Abstract

With the rapid development of the military industry and the increasing focus on the safety of those in these fields, there is an increasing search for solutions to existing and emerging weapons for the user and the environment. In this case, components for firearm suppression are used to reduce the effects of noxious impulse sound, to minimize the severity of the weapon’s recoil to the user’s body, and maintain important accuracy, maneuverability and other parameters. The analysis and investigation of silencer designs can provide essential values for acoustic characteristics that reduce risk in real situations. The gun silencer analysis was performed in two steps. The modeling processes of the silencer configuration were performed to choose the optimal construction, and the main parameters were selected, including different angles and forms of the tilt. The angle of inclination of the partitions was changed to 60° and 135°. Due to the reduced results observed in the last zones with closed cavities and created additional configurations, the number of partitions was shortened by three partitions and the angle of inclination was adjusted to 60°; the simulation of the initial variant was also supplemented with 135° partitions. The second step was an experimental validation of the optimal tilt angle and form according to the modeling data. The silencer was found to achieve a sound pressure damping value and the sound pressure level during the shot was reduced to below a dangerous level. The search to find the optimal configurations will lead to the parameters of production and efficiency.

1. Introduction

Data obtained during experimental tests using acoustic and force sensors have been applied to model the shooting process. These methods identified the main characteristics of the shot being executed, and the parameters of firearms and their accessories (sights, mufflers, etc.). The following methods were identified and applied to the main indicators of the shot being performed. Therefore, it becomes very important for both firearms and their accessories (silencers, scopes, etc.) to be the subject of much research around the world because state authorities require very strict accuracy and reliability in the maintenance of their weapons. A modern firearm silencer is far superior to ear-level protection and the only possible form of suppression that can make weapons safe for hearing. To protect the shooter’s hearing, modern firearms use a silencer. This provides better protection for the shooter’s hearing than headphones and provides maximum effective suppression when using firearms [1,2,3]. Acoustic effects during shooting account for the majority of hearing loss [4,5,6,7]. Many of the early silencers were mostly empirical in nature [8,9,10,11].

Acoustic trauma is one of the most damaging factors for people near the center of the gun shot. Often the sound pressure level of weapons exceeds 160 dB, which is particularly dangerous to health and can cause deafness. To prevent these issues, attenuation equipment is used that reduces the maximum sound level values to less than 140 dB, which is defined as the threshold for pulsed sound damage.

The main purpose of the silencer is to make it difficult to locate the shooter during the shot, but when referring to nonmilitary weapons, the main task becomes the protection of the shooter’s hearing [12,13]. This is done by removing the flash of fire that occurs during the shot, making it difficult to identify the location of the shooter [14,15,16,17]. It is important to mention that the use of a silencer suppresses the sound of the shot. This manifests itself through the effect of gases coming out of the silencer. This effect is manifested by the discontinuity of the gas flow and the beginning of its swirling. The exit velocity and temperature of these gases also decrease as a result of the change in the internal energy of the gas.

When firing, sound is made up of many acoustic waves resulting from a combination of four main components: a gunpowder gas flow wave; shock wave generated by the supersonic movement of a bullet; a wave consisting of a column of air displaced from a rifle in a tube in front of a bullet; an acoustic wave generated in response to parts of a weapon during firing.

Many research studies [15,18,19,20,21] examined many different devices placed on the front of a weapon. The main reason for modifying the silencer elements is to minimize acute overpressure by using various shapes [15]. Constructive solutions facilitate silencer production, especially using silencers with arbitrary but axially uniform cross sections [18]. For this, various mechanical elements can be used, which not only ensure the reduction of sound pressure, but also open the way for the development of new modifications, which are very relevant in ensuring the comfort of the shooter during the shot [19]. Various recoil-reducing solutions were examined, which allowed the reduction of recoil by up to 70% [20]. Additionally, the use of Generalized Cross-Correlation (GCC) and the Mean-Squared Error (MSE) optimization tools to optimize these structural parameters made it possible to significantly complicate the location of the shooter during the shot [21]. It should be noted that the results of these simulations were not validated by experimental studies. The results obtained by analyzing the dynamics of the shot showed that some of the results differ from the results obtained under the normal conditions of the shot [22,23,24]. Barriers made of woven wire mesh were used to improve dynamic parameters [22], including compact polymer fiber [23] and grid structures [24]. Carson and Sahni [25] examined damping devices in more detail both theoretically and experimentally, using three methods: acoustic theory, explosion theory and one-dimensional flow theory. Because the bullet accelerates at high temperatures and high pressures, an explosion wave in the front of the weapon occurs when the propellant explodes [25,26,27,28,29]. As the energy at the front of the weapon increases, the intensity of the pulse wave is estimated accordingly.

