1. Introduction

Assembly of complex products found in various industries (such as aviation, automotive, medical, and heavy-duty machinery) is extremely complex and involves many thousands of parts and operations, as well as huge amounts of human resources and machinery. Controlling, monitoring, and documenting the assembly processes becomes a major challenge. From the supply-chain perspective, the challenge is to trace and document the parts, sub-assemblies, and operations, from the bottom level up to the final assembled product. Safety and security go hand in hand in the production of these assemblies [

1], and even more so for the medical devices industry.

This paper describes a framework for automating the documentation and verification processes along the assembly of complex assembled products. This is achieved by tracing and validating the proposed concept of Bill-Of-Assembly (BOA) is which incorporates data from the bill of materials (BOM), the bill of operations and processes, and the bill of resources (machines and/or operators). The automation is accomplished by integrating smart contracts into all the stages of the assembly according to the BOA, to attain full traceability of the product sub-assemblies, parts, and processes. This integration enables automated verifications and authorizations for the many stages of the supply chain and the assembly process. The result is an advanced assembly data structure that could be the backbone of the product’s digital twin (DT). The proposed smart contracts are based on a platform of blockchain that gives it the advantages of immutability and security.

While the aircraft industry requires strict traceability [

2], supply chains of other complex products such as automobiles often lack traceability and documentation. However, legal authorities such as the National Highway Traffic Safety Administration of the USA, or Federal Motor Transport Authority of Germany, require end-to-end traceability of parts [

3].

Zhuang et al. [

4] stated that: “The complexity of large assemblies has fostered segmentation and decentralization of production chains and exacerbate their information management. Consequently, interoperability, as well as data integration and exchange, have become a major challenge in discrete assembly processes and induce the need for innovative traceability solutions”. To tackle this challenge there were several attempts to use blockchain technology. For example, Della Valle and Oliver [

5,

6] focused on data management and traceability. Furthermore, Wang, et al. [

7] used a blockchain solution in an aircraft assembly setting. Kuhn et al. [

8] developed a decentralized blockchain application called TokenTrail, which focuses on the specific traceability requirements of multi-hierarchical assembly structures. This is an important proof of concept that supports the use of smart contracts, as advocated in our paper and in Khan, et al. [

9] and Westerkamp et al. [

10].

Traceability becomes crucial for the identification of defective parts in recalls, and even more so when multiple suppliers are involved [

11]. Defective parts must be rapidly identified among massive number of vehicles. The prohibitive cost of manual investigation in such cases increase the attractiveness of automating the traceability [

3]. Another challenge is the detection of counterfeit parts, especially in after-sales markets [

11,

12]. Dasaklis et al. [

13] suggested a framework for supply chain traceability based on blockchain tokens. However, they did not use the approach as suggested here.

Smart contracts are contract paragraphs written in computer programs [

14]. Smart contracts are automatically implemented when prerequisites are met, thus preventing human errors. Smart contracts automatically perform transactions, and are stored, replicated and replaced (if needed) in distributed ledgers [

15]. To attain the trust of all stakeholders of the assembled product, the contracts must be decentralized programs cryptographically protected with verified immutability. The straightforward application of such smart contracts must operate as on a blockchain network [

16]. To attain immutability (prevent tampering with the code), smart contracts should be copied to each node of the blockchain network [

8]. It has also been validated using a case-study presented by Eryilmaz et al. [

17].

In the proposed framework, at each stage of the assembly the smart contracts will contain prerequisites of verifying the traceability of the assembled components and sub-assemblies. Only after the verification will the smart contracts enable data to be inserted into the product documentation. In that way, overall traceability is maintained with full documentation.

The paper continues as follows:

Section 2 describes the proposed Bill of Assembly (BOA) and the process of its generation.

Section 3 focuses on the integration of smart contracts for constructing the BOA.

Section 4 discusses the advantages and frailties of the proposed BOA and its construction method.

Section 5 concludes the paper with the main conclusions and future research potential.

