Improving the Creep Resistance of Hardened Cement Paste through the Addition of Wollastonite Microfibers: Evaluation Using the Micro-Indentation Technique

Abstract

1. Introduction

2. Materials and Experimental Methods

2.1. Materials and Mixture Proportions

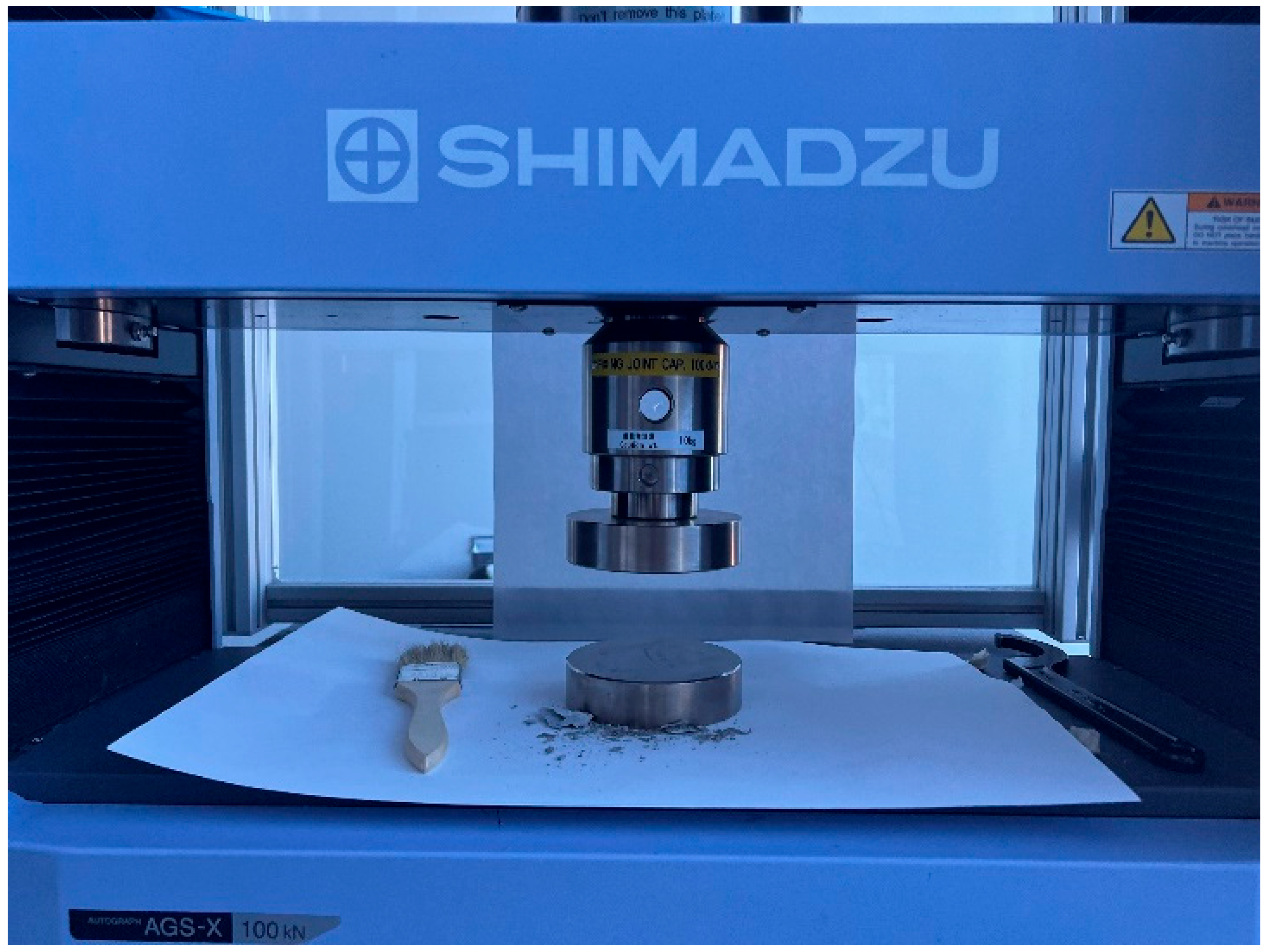