The increasing energy at the front of the weapon forces a scrupulous assessment of the intensity of the pulsating wave. The shock wave generated during the shot has a negative impact on the environment and people. This is determined by its features if we compare it with other types of sound. Those features are manifested with high wave energy, low frequency and long propagation distance [30,31,32,33,34]. Prior to this, research was conducted by the authors of an article on weapons suppression systems [19,35]. They examined the regularities of the change of the resulting force of the compensator sound pressure and the time of the shot by theoretical and experimental methods.

Silencers are usually mounted on weapons that develop sound pressure at the mouth that is dangerous to human hearing. The design of this device is very important to create an optimized combination of acoustic characteristics that limits and suppresses the health-threatening sound pressure value generated during a shot. This study analyzes reactive type silencers, the internal design of which directs, delays and reduces the gas flow, thus achieving the suppression of the sound pressure level generated during the collision with atmospheric conditions.

The design of silencers must take into account aspects of their weight, maneuverability, stability during repeated shots and the generation of resonant frequencies due to structural elements, which determine their ultimate effectiveness and the situation created by the user.

This study analyzes damping devices for recreational, nonmilitary use. The new damping device would be a mixture between a silencer and a muzzle brake to reduce noise and kickback. The main advantage of the device under study is that the sound attenuation is mainly in the area of the shooter, and in the direction of the shot the sound attenuation is up to 30% (and according to this indicator, the device is not classified as a silencer). As a result, the muffler can be used for leisure purposes, as if the sound attenuation in the direction of the shot is more than 30%, the muffler would be classified as such. Separate silencers and muzzle brakes are widely described in both scientific and patent material. However, information on devices with the desired damping–braking properties is almost non-existent. Furthermore, this type of equipment is not sold. The following problems with suppressors or muzzle brakes are commonly considered in the scientific literature: impact on bullet trajectory [36,37]; effects of sound pressure during shooting on hearing [38,39,40,41]; reducing the sound pressure level of firearms through the use of various types of silencers. However, issues related to the adaptation of the device to recreational weapons are not addressed. To reduce undesirable phenomena that occur during the shot, such as recoil and sound, this paper proposes a device that combines the features of a silencer and a muzzle brake. This makes it possible to ensure that it will not be classified as a muffler (due to the reduction limits set by law for the suppression of the shot), because the sound reduction in the direction of the shot will be reduced no more than 30%, and the sound reduction itself will be carried out in the area of the shooter’s impact. It is clear that individual silencer and muzzle brake solutions have existed before to reduce the sound of the shot, but systems similar to the one proposed in this paper do not appear in either patents or scientific literature. This is explained by the fact that a comprehensive solution is still being sought. Most of the research is focused on the influence of a silencer and a muzzle brake on the trajectory of the bullet [36,37], the examination of the visual effect during photography [40,41,42,43], and research on various types of silencers themselves [1,44,45] Additionally, there are no weapons on the market that do not require a special permit for sound suppression (silencers are subject to special restrictions on use at the level of law), which are more intended for entertainment.

The scientific novelty of this work is defined as the structural optimization of the tilts of silencer elements in order to reduce the acoustic impact in the shooter’s area. This was performed by creating models and experimentally validating the tilts by choosing the optimal angles.

2. Materials and Methods

The test silencer (Figure 1a) consists of an outer casing and structural elements that allow it to be easily mounted to the weapon in use and to generate scattering sound waves. The object of the research is an expansion chamber and eleven separate spaces to which the gas is directed on the conical surfaces, thus delaying their exit from the mouth and weakening the sound pressure level. Because the damper is exposed to high heat fluxes with frequent repetitions of shots in the short term, it is necessary to choose the materials responsibly. In the construction of the individual partition elements, the first one, which is in the transition position from the mouth of the weapon and is made of stainless steel, is further laid with aluminum with a thicker coating. With a seamless construction, the spectrum of materials predominates between titanium alloys, aluminum and stainless steel. The outer casing is in most cases made of aviation-grade 7 aluminum and anodized with a thicker layer.

Figure 1.

The total view (a), 3D model (b) and the silencer finite element grid (c).

The calculations were performed by modeling Solidworks flow simulations in a software package environment that solves the specified problems using the finite element method. They compared the acoustic characteristics of dampers of various design configurations. The construction of the damping device consists of a partition divided into spaces by internal partitions, which direct the flow to the holding and dissipating zones with conical surfaces, and the outer housing together with the cover traps the air inside the damper (Figure 1b).

The sound pressure p is calculated using the Helmholtz Equation (1) [46].

where k = 2πf/c is the wavelength, q is fluid density, f is the frequency and c is the speed of sound; g equals the bipolar source term, representing the acceleration per unit volume. Using this equation, the solution can be found in the frequency domain using a parametric solver. The transmission loss of the silencer is calculated using Equation (2) [46].

where win and wout describe the acoustics at the inlet and outlet of the silencer. The acoustic effect is calculated using Equations (3) and (4) [46].

