Color Change, Biaxial Flexural Strength, and Fractographic Analysis of Resin-Modified CAD/CAM Ceramics Subjected to Different Surface Finishing Protocols

Abstract

1. Introduction

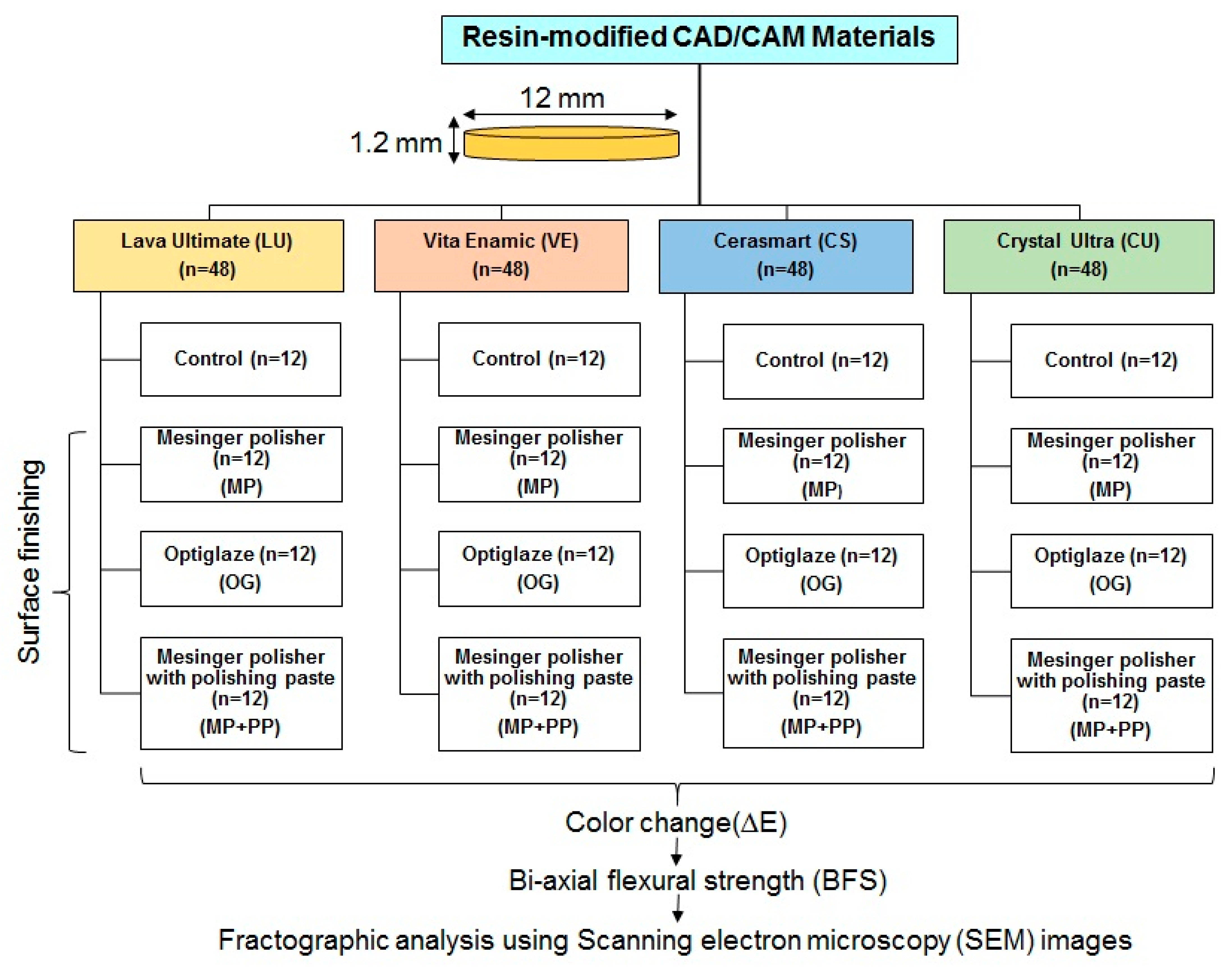

2. Materials and Methods

2.1. Specimen Preparation and Surface Finishing Protocol

2.2. Coffee Staining and Color Change Analysis Using Spectrophotometer

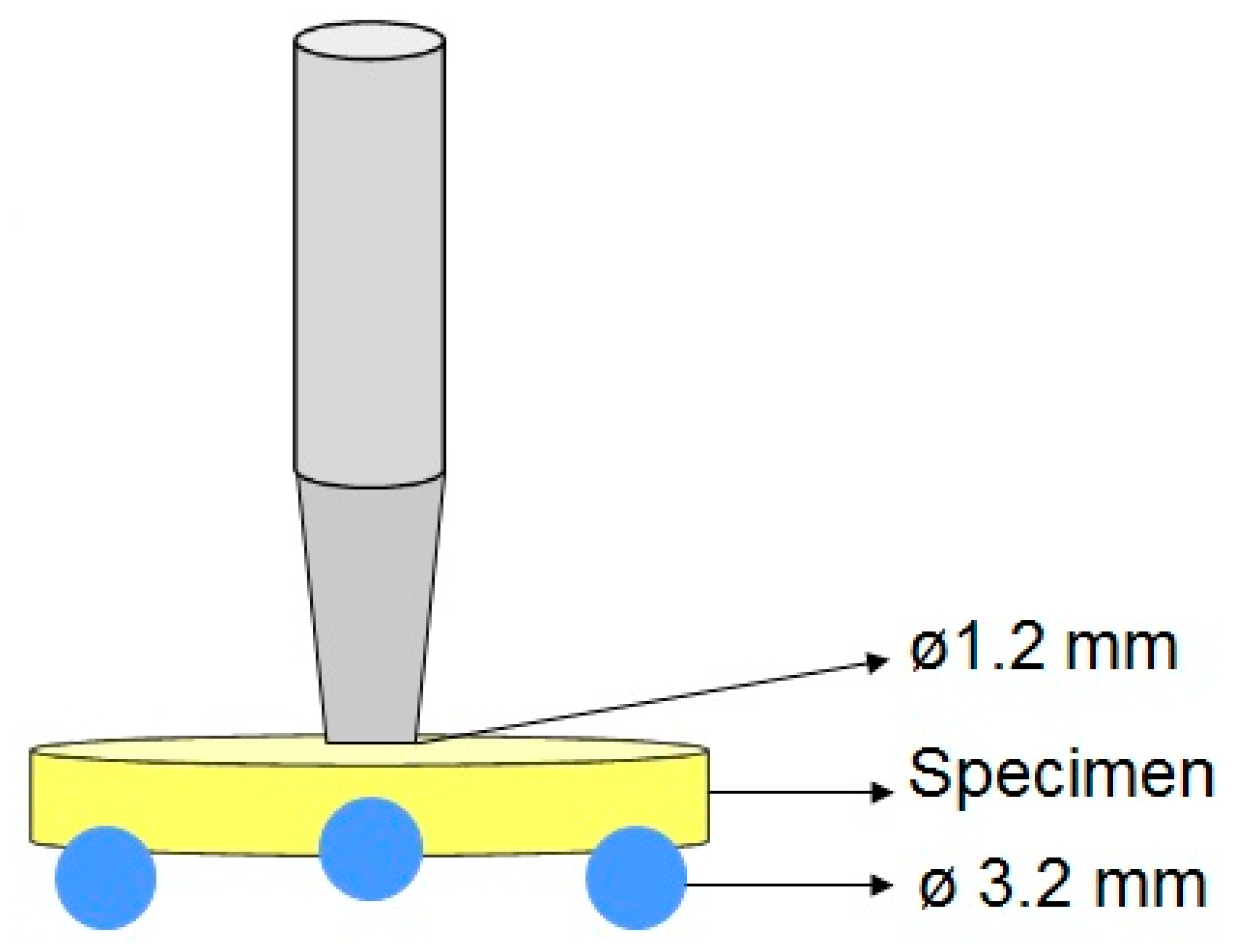

2.3. Biaxial Flexural Strength (BFS) Testing

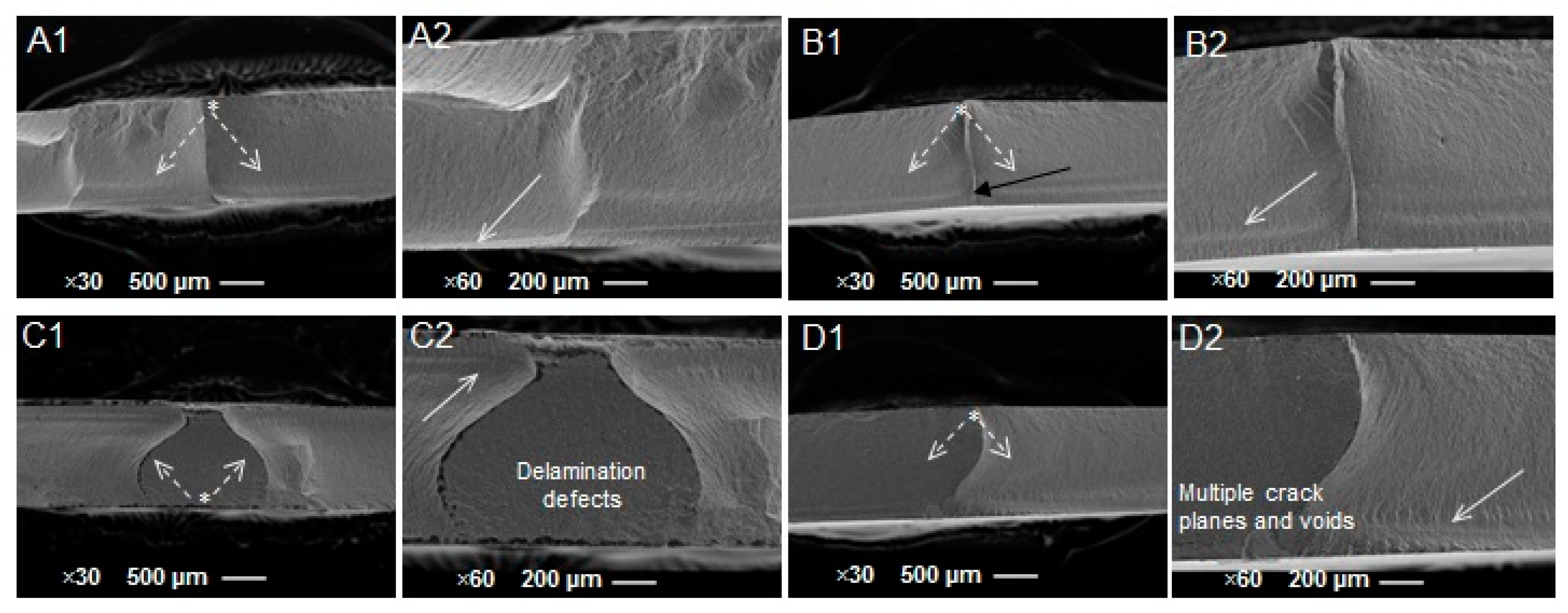

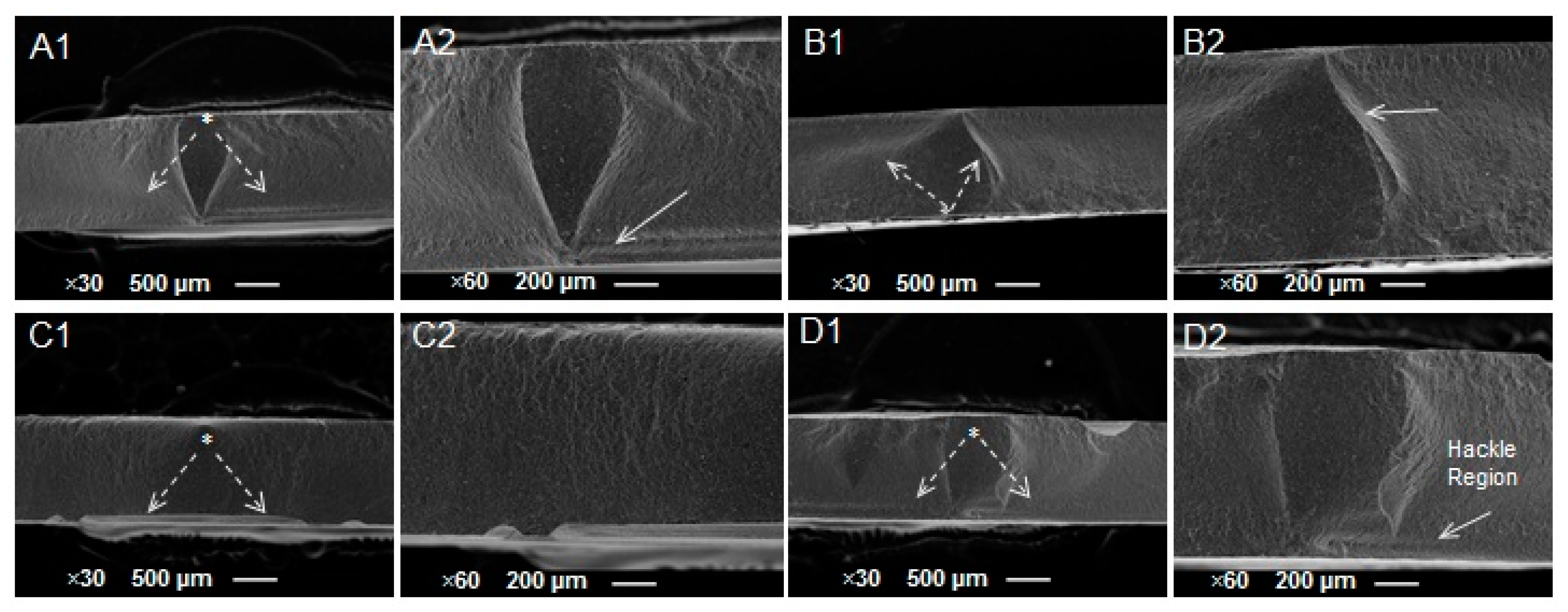

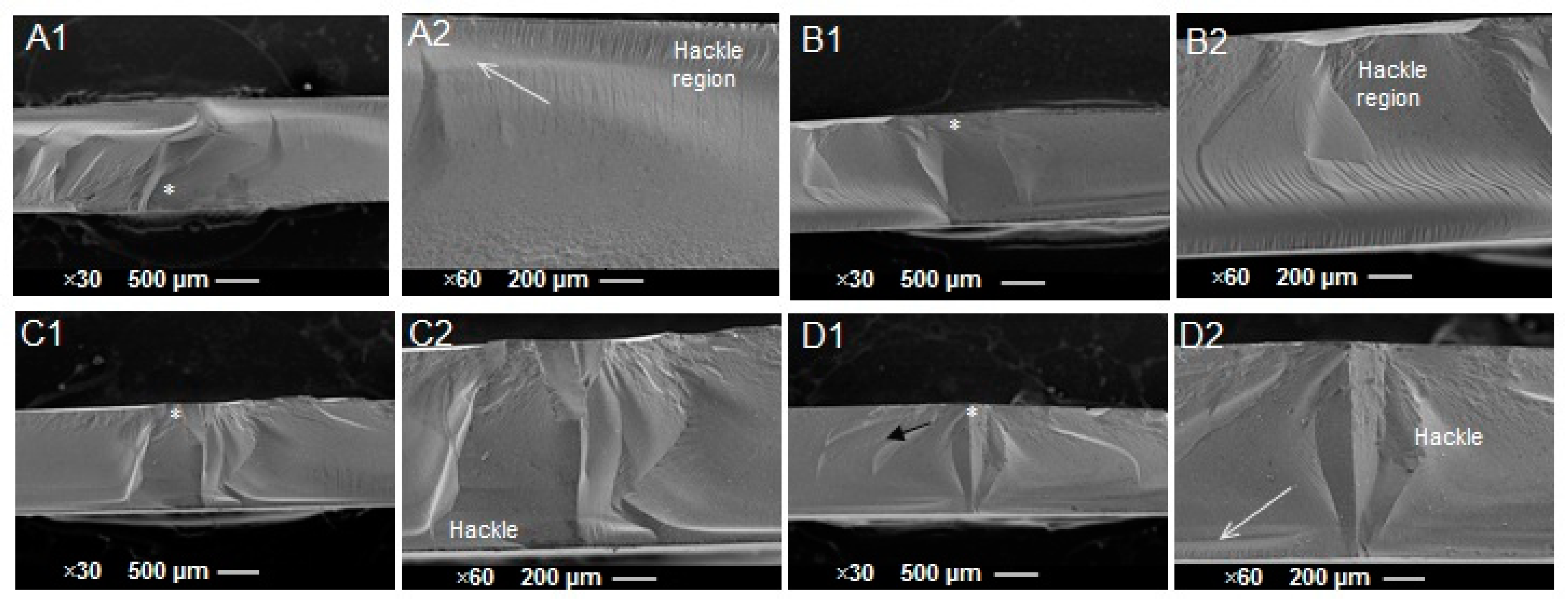

2.4. Fractographic Analysis Using Scanning Electron Microscope (SEM) Images

2.5. Statistical Analysis

3. Results

3.1. Color Change (ΔE)

3.2. Biaxial Flexural Strength (BFS)