2.2. Compressive Strength Experiment

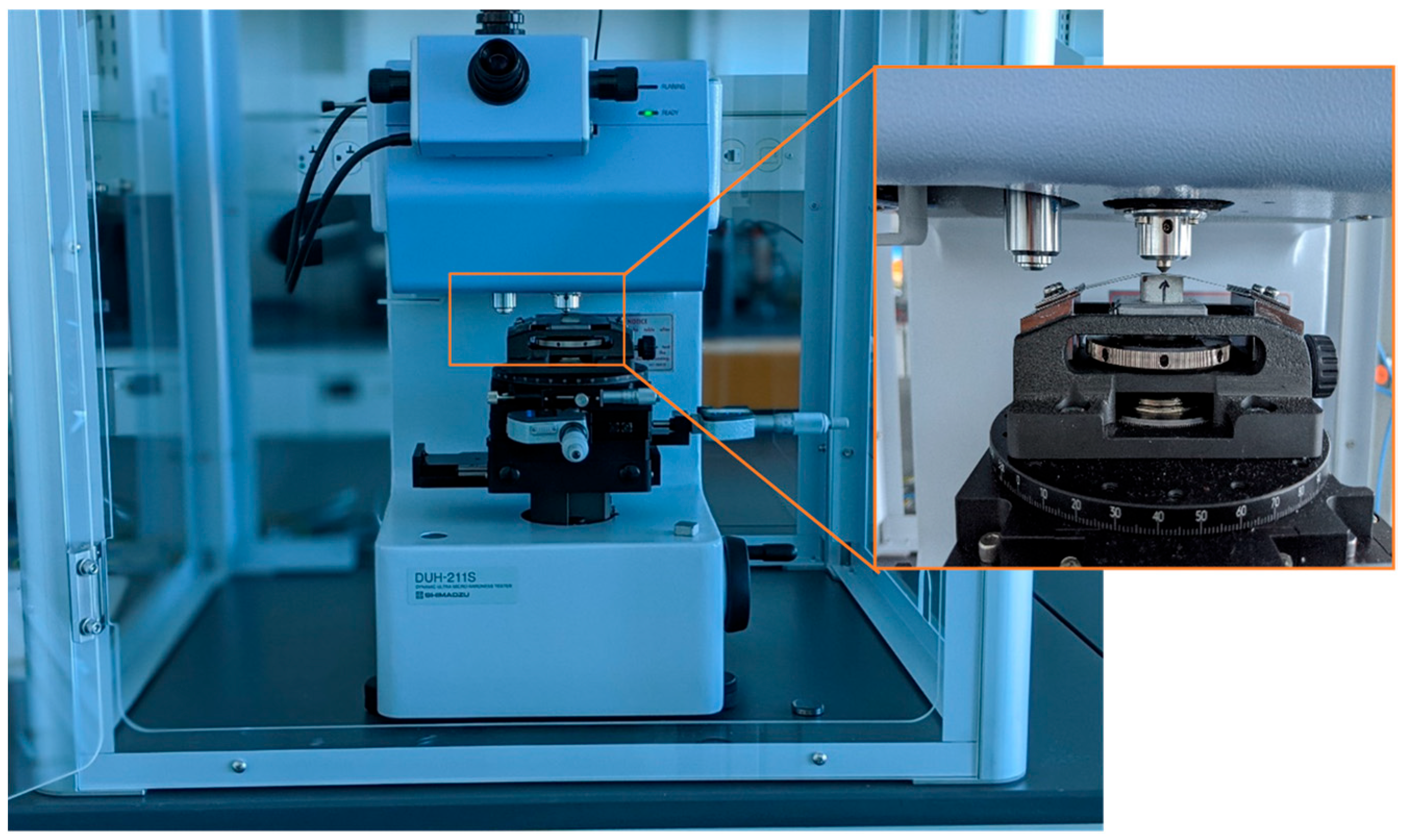

2.3. Microindentation for Creep Response Evaluation

3. Results and Discussion

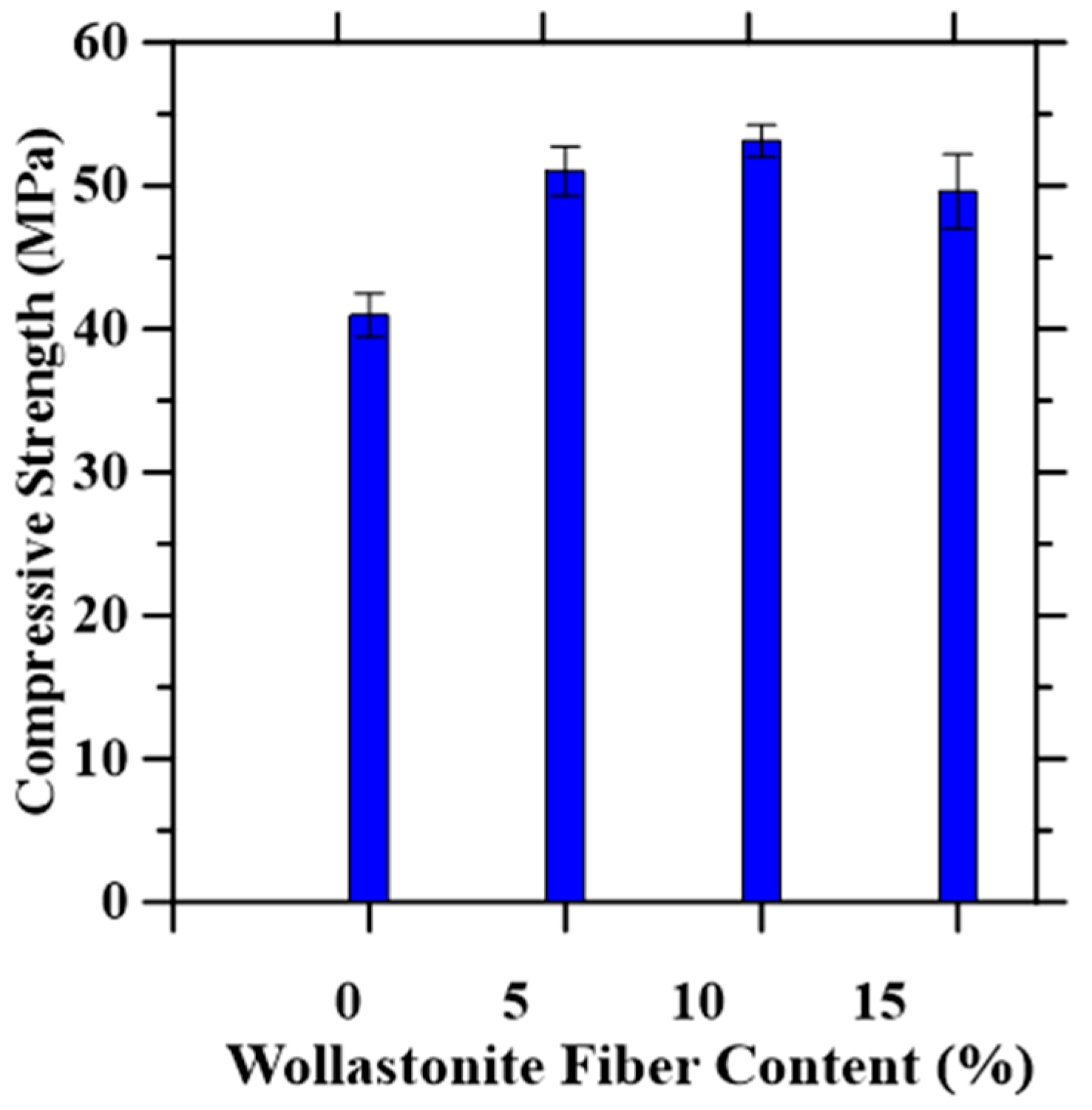

3.1. Compressive Strength

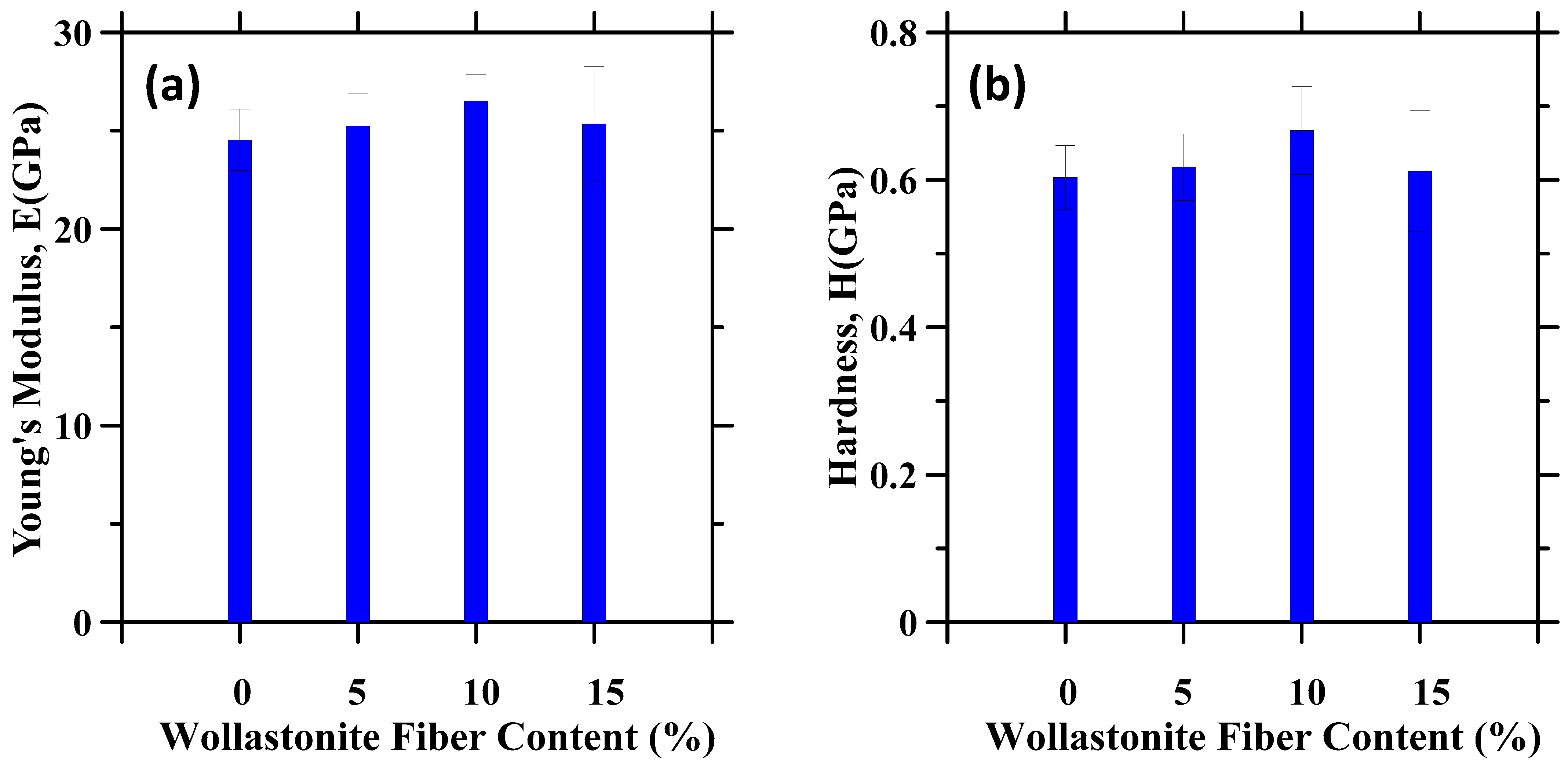

3.2. Creep Response from Micro Indentation Experiments

4. Conclusions

- The compressive strength of the hardened cement paste increases with the introduction of wollastonite fibers into the matrix. The mixture containing 10% wollastonite fibers as mass-based cement replacement was found to be optimal in terms of compressive strength.

