1. Introduction

The radial piston motor is a versatile hydraulic motor that operates at low speeds and delivers high torque [

1]. It features a compact size, lightweight design, minimal torque fluctuations, balanced radial forces, excellent starting efficiency, and reliable operation even at extremely low speeds. The harsh working environment requires the motor to work more reliably, and radial piston motors have different types and a large number of friction pairs. These friction pairs directly affect the reliability and life of the motors, which include the valve plate/cylinder block pair, piston/cylinder block pair, roller/piston pair, and roller/cam ring pair [

2].

It is crucial to recognize that in high-pressure conditions, the contact interfaces within hydraulic systems, such as piston/cylinder assemblies and valve stems/seats, experience elevated stress and friction. An in-depth examination of the tribological properties of these components under high pressure is pivotal for enhancing design optimization, minimizing energy dissipation, and boosting the overall efficiency and reliability of the system. By understanding the wear and friction mechanisms at play in high pressure [

3,

4], one ensures the stable operation of the system even under extreme circumstances, thereby safeguarding the stability and dependability of hydraulic machinery.

Currently, there are two commonly used lubrication methods for the roller/piston pair: oil film lubrication and adding bearing bush. Oil film lubrication ensures the normal operation of the machine by transmitting lubricating oil through the plunger’s oil groove [

5]. In oil film lubrication, the width of the oil groove is intimately linked to the performance of the machine, and it is susceptible to issues such as inadequate lubrication, high temperatures, and shortened lifespan. Furthermore, its shortcomings become particularly prominent under low speed and heavy load conditions. The above-mentioned piston structure requires high oil cleanliness (to prevent high-pressure leakage caused by particle scratches) and is prone to cause stress singularities at the friction interface when the piston oil chamber is switched between high and low pressure. In contrast, the self-lubricating bearing bush, unlike oil film lubrication [

6,

7], is inherently designed with lubrication requirements in mind. It eliminates the need for frequent oil replenishment during operation, significantly reducing maintenance overhead. Their structural simplicity and ease of installation make them versatile, which in turn contributes to a reduced risk of fire and leakage incidents, thereby enhancing the overall reliability of the equipment and operational safety. The self-lubricating bearing bush stands out in terms of economic efficiency, environmental friendliness, performance, and safety, solidifying its position as a critical component of modern industry. The self-lubricating bearing bush represents a progressive and sustainable bearing technology for the modern industrial landscape. Therefore, a three-layer self-lubricating bearing bush is considered a better lubrication method.

Some work has been carried out previously on the key friction pairs of hydraulic motors. For example, according to different lubrication conditions, Lewis et al. [

8] examined the wear property of the cloth material under both dry and oil lubrication conditions and found that it outperformed the sintered bronze material. Wang et al. [

9] mainly studied the friction performance of different types of textured surfaces between the roller and piston in hydraulic motors and found that textured surfaces can significantly improve the friction properties between the roller and piston and reduce friction loss and energy loss. Prior research on friction pairs concentrated on the wear of cam rollers [

10] or the piston ring/side contact [

11,

12]. Because the radial piston motors usually operate at a low speed of 0.6–100 rpm, the relative sliding velocity between the friction pairs is too low to create a high-quality dynamic pressure oil film. In turn, the wear between the friction pairs is exacerbated, so it is necessary to rely on self-lubricating materials to improve the lubrication state between the friction pairs. The MS series motors use three layers of sliding bushing bush between the roller and the piston [

13], with the top layer being composed of a modified PEEK material. All these demonstrate the key role of self-lubricating materials in friction and wear.

The high-temperature stability, chemical resistance, self-lubrication, and strong mechanical properties of PEEK meet the needs of transmission components. Fiber, when used as a filling system, can not only effectively bear a portion of the load but also, through its synergistic effect with PEEK, significantly enhance the overall properties of composite materials. Song et al. [

14] studied CF/PEEK composites under different technological conditions and obtained the variation laws of the frictional properties, bearing bush capacity, and wear resistance of CF/PEEK composites with different contents. Xie et al. [

15] analyzed the main mechanism of frictional properties of CF/PEEK composites and the influence on properties caused by different axial and radial microstructures of fiber when carbon fiber is used as a fiber material to fill the matrix. For specific needs, Kang et al. [

16] investigated the failure of SCF/PEEK composites under bidirectional tensile stress. Ideal stress distribution was obtained, simulation and experimental results were validated, and an improved cross-shaped specimen was proposed to apply bidirectional stress. Nayan et al. [

17] investigated the tribological behavior of pure PEEK and CF/PEEK on stainless steel under dry and water lubrication conditions, and the study showed that the composite material performed better.

