Cuckoo Coupled Improved Grey Wolf Algorithm for PID Parameter Tuning

Abstract

:1. Introduction

2. Traditional GWO Algorithm

2.1. Social Class of the Grey Wolf

2.2. Mathematical Model of the Traditional GWO Algorithm

- ①.

- Look for prey;

- ②.

- Surround prey;

- ③.

- Attack prey.

3. CSO_IGWO

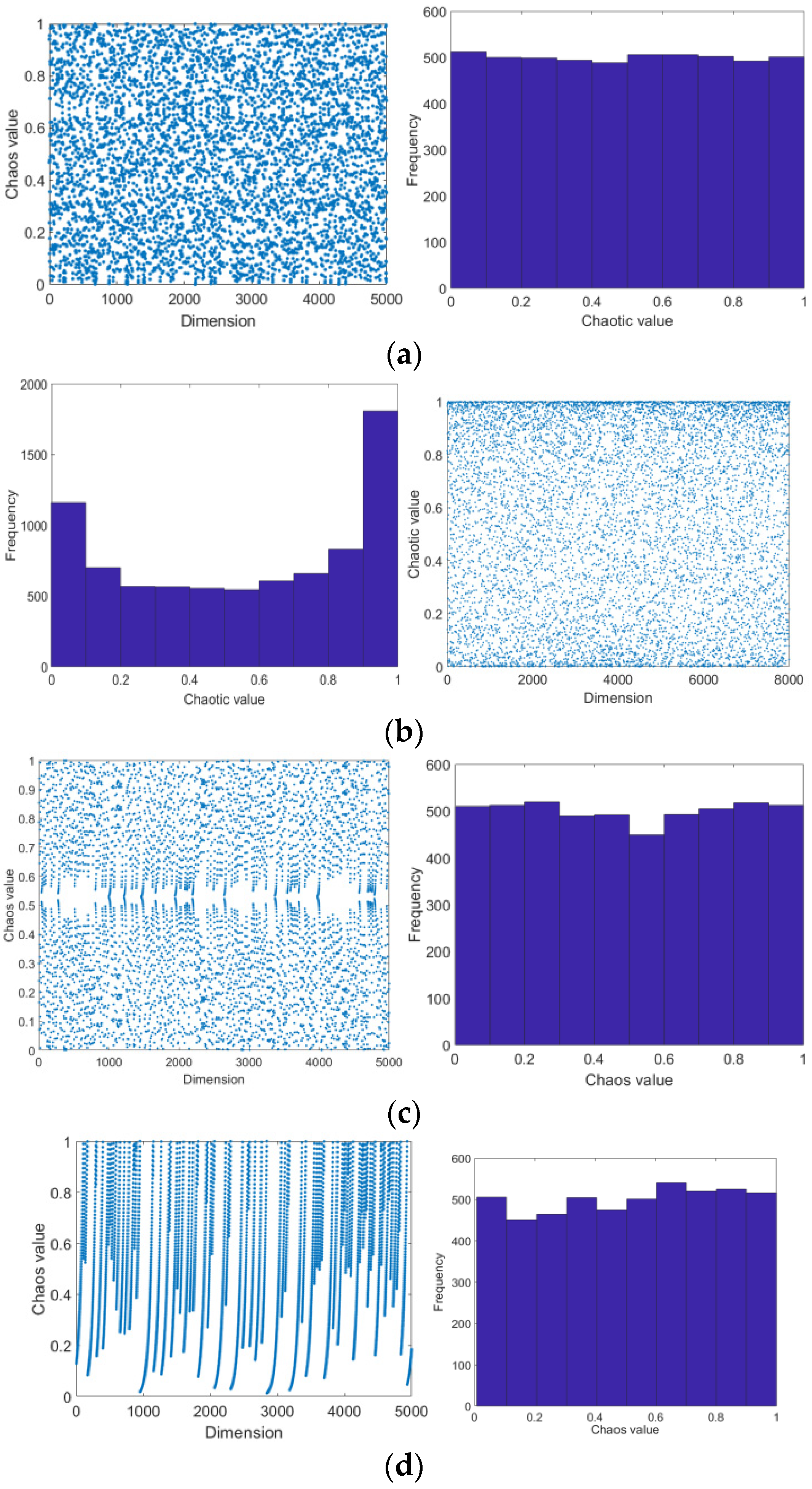

3.1. Tent Chaotic Map Initial Population

3.2. Nonlinear Control Parameter Strategy

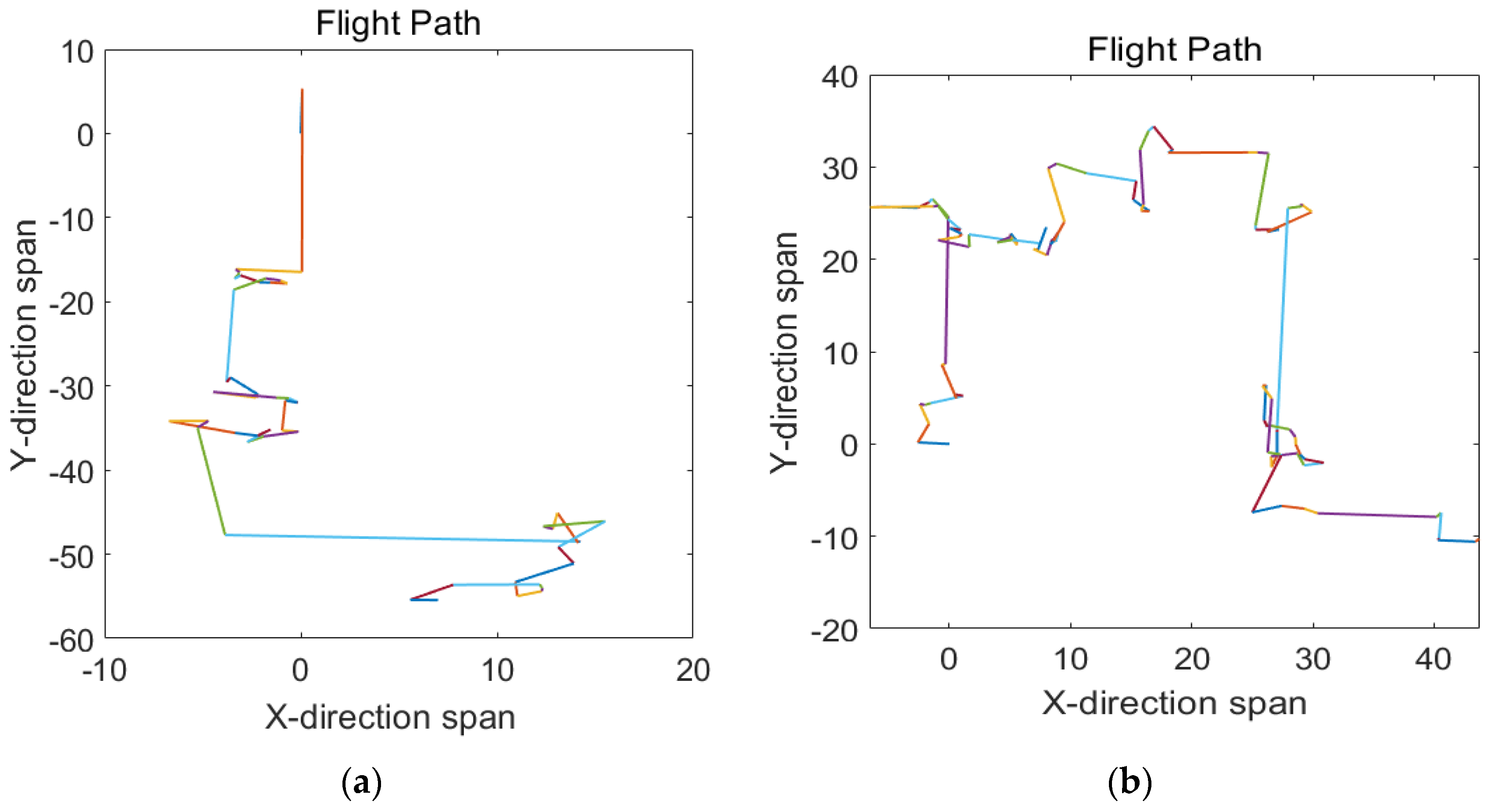

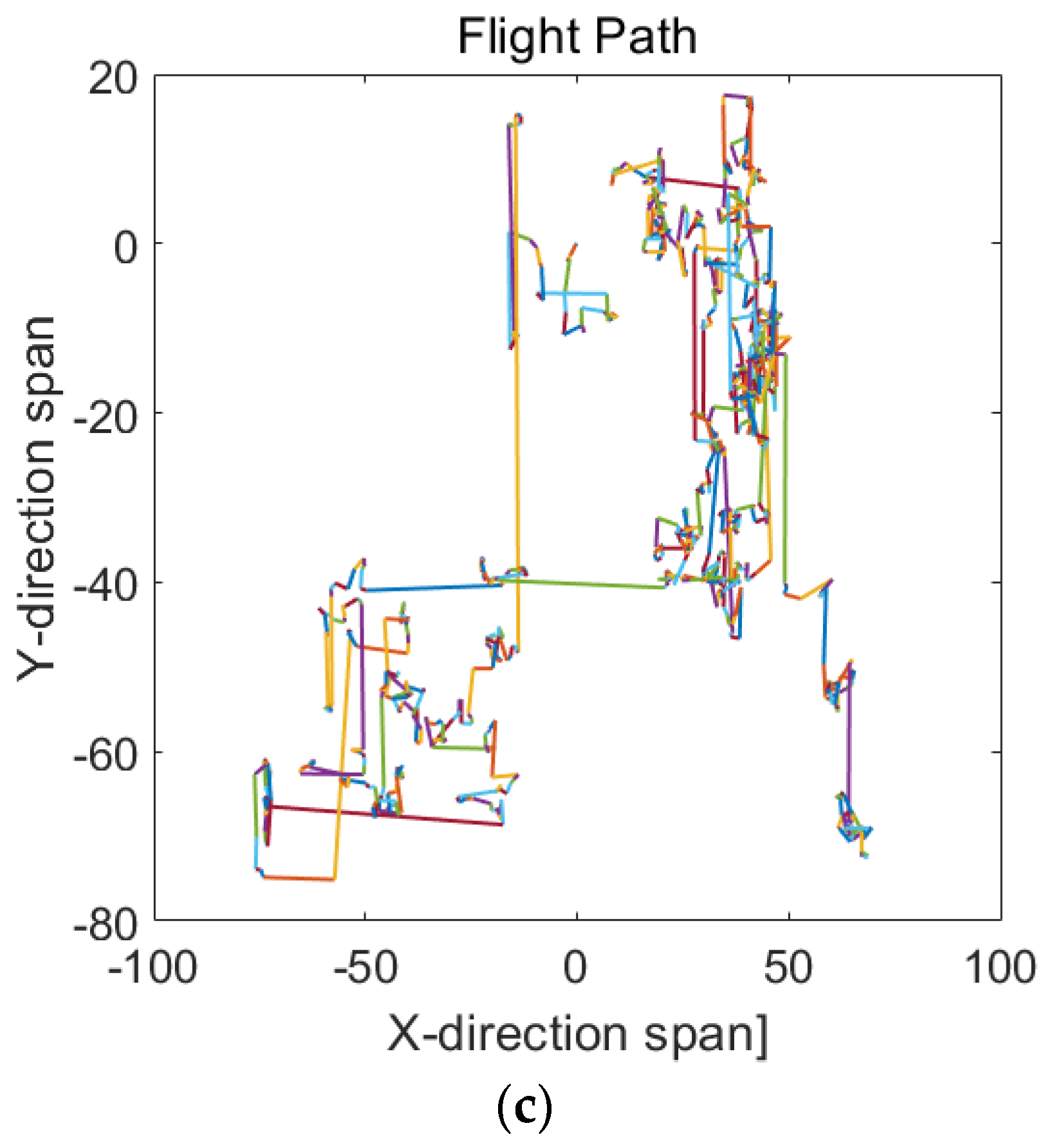

3.3. CSO Algorithm Coupling for an Improved GWO Algorithm

| Algorithm 1 CSO_GWO algorithm. |

| Initialising population with a chaotic tent map Initialise , , and Calculate the fitness value of each individual = Best individual = Suboptimal individual = Third best individual While (t < Max_iter) For each individual in the population Use Equation (13) to update the current position of the individual End for Update with Equation (9) Update A and C with Equation (3) Calculate fitness of all individuals Update , and End While Return |

