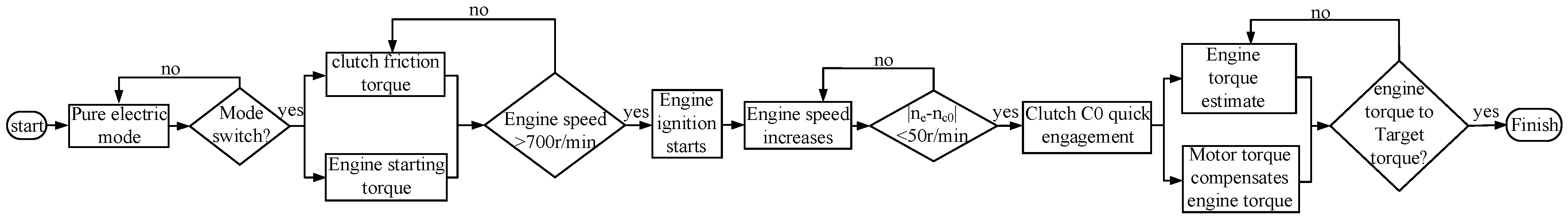

3. Optimization of Control Policy for Driver Source Switching

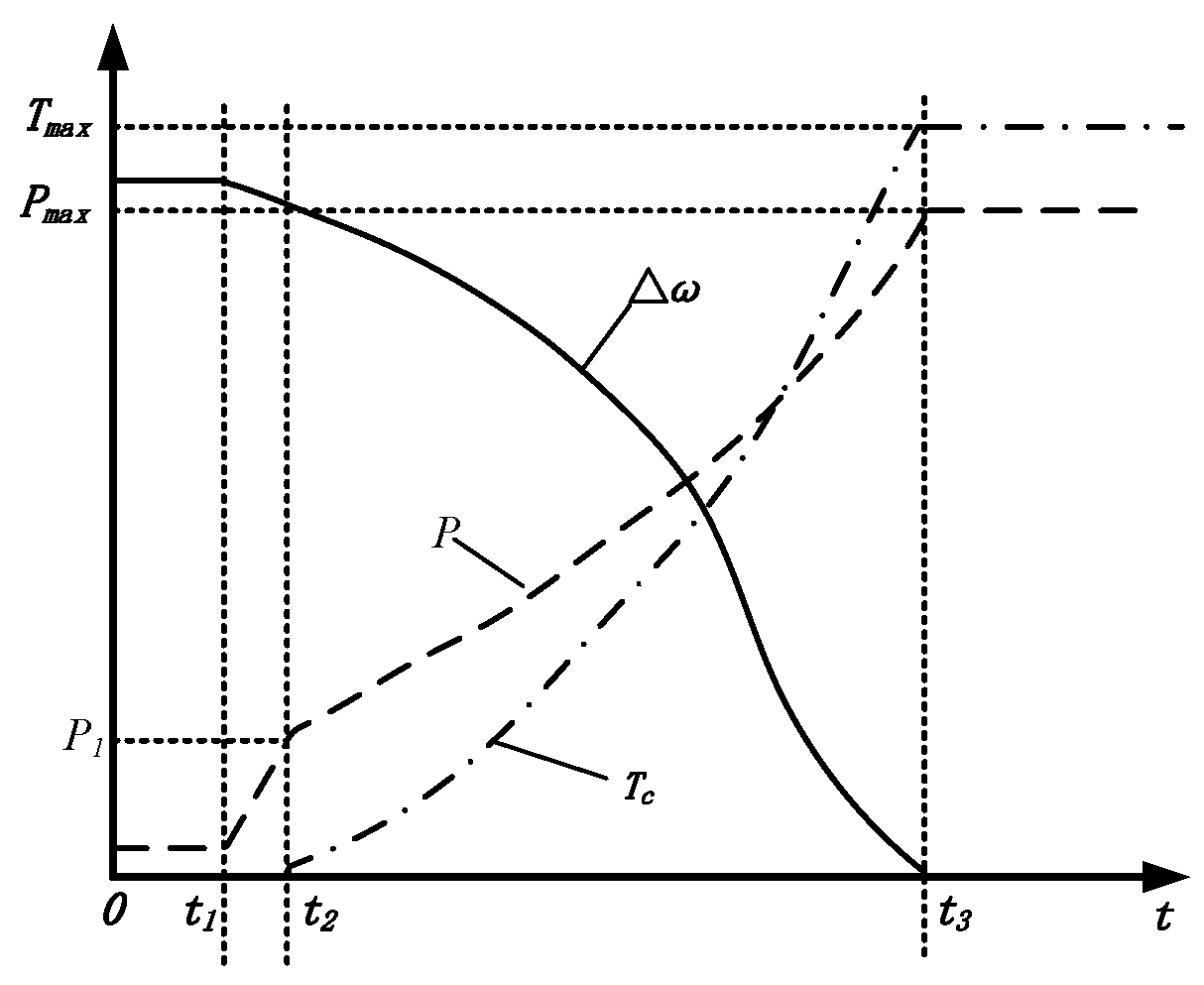