The scholars considered the influence of various factors on the inherent characteristics of self-lubricating materials. Pang et al. [

18,

19] studied the friction and wear characteristics of pure PEEK and the 20% CF-modified PEEK at high temperatures and obtained the differences in wear mechanisms of different materials under different temperature differences. Nikonovich et al. [

20] studied the mechanical and tribological properties of four modified PEEKs at different temperatures in air and vacuum. Yingna Liang et al. studied the friction and wear characteristics of different surface bionic structures under seawater lubrication conditions. Liang et al. [

21,

22,

23] studied the friction and wear characteristics of different surface bionic structures under seawater lubrication conditions, discovering that the hemispherical pit structure can effectively store wear debris and improve abrasive wear between friction pairs. Zhu et al. [

24] used four different surface treatment processes to obtain the friction and wear performance of each modified material.

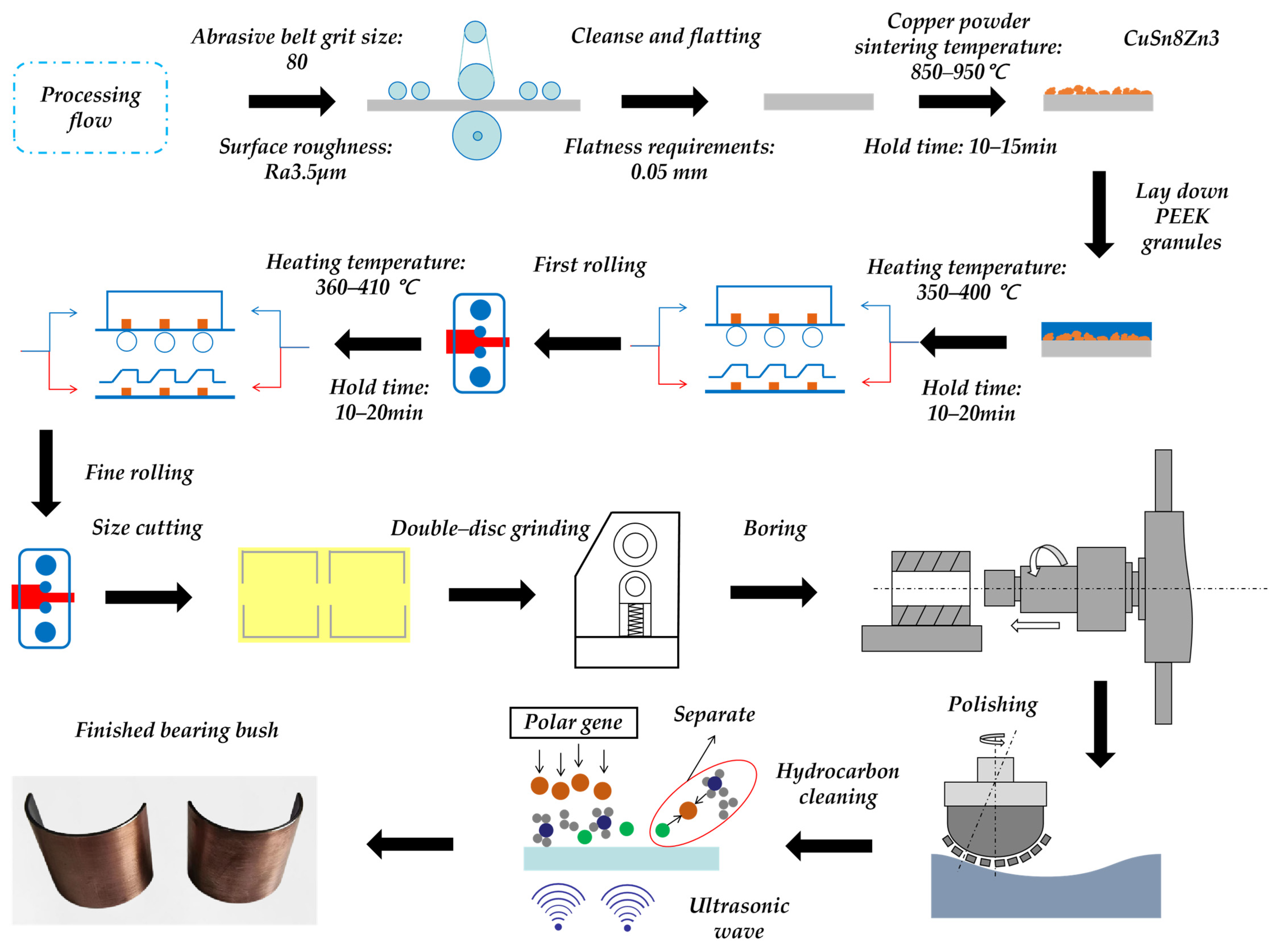

After adding the bearing bush, the direct friction between the roller and the piston becomes the friction between the roller and the self-lubricating material. In most cases, however, it is of primary concern to develop polymeric composites that possess low friction and low wear properties under dry sliding conditions against smooth metallic counterparts. Therefore, it is significant to study the tribological properties of polymers under boundary lubrication conditions. In this study, a three-layer self-lubricating bearing bush lubrication scheme exhibiting superior comprehensive performance was adopted [

25,

26]. The reinforcement phase of PEEK was reinforced with a 15% filling ratio of SCF. A rational distribution of the three-layer composite bearing bush was employed to simulate its friction and wear performance under conditions of low speed and heavy load within radial piston motors [

27]. This has a positive impact on the innovative development of new materials (such as high-performance alloys and composite materials) and new surface treatment technologies (such as coatings and surface hardening) for research on friction and wear under high pressure.

3. Tests Results

3.1. Friction and Wear

In order to analyze the impact of varying test pressures on the tribological wear characteristics of the three-layer composite bearing bush, a simulated test was conducted for 3 h for each group.

