Regolith-Rich PEEK Composite Bricks: Steps Towards Space-Ready Lunar Construction Materials

Abstract

1. Introduction

1.1. Insights from Previous PLA-Based Samples

1.2. Organic Phase Selection

2. The Manufacturing Process and Parameter Refinement

- Drying: Both the regolith simulant and the binder are dried to remove moisture. For PEEK, drying is performed at 80 °C for 12 h, and for EAC-1a at 250 °C for 2 h, using a Memmert UN30 universal oven.

- Sieving: The regolith simulant is sieved to ensure that only particles within a specific size range are included in the process. The previous study demonstrated that a heterogeneous particle size distribution enhances the mechanical properties of the parts, especially when all particles are below 500 μm. Consequently, this threshold is set during sieving, performed using a Nexopart EML 200 sieve machine.

- Mixing and Mold Filling: The dried regolith simulant and binder are mixed in the desired weight percentage (wt%) for a few minutes before being transferred into a metallic mold for shaping.

- Compaction: The mixture within the mold is compacted using a press at the specified pressure level. Depending on the sample size and compaction pressure, the mixture is compacted using either a toggle press with a 2 kN load sensor or a 10-ton Unicraft WPP 10 hydraulic press.

- Curing: The compacted green body undergoes heating to a temperature above the melting point of the binder. PLA-based samples show no significant differences within a narrow range above its melting point. For PEEK, curing is conducted at 400 °C using a Carbolite Gero STF 15/450 tube furnace. A preliminary study shows no significant variation in the material properties at higher temperatures, though shorter curing times are achievable. Both air and vacuum curing are examined, with a uniform curing time of 3 h chosen for consistency. For vacuum curing, an Edwards RV3 vacuum pump is used to maintain pressures of 0.17–0.23 mbar.

- Cooling: After curing, samples are cooled in air at room temperature, as this parameter has no impact on the final properties of the processed parts.

