Viscosity of Clayey Soils: Experimental Studies

Abstract

1. Introduction

- -

- The deformability and strength of clay soils differ significantly from the deformability and strength of sandy, semi-rocky and rocky soils, especially when the time factor is taken into account;

- -

- The rheological properties of clay soils are always manifested in the interaction of soils with structures and the surrounding geological environment, which equally applies to the processes of creep, relaxation and changes in soil strength over time. These processes significantly influence the nature of the formation and transformation of the stress–strain state of clay soil masses in space and time, ultimately determining the operating conditions and stability of structures;

- -

- The historical development of soil rheology, particularly in relation to the calculations of foundation structures, initially focused on the study of creep deformations under shear conditions;

- -

- Rheological tests of clay soils differ from conventional, standard tests in that they pay special attention to the study of processes occurring in time. These processes manifest depending on the testing regime, testing conditions, and the moisture content of the clay soils.

2. Materials and Methods

- Making twin samples of clay soil;

- Assembly of the sample in the simple shear device;

- Setting the test parameters.

2.1. Making Twin Samples of Clay Soil

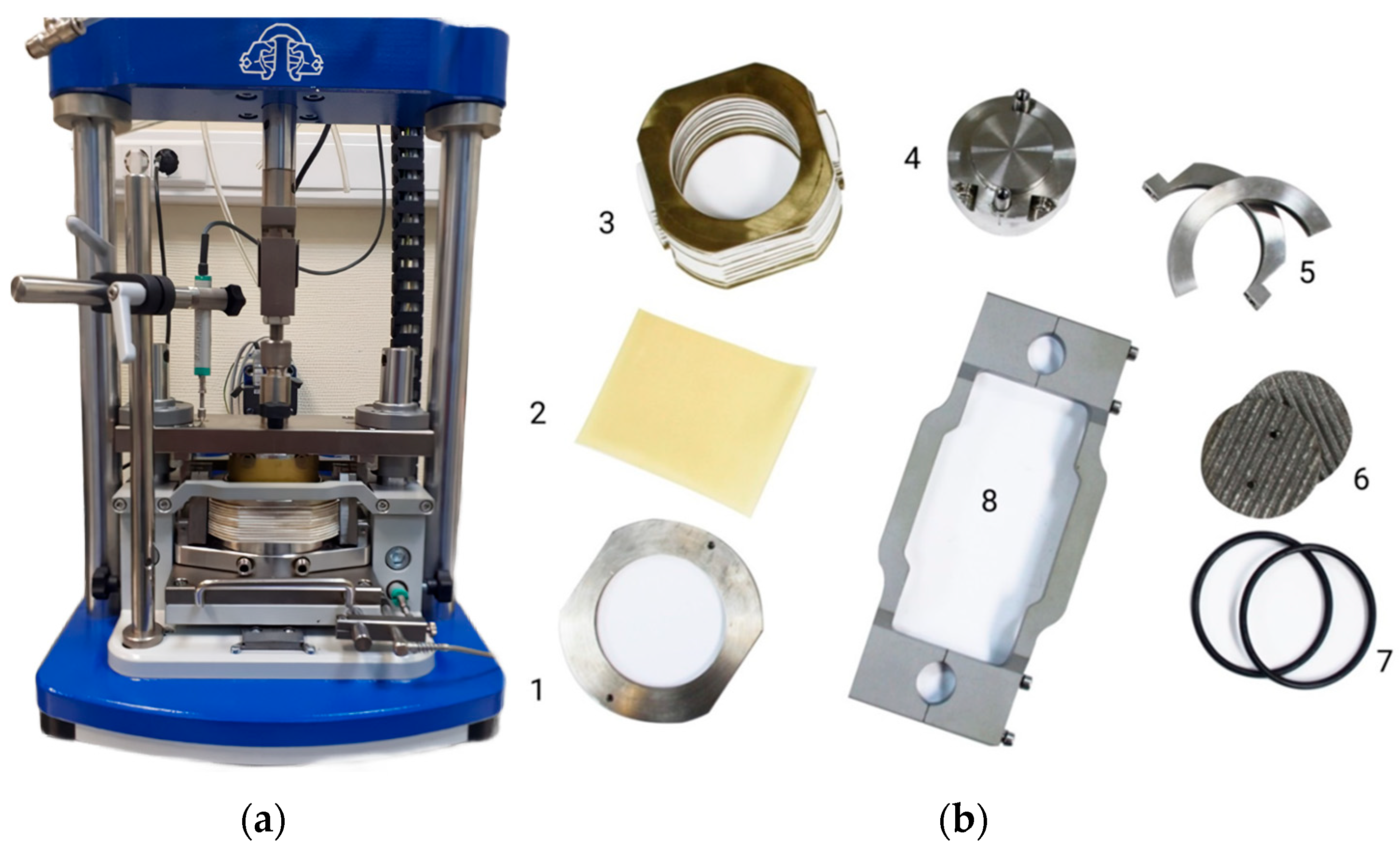

2.2. Assembly of the Sample in the Simple Shear Device