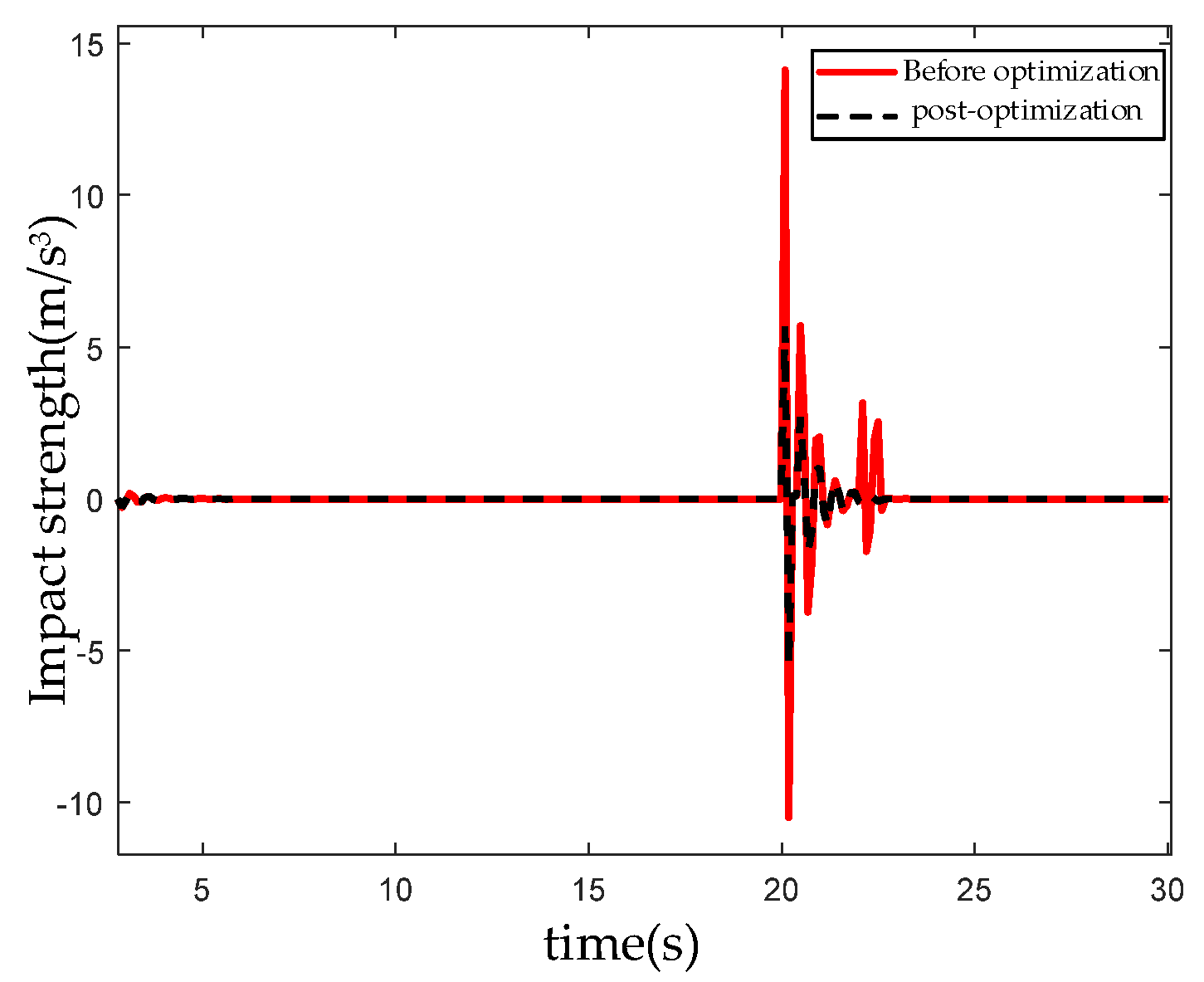

3.1. Evaluation Indicators of Mode-Switching Quality

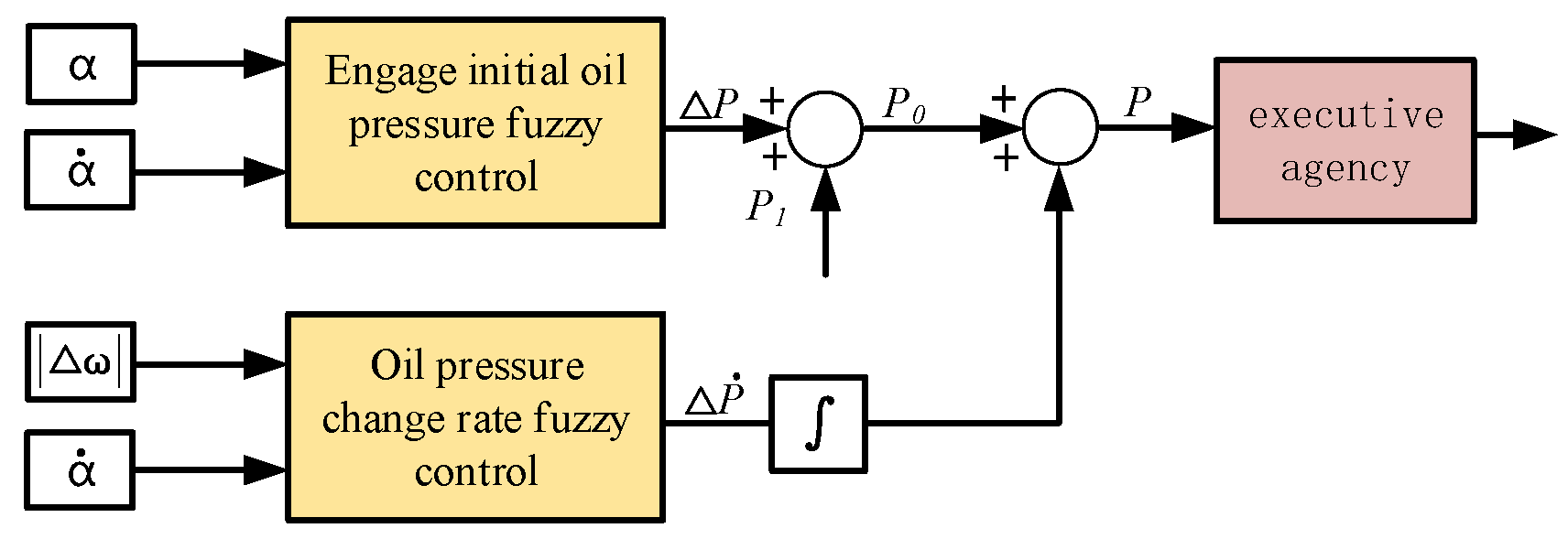

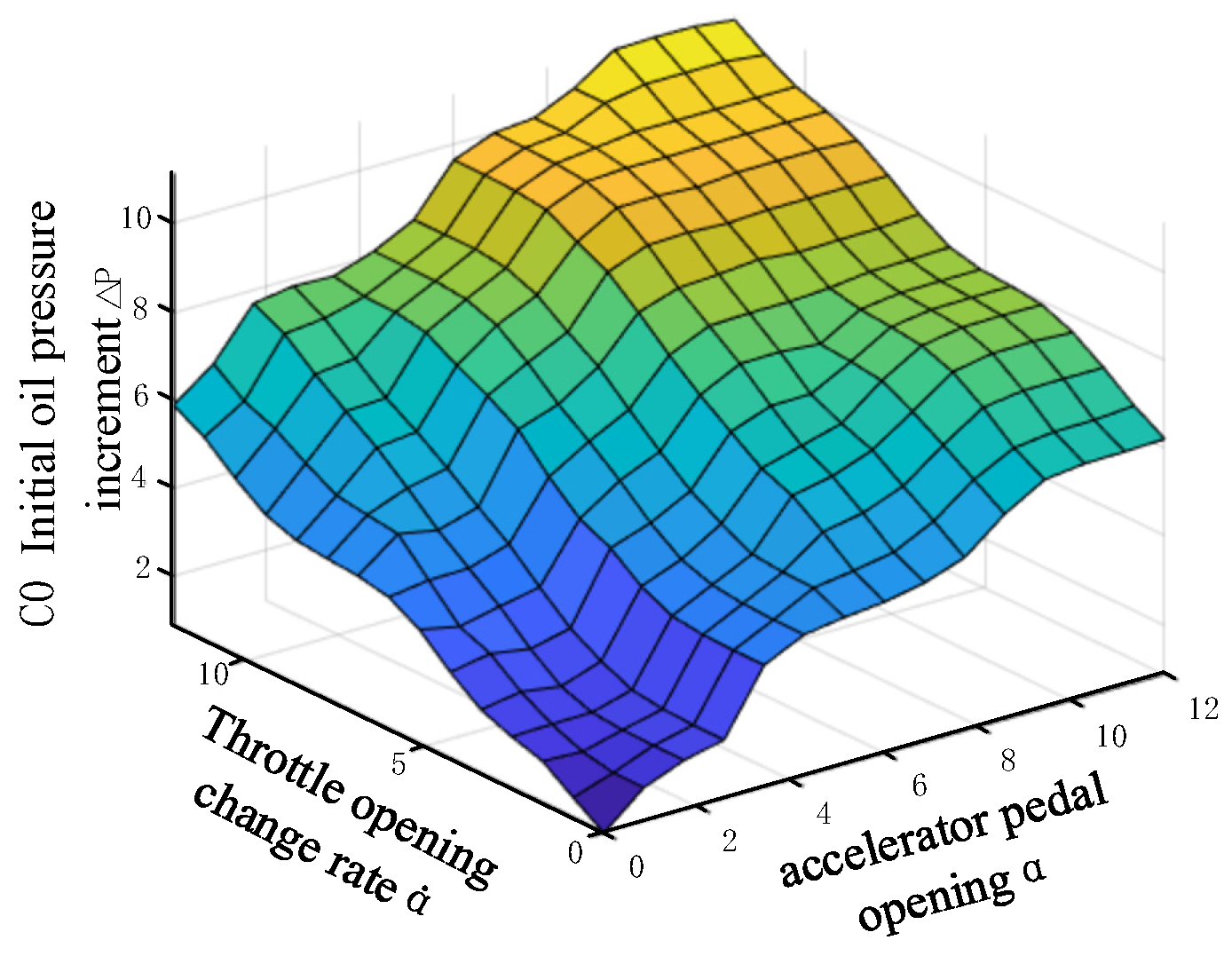

