Abstract

The impact risk evaluation for the strip filling of working faces has always been a research hotspot and a difficulty in the field of rock bursts. In this paper, the concept of the critical filling rate is first proposed, and the criterion for identifying the impact risk of the strip filling of a working face is established. Then, the membership function of coal body stress and the coal seam elastic energy index to impact risk was established, and the classification index of the impact risk grade was formed. On this basis, the overall and local evaluation method of the rock burst hazard for the strip filling of working faces was proposed. Finally, the C8301 working face of the Yunhe coal mine was taken as the engineering background, and the impact risk evaluation was carried out. It was found that the overall risk of the C8301 working face was determined as a strong impact risk, and there were six local risk areas, which included two weak impact risk areas, two medium impact risk areas, and two strong impact risk areas. This study can provide guidance and a reference for the impact risk evaluation of strip-filling mining under the same or similar conditions.

1. Introduction

China is a major coal country with proven resources accounting for approximately 12.1% of the world’s total. At the same time, it is also the largest coal producer and consumer in the world [1,2,3]. As the most important basic energy source, coal still plays a very important role in economic and social development [4,5,6,7,8,9]. In the process of deep mining, under the influence of “three highs and one disturbance”, the mechanical properties and engineering response characteristics of coal rock will change greatly, and rock burst accidents will frequently occur [10,11,12]. Strip-filling mining technology has significant advantages in rock formation motion control, rock burst prevention and control, surface subsidence control, and coal resource recovery rate improvement. It is also the main technical choice for solving deep resource mining. However, under different filling parameters and mining conditions, there are significant differences in the effectiveness of strip-filling mining in reducing rock burst pressure. For working faces with strip coal pillars, a high mining intensity, and a low enrichment rate, there is still a possibility of a rock burst occurring. Identifying and evaluating the risk of rock bursts in strip-filling mining is an important part of preventing and controlling rock bursts under deep conditions.

At present, domestic and foreign experts and scholars have conducted a large amount of research work on the impact risk of deep-well strip-filling mining faces. Jiang et al. [13] revealed the mechanism of a rock burst around the separation zone of the key stratum of deep strip mining through the investigation and analysis of multiple rock burst accidents that occurred in strip mining. The mechanical model of key stratum separation was established, and the main reasons for the significant increase in the stress concentration caused by the transfer of the load above the critical layer to the surrounding area of the key stratum separation zone were pointed out. Fang et al. [14] studied the rock burst mechanism of the hard roof face of the mining of a large mining depth strip. They proposed that the rock burst of the strip face is closely related to the nature of coal rock, the depth of mining, the thickness of the hard roof, and the periodic pressure of the roof. They also proposed prediction and forecasting methods, such as the drill cuttings method and prevention and control measures for coal-blasting pressure relief and flexible support. Feng et al. [15] pointed out that the enrichment rate is the key to controlling surface settlement and preventing rock bursts. Four ultra-high-water goaf-filling and mining technologies were proposed, which included open, bag, hybrid, and segmented barriers. These technologies were successfully applied in the goaf under two different conditions: the thin coal seam of the Tianzhuang Mine and the thick coal seam of the Taoyi Mine. Jiang et al. [16] carried out discrete element numerical simulation of the caving method and filling method of giant thick magmatic rock, and the control effect of filling mining on magmatic rock migration and mining stress was analyzed. He et al. [17] analyzed the relationship between the stress distribution characteristics of the working face of a thin coal seam and the mining height through numerical simulation and found that the stress drop of the coal body in front of the thin coal seam and the elastic deformation energy released per unit volume of the coal body were greater than those released by the thick coal seam. It was easy to induce a rock burst of the thin coal seam under the influence of a dynamic load. Smoliński et al. [18,19] studied the influence of gangue in the goaf on the mechanical state of the surrounding rock in longwall mining face via numerical simulation and constructed a geomechanical evaluation model. Most of the above studies focused on the study of filling material components, the optimization of the filling process, and the control of the filling effect on the fracture of thick hard-rock layers and surface subsidence. However, in-depth research on the effects of goaf filling on the distribution of the supporting pressure and the identification of the impact risk of the working face is lacking.

In terms of rock burst risk assessment, on the basis of analyzing the main factors affecting the occurrence of rock bursts, Mao et al. [20] presented a systematic discussion of several methods, the scope of application, and the evaluation of impact risk indicators for evaluating impact risk. Jiang et al. [21] proposed an impact risk evaluation method based on the increment in stress generated by various influencing factors on the basis of self-weight stress. By using an engineering analogy, theoretical research, and actual measurement, the increment in stress generated by each inducement factor was estimated. The ratio of the total stress of the coal body to the uniaxial compressive strength of the coal body obtained by adding increments in stress was used as an equivalent indicator for evaluating the impact risk. It could more quantitatively reflect the impact danger area and degree during face mining. Zhang et al. [22] analyzed the factors affecting the rock burst, and a variable-weight identification model for the comprehensive evaluation of the impact risk degree of coal rock was established with impact hazards according to the attribute identification theory. The variable-weight coefficient was determined by using the contribution rate of each evaluation factor in the location to be evaluated. The impact hazard degree was comprehensively evaluated by using the given confidence degree, and the attribute identification and classification were carried out. Tan et al. [23] considered the difference in energy accumulation and release of the coal rock medium and the main control effect of deep high stress on rock bursts. Two indicators were proposed: the combined impact energy velocity index of coal rock and the impact energy velocity index of unloading pressure. In addition, the evaluation index system for deep coal rock’s impact tendency was improved. Based on field monitoring and seismology, Mutke et al. [24] proposed a criterion for impact hazard assessment and successfully verified it in the field.

The existing evaluation methods provide good results for the impact risk assessment of a whole mining area and the traditional collapse of a coal mining face. However, there is still a lack of effective theories and methods for the “risk area-hazard level” of rock bursts under strip-filling mining conditions. Based on this, this paper proposes an evaluation method for the effectiveness of filling anti-impact. The method can qualitatively analyze whether filling can effectively prevent a rock burst. A method to identify and evaluate the impact hazard of filling a working face based on fuzzy mathematics is proposed, which provides guidance for the prevention and control of rock bursts in strip-filling mining.

