Study on the Energy Release Law of Overburden Rock Breaking and Anti-Rockburst Technology in the Knife Handle Working Face of a Gently Inclined Coal Seam

Abstract

:1. Introduction

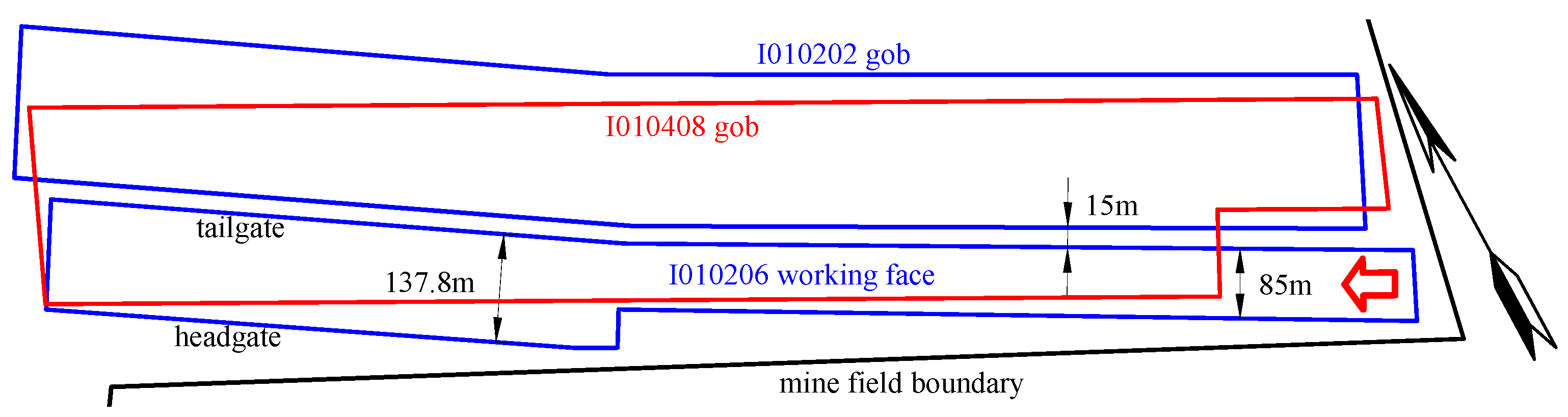

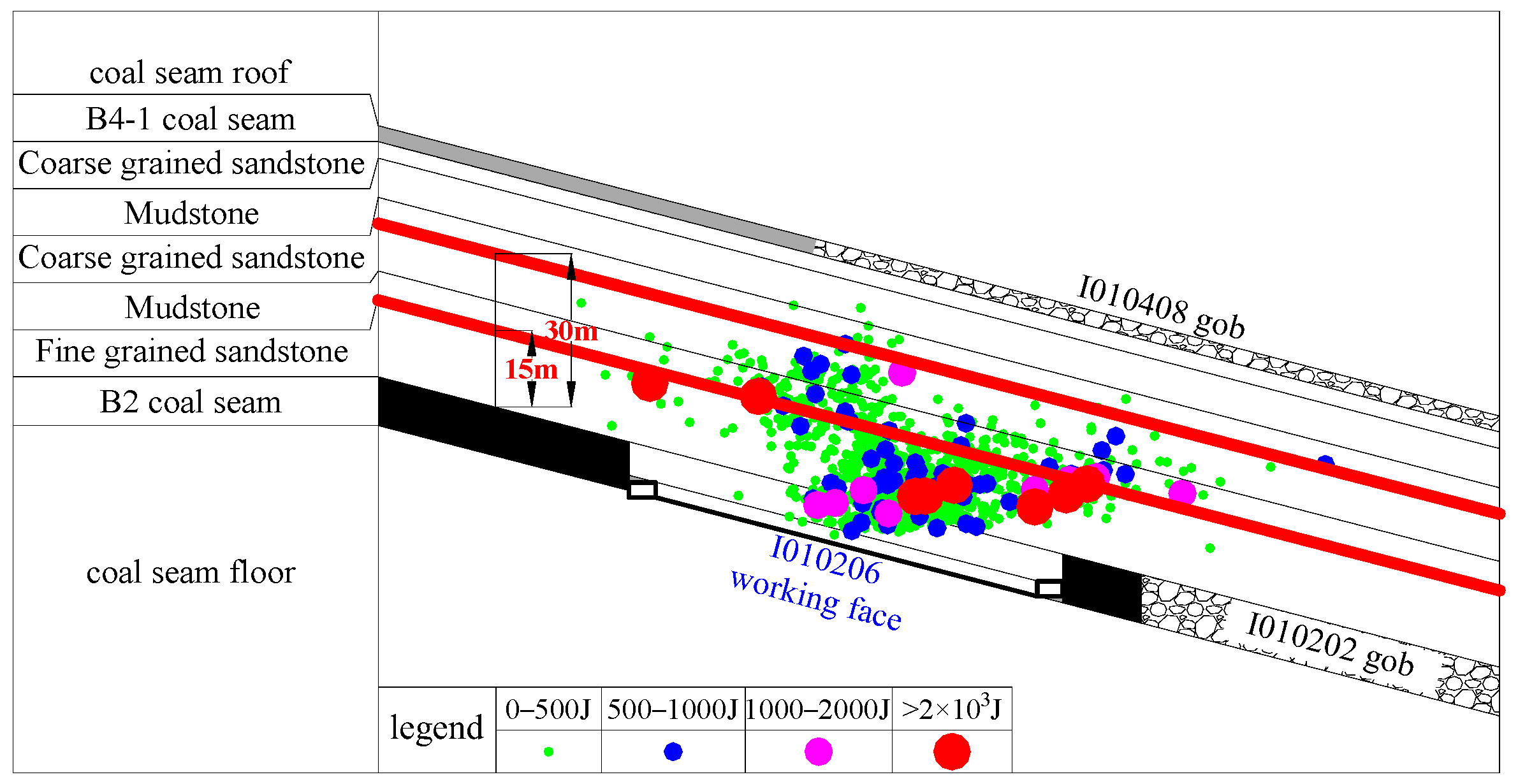

2. Engineering Background

3. Knife Handle-Type Working Face Overlying Rock Breaking and Inducing Mechanism

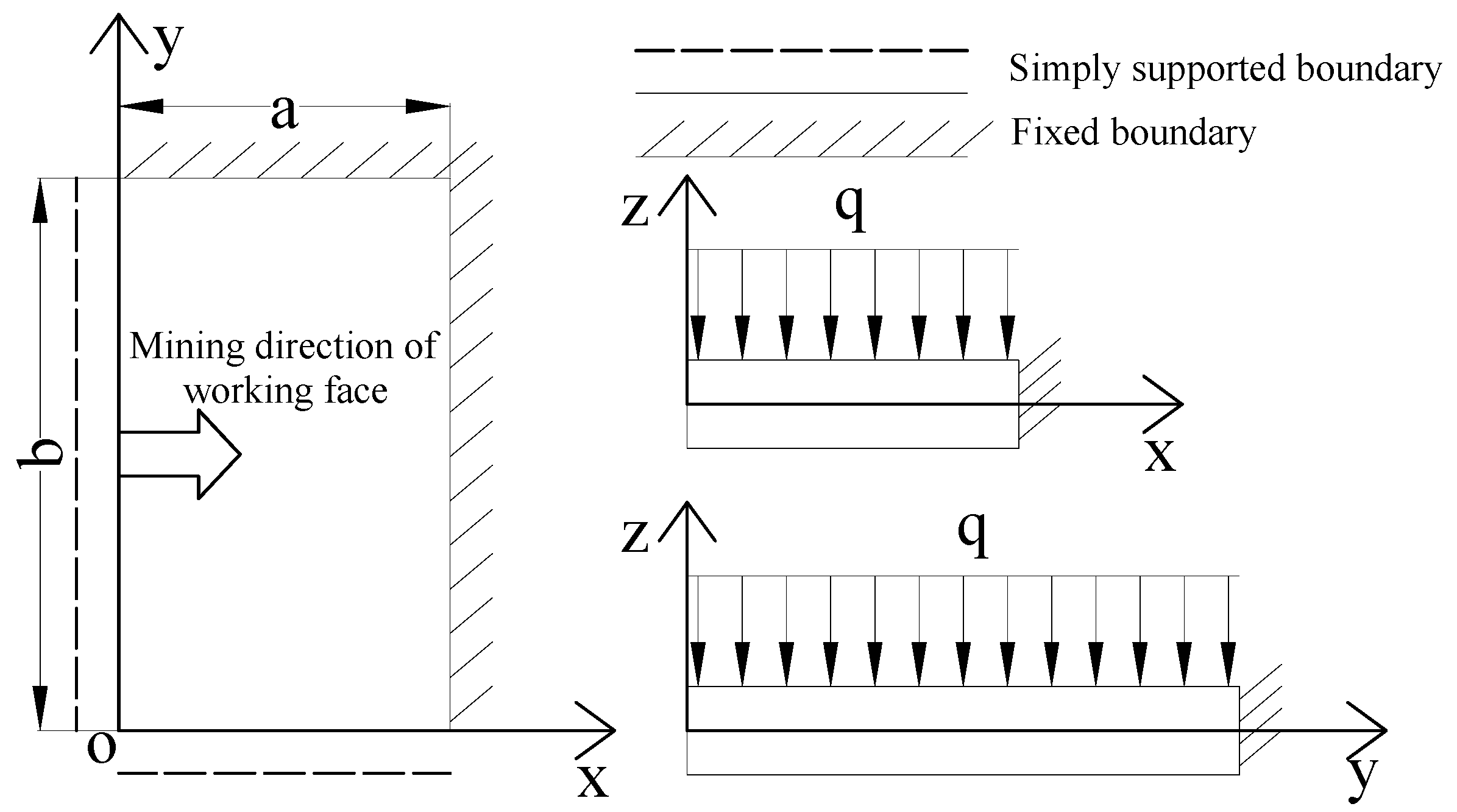

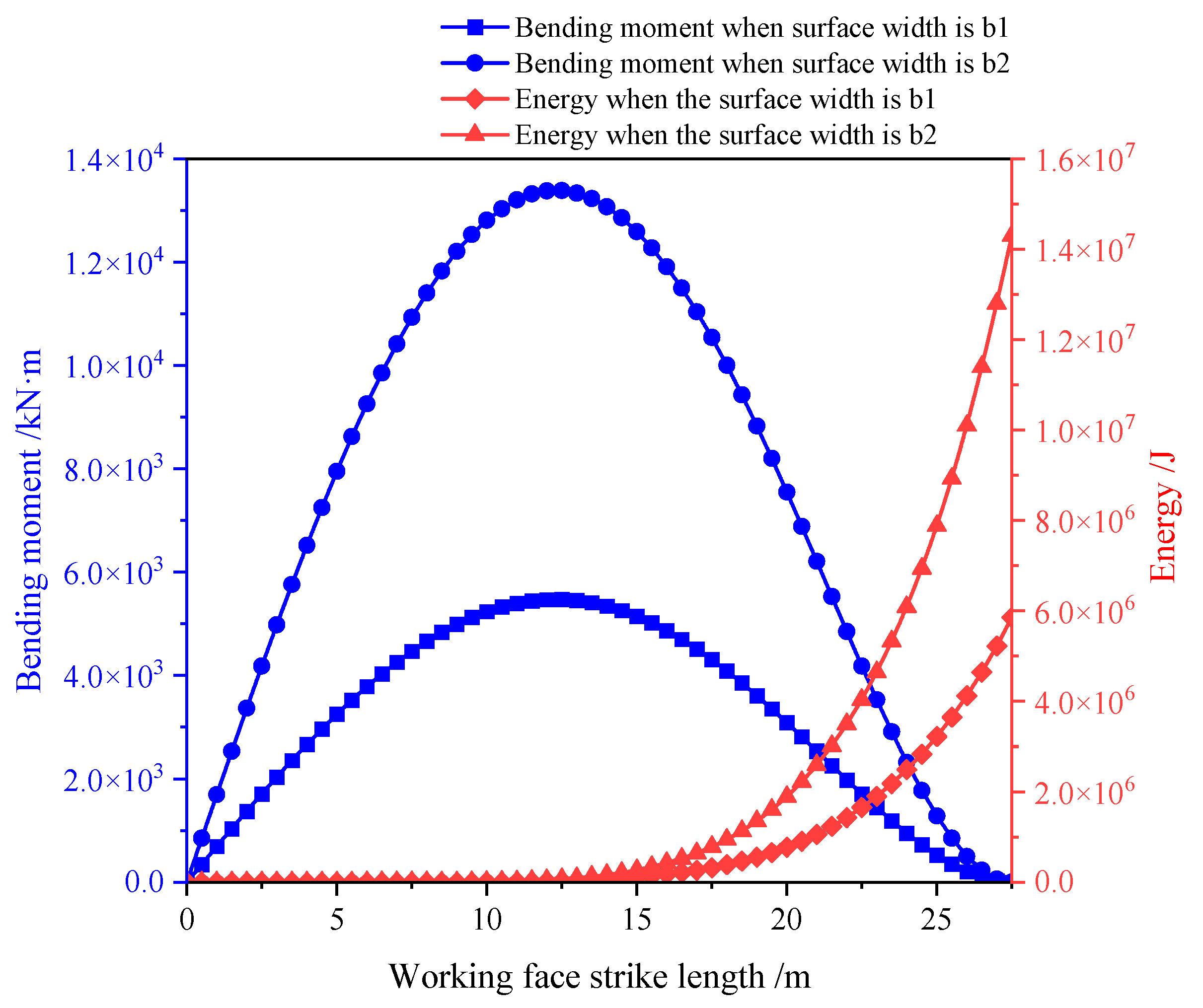

3.1. Stope Roof Model