2. State-of-the-Art Literature Review

The following literature review includes state-of-the-art papers that describe the usage of blockchain technology in numerous different domains. However, none of these papers deal with the sophistication of a complex assembly process, and the continual dynamic generation of accumulated sub-assemblies. A complex sub-assembly such as an engine is composed of many sub-assemblies. A non-compliant fastening operation (with the right parts) in one of the many sub-assemblies of the engine that may cause a defective engine. Such additions of considerations regarding the specifications of the assembly dramatically increase the complexity of the problem. In the following paragraphs we review state-of-the-art literature. However, we found only scant evidence for considering the aforementioned complexity in the current literature. This gap in the literature supports the motivation for this paper.

Several research papers described the use of additional technology on top of the combination of blockchain with supply chain. Prause [

18] considered the case of autonomous delivery robots between different links of a supply chain to illustrate that the concepts of Industry 4.0, blockchains and smart contracts fit well together, and complement each other. Sharif et al. [

19] described the usage of an advanced RFID system with blockchain for implementing traceability of various products, such as bottles and canned liquids, throughout the supply chain.

Dolgui et al. [

20] proposed a modeling approach that enables emulation of blockchain operations in the supply chain, and schedules its operation while helping the monitoring process by frequent updates.

Bottoni et al. [

21] emphasized the “intelligent” part of an Intelligent Smart Contract, and they attributed the “smartness” to a contract automated execution on the blockchain, and “intelligence” to planning optimization of the execution and its parameters.

Chiacchio et al. [

22] proposed an immutable token solution for the track and trace of a pharmaceutical supply chain. They present a decentralized solution based on non-fungible tokens (NFTs). This solution improved the track and trace capability of the standard serialization process. Non-fungible tokens are imprinted into the blockchain and inherit all the advantages provided by this technology. However, the described pharmaceutical product did not change throughout the supply chain, while sub-assemblies and assemblies change during the supply chain.

Rich research was conducted on the use of blockchain technology in various industries. Some examples are as follows:

Song et al. [

23] and Li and Song [

24] focused on the impact of blockchain on supply chain traceability in general. Hastig et al. [

25] presented business requirements and critical success factors for implementation in cobalt mining and pharmaceutical industries. Demestichas et al. [

26] and Mirabelli et al. [

27] described the research of blockchain applications in agricultural supply chains. Agrawal et al. [

28] described a case study of the textile and clothing industry using a blockchain-based framework for supply chain traceability. Wang et al. [

29] dealt with traceability in the precast construction industry. They proposed a blockchain-based framework for improving supply chain traceability and information sharing. Musamih et al. [

30] proposed a blockchain-based approach for drug traceability in a healthcare supply chain. It should be emphasized that once the drug was labeled, no change was necessary. This is very different from assembly, where the parts are being combined into sub-assemblies. Centobelli et al. [

31] proposed the integrated framework for designing circular blockchain platforms. A circular blockchain platform was designed in a supply chain, including manufacturer, reverse logistics service provider, selection center, recycling center, and landfill.

All the above studies did not deal with complex assembly and their tracing is of a unique product entity. They did not deal with a situation where the tracing is a dynamic process of accumulation of parts and sub-assemblies. Such a process requires a very different approach as part of the information gathered throughout the assembly process. An exception that does deal with the complexity of the assembly process is Kuhn et al. [

8].

Kuhn et al. [

8] enabled extra flexibility in tracing parts by using fungible tokens in a system called “TokenTrail”. This system enables the use of alternative parts that play an identical role in the sub-assembly. However, their focus was on the technological aspects of the blockchain implementation, rather than the operational aspects that are the focus of this paper.