3.3. Fractographic Analysis

4. Discussion

5. Conclusions

- (a)

- The OG surface finishing protocol provides the least color changes and the highest BFS.

- (b)

- MP+PP has comparable performance to the OG protocol, and there was a statistically insignificant difference between the two protocols except for the BFS of LU.

- (c)

- In comparison with the OG and MP+PP protocols, the MP protocol resulted in the lowest BFS and the highest color changes.

- (d)

- Among the materials tested, VE demonstrated the least color changes, and CS showed the highest BFS following surface finishing.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Alhassan, M.; Maawadh, A.; Labban, N.; Alnafaiy, S.M.; Alotaibi, H.N.; BinMahfooz, A.M. Effect of Different Surface Treatments on the Surface Roughness and Gloss of Resin-Modified CAD/CAM Ceramics. Appl. Sci. 2022, 12, 11972. [Google Scholar] [CrossRef]

- Miyazaki, T.; Hotta, Y.; Kunii, J.; Kuriyama, S.; Tamaki, Y. A review of dental CAD/CAM: Current status and future perspectives from 20 years of experience. Dent. Mater. J. 2009, 28, 44–56. [Google Scholar] [CrossRef] [PubMed]

- Fasbinder, D.J. Digital dentistry: Innovation for restorative treatment. Compend. Contin. Educ. Dent. 2010, 31, 2–11. [Google Scholar] [PubMed]

- Fasbinder, D.J. Computerized technology for restorative dentistry. Am. J. Dent. 2013, 26, 115–120. [Google Scholar] [PubMed]

- Joda, T.; Brägger, U. Digital vs. conventional implant prosthetic workflows: A cost/time analysis. Clin. Oral Implant. Res. 2015, 26, 1430–1435. [Google Scholar] [CrossRef]

- Carrabba, M.; Vichi, A.; Vultaggio, G.; Pallari, S.; Paravina, R.; Ferrari, M. Effect of Finishing and Polishing on the Surface Roughness and Gloss of Feldspathic Ceramic for Chairside CAD/CAM Systems. Oper. Dent. 2017, 42, 175–184. [Google Scholar] [CrossRef]

- Gracis, S.; Thompson, V.P.; Ferencz, J.L.; Silva, N.R.; Bonfante, E.A. A new classification system for all-ceramic and ceramic-like restorative materials. Int. J. Prosthodont. 2015, 28, 227–235. [Google Scholar] [CrossRef] [PubMed]

- Awada, A.; Nathanson, D. Mechanical properties of resin-ceramic CAD/CAM restorative materials. J. Prosthet. Dent. 2015, 114, 587–593. [Google Scholar] [CrossRef]