4. Numerical Data Experiment and Simulation Analysis

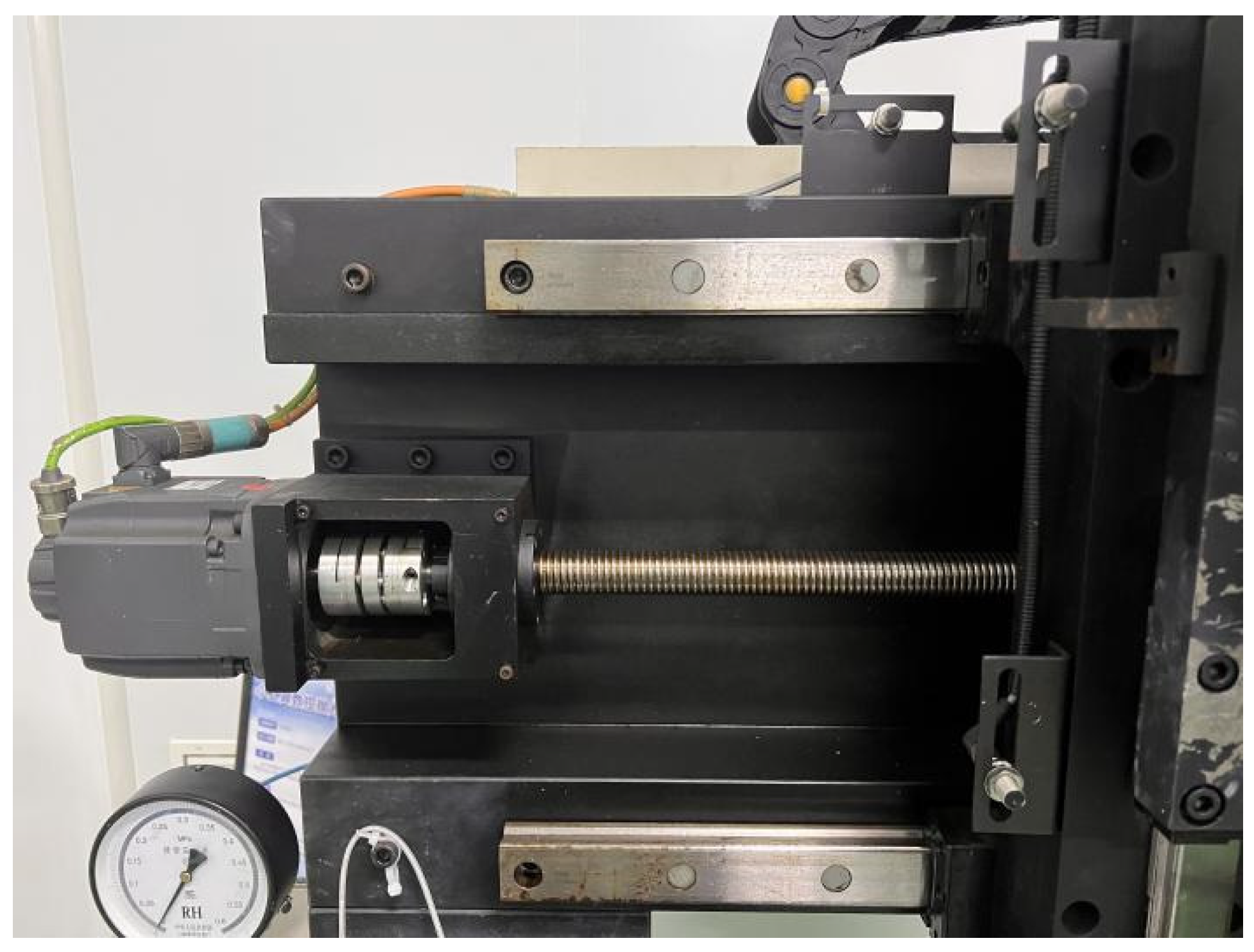

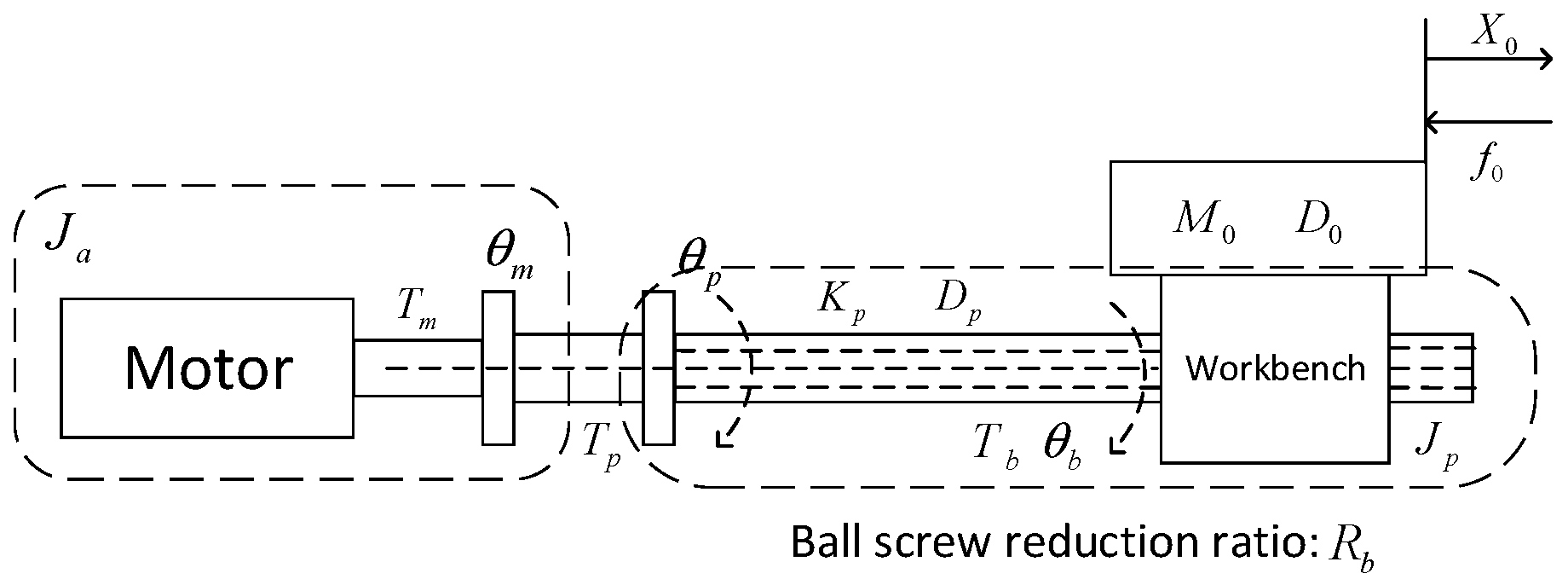

4.1. Mathematical Model of a Servo Motor System

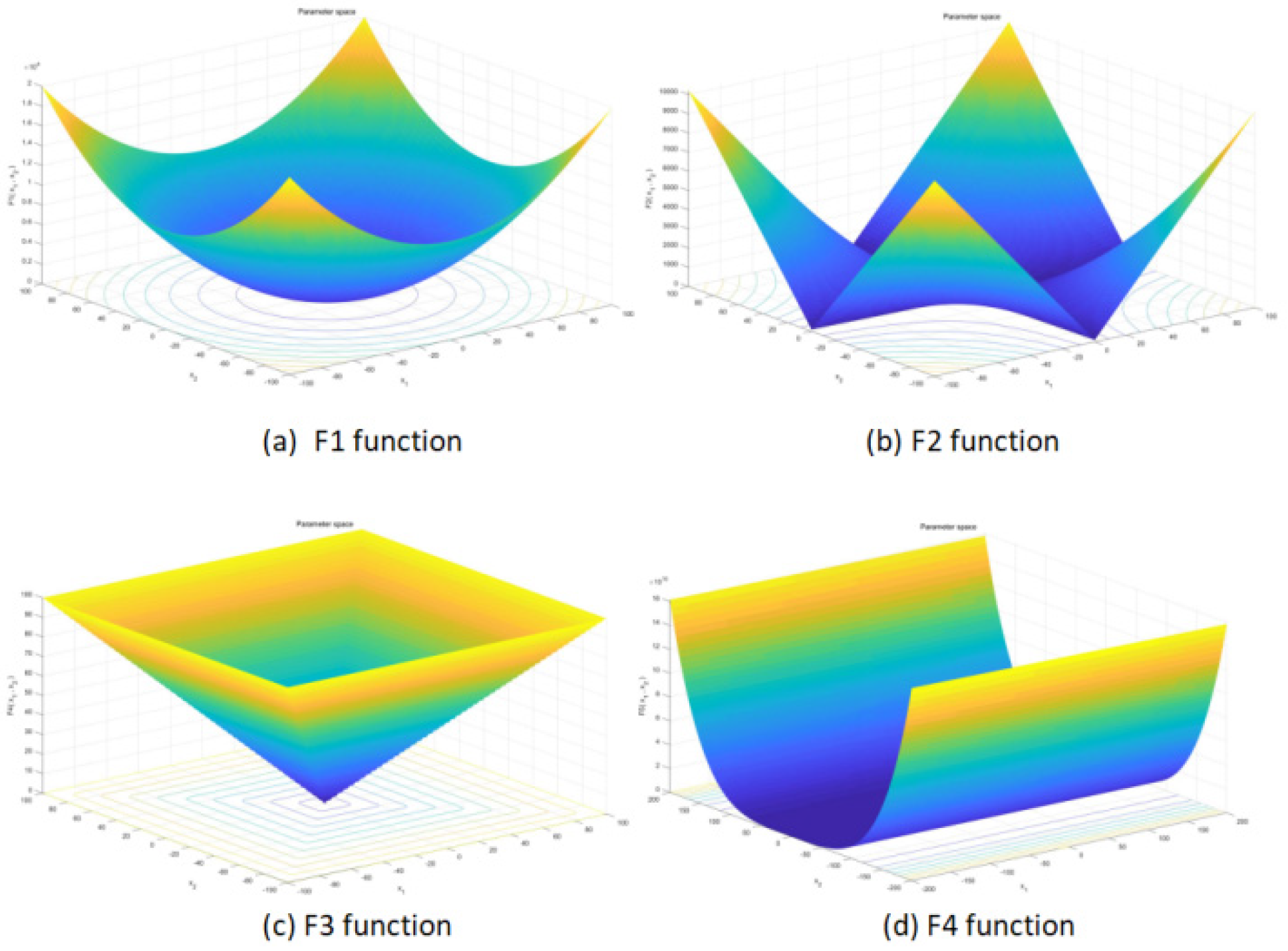

4.2. Benchmark Functions

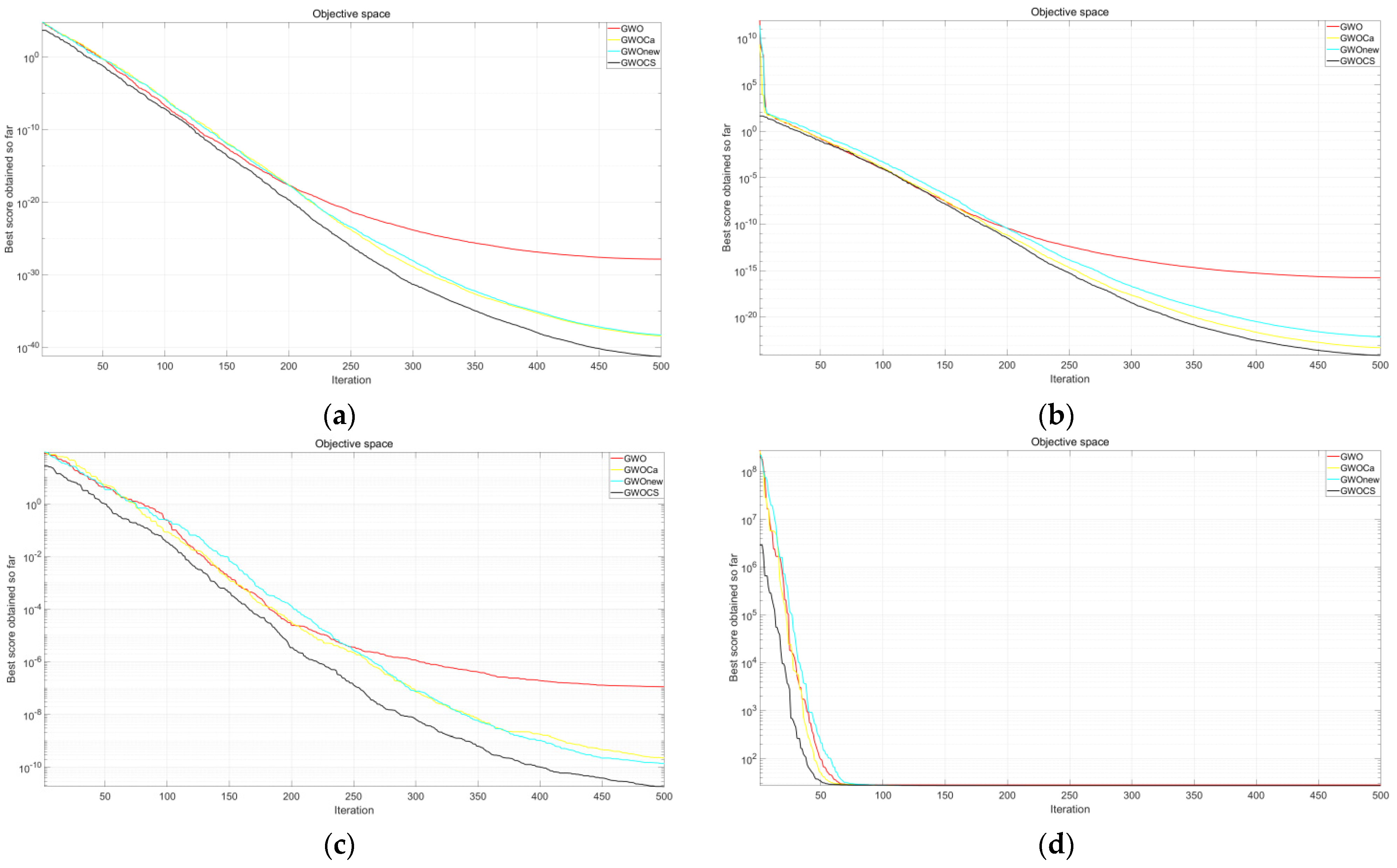

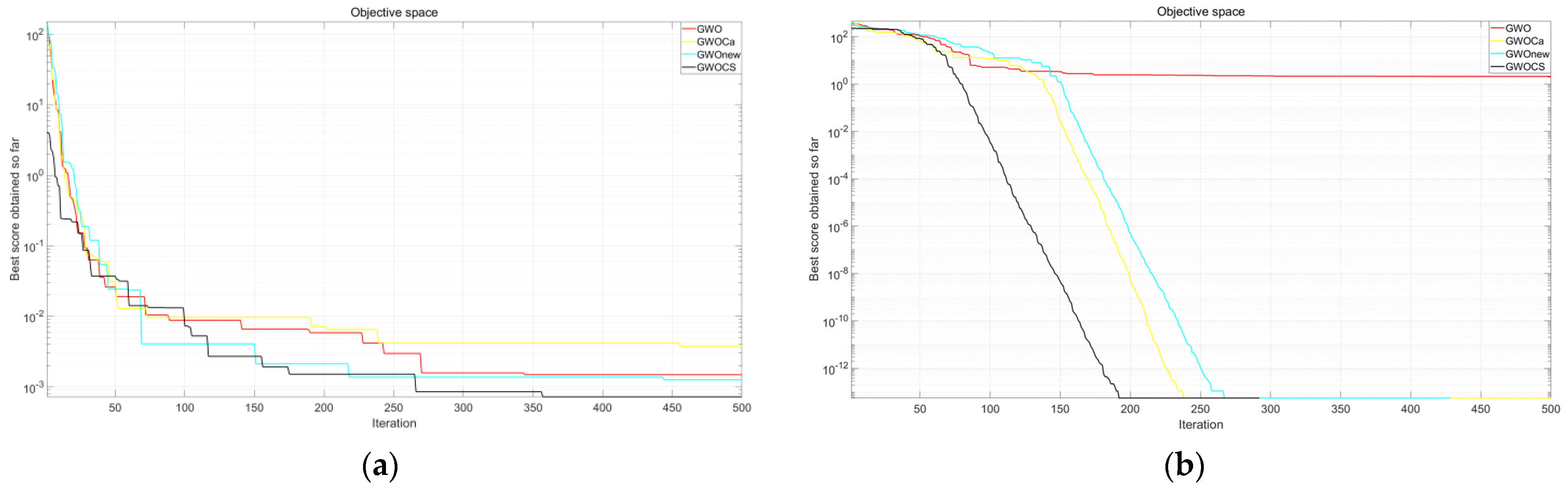

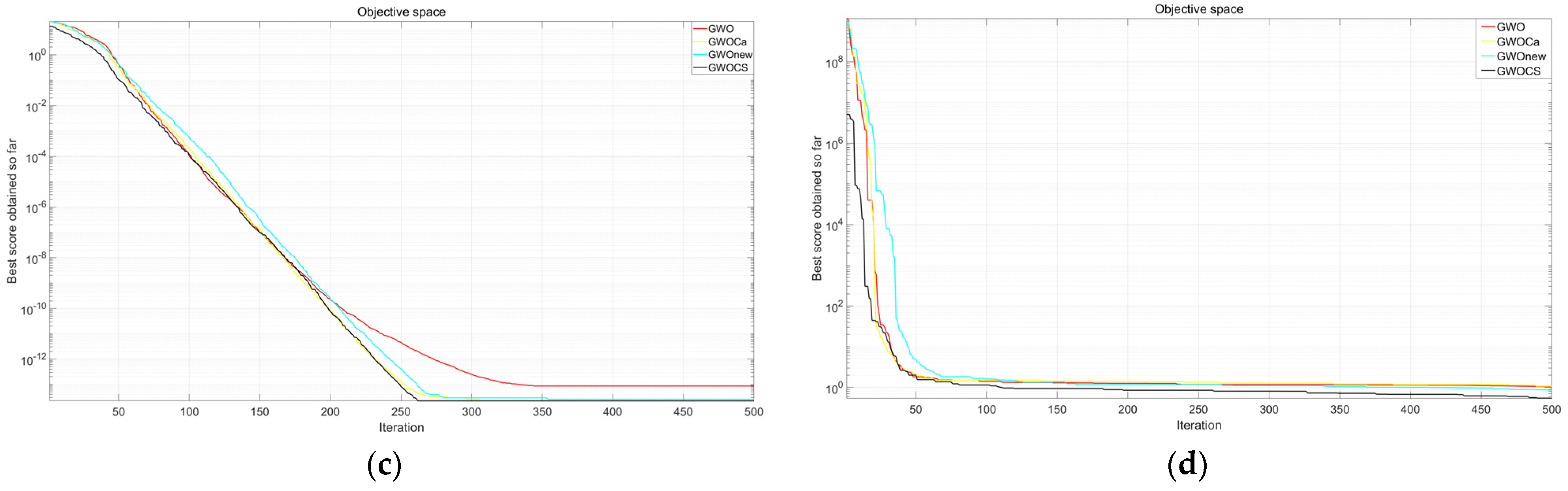

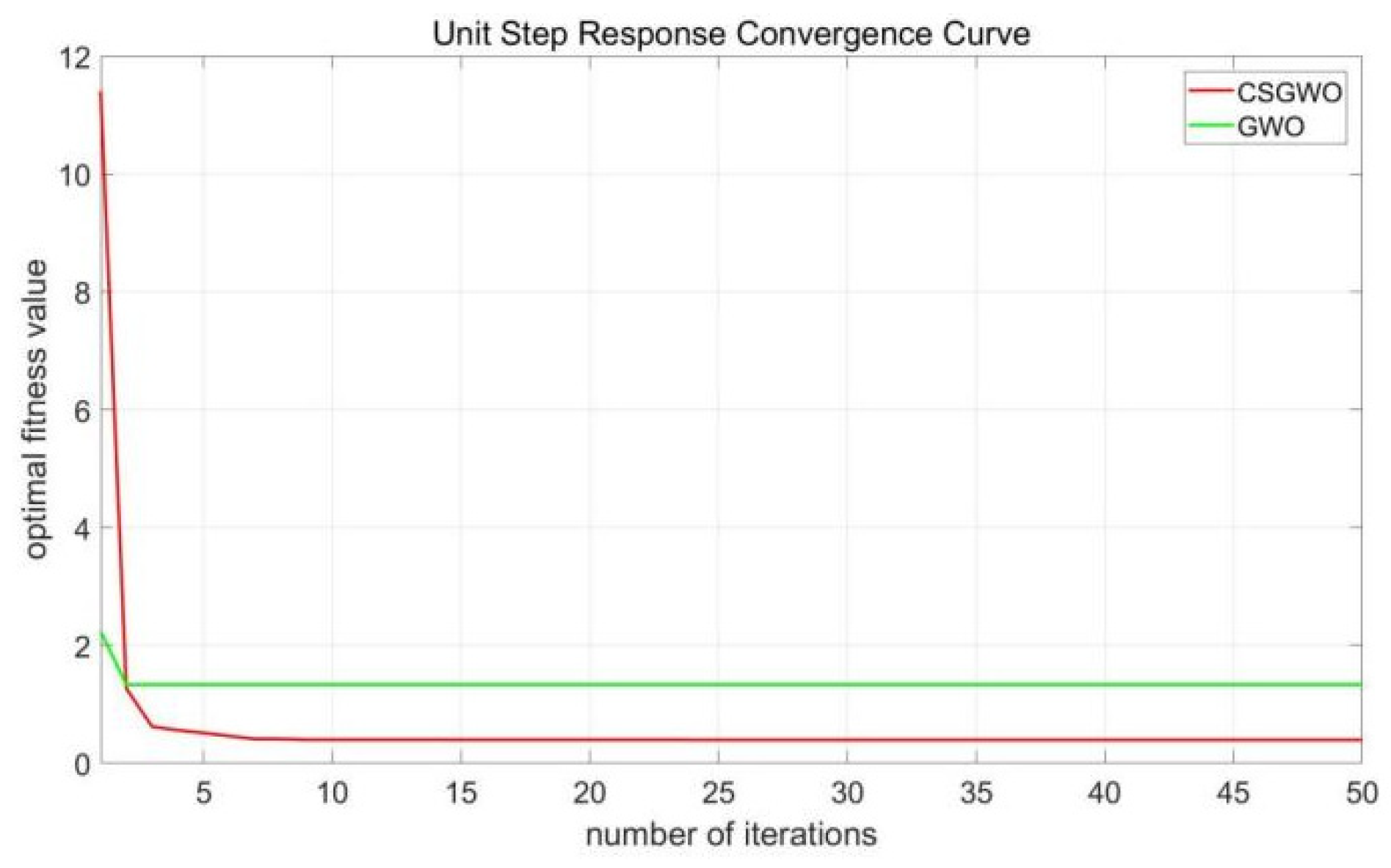

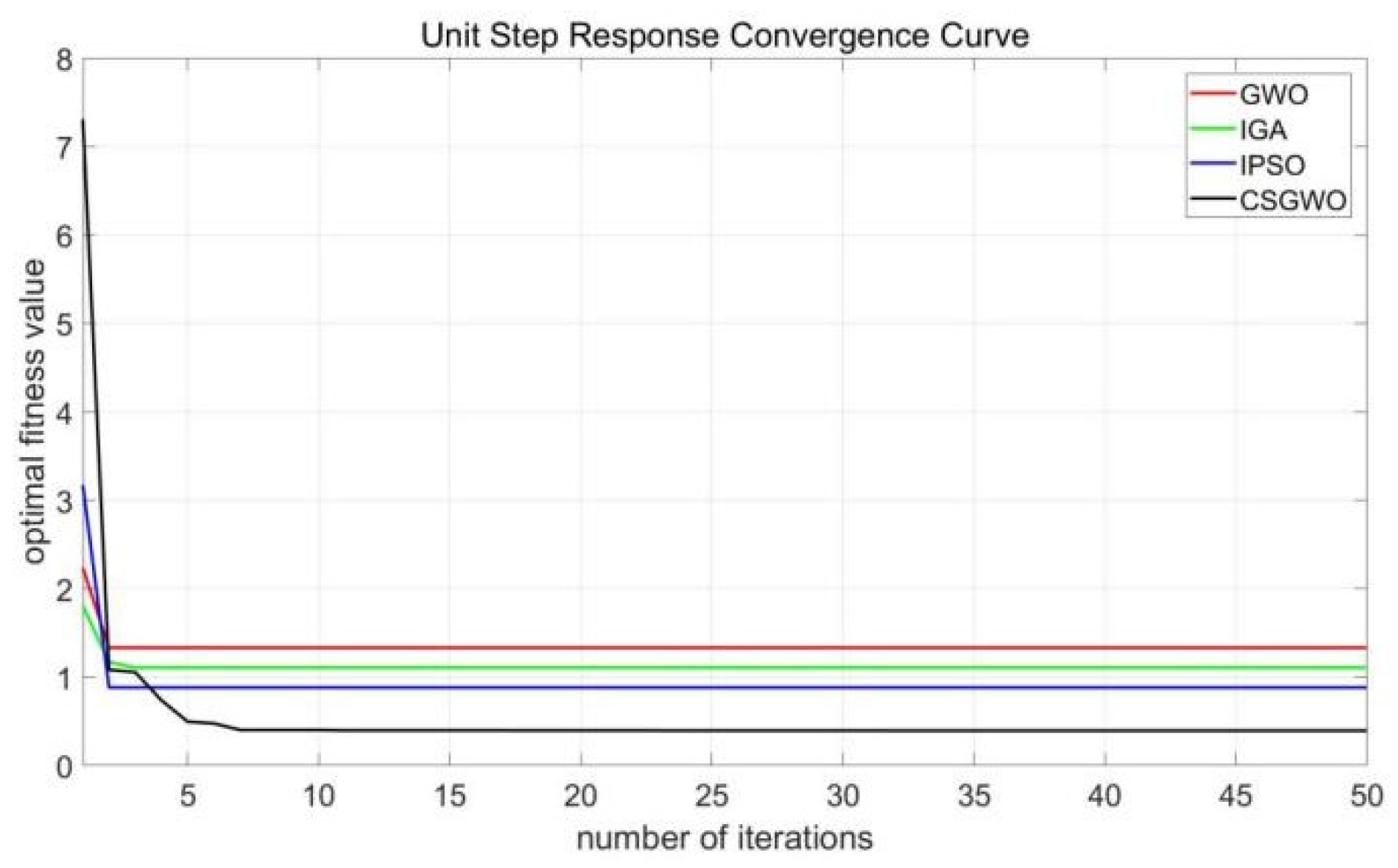

4.3. Comparison with the Traditional GWO Algorithm

4.4. Analysis of the Parameter Setting Experiment

- Step 1: Initialise the parameters of CWO, such as population size N, maximum iterations (Max_iter), initial value , final value of , parameters A and C, and the nonlinear modulation index ;

- Step 2: Use tent mapping to generate individual populations and calculate the fitness value of each individual;