2. Impact Hazard Identification Criteria

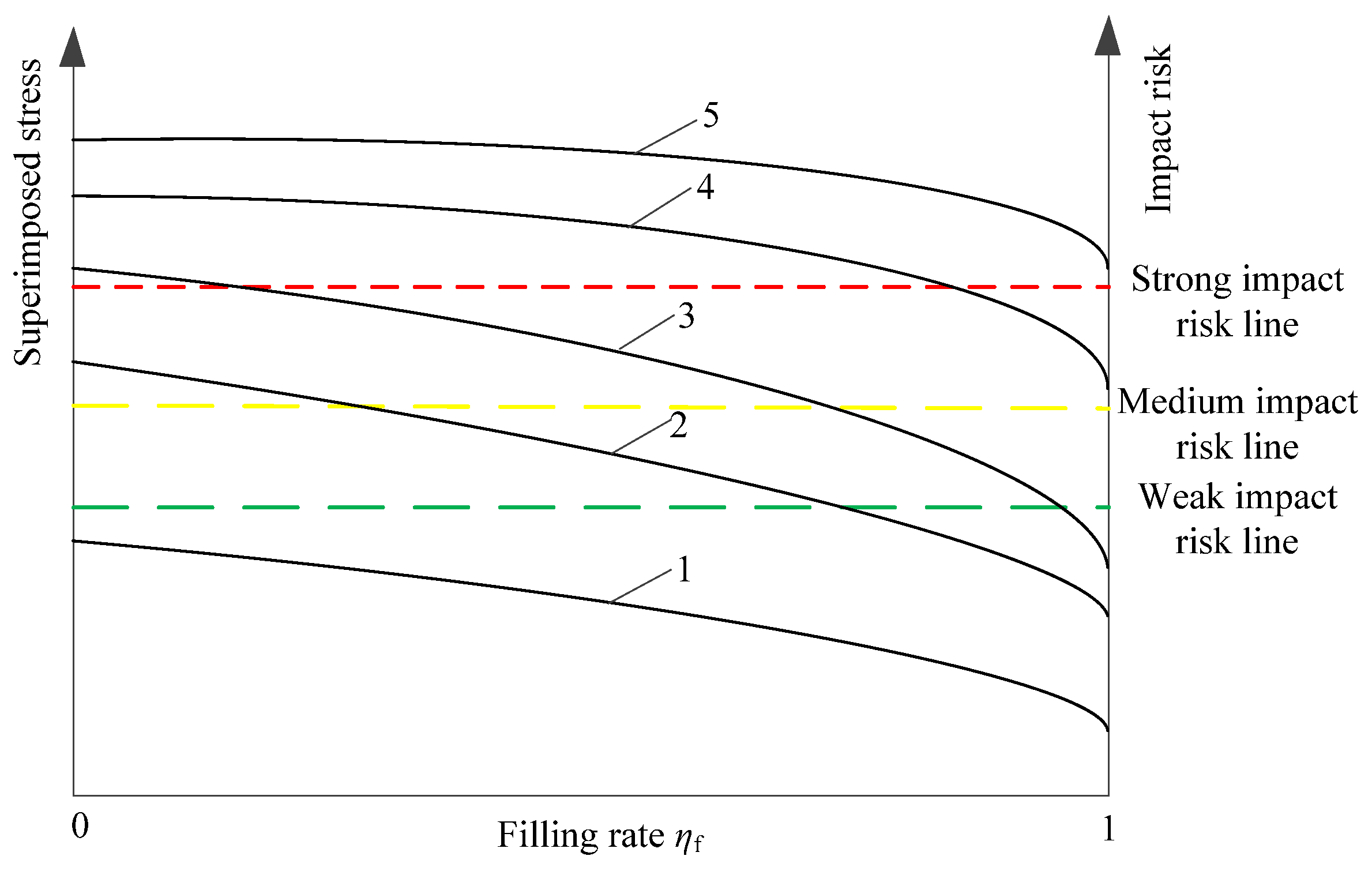

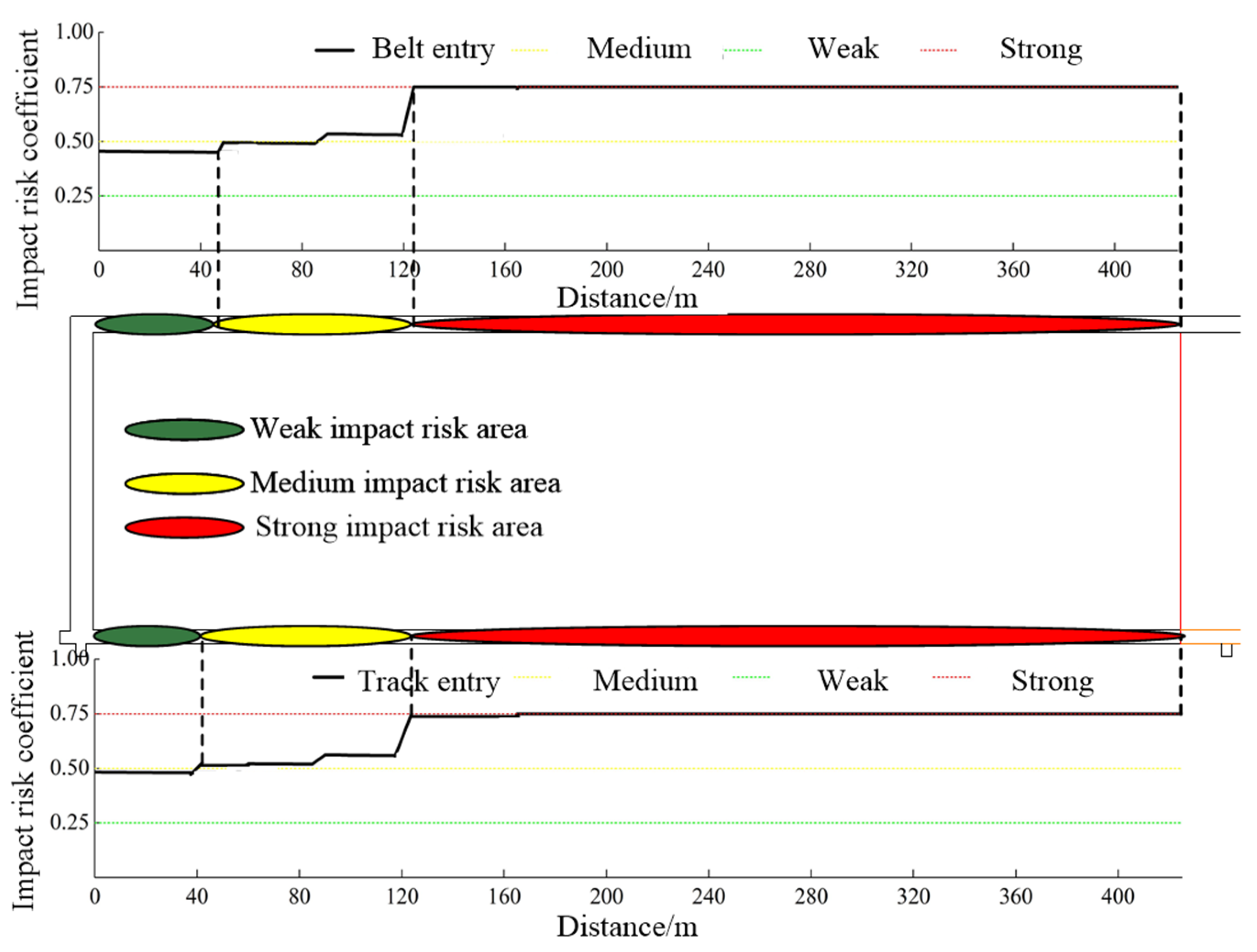

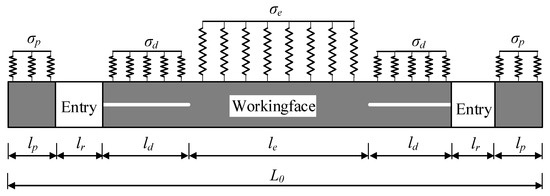

The total stress of the strip filling of working faces after superimposed static stress and dynamic stress was compared with the strength of the coal body. At the same time, according to the third chapter of the “Detailed Rules for Prevention and Control of Coal Mine Rock Burst” issued by China National Mine Safety Administration, the impact risk is divided into four categories: no impact risk, weak impact risk, medium impact risk, and strong impact risk according to the ratio [25]. The relationship between the filling rate and the impact risk of the strip filling of the working face was obtained, as shown in Figure 1.

Figure 1.

Relationship between the filling rate and the impact risk of the strip filling of working face: 1—using the caving method to manage the goaf roof; 2, 3, 4—using filling mining method to manage the roof of goaf; and 5—using caving method or filling mining method to manage the roof of goaf.

The concept of a critical filling rate was proposed. When the strip of working faces adopts filling mining, the filling rate determines the movement characteristics of the overlying rock in the goaf and its dynamic loading effect on the coal body. The greater the filling rate, the weaker the dynamic loading effect of overlying rock movement, and the smaller the total stress of the coal body in the strip working face, indicating a negative correlation between the total stress and the filling rate. When the total stress is less than the impact risk line, this filling rate is the critical filling rate for the corresponding impact hazard level. In Figure 1, the critical filling rate is the filling rate when the total stress curve intersects with the weak impact risk line, medium impact risk line, or strong impact risk line, according to the relevant engineering experience and field monitoring results. The five curves represent the relationship between filling rate and impact risk under five mining geological conditions, respectively. This is specifically expressed as follows:

- Filling rate ηf = 0 represents the working face being unfilled, i.e., using the caving method to manage the goaf roof. If the total stress of the working face is lower than the weak impact risk line, it indicates that the overall level of the support pressure of the strip working face is lower than the minimum stress value that induces impact, and the strip working face has no impact risk. At this time, although filling mining can slow down the dynamic pressure manifestation of the coal body in front of the working face, it has no essential impact on the hazard level of the strip working face, as shown in curve 1 in Figure 1.

- For strip working faces with a medium or higher hazard level using the caving method, filling mining can significantly reduce the impact risk of the working face, as shown in curves 2, 3, and 4 in Figure 1. When the filling rate ηf increases, the intensity and range of fracture motion of low-level rock beams decrease, resulting in a decrease in dynamic stress and a decrease in the impact risk. There are one or more critical filling rates. When the filling rate is greater than the critical filling rate, the impact risk is reduced to weak or below. This indicates that filling mining effectively reduces the impact risk in strip working faces. When the filling rate is less than the critical filling rate, the total stress is still greater than the critical stress for impact to occur. The impact risk after filling is still moderate or above. This indicates that the use of filling mining as a single measure cannot effectively eliminate the impact risk. In this case, other anti-impact measures should also be carried out.

- Curve 5 in Figure 1 indicates that regardless of filling or not, the impact risk of the strip working face is always strong. The possibility of a rock burst is extremely high, which indicates the working face is unsafe and unable to be worked upon.

3. Impact Hazard Evaluation Method

3.1. Indicators and Membership Functions Determination

3.1.1. Stress State of Coal

- 1.

- Coal body

The causes for rock bursts are mainly related to the stress distribution, strength, and inherent impact tendency of the coal body [26,27]. To quantitatively analyze the influence law of sensitivity factors on the impact risk of the filling working face, the membership function U(x) of the impact risk of the filling working face is established as follows:

where σ is the coal seam abutment pressure; [σc] is the uniaxial compressive strength of the coal; and WET is the elastic energy index of the coal seam.

The impact risk is approximately linear with the stress level of the coal seam, and the ratio of abutment pressure to coal strength is one of the key factors [28,29]. Under the condition of a given coal strength, the greater the abutment pressure, the more load is transferred from the overlying strata to the coal, and the higher the risk of coal impact instability.