3. Mechanical Characterization Campaign

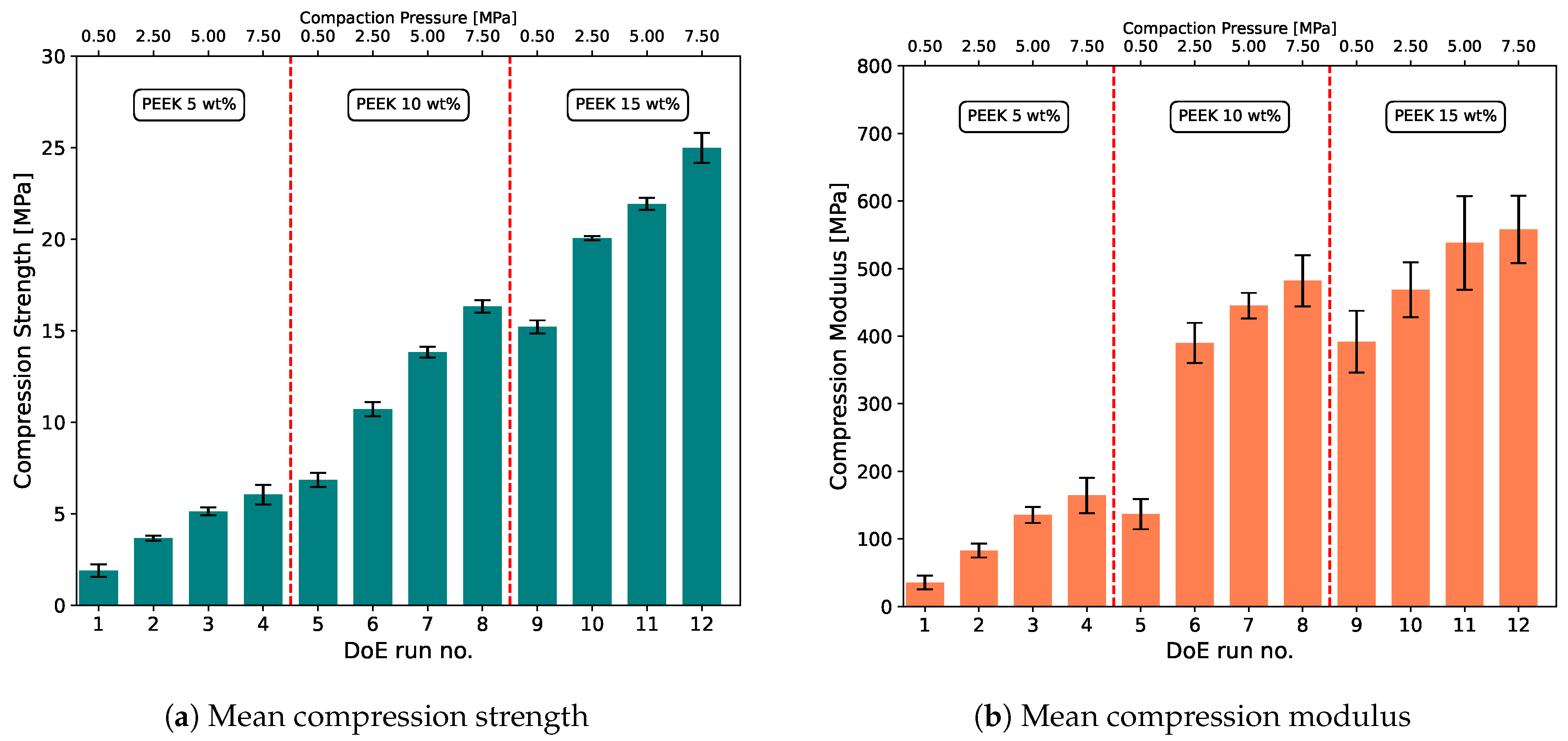

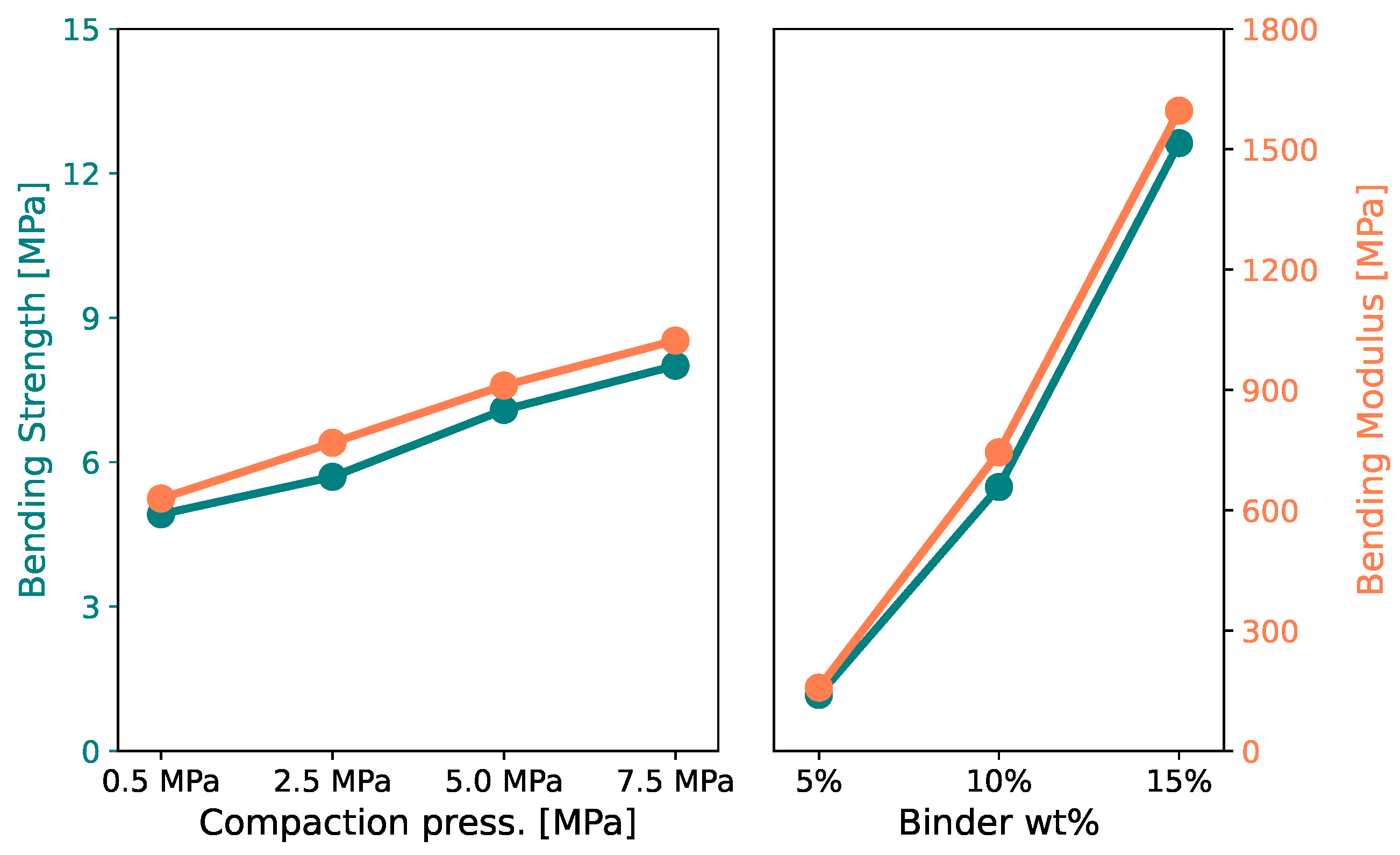

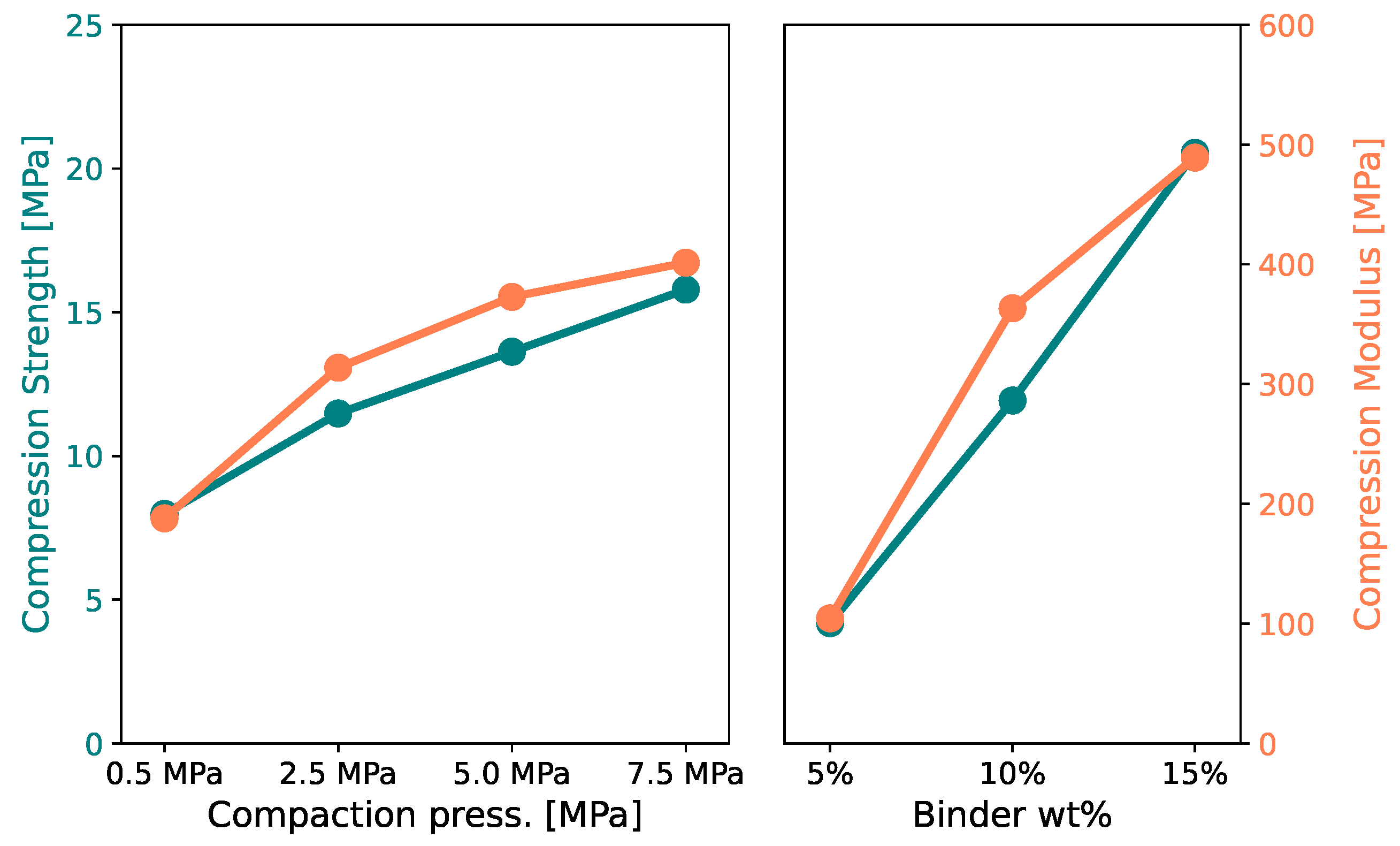

Bending and Compression Tests

4. Discussion on the Material Properties