- Coldea, A.; Swain, M.V.; Thiel, N. Mechanical properties of polymer-infiltrated-ceramic-network materials. Dent. Mater. 2013, 29, 419–426. [Google Scholar] [CrossRef]

- Ruse, N.D.; Sadoun, M.J. Resin-composite blocks for dental CAD/CAM applications. J. Dent. Res. 2014, 93, 1232–1234. [Google Scholar] [CrossRef]

- Stawarczyk, B.; Liebermann, A.; Eichberger, M.; Güth, J.F. Evaluation of mechanical and optical behavior of current esthetic dental restorative CAD/CAM composites. J. Mech. Behav. Biomed. Mater. 2015, 55, 1–11. [Google Scholar] [CrossRef] [PubMed]

- Alghamdi, W.; Labban, N.; Maawadh, A.; Alsayed, H.; Alshehri, H.; Alrahlah, A.; Alnafaiy, S. Influence of Acidic Environment on the Hardness, Surface Roughness and Wear Ability of CAD/CAM Resin-Matrix Ceramics. Materials 2022, 15, 6146. [Google Scholar] [CrossRef]

- Arnetzl, G.; Arnetzl, G.V. Hybrid materials offer new perspectives. Int. J. Comput. Dent. 2015, 18, 177–186. [Google Scholar]

- Wright, M.D.; Masri, R.; Driscoll, C.F.; Romberg, E.; Thompson, G.A.; Runyan, D.A. Comparison of three systems for the polishing of an ultra-low fusing dental porcelain. J. Prosthet. Dent. 2004, 92, 486–490. [Google Scholar] [CrossRef] [PubMed]

- Herion, D.T.; Ferracane, J.L.; Covell, D.A., Jr. Porcelain surface alterations and refinishing after use of two orthodontic bonding methods. Angle Orthod. 2010, 80, 167–174. [Google Scholar] [CrossRef]

- Maciel, L.; Silva, C.; de Jesus, R.; Concílio, L.; Kano, S.; Xible, A. Influence of polishing systems on roughness and color change of two dental ceramics. J. Adv. Prosthodont. 2019, 11, 215–222. [Google Scholar] [CrossRef] [PubMed]

- Fischer, H.; Schäfer, M.; Marx, R. Effect of surface roughness on flexural strength of veneer ceramics. J. Dent. Res. 2003, 82, 972–975. [Google Scholar] [CrossRef] [PubMed]

- Heintze, S.D.; Cavalleri, A.; Forjanic, M.; Zellweger, G.; Rousson, V. Wear of ceramic and antagonist—A systematic evaluation of influencing factors in vitro. Dent. Mater. 2008, 24, 433–449. [Google Scholar] [CrossRef] [PubMed]

- Sasahara, R.M.; Ribeiro Fda, C.; Cesar, P.F.; Yoshimura, H.N. Influence of the finishing technique on surface roughness of dental porcelains with different microstructures. Oper. Dent. 2006, 31, 577–583. [Google Scholar] [CrossRef]

- Tholt de Vasconcellos, B.; Miranda-Júnior, W.G.; Prioli, R.; Thompson, J.; Oda, M. Surface roughness in ceramics with different finishing techniques using atomic force microscope and profilometer. Oper. Dent. 2006, 31, 442–449. [Google Scholar] [CrossRef]

- Kursoglu, P.; Karagoz Motro, P.F.; Kazazoglu, E. Correlation of surface texture with the stainability of ceramics. J. Prosthet. Dent. 2014, 112, 306–313. [Google Scholar] [CrossRef] [PubMed]

- Igiel, C.; Lehmann, K.M.; Ghinea, R.; Weyhrauch, M.; Hangx, Y.; Scheller, H.; Paravina, R.D. Reliability of visual and instrumental color matching. J. Esthet. Restor. Dent. 2017, 29, 303–308. [Google Scholar] [CrossRef] [PubMed]

- Lehmann, K.; Devigus, A.; Wentaschek, S.; Igiel, C.; Scheller, H.; Paravina, R. Comparison of visual shade matching and electronic color measurement device. Int. J. Esthet. Dent. 2017, 12, 396–404. [Google Scholar] [PubMed]

- Shen, C.; Rawls, H.R.; Esquivel-Upshaw, J.F. (Eds.) Phillips’ Science of Dental Materials, 13th ed.; Elsevier/Saunders: St. Louis, MO, USA, 2022. [Google Scholar]

- McCabe, J.; Angus, W. Applied Dental Materials, 9th ed.; Blackwell: Oxford, UK, 2008. [Google Scholar]

- Mohammadi-Bassir, M.; Babasafari, M.; Rezvani, M.B.; Jamshidian, M. Effect of coarse grinding, overglazing, and 2 polishing systems on the flexural strength, surface roughness, and phase transformation of yttrium-stabilized tetragonal zirconia. J. Prosthet. Dent. 2017, 118, 658–665. [Google Scholar] [CrossRef]

- Mohammadibassir, M.; Rezvani, M.B.; Golzari, H.; Moravej Salehi, E.; Fahimi, M.A.; Kharazi Fard, M.J. Effect of Two Polishing Systems on Surface Roughness, Topography, and Flexural Strength of a Monolithic Lithium Disilicate Ceramic. J. Prosthodont. 2019, 28, e172–e180. [Google Scholar] [CrossRef]