Equations (2)–(4) were specified as variables in the program, and the input pressure value (pi) was assumed to be 1 bar. The model uses sonic boundary conditions at the solid boundaries as described in Equation (5) [46]

Additionally, in order to achieve the validation of the experimental method and the simulation, it is necessary to establish analogous conditions. The running speeds and other parameters of the firing elements used are provided by the manufacturers and the ambient pressure is known. The Autodesk Inventor Professional software package was used to create the model. The dimensions were taken by reproducing a real object, modeling the same structural elements, and defining them for easy modification by analyzing other configurations. When joints are not important in the study, unimportant objects such as threads and edges are eliminated.

It is assumed that the use of this silencer is subject to incomplete design optimality and maximum values of acoustic characteristics, which may lead to deviations in the use of firearms of another caliber, thus posing a health risk. By modernizing the device, the aim is to improve its characteristics, to create an easily technologically feasible structure that does not lose its mechanical and acoustic properties.

The method also includes grid generation and definition of the initial conditions. In the process of creating a finite element grid, the geometry is divided into a grid of three-dimensional objects from tetrahedra (Figure 1c), forming 194,455 points and 100,136 elements. The inlet speed is 730 m/s, according to the manufacturer’s specifications, and the resulting temperature of 1500 K and a pressure of 2 MPa at atmospheric pressure and temperature shall be used to define the parameters required for the calculation.

Utilizing the functionality of the software package used, the distribution of velocity trajectories of different structures in the internal airflow damping zones, and the change of sound pressure level and velocity at the entry and exit points are analyzed. By comparing these characteristics, it is possible to gather information about the importance of structural elements in flow control and the preliminary efficiency of the final acoustic characteristics of the device in performing calculations in virtual space.

By testing various configurations of firearms and devices, the test equipment allows one to determine the following acoustic characteristics of the damping devices:

- -

- values of sound pressure over time;

- -

- spectral distribution of sound pressure;

- -

- the effectiveness of the suppression in the zones.

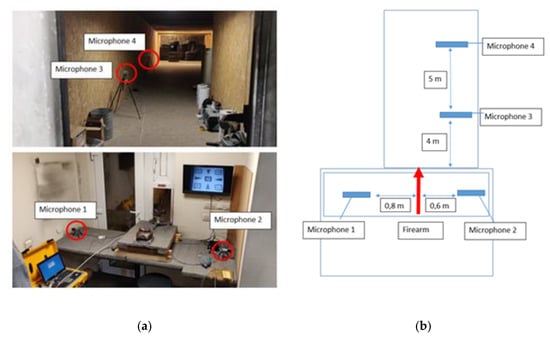

In the preparation stage, it is important to correctly select and position the data detection equipment in order to create the values for the parameter fields of the intended zones; therefore the orientation is based on the scheme in Figure 2.

Figure 2.

Experimental site (a) consisting of the range of the shooter, the range of the bullet and a layout of the microphones (b).

In this study, short and high-frequency acoustic pulses of more than 140 dB prevail during the shot, so high-quality vibration measuring instruments from the Danish company Brüel & Kjær are used. Vibration and other dynamic measurement and analysis equipment is used to test the acoustic characteristics, including Brüel & Kjær Mobile Diagnostics Toolbox Type 7927, with a Dell Computer and Grass 46DP Microphones. Measuring points 1 and 2 (microphones 1 and 2 in Figure 2a) are located at a distance of 0.8 and 0.6 m from the shooter on the left and right sides, respectively. The position of measuring points 3 and 4 (microphones 3 and 4 in Figure 2a) are at a distance of 4 and 9 m from the source of the shot.

In the developed infrastructure, which can capture important acoustic characteristics of the investigated silencers and ensure a sufficiently high repetition of the experiment, it was possible to obtain data that are convenient to compare with the values determined during the simulations.

A Merkel RX Helix Black 308 Win firearm and 308 WIN (weight 165 g, gunpowder weight 10.69 g; ballistic factor 0.404) bullets with the characteristics given in Table 1 were used for the study.

Table 1.

Bullet 308 WIN characteristics.

During the experiment, the data are analyzed after recording the results when the weapon was without and with a silencer during the shot. Sound pressure measurements were performed using 308 WIN caliber bullets and the sound pressure is expressed in dB.

3. Results and Discussion

After processing the data and systematizing the results of the tests performed for the first configuration of the damper in the field of longitudinal velocity change, it is observed that the inlet and outlet velocities do not differ, except at the first gas storage space deflection and damping, where the gas in the mixing spaces reaches ~732 m/s (Figure 3a).

Figure 3.

Longitudinal velocity distribution (a), geometric pressure distribution (b) and sound pressure distribution and flow lines (c).

Analyzing the pressure distribution in the geometry, a decrease in values is observed after the first space deflection, in which eddies are generated, reducing the energy of the expanding gas (Figure 3b). However, the last three partitions show a decreasing pressure field, as the length of the structure may not be optimal, but good damping parameters are maintained.

The results defining the sound pressure distribution show vortex zones in the partition spaces in the expansion zone, where the maximum efficiency of the structure in controlling the gas flow and reducing its energy is achieved (Figure 3c). The sound pressure level continues to decrease, and a value of 119.6 dB is obtained at the mouth.

