Energy Efficiency Optimization in Onboard SWRO Desalination Plants Based on a Genetic Neuro-Fuzzy System

Abstract

1. Introduction

2. Materials and Methodology

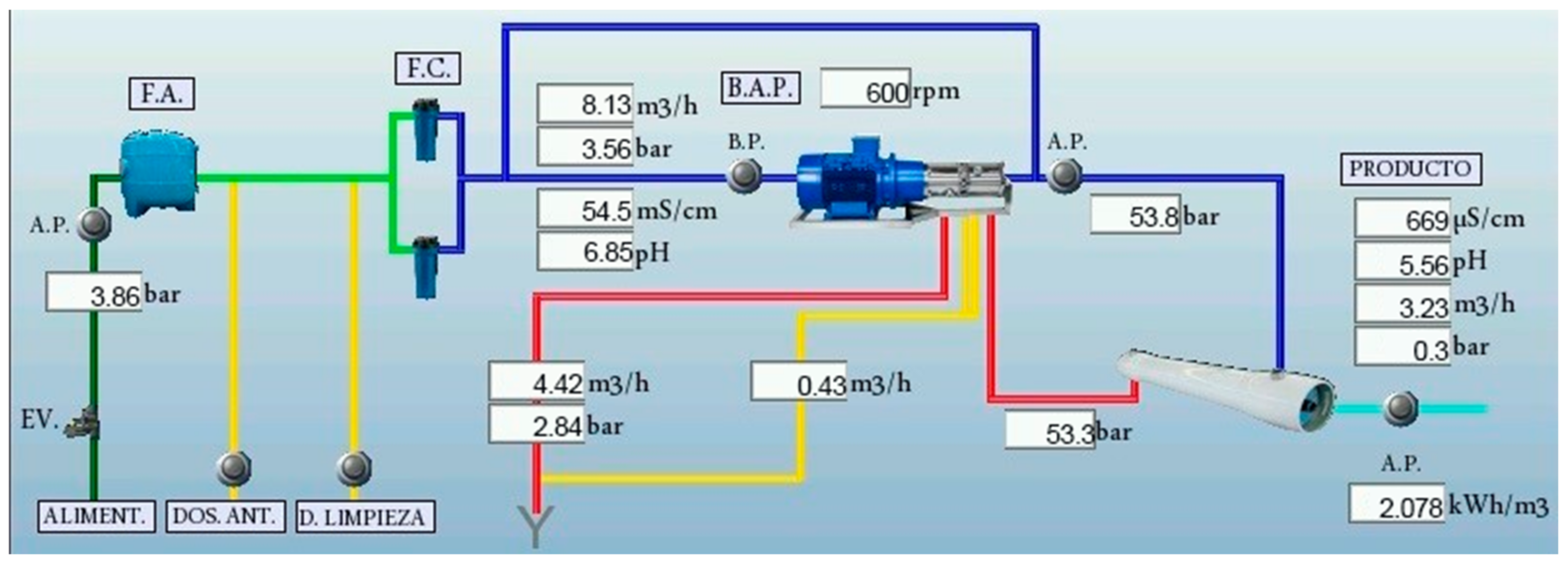

2.1. Desalination Plant and Data Collection

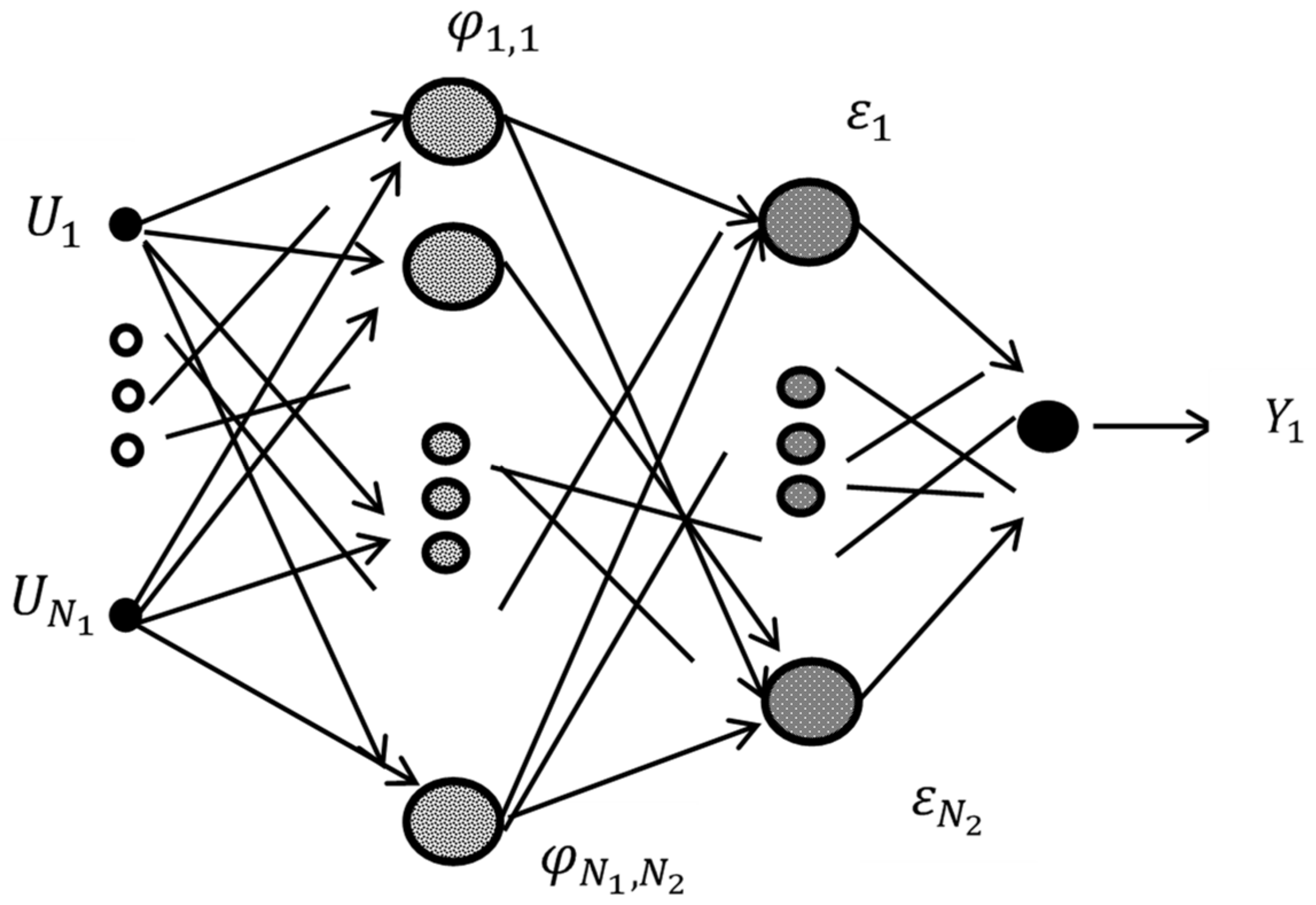

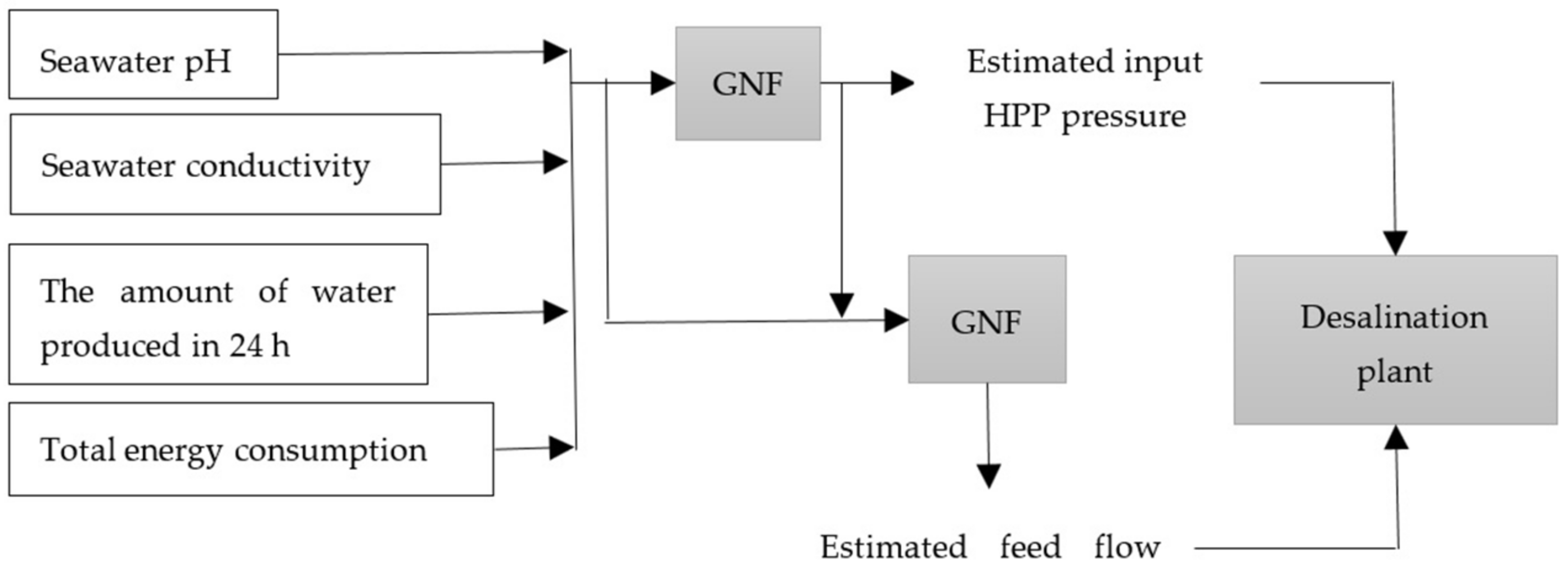

2.2. Artificial Intelligence Method

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Krile, S. Fresh Water Supply from Different Sources in the Shipping. Procedia Eng. 2016, 149, 190–196. [Google Scholar] [CrossRef]

- WHO. Guidelines for Drinking-Water Quality, 4th Edition, Incorporating the 1st Addendum. 2017. Available online: http://www.who.int/water_sanitation_health/publications/drinking-water-quality-guidelines-4-including-1st-addendum/en/ (accessed on 4 October 2022).