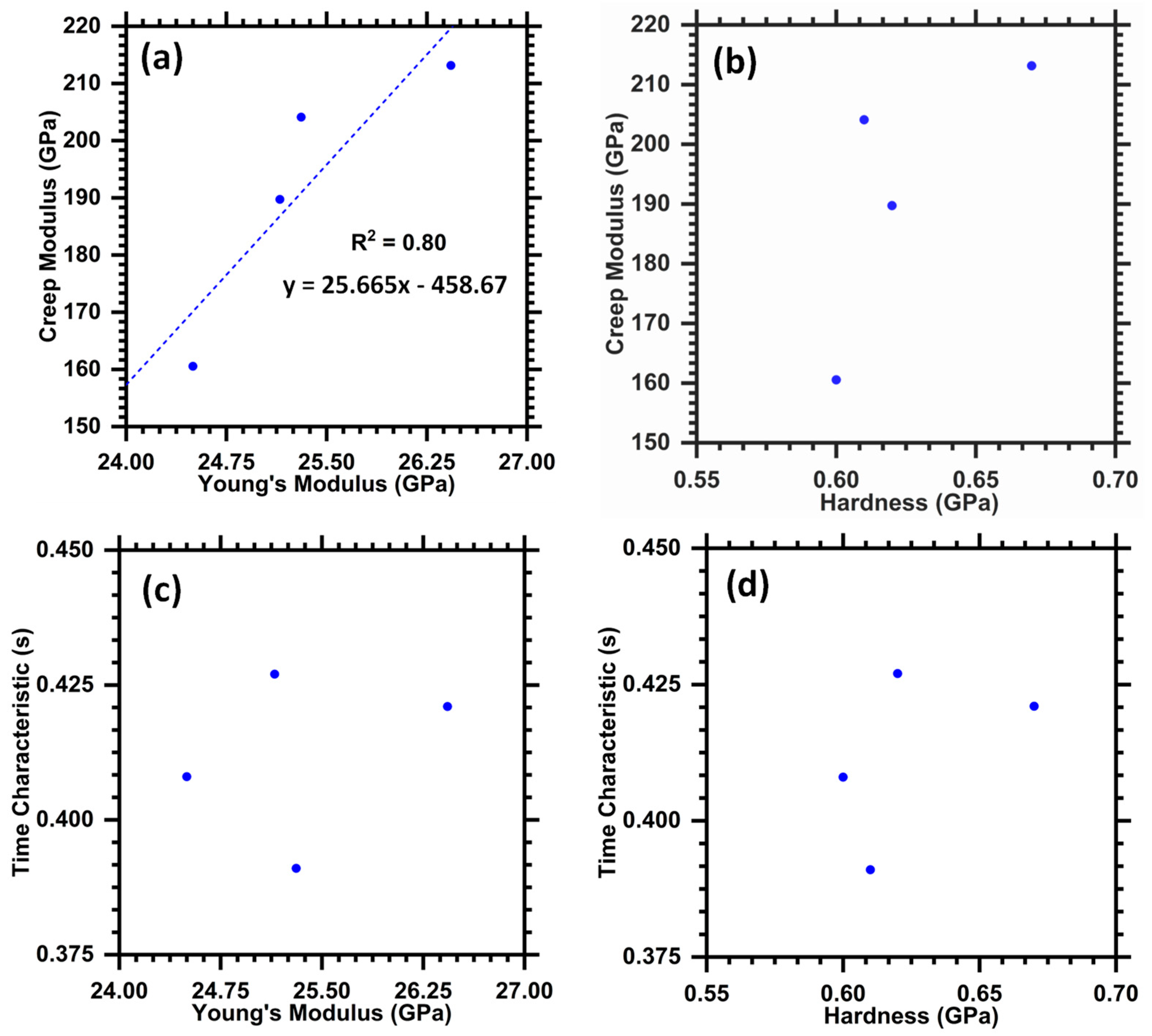

- Enhancement in the indentation modulus and hardness was observed with up to 10% wollastonite fiber content. While the average elastic modulus increased from 24 GPa to 26 GPa with 10% wollastonite fiber incorporation with respect to control-hardened cement paste, the average indentation hardness increased from 0.6 GPa to 0.68 GPa for the same dosage of wollastonite fibers.