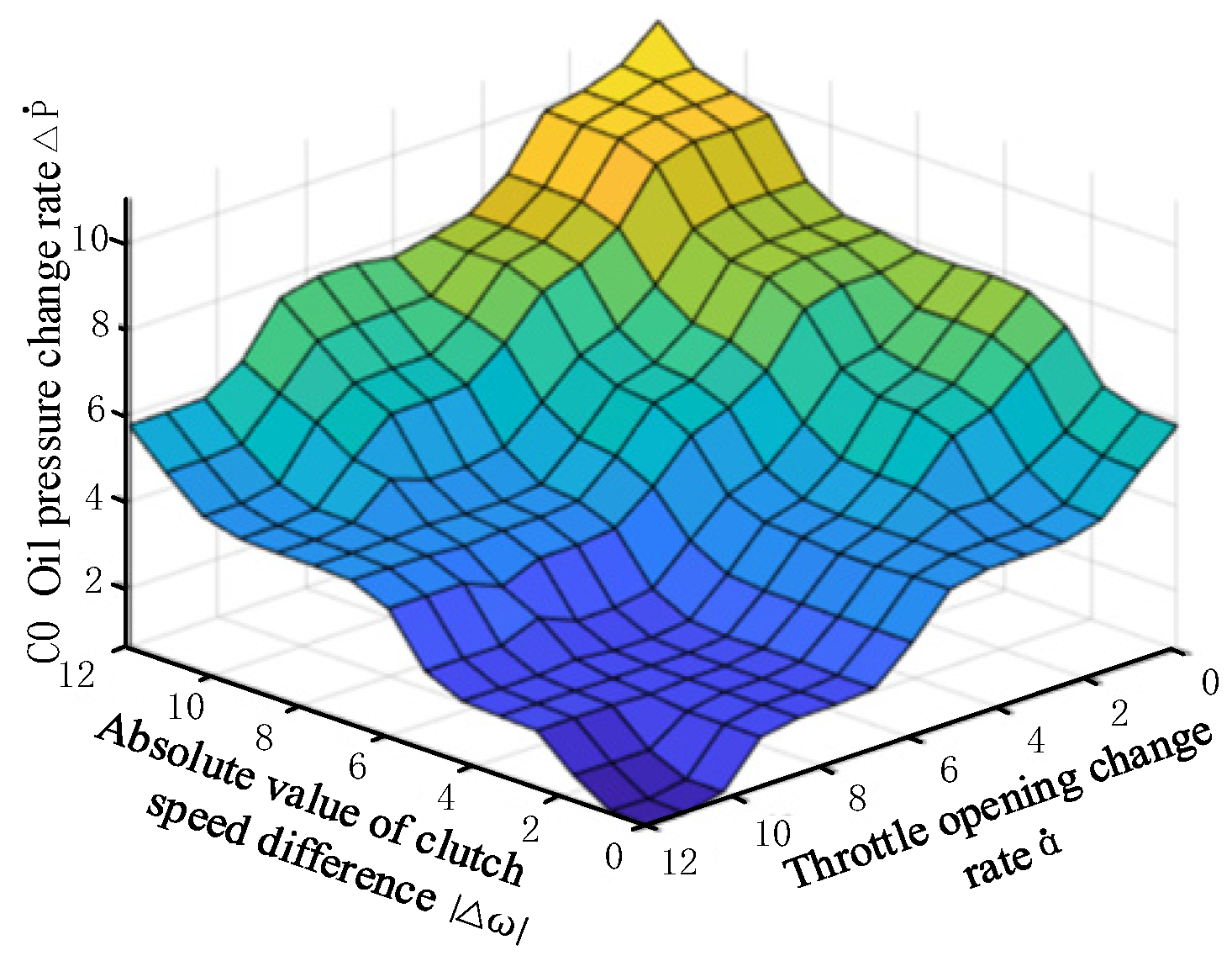

3.2. Fuzzy Control Strategy of Clutch Oil Pressure

- (1)

- Engaging the initial oil pressure fuzzy control stage.