3.2. Analysis of Roof Breakage Induction Mechanism

4. Numerical Simulation Analysis of Knife Handle Working Face

4.1. Materials and Methods

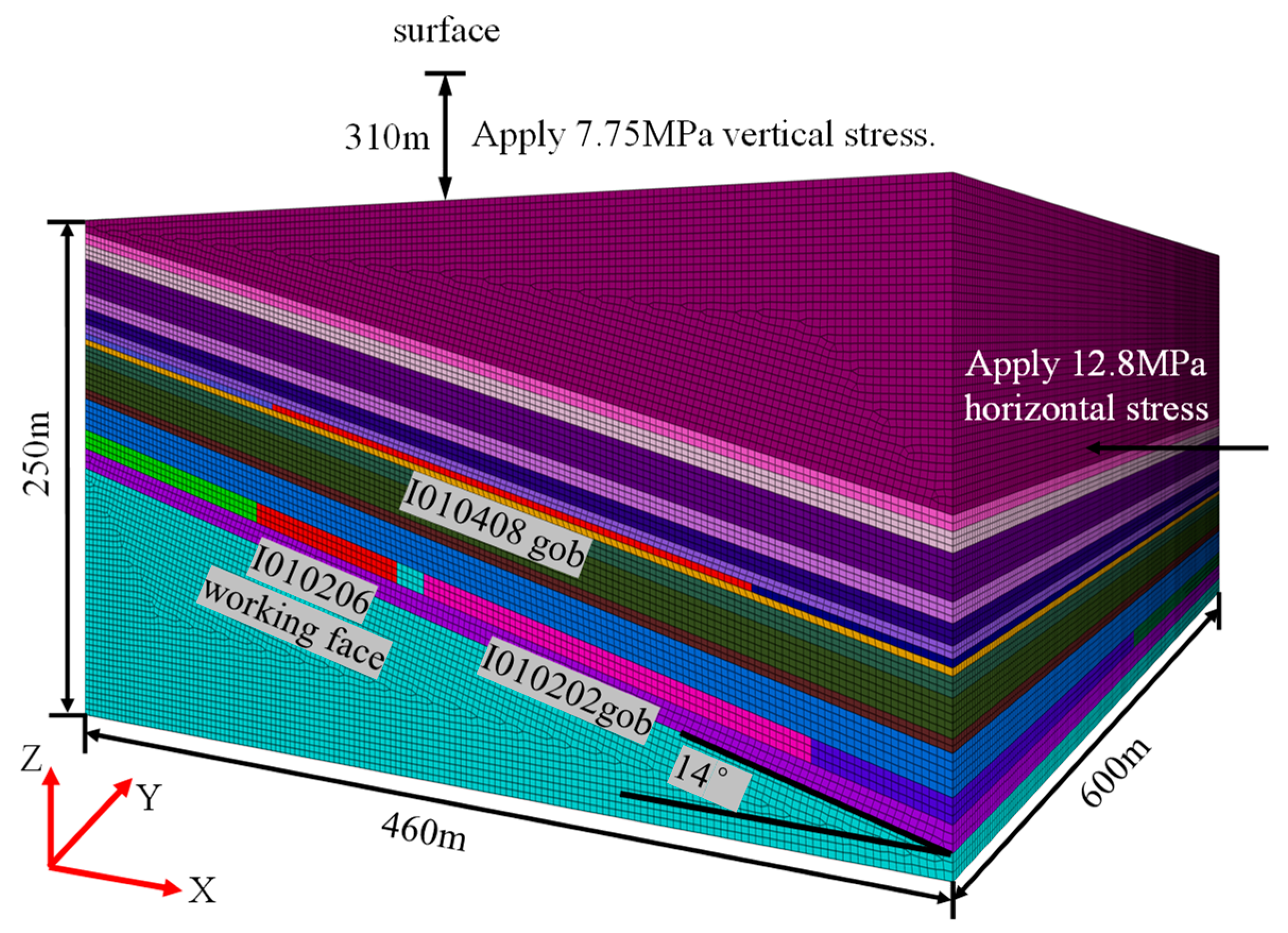

4.1.1. Building the Numerical Model

4.1.2. Experimental Scheme

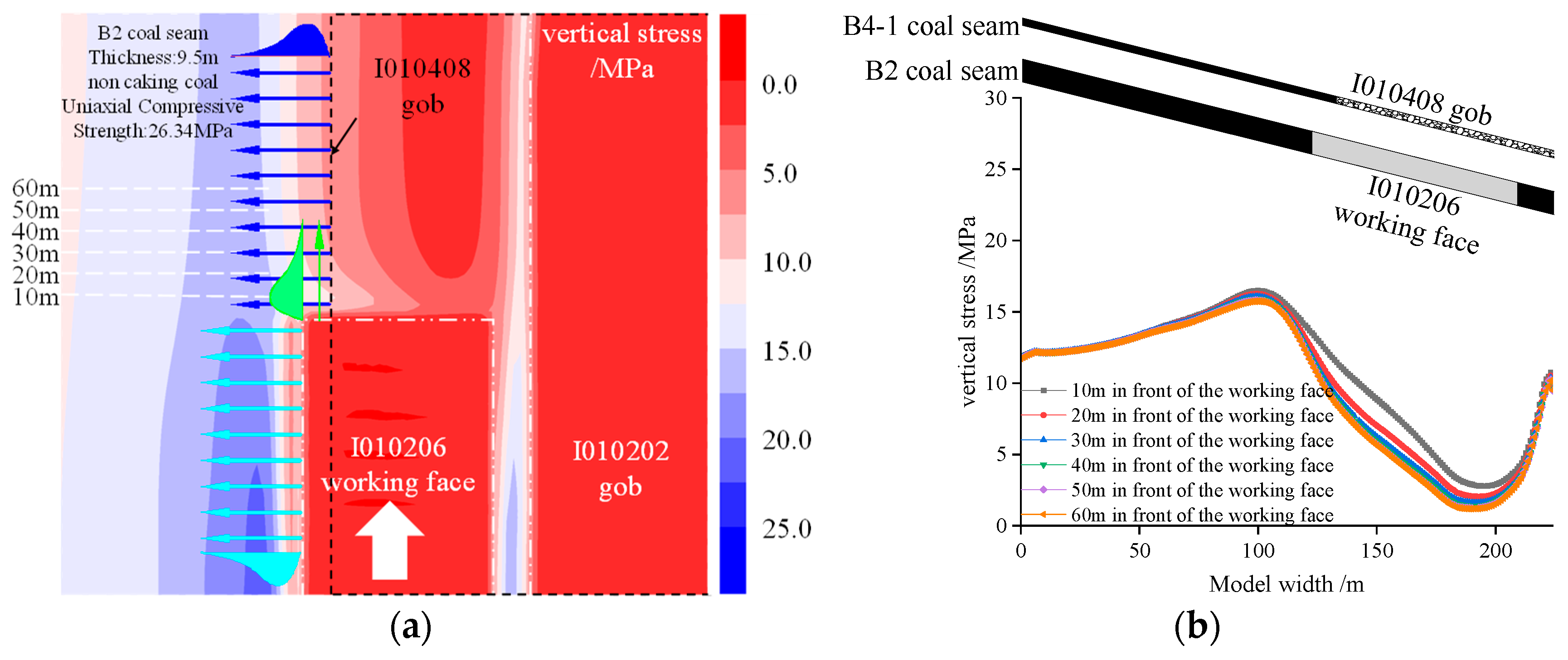

4.2. Evolution Rules of Support Pressure of Knife Handle Working Surface

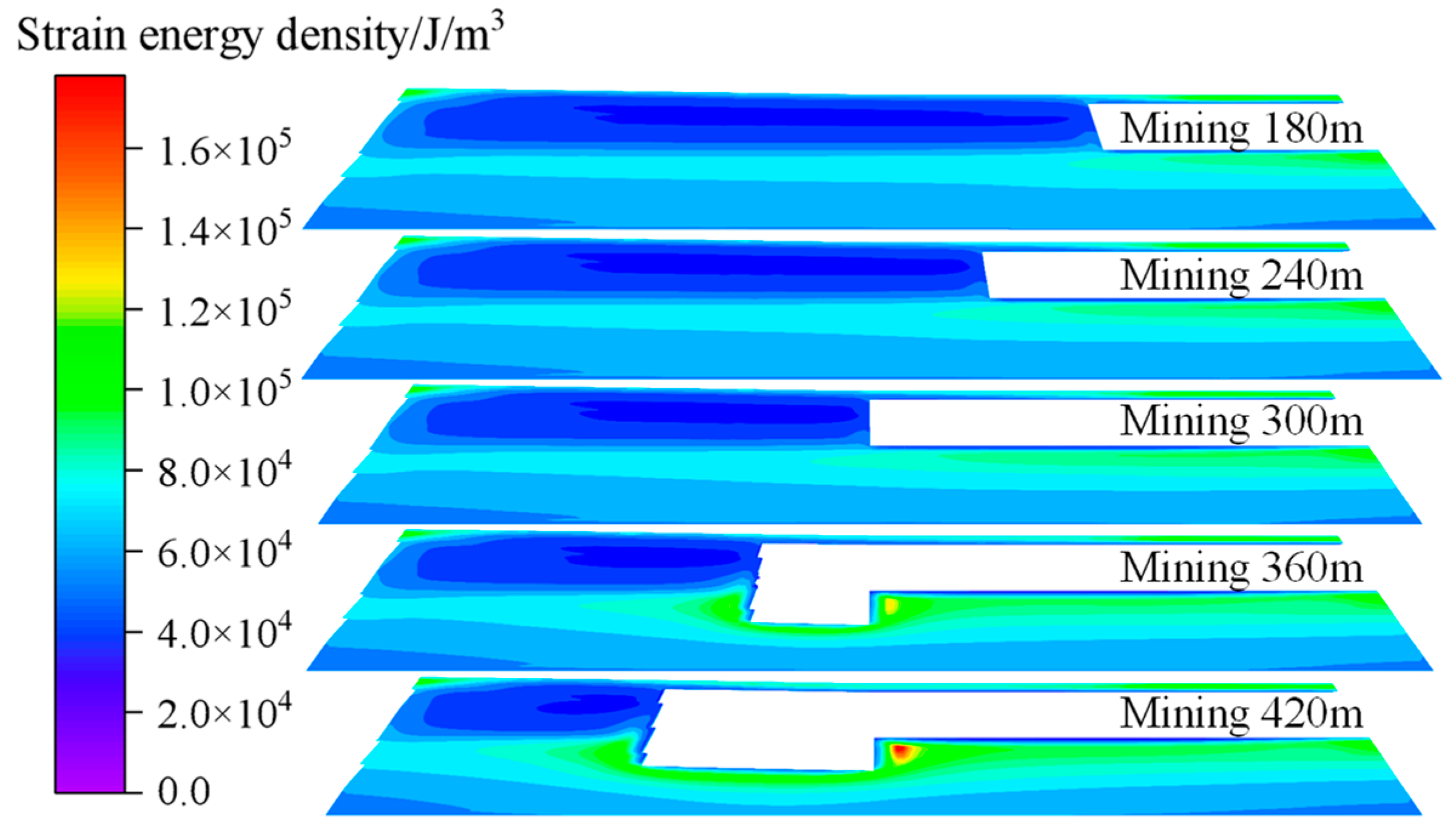

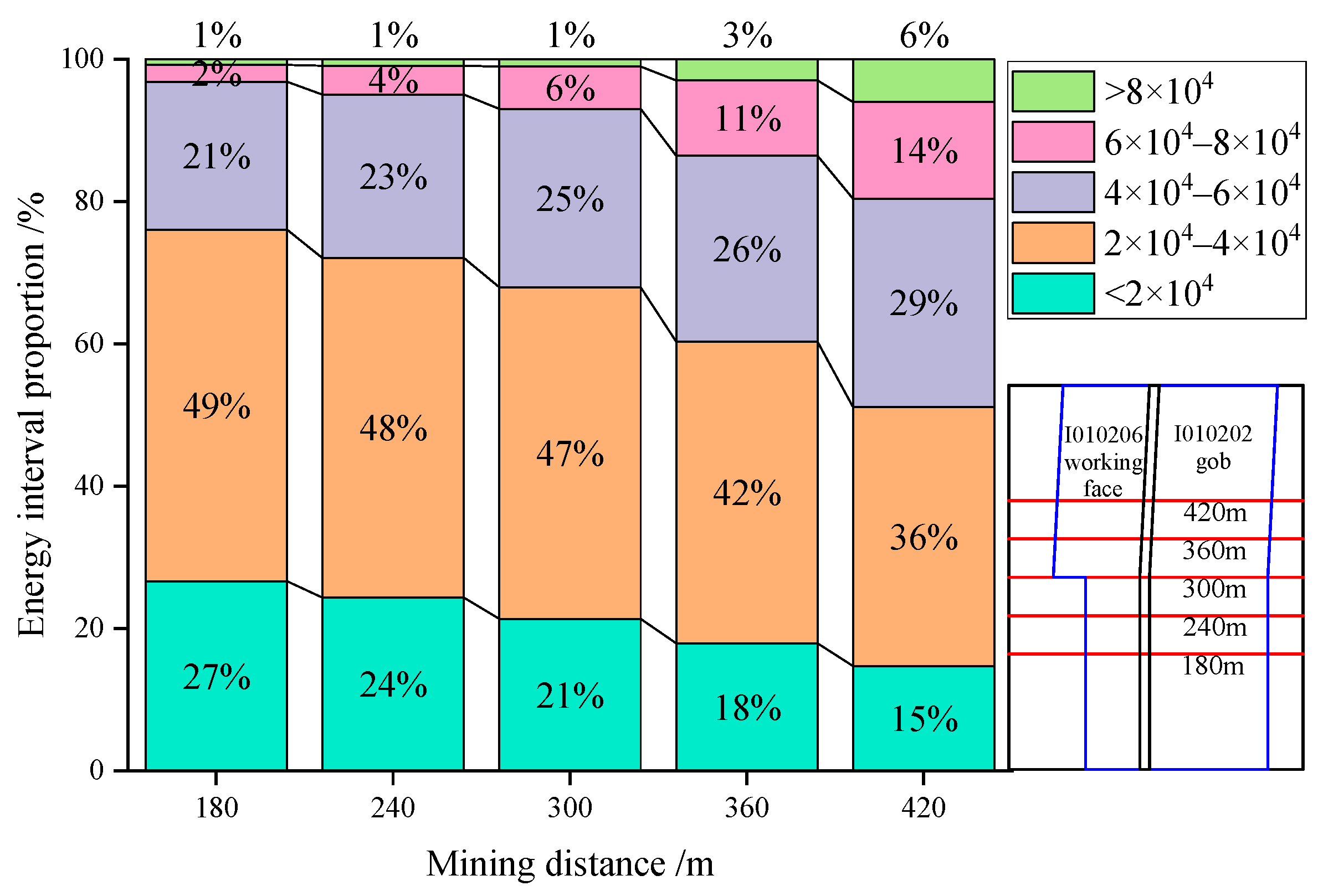

