Condition and Performance Assessment of Irrigation Infrastructure at Agri-Parks in Gauteng Province, South Africa

Abstract

1. Introduction

2. Materials and Methods

2.1. Study Sites

2.2. Experimental Layout

2.3. Data Collection

2.3.1. Condition Assessment

2.3.2. Performance Assessment

- Conveyance efficiency

- Distribution uniformity

2.4. Statistical Analyses

3. Results

3.1. State of Infrastructural Condition

3.2. Water Conveyance Efficiency

3.3. Emitter Discharges

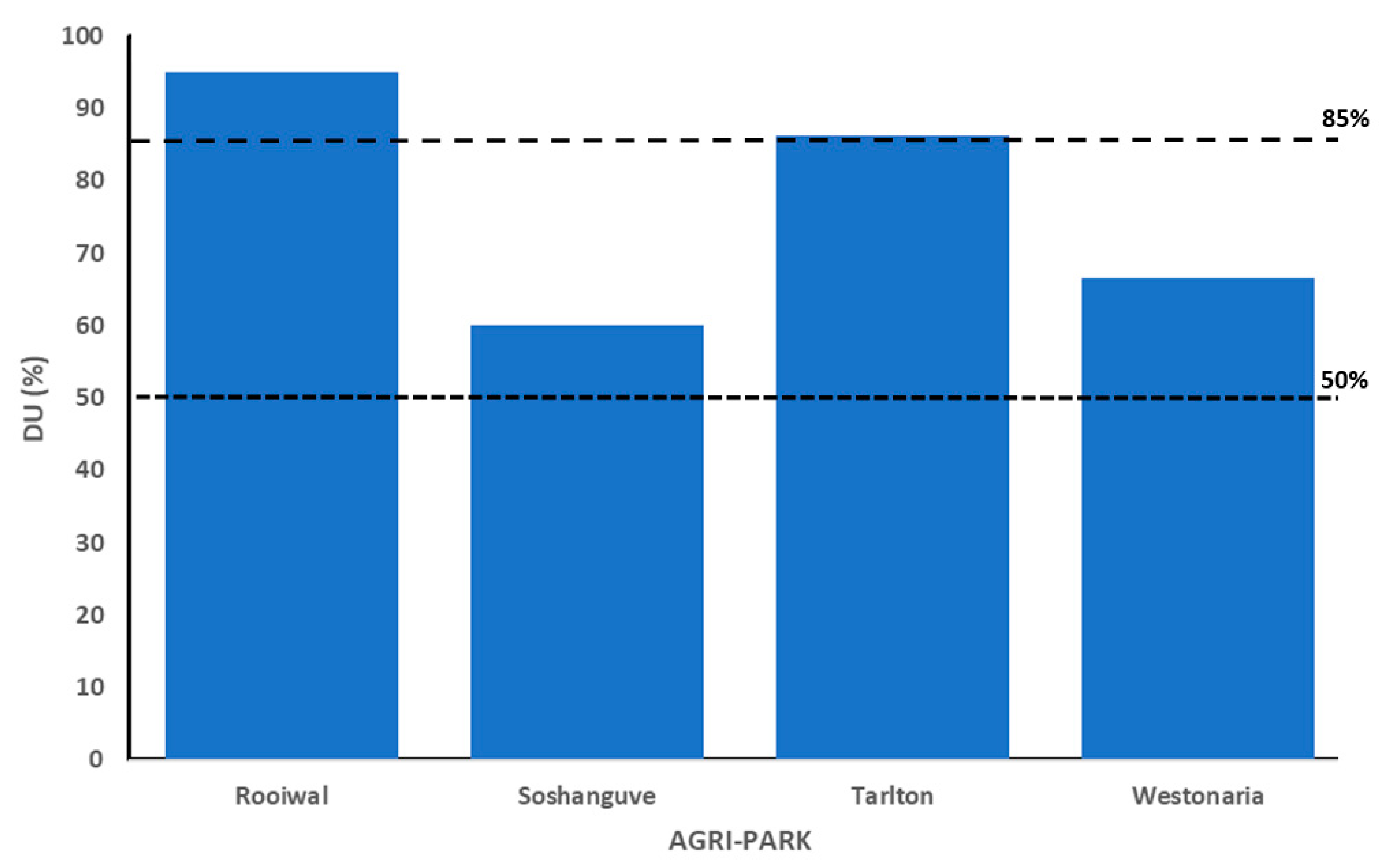

3.4. Distribution Uniformity

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Dwivedi, D.K.; Gontia, N.K.; Chavda, J.M. Hydraulic performance evaluation of min sprinkler system. Afr. J. Agric. Res. 2015, 10, 4950–4966. [Google Scholar]