The ratio of coal stress to its uniaxial compressive strength is recorded as Ic1, which is

The necessary condition for the coal impact instability is that the abutment pressure exceeds the uniaxial compressive strength of coal [30]. According to the engineering practice experience, if the coal body stress is smaller than the uniaxial compressive strength of 1.5 times the coal seam, then a rock burst does not occur in the coal body; when the coal stress is equal to 1.5–2.0 times the uniaxial compressive strength of the coal seam, there is a weak impact risk; if the coal stress is between 2.0 and 2.5 times of the uniaxial compressive strength of the coal seam, there is a medium impact risk; and when the coal stress is greater than 2.5 times the uniaxial compressive strength of the coal seam, the coal seam has a strong impact risk. The membership function of coal stress ratio Ic1 to local impact risk is established [31], as shown in Equation (3):

- 2.

- Strip coal pillar

The impact risk of the strip working face is related to the stress concentration coefficient of the strip coal pillar. In the process of roadway excavation, a large number of large-diameter boreholes are constructed on the inside of the strip coal pillar, which destroys the integrity and causes plastic damage to the shallow, which reduces its effective bearing capacity. Therefore, the abutment pressure is transferred to the deeper parts. In the middle of the strip coal pillar with a certain width, the coal is in a three-way stress state, and its bearing capacity is much greater than that of the shallow surrounding rock. Generally, this part of the coal exists in an elastic area. The coal in the elastic area maintains its structural integrity and is the main load-bearing body for the overlying strata. The width of the elastic area determines the overall bearing capacity of the strip coal pillar. The larger the elastic area, the stronger the bearing capacity of the strip coal pillar and the stronger the ability to gather the elastic deformation energy. Conversely, the smaller the elastic area, the weaker the bearing capacity of the strip coal pillar and the more likely the overall impact instability of the working face [32]. The size of the elastic area is affected by many factors, such as working face width, size and depth of the pressure relief boreholes, burial depth, coal strength, and coal seam thickness.

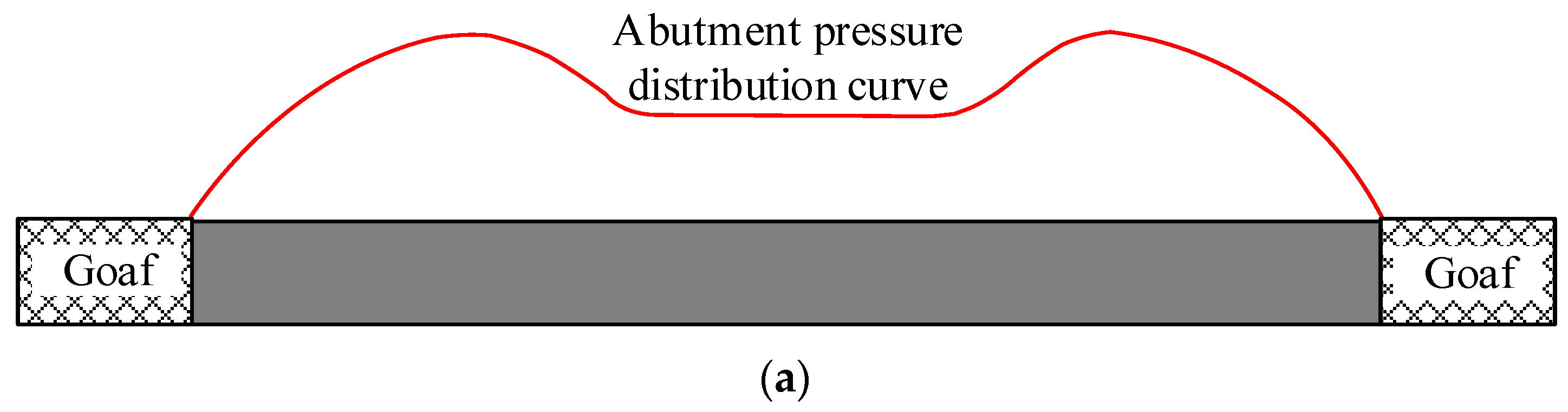

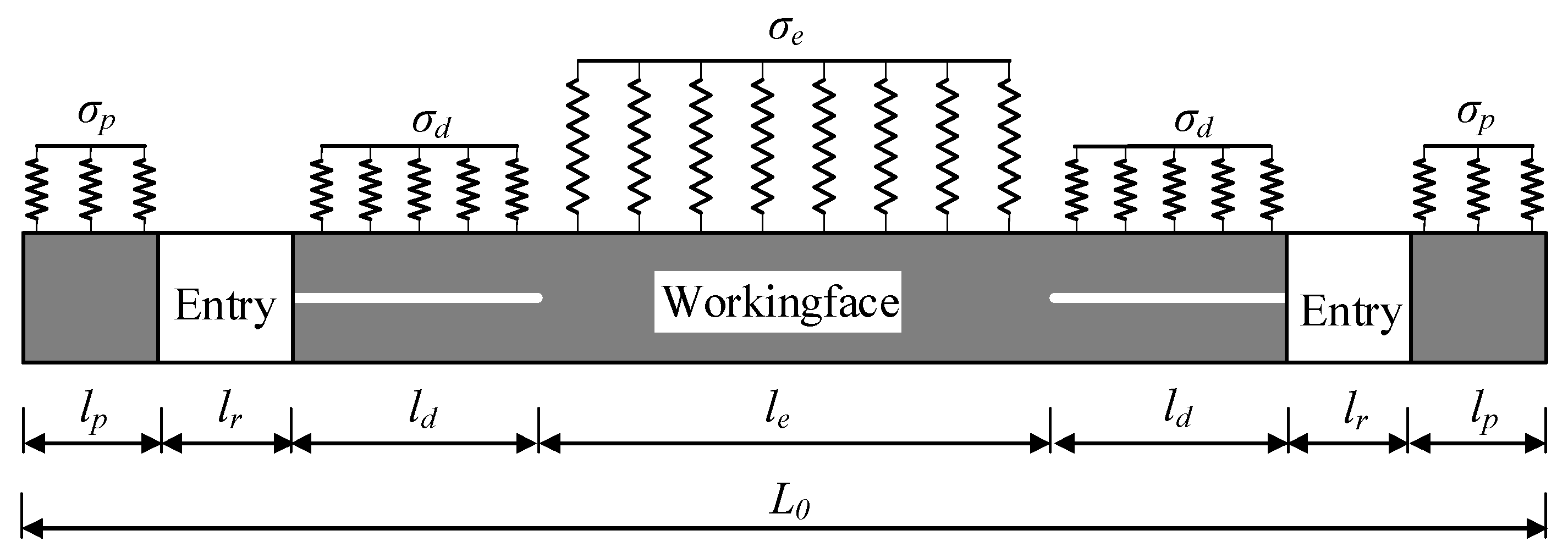

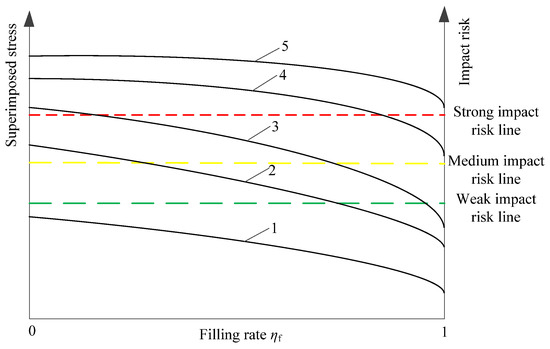

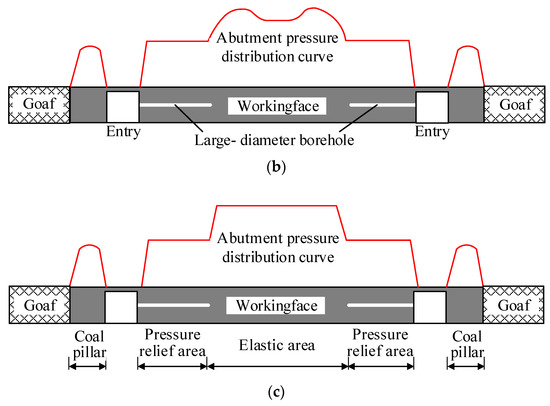

Before the coal mining on both sides, the working face is subjected to the static load transmitted by the overlying strata, and the abutment pressure is evenly distributed. After mining on both sides, the strip coal pillar is formed and produces a certain range of plastic area under abutment pressure. When the strength and size of the strip coal pillar (the width of the elastic area is sufficient) can support the load transmitted by the overlying strata, the lateral abutment pressure distribution of the strip coal pillar shows a pattern of increasing from the boundary of the coal pillar to the center, then decreasing and finally stabilizing, and the overall distribution of the abutment pressure is similar to the “saddle-shape”, as shown in Figure 2a.

Figure 2.

Schematic diagram of the evolution of abutment pressure in strip working face. (a) Formation of goaf on both sides; (b) excavation of roadways; and (c) balanced stress state.

In the process of roadway excavation, a large number of large-diameter boreholes were constructed inside the strip coal pillar. The peak lateral abutment pressure shifted to the center of the coal pillar with a saddle shape, as shown in Figure 2b. Along with the continuous roof subsidence caused by the mining of the working face, the coal at the edge of the elastic area of the strip coal pillar changed into plastic. It leads to an increase in the plastic area and a decrease in the elastic area, which eventually causes a decrease in the overall bearing capacity. At this time, the abutment pressure distribution appeared to be in a ‘platform’. The bearing capacity of the strip coal pillar shows obvious regional differences, which could be divided into five regions. Each region is in a relatively balanced stress state, as shown in Figure 2c.