The effectiveness of silencers is based on the reduction of sound pressure and noise and the loss of sound transmission. Sound reduction can be defined as the difference between the sound powers generated with and without a silencer. Noise reduction is the difference between the sound pressure level entering and leaving the structure. The sound transmission loss is described by the silencer characteristic, which is a logarithmic comparison of the sound power with a reference value.

The silencer is characterized by structural elements that create zones of diversion and expansion of the expanding gas generated during the flying firing element, which over time reduces and delays the amount of energy and generated sound pressure entering the environment.

The determination of the acoustic characteristics is performed by mounting the test rig on a selected firearm with a specified set of tests. An infrastructure with defined areas that are important for the experiment is created for the shooting, and special equipment for capturing the desired data are applied.

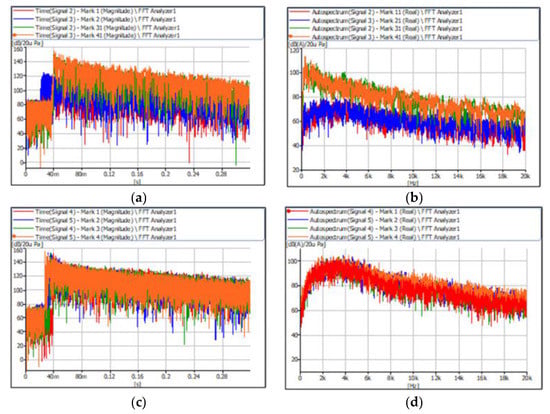

Comparison graphs of the four-point sound pressures (at the microphone locations shown in Figure 2) with and without a damping system are given in Figure 4.

Figure 4.

Graphs comparing the sound pressure at 4 points (Figure 3) with and without the damping system, showing the temporal (a,c) and spectral density plots (b,d) of the sound pressure. A damping system is used with the red and blue curves, and the green and orange curves describe when a damping system is not used.

The results of the sound pressure measurements (Figure 4) during the shot showed that the values of the damping device in the shooter area are reduced by 30.2 dB at point 1 and 30.1 dB at point 2 compared to when the damping device was not used. When evaluating the results of the sound pressure measurements at points 3 and 4, it was found that the silencer had almost no effect on the sound pressure value at point 3 (with damping device 153, without damping device 153.9 dB) and point 4 (with damping device 153.9, without damping device 155 dB).

An investigation of acoustic characteristics of silencer configurations was performed. In the second configuration, the spaces between the partitions are separated (Figure 5), thus isolating the gas expansion chamber and changing the effect on the acoustic characteristics. The three-dimensional model of finite elements is divided into a structure of 201,035 points and 103,438 elements.

Figure 5.

Second reactive silencer configuration.

Repeating the initial conditions gave results in which the maximum of the velocities at the first guide cone was observed and maintained until the exit in the area of variation of the speeds of the longitudinal section. The further zones in this case show the movement of the air flow with a speed of up to 340 m/s, but the configuration of the enclosed spaces shows low efficiency starting from the eighth partition, so it is worth adjusting the geometry and analyzing its effect on the characteristics (Figure 3).

In the analysis of the pressure distribution in geometry, we also see a decreasing gas level outside the eighth partition (Figure 3a). The results obtained in the zone of the first partition show the maximum pressure values due to the transition from the mouth, and eddy flows are observed in the gas expansion chamber, which dampen the pressure characteristics and create a sound delay.

The results of the sound pressure distribution are observed in the eddy zones in the bulkhead spaces, and in the gas expansion chamber, resulting in increased silencer efficiency parameters. The decrease in acoustic power is visible throughout the gas path of the installation, and a value of 149.7 dB is recorded at the eighth bulkhead, where the loss of efficiency was detected (Figure 3b). A value of 126.2 dB is reached due to atmospheric resistance monitoring.

By analyzing the possible changes in the acoustic characteristics of the reactive silencer models with closed and connected partitions due to the geometry, additional experimental configurations were developed by varying the position and parameters of the structural elements (Figure 3c).

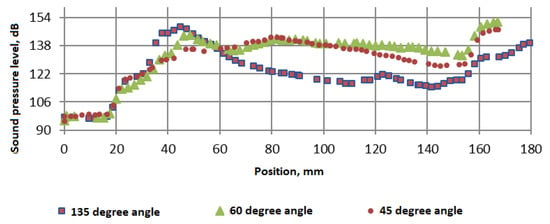

Based on the initial results from the open cavity type damper (Figure 1a), the angle of inclination of the partitions is changed to 60° (Figure 6a) and 135° (Figure 6b). Due to the reduced results observed in the last zones with closed cavities and additional configurations created, their partitions are shortened by three partitions (Figure 6c), their tilt angle is adjusted to 60° (Figure 6d); additionally, the simulation of the initial version is supplemented by 135° partitions.

Figure 6.