- Jin, J.; Takahashi, H.; Iwasaki, N. Effect of test method on flexural strength of recent dental ceramics. Dent. Mater. J. 2004, 23, 490–496. [Google Scholar] [CrossRef]

- Alfouzan, A.F.; Alnafaiy, S.M.; Alsaleh, L.S.; Bawazir, N.H.; Al-Otaibi, H.N.; Taweel, S.M.A.; Alshehri, H.A.; Labban, N. Effects of background color and thickness on the optical properties of CAD-CAM resin-matrix ceramics. J. Prosthet. Dent. 2022, 128, 497.e1–497.e9. [Google Scholar] [CrossRef]

- Alfouzan, A.F.; Al-Otaibi, H.N.; Labban, N.; Taweel, S.M.A.; Al-Tuwaijri, S.; AlGazlan, A.S.; Tashkandi, E.A. Influence of thickness and background on the color changes of CAD/CAM dental ceramic restorative materials. Mater. Res. Express 2020, 7, 055402. [Google Scholar] [CrossRef]

- Kilinc, H.; Turgut, S. Optical behaviors of esthetic CAD-CAM restorations after different surface finishing and polishing procedures and UV aging: An in vitro study. J. Prosthet. Dent. 2018, 120, 107–113. [Google Scholar] [CrossRef]

- Sen, N.; Us, Y.O. Mechanical and optical properties of monolithic CAD-CAM restorative materials. J. Prosthet. Dent. 2018, 119, 593–599. [Google Scholar] [CrossRef]

- Incesu, E.; Yanikoglu, N. Evaluation of the effect of different polishing systems on the surface roughness of dental ceramics. J. Prosthet. Dent. 2020, 124, 100–109. [Google Scholar] [CrossRef]

- Steiner, R.; Beier, U.S.; Heiss-Kisielewsky, I.; Engelmeier, R.; Dumfahrt, H.; Dhima, M. Adjusting dental ceramics: An in vitro evaluation of the ability of various ceramic polishing kits to mimic glazed dental ceramic surface. J. Prosthet. Dent. 2015, 113, 616–622. [Google Scholar] [CrossRef] [PubMed]

- Alaqeel, S. Effect of Grit-blasting on the Color Stability of Zirconia Ceramics Following Exposure to Beverages. Cureus 2020, 12, e7170. [Google Scholar] [CrossRef] [PubMed]

- Rajesh, S.; Kamalakanth, S.; Savitha, D.; Karkala, S.S.; Mallikarjuna, R.; John, F. Resin-matrix ceramics—An overview. Int. J. Recent Sci. Res. 2015, 6, 7414–7417. [Google Scholar]

- Paravina, R.D.; Ghinea, R.; Herrera, L.J.; Bona, A.D.; Igiel, C.; Linninger, M.; Sakai, M.; Takahashi, H.; Tashkandi, E.; Perez Mdel, M. Color difference thresholds in dentistry. J. Esthet. Restor. Dent. 2015, 27 (Suppl. S1), S1–S9. [Google Scholar] [CrossRef]

- Acar, B.; Egilmez, F. Effects of various polishing techniques and thermal cycling on the surface roughness and color change of polymer-based CAD/CAM materials. Am. J. Dent. 2018, 31, 91–96. [Google Scholar]

- Almejrad, L.; Yang, C.C.; Morton, D.; Lin, W.S. The Effects of Beverages and Surface Treatments on the Color Stability of 3D-Printed Interim Restorations. J. Prosthodont. 2022, 31, 165–170. [Google Scholar] [CrossRef]

- Hepdeniz, O.K.; Temel, U.B.; Ugurlu, M.; Koskan, O. The effect of surface sealants with different filler content on microleakage of Class V resin composite restorations. Eur. J. Dent. 2016, 10, 163–169. [Google Scholar] [CrossRef] [PubMed]

- Al Amri, M.D.; Labban, N.; Alhijji, S.; Alamri, H.; Iskandar, M.; Platt, J.A. In Vitro Evaluation of Translucency and Color Stability of CAD/CAM Polymer-Infiltrated Ceramic Materials after Accelerated Aging. J. Prosthodont. 2021, 30, 318–328. [Google Scholar] [CrossRef]

- Thompson, G.A.; Luo, Q. Contribution of postpolymerization conditioning and storage environments to the mechanical properties of three interim restorative materials. J. Prosthet. Dent. 2014, 112, 638–648. [Google Scholar] [CrossRef]

- Çakmak, G.; Yilmaz, H.; Aydoğ, Ö.; Yilmaz, B. Flexural strength of CAD-CAM and conventional interim resin materials with a surface sealant. J. Prosthet. Dent. 2020, 124, 800.e1–800.e7. [Google Scholar] [CrossRef] [PubMed]

- Flury, S.; Peutzfeldt, A.; Lussi, A. Influence of surface roughness on mechanical properties of two computer-aided design/computer-aided manufacturing (CAD/CAM) ceramic materials. Oper. Dent. 2012, 37, 617–624. [Google Scholar] [CrossRef] [PubMed]