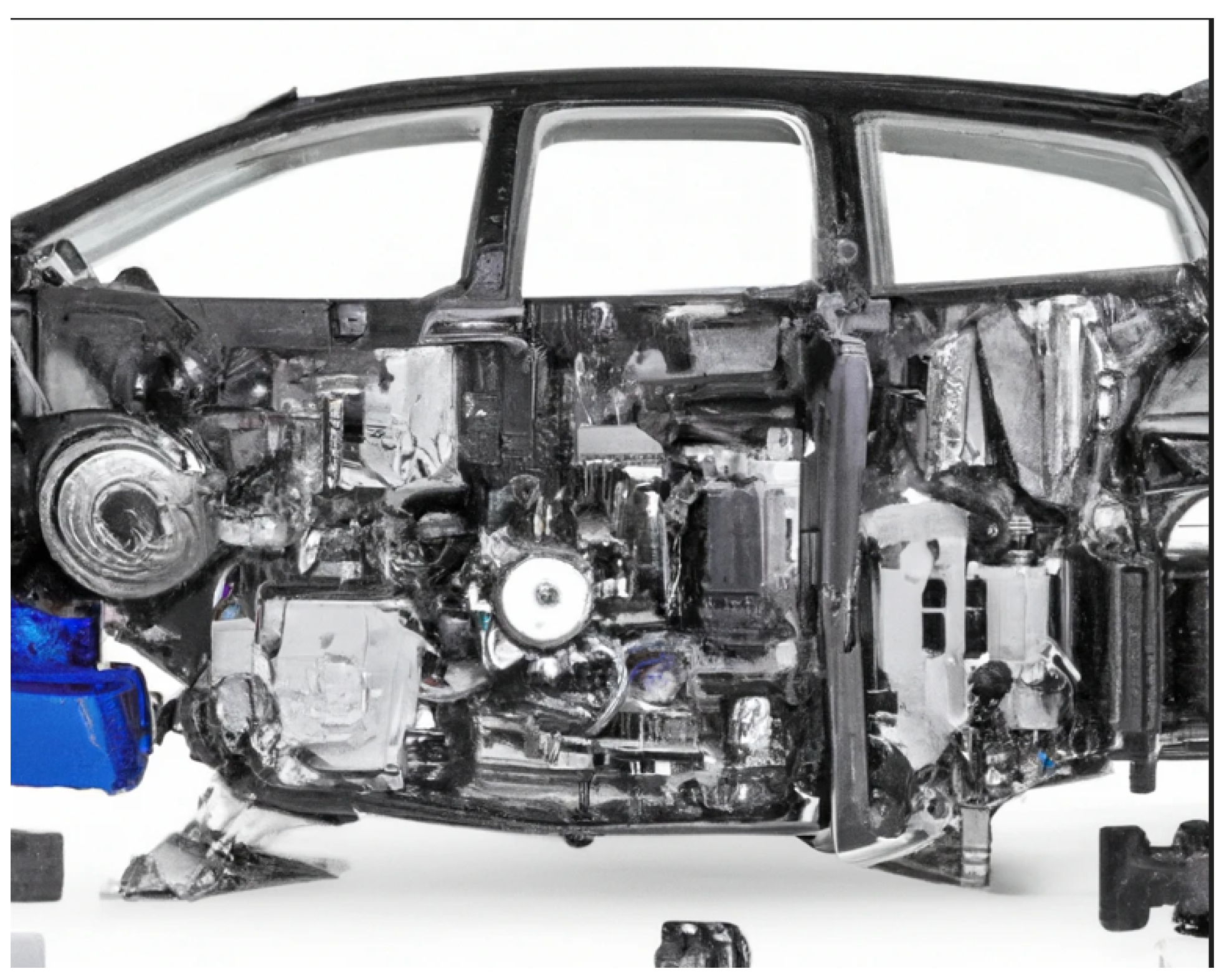

Complex assembly such as aircraft assembly or automotive assembly includes thousands of parts and sub-assemblies (see

Figure 1). The complexity also stems from the complex hierarchy of the product structure. The construction of this hierarchical structure is a dynamic process in which a larger sub-assembly must verify adaptability and compliance of its sub-assembly constituents and their hierarchy of sub-assemblies.

The complexity is extended by the variety of final assembly products (exacerbated by the customized mass production). Moreover, the variety of regulation requirements (including international and domestic regulations) and the need for their traceability make the process even more complex.