Configurations of test silencers: the angle of inclination of the partitions is changed to 60° (a), 135° (b), shortened by three partitions (c), shortened by three partitions and with the angle of inclination 60° (d), the same modification as d but with angle 135° (e).

After the simulation and systematization of the results, the changes made by the structural elements between the sound pressure values of the different configurations are observed. Examining the position dependence, the 25 mm spacing shows the exit of the silencer mouth. Further values indicate the path to the barrel mouth where the attachment area to the weapon is located, and the firing element passes into the environment of the other device (Figure 6). Comparing the variations in the 45° model, the pressure level varies in the range of 147.2–119.6 dB, while in the 60° version 151.5–120.6 dB values are recorded, and in the 135° configuration, 139.7–117.8 dB results are obtained in the direction of exposure to atmospheric conditions. A comparison of the sound pressure level in the open cavity models (without being shortened by three partitions) is given in Figure 7. The typical variants are presented as when the angle of inclination of the partitions is 45° and the comparison is when the angle of inclination of the partitions was changed in 60° and 135°.

Figure 7.

Comparison of sound pressure level in open cavity models.

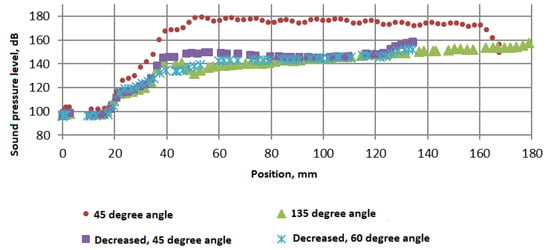

In addition to the simulation data of the partitioned cavity model (with the variation shortened by three partitions), the results between the sound pressure values of the different configurations are calculated and presented, which show the ideal design change factors for the silencer. Compared to the variations in the 45° model, the pressure level varied between 149.7 and 126.2 dB, with the 135° variant receiving 157.5–115.3 dB and the shortened 45° configuration receiving 158.1–116.4 dB results, while the 60° variant recorded 152.2–115.5 dB in the direction of entry to atmospheric conditions (Figure 8).

Figure 8.

Comparison of sound pressure level in closed cavity models.

Analyzing the obtained theoretical sound pressure results in six different cases; it was found that the (open) silencer in the unoccupied spaces achieves the best damping of 30.9 dB with 60° tilt partitions, and the separation of spaces (closed) results in a 42.2 dB sound pressure level reduction in the 135° tilt configuration. In the 45° tilt variants of the same length, a 14.9% lower efficiency was observed in the closed case, but the value was improved 1.9 times after shortening the damper. Theoretical studies of damper configurations showed the following results: 1. Open damper configuration and partition tilt angle 45°—damping level 27.6 dB; 2. open silencer configuration and partition tilt angle 60°—damping level 30.9 dB; 3. open damper configuration and partition angle 135°—damping level 21.9 dB; 4. closed damper configuration and bulkhead tilt angle 45°—damping level 23.5 dB; 5. closed damper configuration and partition angle 135°—damping level 42.2 dB; 6. closed silencer configuration shortened by three bulkheads and bulkhead heeling angle 45°—damping level 41.7 dB; 7. closed damper configuration shortened by three bulkheads and bulkhead tilt angle 60°—damping level 37.6 dB.

4. Conclusions

The research of silencers was performed and analyzed during which the equipment was selected and the acoustic characteristics that show the efficiency of the devices in the direction under study were investigated.

During the theoretical test, the geometry of the damper used in the experiment was designed further and the environmental conditions as close to the real situation as possible were defined. The result of the sound test was 27.6 dB (a sound pressure damping value) during the theoretical test.

In an experimental study and analysis of the results, the silencer was found to achieve a sound pressure damping value of 30.1 dB using 308 WIN ammunition at the selected speed and theoretical calculations, and a high level of identity could be observed in both cases. During the experiment, evaluating the data recorded by the formed microphone field, the most effective reduction of acoustic characteristics dangerous to humans were at the 0.8 and 0.6 m positions from the left and right, respectively, compared to the results obtained behind the mouth.

After creating the silencer configurations by changing the position, direction and connection components of the structural elements, the values of the acoustic characteristics were obtained using theoretical calculations. Moreover, in the configuration change of the model studied in the experiment, an increase of up to 30.9 dB damping was observed by modifying the partition angle from 45° to 60°. Furthermore, by changing the design to closed cavity distribution, it was possible to reach a reduction of 41.7 dB by shortening the device with 45° partition tilt.

For better results, different combinations of elements need to be analyzed due to the changing features of flow parameters. Due to the variable bullet speed, the use of different ammunition requires the development of an optimal design adapted to the widest possible range of conditions. It is necessary to take into account the technological nuances of production and to apply different methods to find the most efficient model that produces the best damping characteristics. This ensures that the sound pressure level during the shot is reduced to below a dangerous level and ensures safe use.