- Morison, J.I.L.; Baker, N.R.; Mullineaux, P.M.; Davies, W.J. Improving water use in crop production. Philos. Trans. R. Soc. B 2008, 363, 639–658. [Google Scholar] [CrossRef] [PubMed]

- Kumar, A.; Saini, M.; Patil, R.B.; Al-Dahidi, S.; Mellal, M.A. Reliability, availability, maintainability, and dependability analysis of tube-wells integrated with underground pipelines in agricultural fields for irrigation. Adv. Mech. Eng. 2022, 14, 1–17. [Google Scholar] [CrossRef]

- Rather, N.U.R.; Baba, M.A. Performance evaluation of Sprinkler Irrigation System in Ganderbal District J & K State. Curr. J. Appl. Sci. Technol. 2017, 25, 1–7. [Google Scholar]

- Khaloui, M.R.; Kashkuli, H.A.; Dehkordi, D.K. Evaluation of drip irrigation systems in Gachsaran region. Adv. Environ. Biol. 2014, 8, 2326–2334. [Google Scholar]

- Çakmak, B. Evaluation of irrigation system performance with comparative indicators in irrigation schemes, Kizilirmak Basin, Turkey. Pak. J. Biol. Sci. 2003, 6, 697–706. [Google Scholar] [CrossRef]

- DWAF (Department of Water Affairs and Forestry, Republic of South Africa). National Water Resource Strategy; DWAF: Pretoria, South Africa, 2004.

- DWA (Department of Water Affairs, Republic of South Africa). National Water Resource Strategy, 2nd ed.; Department of Water Affairs, Republic of South Africa: Pretoria, South Africa, 2013.

- De Clercq, W.; De Witt, M.; Laker, G. Challenges, and opportunities for water conservation in irrigated agriculture in South Africa. S. Afr. J. Plant Soil 2021, 38, 238–246. [Google Scholar] [CrossRef]

- Levidow, L.; Zaccaria, D.; Maia, R.; Vivas, E.; Todorovic, M.; Scardigno, A. Improving water-efficient irrigation: Prospects and difficulties of innovative practices. Agric. Water Manag. 2014, 146, 84–94. [Google Scholar] [CrossRef]

- Martinez, J.; Reca, J. Water use efficiency of surface drip irrigation versus an alternative subsurface drip Irrigation method. J. Irrig. Drain. Eng. 2014, 140, 04014030. [Google Scholar] [CrossRef]

- Porter, W.M. Factors to Consider in Selecting a Farm Irrigation System; UGA Cooperative Extension Bulletin 822; University of Georgia: Athens, GA, USA, 2022. [Google Scholar]

- Hill, R.W.; Banks, S. Sprinklers, Crop Water Use, and Irrigation Time; Utah State University Extension Electronic Publishing: Farmington, UT, USA, 2000. [Google Scholar]

- Berbel, J.; Gutierrez-Martin, C.; Exposito, A. Impacts of irrigation efficiency improvement on water use, water consumption and response to water price at field level. Agric. Water Manag. 2018, 203, 423–429. [Google Scholar] [CrossRef]

- Shahid, M.A.; Chauhdary, J.N.; Usman, M.; Qamar, M.U.; Shabbir, A. Assessment of Water Productivity Enhancement and Sustainability Potential of Different Resource Conservation Technologies: A Review in the Context of Pakistan. Agriculture 2022, 12, 1058. [Google Scholar] [CrossRef]

- Friedlander, L.; Tal, A.; Lazarovitch, N. Technical considerations affecting adoption of drip irrigation in sub-Saharan Africa. Agric. Water Manag. 2013, 126, 125–132. [Google Scholar] [CrossRef]

- Niragire, T.; Süheri, S.; Pande, S.K. Performance Evaluation of Hand-Move Sprinkler Irrigation System: A Case Study in Rwanda. Int. J. Innov. Approaches Agric. Res. 2021, 5, 37–51. [Google Scholar] [CrossRef]

- Sinha, B.L. A study on performance evaluation of sprinkler irrigation system at farmers field in Chhattisgarh plain. Pharma Innov. 2022, 11, 485–489. [Google Scholar]

- Murray-Rust, D.H.; Snellen, W.B. Irrigation System Performance Assessment and Diagnosis; International Irrigation Management Institute: Colombo, Sri Lanka, 1993; 148p. [Google Scholar]

- Ahaneku, I.E. Performance evaluation of portable sprinkler irrigation system in Ilorin, Nigeria. Indian J. Sci. Technol. 2010, 3, 853–857. [Google Scholar] [CrossRef]

- PMG (Parliamentary Monitoring Group). Agri-Parks Progress Report. Agriculture, Land Reform and Rural Development, 22 October 2019. Available online: https://pmg.org.za/committee-meeting/29122/ (accessed on 20 January 2021).