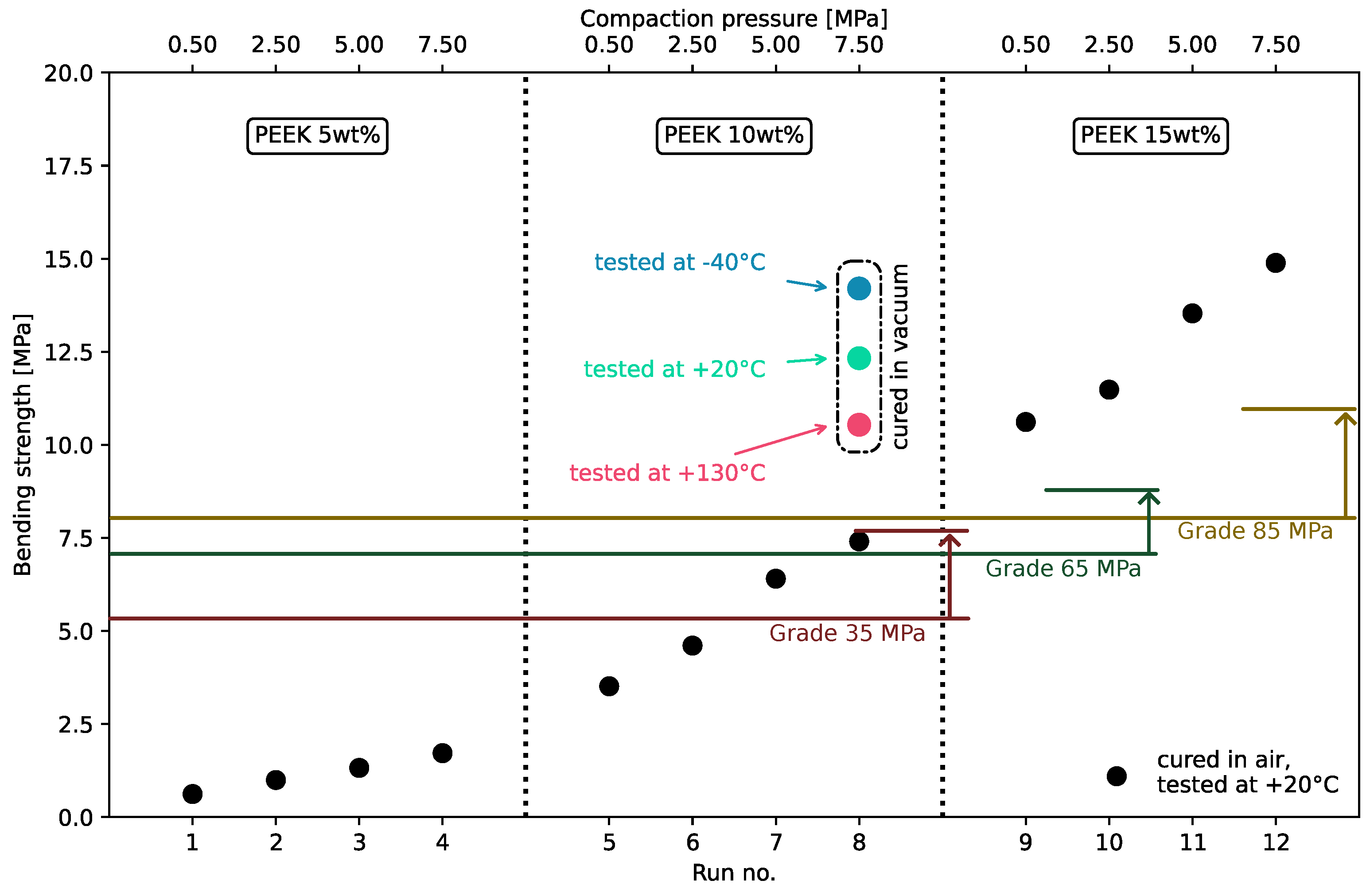

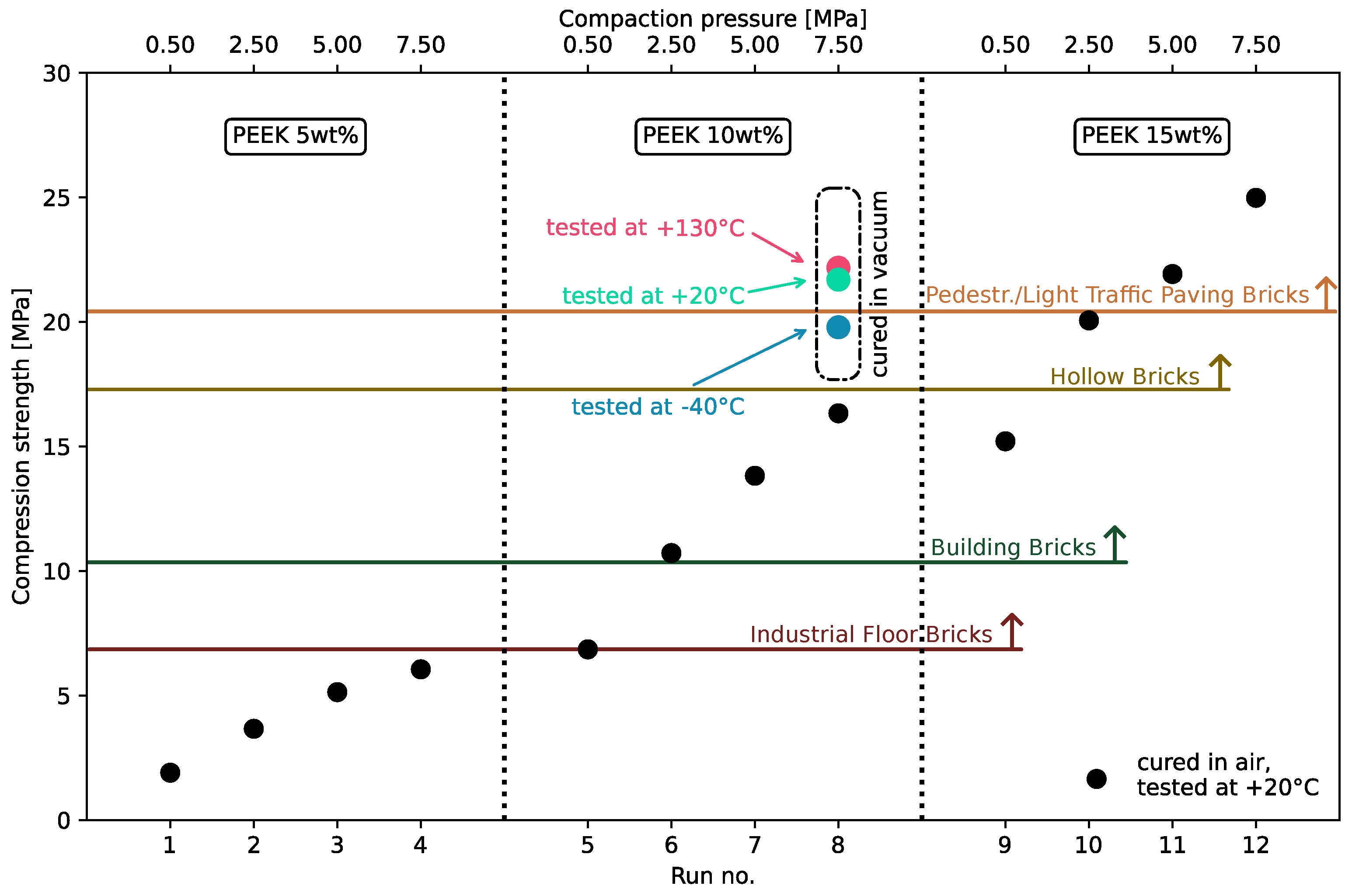

4.1. Impact of the Process Parameters

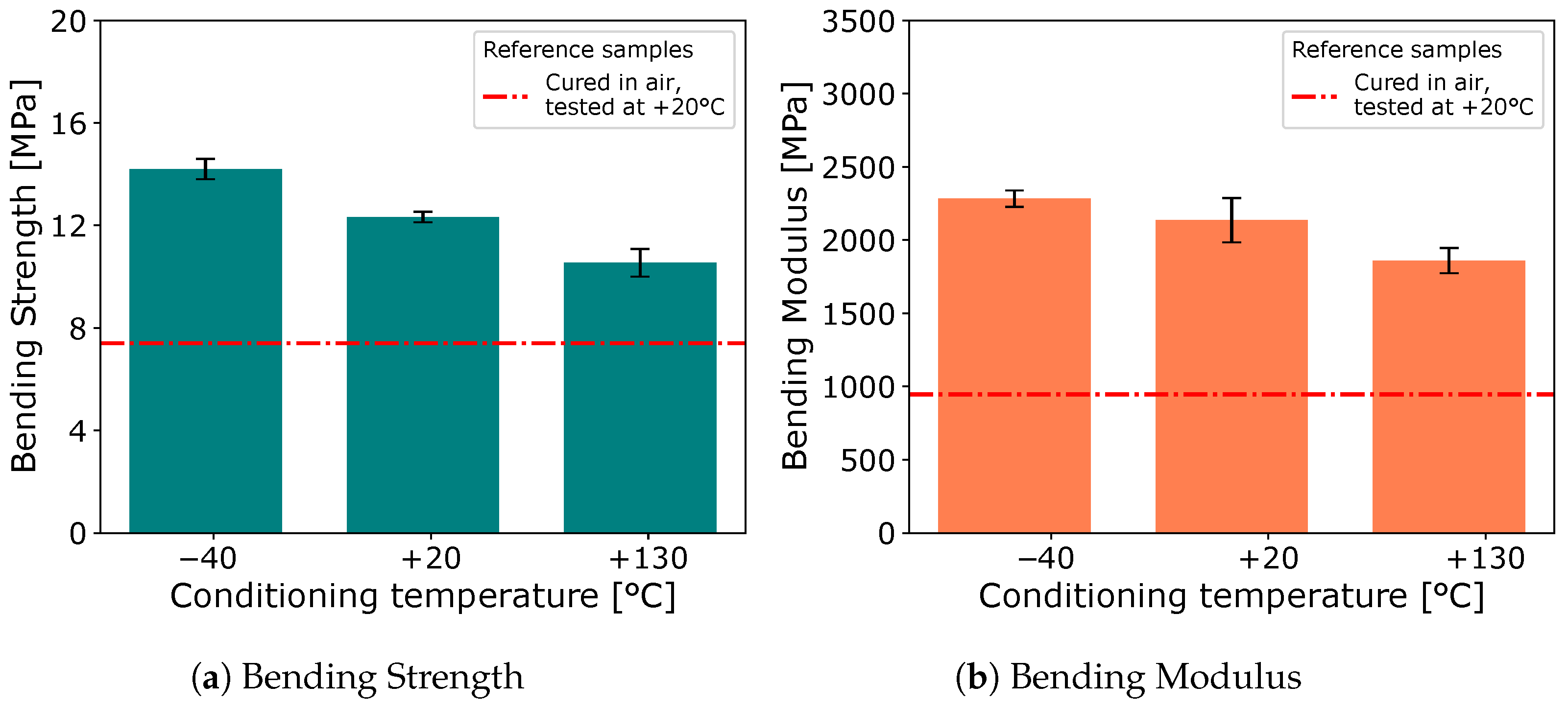

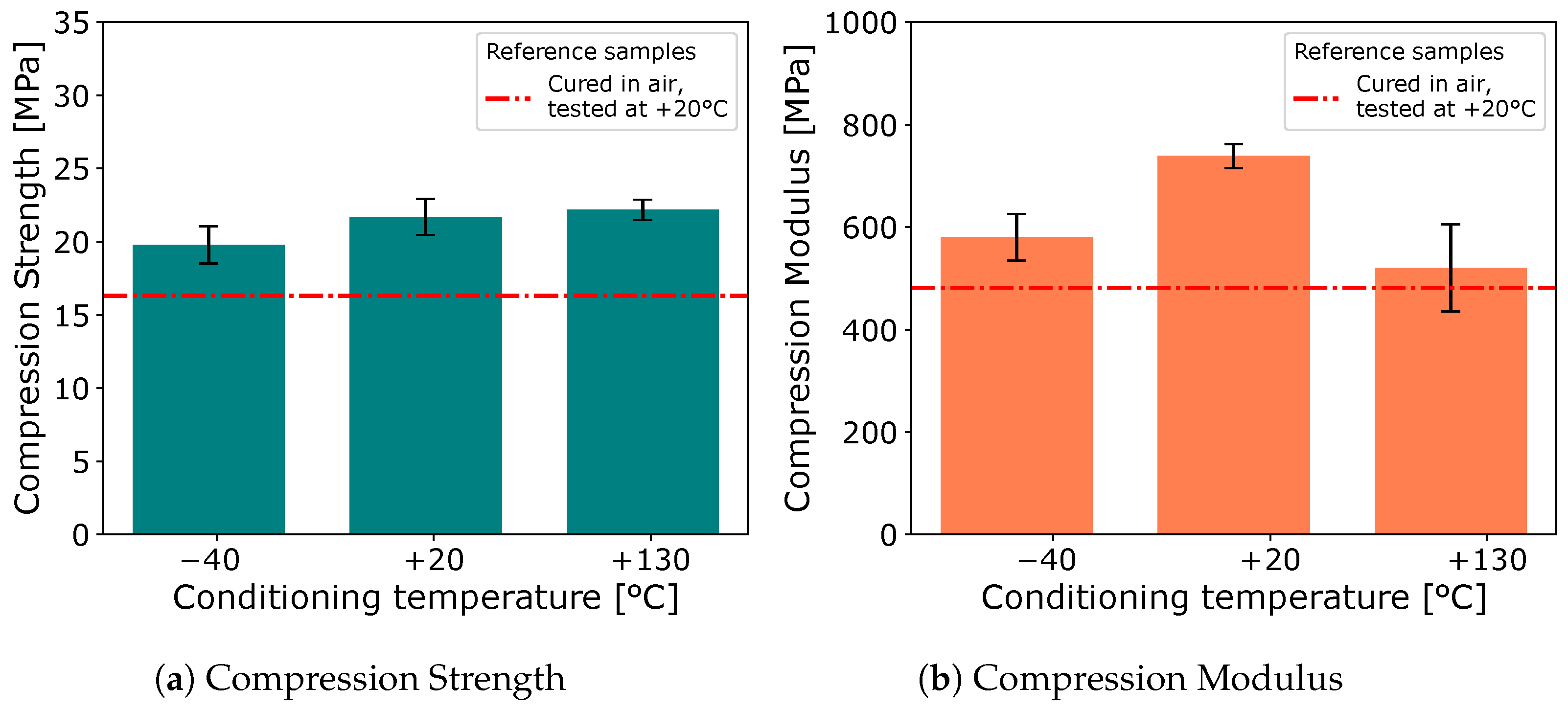

4.2. Effects of Vacuum Processing and Temperature Testings

4.3. Comparison with Standards for Bricks Classification

5. Conclusions

- A binder content of 5 wt% met and exceeded equivalent compression strength requirements for lunar applications, including building and paving bricks.