4.3. Energy Evolution Characteristics of Overlying Rock in Knife Handle Working Face

5. Measures for Preventing and Controlling Dynamic Disasters in Knife Handle Working Surfaces

5.1. Pre-Cracking Blasting Control Measures

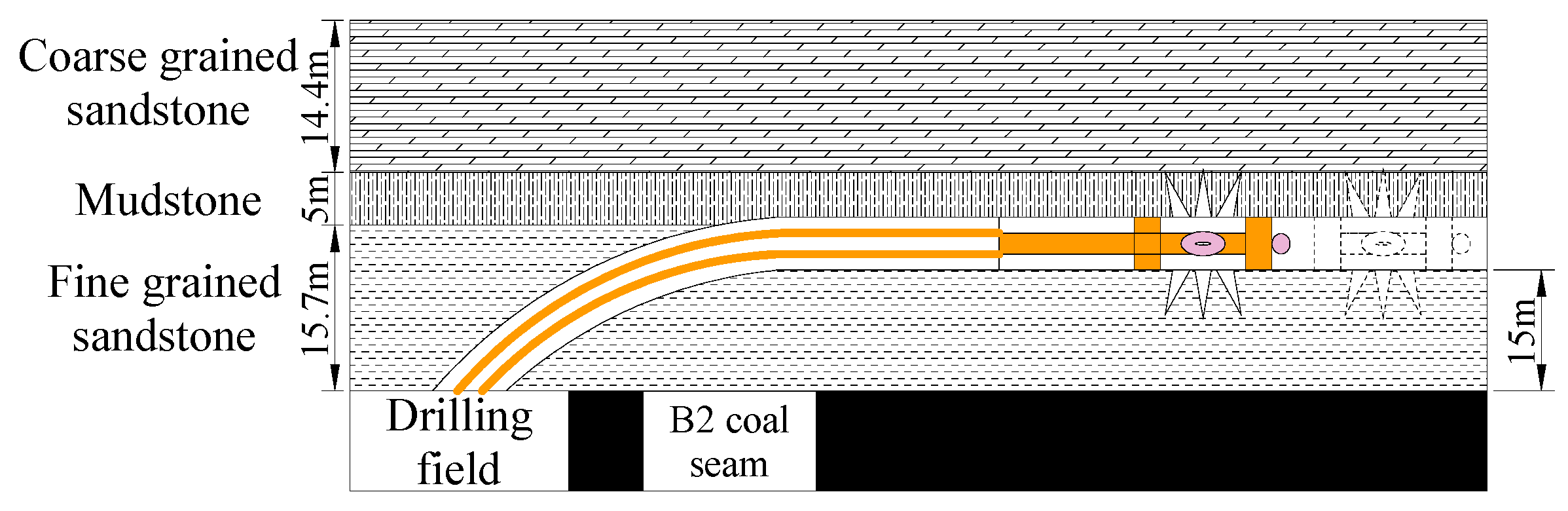

5.2. Hydraulic Fracturing Advanced Anti-Rockburst Technology

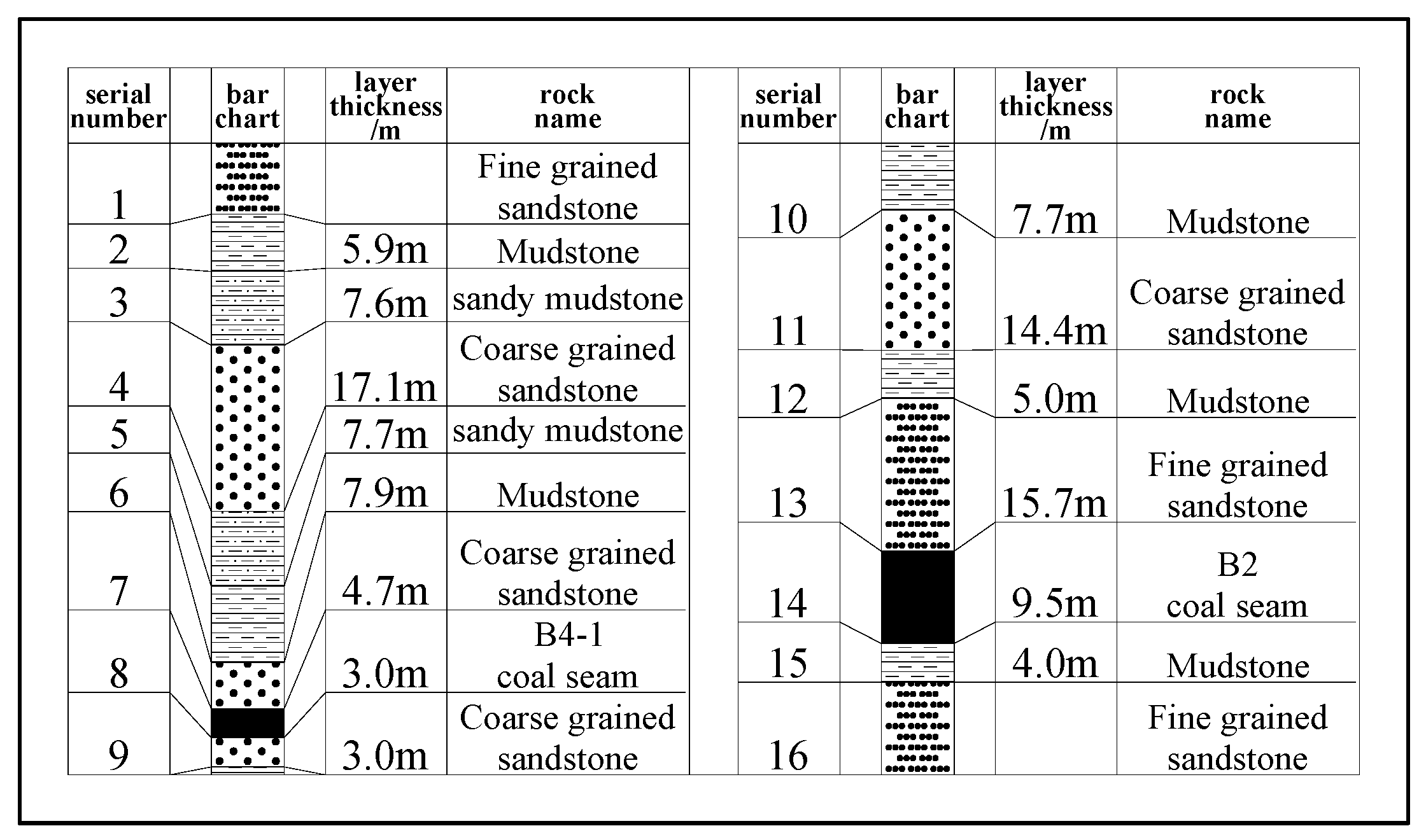

5.2.1. Identification of Key Layers of Overlying Rock

5.2.2. Identification of Energy Release Horizon of Overlying Strata

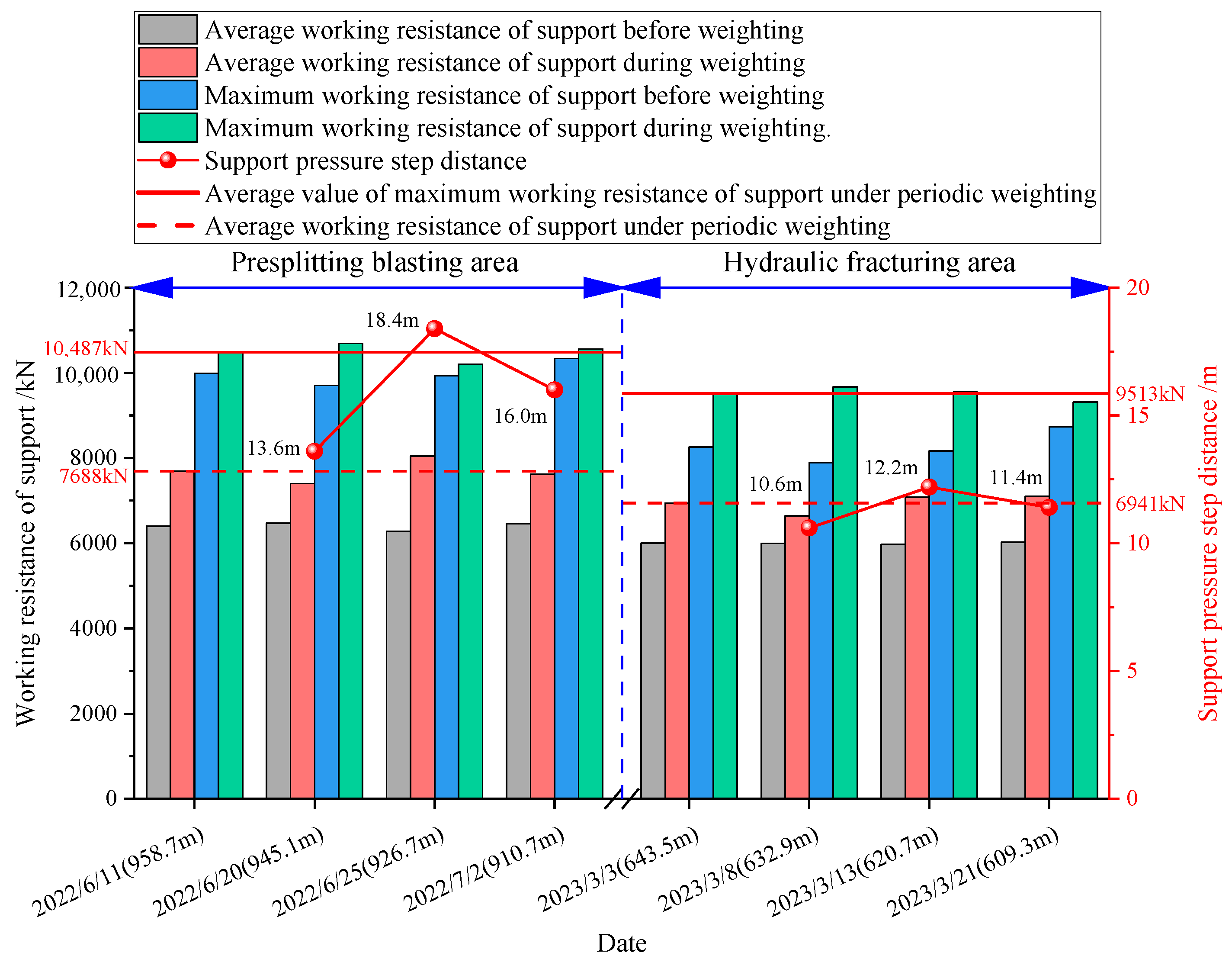

5.3. Effect Test of Pressure Relief Measures

6. Conclusions

- (1)

- Based on the actual conditions of the working face, a mechanical model of the roof’s periodic fracture thin plate was established for quantitative analysis, and a mechanical model of the roof with simple support on both sides and fixed support on both sides was determined. As the width of the working face increases, the load on the roof increases and the load of overlying strata is transferred to the coal in front of the working face. The coal inclines to the upper and lower sides of the working face. The high static load is caused by the lateral support pressure of the gob and the high dynamic load is caused by the large-area collapse of the roof; they are more likely to induce rock burst.

- (2)

- Through numerical simulation, the evolution and energy release rules of the advanced support pressure are revealed in the knife handle working face. The results show that when the working surface width increases from 85 m to 137.8 m, the peak value of the advanced supporting pressure of the working surface increases from 10.31 MPa to 14.62 MPa; the increase of support pressure is 4.31MPa. The peak strain energy density of the working face increases from 1.21 × 105 J/m3 to 1.78 × 105 J/m3. As the width of the working face increases, the peak strain energy density shows an increasing trend, and the large energy area gradually increases when the working face advances.