- Bengson, S.A. Drip irrigation to revegetate mine wastes in an arid environment. J. Range Manag. 1977, 30, 143–147. [Google Scholar] [CrossRef]

- Al-Barqawi, H.; Zayed, T. Condition rating model for underground infrastructure sustainable water mains. J. Perform. Constr. Facil. 2006, 20, 126–135. [Google Scholar] [CrossRef]

- Ascough, G.W.; Kiker, G.A. The effect of irrigation uniformity on irrigation water requirements. Water SA 2002, 28, 235–242. [Google Scholar] [CrossRef]

- Ngasoh, F.G.; Anyadike, C.C.; Mbajiorgu, C.C.; Usman, M.N. Performance evaluation of sprinkler irrigation system at Mambilla Beverage Limited, Kakara-Gembu, Taraba State—Nigeria. Niger. J. Technol. 2018, 37, 268–274. [Google Scholar] [CrossRef]

- Reinders, F. Drip irrigation performance testing. Agri About 2023, 118, 24–28. Available online: www.agriabout.com (accessed on 14 March 2023).

| Scale | Linguistic Scale | Criteria | Action Needed |

|---|---|---|---|

| 9–10 | Excellent | Newly/recently installed. | No action required. |

| 8–9 | Very good | Like new with no signs of corrosion or deterioration. | Reassess in 15 years. |

| 6–8 | Good | Coatings, linings still intact. Remaining wall thickness more than 90% of original. | Reassess in 10 years. Schedule for cathodic protection within next 5–10 years. |

| 4–6 | Moderate | Some damage to coatings and/or linings noted. Remaining wall thickness 75% or more of original. | Reassess in 3–5 years. Schedule for lining and rehabilitation within next 5–10 years. |

| 3–4 | Poor | Significant signs of internal/external corrosion. Collapse inevitable. No lining or coatings. Leaking. Remaining wall thickness 50–75% of original. | Schedule for rehabilitation or replacement within next 3–5 years. |

| <3 | Critical | Severe internal or external corrosion. Collapse evident. Large cracks/holes. Remaining wall thickness less than 50% of original. Breakage rate > 3. | Immediate repair or replacement required. |

| Irrigation System Component | CI | |||

|---|---|---|---|---|

| Rooiwal | Soshanguve | Tarlton | Westonaria | |

| Pump–Tank | 5.99 | 6.29 | 6.25 | 5.61 |

| Tank–Booster pump | 4.71 | 4.10 | 4.90 | 4.43 |

| Booster pump–Filter unit | 4.90 | 2.73 | 5.54 | 2.12 |

| Filter unit–Manifold | 5.52 | 5.48 | 5.65 | 5.60 |

| Infield | 5.04 | 5.00 | 5.05 | 5.02 |

| Section | CE (%) | |||

|---|---|---|---|---|

| Rooiwal | Soshanguve | Tarlton | Westonaria | |

| Main pump–Tank | 94 | 86 | 83 | 89 |

| Tank–Booster pump | 97 | 99 | 91 | 98 |

| Booster pump–Filter unit | 93 | 99 | 94 | 73 |

| Filter unit–Manifold | 92 | 81 | 93 | 96 |

| Overall CE (%) | 78 | 68 | 66 | 61 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mutema, M.; Dhavu, K.; Mothapo, M. Condition and Performance Assessment of Irrigation Infrastructure at Agri-Parks in Gauteng Province, South Africa. Appl. Sci. 2023, 13, 5040. https://doi.org/10.3390/app13085040

Mutema M, Dhavu K, Mothapo M. Condition and Performance Assessment of Irrigation Infrastructure at Agri-Parks in Gauteng Province, South Africa. Applied Sciences. 2023; 13(8):5040. https://doi.org/10.3390/app13085040

Chicago/Turabian StyleMutema, Macdex, Khumbulani Dhavu, and Manoshi Mothapo. 2023. "Condition and Performance Assessment of Irrigation Infrastructure at Agri-Parks in Gauteng Province, South Africa" Applied Sciences 13, no. 8: 5040. https://doi.org/10.3390/app13085040

APA StyleMutema, M., Dhavu, K., & Mothapo, M. (2023). Condition and Performance Assessment of Irrigation Infrastructure at Agri-Parks in Gauteng Province, South Africa. Applied Sciences, 13(8), 5040. https://doi.org/10.3390/app13085040