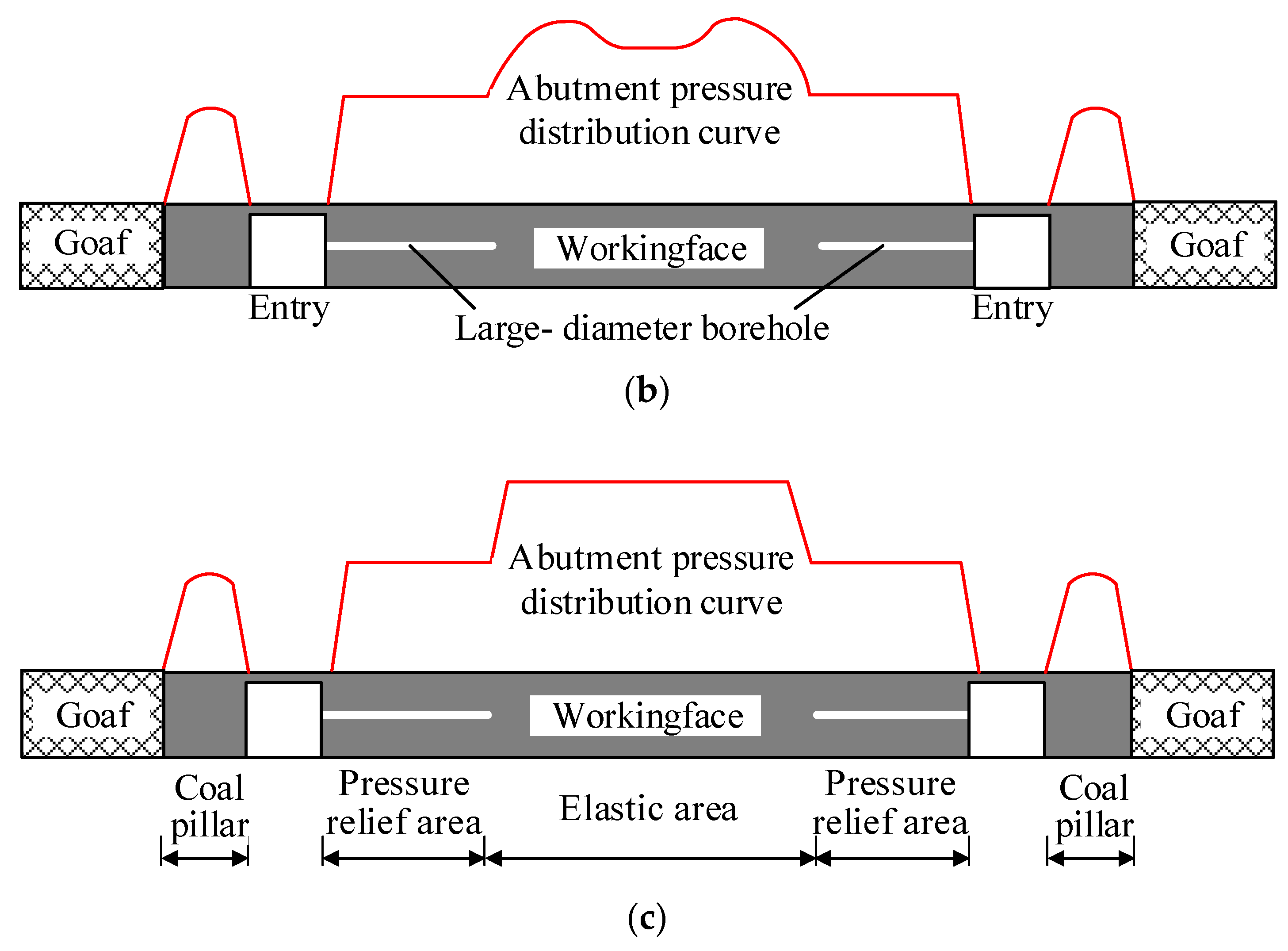

The bearing capacity of the strip working face is closely related to the working face width, coal pillar width, elastic area, and pressure relief boreholes. The coal pillar is affected by the lateral abutment pressure of the adjacent goaf, the coal fracture is developed, and the bearing capacity is weak. The coal in the pressure relief area is subject to plastic damage due to large-diameter boreholes, resulting in a weak bearing capacity. The coal in the elastic area is structurally intact and is subject to three-dimensional stresses from the roof, floor, and coal bodies in the pressure relief areas on both sides, making it the main load-bearing for transmitting loads to the overlying strata. A simplified mechanical model of the coal stress is established, as shown in Figure 3.

Figure 3.

Simplified mechanical model of the coal stress.

According to the principle of energy conservation, the load distribution relationship of each part of the coal is as follows:

where δe is the load borne by the coal in the elastic area; δd is the load borne by the coal in the pressure relief area; and δp is the load borne by the coal pillar.

The bearing load of coal in the pressure relief area can be expressed as follows:

where ld is the width of the pressure relief area and σd(x) is the abutment pressure distribution function of coal in the pressure relief area, which is affected by factors such as the depth of pressure relief borehole, the characteristics of coal-rock mass, and the stress monitoring threshold.

The load of the coal pillar can be expressed as follows:

where lp is the width of the coal pillar and σp(x) is the abutment pressure distribution function of the coal pillar, which is affected by factors such as the coal pillar width and the characteristics of coal-rock mass.

The size relationship of each part of the strip coal pillar is as follows:

where lr is the width of the roadway and le is the width of the elastic area.

The bearing capacity of the strip coal pillar can be expressed by the following equations, in which the ratio of the abutment pressure to the bearing capacity is denoted as Ic2, which is

where is the overall bearing capacity of the coal in the working face; λ is the ratio of the bearing capability of the elastic area to the uniaxial compressive strength of the coal seam, with a value of λ = 3~5; and σz is the total stress of the coal after the dynamic and static loads on the working face are superimposed.

According to engineering practice experience, when the total stress acting on the strip coal pillar is greater than the overall bearing capacity of the working face, there is a possibility of overall impact risk [33]. If the total stress on the strip coal pillar is between 1.0 and 1.5 times the overall bearing capacity of the coal body in the working face, the working face has a weak overall impact risk; when the total stress on the strip coal pillar is between 1.5 and 2.0 times the overall bearing capacity of the coal body in the working face, it has a medium overall impact risk; if the total stress on the strip coal pillar is 2.0 times the overall bearing capacity of the working face coal body, then the working face has a strong overall impact risk. The membership function of the coal pillar stress ratio Ic2 to the overall impact risk is , as shown in Equation (10):

3.1.2. Elastic Energy Index of Coal Seam

The elastic energy index WET is an important index to measure the rock burst tendency of the coal seam, and it is also the main parameter to evaluate the impact risk of the coal seam. The engineering practice shows that when WET < 2, the possibility of spontaneous impact of the coal seam is low; when 2 ≤ WET < 3.5, the coal seam has a weak impact risk; when 3.5 ≤ WET < 5, the coal seam has a medium impact risk; and when WET ≥ 5, the coal seam has a strong impact risk. The greater the WET value of the elastic energy index, the higher the possibility of coal seam impact instability. The membership degree of elastic energy index WET and coal seam impact risk is [31]:

It should be noted that the propensity for coal impact is a property of coal accumulation deformation energy and impact damage generation, which is an inherent attribute of coal and is independent of the stress state of the coal seam. However, when the occurrence state and physical and mechanical properties of the coal seam change, the propensity for coal impact will also change.

3.2. Impact Hazard Level Classification

Based on the comprehensive index method, the impact hazard of the working face can be classified into four levels, which are no impact risk, weak impact risk, medium impact risk, and strong impact risk. The membership degree of the local and overall impact risks of the coal can be used [34]. The numerical range of [0, 1] is uniformly divided into four levels with an interval of 0.25, as shown in Table 1.

Table 1.

Impact hazard level classification of strip filling of working face.

According to the influence of coal seam stress state and impact tendency on the impact instability of the coal, the equations of local impact risk and overall impact risk index of filling working face are established as follows:

where U1 is the index of local impact risk; U2 is the index of overall impact risk; w1 is the weight coefficient of the impact tendency of coal on the impact risk; w2 is the weight coefficient of the influence of the stress state of coal on the local impact risk, w1 + w2 = 1; and w3 is the weight coefficient of the influence of the stress state of coal on the overall impact risk, w1 + w3 = 1.

According to engineering experience, the influence coefficients of coal stress state and impact tendency on impact risk are generally equal, which exists as w1 = w2 = w3 = 0.5 [35]. The weighting coefficients of each factor should be adjusted appropriately according to the actual geological and mining technical conditions. If there are one or more strong impact tendencies in the identification results of coal seam and roof/floor impact tendency, it indicates that the coal seam and roof/floor have a high capacity for accumulating elastic deformation energy and the possibility of local and overall impacts in the working face increases significantly. Therefore, the impact of the elastic energy index on impact risk should be increased. If the pending working face is located in the influence area of the remaining coal pillar in the same coal seam, the fault-cutting coal pillar or the coal pillar affected by the remaining coal pillar in the overlying coal seam, the basic static load borne by the working face coal is relatively large, and the stress increment threshold value for overall impact instability is lowered. Therefore, the influence coefficient of coal stress state on overall impact risk should be increased. If the working face includes areas with severe changes in dip angle, faults, connections, or proximity to the goaf, the localized coal bodies in these areas are prone to stress concentration, which can easily lead to high-stress-induced or high-stress gradient-induced impact instability. In this case, the influence coefficient of the coal stress state on local impact risk should be increased.