The automotive industry assembles very complex products such as trucks, tractors and a variety of cars.

Figure 1 illustrates some of the complexity of regular cars, made of thousands of parts and sub-assemblies. The assembly processes are hierarchical, generating a hierarchy of sub-assemblies [

32]. In this hierarchy, each sub-assembly must have a full verification and traceability of its constituent parts and components. The traceability structure and execution are, therefore, totally different from those described in products such as bottles and cans, which have no internal complexity and have no dynamic structure of sub-assemblies.

Based on the above discussion and references, it is clear that none of the previous research dealt with the traceability of dynamic structure of sub-assemblies that are becoming part of other sub-assemblies. The traceability of sub-assemblies of this form is much more complex and challenging than in the cases mentioned in the literature. Based on this finding our research question is: How could a complex assembly operation with a dynamic accumulative structure of its sub-assemblies be effectively traced?

BOM documentation is the core data structure in the entire life cycle of assembled products. When the BOM contains enough information, it could be the primary data source for any investigation. The investigation can focus on the part, or on sub-assemblies, or processes, whether for knowledge extraction, or for simulation [

4]. Therefore, in our proposed model we adopt the approach of centralizing the development of product data around the BOM. However, in complex assemblies, such as aircraft assembly, there are many thousands of parts and processes that complicate the construction of a unified BOM [

33]. In some domains there are very different versions of BOMs: engineering BOM, static service BOM (SBOM) [

34], process BOM (PBOM), manufacturing BOM (MBOM), and maintenance BOM (WBOM) [

7]. In these cases, it is obvious that constructing a unified BOM is a considerable challenge [

33]. We do, however, propose a unifying approach so that the product will have a single unique documentation database. In our proposed unified approach, we heavily deploy smart contracts as a mechanism for automating validation and enabling reliable traceability.

3. Bill of Assembly (BOA)

Current research already proposes to extend the assembly data and infer processes from BOMs. Ebrahimi & Åkesson [

35] extracted data from the BOM to find assembly sequences feasibility. Yunitarini & Widiaswanti [

36] proposed an integrated computer-aided process planning (CAPP) and BOM. The process planning is based on the BOM, since, before planning the assembly processes on a workpiece or a part, the assembler must know the parts and process specifications and product structure. Cohen et al. [

37] extended the BOM to BOA and the current paper expands on their approach. Wang and Li. [

38] introduced the reconstruction process of the BOM, and the BOM consistency reconstruction mechanism of complex products. This extended BOA is then used for generating a digital twin. The reconstruction process affects the whole framework of their proposed method, and it is very different from constructing the digital twin simultaneously with the physical construction, which is the subject of this paper. Kuczenski et al. [

39] demonstrated the solution to the problem of assembly product design and redesign by developing a distributed software. The results demonstrate that the problem of automated product system models (PSM) construction is achievable.

The Proposed BOA

The proposed BOA is depicted in

Figure 2 and is composed of the following information:

The BOM—includes information regarding the assembly structure;

Part parameters (from engineering BOM)—includes information regarding the sizes and features that characterize each of the parts in the BOM;

Assembly activities (from the PBOM), their times and precedence relations—related to the BOM;

Manufacturing activities (from the MBOM), the machines, tools, and manufacturing processes, and their parameters.

In

Figure 2, the final assembly is composed of three sub-assemblies (S.A. 1, S.A. 2, S.A. 3), and sub-assembly 1 is composed of two sub-assemblies (S.A. 1.1, S.A. 1.2) and their raw materials (RM1,…RM4). The shaded part (in grey) of S.A. 1.1 denotes the completed assembly activities related to S.A. 1.1. Sub-assembly 1.1 (S.A. 1.1.) is further described using an activity precedence diagram in an exploded view, at the bottom of

Figure 1. The completed activities are shaded in grey. The processing of each sub-assembly requires the automatic verification of the identity of all its parts using smart contracts. At the lower level of parts and raw materials, a smart tag (hardware chip) has to be scanned for identity verification. At higher levels, the smart contracts of the lower level communicate the completion of their sub-assemblies to the smart contract related to the higher level. This hand-off process requires cryptographic verification of the smart-contract identity between levels.