- The compression strength needed for lunar concrete applications, such as basement walls, slabs, and reinforced beams, was achieved with 5 wt% binder.

- At 10 wt%, the composite satisfied strength requirements for similar Earth-based structures.

- Bending strength results mirrored these trends, with 5 wt% meeting the equivalent performance for conventional and reinforced concretes on the Moon, and 10 wt% ensuring compliance for Earth-based requirements.

- Vacuum curing significantly enhanced mechanical properties, enabling compatibility with all lunar and most Earth-based requirements.

- Binder weight percentage and powder compaction positively influenced all mechanical properties. The minimal binder content and low pressures used in the process underscore its scalability for larger structures.

- Thermal and Mechanical Constraints: The performance of PEEK-based composites under the combined extreme thermal cycling and radiation exposure on the Moon requires further validation. Current tests only partially replicate lunar conditions, and additional experimentation under representative environments will be crucial.

- Processing Efficiency: Achieving vacuum processing on a medium to large scale with precise temperature control poses significant engineering challenges, especially given the limited power and mass budget of lunar missions.

- Material Availability: While regolith is abundant on the Moon surface, ensuring the uniformity of particle size and composition for consistent performance remains a logistical and processing challenge at the time.

- Environmental Testing: Conduct extended experiments under conditions that more accurately mimic the lunar environment, including prolonged exposure to high vacuum, thermal cycling, and micro-meteoroid impacts. To address these added issues in the real environment, novel solutions could be proposed such as the integration of additional fillers or external coatings to improve radiation resistance, and mechanical toughness.

- Automation and In Situ Adaptability: Develop autonomous systems for regolith collection, material processing, and construction to align with lunar mission constraints.

- Multi-functional Applications: Investigate the feasibility of these composites in multi-functional roles, such as structural components that also serve as radiation shielding or thermal insulation.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| PEEK | Multidisciplinary Digital Publishing Institute |

| ISRU | In Situ Resource Utilization |

| PLA | Polylactic Acid |

| TPI | Thermoplastic Polyimide |

| PPS | Polyphenylene Sulfide |

| PTFE | Polytetrafluoroethylene |

| PEI | Polyetherimide |

| TML | Total Mass Loss |

| CTE | Coefficient of Thermal Expansion |

| Tg | Glass Transition Temperature |

| Tm | Melting Temperature |

| wt% | Weight Percentage |

| pc | Compaction Pressure |

| DoE | Design of Experiment |

| Tensile Strength | |

| LT | Low Temperature |

| RT | Room Temperature |

| HT | High Temperature |

Appendix A

Appendix A.1

| DoE Run | Compression | Bending | ||||||

|---|---|---|---|---|---|---|---|---|

| Strength | Modulus | Strength | Modulus | |||||

| R01 | 1.90 | 0.31 | 35.46 | 10.30 | 0.62 | 0.07 | 66.02 | 11.07 |

| R02 | 3.66 | 0.12 | 82.70 | 10.27 | 1.00 | 0.11 | 109.58 | 37.94 |

| R03 | 5.13 | 0.20 | 135.42 | 11.91 | 1.32 | 0.17 | 210.03 | 18.51 |

| R04 | 6.05 | 0.48 | 164.24 | 26.24 | 1.72 | 0.09 | 245.42 | 15.39 |

| R05 | 6.85 | 0.34 | 136.50 | 22.20 | 3.52 | 0.28 | 498.38 | 33.56 |

| R06 | 10.72 | 0.35 | 389.89 | 29.80 | 4.61 | 0.28 | 709.82 | 47.29 |

| R07 | 13.82 | 0.26 | 445.04 | 19.02 | 6.40 | 0.48 | 823.67 | 86.22 |

| R08 | 16.33 | 0.31 | 481.93 | 37.73 | 7.41 | 0.43 | 946.60 | 75.44 |

| R09 | 15.21 | 0.32 | 391.87 | 45.70 | 10.61 | 0.29 | 1323.45 | 65.71 |

| R10 | 20.06 | 0.10 | 468.49 | 40.61 | 11.48 | 0.33 | 1485.39 | 75.24 |

| R11 | 21.92 | 0.29 | 537.92 | 69.27 | 13.53 | 0.38 | 1699.09 | 71.91 |

| R12 | 24.98 | 0.73 | 558.02 | 49.91 | 14.89 | 0.48 | 1877.45 | 96.1 |

| Cond. Temp. | Compression | Bending | ||||||

|---|---|---|---|---|---|---|---|---|

| Strength | Modulus | Strength | Modulus | |||||

| −40 °C | 19.79 | 1.13 | 580.49 | 45.49 | 14.20 | 0.35 | 2282.89 | 55.73 |

| +20 °C | 21.70 | 1.10 | 738.70 | 23.18 | 12.33 | 0.18 | 2135.97 | 151.59 |

| +130 °C | 22.17 | 0.63 | 520.66 | 84.93 | 10.54 | 0.48 | 1859.95 | 86.11 |

Appendix B

Appendix B.1

| Ref. | Min. | DoE Run No. | Vacuum Proc. | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Standard | Cat. | [MPa] | 01 | 02 | 03 | 04 | 05 | 06 | 07 | 08 | 09 | 10 | 11 | 12 | HT | RT | LT |

| IBC [64] | - | 10.3 | C* | C* | C* | C* | C* | C | C | C | C | C | C | C | C | C | C |

| ASTM | T/H | 6.9 | C* | C* | C* | C* | C* | C | C | C | C | C | C | C | C | C | C |

| C410 a [18] | M/L | 13.8 | N | C* | C* | C* | C* | C* | C | C | C | C | C | C | C | C | C |

| ASTM C62 b [19] | NW | 10.3 | C* | C* | C* | C* | C* | C | C | C | C | C | C | C | C | C | C |

| MW | 17.2 | N | C* | C* | C* | C* | C* | C* | C* | C* | C | C | C | C | C | C | |

| SW | 20.7 | N | C* | C* | C* | C* | C* | C* | C* | C* | C* | C | C | C* | C | C | |

| ASTM | MW | 17.2 | N | C* | C* | C* | C* | C* | C* | C* | C* | C | C | C | C | C | C |

| C652 c [20] | SW | 20.7 | N | C* | C* | C* | C* | C* | C* | C* | C* | C* | C | C | C* | C | C |

| ASTM | MX/NX | 20.7 | N | C* | C* | C* | C* | C* | C* | C* | C* | C* | C | C | C* | C | C |

| C902 d [63] | SX | 55.2 | N | N | N | N | N | C* | C* | C* | C* | C* | C* | C* | C* | C* | C* |

| Exp. Val. | DoE Run No. | Vacuum Proc. | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| [MPa] | 01 | 02 | 03 | 04 | 05 | 06 | 07 | 08 | 09 | 10 | 11 | 12 | HT | RT | LT | |