- (2)

- Fuzzy control stage of oil pressure change rate

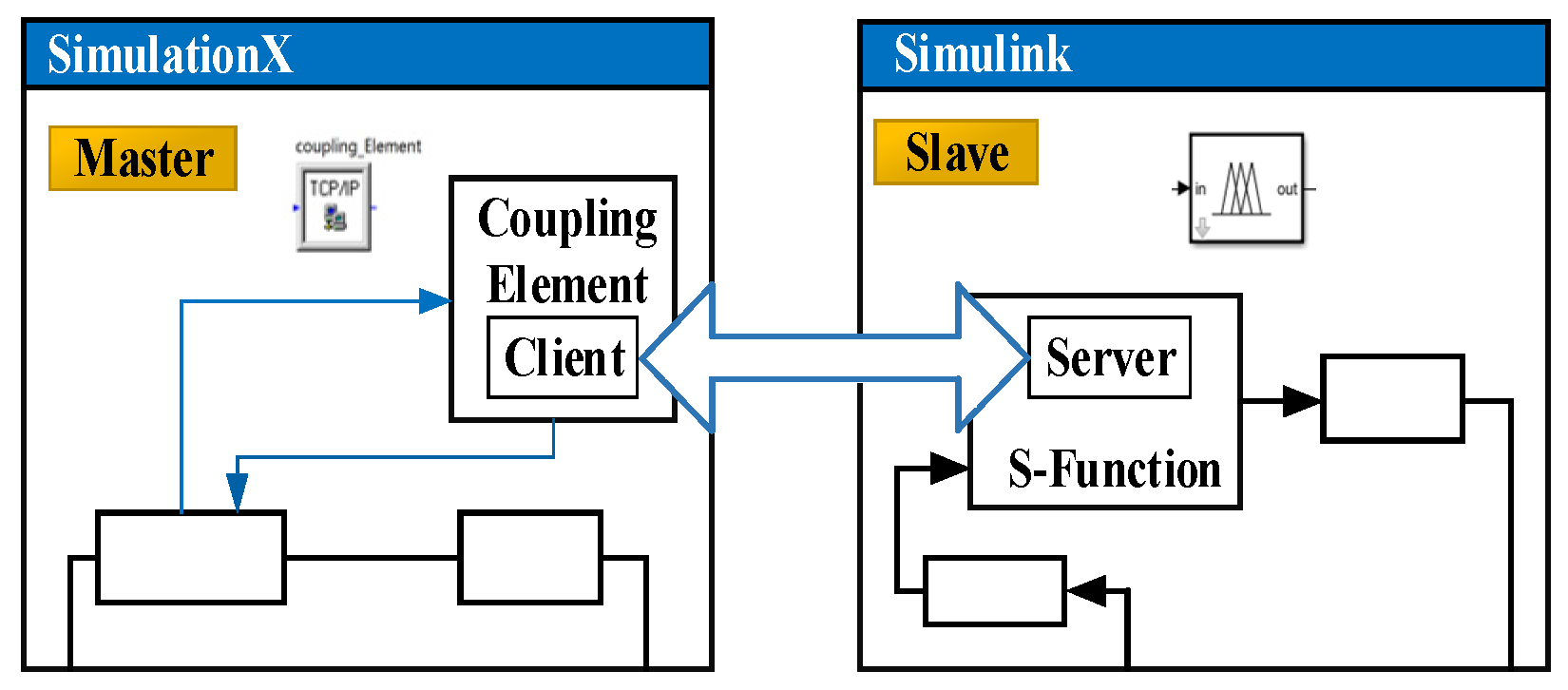

3.3. SimulationX and Matlab/Simulink Interact Analysis

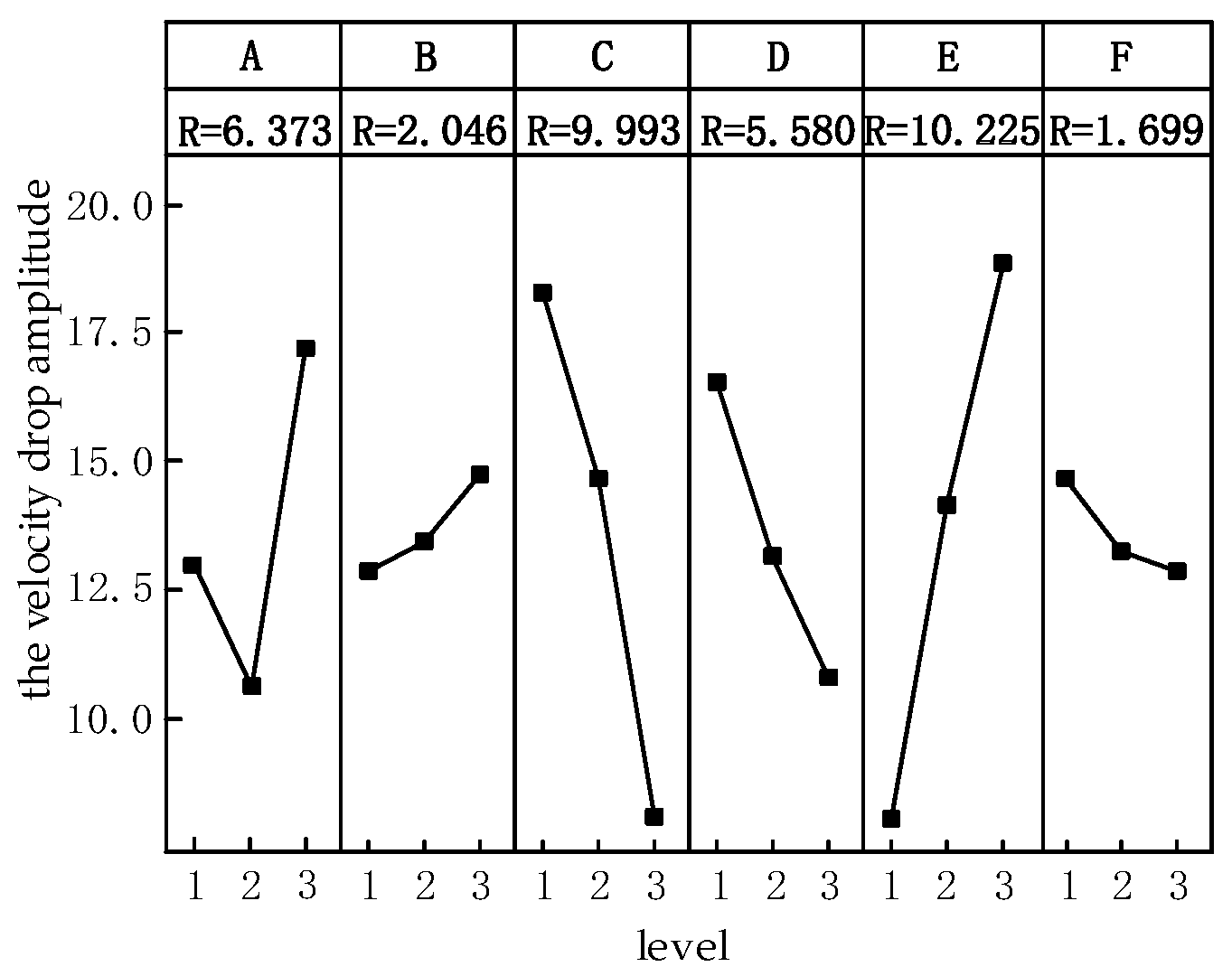

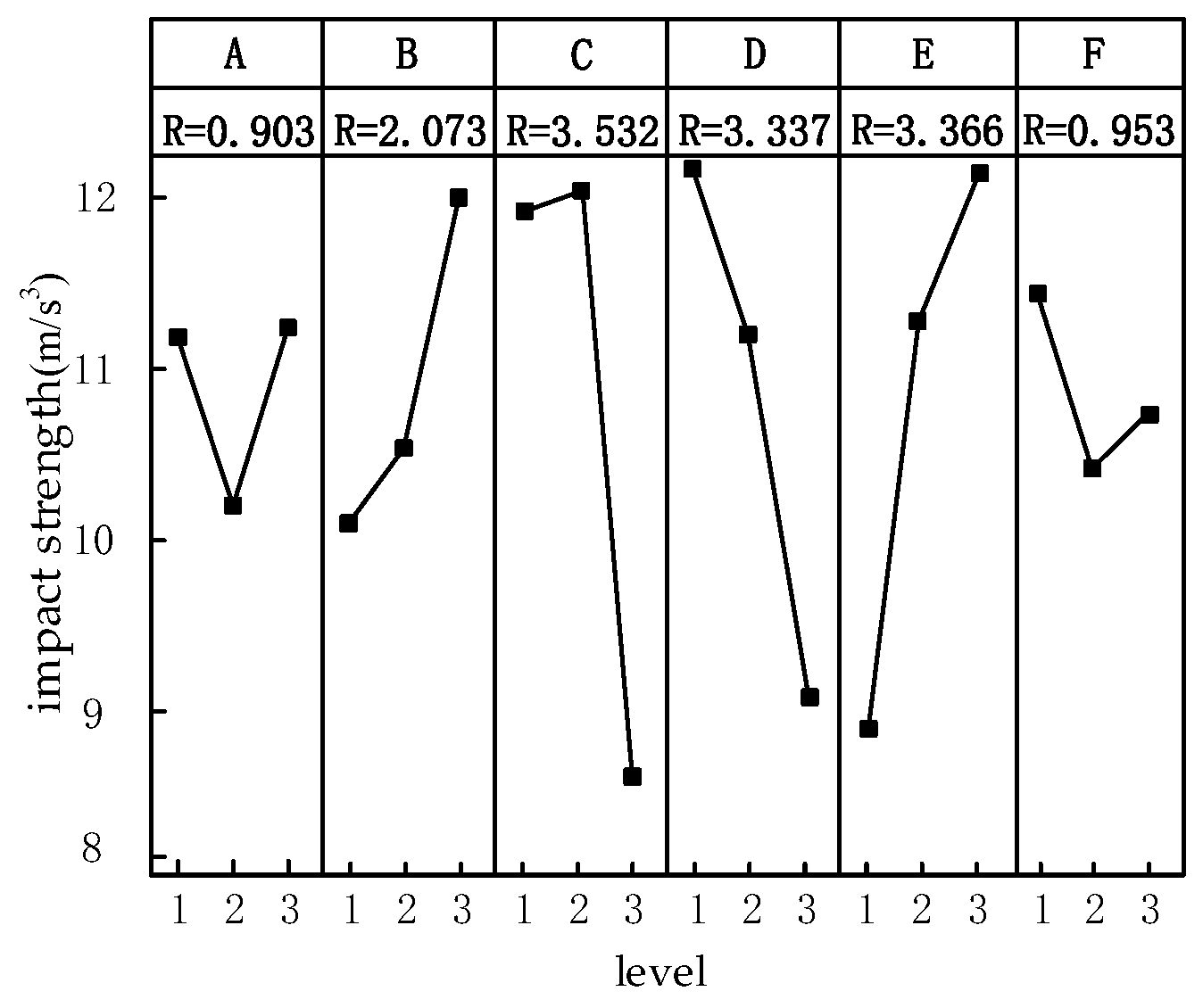

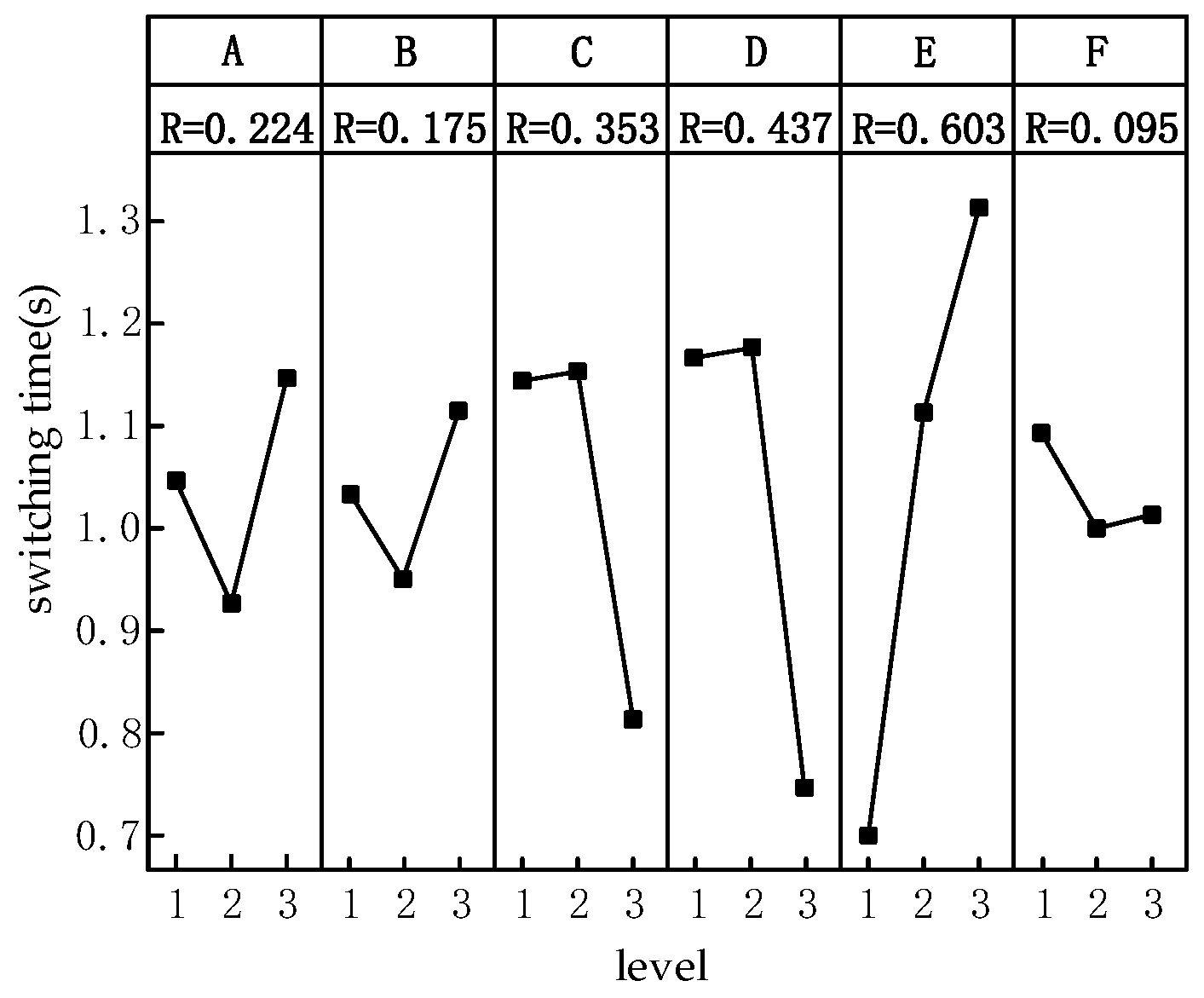

4. Clutch-Switching Timing Optimization Based on an Orthogonal Test

4.1. Analyze Simulation Results Using Range Method

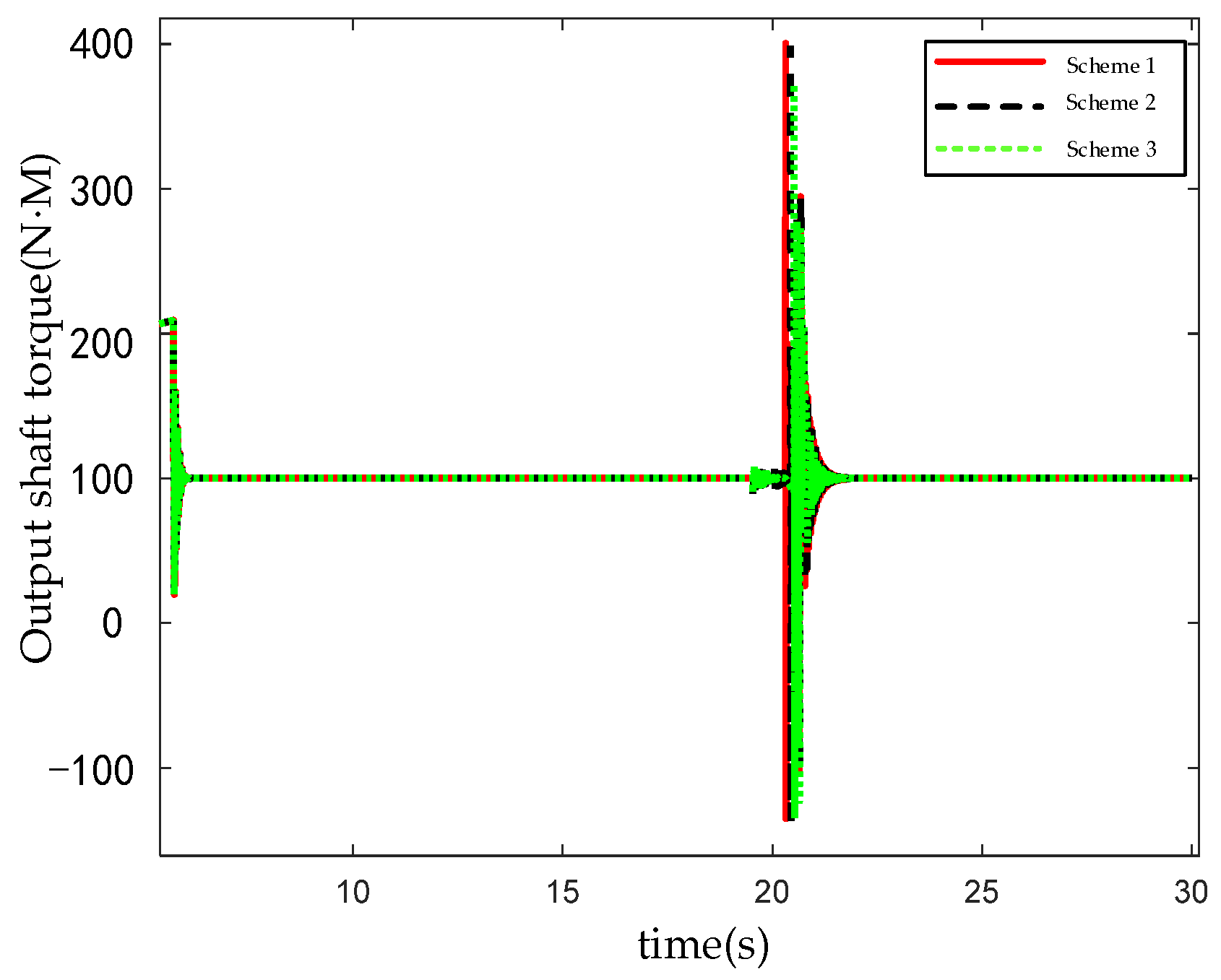

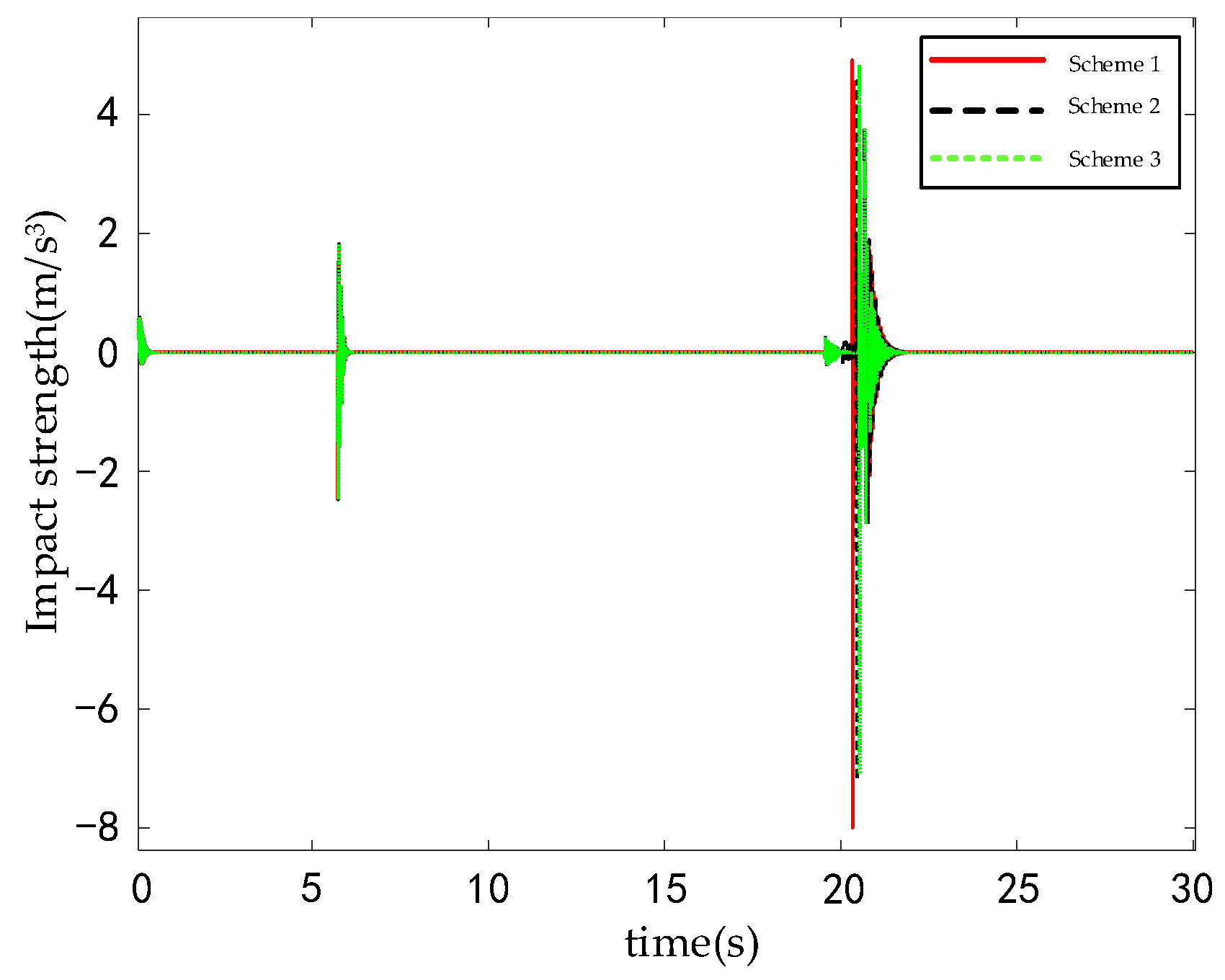

4.2. Hardware-in-the-Loop Simulation Test Verification

5. Conclusions

6. Patents

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Huai, Z. The logic and institutional flaws of EU enterprise supply chain due diligence regulation from the perspective of foreign-related legal rule. Ger. Stud. 2023, 38, 102–134+155. [Google Scholar]

- Pascuzzi, S.; Łyp-Wrońska, K.; Gdowska, K.; Paciolla, F. Sustainability Evaluation of Hybrid Agriculture-Tractor Powertrains. Sustainability 2024, 16, 1184. [Google Scholar] [CrossRef]

- Zhou, S.; Walker, P.; Tian, Y.; Zhang, N. Mode switching analysis and control for a parallel hydraulic hybrid vehicle. Veh. Syst. Dyn. 2021, 59, 928–948. [Google Scholar] [CrossRef]