As can be seen in

Figure 2, the BOM is the basis for the proposed BOA of each product (workpiece) and the backbone for the additional information. The novelty of the proposed additions to the BOM is encapsulated in an extended activity diagram associated with each sub-assembly in the BOM, detailing all its processes and parameters (example is depicted in

Figure 1 for S.A. 1.1). Assembly lines are characterized by an evolutionary assembly of their final product as the main workpiece flows through the workstations.

We define the workpiece (WP) to be the main product in the process, meaning that it is the main product part in its evolution.

While regular activity diagrams have precedence constraints between nodes and activity times, the proposed diagrams have additional information on: (1) the processed material or sub-assembly, (2) the machine or tool used at each activity, (3) activity static information, and (4) activity dynamic information (workpiece related).

These are very important additions of information to the regular precedence diagrams. Our proposed scheme includes the smart-contract verification of the compliance of dynamic data to the static data. We use

Figure 1 for illustrating the verification. In

Figure 1, the static data specify that the activation of task 6 is dependent on the completion of tasks 4 and 5. The suggested role of the smart contract is to verify these completions by monitoring them, before allowing activity 6 to begin. Activity 6 generates the various measures. These measures are compared against the static data ranges of each parameter. Thus, the verifications related to

Figure 1 are as follows:

Depth: dynamic measure = (5.1), static range = depth (4.5–5.5), Verification result: Compliance;

Diameter: dynamic measure = (3.95), static range = diameter (3.6–4.4), Verification result: Compliance;

Length: dynamic measure = (19.90), static range = length (19.8–20.2), Verification result: Compliance;

Width: dynamic measure = (10.01), static range = width (9.85–10.15), Verification result: Compliance.

Two important parameters for each activity are the standard time estimation (static data for an activity) and actual activity time measure (dynamic data). Activity 6 finishes at time: 10:01:07—this is a dynamic timestamp that enables the computation of the actual process time in comparison with the start time: 10:01:07–09:55:00 = 6:07 min, which could be compared to the standard time of 5 min and gives the efficiency of 5/6:07 = 0.817 = 81.7%.

The actual activity time for each workpiece is computed as the subtraction of the entry timestamp from the exit timestamp of the workpiece. This additional data as well as all BOA data must be directly accessible to the organization’s data systems.

To assess the efficiency for each sub-assembly, the standard times of all the activities are summarized for all assembly operations of that sub-assembly, to form its expected time. The availability of standard times and timestamps at the workpiece entrance and exit allow the efficiency of the assembly processes to be tracked at any time during the production. In addition, these data enable tracking of the inefficient waiting times for parts and sub-assemblies. This information has not been part of any analytical tool so far. To illustrate this point, we use an example: The construction of sub-assembly 1.1 is carried out using seven activities with seven standard times and indication of two raw materials (RM1, RM2), as shown in

Table 1.

The sum of the standard times of all S.A. 1.1 activities is: 2 + 3 + 1 + 4 + 3 + 5 + 3 = 20.

Now, we measure at each activity ending time the actual time it was performed. For example, suppose activities 1, 2, 4, 5 were completed as follows:

Activity 1: 3 min, 150% of standard (2 min).

Activity 2: 4 min, 133% of standard (3 min).

Activity 4: 5 min, 120% of standard (4 min).

Activity 5: 4.5 min, 150% of standard (3 min).