- Lohbauer, U.; Müller, F.A.; Petschelt, A. Influence of surface roughness on mechanical strength of resin composite versus glass ceramic materials. Dent. Mater. 2008, 24, 250–256. [Google Scholar] [CrossRef] [PubMed]

- Nakamura, Y.; Hojo, S.; Sato, H. The effect of surface roughness on the Weibull distribution of porcelain strength. Dent. Mater. J. 2010, 29, 30–34. [Google Scholar] [CrossRef]

- Scherrer, S.S.; Lohbauer, U.; Della Bona, A.; Vichi, A.; Tholey, M.J.; Kelly, J.R.; van Noort, R.; Cesar, P.F. ADM guidance-Ceramics: Guidance to the use of fractography in failure analysis of brittle materials. Dent. Mater. 2017, 33, 599–620. [Google Scholar] [CrossRef]

- Quinn, G.D.; Giuseppetti, A.A.; Hoffman, K.H. Chipping fracture resistance of dental CAD/CAM restorative materials: Part I—Procedures and results. Dent. Mater. 2014, 30, e99–e111. [Google Scholar] [CrossRef]

- Poggio, C.; Dagna, A.; Chiesa, M.; Colombo, M.; Scribante, A. Surface roughness of flowable resin composites eroded by acidic and alcoholic drinks. J. Conserv. Dent. 2012, 15, 137–140. [Google Scholar] [CrossRef]

- Al Taweel, S.M.; Fouzan, A.A.; Al-Otaibi, H.N.; Labban, N.; AlShehri, H.A. Thermal-cycling, simulated brushing, and beverages induced color changes and roughness of CAD/CAM poly (methyl methacrylate) denture resins. Mater. Res. Express 2021, 8, 125401. [Google Scholar] [CrossRef]

- Pouryahya, R.; Ranjbar Omrani, L.; Ahmadi, E.; Rafeie, N.; Abbasi, M. Effect of charcoal-based dentifrices on surface roughness of an aged resin composite. Minerva Dent. Oral Sci. 2023, 72, 24–30. [Google Scholar] [CrossRef]

| Material | Shade | Composition | Manufacturer |

|---|---|---|---|

| Lava Ultimate Restorative | A2-HT | Bis-GMA, Bis-EMA, UDMA, and TEGDMA with zirconia and silica nanoparticles and silica/zirconia nanoclusters | 3M ESPE, St. Paul, MN, USA |

| Vita Enamic | 2M2-HT | Feldspathic ceramic containing aluminum oxide infiltrated by Bis-GMA and UDMA cross-linked polymers | Vita Zahnfabrik, H. Rauter GmbH & Co., Bad Säckingen, Germany |

| Cerasmart | A2-HT | UDMA, DMA, and Bis-MEPP with barium and silica glass nanoparticle fillers | GC America, Alsip, IL, USA |

| Crystal Ultra | A2-C | Ceramic-like inorganic silicate glass fillers infiltrated by Bis-GMA, UDMA, and BUDMA cross-linked polymers | Digital Dental, Scottsdale, AZ, USA |

| Surface Finishing Kits | Abbreviation | Manufacturer |

|---|---|---|

| LUSTER Meisinger Polisher | MP | Meisinger, Hager & Meisinger GmbH, Neuss, Germany |

| OPTIGLAZE™ | OG | GC America Inc., Alsip, IL, USA |

| LUSTER Meisinger Polisher + DirectDia Paste | MP+PP | SHOFU Dental GmbH, Ratingen, Germany |

| Variation Recourses | Sum of Squares | df | Mean Square | F | Sig |

|---|---|---|---|---|---|

| Materials | 27.66 | 3 | 9.22 | 45.92 | 0.000 * |

| surface finishing | 13.68 | 3 | 4.56 | 22.71 | 0.000 * |

| Materials × surface finishing | 3.61 | 9 | 0.40 | 2.00 | 0.042 * |

| Group | LU | VE | CS | CU | Overall |

|---|---|---|---|---|---|

| Control | 2.98 ± 0.36 | 1.75 ± 0.73 | 2.79 ± 0.23 | 2.06 ± 0.61 | 2.39 ± 0.49 |

| MP | 2.05 ± 0.36 | 1.37 ± 0.46 | 2.49 ± 0.34 | 1.92 ± 0.48 | 1.96 ± 0.43 |

| OG | 1.75 ± 0.38 | 1.21 ± 0.33 | 2.03 ± 0.51 | 1.69 ± 0.53 | 1.67 ± 0.44 |

| MP+PP | 2.00 ± 0.34 | 1.22 ± 0.32 | 2.29 ± 0.42 | 1.88 ± 0.31 | 1.85 ± 0.35 |

| Overall | 2.19 ± 0.38 | 1.39 ± 0.46 | 2.40 ± 0.38 | 1.89 ± 0.48 | 1.97 ± 0.43 |