- Step 3: The fitness function value for each candidate is calculated. According to the order of fitness values from large to small, the individuals corresponding to the first three fitness values are taken as , , and , and their corresponding location information is respectively , , and ;

- Step 4: To find the best location of prey, use Equation (9) to calculate the nonlinear change parameter , and then update the A and C values according to Equation (3);

- Step 5: Use Equation (13) to update the position of population individuals, recalculate fitness values, and update the , , and values;

- Step 6: Determine whether reaches the Max_iter value; if it is reached, the best solution (that is, the fitness value of ) will be output; otherwise, return to Step 3 to continue execution.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- O’Dwyer, A. PI and PID Controller Tuning Rules for Time Delay Processes: A Summary. In Proceedings of the Irish Signals and Systems Conference, Dublin, Ireland, June 1999; Available online: https://arrow.tudublin.ie/cgi/viewcontent.cgi?article=1074&context=engscheleart (accessed on 1 November 2023).

- Joseph, S.B.; Dada, E.G.; Abidemi, A.; Oyewola, D.O.; Khammas, B.M. Metaheuristic algorithms for PID controller parameters tuning: Review, approaches and open problems. Heliyon 2022, 8, e09399. [Google Scholar] [CrossRef] [PubMed]

- Nabati, E.G.; Engell, S. Online Adaptive Robust Tuning of PID Parameters. IFAC Proc. Vol. 2012, 45, 625–630. [Google Scholar] [CrossRef]

- Borase, R.P.; Maghade, D.K.; Sondkar, S.Y.; Pawar, S.N. A review of PID control, tuning methods and applications. Int. J. Dyn. Control. 2021, 9, 818–827. [Google Scholar] [CrossRef]

- Guo, Y.-Q.; Zha, X.-M.; Shen, Y.-Y.; Wang, Y.-N.; Chen, G. Research on PID position control of a hydraulic servo system based on kalman genetic optimization. Actuators 2022, 11, 162. [Google Scholar] [CrossRef]

- Xiao, L. Parameter tuning of PID controller for beer filling machine liquid level control based on improved genetic algorithm. Comput. Intell. Neurosci. 2021, 2021, 7287796. [Google Scholar] [CrossRef] [PubMed]

- Cárdenas, J.A.; Carrero, U.E.; Camacho, E.C.; Calderón, J.M. Optimal PID ø axis Control for UAV Quadrotor based on Multi-Objective PSO. IFAC-PapersOnLine 2022, 55, 101–106. [Google Scholar] [CrossRef]

- Ye, Y.; Yin, C.-B.; Gong, Y.; Zhou, J.-J. Position control of nonlinear hydraulic system using an improved PSO based PID controller. Mech. Syst. Signal Proc. 2017, 83, 241–259. [Google Scholar] [CrossRef]

- Mirjalili, S.; Mirjalili, S.M.; Lewis, A. Grey wolf optimizer. Adv. Eng. Softw. 2014, 69, 46–61. [Google Scholar] [CrossRef]