2.3. Setting the Test Parameters

3. Results

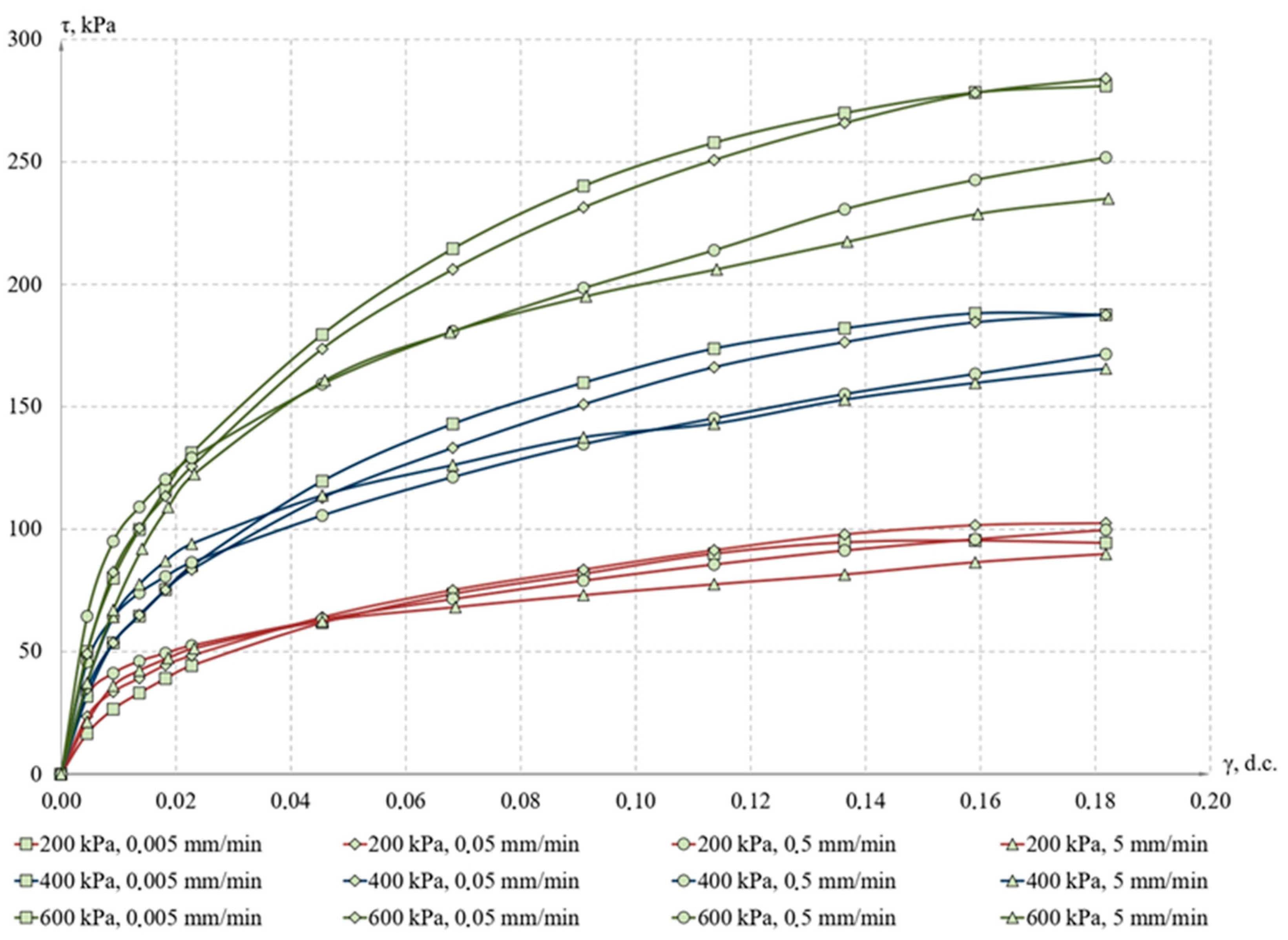

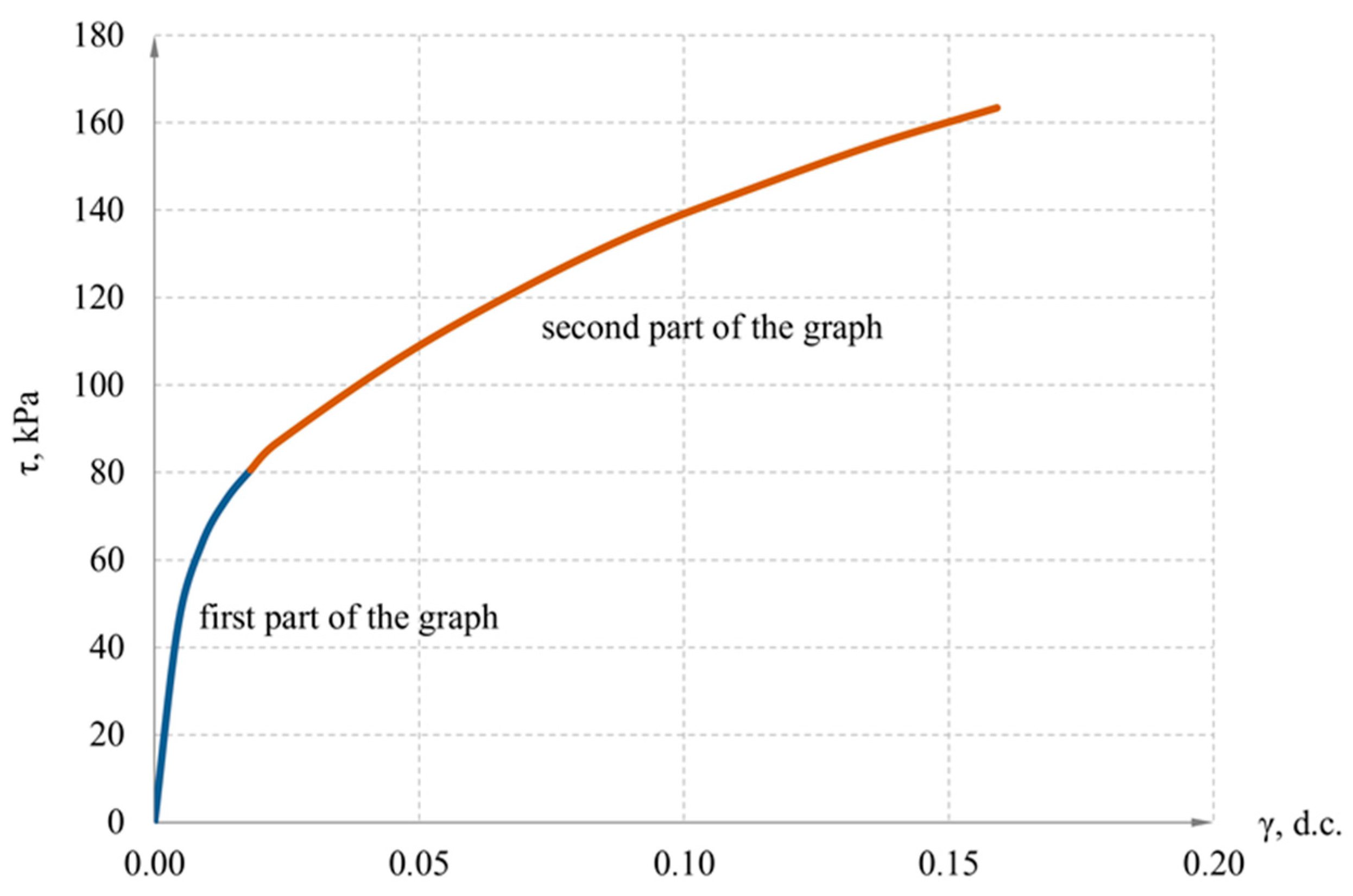

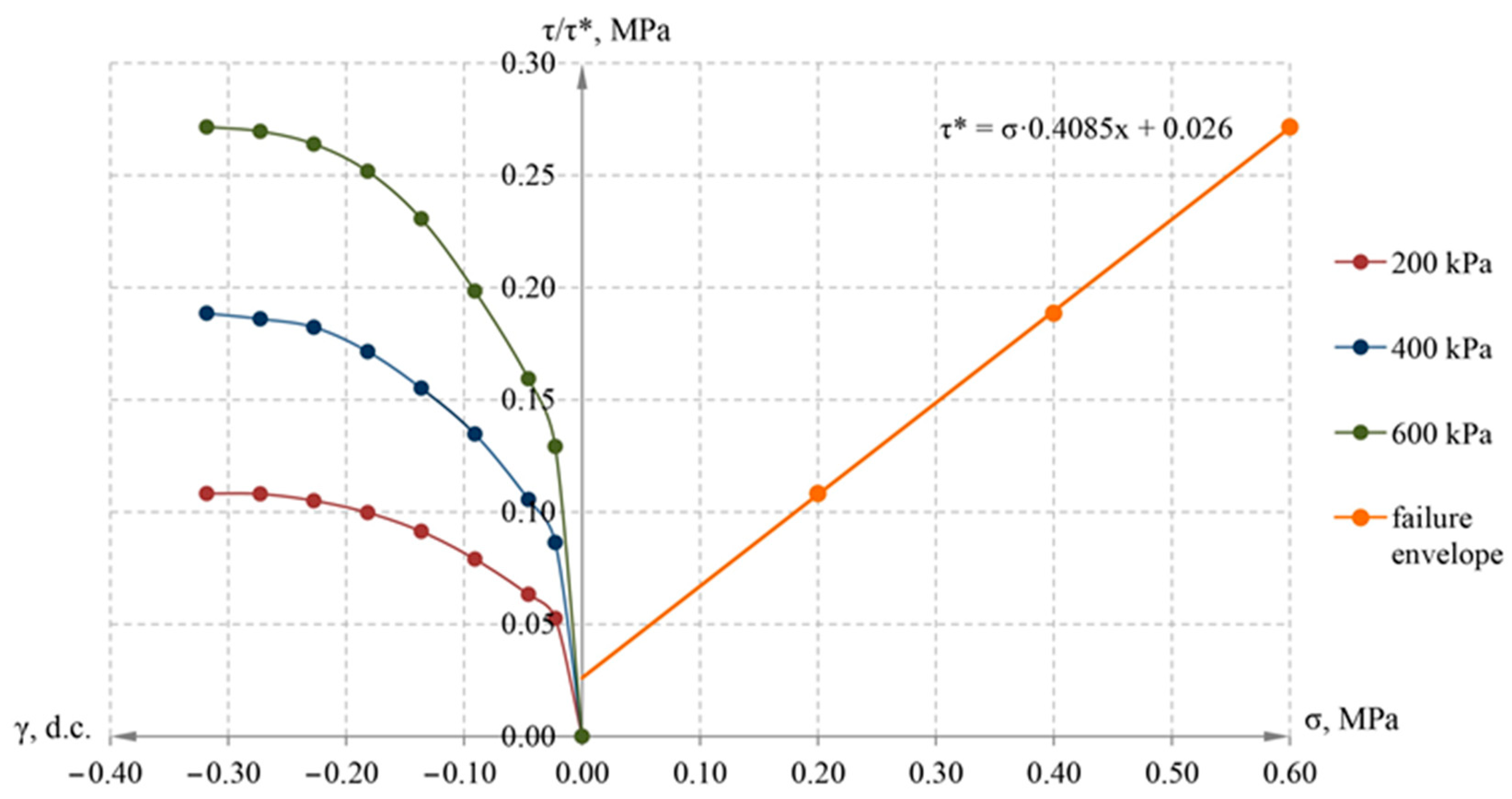

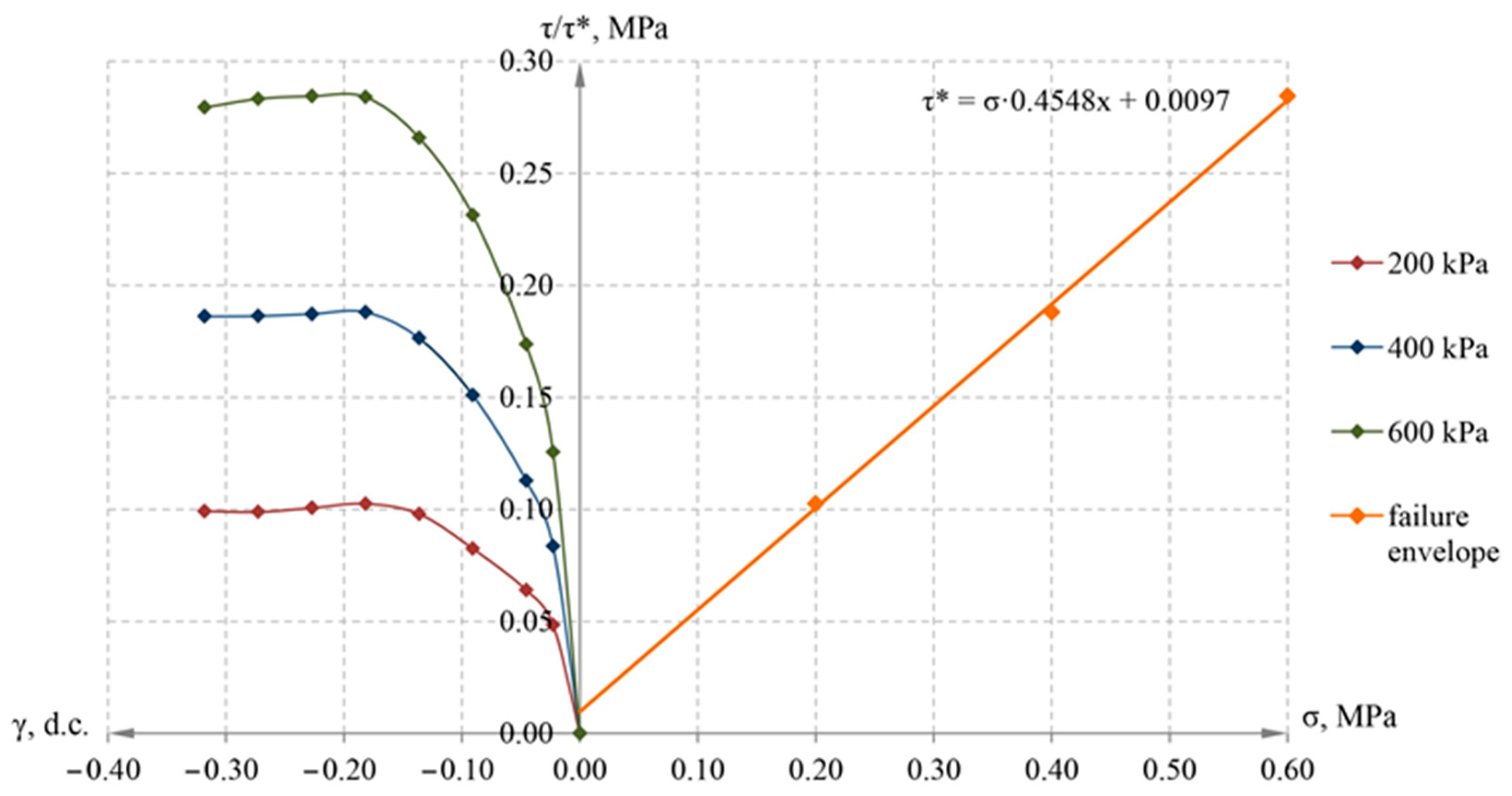

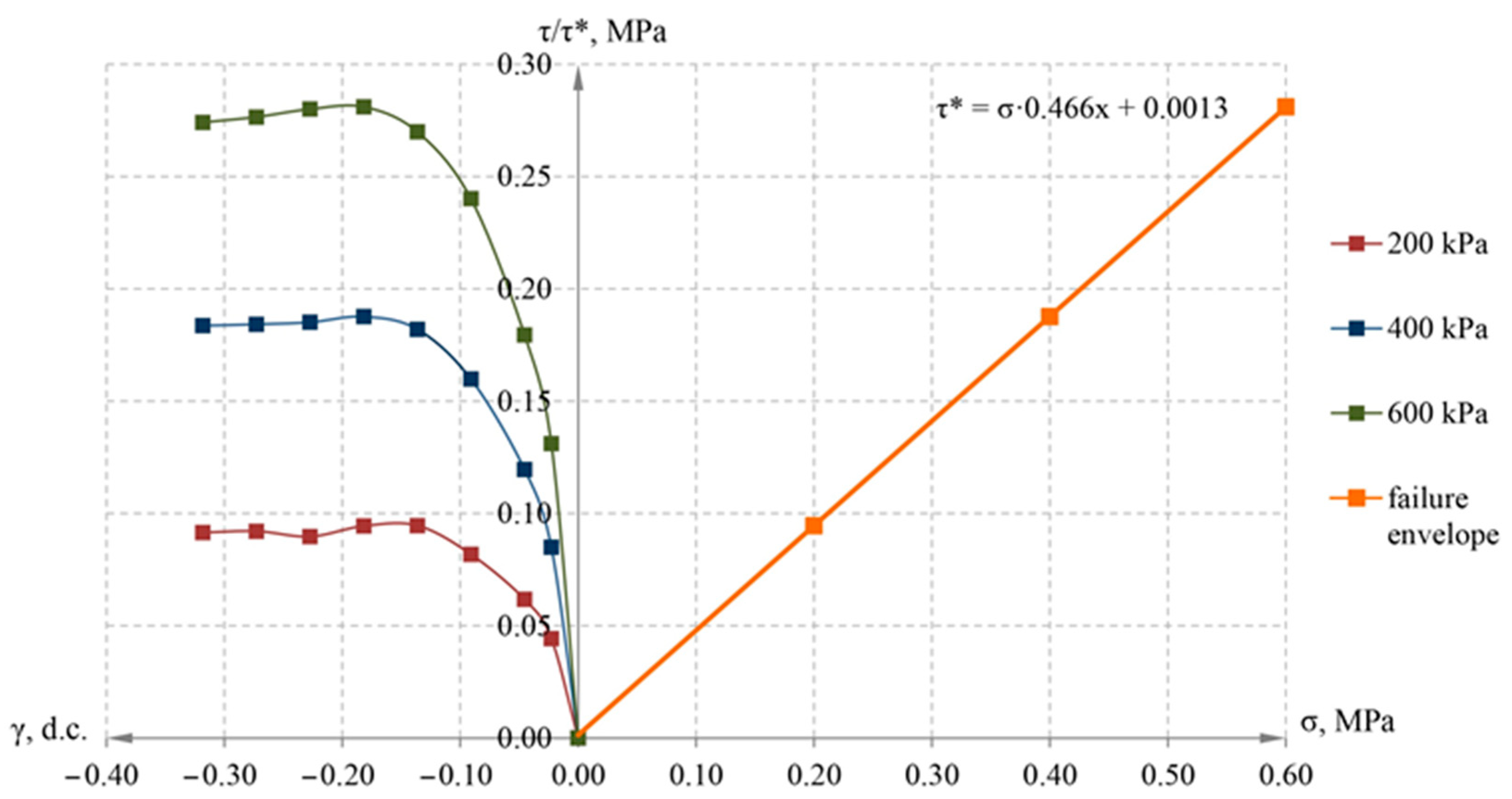

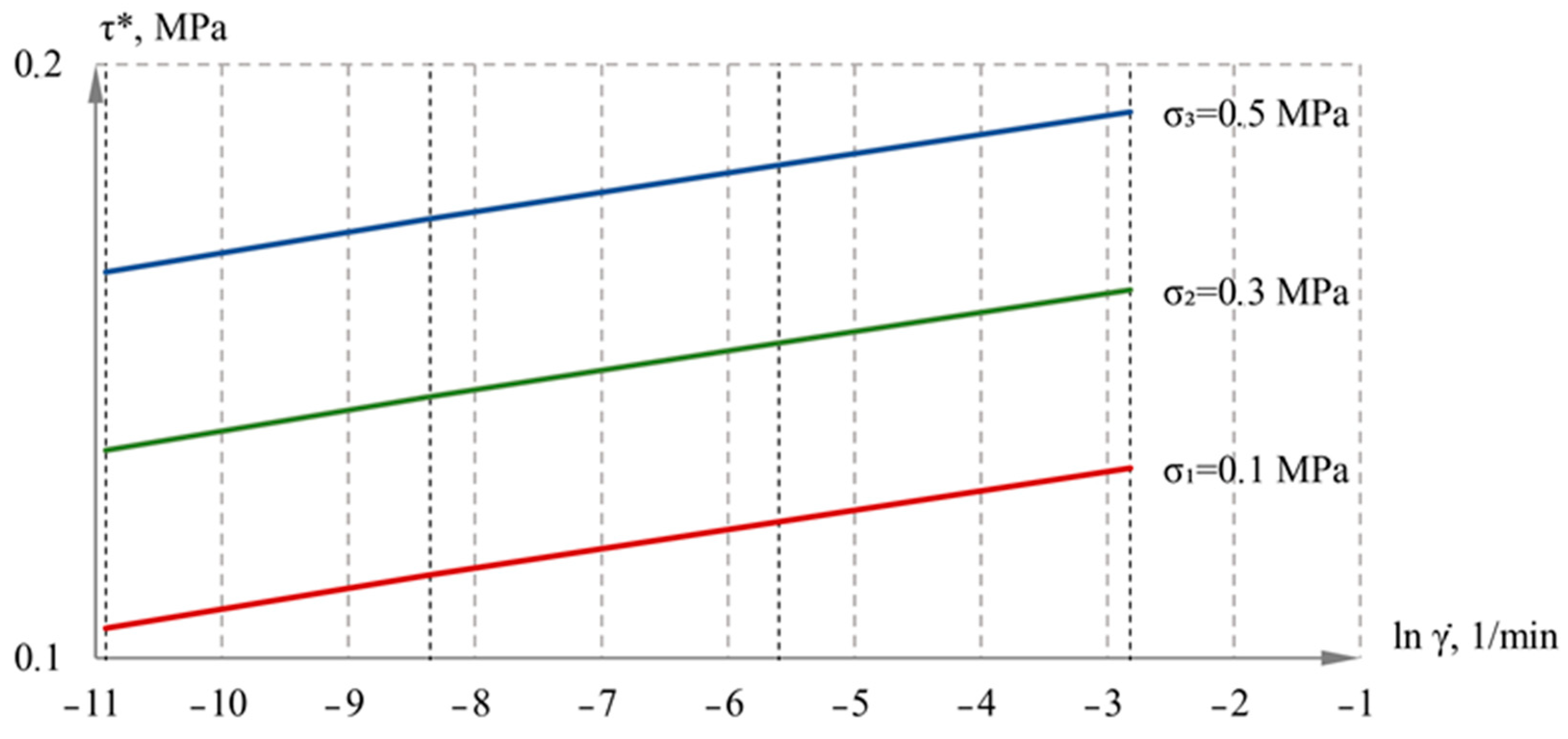

3.1. Experiment to Determine the Viscosity Coefficient of Clay Soil

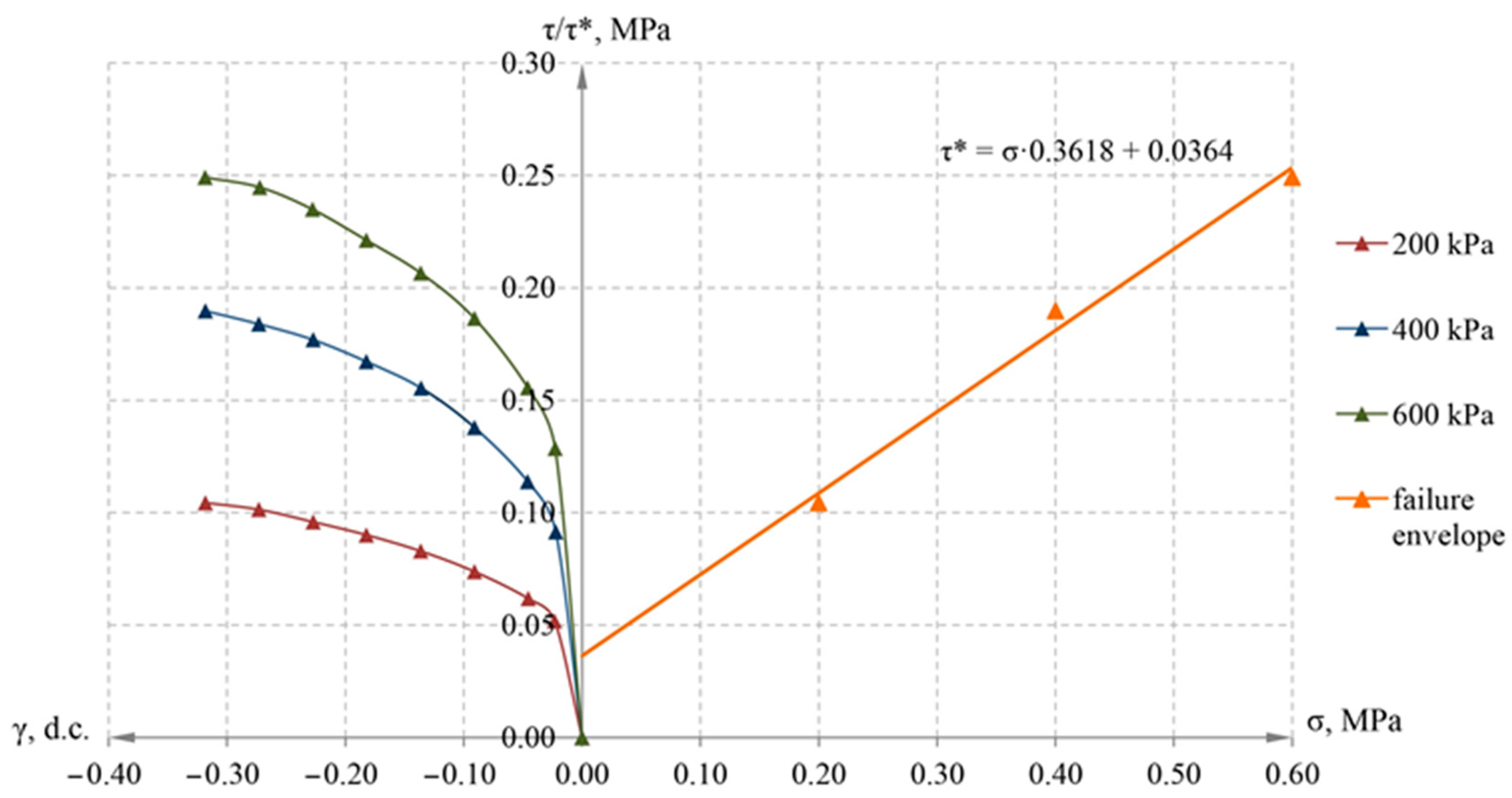

3.2. Effect of Shear Rate on Ultimate Shear Resistance of Clay Soil

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Vyalov, S.S. Rheological Foundations of Soil Mechanics: Textbook for Construction Universities; Vysshaya Shkola: Moscow, Russia, 1978; p. 447. [Google Scholar]