Figure 4 displays the wear diagram of the SCF-modified bearing bush under different test pressures.

From

Figure 4, it can be observed that the wear caused by the roller on the bearing bush is irregularly distributed along the axis direction of the bearing bush. The wear area near the end face of the bearing is larger, and with the continuous increase of the test pressure, the wear area on the bearing surface gradually expands. In the wear area of the SCF-modified bearing, there are no significant wear marks, and the morphology of the ear surface is relatively smooth, with some debris. Additionally, there are a few pits on the material surface, which result in the formation of local transfer films, indicating that the primary wear mechanism is adhesive wear. The frictional torque of the SCF-modified bearing bush under the different test pressures is shown in

Figure 5.

As depicted in

Figure 5, a moderate increase in experimental pressure is accompanied by a corresponding rise in friction torque. However, a non-trivial observation emerges where the friction torque at 25 MPa does not exhibit a proportional rise with the increment in testing pressure. Instead, it displays a plateau or even a decrementary behavior, suggesting a deviation from the conventional linear relationship. The frictional torque curve’s trend change is influenced by a multitude of factors, including but not limited to tribological surface topography, interfacial effects, and wear mechanisms. These factors can act independently or in combination, necessitating a detailed analysis that takes into account experimental conditions and material properties for a comprehensive understanding.

As the text pressure continues to rise, the pressure experienced by the three-layer self-lubricating bearing bush plate naturally increases. Due to its relatively soft nature, it is susceptible to compressive deformation under increased pressure. The compactness of the self-lubricating layer is enhanced, and the fibers filled in the self-lubricating layer can be better embedded in the PEEK matrix. This prevents wear from fractured fibers, subsequently contributing to a reduction in the friction coefficient of the three-component composite journal bearing. Therefore, when the test pressure reaches 25 MPa and above, the bearing bush surface is not easy to accumulate, and it is easier to increase the interface slip and form a lubricating film.