- World Health Organization. A Global Overview of National Regulations and Standards for Drinking-Water Quality; World Health Organization: Geneva, Switzerland, 2018. [Google Scholar]

- Garcia, C.; Mestre-Runge, C.; Morán-Tejeda, E.; Lorenzo-Lacruz, J.; Tirado, D. Impact of Cruise Activity on Freshwater Use in the Port of Palma (Mallorca, Spain). Water 2020, 12, 1088. [Google Scholar] [CrossRef]

- Shammi, M.; Mostafizur, M.R. Desalination technologies and potential mathematical modeling for sustainable water–energy nexus. Water Eng. Model. Math. Tools 2021, 251–269. [Google Scholar] [CrossRef]

- Macharia, P.; Kreuzinger, N.; Kitaka, N. Applying the Water-Energy Nexus for Water Supply—A Diagnostic Review on Energy Use for Water Provision in Africa. Water 2020, 12, 2560. [Google Scholar] [CrossRef]

- Balcombe, P.; Brierley, J.; Lewis, C.; Skatvedt, L.; Speirs, J.; Hawkes, A.; Staffell, I. How to decarbonise international shipping: Options for fuels, technologies and policies. Energy Convers. Manag. 2019, 182, 72–88. [Google Scholar] [CrossRef]

- Padrón, I.; Avila, D.; Marichal, G.N.; Rodríguez, J.A. Assessment of Hybrid Renewable Energy Systems to supplied energy to Autonomous Desalination Systems in two islands of the Canary Archipelago. Renew. Sustain. Energy Rev. 2019, 101, 221–230. [Google Scholar] [CrossRef]

- Zhong, R.Y.; Xu, X.; Klotz, E.; Newman, S.T. Intelligent Manufacturing in the Context of Industry 4.0: A Review. Engineering 2017, 3, 616–630. [Google Scholar] [CrossRef]

- Alshehri, M.; Kumar, M.; Bhardwaj, A.; Mishra, S.; Gyani, J. Deep Learning Based Approach to Classify Saline Particles in Sea Water. Water 2021, 13, 1251. [Google Scholar] [CrossRef]