| [25] | (<17) a | C | C | C | C | C | C | C | C | C | C | C | C | C | C | C |

| (17–24) b | N | C* | C* | C* | C* | C* | C* | C* | C* | C | C | C | C | C | C | |

| (21–28) c | N | C* | C* | C* | C* | C* | C* | C* | C* | C* | C | C | C* | C | C | |

| (21–48) d | N | C* | C* | C* | C* | C* | C* | C* | C* | C* | C | C | C* | C | C | |

| (28–48) e | N | N | C* | C* | C* | C* | C* | C* | C* | C* | C* | C* | C* | C* | C* | |

| (69–109) f | N | N | N | N | N | N | C* | C* | C* | C* | C* | C* | C* | C* | C* | |

| Grade | Exp. Value(s) | DoE Run No. | Vacuum Proc. | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| [MPa] | 01 | 02 | 03 | 04 | 05 | 06 | 07 | 08 | 09 | 10 | 11 | 12 | HT | RT | LT | ||

| [65] a | 20 MPa | 3.5 | E* | E* | E* | E* | E | E | E | E | E | E | E | E | E | E | E |

| [26] b | 35 MPa | 5.2–7.6 | N | E* | E* | E* | E* | E* | E | E | E | E | E | E | E | E | E |

| 65 MPa | 7.2–10 | N | N | E* | E* | E* | E* | E* | E | E | E | E | E | E | E | E | |

| 85 MPa | 8.0–11 | N | N | N | E* | E* | E* | E* | E* | E | E | E | E | E | E | E | |

| [66] | LWplain c | 4.4 | N | E* | E* | E* | E* | E | E | E | E | E | E | E | E | E | E |

| LWP d | 4.6–5.3 | N | E* | E* | E* | E* | E | E | E | E | E | E | E | E | E | E | |

| LWS e | 5.2–7.9 | N | E* | E* | E* | E* | E* | E | E | E | E | E | E | E | E | E | |

| NWHS f | 6.9 | N | N | E* | E* | E* | E* | E* | E | E | E | E | E | E | E | E | |

| [67] g | 0.5 %vol | 8.2 | N | N | N | E* | E* | E* | E* | E* | E | E | E | E | E | E | E |

| 1.0 %vol | 10.1 | N | N | N | E* | E* | E* | E* | E* | E | E | E | E | E | E | E | |

| 1.5 %vol | 12.3 | N | N | N | N | E* | E* | E* | E* | E* | E* | E | E | E* | E | E | |

| 2.0 %vol | 14.5 | N | N | N | N | E* | E* | E* | E* | E* | E* | E* | E | E* | E* | E* | |

References

- Vallerani, E.; Ori, G.G.; Torre, A.; Grasso, M.; Guizzo, G.P.; Vukman, I. ISRU: Perspectives for Lunar Development. In Proceedings of the 57th International Astronautical Congress, Valencia, Spain, 2–6 October 2006; pp. 1–15. [Google Scholar] [CrossRef]

- Tilman, S.; Doris, B.; Torrence, V.J. The Encyclopedia of the Solar System; Elsevier: Amsterdam, The Netherlands, 2014. [Google Scholar] [CrossRef]

- Anand, M.; Crawford, I.; Balat-Pichelin, M.; Abanades, S.; Westrenen, W.; Péraudeau, G.; Jaumann, R.; Seboldt, W. A brief review of chemical and mineralogical resources on the Moon and likely initial In Situ Resource Utilization (ISRU) applications. Planet. Space Sci. 2012, 74, 42–48. [Google Scholar] [CrossRef]

- Cannon, K.M.; Mueller, R.P. Regolith Processing. In Handbook of Space Resources; Badescu, V., Zacny, K., Bar-Cohen, Y., Eds.; Springer International Publishing: Cham, Switzerland, 2023; pp. 399–427. [Google Scholar] [CrossRef]

- Torre, R.; Cowley, A.; Ferro, C. Low binder content bricks: A regolith-based solution for sustainable surface construction on the Moon. Discov. Appl. Sci. 2024, 6, 88. [Google Scholar] [CrossRef]

- Torre, R.; Cowley, A. Low binder content bricks: State of the art progress towards a sustainable surface construction on the Moon. In Proceedings of the Space Resources Week, Luxembourg, 25–27 March 2024. [Google Scholar]

- Ferro, C.G.; Florenzano, D.; Pastore, A.; Pasqualin, L.; Agozzino, M.; Fesa, S.; Tawfik, H.; Almatari, K.; Aimasso, A.; Valvano, S.; et al. Beyond Earth: A multidisciplinary approach to developing sustainable lunar outposts with the MOSS project. In Proceedings of the 75th International Astronautical Congress (IAC), Milan, Italy, 14–18 October 2024. [Google Scholar]

- Jakus, A.; Koube, K.; Geisendorfer, N.; Shah, R. Robust and Elastic Lunar and Martian Structures from 3D-Printed Regolith Inks. Sci. Rep. 2017, 7, 44931. [Google Scholar] [CrossRef] [PubMed]

- Liu, M.; Weizhe, T.; Duan, W.; Li, S.; Dou, R.; Wang, G.; Liu, B.; Wang, L. Digital light processing of lunar regolith structures with high mechanical properties. Ceram. Int. 2018, 45, 5829–5836. [Google Scholar] [CrossRef]

- Chen, T.; Chow, B.; Wang, M.; Shi, Y.; Zhao, C.; Qiao, Y. Inorganic–Organic Hybrid of Lunar Soil Simulant and Polyethylene. J. Mater. Civ. Eng. 2015, 28, 06015013. [Google Scholar] [CrossRef]

- Chen, T.; Chow, B.; Wang, M.; Zhong, Y.; Qiao, Y. High-Pressure Densification of Composite Lunar Cement. J. Mater. Civ. Eng. 2017, 29, 06017013. [Google Scholar] [CrossRef]

- Chen, T.; Chow, B.; Zhong, Y.; Wang, M.; Kou, R.; Qiao, Y. Formation of Polymer Micro-Agglomerations in Ultralow-Binder-Content Composite based on Lunar Soil Simulant. Adv. Space Res. 2017, 61, 830–836. [Google Scholar] [CrossRef]

- Oh, K.; Chen, T.; Kou, R.; Yi, H.; Qiao, Y. Ultralow-Binder-Content Thermoplastic Composites Based on Lunar Soil Simulant. Adv. Space Res. 2020, 66, 2245–2250. [Google Scholar] [CrossRef]

- Pichard, P.L.; Cowley, A.; Hand, A.; Schild, T.; Adiaconitei, A.; Katrakova-Kruger, D.; Spanheimer, V.; Ochsner. Regolith-based composite manufacturing by Fused Deposition Modelling (FDM). In Proceedings of the Space Resources Week, Luxembourg, 3–5 May 2022. [Google Scholar]

- Zhu, Y.; Romain, C.; Williams, C. Sustainable polymers from renewable resources. Nature 2016, 540, 354–362. [Google Scholar] [CrossRef] [PubMed]

- Williams, J.P.; Paige, D.; Greenhagen, B.; Sefton-Nash, E. The global surface temperatures of the Moon as measured by the Diviner Lunar Radiometer Experiment. Icarus Lunar Reconnaiss. Orbiter–Part II 2017, 283, 300–325. [Google Scholar] [CrossRef]

- Landis, G.A. Degradation of the lunar vacuum by a moon base. Acta Astronaut. 1990, 21, 183–187. [Google Scholar] [CrossRef]