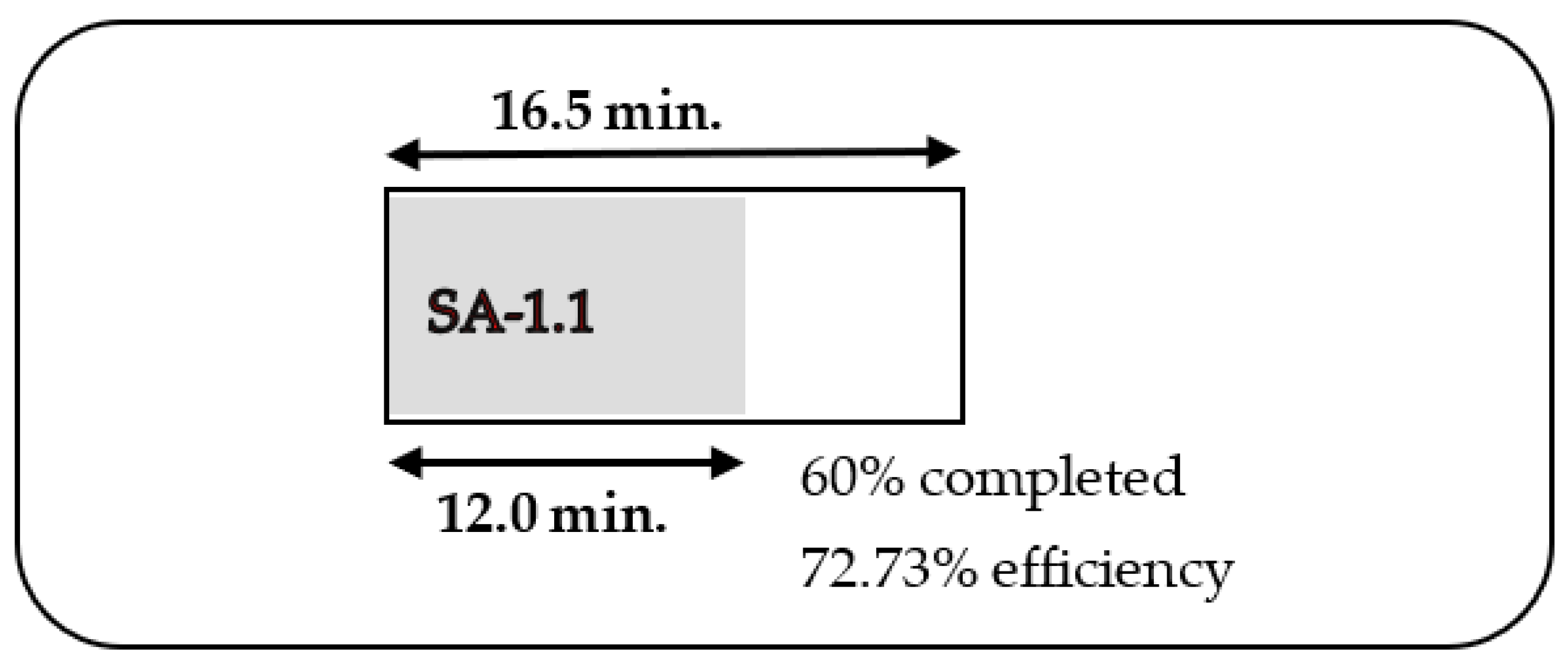

So, the completed standard work (for activities 1, 2, 4, 5) is: 2 + 3 + 4 + 3 = 12.

Out of 20, 12 is 60% of the total standard time for S.A 1.1.

The actual execution time (activities 1, 2, 4, 5) is: 3 + 4 + 5 + 4.5 = 16.5 min (see

Figure 3).

The efficiency of the execution time (as shown in

Figure 2) is: 12/16.5 = 72.73%.

The BOA system is also storing historical documentation of the efficiency and other measures in the recent time window (rolling horizon). These data enable the analysis and the discovery of trends that require intervention and maintenance.

Advantages of the BOA implementation based on smart contracts:

Automated verification of part ID;

Automated verification of accumulated data;

Intuitive data structure;

Embedded quality control via smart contracts;

Automated measures documentation and efficiency measures reporting.

Downsides of the BOA implementation based on smart contracts:

Rigid structure that does not allow fast changes;

The verification is complicated and sophisticated;

The smart contracts need explicit definition of alternative parts and sub-assemblies;

The smart contracts are not forgiving, even for minor and acceptable deviations from specifications.