It is worth noting that

Figure 5 shows the frictional torque drop at 7000 s for the case of 25 MPa. The addition of SCF filled the holes between the PEEK and PTFE molecular chains fully. With the progress of friction tests, the area of exposed carbon fibers in the interface began to grow, where the carbon fibers’ surface, grafted with numerous active functional groups, had notably improved its surface wettability, thus enhancing the shear strength between layers of the carbon fiber composite material significantly [

30,

31,

32]. The self-lubricating material was coated evenly on the fiber surface, which covered the fiber’s grooves almost entirely. This configuration makes the fiber–matrix interface less prone to damage and enables effective stress transfer to the carbon fiber, thereby enhancing the material’s structural strength and durability. The quality of the transfer film plays a key role in the wear resistance of the bearing bush, which is due to the continuous improvement of the uniformity and continuity of the transfer film in the friction process. With time’s passage, the frictional torque, which was being measured, exhibited a slow downward trend as a result.

It is directly proportional to the test pressure, according to Equation (1), that the friction torque of the bearing bush is.

where

T is the frictional torque,

P is the test pressure,

D is the piston diameter,

μ is the friction coefficient, and

r is the roller diameter.

As the test pressure mounts, the friction torque also experiences an uptrend. However, under certain pressure conditions, the friction torque does not uniformly escalate with the test pressure. Instead, it may exhibit a trend of stability or even diminish. The addition of SCF fully fills the intermolecular voids between the PEEK and polytetrafluoroethylene (PTFE) chains, resulting in a decrease in the friction torque of the composite material. By calculating the friction torque under different pressures, the friction coefficient of the SCF-modified bearing bush under different pressures can be obtained, as shown in

Figure 6.

The friction coefficient of the SCF-modified bearing bush exhibits a consistent trend as the experimental pressure varies. Specifically, as the experimental pressure increases from 15 MPa to 25 MPa, the friction coefficient of the SCF-modified bearing bush decreases significantly, from 0.420 to 0.296. However, when the experimental pressure increases from 25 MPa to 30 MPa, the friction coefficient of the SCF-modified bearing bush rises, but the increase is not substantial.

3.2. Wear Mechanism

As shown in

Figure 7, the wear area of the SCF-modified bearing bush was photographed using a confocal scanning laser microscope, thus revealing the microscopic wear morphology of the modified bush under different test pressures.

As depicted in

Figure 7, the phenomenon of stacking on the surface of the SCF-modified bearing bush is relatively noticeable when the test pressure is at 15 and 20 MPa, while at test pressures of 25 MPa and above, specifically 30 MPa, there is no obvious sign of stacking. Upon observation, it was noted that only a few isolated regions under certain pressures exhibited furrows on the worn surface. These furrows were not highly concentrated, and the extent of scratching was not severe, attributed to the slight furrows caused by the peeling metal particles on the roller. The self-lubricating layer of the bearing bush generates a less severe furrow scratch due to the small size of the metal particles.

With the continuous increase of experimental pressure, severe accumulation occurs at the friction boundary, accompanied by a large number of fiber shear fractures and fiber edge peeling. During the friction process, the carbon fiber has varying degrees of wear, with some of the carbon fiber being cut or scattered and the carbon fiber adhering to the matrix material and lubricant. It can be seen that the carbon fiber-modified bearing bush is more sensitive to speed changes and is seriously damaged in high-speed working conditions. The friction coefficient is related to the bonding strength of the interface between the filler fiber and the matrix and the antifriction effect of the lubricant. The amount of wear is related to the bearing capacity of high-strength carbon fiber and the formation of a well-established dual sliding surface transfer film.

The wear mechanism of the modified bearing bush was analyzed through the use of scanning electron microscopy (SEM) under different test pressures, with the results presented in

Figure 8. As the test pressure continues to increase, the pressure exerted on the three-layer composite bearing bush also rises. Due to the soft nature of its self-lubricating layer, it is prone to compression deformation under increased pressure, which in turn enhances the compactness of the self-lubricating layer. During this process, the fibers embedded within the self-lubricating layer are able to more tightly integrate with the PEEK matrix, reducing wear caused by fiber breakage and subsequently lowering the friction coefficient of the three-layer composite bearing bush. Moreover, with the escalation of test pressure, PTFE solid lubricant is able to more effectively fill the wear areas, thereby preventing the extensive material disintegration caused by localized wear.