- Goldshtejn, M.N. Mechanical Properties of Soils; Stroyizdat: Moscow, Russia, 1977; p. 256. [Google Scholar]

- Maslov, N.N. Long-Term Stability and Deformation of Displacement Retaining Walls; Energiya: Moscow, Russia, 1968; p. 467. [Google Scholar]

- Maslov, N.N. Fundamentals of Soil Mechanics and Engineering Geology; Vysshaya Shkola: Moscow, Russia, 1968; p. 632. [Google Scholar]

- Ter-Stepanyan, G.I. Phenomenon of sudden restructuring of soil structure under deformation. Eng. Geol. 1988, 3, 11–26. [Google Scholar]

- Meschyan, S.R. Creep of Clay Soils; Publishing House of the Academy of Sciences of the Armenian SSR: Yerevan, Armenia, 1967; p. 320. [Google Scholar]

- Meschyan, S.R. Rheological Processes in Clay Soils (Considering Special Factors); Ayastan: Yerevan, Armenia, 1992; p. 395. [Google Scholar]

- Meschyan, S.R. Experimental Rheology of Clay Soils; Gitutyun: Yerevan, Armenia, 2005; p. 498. [Google Scholar]

- Goldin, A.L. Study of Compaction Processes of Cohesive Soils Taking Creep into Account. Ph.D. Dissertation, All-Union Scientific Research Institute of Hydraulic Engineering named after. B.E. Vedeneeva, Leningrad, Russia, 1965. [Google Scholar]

- Ter-Martirosyan, Z.G. Rheological Parameters of Soils and Foundation Calculations; Strojizdat: Moscow, Russia, 1990; p. 200. [Google Scholar]

- Florin, V.A. Fundamentals of Soil Mechanics. Volume 1; Strojizdat: Leningrad, Russia, 1959; p. 356. [Google Scholar]

- Florin, V.A. Fundamentals of Soil Mechanics. Volume 2; Gosstroyizdat: Leningrad, Russia, 1961; p. 543. [Google Scholar]