4. Integrating Smart Contracts in BOA

In this section we first discuss the current state of the art in the deployment of smart contracts in logistics and supply chains. We then discuss the implications and describe our suggested method for using the smart contracts in the process of building the product BOA. For reliable traceability, the smart contracts should be applied throughout the entire supply chain process. At the end of the production process, the final assembly requires intense application of smart contracts. At this stage, the BOA is developed along the assembly line, and therefore must be controlled by the assembly line’s stations.

The use of smart contracts in logistics and supply chains has gathered interest and experience in recent years, asserting the ability of smart contracts to provide traceability in various supply chains in different industries. The following cases are just samples from the literature on this subject. Seifermann et al. [

40] developed requirements for tracking and tracing using blockchain technology. They present a model that has been implemented in a proof of concept for traceability and tracking using smart contracts in the Ethereum blockchain. Kuhn et al. [

8] developed a decentralized blockchain application that meets rigorous traceability requirements of various assembly products and sub-assemblies. Their application combines an Ethereum network and a Proof-of-Authority consensus. The traceability is supported by special tokens that combine cryptography and data of complex assembly processes and structures. Casino et al. [

41] presented a case study in the dairy sector of blockchain-based food supply chain traceability. They implemented a set of functions to provide an end-to-end traceability flow, from raw materials acquisition to end customers’ product delivery.

The suggested method starts at the very beginning of the supply chain by verification of the raw materials. In case the raw materials are produced by automated machines, the verification could be done as part of the automated process by the attachment of smart tags (with a cryptographic shielding layer). In case the process is not automated, the smart tag authorization involves the people in charge (and their identity verification). From this point on, the verifications along the supply chain could and should be done by smart contracts. This automates the verification process and provides secure traceability.

For each sub-assembly, there is a separate smart contract that has the information about the structure of the sub-assembly, and its precedence activities. For a given sub-assembly, the smart contract detects the availability of the sub-assembly components via scanning (e.g., RFID tags could be scanned with antennas [

42]). Of course, the smart contract must verify the authenticity of the parts (checking the cryptography), and their compliance with the technical requirements of the sub-assembly.

In

Figure 4 we describe the verification logic of the smart contract related to activity 6 from

Figure 2.

Figure 4 demonstrates that the main process starts after the arrival of the workpiece at the workstation where activity 6 is performed. This arrival invokes the verification agent of activity 6. At the beginning, the agent of activity 6 is waiting for the completion tokens of predecessor activities 4 and 5 to initiate the smart contract verifications. The arrival of tokens 4 and 5 starts the verification process: first the tokens’ authenticity is verified, then the operator identity is verified, then the raw material authenticity and type are verified, then the machine type and its suitability are verified. If all the verifications are successful, activity 6 is authorized and the timestamp is recorded. Activity 6 starts formally at this moment, and the static parameters relevant to Machine 3 are inserted by the smart contract code. Next, the processing stage is performed and at the end of the processing the measures are taken for all the relevant parameters (e.g., depth, diameter, length, width). The actual measures are compared to the static data and a decision is made about their compliance. If all measures are found compliant, activity 6 is cleared for completion and termination. A timestamp is recorded, and a token of the completion is distributed and transferred to the succeeding activities.

5. Discussion

The data accumulation along the assembly process of each product is a gradual process. However, even before each product is produced, its static data are already available. The static data are derived from the product development and design, as well as the assembly production plans for each product. These are the standard data of the product structure, the related assembly activities, and their (the product structure, and assembly activities) specifications.

The dynamic data are the data that come with the actual raw materials, assembly activities and the sub-assembly measured parameters. Thus, the verification processes only need to compare the static and dynamic data. In other words, if the data collection and the verifications and authorizations are automated, the whole control process can also be automated. We therefore suggest doing exactly this by using smart contracts.

Smart contracts are open-source programs readable by humans and executed automatically, exactly as implemented. They are usually protected by both cryptography and wide distribution (much like blockchain practices), rendering them as immutable. This makes them immune to fraud, counterfeiting, or censorship [

43]. These characteristics make smart contracts the technique of choice when traceability is needed. This section discusses the ways to apply the smart contracts in the proposed framework.