Author Contributions

Conceptualization, A.K. and K.K.; methodology, A.K., J.M. and K.K.; software, G.B. and V.G.; validation, A.K., G.B. and V.G.; formal analysis, J.S. and M.R.; investigation, A.K.; resources, A.K.; data curation, G.B. and V.G.; writing—original draft preparation, A.K., J.M., J.S. and M.R.; writing—review and editing, A.K., J.M., J.S. and M.R.; visualization, G.B. and V.G.; supervision, A.K.; project administration, J.M.; funding acquisition, A.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data supporting reported results can be obtained after request.

Conflicts of Interest

The authors declare no conflict of interest.

Nomenclature

| c | the speed of sound |

| E0, E100, E200, E300 | the bullet energy, when the bullet speed is 0, 100, 200 and 300 m/s |

| f | the frequency |

| g | the bipolar source term, representing the acceleration per unit volume |

| k | the wavelength |

| q | the fluid density |

| p | the sound pressure |

| pi | the input pressure value |

| TL | the transmission loss of the silencer |

| V0, V100, V200, V300 | the bullet speeds |

| win | the acoustics at the inlet of the silencer |

| wout | the acoustics at the outlet of the silencer |

References

- Arslan, H.; Ranjbar, M.; Secgin, E.; Celik, V. Theoretical and Experimental Investigation of Acoustic Performance of Multi-Chamber Reactive Silencers. Appl. Acoust. 2020, 157, 106987. [Google Scholar] [CrossRef]

- Strong, B.L.; Ballard, S.-B.; Braund, W. The American College of Preventive Medicine Policy Recommendations on Reducing and Preventing Firearm-Related Injuries and Deaths. Am. J. Prev. Med. 2016, 51, 1084–1089. [Google Scholar] [CrossRef] [PubMed]

- Hamilton, D.; Lemeshow, S.; Saleska, J.L.; Brewer, B.; Strobino, K. Who Owns Guns and How Do They Keep Them? The Influence of Household Characteristics on Firearms Ownership and Storage Practices in the United States. Prev. Med. 2018, 116, 134–142. [Google Scholar] [CrossRef] [PubMed]

- Junuzovic, M.; Midlöv, P.; Lönn, S.L.; Eriksson, A. Swedish Hunters’ Safety Behaviour and Experience of Firearm Incidents. Accid. Anal. Prev. 2013, 60, 64–70. [Google Scholar] [CrossRef] [PubMed]

- Jones, H.G.; Greene, N.T.; Ahroon, W.A. Human Middle-Ear Muscles Rarely Contract in Anticipation of Acoustic Impulses: Implications for Hearing Risk Assessments. Hear. Res. 2019, 378, 53–62. [Google Scholar] [CrossRef]

- Chau, J.K.; Cho, J.J.W.; Fritz, D.K. Evidence-Based Practice. Otolaryngol. Clin. N. Am. 2012, 45, 941–958. [Google Scholar] [CrossRef] [PubMed]

- Guida, H.L.; Taxini, C.L.; Gonçalves, C.G.d.O.; Valenti, V.E. Evaluation of Hearing Protection Used by Police Officers in the Shooting Range. Braz. J. Otorhinolaryngol. 2014, 80, 515–521. [Google Scholar] [CrossRef]

- Kim, D.; Cheong, C.; Jeong, W.B. The Use of a Hybrid Model to Compute the Nonlinear Acoustic Performance of Silencers for the Finite Amplitude Acoustic Wave. J. Sound Vib. 2010, 329, 2158–2176. [Google Scholar] [CrossRef]

- Kirby, R.; Amott, K.; Williams, P.T.; Duan, W. On the Acoustic Performance of Rectangular Splitter Silencers in the Presence of Mean Flow. J. Sound Vib. 2014, 333, 6295–6311. [Google Scholar] [CrossRef]

- Davis, R.R.; Clavier, O. Impulsive Noise: A Brief Review. Hear. Res. 2017, 349, 34–36. [Google Scholar] [CrossRef]

- Miller, M.T. Crime Scene Reconstruction. In Crime Scene Investigation Laboratory Manual; Elsevier: Amsterdam, The Netherlands, 2018; pp. 191–200. ISBN 978-0-12-812845-9. [Google Scholar]

- Fairmont, I.; Duffy, J.; Portnuff, C.; Mann, S. Bullet Fragment in the Eustachian Tube Presenting as Conductive Hearing Loss and Lead Toxicity. Otolaryngol. Case Rep. 2021, 21, 100380. [Google Scholar] [CrossRef]

- Naranjo-Alcazar, J.; Perez-Castanos, S.; Zuccarello, P.; Torres, A.M.; Lopez, J.J.; Ferri, F.J.; Cobos, M. An Open-Set Recognition and Few-Shot Learning Dataset for Audio Event Classification in Domestic Environments. Pattern Recognit. Lett. 2022, 164, 40–45. [Google Scholar] [CrossRef]

- Meng, X.; Wang, Z.; Zhang, Z.; Wang, F. A Method for Monitoring the Underground Mining Position Based on the Blasting Source Location. Meas. Sci. Rev. 2013, 13, 45–49. [Google Scholar] [CrossRef]