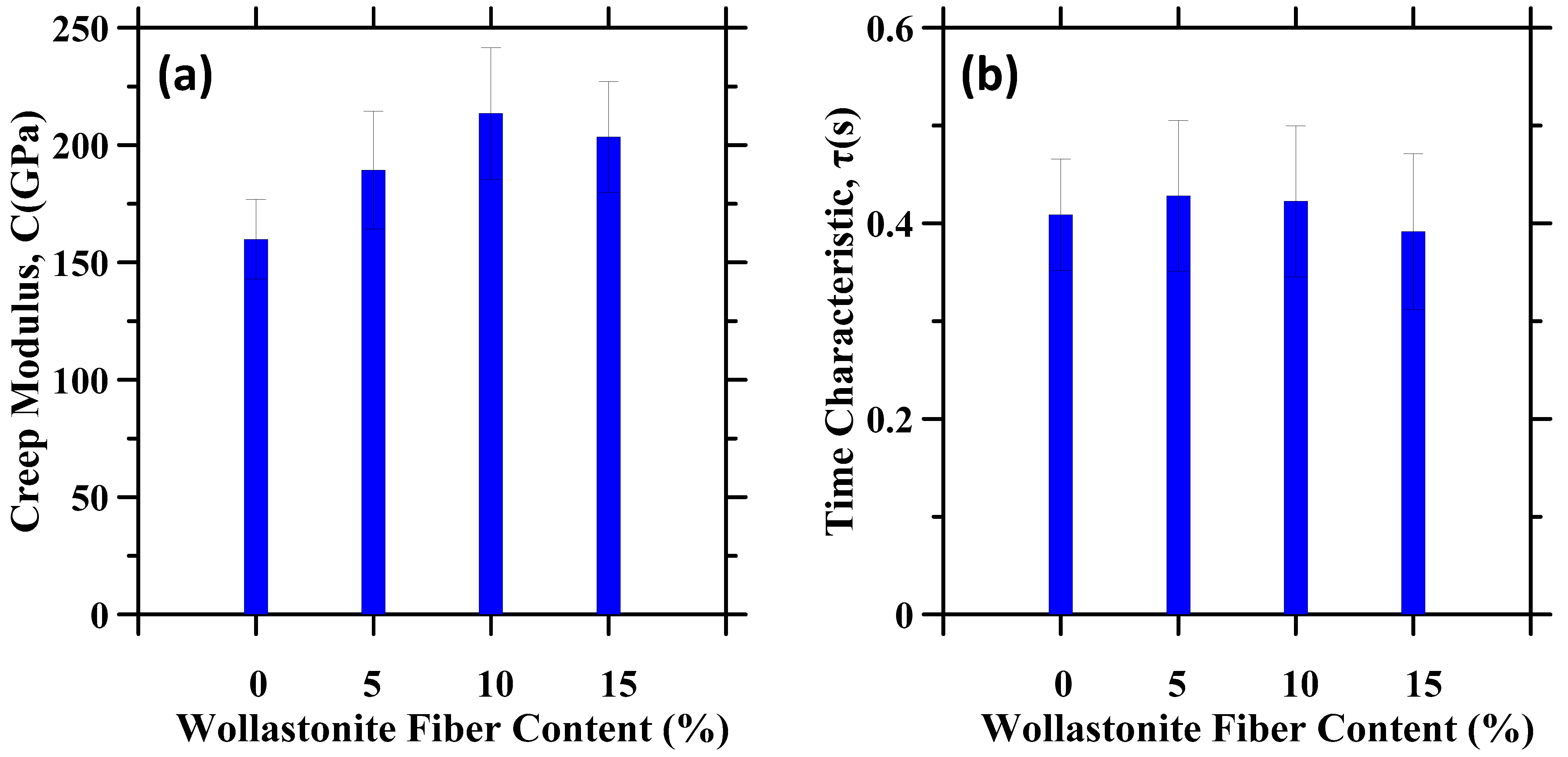

- The creep modulus showed significant improvement with increasing wollastonite content up to 10%. This can be explained by two facts. First, there are chemical similarities between the wollastonite fiber and the C-S-H in cement paste. Because of this chemical similarity, wollastonite fibers naturally have better compatibility and bonding with the cement paste as explored and established elsewhere [62,63,64,65]. A better bond between the fiber and the matrix likely translates into better creep performance. Second, the micro-reinforcing effect [39] of the wollastonite fibers arrests creep-induced microcracking in the hardened cement paste thereby improving the creep-tolerance of the composite. Overall, the significantly higher creep modulus observed in the wollastonite fiber reinforced samples compared to the control samples suggests that the incorporation of fibers has effectively reinforced the material, enabling it to better withstand sustained loading and resist excessive deformation. Besides, the practical applications of wollastonite in terms of significant cement replacement also reduce cement consumption, which causes 5% of global dioxide emissions.

- The fact that no significant difference in the time characteristic (i.e., the shape of the creep curve) is observed between the control and fiber reinforced samples suggests that the fibers have not significantly affected the time-dependent behavior of the material. This means that the material still likely undergoes the same three stages of deformation (primary, secondary, and tertiary creep) over time under sustained loading, but with a higher resistance to deformation.

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hu, Z.; Wyrzykowski, M.; Griffa, M.; Scrivener, K.; Lura, P. Young’s modulus and creep of calcium-silicate-hydrate compacts measured by microindentation. Cem. Concr. Res. 2020, 134, 106104. [Google Scholar] [CrossRef]

- Vandamme, M.; Ulm, F.-J. Nanogranular origin of concrete creep. Proc. Natl. Acad. Sci. USA 2009, 106, 10552–10557. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.J.; Sorelli, L.; Vandamme, M.; Ulm, F.-J.; Chanvillard, G. A Coupled Nanoindentation/SEM-EDS Study on Low Water/Cement Ratio Portland Cement Paste: Evidence for C-S-H/Ca(OH)2Nanocomposites. J. Am. Ceram. Soc. 2010, 93, 1484–1493. [Google Scholar] [CrossRef]

- Zhou, Y.; Chen, W.; Yan, P. Measurement and modeling of creep property of high-strength concrete considering stress relaxation effect. J. Build. Eng. 2022, 56, 104726. [Google Scholar] [CrossRef]