- Mitchell, T. Machine Learning; McGraw Hill: New York, NY, USA, 1997; Volume 70428077. [Google Scholar]

- Hernández, A.; Castejón, C.; García-Prada, J.C.; Padrón, I.; Marichal, G.N. Wavelet Packets Transform processing and Genetic Neuro-Fuzzy classification to detect faulty bearings. Adv. Mech. Eng. 2019, 11, 1–10. [Google Scholar] [CrossRef]

- Marichal, G.N.; Ávila, D.; Hernández, Á.; Padrón, I.; Castejón, C. Feature Extraction from Indirect Monitoring in Marine Oil Separation Systems. Sensors 2018, 18, 3159. [Google Scholar] [CrossRef]

- Marichal, G.N.; del Castillo, M.L.; López, J.; Padrón, I.; Artés, M. An Artificial Intelligence Approach for Gears Diagnostics in AUVs. Sensors 2016, 16, 529. [Google Scholar] [CrossRef]

- Plasencia, G.N.M.; Camacho-Espino, J.; Prats, D.; Suárez, B.P. Machine Learning Models Applied to Manage the Operation of a Simple SWRO Desalination Plant and Its Application in Marine Vessels. Water 2021, 13, 2547. [Google Scholar] [CrossRef]

- Azad, A.; Aghaei, E.; Jalali, A.; Ahmadi, P. Multi-objective optimization of a solar chimney for power generation and water desalination using neural network. Enegry Convers. Manag. 2021, 238, 114152. [Google Scholar] [CrossRef]

- Pohl, R.; Kaltschmitt, M.; Höllander, R. Investigation of different operational strategies for the variable operation of a simple reverse osmosis unit. Desalination 2009, 249, 1280–1287. [Google Scholar] [CrossRef]

- Cabrera, P.; Carta, J.A.; González, J.; Melián, G. Wind-driven SWRO desalination prototype with and without batteries: A performance simulation using Machine Learning Models. Desalination 2018, 435, 77–96. [Google Scholar] [CrossRef]

- Avila, D.; Marichal, G.N.; Hernández, Á.; Luis, F.S. Hybrid renewable energy systems for energy supply to autonomous desalination systems on Isolated Islands. Des. Anal. Appl. Renew. Energy Syst. 2021, 23–51. [Google Scholar] [CrossRef]

- Al Aani, S.; Bonny, T.; Hasan, S.W.; Hilal, N. Can machine language and artificial intelligence revolutionize process automatio for water treatment and desalination? Desalination 2019, 458, 84–96. [Google Scholar] [CrossRef]

- Cordón, O.; Gomide, F.; Herrera, F.; Hoffmann, F.; Magdalena, L. Ten years of genetic fuzzy systems: Current framework and new trends. Fuzzy Sets Syst. 2004, 141, 5–31. [Google Scholar] [CrossRef]

- Nobre, F.S.M. Genetic-neuro-fuzzy systems: A promising fusion. IEEE Int. Conf. Fuzzy Syst. 1995, 1, 259–266. [Google Scholar] [CrossRef]

- Jang, J.S.R. ANFIS: Adaptive-Network-Based Fuzzy Inference System. IEEE Trans. Syst. Man Cybern 1993, 23, 665–685. [Google Scholar] [CrossRef]

- Kohonen, T. The Self-Organizing Map. Proc. IEEE 1990, 78, 1464–1480. [Google Scholar] [CrossRef]

- Rajasekaran, S.; Pai, G.A.V. Neural Networks, Fuzzy Logic and Genetic Algorithm: Synthesis and Applications; PHI Learning Pvt. Ltd.: New Delhi, India, 2003. [Google Scholar]

- Chen, S.; Cowan, C.F.N.; Grant, P.M. Orthogonal Least Squares Learning Algorithm for Radial. IEEE Trans. Neural Netw. 1991, 2, 302–309. Available online: https://core.ac.uk/download/pdf/1497907.pdf (accessed on 5 October 2022).