- (3)

- In view of on-site impact risk factors such as higher energy concentration on the roof when the width of the working surface increases, and stronger dynamic load disturbance when the hard roof collapses, measures for advanced weakening of the hydraulic fracturing roof are proposed; the hydraulic fracturing layer is determined through the identification of key overlying rock layers and energy release layers. Support pressure and microseismic data are used to analyze the working face rockburst prevention and control plans. After using hydraulic fracturing technology, the working face roof pressure step distance was reduced, and the frequency of microseismic energy was significantly reduced, which reduced the risk of working face impact and ensured safe mining of the working face.

- (4)

- The testing of the hydraulic fracturing effect on the working face needs to be further studied and solved in actual situations. In addition to support pressure and microseismic signals, transient electromagnetic detection and borehole peeking are also often used to test the pressure relief effect. Different methods will be used in future research. Comparative analysis of fracturing effects can further improve the accuracy of monitoring results. In addition, microseismic events and acoustic emission events during the mining process can be analyzed in depth, impact risk evaluation indicators and discrimination criteria can be determined, and impact risk can be evaluated timely and accurately to ensure safe mining on the working face.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, L.; Zhou, H.; Rong, T.; Ren, W. Research on the evolution rules and disturbance characteristics of stress field in deep coal mining. Chin. J. Rock Mech. Eng. 2019, 38, 2944–2954. [Google Scholar]

- Xie, H.; Zhou, H.; Xue, D.; Wang, W.; Zhang, R.; Gao, F. Research and thinking on deep coal mining and ultimate mining depth. J. China Coal Soc. 2012, 37, 535–542. [Google Scholar]

- He, M.; Xie, H.; Peng, S.; Jiang, Y. Research on rock mass mechanics in deep mining. Chin. J. Rock Mech. Eng. 2005, 24, 2803–2813. [Google Scholar]

- Pan, J.; Qi, Q.; Liu, S.; Wang, S.; Ma, W.; Kang, X. Characteristics, types and source prevention and control technology of rock bursts in deep coal mining in my country. J. China Coal Soc. 2020, 45, 111–121. [Google Scholar]

- Zhao, T.; Zhang, H.; Chen, Y.; Tan, Y. Evolution of support pressure distribution and its impact on coal and rock mass damage. J. Liaoning Tech. 2010, 29, 420–423. [Google Scholar]

- He, J.; Dou, L.; Wang, S.; Shan, C. Research on the mechanism and types of impact mine pressure induced by hard roof. J. Min. Saf. Eng. 2017, 34, 1122–1127. [Google Scholar]

- Mou, Z.; Dou, L.; Li, X.; Zhang, M. Research on the influence of roof rock layers on impact mine pressure. J. China Univ. Min. Technol. 2010, 39, 40–44. [Google Scholar]

- Cui, F.; Jia, C.; Lai, X.; Chen, J. Research on the evolution characteristics and stability of the overlying rock structure in upward mining of coal seams prone to strong impact at close range. Chin. J. Rock Mech. Eng. 2020, 39, 507–521. [Google Scholar]

- Wang, X.; Lu, M.; Gao, Y.; Luo, W.; Liu, W. Structural mechanical characteristics and instability law of roof key block breaking in gob-side roadway. Adv. Civ. Eng. 2020, 2020, 6682303. [Google Scholar] [CrossRef]

- Pu, H.; Miao, X. Influence of key layer movement in mining overburden on surrounding rock support pressure distribution. Chin. J. Rock Mech. Eng. 2002, 21, 2366–2369. [Google Scholar]

- Suchowerska, A.M.; Merifield, R.S.; Carter, J.P. Vertical stress changes in multi-seam mining under supercritical longwall panels. Int. J. Rock Mech. Min. Sci. 2013, 61, 306–320. [Google Scholar] [CrossRef]

- Dou, L.; He, J.; Cao, A.; Gong, S.; Cai, W. Principle and prevention of dynamic and static load superposition of coal mine shock pressure. J. China Coal Soc. 2015, 40, 1469–1476. [Google Scholar]

- He, J.; Dou, L.; Cao, A.; Gong, S.-Y.; Lv, J.-W. Rock burst induced by roof breakage and its prevention. J. Cent. South Univ. 2012, 19, 1086–1091. [Google Scholar] [CrossRef]

- Cao, A.; Dou, L.; Bai, X.; Liu, Y.; Yang, K.; Li, J.; Wang, C. The occurrence mechanism and management status and problems of mine earthquakes in my country’s coal mines. J. China Coal Soc. 2023, 48, 1894–1918. [Google Scholar]

- Jiang, F.; Feng, Y.; Kouame, K.R.A.; Wang, J. Research on the “creep type” impact mechanism of extra-thick coal seams under high geostress. Chin. J. Geotech. Eng. 2015, 37, 1762–1768. [Google Scholar]

- Li, N.; Wang, E.; Ge, M.; Liu, J. The fracture mechanism and acoustic emission analisis of hard roof: A physical modeling study. Arab. J. Geosci. 2015, 8, 1895–1902. [Google Scholar] [CrossRef]

- Pan, J. Research on coal mine rock burst initiation theory and its complete set of technical systems. J. China Coal Soc. 2019, 44, 173–182. [Google Scholar]

- Zhao, S. Mechanism and engineering practice of synergistic anti-collision mechanism and engineering practice of deep hole roof pre-splitting blasting. J. China Coal Soc. 2021, 46, 3419–3432. [Google Scholar]

- Chai, J. Investigation of Spontaneous Combustion Zones and Index Gas Prediction System in Goaf of “Isolated Island” Working Face. Fire 2022, 5, 67. [Google Scholar] [CrossRef]

- Bosikov, I.I.; Martyushev, N.V.; Klyuev, R.V.; Savchenko, I.A.; Kukartsev, V.V.; Kukartsev, V.A.; Tynchenko, Y.A. Modeling and Complex Analysis of the Topology Parameters of Ventilation Networks When Ensuring Fire Safety While Developing Coal and Gas Deposits. Fire 2023, 6, 95. [Google Scholar] [CrossRef]

- Zhao, X.; Huang, B.; Grasselli, G. Numerical Investigation of the Fracturing Effect Induced by Disturbing Stress of Hydrofracturing. Front. Earth Sci. 2021, 22, 2296–6463. [Google Scholar] [CrossRef]

- Grant, A.G. Fluid effect on velocity and attenuation in sandstone. J. Acoust. Soc. Am. 1994, 96, 1158–1173. [Google Scholar]

- Pan, J.; Ma, W.; Liu, S.; Gao, J. Experiment on directional pre-cracking and anti-scour technology of water jet prefabricated slots in hard roof. Chin. J. Rock Mech. Eng. 2021, 40, 1591–1602. [Google Scholar]

- Tang, S.B.; Huang, R.Q.; Wang, S.Y.; Bao, C.; Tang, C. Study of the fracture process in heterogeneous materials around boreholes filled with expansion cement. Int. J. Solids Struct. 2017, 112, 1–15. [Google Scholar] [CrossRef]