- ASTM C410-13(2017); Standard Specification for Industrial Floor Brick. ASTM International: West Conshohocken, PA, USA, 2017. [CrossRef]

- ASTM C62-17; Standard Specification for Building Brick (Solid Masonry Units Made From Clay or Shale). ASTM International: West Conshohocken, PA, USA, 2017. [CrossRef]

- ASTM C652-21; Standard Specification for Hollow Brick (Hollow Masonry Units Made From Clay or Shale). ASTM International: West Conshohocken, PA, USA, 2021. [CrossRef]

- Benaroya, H.; Bernold, L. Engineering of lunar bases. Acta Astronaut. 2008, 62, 277–299. [Google Scholar] [CrossRef]

- Montes, C.; Broussard, K.; Gongre, M.; Simicevic, N.; Mejia, J.; Tham, J.; Allouche, E.; Davis, G. Evaluation of Lunar Regolith Geopolymer Binder as a Radioactive Shielding Material for Space Exploration Applications. Adv. Space Res. 2015, 56, 1212–1221. [Google Scholar] [CrossRef]

- Goulas, A.; Binner, J.G.; Engstrøm, D.S.; Harris, R.A.; Friel, R.J. Mechanical behaviour of additively manufactured lunar regolith simulant components. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2019, 233, 1629–1644. [Google Scholar] [CrossRef]

- Lee, S.; van Riessen, A. A Review on Geopolymer Technology for Lunar Base Construction. Materials 2022, 15, 4516. [Google Scholar] [CrossRef]

- Neville, G.B. The Concrete Manual; International Code Council: Falls Church, VA, USA, 2015. [Google Scholar]

- Job, T.; Ananth, R. Mechanical Properties of Steel Fiber-Reinforced Concrete. J. Mater. Civ. Eng. 2007, 19, 385–392. [Google Scholar] [CrossRef]

- ECSS-Q-ST-70-02C; Space Product Assurance. ECSS Secretariat ESA ESTEC: Noordwijk, The Netherlands, 2008; Chapter Thermal Vacuum Outgassing Test for the Screening of Space Materials.

- NASA. Outgassing Data for Selecting Spacecraft Materials; NASA: Washington, DC, USA, 2017.

- Rae, P.; Brown, E.; Orler, E. The mechanical properties of poly(ether-ether-ketone) (PEEK) with emphasis on the large compressive strain response. Polymer 2007, 48, 598–615. [Google Scholar] [CrossRef]

- Feng, X.; Liu, J. High Performance Polymers and Their Nanocomposites; Scrivener Publishing LLC: Beverly, MA, USA, 2018; Chapter Thermoplastic Polyimide (TPI); pp. 149–219. [Google Scholar] [CrossRef]

- Seo, K.; Park, L.; Baek, J.; Brostow, W. Thermal behaviour of poly (phenylene sulfide) and its derivatives. Polymer 1993, 34, 2524–2527. [Google Scholar] [CrossRef]

- Calleja, G.; Jourdan, A.; Ameduri, B.; Habas, J.P. Where is the glass transition temperature of poly(tetrafluoroethylene)? A new approach by dynamic rheometry and mechanical tests. Eur. Polym. J. 2013, 49, 2214–2222. [Google Scholar] [CrossRef]

- Ding, S.; Zou, B.; Wang, P.; Ding, H. Effects of nozzle temperature and building orientation on mechanical properties and microstructure of PEEK and PEI printed by 3D-FDM. Polym. Test. 2019, 78, 105948. [Google Scholar] [CrossRef]

- Reichmanis, E.; Frank, C.W.; O’Donnell, J.H.; Hill, D.J.T. Radiation Effects on Polymeric Materials. In Irradiation of Polymeric Materials; American Chemical Society: Washington, DC, USA, 1993; Chapter 1; pp. 1–8. [Google Scholar] [CrossRef]

- Tavlet, M.; van der Burgt, H. Radiation resistance and other safety aspects of high-performance plastics by ERTA. In Proceedings of the Workshop on Advanced Materials for High Precision Detectors, Archamps, France, 28–30 September 1994; pp. 157–167. [Google Scholar] [CrossRef]

- Yamaoka, H.; Miyata, K. Radiation effects on organic insulator films at low temperature. J. Nucl. Mater. 1985, 133–134, 788–790. [Google Scholar] [CrossRef]

- Sasuga, T.; Hayakawa, N.; Yoshida, K.; Hagiwara, M. Degradation in tensile properties of aromatic polymers by electron beam irradiation. Polymer 1985, 26, 1039–1045. [Google Scholar] [CrossRef]

- Mitsui Chemicals Inc. Radiation Resistance of AURUM - Technical Literature F-07; Mitsui Chemicals Inc.: Tokyo, Japan, 2018. [Google Scholar]

- Oshima, A.; Ikeda, S.; Seguchi, T.; Tabata, Y. Improvement of radiation resistance for polytetrafluoroethylene (PTFE) by radiation crosslinking. Radiat. Phys. Chem. 1997, 49, 279–284. [Google Scholar] [CrossRef]

- ESA. ESMAT (ESTEC Materials); ESA: Noordwijk, The Netherlands, 2017. [Google Scholar]

- Mohammadian-Kohol, M.; Asgari, M.; Shakur, H. Effect of gamma irradiation on the structural, mechanical and optical properties of polytetrafluoroethylene sheet. Radiat. Phys. Chem. 2018, 145, 11–18. [Google Scholar] [CrossRef]

- Tegginamath, A.; Petru, M. A Review: Thermoplastic Composites in Aerospace Applications. In Proceedings of the 62nd International Conference of Machine Design Departments (ICMD 2022), Harrachov, Czech Republic, 13–15 September 2022; Atlantis Press: Dordrecht, The Netherlands, 2024; pp. 329–336. [Google Scholar] [CrossRef]

- Indu Shekar, R.; Kotresh, T.M.; Damodhara Rao, P.M.; Kumar, K. Properties of high modulus PEEK yarns for aerospace applications. J. Appl. Polym. Sci. 2009, 112, 2497–2510. [Google Scholar] [CrossRef]

- Mohammed, M.H.; Banks, W.M.; Hayward, D.; Liggat, J.J.; Pethrick, R.A.; Thomson, B. Physical properties of poly(ether ether ketone) exposed to simulated severe oilfield service conditions. Polym. Degrad. Stab. 2013, 98, 1264–1270. [Google Scholar] [CrossRef]

- Bieglo GmbH. Product Data—Dexnyl PEEK, Technical Data Sheet; Bieglo GmbH: Hamburg, Germany, 2021. [Google Scholar]

- VICTREX. Product Data–VICTREX CT 100, Technical Data Sheet; VICTREX: Middlesbrough, UK, 2023. [Google Scholar]

- Mitsui Chemicals Inc. AURUM PL450C Thermoplastic Polyimide, Technical Data Sheet N. 961002; Mitsui Chemicals Inc.: Tokyo, Japan, 2018. [Google Scholar]

- Mitsui Chemicals Inc. Low-Temperature Properties of AURUM—Technical Literature F-10; Mitsui Chemicals Inc.: Tokyo, Japan, 2018. [Google Scholar]