- Li, H.; Li, Y.; Jin, C.; Liu, J.; Liu, Y.; Mu, J. Meso-scale modelling of the effect of coarse aggregate properties on the creep of concrete. J. Build. Eng. 2022, 54, 104660. [Google Scholar] [CrossRef]

- Li, L.; Dabarera, A.G.; Dao, V. Basic tensile creep of concrete with and without superabsorbent polymers at early ages. Constr. Build. Mater. 2022, 320, 126180. [Google Scholar] [CrossRef]

- Ichinose, L.; Watanabe, E.; Nakai, H. An experimental study on creep of concrete filled steel pipes. J. Constr. Steel Res. 2001, 57, 453–466. [Google Scholar] [CrossRef]

- Giorla, A.B.; Dunant, C.F. Microstructural effects in the simulation of creep of concrete. Cem. Concr. Res. 2018, 105, 44–53. [Google Scholar] [CrossRef]

- Wittmann, F.H.; Bazgant, Z.P. Creep and Shrinkage in Concrete Structures; John Wiley & Sons: Chichester, UK, 1982. [Google Scholar]

- Ross, A.D. Creep of Concrete under Variable Stress. ACI J. Proc. 1958, 54, 739–758. [Google Scholar] [CrossRef]

- Gillen, M. Short-term creep of concrete at elevated temperatures. Fire Mater. 1981, 5, 142–148. [Google Scholar] [CrossRef]

- Bazant, Z.P.; Baweja, S. Creep and Shrinkage Prediction Model for Analysis and Design of Concrete Structures: Model B3-Short Form. Spec. Publ. 2000, 194, 85–100. [Google Scholar] [CrossRef]

- Bažant, Z.P.; Hauggaard, A.B.; Baweja, S.; Ulm, F.J. Microprestress-Solidification Theory for Con-crete Creep. I: Aging and Drying Effects. J. Eng. Mech. 1997, 123, 1188–1194. [Google Scholar]

- Schneider, U.; Piasta, J.; Nägele, E.; Piasta, W. Stress corrosion of cementitious materials in sulphate solutions. Mater. Struct. 1990, 23, 110–115. [Google Scholar] [CrossRef]

- Dilger, W.H. Creep Analysis of Prestressed Concrete Structures Using Creep-Transformed Section Properties. PCI J. 1982, 27, 98–119. [Google Scholar] [CrossRef]

- Bazant, Z.P.; Hubler, M.; Yu, Q. Pervasiveness of Excessive Segmental Bridge Deflections: Wake-Up Call for Creep. ACI Struct. J. 2011, 108, 766–774. [Google Scholar] [CrossRef]

- Sprince, A.; Pakrastinsh, L.; Korjakins, A. Creep behavior of high performance fiber reinforced concrete (HPFRC). In Proceedings of the 4th International Conference Civil Engineering’13, Jelgava, Latvia, 16–17 May 2013. [Google Scholar]

- Mallick, S.; Anoop, M.B.; Rao, K.B. Creep of cement paste containing fly ash—An investigation using microindentation tech-nique. Cem. Concr. Res. 2019, 121, 21–36. [Google Scholar] [CrossRef]

- Mallick, S.; Anoop, M.B.; Rao, K.B. Early age creep of cement paste—Governing mechanisms and role of water-A mi-croindentation study. Cem. Concr. Res. 2019, 116, 284–298. [Google Scholar] [CrossRef]

- Mangat, P.S.; Azari, M.M. Compression creep behaviour of steel fibre reinforced cement composites. Mater. Struct. 1986, 19, 361–370. [Google Scholar] [CrossRef]

- Mangat, P.S.; Azari, M.M. A theory for the creep of steel fibre reinforced cement matrices under compression. J. Mater. Sci. 1985, 20, 1119–1133. [Google Scholar] [CrossRef]

- Bissonnette, B.; Pigeon, M. Tensile creep at early ages of ordinary, silica fume and fiber reinforced concretes. Cem. Concr. Res. 1995, 25, 1075–1085. [Google Scholar] [CrossRef]

- Rouse, J.M.; Billington, S.L. Creep and Shrinkage of High-Performance Fiber-Reinforced Cementitious Composites. ACI Mater. J. 2007, 104, 129–136. [Google Scholar]

- Zhang, J. Modeling of the influence of fibers on creep of fiber reinforced cementitious composite. Compos. Sci. Technol. 2003, 63, 1877–1884. [Google Scholar] [CrossRef]

- Garas, V.Y.; Kahn, L.F.; Kurtis, K.E. Short-term tensile creep and shrinkage of ultra-high performance concrete. Cem. Concr. Compos. 2009, 31, 147–152. [Google Scholar] [CrossRef]

- Bong, S.H.; Nematollahi, B.; Xia, M.; Ghaffar, S.H.; Pan, J.; Dai, J.-G. Properties of additively manufactured geopolymer incorporating mineral wollastonite microfibers. Constr. Build. Mater. 2022, 331, 127282. [Google Scholar] [CrossRef]

- Mohiuddin, M.G.; Malagavelli, V.; Balguri, P.K. Influence of wollastonite—GGBS on properties of ternary blended self compacting concrete. Mater. Today Proc. 2022, 62, 3027–3032. [Google Scholar] [CrossRef]

- Dutkiewicz, M.; Yücel, H.E.; Yıldızhan, F. Evaluation of the Performance of Different Types of Fibrous Concretes Produced by Using Wollastonite. Materials 2022, 15, 6904. [Google Scholar] [CrossRef]