- Hristov, N.; Kari, A.; Jerković, D.; Savić, S.; Sirovatka, R. Simulation and Measurements of Small Arms Blast Wave Overpressure in the Process of Designing a Silencer. Meas. Sci. Rev. 2015, 15, 27–34. [Google Scholar] [CrossRef]

- Brożek-Mucha, Z. A Study of Gunshot Residue Distribution for Close-Range Shots with a Silenced Gun Using Optical and Scanning Electron Microscopy, X-Ray Microanalysis and Infrared Spectroscopy. Sci. Justice 2017, 57, 87–94. [Google Scholar] [CrossRef] [PubMed]

- Monturo, C. Ammunition. In Forensic Firearm Examination; Elsevier: Amsterdam, The Netherlands, 2019; pp. 21–71. ISBN 978-0-12-814539-5. [Google Scholar]

- Fang, Z.; Liu, C.Y. Semi-Weak-Form Mesh-Free Method for Acoustic Attenuation Analysis of Silencers with Arbitrary but Axially Uniform Transversal Sections. J. Sound Vib. 2019, 442, 752–769. [Google Scholar] [CrossRef]

- Kilikevicius, A.; Skeivalas, J.; Jurevicius, M.; Turla, V.; Kilikeviciene, K.; Bureika, G.; Jakstas, A. Experimental Investigation of Dynamic Impact of Firearm with Suppressor. Indian J. Phys. 2017, 91, 1077–1087. [Google Scholar] [CrossRef]

- Lu, Y.; Zhou, K.; He, L.; Li, J.; Huang, X. Research on the Floating Performance of a Novel Large Caliber Machine Gun Based on the Floating Principle with Complicated Boundary Conditions. Def. Technol. 2019, 15, 607–614. [Google Scholar] [CrossRef]

- Mäkinen, T.; Pertilä, P. Shooter Localization and Bullet Trajectory, Caliber, and Speed Estimation Based on Detected Firing Sounds. Appl. Acoust. 2010, 71, 902–913. [Google Scholar] [CrossRef]

- Xiao, W.; Andrae, M.; Gebbeken, N. Experimental and Numerical Investigations on the Shock Wave Attenuation Performance of Blast Walls with a Canopy on Top. Int. J. Impact Eng. 2019, 131, 123–139. [Google Scholar] [CrossRef]

- Mouritz, A.P. Advances in Understanding the Response of Fibre-Based Polymer Composites to Shock Waves and Explosive Blasts. Compos. Part A Appl. Sci. Manuf. 2019, 125, 105502. [Google Scholar] [CrossRef]

- Hu, X.-D.; Zhao, G.-F.; Deng, X.-F.; Hao, Y.-F.; Fan, L.-F.; Ma, G.-W.; Zhao, J. Application of the Four-Dimensional Lattice Spring Model for Blasting Wave Propagation around the Underground Rock Cavern. Tunn. Undergr. Space Technol. 2018, 82, 135–147. [Google Scholar] [CrossRef]

- Carson, R.A.; Sahni, O. Numerical Investigation of Channel Leak Geometry for Blast Overpressure Attenuation in a Muzzle Loaded Large Caliber Cannon. J. Fluids Eng. 2014, 137, 021102. [Google Scholar] [CrossRef]

- Scaling of Air Blast Waves. Fundamental Studies in Engineering; Elsevier: Amsterdam, The Netherlands, 1991; Volume 12, pp. 49–69. ISBN 978-0-444-88156-4. [Google Scholar]

- Explosions and Pressure Waves. Industrial Safety Series; Elsevier: Amsterdam, The Netherlands, 1994; Volume 3, pp. 445–462. ISBN 978-0-444-89863-0. [Google Scholar]

- Phadnis, V.A.; Silberschmidt, V.V. 8.14 Composites Under Dynamic Loads at High Velocities. In Comprehensive Composite Materials II.; Elsevier: Amsterdam, The Netherlands, 2018; pp. 262–285. ISBN 978-0-08-100534-7. [Google Scholar]

- Phadnis, V.A.; Roy, A.; Silberschmidt, V.V. Dynamic Damage in FRPs. In Dynamic Deformation, Damage and Fracture in Composite Materials and Structures; Elsevier: Amsterdam, The Netherlands, 2016; pp. 193–222. ISBN 978-0-08-100870-6. [Google Scholar]

- Fang, B.; Wang, Y.-G.; Zhao, Q. On Multi-Dimensional Linear Stability of Planar Shock Waves for Chaplygin Gases. Appl. Math. Lett. 2020, 102, 106085. [Google Scholar] [CrossRef]

- Yazdandoost, F.; Sadeghi, O.; Bakhtiari-Nejad, M.; Elnahhas, A.; Shahab, S.; Mirzaeifar, R. Energy Dissipation of Shock-Generated Stress Waves through Phase Transformation and Plastic Deformation in NiTi Alloys. Mech. Mater. 2019, 137, 103090. [Google Scholar] [CrossRef]