- Mitsui Chemicals Inc. Outgassing from AURUM—Technical Literature I-02; Mitsui Chemicals Inc.: Tokyo, Japan, 2018. [Google Scholar]

- Kantor, L.; Michalik, K.; Laska, J. Engineering polymers with high mechanical and thermal resistance for electric motors. Sci. Technol. Innov. 2017, 1, 39–43. [Google Scholar] [CrossRef][Green Version]

- The Chemours Company. Product Data—Teflon FEP, Technical Data Sheet C-10597; The Chemours Company: Wilmington, DE, USA, 2017. [Google Scholar]

- Kirby, R.K. Thermal Expansion of Polytetrafluo roethylene (Teflon) From −190° to +300 °C. J. Res. Natl. Bur. Stand. 1956, 57, 91. [Google Scholar] [CrossRef]

- Reed, R.; Schramm, R.; Clark, A. Mechanical, thermal, and electrical properties of selected polymers. Cryogenics 1973, 13, 67–82. [Google Scholar] [CrossRef]

- Sabic. Product Data—ULTEM 9085, Technical Data Sheet; Sabic: Riyadh, Saudi Arabia, 2024. [Google Scholar]

- Cruz, P.; Shoemake, E.D.; Adam, P.; Leachman, J. Tensile strengths of polyamide based 3D printed polymers in liquid nitrogen. IOP Conf. Ser. Mater. Sci. Eng. 2015, 102, 012020. [Google Scholar] [CrossRef]

- Volkov, Y.; Vorob’ev, E.; Drozdov, A.E.A. Effect of a Temperature on the Mechanical Characteristics of ULTEM 9085 Thermoplastic Produced by Additive Technology. Strength Mater. 2020, 52, 414–418. [Google Scholar] [CrossRef]

- Ching, Y.C.; Gunathilake, T.U.; Ching, K.Y.; Chuah, C.H.; Sandu, V.; Singh, R.; Liou, N.S. 18—Effects of high temperature and ultraviolet radiation on polymer composites. In Durability and Life Prediction in Biocomposites, Fibre-Reinforced Composites and Hybrid Composites; Jawaid, M., Thariq, M., Saba, N., Eds.; Woodhead Publishing: Sawston, UK, 2019; pp. 407–426. [Google Scholar] [CrossRef]

- Bragaglia, M.; Cherubini, V.; Nanni, F. PEEK—TiO2 composites with enhanced UV resistance. Compos. Sci. Technol. 2020, 199, 108365. [Google Scholar] [CrossRef]

- Duncan, A.R.; Erlank, A.J.; Sher, M.K.; Abraham, Y.C.; Willis, J.P.; Ahrens, L.H. Some trace element constraints on lunar basalt genesis. In Proceedings of the Lunar and Planetary Science Conference Proceedings, Houston, TX, USA, 15–19 March 1976; pp. 1659–1671. [Google Scholar]

- Engelschiøn, V.; Eriksson, S.; Cowley, A.; Fateri, M.; Meurisse, A.; Kueppers, U.; Sperl, M. EAC-1A: A novel large-volume lunar regolith simulant. Sci. Rep. 2020, 10, 5473. [Google Scholar] [CrossRef]

- ASTM D790-17; Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials. ASTM International: West Conshohocken, PA, USA, 2017. [CrossRef]

- ASTM D695-15; Standard Test Method for Compressive Properties of Rigid Plastics. ASTM International: West Conshohocken, PA, USA, 2015. [CrossRef]

- ASTM C902-20; Standard Specification for Pedestrian and Light Traffic Paving Brick. ASTM International: West Conshohocken, PA, USA, 2020. [CrossRef]

- International Building Code; International Code Council: Falls Church, VA, USA, 2020.

- Kumar, M. Strength characteristics of self-curing concrete. Int. J. Res. Eng. Technol. 2012, 1, 51–57. [Google Scholar] [CrossRef]

- Kayali, O.; Haque, M.; Zhu, B. Some characteristics of high strength fiber reinforced lightweight aggregate concrete. Cem. Concr. Compos. 2003, 25, 207–213. [Google Scholar] [CrossRef]

- Song, P.; Hwang, S. Mechanical properties of high-strength steel fiber-reinforced concrete. Constr. Build. Mater. 2004, 18, 669–673. [Google Scholar] [CrossRef]

| Tm | Tg | CTE b | TML | Refs. | |||||

|---|---|---|---|---|---|---|---|---|---|

| °C | °C | 1/°C | LT c | RT | HT d | @10GMy | |||

| PEEK DEXNYL | 343 | 143 | 46 | 200 | 90 | 35 | stable | 0.14 | [28,36,45,46] |

| TPI PL450C | 388 | 250 | 55 | 189 | 92 | 58 | stable | 0.58 | [47,48,49] |

| PPS | 280 | 85 | 52 | 260 | 93 | 3.5 | stable | 0.05 | [28,31,36,50] |

| PTFE TEFLON | 260 | a | 124 | 140 | 21 | 2 | lowers | 0.01 | [28,51,52,53] |

| PEI ULTEM | 340 | 217 | 65 | 101 | 86 | 17 | stable | 0.40 | [28,54,55,56] |

| Compaction Pressure | Organic Phase wt% | Grain Size Distribution | Curing Temp. | Curing | Cooling Mode | |

|---|---|---|---|---|---|---|

| Level | P.1 | P.2 | P.3 | P.4 | P.5 | P.6 |

| 1 | MPa | 5% | <500 μm | 400 °C | 3 h air/vacuum | in air |

| 2 | MPa | 10% | ||||

| 3 | MPa | 15% | ||||

| 4 | MPa | − |

| DoE Run No. | 01 | 02 | 03 | 04 | 05 | 06 | 07 | 08 | 09 | 10 | 11 | 12 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Organic phase | wt% | 5% | 5% | 5% | 5% | 10% | 10% | 10% | 10% | 15% | 15% | 15% | 15% |

| Comp. press. | MPa | 0.50 | 2.50 | 5.00 | 7.50 | 0.50 | 2.50 | 5.00 | 7.50 | 0.50 | 2.50 | 5.00 | 7.50 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Torre, R.; Ferro, C.G.; Bono, L.; Cowley, A. Regolith-Rich PEEK Composite Bricks: Steps Towards Space-Ready Lunar Construction Materials. Appl. Sci. 2025, 15, 679. https://doi.org/10.3390/app15020679

Torre R, Ferro CG, Bono L, Cowley A. Regolith-Rich PEEK Composite Bricks: Steps Towards Space-Ready Lunar Construction Materials. Applied Sciences. 2025; 15(2):679. https://doi.org/10.3390/app15020679

Chicago/Turabian StyleTorre, Roberto, Carlo Giovanni Ferro, Lorenzo Bono, and Aidan Cowley. 2025. "Regolith-Rich PEEK Composite Bricks: Steps Towards Space-Ready Lunar Construction Materials" Applied Sciences 15, no. 2: 679. https://doi.org/10.3390/app15020679

APA StyleTorre, R., Ferro, C. G., Bono, L., & Cowley, A. (2025). Regolith-Rich PEEK Composite Bricks: Steps Towards Space-Ready Lunar Construction Materials. Applied Sciences, 15(2), 679. https://doi.org/10.3390/app15020679