- Virta, R.L.; Revette, D. Wollastonite. Min. Eng. 2006, 58, 6162. [Google Scholar]

- Azarov, G.M.; Maiorova, E.V.; Oborina, M.A.; Belyakov, A.V. Wollastonite raw materials and their applications (a review). Glas. Ceram. 1995, 52, 237–240. [Google Scholar] [CrossRef]

- Chan, J.X.; Wong, J.F.; Hassan, A.; Mohamad, Z.; Othman, N. Mechanical properties of wollastonite reinforced thermoplastic composites: A review. Polym. Compos. 2020, 41, 395–429. [Google Scholar] [CrossRef]

- Somtürk, S.M.; Emek, I.Y.; Senler, S.; Eren, M.; Kurt, S.Z.; Orbay, M. Effect of wollastonite extender on the properties of exterior acrylic paints. Prog. Org. Coat. 2016, 93, 34–40. [Google Scholar] [CrossRef]

- Demidenko, N.I.; Podzorova, L.I.; Rozanova, V.S.; Skorokhodov, V.A.; Shevchenko, V. Wollastonite as a New Kind of Natural Material (A Review). Glas. Ceram. 2002, 58, 308–311. [Google Scholar] [CrossRef]

- Nikonova, N.S.; Tikhomirova, I.N.; Belyakov, A.V.; Zakharov, A.I. Wollastonite in Silicate Matrices. Glas. Ceram. 2003, 60, 342–346. [Google Scholar] [CrossRef]

- Low, N.M.; Beaudoin, J.J. The effect of wollastonite micro-fibre aspect ratio on reinforcement of Portland cement-based ma-trices. Cem. Concr. Res. 1993, 23, 981–989. [Google Scholar] [CrossRef]

- Low, N.M.; Beaudoin, J.J. Mechanical properties of high performance cement binders reinforced with wollastonite micro-fibres. Cem. Concr. Res. 1992, 22, 981–989. [Google Scholar] [CrossRef]

- Dey, V.; Kachala, R.; Bonakdar, A.; Mobasher, B. Mechanical properties of micro and sub-micron wollastonite fibers in ce-mentitious composites. Constr. Build. Mater. 2015, 82, 351–359. [Google Scholar] [CrossRef]

- Dey, V.; Kachala, R.; Bonakdar, A.; Neithalath, N.; Mobasher, B. Quantitative 2D Restrained Shrinkage Cracking of Cement Paste with Wollastonite Microfibers. J. Mater. Civ. Eng. 2016, 28, 04016082. [Google Scholar] [CrossRef]

- Doner, S.; Lyngdoh, G.A.; Nayak, S.; Das, S. Fracture response of wollastonite fiber-reinforced cementitious composites: Evaluation using micro-indentation and finite element simulation. Ceram. Int. 2022, 48, 15493–15503. [Google Scholar] [CrossRef]

- Lyngdoh, G.; Doner, S.; Nayak, S.; Das, S. Finite Element-Based Numerical Simulations to Evaluate the Influence of Wollastonite Microfibers on the Dynamic Compressive Behavior of Cementitious Composites. Materials 2021, 14, 4435. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Galin, L.A. Contact Problems: The Legacy of L.A. Galin; Springer: Dordrecht, The Netherlands, 2008. [Google Scholar] [CrossRef]

- Das, S.; Yang, P.; Singh, S.S.; Mertens, J.C.; Xiao, X.; Chawla, N.; Neithalath, N. Effective properties of a fly ash geopolymer: Synergistic application of X-ray synchrotron tomography, nanoindentation, and homogenization models. Cem. Concr. Res. 2015, 78, 252–262. [Google Scholar] [CrossRef]

- Vandamme, M.; Ulm, F.-J. Nanoindentation investigation of creep properties of calcium silicate hydrates. Cem. Concr. Res. 2013, 52, 38–52. [Google Scholar] [CrossRef]

- Wei, Y.; Gao, X.; Liang, S. Nanoindentation-based study of the micro-mechanical properties, structure, and hydration degree of slag-blended cementitious materials. J. Mater. Sci. 2016, 51, 3349–3361. [Google Scholar] [CrossRef]

- Zhu, W.; Hughes, J.J.; Bicanic, N.; Pearce, C.J. Nanoindentation mapping of mechanical properties of cement paste and natural rocks. Mater. Charact. 2007, 58, 1189–1198. [Google Scholar] [CrossRef]

- Pichler, C.; Lackner, R. Identification of Logarithmic-Type Creep of Calcium-Silicate-Hydrates by Means of Nanoindentation. Strain 2009, 45, 17–25. [Google Scholar] [CrossRef]

- Jones, C.A.; Grasley, Z.C. Short-term creep of cement paste during nanoindentation. Cem. Concr. Compos. 2011, 33, 12–18. [Google Scholar] [CrossRef]

- Constantinides, G.; Ravi Chandran, K.; Ulm, F.-J.; Van Vliet, K. Grid indentation analysis of composite microstructure and mechanics: Principles and validation. Mater. Sci. Eng. A 2006, 430, 189–202. [Google Scholar] [CrossRef]

- Pourbeik, P.; Beaudoin, J.J.; Alizadeh, R.; Raki, L. Creep of 45 year old cement paste: The role of structural water. Mater. Struct. 2016, 49, 739–750. [Google Scholar] [CrossRef]