As shown in

Figure 8, the SCF-modified three-layer composite bearing bush did not show obvious SCF peel modification of the PEEK matrix. However, under the test pressure of 15 MPa, the extrusion action on the micro-convex surface of the self-lubricating layer is not enough to make it smooth, and obvious material avulsion and micro-cracks are produced. When the test pressure increased to 30 MPa, the bulges on the wear surface were smoothed, and the material avulsion phenomenon was significantly reduced.

3.3. EDS Spectral Analysis

Different friction morphologies of the bearing bush under various pressure conditions were selected, and the test results are shown in

Figure 9. When the applied pressure rises from 15 to 25 MPa, a notable improvement in the surface finish is observed, reflecting the increased densification of the natural lubrication layer. At this higher pressure range of 20 to 30 MPa, individual carbon fibers demonstrated compromised integrity, with isolated instances of failure resulting in fragmented fibers rather than complete fiber breakage or removal. The material that detaches from the pure PEEK base mostly appears in the form of debris, which is expelled from the friction interface. Consequently, no transfer film is formed on the metal counterface [

33]. The content of fluorine elements on the friction surface of the metal counterface represents the degree to which material is effectively transferred from the matrix to the metal mating surface during the friction process [

34].

After completing the friction test, an Energy Dispersive Spectroscopy (EDS) analysis was conducted on the counterface of the bearing bush, as depicted in

Figure 10. The EDS analysis provided elemental composition data, revealing the elemental distribution and potential material transfer or degradation that occurred during the friction interaction. Further observation of the distribution maps of carbon, oxygen, and sulfur elements on the bearing bush counterface revealed that these elements have relatively high contents on the surface. The carbon and oxygen elements are primarily derived from the PEEK resin matrix and the filled PTFE, respectively, while the sulfur element is mainly from the PTW resin matrix. At different wear locations, the distribution of carbon in the resin accumulation friction morphology is more extensive, which is linked to the particles impurities predominantly being resin-based.

The distribution of oxygen is relatively uniform across various pressures. The distribution degree of sulfur increases first and then decreases with the gradual increase of pressure. Given that the chemical composition of the rollers consists of GCr15SiMn with sulfur less than 0.020%, it can be essentially ascertained that they originate from the PTW resin matrix. Based on the changing pattern of friction coefficients under different operating conditions, it is inferred that the addition of a small amount of PTW facilitates its complete transfer to the friction interface, thereby promoting the growth of the transfer film. It can be observed from the distribution map of zinc that there is basically no zinc present at the location of carbon fibers, which proves that it originates from the bearing itself. During the frictional wear between the metal and the self-lubricating bearing bush, the film that grows plays a crucial role in not only decreasing the friction coefficient but also boosting the bearing capacity.

3.4. Low Speed and Heavy Load

Figure 11 shows the friction torque curves of the SCF-modified three-layer composite bearing bush under three groups of different pressure levels, respectively. In the initial period of the test, the friction coefficient of the bearing bush first increased and then slowly decreased, and regular changes were obtained after a period of running-in process. According to the friction torque of the bearing bush under the condition of low speed and heavy load, the friction coefficient of the SCF-modified bearing bush is relatively stable under 28 MPa and 30.5 MPa. When the maximum pressure is 33 MPa, the friction coefficient of the SCF-modified bearing bush increases slowly.

As can be seen from

Figure 12, with the increase of experimental pressure, the wear depth of the bearing bush gradually increases. At 33 MPa, there is obvious material accumulation in the worn and non-worn parts of the bearing bush. With the increasing pressure, the difference in abrasion depth of the modified bearing bush becomes smaller. Therefore, combined with the dynamic change process of the friction coefficient of the bearing bush, it can be determined that the tribological performance of the SCF-modified bearing bush is improved. The excellent frictional properties of the SCF-modified bearing bush are more and more prominent under extremely high pressure.