| Materials | Surface Finishing | Dunnett’s Multiple Comparison | |||

|---|---|---|---|---|---|

| Control | MP | OG | MP+PP | ||

| LU | Control | 1 | |||

| MP | 0.000 * | 1 | |||

| OG | 0.000 * | 0.427 | 1 | ||

| MP+PP | 0.000 * | 1.000 | 0.440 | 1 | |

| VE | Control | 1 | |||

| MP | 0.597 | 1 | |||

| OG | 0.187 | 0.909 | 1 | ||

| MP+PP | 0.197 | 0.926 | 1.000 | 1 | |

| CS | Control | 1 | |||

| MP | 0.115 | 1 | |||

| OG | 0.002 * | 0.106 | 1 | ||

| MP+PP | 0.012 * | 0.749 | 0.699 | 1 | |

| CU | Control | 1 | |||

| MP | 0.987 | 1 | |||

| OG | 0.554 | 0.856 | 1 | ||

| MP+PP | 0.923 | 1.000 | 0.883 | 1 | |

| Variation Recourses | Sum of Squares | df | Mean Square | F | Sig |

|---|---|---|---|---|---|

| Materials | 21,212.23 | 3 | 7070.74 | 825.85 | 0.000 * |

| surface finishing | 22,925.81 | 3 | 7641.93 | 892.57 | 0.000 * |

| Materials × surface finishing | 1480.94 | 9 | 164.55 | 19.21 | 0.000 * |

| Group | LU | VE | CS | CU | Overall |

|---|---|---|---|---|---|

| Control | 136.17 ± 2.37 | 123.42 ± 3.07 | 141.02 ± 4.19 | 121.88 ± 2.08 | 130.62 ± 2.93 |

| MP | 139.70 ± 1.89 | 127.48 ± 2.51 | 145.39 ± 2.93 | 123.73 ± 2.93 | 134.08 ± 2.56 |

| OG | 156.75 ± 2.76 | 149.93 ± 2.59 | 174.17 ± 3.83 | 138.16 ± 3.03 | 154.75 ± 3.05 |

| MP+PP | 156.37 ± 4.29 | 146.12 ± 1.94 | 172.21 ± 2.80 | 138.63 ± 2.09 | 153.33 ± 2.78 |

| Overall | 147.25 ± 2.83 | 136.74 ± 2.53 | 158.20 ± 3.44 | 130.60 ± 2.53 | 143.19 ± 2.83 |

| Materials | Surface Finishing | Dunnett’s Multiple Comparison | |||

|---|---|---|---|---|---|

| Control | MP | OG | MP+PP | ||

| LU | Control | 1 | |||

| MP | 0.004 * | 1 | |||

| OG | 0.000 * | 0.000 * | 1 | ||

| MP+PP | 0.000 * | 0.000 * | 1.000 | 1 | |

| VE | Control | 1 | |||

| MP | 0.011 * | 1 | |||

| OG | 0.000 * | 0.000 * | 1 | ||

| MP+PP | 0.000 * | 0.000 * | 0.003 | 1 | |

| CS | Control | 1 | |||

| MP | 0.044 * | 1 | |||

| OG | 0.000 * | 0.000 * | 1 | ||

| MP+PP | 0.000 * | 0.000 * | 0.638 | 1 | |

| CU | Control | 1 | |||

| MP | 0.406 | 1 | |||

| OG | 0.000 * | 0.000 * | 1 | ||

| MP+PP | 0.000 * | 0.000 * | 0.998 | 1 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alhassan, M.; Maawadh, A.; Labban, N.; Shono, N.; Alebdi, A.; Alhijji, S.; BinMahfooz, A.M. Color Change, Biaxial Flexural Strength, and Fractographic Analysis of Resin-Modified CAD/CAM Ceramics Subjected to Different Surface Finishing Protocols. Appl. Sci. 2023, 13, 3415. https://doi.org/10.3390/app13063415

Alhassan M, Maawadh A, Labban N, Shono N, Alebdi A, Alhijji S, BinMahfooz AM. Color Change, Biaxial Flexural Strength, and Fractographic Analysis of Resin-Modified CAD/CAM Ceramics Subjected to Different Surface Finishing Protocols. Applied Sciences. 2023; 13(6):3415. https://doi.org/10.3390/app13063415

Chicago/Turabian StyleAlhassan, Mona, Ahmed Maawadh, Nawaf Labban, Nourah Shono, Ahmad Alebdi, Saleh Alhijji, and Abdulelah M. BinMahfooz. 2023. "Color Change, Biaxial Flexural Strength, and Fractographic Analysis of Resin-Modified CAD/CAM Ceramics Subjected to Different Surface Finishing Protocols" Applied Sciences 13, no. 6: 3415. https://doi.org/10.3390/app13063415

APA StyleAlhassan, M., Maawadh, A., Labban, N., Shono, N., Alebdi, A., Alhijji, S., & BinMahfooz, A. M. (2023). Color Change, Biaxial Flexural Strength, and Fractographic Analysis of Resin-Modified CAD/CAM Ceramics Subjected to Different Surface Finishing Protocols. Applied Sciences, 13(6), 3415. https://doi.org/10.3390/app13063415