| Parameter | Unit Values/Characteristics |

|---|---|

| Production capacity | 80–100 m3/day |

| High-pressure pump (HPP) operating pressure | 20.8–57 Bar |

| HPP maximum pressure | 57 Bar |

| HPP nominal RPM | 600 |

| Feed flow rate | 8.01–10.15 m3/h |

| Permeate flow rate | 3.09–4.15 m3/h |

| General energy consumption | 3.8–9 kWh |

| Total specific energy consumption (Salino pressure center) | 1.97–2.5 kWh/m3 |

| Type of membrane | Hydranautics SWC4 MAX (Spiral wound) |

| Permeate recovery rate | 34–43% |

| Sample Number | Seawater pH | Seawater Conductivity (mS/cm) | Feed Flow Rate (m3/h) | HPP Outlet Pressure (Bar) | Permeate Conductivity (μS/cm) | Permeate Flow Rate (m3/h) | Total Energy Consumption (kWh) |

|---|---|---|---|---|---|---|---|

| 1 | 6.85 | 54.5 | 8.13 | 53.8 | 669 | 3.23 | 6.712 |

| … | … | … | … | … | … | … | … |

| 300 | 6.86 | 54.2 | 8.11 | 53.7 | 661 | 3.32 | 6.684 |

| … | … | … | … | … | … | … | … |

| 500 | 6.87 | 53.6 | 9.18 | 55.2 | 592 | 3.63 | 7.794 |

| … | … | … | … | … | … | … | … |

| 580 | 6.85 | 53.6 | 9.81 | 56.2 | 561 | 3.89 | 8.568 |

| … | … | … | … | … | … | … | … |

| 660 | 6.85 | 54.1 | 8.8 | 54.7 | 619 | 3.57 | 7.393 |

| … | … | … | … | … | … | … | … |

| 900 | 6.86 | 54.3 | 8.09 | 53.9 | 669 | 3.2 | 6.67 |

| … | … | … | … | … | … | … | … |

| 1149 | 6.85 | 54.6 | 8.13 | 53.6 | 658 | 3.24 | 6.678 |

| Genetic Neuro-Fuzzy Output (m3/h) | Real Feed Flow Rate (m3/h) | Genetic Neuro-Fuzzy Output (Bar) | Real HPP (Bar) |

|---|---|---|---|

| 8.7748 | 8.76 | 56.584 | 56.2 |

| 8.1005 | 8.11 | 53.7296 | 53.6 |

| 9. 7989 | 9.83 | 53.7027 | 54 |

| 8.1168 | 8.13 | 53.733 | 53.8 |

| 8.1023 | 8.10 | 56.0792 | 56.1 |

| 9.1191 | 9.13 | 53.74 | 53.5 |

| 9.1303 | 9.11 | 53.7342 | 53.7 |

| 9.4670 | 9.46 | 54.7407 | 54.6 |

| 8.7748 | 8.81 | 53.7927 | 53.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

López, Á.H.; Camacho-Espino, J.; Peñate Suárez, B.; Plasencia, G.N.M. Energy Efficiency Optimization in Onboard SWRO Desalination Plants Based on a Genetic Neuro-Fuzzy System. Appl. Sci. 2023, 13, 3392. https://doi.org/10.3390/app13063392

López ÁH, Camacho-Espino J, Peñate Suárez B, Plasencia GNM. Energy Efficiency Optimization in Onboard SWRO Desalination Plants Based on a Genetic Neuro-Fuzzy System. Applied Sciences. 2023; 13(6):3392. https://doi.org/10.3390/app13063392

Chicago/Turabian StyleLópez, Ángela Hernández, Jorge Camacho-Espino, Baltasar Peñate Suárez, and Graciliano Nicolás Marichal Plasencia. 2023. "Energy Efficiency Optimization in Onboard SWRO Desalination Plants Based on a Genetic Neuro-Fuzzy System" Applied Sciences 13, no. 6: 3392. https://doi.org/10.3390/app13063392

APA StyleLópez, Á. H., Camacho-Espino, J., Peñate Suárez, B., & Plasencia, G. N. M. (2023). Energy Efficiency Optimization in Onboard SWRO Desalination Plants Based on a Genetic Neuro-Fuzzy System. Applied Sciences, 13(6), 3392. https://doi.org/10.3390/app13063392