When the impact risk index U ≥ 1, the impact risk is extremely high, and it is prohibited to mine that working face. When the impact risk index is 0.5 ≤ U < 1, the impact risk is relatively high, and the working face can be mined after taking anti-impact measures. When the impact risk index U < 0.5, the impact risk is weak, indicating that the possibility of spontaneous impact is low.

4. Case Investigations

4.1. Engineering Overview

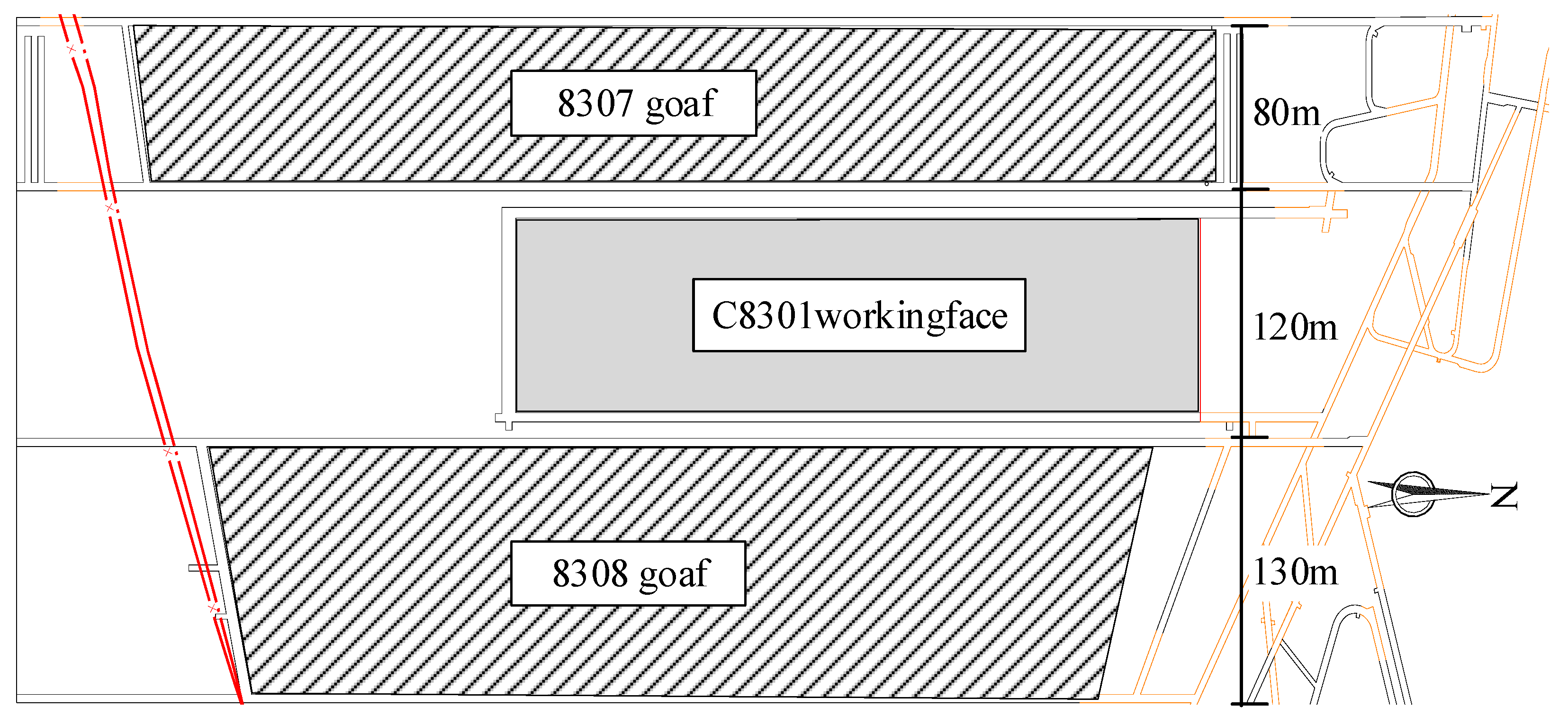

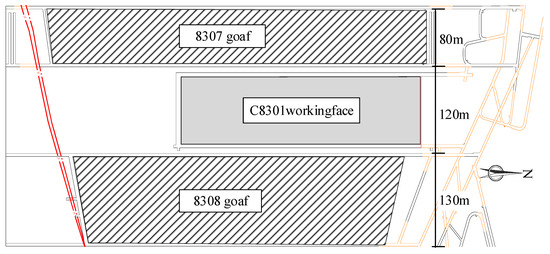

The Yunhe coal mine is located in the northern outcrop area of the Jibei coalfield and Tangkou exploration area in Jining City, Shandong Province. Due to a large amount of coal covered by ground buildings (structures), the strip mining method was used in the early stage of the mine, resulting in a large number of dull coal resources in the minefield. To safely recover this part of the remaining coal pillars and ensure the sustainable development of the mine, the Yunhe coal mine has carried out a systematic study of filling and replacing strip coal pillars.

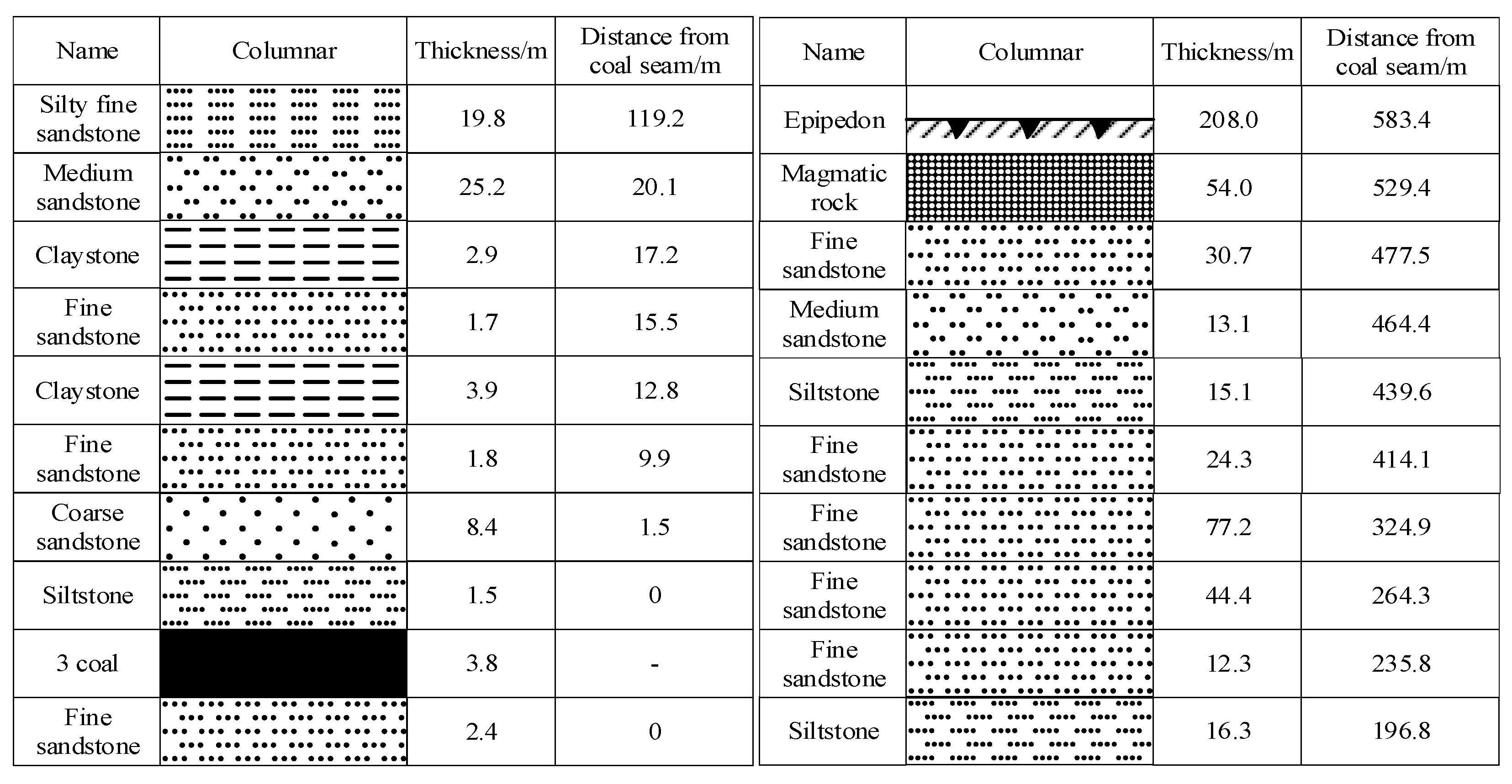

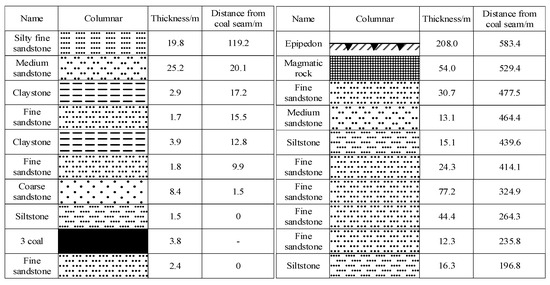

The C8301 working face is the first strip filling of a working face in the Yunhe coal mine, which is located in the south of the eighth mining area. The surrounding mining situation is as follows: to the east is the 8308 goaf, to the south is the T5-4 fault protection coal pillar, to the west is the 8307 goaf, and to the north is the −725 east wing track roadway protection coal pillar. The dip length of the C8301 working face is 96 m, the strike length is 424 m, and the mining depth is 698~808 m with an average of 778 m. The position of the working face is shown in Figure 4. Comprehensive mechanized dip longwall backward mining is adopted once mining is at full height. The roof of the goaf is managed by a super-high-water full-filling method. The thickness of the coal seam is 3.2 m, and the structure of the coal seam is simple. The largest single layer thickness in the range of 20 m above the coal seam is 8.4 m grit sandstone. The occurrence characteristics of the coal seam roof are shown in Figure 5.