- Arutyunyan, N.K. Some Questions of the Theory of Creep; State Publishing House of Technical and Theoretical Literature: Moscow, Russia, 1952; p. 324. [Google Scholar]

- Tertsagi, K. Theory of Soil Mechanics; Gostroyizdat: Moscow, Russia, 1961; p. 507. [Google Scholar]

- Gersevanov, N.M. Theoretical Foundations of Soil Mechanics and Their Practical Applications; Strojizdat: Moscow, Russia, 1948; p. 248. [Google Scholar]

- Cytovich, N.A. Soil Mechanics; State Publishing House of Literature on Construction, Architecture, and Building Materials: Moscow, Russia, 1963; p. 437. [Google Scholar]

- Zareckij, Y.K.; Chumichev, B.D.; Shchebolev, A.G. Viscoplasticity of Ice and Frozen Ground; Science: Novosibirsk, Russia, 1986; p. 182. [Google Scholar]

- Ter-Martirosyan, Z.G.; Ter-Martirosyan, A.Z. Soil Mechanics in High-Rise Construction with Developed Underground Part: Textbook; ASV: Moscow, Russia, 2020; p. 946. [Google Scholar]

- Boley, K.; Strokova, L.A. Determination of creep characteristics of clayey soils. News Tomsk. Polytech. Univ. 2007, 2, 42–44. [Google Scholar]

- Tafili, M.; Triantafyllidis, T. A simple hypoplastic model with loading surface accounting for viscous and fabric effects of clays. Int. J. Numer. Anal. Methods Geomech. 2020, 44, 2189–2215. [Google Scholar] [CrossRef]

- Ren, P.; Wang, P.; Zhang, H.; Tang, Y. Nonlinear behavior of clay creep and its fractional derivative creep model. Eng. Mech. 2020, 37, 153–160. [Google Scholar] [CrossRef]