- Banerjee, P.; Ivantysynova, M. Development of a Torque-Based Control Strategy for a Mode-Switching Hydraulic Hybrid Passenger Vehicle; SAE Technical Paper; Purdue University: West Lafayette, IN, USA, 2018. [Google Scholar]

- Oubelaid, A.; Albalawi, F.; Rekioua, T.; Ghoneim, S.S.; Taib, N.; Abdelwahab, S.A.M. Intelligent torque allocation based coordinated switching strategy for comfort enhancement of hybrid electric vehicles. IEEE Access 2022, 10, 58097–58115. [Google Scholar] [CrossRef]

- Zhu, Z.; Sheng, J.; Zhang, H.; Wang, D.; Chen, L. Research on control strategy of rotating tillage condition of hybrid tractor with dual flow coupling configuration. J. Agric. Mach. 2024, 55, 393–400+414. [Google Scholar]

- Qing, D.; Liu, D.; Du, B. Power source torque coordination control for heavy hybrid electric vehicle drive mode switching. Highw. Traffic Technol. 2012, 29, 151–158. [Google Scholar]

- Yu, J.; Cao, Z.; Cheng, M.; Pan, R. Hydro-mechanical power split transmissions: Progress evolution and future trends. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2019, 233, 727–739. [Google Scholar] [CrossRef]