Figure 4.

The C8301 working face layout.

Figure 5.

Roof and floor strata histogram of the C8301 working face.

4.2. Impact Hazard Evaluation

4.2.1. Overall Impact Risk

According to the previous analysis, the elastic energy index of coal and the stress state of the strip coal pillar are the factors affecting the overall impact risk of the strip filling of the working face. The weight coefficient of the influence of two parameters on the overall burst risk is w1 = w2 = 0.5; the evaluation equation of the overall burst risk of the strip filling of the working face is established as follows:

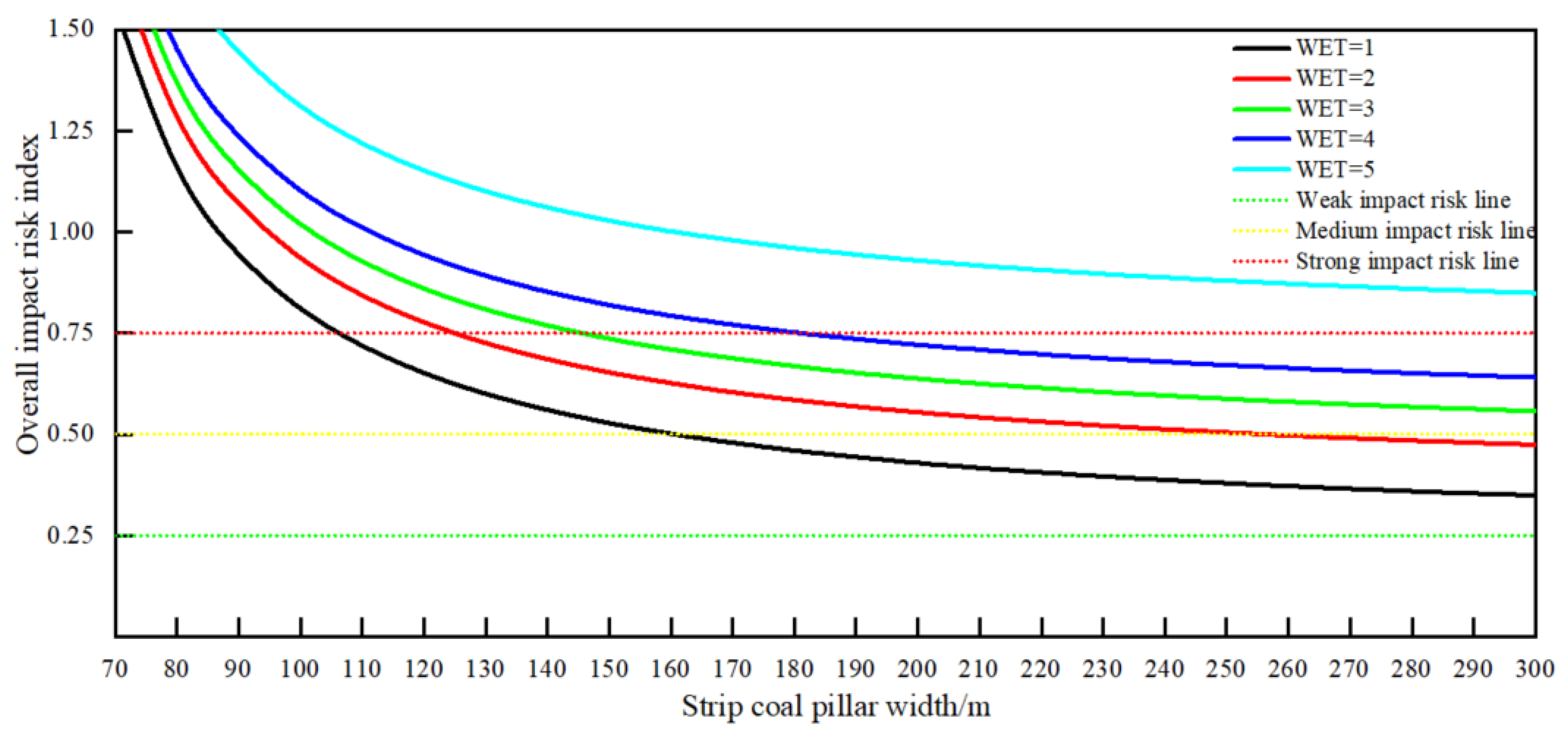

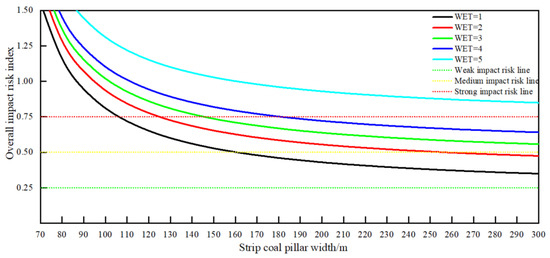

According to the mining technical conditions of the C8301 working face, L1 = 80 m, L2 = 130 m, lp = 8 m, ld = 15 m, lr = 4 m, σd = [σc] = 11.09 MPa, λ = 4, and γ = 25 kN/m3. Putting the relevant parameters into Equation (14), the relationship between the elastic energy index and the width of the strip coal pillar on the overall impact risk of the working face is shown in Figure 6.

Figure 6.

The variation of elastic energy index and strip coal pillar width on the overall impact risk.

Therefore, under the condition of the symmetrical hanging roof structure, the overall impact risk coefficient of the strip coal pillar gradually decreases with the increase in the width of the strip coal pillar. It shows that the increase in the width of the coal body in the elastic bearing area can not only share more load but also helps to reduce the average stress level of the coal body in the elastic area after stress averaging, which is beneficial to reducing the overall impact hazard level of the strip working face. In addition, with the increase in the elastic energy index, the critical width of the strip coal pillar gradually increases when the overall impact risk occurs. It shows that the increase in elastic energy of the coal seam has a significant effect on the overall impact risk of the strip working face.

The width of the strip coal pillar in the C8301 working face is 120 m. The original elastic energy index of the coal body is WET0 = 3.52, and U2 = 0.9 is calculated. The overall impact risk of the strip coal pillar is strong. It means that the possibility of the overall impact of the strip coal pillar is very high; measures must be taken to weaken the ability of coal to gather elastic energy and reduce the stress concentration degree of the strip coal pillar before mining.

4.2.2. Local Impact Risk

From the mechanical mechanism of rock bursts, when the load of the coal body exceeds the limit of its bearing capacity, the coal body has the mechanical condition of impact instability. The impact tendency of the coal seam is the internal property of impact instability. In this section, the membership function of the stress state and the impact tendency of the coal body to rock bursts are proposed by using fuzzy mathematics. Before mining, the dangerous area of rock bursts is divided and classified, and the rock burst prevention design is carried out. During the mining of the working face, the evaluation results are verified by monitoring methods such as microseismic, stress, and drilling cuttings.

According to the mining geological conditions of C8301 working face, the semi-quantitative analysis of self-weight stress, tectonic stress, and mining stress is carried out by using the multi-factor coupling calculation method of impact risk based on stress superposition, and the impact risk area of strip working face is divided and classified.

- 1.

- Vertical stress of mining roadway

According to the cross-section diagram of belt entry and track entry of the C8301 working face, the elevation of the coal seam floor changes linearly with the mining direction. The surface elevation is +38 m. The intersection points of the belt entry, the track entry, and the open-off cut of the C8301 working face are taken as the origin of the coordinates. The x-axis is along the axis of the roadway, and the vertical stress is the y-axis. The rectangular Cartesian coordinate system for self-weight stress calculation is established as follows:

The mining area of the C8301 working face is in a syncline structure. Under the action of the stress field, the syncline axis and two wings are the concentration areas of tectonic stress, and the top angle of the syncline structure is greater than 110°. According to the previous analysis, the overlying strata movement of the filling mining face has an obvious time effect. The filling effect of the goaf will affect the height and strength of the overlying strata movement, which leads to the obvious lag characteristics of the evolution time of the abutment pressure of the coal seam. The designed filling rate of the super-high-water material in the goaf is not less than 80%. According to the roof structure, lithology, mining width, and mining conditions on both sides of the working face, the stress increment concentration coefficient of each influencing factor during the mining period of the working face is obtained as shown in Table 2, and the vertical stress calculation formula of the belt and track entry is obtained as follows.