One of the key issues is the verification of the raw materials and sub-assemblies for traceability purposes. We first focus on fundamental parts (and raw materials). These parts should have an attached identifier such as RFID tag [

42], a microchip, or a small IoT-enabled sensor [

44]. A much less attractive option would be a barcode. Some type of cryptographic rule should be incorporated into these identification tags to authenticate the part identity, and its embedded data. Some discrete data must be shared between the suppliers along the supply chain in order to facilitate the smart contract process. Once the parts are authenticated and verified, the sub-assembly containing them carries on the verification process, as described in the previous section.

To enable traceability through the whole supply chain, the various links in the chain must be coordinated seamlessly to enable smooth operation of the smart contracts. This requires them to be part of the distributed ledger that the smart contracts use, to coordinate passwords for authentication, and to have communications channels to be able to communicate with each other.

The proposed technique has the potential to automate large parts of the assembly process dedicated to verification and control. This is especially crucial in certain industries where regulations require a high level of traceability such as the food, pharmaceutical, spacecraft and aircraft industries [

2].

The proposed framework has its own limitations. First, it requires a high-level computerized environment through the entire supply chain. Second, it requires close coordination between the various links in the supply chain. Third, any deviation from the pre-planned smart contract is very difficult to handle as a new smart contract would be required (usually involving and requiring the consent of two or more organizations in the supply chain). Fourth, any change in the static data has to be made before the product is assembled. Finally, we did not delve into the scenarios where the verification or authentication fails, but in such cases the automated advantage of the proposed system fades.

The proposed BOA data structure could be a main core of a digital twin database. At the end of the assembly line, the BOA is a full documentation of the AS-BUILT BOM, and many other parameters. This includes the sensors and sub-assemblies of the full product. This is, however, still far from being the actual digital twin that emulates the behavior of the product under different scenarios. The mutual effects of the sub-assemblies on each other is the first additional necessary layer to be added to the BOA (e.g., in the automotive industry, a car cooling system if operated cools the engine). Then, the effect of the controls over the various sub-systems is a second added layer (e.g., pressing the brake pedal activates the braking system and the brakes). Finally, the effect of some of the product parts on the environment (and vice versa) is the third layer (e.g., the wheels, which are locked by the brakes, have an intensive friction force on the road, which halts the car). So, with these additional three layers, the foundations of a digital twin are ready for simulation.

6. Conclusions

In this paper we describe a full framework that supports automated verification and documentation of the assembly process via the proposed BOA. This ensures traceability throughout the supply chain, for a given assembly process. The related documentation and repeated confirmations, authorizations, and certifications, require substantial effort and have numerous chances for human errors. Therefore, digitalization and automation of these processes has a great value. To facilitate this digitalization, we propose the extended bill of assembly (BOA) as the backbone of the traceable documentation of each assembled product. For automating the entire control and documentation process, we suggest a framework that uses smart-contract technology enforcing the extended BOA. This framework offers traceable and protected documentation of the assembly process, providing security, safety, and full traceability, for the full assembled product. In other words, the proposed framework provides security measures needed to prevent counterfeit parts, hostile hacking, and an unauthorized approach to the assembly documentation throughout the entire supply chain. Moreover, using the proposed framework with a smart contract for each assembly activity automates the control, documentation, authorization, and certification activities throughout the entire assembly process.

Practitioners can directly benefit from this paper by implementing the BOA structure in their respective organizations. Maintaining a BOA (even manually) enables full built-in traceability for components and sub-assemblies. Automating the validation and some of the documentation of the BOA by implementing smart contracts is another benefit for practitioners.

Future research may be pursued in several directions: (1) performing case studies to validate and improve the suggested framework. (2) Extending the proposed approach to facilitate the usage of the BOA in constructing a digital twin (

Section 5 briefly discusses this option). (3) Using the BOA accumulated data of each product, in a shopfloor, to better plan and schedule the assembly process.