- Li, J.; Zhai, Z.; Song, Z.; Fu, S.; Zhu, Z.; Mao, E. Optimization of the transmission characteristics of an HMCVT for a high-powered tractor based on an improved NSGA-II algorithm. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2022, 236, 2831–2849. [Google Scholar] [CrossRef]

- Pettersson, K.; Heybroek, K.; Mattsson, P.; Krus, P. A novel hydromechanical hybrid motion system for construction machines. Int. J. Fluid Power 2017, 18, 17–28. [Google Scholar] [CrossRef]

- Sun, X.; Lu, Z.; Chn, Y. Lightweight design of hydraulic mechanical continuously variable transmission box based on weight optimization. J. Hunan Agric. Univ. (Nat. Sci. Ed.) 2022, 48, 363–369. [Google Scholar] [CrossRef]

- Hua, Y.; Xia, G.; Tang, X. Wavelet neural network PID control of tractor hydraulic mechanical transmission. J. Hefei Univ. Technol. (Nat. Sci. Ed.) 2020, 43, 26–30+107. [Google Scholar]

- Zhu, Z.; Zeng, L.; Lin, Y.; Chen, L.; Zou, R.; Cai, Y. Adaptive energy management strategy for hybrid tractors based on performance prediction. J. Xi’an Jiaotong Univ. 2023, 57, 201–210. [Google Scholar]