- Zhu, Z.-Y.; Luo, F.; Zhang, Y.-Z.; Zhang, D.-J.; He, J.-L. A creep model for frozen sand of Qinghai-Tibet based on Nishihara model. Cold Reg. Sci. Technol. 2019, 167, 102843. [Google Scholar] [CrossRef]

- Ning, X.; Xiao, N.; Zhang, C.; He, B.; Xie, J. Study on the nonlinear creep model of expansive soil. J. Nat. Disasters 2017, 26, 149–155. [Google Scholar] [CrossRef]

- Haghighat, E.; Rassouli, F.S.; Zoback, M.D.; Juanes, R. A viscoplastic model of creep in shale. Geophysics 2020, 85, 155–166. [Google Scholar] [CrossRef]

- Gu, R.-G.; Zou, Y.; Fang, Y.-G.; Hu, Y.-G. Rheological model of soft soils using nonlinear instantaneous elastic modulus. Rock Soil Mech. 2018, 39, 237–241. [Google Scholar] [CrossRef]

- Ter-Martirosyan, Z.G.; Sobolev, E.S.; Ter-Martirosyan, A.Z. Rheological models developed on the basis of triaxial tests. Int. J. Appl. Eng. Res. 2016, 11, 1719–1723. [Google Scholar]

- Bodas Freitas, T.M.; Potts, D.M.; Zdravkovic, L. A time dependent constitutive model for soils with isotach viscosity. Comput. Geotech. 2011, 38, 809–820. [Google Scholar] [CrossRef]

- Yin, J.-H.; Tong, F. Constitutive modeling of time-dependent stress-strain behaviour of saturated soils exhibiting both creep and swelling. Can. Geotech. J. 2011, 48, 1870–1885. [Google Scholar] [CrossRef]

- Sobolev, E.S. Creep and Vibration Creep of Sandy Soils at the Bases of Buildings and Structures. Ph.D. Dissertation, Federal State Budgetary Educational Institution of Higher Professional Education “Moscow State University of Civil Engineering”, Moscow, Russia, 2014. [Google Scholar]

- GOST 30416-2020; Soils. Laboratory Testing. General. Izdatelstvo Russian Institute of Standardization: Moscow, Russia, 2021; p. 21.

- Mirny, A.Y. Triaxial Testing of Soils: Theory and Practice: Monograph; “Academic Science”—GeoMarkketing LLC: Moscow, Russia, 2015; p. 144. [Google Scholar]

- GOST R 71042-2023; Soils. Determination of Strength Characteristics by Simple Shear Method. Russian Institute of Standardization: Moscow, Russia, 2023; p. 18.

- Kornoukhov, M.B. Shear Resistance of Clay Soils during the Development of Deformation. Ph.D. Thesis, Moscow Civil Engineering Institute, Moscow, Russia, 1990. [Google Scholar]

- Bronshtein, I.N.; Semendyaev, K.A. Handbook of Mathematics; State Publishing House of Physical and Mathematical Literature: Moscow, Russia, 1962; p. 608. [Google Scholar]

| Type of Clay Soil | Plasticity Index | Index of Liquidity | Density, g/cm3 | Moisture, % | Cohesion, kPa | Internal Friction Angle, Deg. |

|---|---|---|---|---|---|---|

| Fluid-plastic loam | 0.11 | 0.80 | 2.20 | 22 | 1.30–36.40 * | 19.89–24.98 * |

| Vertical Stress, kPa | Shear Displacement Rate, mm/min | Soil Viscosity at the First Section, kPa·min | Soil Viscosity at the Second Section, kPa·min |

|---|---|---|---|

| 200 | 5 | 226 | 133 |

| 0.5 | 2310 | 1707 | |

| 0.05 | 21,296 | 21,780 | |

| 0.005 | 194,920 | 221,320 | |

| 400 | 5 | 414 | 259 |

| 0.5 | 3802 | 3023 | |

| 0.05 | 36,740 | 40876 | |

| 0.005 | 374,000 | 426,800 | |

| 600 | 5 | 539 | 418 |

| 0.5 | 5680 | 4466 | |

| 0.05 | 55,264 | 61,732 | |

| 0.005 | 576,840 | 610,720 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ter-Martirosyan, A.Z.; Ermoshina, L.Y.; Anzhelo, G.O. Viscosity of Clayey Soils: Experimental Studies. Appl. Sci. 2024, 14, 5974. https://doi.org/10.3390/app14145974

Ter-Martirosyan AZ, Ermoshina LY, Anzhelo GO. Viscosity of Clayey Soils: Experimental Studies. Applied Sciences. 2024; 14(14):5974. https://doi.org/10.3390/app14145974

Chicago/Turabian StyleTer-Martirosyan, Armen Z., Lyubov Yu. Ermoshina, and George O. Anzhelo. 2024. "Viscosity of Clayey Soils: Experimental Studies" Applied Sciences 14, no. 14: 5974. https://doi.org/10.3390/app14145974

APA StyleTer-Martirosyan, A. Z., Ermoshina, L. Y., & Anzhelo, G. O. (2024). Viscosity of Clayey Soils: Experimental Studies. Applied Sciences, 14(14), 5974. https://doi.org/10.3390/app14145974