- Otsuka, F.; Matsukiyo, S.; Hada, T. PIC Simulation of a Quasi-Parallel Collisionless Shock: Interaction between Upstream Waves and Backstreaming Ions. High Energy Density Phys. 2019, 33, 100709. [Google Scholar] [CrossRef]

- Xu, H.; Gao, J.; Yao, A.; Yao, C. The Relief of Energy Convergence of Shock Waves by Using the Concave Combustion Chamber under Severe Knock. Energy Convers. Manag. 2018, 162, 293–306. [Google Scholar] [CrossRef]

- Tonicello, N.; Lodato, G.; Vervisch, L. Entropy Preserving Low Dissipative Shock Capturing with Wave-Characteristic Based Sensor for High-Order Methods. Comput. Fluids 2020, 197, 104357. [Google Scholar] [CrossRef]

- Selech, J.; Kilikevičius, A.; Kilikevičienė, K.; Borodinas, S.; Matijošius, J.; Vainorius, D.; Marcinkiewicz, J.; Staszak, Z. Force and Sound Pressure Sensors Used for Modeling the Impact of the Firearm with a Suppressor. Appl. Sci. 2020, 10, 961. [Google Scholar] [CrossRef]

- Carlucci, D.E.; Decker, R.; Vega, J.; Ray, D. Measurement of In-Bore Side Loads and Comparison to First Maximum Yaw. Def. Technol. 2016, 12, 106–112. [Google Scholar] [CrossRef]

- Courtney, E.; Couvillion, R.; Courtney, A.; Courtney, M. Effects of Sound Suppressors on Muzzle Velocity, Bullet Yaw and Drag. In Proceedings of the 30th International Symposium on Ballistics, San Antonio, TX, USA, 18 December 2017; DEStech Publications, Inc: Lancaster, PA, USA. [Google Scholar]

- Mlynski, R.; Kozlowski, E. Selection of Level-Dependent Hearing Protectors for Use in An Indoor Shooting Range. IJERPH 2019, 16, 2266. [Google Scholar] [CrossRef]

- Murphy, W.J.; Tasko, S.M.; Finan, D.; Meinke, D.K.; Stewart, M.; Lankford, J.E.; Campbell, A.R.; Flamme, G. Referee Whistles Part II—Outdoor Sound Power Assessment. J. Acoust. Soc. Am. 2019, 145, 1816. [Google Scholar] [CrossRef]

- Skrodzka, E.; Wicher, A.; Gołe¸biewski, R. A Review of Gunshot Noise as Factor in Hearing Disorders. Acta Acust. United Acust. 2019, 105, 904–911. [Google Scholar] [CrossRef]

- Stewart, M. What to Know About Firearm Suppressors and Hearing Loss: Does a Firearm Suppressor Always Do Enough to Protect Hearing? No. Should Firearm Users Also Wear Hearing Protection? Yes. Leader 2018, 23, 18–20. [Google Scholar] [CrossRef]

- Murphy, W.J.; Campbell, A.R.; Flamme, G.A.; Tasko, S.M.; Lankford, J.E.; Meinke, D.K.; Finan, D.S.; Stewart, M.; Zechmann, E.L. Developing a Method to Assess Noise Reduction of Firearm Suppressors for Small-Caliber Weapons. Proc. Mtgs. Acoust. 2018, 30, 040004. [Google Scholar]

- Murphy, W.J.; Campbell, A.R.; Flamme, G.A.; Tasko, S.M.; Lankford, J.E.; Meinke, D.K.; Finan, D.S.; Zechmann, E.L.; Stewart, M. The Attenuation of Firearm Suppressors as a Function of Angle and Bullet Velocity. In Proceedings of the National Hearing Conservation Association, Orlando, FL, USA; 2018. [Google Scholar] [CrossRef]

- Murphy, W.J.; Flamme, G.A.; Campbell, A.R.; Zechmann, E.L.; Tasko, S.M.; Lankford, J.E.; Meinke, D.K.; Finan, D.S.; Stewart, M. The Reduction of Gunshot Noise and Auditory Risk through the Use of Firearm Suppressors and Low-Velocity Ammunition. Int. J. Audiol. 2018, 57, S28–S41. [Google Scholar] [CrossRef]

- Fonseca de Lima, K.; Dea Cirino, P.; Maurios Legat Filho, N.L.; Barbieri, N. Multi-Frequency Sequential and Simultaneous Parametric Shape Optimization of Reactive Silencers. Appl. Acoust. 2021, 171, 107543. [Google Scholar] [CrossRef]

- Amuaku, R.; Amoah Asante, E.; Edward, A.; Bright Gyamfi, G. Effects of Chamber Perforations, Inlet and Outlet Pipe Diameter Variations on Transmission Loss Characteristics of a Muffler Using Comsol Multiphysics. AAS 2019, 4, 104. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).