- Fei, G. Overview of the Application of Genetic Algorithms in the Field of Automatic Control. Electron. World 2017, 9, 51. [Google Scholar] [CrossRef]

- Xiang, Z.; Ji, D.; Zhang, H.; Wu, H.; Li, Y. A simple PID-based strategy for particle swarm optimization algorithm. Inf. Sci. 2019, 502, 558–574. [Google Scholar] [CrossRef]

- Rodríguez, L.; Castillo, O.; Soria, J.; Melin, P.; Valdez, F.; Gonzalez, C.I.; Martinez, G.E.; Soto, J. A fuzzy hierarchical operator in the grey wolf optimizer algorithm. Appl. Soft Comput. 2017, 57, 315–328. [Google Scholar] [CrossRef]

- Kumar, V.; Kumar, D. An astrophysics-inspired Grey wolf algorithm for numerical optimization and its application to engineering design problems. Adv. Eng. Softw. 2017, 112, 231–254. [Google Scholar] [CrossRef]

- Heidari, A.A.; Pahlavani, P. An efficient modified grey wolf optimizer with Lévy flight for optimization tasks. Appl. Soft Comput. 2017, 60, 115–134. [Google Scholar] [CrossRef]

- Chinglemba, T.; Biswas, S.; Malakar, D.; Meena, V.; Sarkar, D.; Biswas, A. Introductory Review of Swarm Intelligence Techniques. In Advances in Swarm Intelligence: Variations and Adaptations for Optimization Problems; Springer: Berlin/Heidelberg, Germany, 2022; pp. 15–35. [Google Scholar]

- Selvaraj, S.; Choi, E. Survey of swarm intelligence algorithms. In Proceedings of the 3rd International Conference on Software Engineering and Information Management, Sydney, Australia, 12–15 January 2020; pp. 69–73. [Google Scholar]

- Phan, H.D.; Ellis, K.; Barca, J.C.; Dorin, A. A survey of dynamic parameter setting methods for nature-inspired swarm intelligence algorithms. Neural Comput. Appl. 2020, 32, 567–588. [Google Scholar] [CrossRef]

- Zhao, Z.Q.; Liu, S.J.; Pan, J.S. A PID parameter tuning method based on the improved QUATRE algorithm. Algorithms 2021, 14, 173. [Google Scholar] [CrossRef]

- Soleimani Amiri, M.; Ramli, R.; Ibrahim, M.F.; Abd Wahab, D.; Aliman, N. Adaptive particle swarm optimization of PID gain tuning for lower-limb human exoskeleton in virtual environment. Mathematics 2020, 8, 2040. [Google Scholar] [CrossRef]

- Caponetto, R.; Fortuna, L.; Porto, D. Parameter tuning of a non integer order PID controller. In Proceedings of the Fifteenth International Symposium on Mathematical Theory of Networks and Systems, Notre Dame, IN, USA, 12–16 August 2002. [Google Scholar]

- Altintas, G.; Aydin, Y. Optimization of fractional and integer order PID parameters using big bang big crunch and genetic algorithms for a MAGLEV system. IFAC-PapersOnLine 2017, 50, 4881–4886. [Google Scholar] [CrossRef]

- Yang, R.; Liu, Y.; Yu, Y.; He, X.; Li, H. Hybrid improved particle swarm optimization-cuckoo search optimized fuzzy PID controller for micro gas turbine. Energy Rep. 2021, 7, 5446–5454. [Google Scholar] [CrossRef]

- Shan, L.; Qiang, H.; Li, J.; Wang, Z. Chaotic optimization algorithm based on Tent mapping. Control Decis. Mak. 2005, 20, 179. [Google Scholar] [CrossRef]

- Wang, Z.; Chen, Y.; Ding, S.; Liang, D.; He, H. A novel particle swarm optimization algorithm with Lévy flight and orthogonal learning. Swarm Evol. Comput. 2022, 75, 101207. [Google Scholar] [CrossRef]

- Guerrero-Luis, M.; Valdez, F.; Castillo, O. A Review on the Cuckoo Search Algorithm. In Fuzzy Logic Hybrid Extensions of Neural and Optimization Algorithms: Theory and Applications; Springer: Berlin/Heidelberg, Germany, 2021; pp. 113–124. [Google Scholar] [CrossRef]

- Hussein, W.A.; Sahran, S.; Abdullah, S.N.H.S. Patch-Levy-based initialization algorithm for Bees Algorithm. Appl. Soft Comput. 2014, 23, 104–121. [Google Scholar] [CrossRef]

- Kommuri, S.K.; Defoort, M.; Karimi, H.R.; Veluvolu, K.C. A Robust Observer-Based Sensor Fault-Tolerant Control for PMSM in Electric Vehicles. IEEE Trans. Ind. Electron. 2016, 63, 7671–7681. [Google Scholar] [CrossRef]

- Li, S.; Liu, H.; Fu, W. An Improved Predictive Functional Control Method with Application to PMSM systems. Int. J. Electron. 2016, 104, 126–142. [Google Scholar] [CrossRef]

- Long, W.; Cai, S.; Jiao, J.; Zhang, W.-Z.; Tang, M.-Z. A hybrid grey wolf optimization algorithm for high-dimensional optimization problems. Control Decis. 2016, 31, 1991. [Google Scholar] [CrossRef]

- Gao, Z.-M.; Zhao, J. An improved grey wolf optimization algorithm with variable weights. Comput. Intell. Neurosci. 2019, 2019, 2981282. [Google Scholar] [CrossRef]