Table 2.

Stress increment concentration factors of impact risk in strip working face.

- 2.

- Impact risk area division

According to Equations (2), (3), (17) and (18), the influence coefficient of the coal stress state on local impact risk is obtained as follows:

According to the geological conditions of the C8301 working face, taking WET = 3.52 and putting it into Equation (11), the influence coefficient of coal elastic energy index on local impact risk can be obtained as follows:

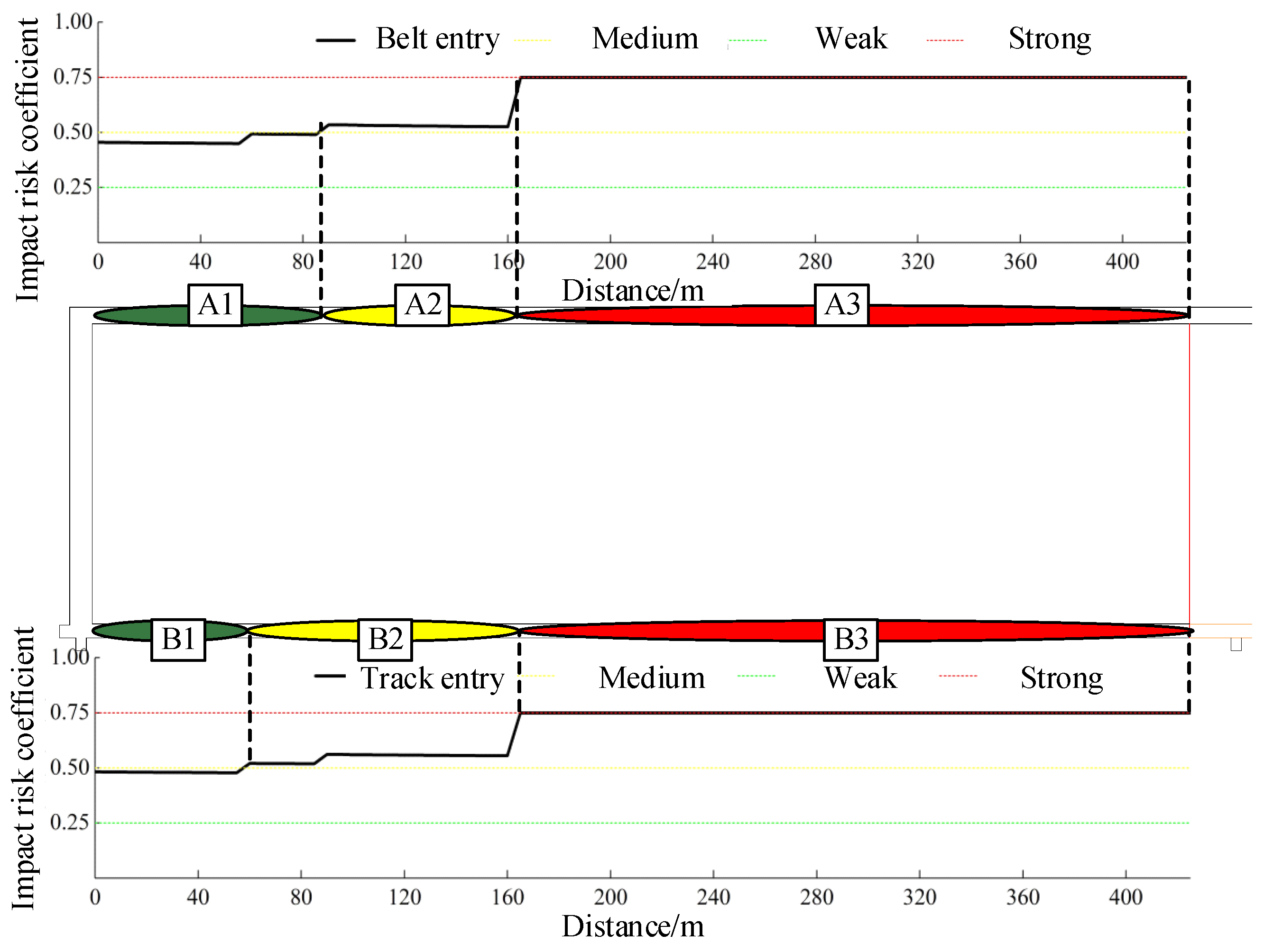

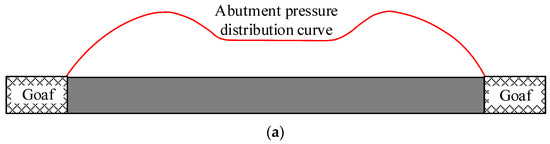

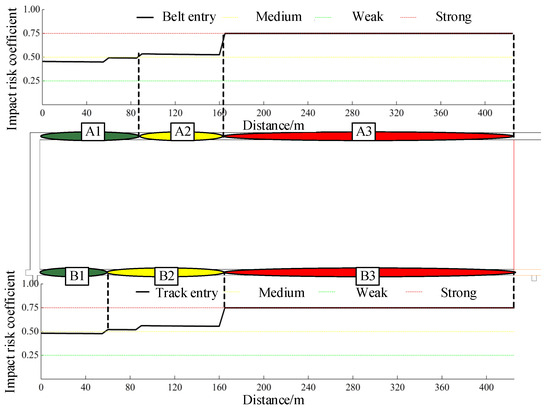

By putting Equations (19)–(21) into Equations (12) and (13), the C8301 working face’s belt entry, track entry, and working face are divided into six impact risk areas, including two weak impact risk areas, two medium impact risk areas, and two strong impact risk areas, as shown in Table 3 and Figure 7.

Table 3.

The C8301 working face impact risk area division.

Figure 7.

Impact risk area division of the C8301 working face.

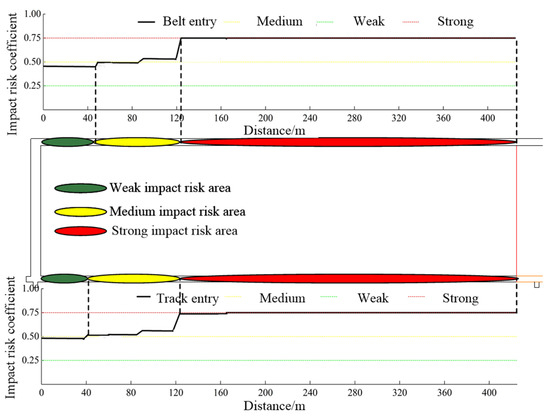

The comprehensive index method is to determine the impact risk level of the mining area by comprehensively analyzing the geological factors and mining technical conditions of the mining area. It is a commonly used impact risk evaluation method in the field of coal mines. The comprehensive index method is used to evaluate the impact risk of the C8301 working face in the Yunhe coal mine, and the evaluation results are shown in Figure 8. Compared with the evaluation results obtained in this paper, the evaluation results obtained by the comprehensive index method have a larger range of strong impact risk areas and medium impact risk areas. This is because filling mining does not consider the significance of filling mining for the prevention and control of rock bursts. For the strip-filling mining face, the impact risk evaluation method proposed in this paper is more applicable, and the evaluation results are more accurate.

Figure 8.

The comprehensive index method is used to divide the impact risk areas of the C8301 working face.

The commonly used pressure relief measures include hydraulic fracturing, large-diameter borehole pressure relief, deep blasting, and so on. Based on the evaluation results of the impact risk of the C8301 working face in the Yunhe coal mine, for the medium impact risk area and the strong impact risk area, it is suggested that the large-diameter borehole pressure relief and the strike blasting roof cutting technology of the coal body can be used to relieve the pressure of the high-stress coal body and the 8.4 m thick hard and thick sandstone above, thereby reducing the stress concentration of the surrounding rock of the roadway. At the same time, it can strengthen the advanced support of the roadway to effectively prevent the occurrence of rock bursts.

5. Discussions

With the transfer of coal mining to deep coal resource mining, the mechanical properties and engineering response characteristics of coal and rock mass will change significantly under the influence of ‘three high and one disturbance’, resulting in frequent rock burst accidents. Strip-filling mining has significant advantages in rock movement and rock burst prevention and control, surface subsidence control, and the improvement of the coal resource recovery rate. It is one of the key technologies for deep coal resource mining. However, for the working face with strip coal pillars and low filling rate, there is still a risk of rock bursts. The evaluation of rock burst risk under this condition is the basis and key to preventing this type of rock burst.

In this paper, a method for evaluating the effectiveness of filling and anti-impact is proposed for the ‘risk area-hazard level’ of rock bursts under the condition of strip-filling mining, which can qualitatively analyze whether the filling is effective in anti-impact. At the same time, a method for evaluating the impact risk of a strip-filling mining face based on fuzzy mathematics is constructed, which provides some guidance for the prevention and control of rock bursts in deep well strip-filling mining faces.