- Cheng, Y.; Liang, Y.; Xu, X. Energy management strategy of HEV based on Gain-power fuel coefficient. China Highw. J. 2022, 35, 343–352. [Google Scholar] [CrossRef]

- Geng, W.; Lou, D.; Zhang, T. Multi-objective energy management strategy for hybrid electric vehicles based on particle swarm optimization. J. Tongji Univ. (Nat. Sci. Ed.) 2020, 48, 1030–1039. [Google Scholar]

- Xiao, X.; Zeng, X.; Dai, Z. A new type of electric vehicle supercapacitor and battery compound power supply system. Acta Electron. 2024, 45, 922–929. [Google Scholar]

- Zhang, X.; Cui, Y.; Yue, Q. Torque coordination control strategy for starting engine in PHEV. J. South China Univ. Technol. (Nat. Sci. Ed.) 2021, 49, 129–139. [Google Scholar]

- Editorial Department of China Highway Journal. An overview of academic research on automotive engineering in China·2017. China Highw. J. 2017, 30, 1–197. [Google Scholar] [CrossRef]

- Qian, W.; Shen, Q.; Wu, P. Research progress of privacy protection technology in big data computing environment. J. Comput. Sci. 2022, 45, 669–701. [Google Scholar]

- Zhu, Z.; Wang, D.; Sun, X. Configuration analysis of hydraulic compound transmission device. J. Jilin Univ. (Eng. Ed.) 2022, 52, 2265–2277. [Google Scholar] [CrossRef]