- Tang, S.; Wang, J.; Chen, P. Theoretical and numerical studies of cryogenic fracturing induced by thermal shock for reservoir stimulation. Int. J. Rock Mech. Min. Sci. 2020, 125, 104160. [Google Scholar] [CrossRef]

- Yang, J.; Chen, K.; Wang, Z.; Pang, N. Advanced weakening control technology for dynamic disasters in hard roofs. J. China Coal Soc. 2020, 45, 3371–3379. [Google Scholar]

- Yu, H. Research on the Movement of Overlying Rock Structure and Appearance of Mine Pressure in Close Coal Seam Mining. Ph.D. Thesis, China University of Mining & Technology (Beijing), Beijing, China, 2015. [Google Scholar]

- Xu, J.; Qian, M. Method for identifying the location of key overlying rock strata. J. China Univ. Min. Technol. 2000, 21–25. [Google Scholar]

- Ahmed, Z.; Wang, S.; Jasim, O.H.; Xu, Y.; Wang, P. Variability effect of strength and geometric parameters on the stability factor of failure surfaces of rock slope by numerical analysis. Arab. J. Geosci. 2020, 13, 1112. [Google Scholar] [CrossRef]

- Yin, Q.; Jing, H.; Liu, R.; Su, H.; Yu, L.; Han, G. Pore characteristics and nonlinear flow behaviors of granite exposed to high temperature. Bull. Eng. Geol. Environ. 2020, 79, 1239–1257. [Google Scholar] [CrossRef]

- Yin, Q.; Wu, J.; Zhu, C.; He, M.; Meng, Q.; Jing, H. Shear mechanical responses of sandstone exposed to high temperature under constant normal stiffness boundary conditions. Geomech. Geophys. Geo-Energ. Geo-Resour. 2021, 7, 35. [Google Scholar] [CrossRef]

- Yin, Q.; Wu, J.; Zhu, C.; Wang, Q.; Zhang, Q.; Jing, H.; Xie, J. The role of multiple heating and water cooling cycles on physical and mechanical responses of granite rocks. Geomech. Geophys. Geo-Energ. Geo-Resour. 2021, 7, 69. [Google Scholar] [CrossRef]

- Qian, M.; Shi, P. Mine Pressure and Rock Formation Control; China University of Mining and Technology Press: Xuzhou, China, 2003. [Google Scholar]

- Liu, H. Mechanics of Materials; Higher Education Press: Beijing, China, 2010. [Google Scholar]

- Banerjee, G.; Ray, A.K.; Singh, G.S.P.; Yadava, K.P. Hard roof management-a key for high productivity in longwall coal mines. J. Mines Met. Fuels 2003, 51, 238–244. [Google Scholar]

- Chhangte, S.; Pijusha, P.R. New blast ability index for hard roof management in blasting gallery method. Geotech. Geol. Eng. 2012, 30, 1357–1367. [Google Scholar]

- Wen, Y.; Guo, Z.; Cao, A.; Wang, S.; Bai, X.; Jiang, S. Analysis of pressure relief effect of roof deep-hole blasting based on microseismic data evaluation. Coal Sci. Technol. 2020, 48, 57–63. [Google Scholar]

- Cong, S.; Cheng, J.; Wang, B.; Wang, Y.; Fan, X. Evaluation method of blasting pressure relief effect based on slot wave velocity tomography. J. Coal Sci. 2018, 43, 426–433. [Google Scholar]

- Xu, W.; Wang, E.; Liu, Z.; Liu, X. Test method of blasting pressure relief effect based on borehole electromagnetic radiation method. J. Coal Sci. 2012, 37, 279–284. [Google Scholar]

- Xie, J.; Han, G.; Sun, K.; Ding, Z.; Hao, X. Anti-scour mechanism and effect test of hard roof pre-splitting blasting in adjacent roadway. J. Coal Sci. 2023, 48, 2078–2091. [Google Scholar]

- Zhu, C.; He, M.; Zhang, X.; Tao, Z.; Yin, Q.; Li, L. Nonlinear mechanical model of anchor with constant resistance and large deformation and analysis of influencing parameters of constant resistance behavior. Geotech. Mech. 2021, 42, 1911–1924. [Google Scholar]

- Cui, F.; Yang, Y.; Lai, X.; Jia, C.; Shan, P. Experimental Study on the Effect of Advancing Speed and Stoping Time on the Energy Release of Overburden in an Upward Mining Coal Working Face with a Hard Roof. Sustainability 2020, 12, 37. [Google Scholar] [CrossRef]

| Serial Number | Rock Character | Density kg/m3 | Cohesion MPa | Internal Friction Angle ° | Tensile Strength MPa | Modulus of Elasticity GPa |

|---|---|---|---|---|---|---|

| 1 | Coarse grained sandstone | 2618 | 6.38 | 28.86 | 3.17 | 10.33 |

| 2 | Sandy mudstone | 2517 | 4.48 | 30.41 | 5.37 | 4.33 |

| 3 | Mudstone | 2543 | 3.47 | 21.32 | 3.55 | 7.57 |

| 4 | Fine-grained sandstone | 2635 | 6.49 | 35.39 | 5.04 | 13.70 |

| 5 | B4-1 coal seam | 1304 | 2.81 | 37.49 | 2.02 | 7.49 |

| 6 | B2 coal seam | 1640 | 2.95 | 28.50 | 2.15 | 4.32 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cui, F.; Sun, J.; Lai, X.; Jia, C.; Zhang, S. Study on the Energy Release Law of Overburden Rock Breaking and Anti-Rockburst Technology in the Knife Handle Working Face of a Gently Inclined Coal Seam. Appl. Sci. 2023, 13, 11809. https://doi.org/10.3390/app132111809

Cui F, Sun J, Lai X, Jia C, Zhang S. Study on the Energy Release Law of Overburden Rock Breaking and Anti-Rockburst Technology in the Knife Handle Working Face of a Gently Inclined Coal Seam. Applied Sciences. 2023; 13(21):11809. https://doi.org/10.3390/app132111809

Chicago/Turabian StyleCui, Feng, Jingxuan Sun, Xingping Lai, Chong Jia, and Suilin Zhang. 2023. "Study on the Energy Release Law of Overburden Rock Breaking and Anti-Rockburst Technology in the Knife Handle Working Face of a Gently Inclined Coal Seam" Applied Sciences 13, no. 21: 11809. https://doi.org/10.3390/app132111809

APA StyleCui, F., Sun, J., Lai, X., Jia, C., & Zhang, S. (2023). Study on the Energy Release Law of Overburden Rock Breaking and Anti-Rockburst Technology in the Knife Handle Working Face of a Gently Inclined Coal Seam. Applied Sciences, 13(21), 11809. https://doi.org/10.3390/app132111809