As can be seen from

Figure 13a, there were many small holes on the surface of the composite material with carbon fiber added. The reason for this phenomenon may be related to the many small holes in the treatment layer of the fiber surface after the modification of carbon fiber. The appearance of these small pores increased the space for molecular flow between the modified materials, increased the activity of the lubricant phase polytetrafluoroethylene, and increased the free volume of the modified materials, resulting in a decrease in the glass transition temperature of the modified materials. In combination with the SEM image, it can be seen that the modified carbon fiber forms a relatively dense treated layer, and the hardness of the interfacial layer is improved, which can effectively reduce the movement and slip of molecular chains between self-lubricating materials, so the high-temperature resistance of the material can be improved to a certain extent. Combined with scanning electron microscope images, it can be seen that the surface of carbon fiber after modification is etched, and small gullies appear in the middle, making its surface more uneven and roughness increased, and changes in oxygen-containing groups reduce the surface energy required for coating of the treatment layer so that the intermolecular force is enhanced.

As can be seen from

Figure 13b, many particles are attached to the surface and grooves of carbon fiber. This is because the solid lubricant PTFE sticks to the surface of the carbon fiber. When the pressure is 28 MPa, the wear surface has a slight interface cracking and desticking phenomenon. It can be seen that only a small number of carbon fiber edges are stripped from the matrix, and the phenomenon of fiber pulling out is almost non-existent. There is a very small number of voids in the matrix, and this phenomenon occurs in the fiber–matrix with low pressure, resulting in the instability of the friction coefficient.

As can be seen from

Figure 13c, it is evident that when the pressure reaches 30.5 MPa, the fracture surface of the worn composite assumes a relatively flat profile. The occurrence of carbon fiber withdrawal is notably diminished, while a considerable number of resin fragments firmly adhere to its surface. Furthermore, the incidence of interface cracking and debonding exhibits a clear reduction, collectively pointing to an enhancement in the material’s structural performance. With the increase of pressure, the fracture phenomenon of carbon fiber composites is improved because the grafted molecular chains on the surface of carbon fiber contain a large number of active functional groups, which can improve the surface wettability of carbon fiber, and thus significantly increase the interlayer shear strength of carbon fiber reinforced composites. The self-lubricating material is uniformly coated on the fiber surface, with the gully on the fiber surface almost entirely covered. This configuration makes the fiber–matrix interface less prone to damage and enables effective stress transfer to the carbon fiber, thereby enhancing the material’s structural strength and durability. Thus, the friction coefficient and abrasion depth of the bearing bush are relatively stable under this pressure.

As can be seen from

Figure 13d, when the pressure reaches 33 MPa, numerous granular PTFE particles emerge on the carbon fiber surface due to the influence of high pressure. This occurrence results in deeper grooves and increased surface roughness of the carbon fiber, potentially affecting its relationship with the surrounding environment. With the extension of wear time, the PTFE layer becomes loose from dense; when subjected to high pressure, the stripped carbon fiber and the substrate lubricating material can complete the self-polymerization reaction well. At the same time, combined with the surface Energy Dispersive Spectroscopy (EDS) spectrum analysis, the carbon fiber surface is coated with a transfer film, a few large polydopamine particles are randomly deposited on the surface, and the surface gullies are almost completely covered. This phenomenon effectively prevents further avulsion separation between the fiber and the base material. Additionally, it enhances the mechanical anchoring force at the interface, thereby improving the bond performance of the composite material’s interface. Furthermore, the entire fiber exhibits a relatively smooth surface, indicating that the self-polymerization process has been completed.

4. Discussion

With the increasing pressure, the friction coefficient of the 15% SCF-modified bearing bush initially decreases and then experiences an increase from 0.420 to 0.296 and then to 0.326. Compared with the PEEK and carbon fiber-modified composite developed by Pang et al. [

35], the average friction coefficient of the PEEK material exhibits an initial increase followed by a decrease as the applied load increases. The loads applied at 75 N, 100 N, and 125 N are much lower than those used in this test. Nonetheless, the material exhibits a frictional morphology that aligns with the characteristics of the low speed and heavy load conditions, suggesting that the 15% SCF-modified bearing bush is indeed capable of functioning effectively under heavy load conditions.

Under dry friction conditions, when the load reaches the critical value, the friction heat on the surface can reach the softening point of the material or cause the surface oxide film to break, leading to a transition in the wear rate. The wear mechanism of SCF/PEEK composites under these conditions is primarily characterized by adhesive wear and slight abrasive wear.