- Yang, J.; Li, M.; Sun, S. Research on vehicle road friendliness based on semi-active adaptive suspension system. China Highw. J. 2011, 24, 120–126. [Google Scholar] [CrossRef]

- Gao, B.; Wan, K.; Chen, Q.; Wang, Z.; Li, R.; Jiang, Y.; Mei, R.; Luo, Y.; Li, K. Operation mode switching control strategy of heavy hybrid electric vehicle. China Highw. J. 2014, 27, 109–119+126. [Google Scholar] [CrossRef]

- Huang, W. Calculation and analysis of engine starting system. For. Mach. Woodwork. Equip. 2021, 49, 65–68. [Google Scholar] [CrossRef]

- Lu, N.; Chen, T.; Zheng, H. Research on joint simulation analysis platform based on electromechanical hydraulic system. Mach. Tools Hydraul. 2023, 51, 71–78. [Google Scholar]

- Zhu, Z.; Sheng, J.; Zhang, H.; Wang, D.; Chen, L. Prediction of headless rivet installation interference by multivariate nonlinear regression model. J. Xi’an Jiaotong Univ. 2024, 58, 157–166. [Google Scholar]

- Cao, F.Y.; Feng, Q.; Yang, C.J. Optimization of clutch switching timing for dual-mode hydraulic mechanical transmission. J. Xi’an Jiaotong Univ. 2021, 55, 86–93. [Google Scholar]

- Gao, Z.; Zheng, C.; Zhao, R. A review of research on active safety verification and validation of autonomous vehicles in real and virtual scenarios. J. Jilin Univ. (Eng. Ed.) 2024, 1–19. [Google Scholar] [CrossRef]

| Origin | df | Adj SS | Adj MS | F Value | p Value | Eminence |

|---|---|---|---|---|---|---|

| Factor A | 2 | 177.36 | 88.678 | 7.19 | 0.009 | *** |

| Factor B | 2 | 16.26 | 8.129 | 0.66 | 0.535 | |

| Factor C | 2 | 396.97 | 198.486 | 16.09 | 0.000 | *** |

| Factor D | 2 | 130.74 | 65.368 | 5.30 | 0.022 | ** |

| Factor E | 2 | 392.59 | 196.296 | 15.91 | 0.000 | *** |

| Factor F | 2 | 14.04 | 7.019 | 0.57 | 0.581 | |

| Factor G | 2 | 2.75 | 1.374 | 0.11 | 0.896 | |

| Error e | 12 | 148.07 | 12.339 |

| Origin | df | Adj SS | Adj MS | F Value | p Value | Eminence |

|---|---|---|---|---|---|---|

| Factor A | 2 | 5.178 | 2.589 | 1.14 | 0.353 | |

| Factor B | 2 | 4.019 | 2.009 | 0.88 | 0.439 | |

| Factor C | 2 | 13.221 | 6.611 | 2.90 | 0.094 | * |

| Factor D | 2 | 19.715 | 19.875 | 4.33 | 0.038 | ** |

| Factor E | 2 | 38.712 | 19.356 | 8.50 | 0.005 | *** |

| Factor F | 2 | 6.630 | 13.315 | 1.46 | 0.272 | |

| Factor G | 2 | 17.337 | 8.722 | 3.83 | 0.052 | |

| Error e | 12 | 27.337 | 2.278 |

| Origin | df | Adj SS | Adj MS | F Value | p Value | Eminence |

|---|---|---|---|---|---|---|

| Factor A | 2 | 12.721 | 6.361 | 2.08 | 0.168 | |

| Factor B | 2 | 11.110 | 5.555 | 1.81 | 0.205 | |

| Factor C | 2 | 43.591 | 21.796 | 7.12 | 0.009 | *** |

| Factor D | 2 | 57.966 | 28.983 | 9.46 | 0.003 | *** |

| Factor E | 2 | 77.674 | 38.837 | 12.68 | 0.001 | *** |

| Factor F | 2 | 2.347 | 1.173 | 0.38 | 0.690 | |

| Factor G | 2 | 2.099 | 1.049 | 0.34 | 0.717 | |

| Error e | 12 | 36.746 | 3.062 |

| Origin | df | Adj SS | Adj MS | F Value | p Value | Eminence |

|---|---|---|---|---|---|---|

| Factor A | 2 | 0.226 | 0.113 | 1.67 | 0.230 | |

| Factor B | 2 | 0.140 | 0.071 | 1.04 | 0.384 | |

| Factor C | 2 | 0.724 | 0.362 | 5.35 | 0.022 | ** |

| Factor D | 2 | 1.137 | 0.568 | 8.41 | 0.005 | *** |

| Factor E | 2 | 1.696 | 0.848 | 12.54 | 0.001 | *** |

| Factor F | 2 | 0.044 | 0.022 | 0.32 | 0.730 | |

| Factor G | 2 | 0.062 | 0.031 | 0.46 | 0.644 | |

| Error e | 12 | 0.811 | 0.068 |

| ca | ei | Speed Drop | Dynamic Load Factor | Impact Strength | Switching Time |

|---|---|---|---|---|---|

| sa | bs | E1C3A2D3B1F3 | E1C3D3F2A3B3 | C3A1E1F2B1D3 | E1D3C3A2B2F2 |

| fp | EC major | EC major | CED major | EDC major | |

| AD mid | DF mid | B mid | AB mid | ||

| BF minor | AB minor | FA minor | F minor | ||

| tv | bs | C1E3A2D3B1F3 | E1C3D3F2A3B3 | E1D3C2A3B1F3 | E1D3C2A3B1F3 |

| fp | CEA major | E major | EDC major | ED major | |

| D mid | CD mid | AB mid | C mid | ||

| BF minor | FAB minor | F minor | ABF minor |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, Z.; Sheng, J.; Zhang, H.; Wang, D.; Chen, L. Optimization of Mode-Switching Quality of Hybrid Tractor Equipped with HMCVT. Appl. Sci. 2024, 14, 6288. https://doi.org/10.3390/app14146288

Zhu Z, Sheng J, Zhang H, Wang D, Chen L. Optimization of Mode-Switching Quality of Hybrid Tractor Equipped with HMCVT. Applied Sciences. 2024; 14(14):6288. https://doi.org/10.3390/app14146288

Chicago/Turabian StyleZhu, Zhen, Jie Sheng, Hongwei Zhang, Dehai Wang, and Long Chen. 2024. "Optimization of Mode-Switching Quality of Hybrid Tractor Equipped with HMCVT" Applied Sciences 14, no. 14: 6288. https://doi.org/10.3390/app14146288

APA StyleZhu, Z., Sheng, J., Zhang, H., Wang, D., & Chen, L. (2024). Optimization of Mode-Switching Quality of Hybrid Tractor Equipped with HMCVT. Applied Sciences, 14(14), 6288. https://doi.org/10.3390/app14146288