| Symbol | Physical Meaning | Parameter |

|---|---|---|

| Moment of inertia of the drive shaft | ||

| Motor output torque | ||

| Torsional stiffness coefficient of a driven shaft | ||

| Output torque of a ball screw driven by a driven shaft | ||

| Moving platform mass | ||

| Moving platform displacement | 0–130 cm | |

| Coupling transmission output torque | ||

| Moment of inertia of a driven shaft | 0.15 kg·m2 | |

| Motor output angle | 0–360° | |

| Driven shaft damping coefficient | ||

| Output angle of a ball screw driven by a driven shaft | 0–360° | |

| Damping coefficient of a moving platform | ||

| Load resistance of a moving platform | ||

| Coupling transmission output angle | 0–360° |

| Function | Dim | Range | |

|---|---|---|---|

| 30 | [−100, 100] | 0 | |

| 30 | [−10, 10] | 0 | |

| 30 | [−100, 100] | 0 | |

| 30 | [−30, 30] | 0 | |

| 30 | [−1.28, 1.28] | 0 | |

| 30 | [−5.12, 5.12] | 0 | |

| 30 | [−5.12, 5.12] | 0 | |

| 30 | [−50, 50] | 0 |

| Function | Dim | Mean | STD | Mean | STD |

|---|---|---|---|---|---|

| GWO | GWO_a | ||||

| F1 | 30 | 8.2498 × 10−28 | 9.20958 × 10−28 | 2.69527 × 10−39 | 3.35115 × 10−39 |

| F2 | 30 | 1.03689 × 10−16 | 6.84302 × 10−17 | 1.28624 × 10−23 | 9.90575 × 10−24 |

| F3 | 30 | 9.80503 × 10−7 | 7.64443 × 10−7 | 3.10067 × 10−10 | 2.6378 × 10−10 |

| F4 | 30 | 27.26432 | 0.730128317 | 2.68 × 10 | 0.577598699 |

| F5 | 30 | 2.06 × 10−3 | 0.000839552 | 1.603 × 103 | 7.747 × 104 |

| F6 | 30 | 7.38971 × 10−14 | 2.60506 × 10−14 | 0 | 0 |

| F7 | 30 | 1.07 × 10−13 | 1.473 × 10−14 | 2.007 × 10−15 | 4.263 × 10−16 |

| F8 | 30 | 6.70 × 10−1 | 1.979 × 10−1 | 5.495 × 10−1 | 1.307 × 10−1 |

| GWO_NEW | CSO_IGWO | ||||

| F1 | 30 | 5.07317 × 10−39 | 5.45724 × 10−39 | 5.48004 × 10−40 | 5.22096 × 10−40 |

| F2 | 30 | 6.76155 × 10−24 | 4.77805 × 10−24 | 6.434 × 10−24 | 3.31312 × 10−24 |

| F3 | 30 | 3.63217 × 10−10 | 2.96633 × 10−10 | 8.10248 × 10−11 | 7.43226 × 10−11 |

| F4 | 30 | 27.12109 | 0.549138876 | 2.66 × 10 | 0.59195957 |

| F5 | 30 | 1.658 × 103 | 8.374 × 104 | 5.81 × 10−4 | 2.323 × 104 |

| F6 | 30 | 0 | 0 | 0 | 0 |

| F7 | 30 | 2.114 × 10−15 | 5.037 × 10−16 | 1.54 × 10−16 | 2.505 × 10−17 |

| F8 | 30 | 7.423 × 10−1 | 1.451 × 10−1 | 3.82 × 10−1 | 1.299 × 10−1 |

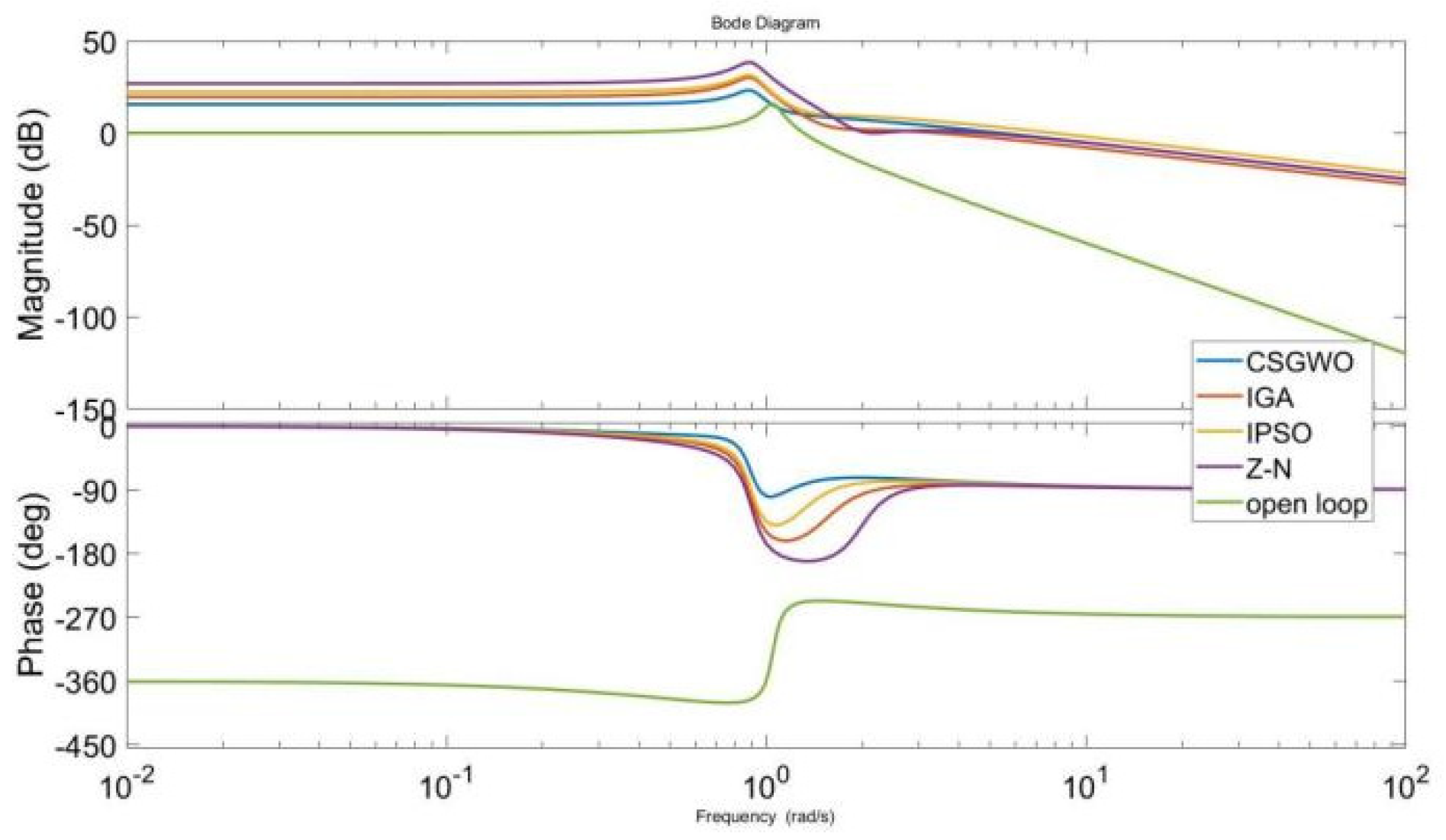

| Tuning Method | ||||

|---|---|---|---|---|

| None | 1.75 | 52.451 | 30.67 | 2 |

| Z–N method | 2.0724 | 25.374 | 8.289 | 0 |

| IPSO method | 1.381 | 14.1 | 7.726 | 0 |

| IGA method | 4.483 | 4.6 | 7.291 | 0 |

| CSO_IGWO method | 2.1316 | 4.5911 | 4.021 | 0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, K.; Xiao, B.; Wang, C.; Liu, X.; Liang, S.; Zhang, X. Cuckoo Coupled Improved Grey Wolf Algorithm for PID Parameter Tuning. Appl. Sci. 2023, 13, 12944. https://doi.org/10.3390/app132312944

Chen K, Xiao B, Wang C, Liu X, Liang S, Zhang X. Cuckoo Coupled Improved Grey Wolf Algorithm for PID Parameter Tuning. Applied Sciences. 2023; 13(23):12944. https://doi.org/10.3390/app132312944

Chicago/Turabian StyleChen, Ke, Bo Xiao, Chunyang Wang, Xuelian Liu, Shuning Liang, and Xu Zhang. 2023. "Cuckoo Coupled Improved Grey Wolf Algorithm for PID Parameter Tuning" Applied Sciences 13, no. 23: 12944. https://doi.org/10.3390/app132312944

APA StyleChen, K., Xiao, B., Wang, C., Liu, X., Liang, S., & Zhang, X. (2023). Cuckoo Coupled Improved Grey Wolf Algorithm for PID Parameter Tuning. Applied Sciences, 13(23), 12944. https://doi.org/10.3390/app132312944