In contrast to the analysis by Pang et al. [

18] on the friction and wear performance of 20% CF/PEEK composites at high temperatures, this paper integrates the lubrication and cooling properties of lubricating oil to substantially mitigate the detrimental effects of frictional heat on self-lubricating materials. This approach effectively curbs the plastic deformation, adhesion, and fiber shedding induced by frictional heat within the composites, thereby enhancing their performance under high-temperature conditions. Consequently, the influence of friction heat on the friction and wear performance of self-lubricating materials is not discussed in this paper. Moreover, the lubricating oil effectively removes wear debris between the friction surfaces, preventing its accumulation on the worn surface, which would either impair or hinder the formation of a transfer film. However, it should be noted that while preventing the formation of transfer film, the lubricating oil concurrently generates a certain level of lubrication between the interacting surfaces, thereby reducing system friction and aiding in material wear reduction.

The load exerts a significant impact on the physical transformation processes occurring within the surface layer of self-lubricating materials. This is due to the fact that the magnitude of the load directly alters the size of the actual contact area on the friction surface, subsequently influencing the temperature of the surface layer and the progression of wear during the friction and wear process.

Under oil lubrication, the wear surface of SCF/PEEK-modified materials exhibits a discernible thinning and smoothing of fibers, which is a clear indication of effective interfacial bonding between the SCF and the matrix. SCF not only assumes a crucial bearing function during the friction process but also prevents the surface micro-convex from cutting the composite matrix. The presence of interfacial gaps between the SCF facilitates the flow of lubricating oil, thus contributing to a lubrication effect that aids in reducing friction between the interacting surfaces.

Based on the EDS (Energy Dispersive Spectroscopy) spectrum analysis, it can be observed that fiber fracturing occurs in the friction morphology of the 15% SCF/PEEK self-lubricating bearing bush under the load of 15 MPa. The observed phenomenon resembles that of fiber stripping and complete pulling out, which is associated with the interfacial bonding strength between the fiber and the resin matrix. The interfacial bond strength is also related to the treatment of the fibers. Currently, the prevalent treatment methods available in the market include oxidative treatment, surface coating, plasma surface modification, chemical grafting, and nanoparticle modification, among which the treatment method employed in this text for carbon fiber is oxidative treatment [

36]. The various methods employed for the surface treatment of carbon fibers often result in varying degrees of damage to the fibers. These processes can introduce new impurities onto the fiber surface, potentially weakening the interfacial bonding strength between the carbon fiber and the matrix. Consequently, this can lead to a reduction in the mechanical properties of the resulting composite materials.

Indeed, Dongdong Li’s [

37] supercritical fluid method is being considered for treating the surface of carbon fiber to improve its interfacial bonding strength, with the ultimate goal of enhancing the friction and wear performance of the bearing bush. This strategy appears to be a promising approach for future developments.

5. Conclusions

The low-speed tribological performances of GCr15SiMn(roller)/SCF-modified PEEK (bearing bush self-lubricating layer) contact were studied by the above tests. The main conclusions are as follows:

(1) The three-layer self-lubricating bearing bush, modified with 15% SCF, achieved an average friction coefficient of 0.296 at 25 MPa and 0.326 at 30 MPa, both of which are lower than the coefficients of 0.420 and 0.375 observed at 15 MPa and 20 MPa, respectively;

(2) The frictional morphology reveals that before wear occurs, the surface of the carbon fiber undergoes etching, leading to a more rugged and uneven texture with heightened surface roughness. Under pressures ranging from 28 MPa to 30.5 MPa, the phenomenon of fiber breakage significantly decreases, with self-lubricating materials uniformly coating the fiber surfaces, effectively transferring stress to the carbon fibers, thereby enhancing the structural strength and durability of the material. Under a pressure of 33 MPa, the stripped carbon fibers and the base material of the self-lubricating material can effectively undergo the self-polymerization process, with the surface grooves almost completely covered, resulting in a relatively smooth surface, and the coefficient of friction and wear depth of the bearing bush being relatively stable.

Notably, all of these demonstrate that the friction and wear performance of the material becomes more pronounced under higher pressure conditions, and it is capable of effectively adapting to the heavy load conditions of the motor.