- Liang, S.; Wei, Y.; Gao, X. Strain-rate sensitivity of cement paste by microindentation continuous stiffness measurement: Im-plication to isotache approach for creep modeling. Cem. Concr. Res. 2017, 100, 84–95. [Google Scholar] [CrossRef]

- Frech-Baronet, J.; Sorelli, L.; Charron, J.P. New evidences on the effect of the internal relative humidity on the creep and re-laxation behaviour of a cement paste by micro-indentation techniques. Cem. Concr. Res. 2017, 91, 39–51. [Google Scholar] [CrossRef]

- Baronet, J.; Sorelli, L.; Charron, J.-P.; Vandamme, M.; Sanahuja, J. A two-scale method to rapidly characterize the logarithmic basic creep of concrete by coupling microindentation and uniaxial compression creep test. Cem. Concr. Compos. 2022, 125, 104274. [Google Scholar] [CrossRef]

- Li, Y.; Liu, Y.; Jin, C.; Mu, J.; Li, H.; Liu, J. Multi-scale creep analysis of river sand and manufactured sand concrete considering the influence of ITZ. Constr. Build. Mater. 2022, 344, 128175. [Google Scholar] [CrossRef]

- Chen, Z.; Sorelli, L.; Benard, P. Creep microindentation of low-density oil well cement and the implication on radial cracking risk of cement sheath. J. Pet. Sci. Eng. 2023, 220, 111155. [Google Scholar] [CrossRef]

- Li, Y.; Liu, Y.; Wang, Z.; Li, H.; Mu, J. Effect of phases on the creep properties of cement paste based on indentation test and homogenization scheme. Constr. Build. Mater. 2022, 317, 125957. [Google Scholar] [CrossRef]

- ASTM International. Standard Test Method for Compressive Strength of Hydraulic Cement Mortars, ASTM International. 2020. Available online: https://compass.astm.org/document/?contentCode=ASTM%7CC0109_C0109M-20B%7Cen-US (accessed on 29 December 2022).

- Xu, S.; Feng, Y.; Liu, J.; Zeng, Q. Micro indentation fracture of cement paste assessed by energy-based method: The method improvement and affecting factors. Constr. Build. Mater. 2020, 231, 117136. [Google Scholar] [CrossRef]

- Borodich, F.M.; Keer, L.M. Evaluation of elastic modulus of materials by adhesive (no–slip) nano–indentation. Proc. R. Soc. A Math. Phys. Eng. Sci. 2004, 460, 507–514. [Google Scholar] [CrossRef]

- Vandamme, M.; Tweedie, C.A.; Constantinides, G.; Ulm, F.-J.; Van Vliet, K.J. Quantifying plasticity-independent creep compliance and relaxation of viscoelastoplastic materials under contact loading. J. Mater. Res. 2012, 27, 302–312. [Google Scholar] [CrossRef]

- Ulm, F.J.; Vandamme, M.; Bobko, C.; Alberto Ortega, J.; Tai, K.; Ortiz, C. Statistical Indentation Techniques for Hydrated Nanocom-posites: Concrete, Bone, and Shale. J. Am. Ceram. Soc. 2007, 90, 2677–2692. [Google Scholar] [CrossRef]

- Nair, N.A.; Sairam, V. Research initiatives on the influence of wollastonite in cement-based construction material—A review. J. Clean. Prod. 2021, 283, 124665. [Google Scholar] [CrossRef]

- Sanna, S.; Schmidt, W.G.; Thissen, P. Formation of Hydroxyl Groups at Calcium-Silicate-Hydrate (C-S-H): Coexistence of Ca–OH and Si–OH on Wollastonite(001). J. Phys. Chem. C 2014, 118, 8007–8013. [Google Scholar] [CrossRef]

- Richardson, I. The calcium silicate hydrates. Cem. Concr. Res. 2008, 38, 137–158. [Google Scholar] [CrossRef]

- Grigoryan, K.G.; Arutunyan, G.A.; Baginova, L.G.; Grigoryan, G.O. Synthesis of calcium hydromonosilicate from diatomite under hydrothermal conditions and its transformation into wollastonite. Theor. Found. Chem. Eng. 2008, 42, 583–585. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Doner, S.; Villada, J.T.; Das, S. Improving the Creep Resistance of Hardened Cement Paste through the Addition of Wollastonite Microfibers: Evaluation Using the Micro-Indentation Technique. Appl. Sci. 2023, 13, 2933. https://doi.org/10.3390/app13052933

Doner S, Villada JT, Das S. Improving the Creep Resistance of Hardened Cement Paste through the Addition of Wollastonite Microfibers: Evaluation Using the Micro-Indentation Technique. Applied Sciences. 2023; 13(5):2933. https://doi.org/10.3390/app13052933

Chicago/Turabian StyleDoner, Sami, Jonathan T. Villada, and Sumanta Das. 2023. "Improving the Creep Resistance of Hardened Cement Paste through the Addition of Wollastonite Microfibers: Evaluation Using the Micro-Indentation Technique" Applied Sciences 13, no. 5: 2933. https://doi.org/10.3390/app13052933

APA StyleDoner, S., Villada, J. T., & Das, S. (2023). Improving the Creep Resistance of Hardened Cement Paste through the Addition of Wollastonite Microfibers: Evaluation Using the Micro-Indentation Technique. Applied Sciences, 13(5), 2933. https://doi.org/10.3390/app13052933