In this paper, the impact risk of strip-filling mining faces is evaluated, and some valuable theories are obtained. However, the impact risk evaluation method proposed in this paper is aimed at the strip-filling mining face. Whether the impact risk assessment under other conditions is applicable needs further study. At the same time, the mechanism and technology for preventing and controlling rock bursts by filling mining, how to effectively use the gangue in the goaf, and how to improve the filling rate need further research to provide a guarantee for the safe mining of deep coal resources.

6. Conclusions

The concept of critical filling rate is proposed, and the identification criterion of the impact risk of strip filling of the working face in deep mines is established. By analyzing the effectiveness of filling mining under five conditions, it is found that the filling rate determines the movement characteristics of overlying strata in goaf and its dynamic loading effect on the coal body. When the critical filling rate is reached, the filling reduces or even eliminates the impact risk. When the filling rate is less than the critical filling rate, the filling mining cannot effectively reduce the dynamic load caused by the movement of overlying rock, resulting in the total stress of the coal body being greater than the critical stress of impact, and a rock burst occurs.

By analyzing the evolution law and mechanical characteristics of the abutment pressure in the coal body, the membership function of the stress state of the coal body and the elastic energy index of the coal seam to the impact risk is obtained. Based on the comprehensive index method, the evaluation method of the local and overall impact risk of the working face in deep strip-filling mining is proposed. The impact hazard level is divided into four levels: no impact risk, weak impact risk, medium impact risk, and strong impact risk.

An overall and local impact risk evaluation was conducted on the C8301 working face, and the impact risk area and hazard level were determined. The calculation results indicate that the overall impact risk of the C8301 working face is strong. The C8301 working face is divided into six impact risk areas, including two weak impact risk areas, two medium impact risk areas, and two strong impact risk areas. Reasonable and effective pressure relief measures must be taken in the impact risk area before mining.

Author Contributions

Conceptualization, D.F. and X.L.; methodology, D.F. and X.L.; validation, Y.C.; formal analysis, S.Y.; investigation, Y.C. and X.S.; resources, X.Z.; writing—original draft preparation, P.G.; writing—review and editing, C.L.; supervision, D.F. and G.L.; project administration, Y.C. and X.S.; funding acquisition, X.Z. and X.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Shandong Energy Group (No. SNKJ2022BJ01-R27), National Natural Science Foundation of China (Nos. 52174122, 52074168), Excellent Youth Fund of Shandong Natural Science Foundation (No. ZR2022YQ49), and Taishan Scholar in Shandong Province (Nos. tspd20210313, tsqn202211150).

Data Availability Statement

The data used to support the findings of this study are available from the corresponding author upon request.

Acknowledgments

The authors gratefully acknowledge the financial support from the Shandong Energy Group (No. SNKJ2022BJ01-R27), National Natural Science Foundation of China (Nos. 52174122, 52074168), Excellent Youth Fund of Shandong Natural Science Foundation (No. ZR2022YQ49), and Taishan Scholar in Shandong Province (Nos. tspd20210313, tsqn202211150).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Xie, H.P.; Wang, J.H.; Ren, H.W.; Liu, J.Z.; Zhou, H.W.; Wu, G.; Ren, S.H. New ideas of coal revolution and layout of coal science and technology development. J. Chin. Coal Soc. 2018, 43, 1187–1197. [Google Scholar]

- Kang, H.P.; Gao, F.Q.; Xu, G.; Ren, H.W. Mechanical behaviors of coal measures and ground control technologies for China’s deep coal mines—A review. J. Rock. Mech. Geotech. 2022, 15, 37–65. [Google Scholar] [CrossRef]

- Jin, Y.X.; Geng, J.; Lv, C.; Chi, Y.; Zhao, T.D. A methodology for equipment condition simulation and maintenance threshold optimization oriented to the influence of multiple events. Reliab. Eng. Syst. Safe 2023, 229, 108879. [Google Scholar] [CrossRef]

- Liu, X.S.; Fan, D.Y.; Tan, Y.L.; Ning, J.G.; Song, S.L.; Wang, H.L.; Li, X.B. New detecting method on the connecting fractured zone above the coal face and a case study. Rock Mech. Rock Eng. 2021, 54, 4379–4391. [Google Scholar] [CrossRef]

- Gao, C.J.; Huang, D.M.; Chang, X.K.; Xi, H. Risk analysis and extension assessment for the stability of surrounding rock in deep coal roadway. Int. J. Environ. Res. Pub. Health 2019, 16, 4752. [Google Scholar] [CrossRef]

- Qi, Q.X.; Pan, Y.F.; Shu, L.Y.; Li, H.Y.; Jiang, D.Y.; Zhao, S.K.; Zou, Y.H.; Pan, J.F.; Wang, K.J.; Li, H.T. Theory and technical framework of prevention and control with different sources in multi-scales for coal and rock dynamic disasters in deep mining of coal mines. J. Chin. Coal Soc. 2018, 43, 1801–1810. [Google Scholar]

- Liu, X.S.; Fan, D.Y.; Tan, Y.L.; Song, S.L.; Li, X.F.; Ning, J.G.; Gu, Q.H.; Ma, Q. Failure evolution and instability mechanism of surrounding rock for close-distance parallel chambers with super-large section in deep coal mines. Int. J. Geomech. 2021, 21, 04021049. [Google Scholar] [CrossRef]

- Zhang, A.L.; Zhang, R.; Gao, M.Z.; Zhang, Z.T.; Jia, Z.Q.; Zhang, Z.P.; Zha, E.S. Failure behavior and damage characteristics of coal at different depths under triaxial unloading based on acoustic emission. Energies 2020, 13, 4451. [Google Scholar] [CrossRef]

- Xie, H.P.; Lu, J.; Li, C.B.; Li, M.H.; Gao, M.Z. Experimental study on the mechanical and failure behaviors of deep rock subjected to true triaxial stress: A review. Int. J. Min. Sci. Technol. 2023, 32, 915–950. [Google Scholar] [CrossRef]

- Zhang, J.X.; Tu, S.H.; Cao, Y.J.; Tan, Y.L.; Xin, H.Q.; Pang, J.L. Coal gangue intelligent separation and backfilling technology and its engineering application in underground coal mine. J. Chin. Univ. Min. Technol. 2021, 50, 417–430. [Google Scholar]

- Chen, S.J.; Wang, H.L.; Wang, H.Y.; Guo, W.J.; Li, X.S. Strip coal pillar design based on estimated surface subsidence in eastern China. Rock Mech. Rock Eng. 2016, 49, 3829–3838. [Google Scholar]

- Jiang, B.Y.; Ji, H.G.; Fu, L.; Gu, S.T.; Zou, T.; Lu, J.X. Research on evaluation index and application of rockburst risk in deep strip mining. Shock Vib. 2020, 2020, 8824323. [Google Scholar] [CrossRef]

- Jiang, F.X.; Wen, J.L.; Bai, W.S.; Wang, G.L.; Li, M. Rock burst risk in surrounding abscission layer of overlying high key strata in deep strip mining mines. J. Chin. Univ. Min. Technol. 2018, 47, 40–47. [Google Scholar]

- Fang, X.Q.; Dou, L.M.; Liu, J.C.; Peng, L.Z.; Mu, Z.L. Manage of rock burst in mine with great mining depth partial extraction and strong roof face. J. Chin. Univ. Min. Technol. 2006, 35, 602–606. [Google Scholar]

- Feng, G.M.; Sun, C.D.; Wang, C.Z.; Zhou, Z. Research on goaf filling methods with super high-water material. J. Chin. Univ. Min. Technol. 2010, 35, 1963–1968. [Google Scholar]

- Jiang, J.Q.; Wu, Q.S.; Zhang, P.P.; Ma, F.W. Dynamic disaster control of backfill mining under supper-thick magmatic rocks. Metal. Min. 2015, 469, 139–142. [Google Scholar]

- He, J.; Dou, L.M.; Cai, W.; Li, Z.H.; Ding, Y.H. Mechanism of dynamic and static combined load inducing rock burst in thin coal seam. J. Chin. Coal Soc. 2014, 39, 2177–2182. [Google Scholar]

- Smoliński, A.; Malashkevych, D.; Petlovanyi, M.; Rysbekov, K.; Rysbekov, K.; Lozynskyi, V.; Sai, K. Research into impact of leaving waste rocks in the mined-out space on the geomechanical state of the rock mass surrounding the longwall face. Energies 2022, 15, 9522. [Google Scholar] [CrossRef]

- Malashkevych, D.; Petlovanyi, M.; Sai, K.; Serhii, Z. Research into the coal quality with a new selective mining technology of the waste rock accumulation in the mined-out area. Min. Min. Depos. 2022, 16, 103–114. [Google Scholar] [CrossRef]

- Lan, H.; Chen, D.K.; Mao, D.B. Current status of deep mining and disaster prevention in China. Coal Sci. Technol. 2016, 44, 39–46. [Google Scholar]

- Jiang, F.X.; Shu, C.X.; Wang, C.W. Impact risk appraisal of stope working faces based on stress superimposition. Chin. J. Rock Mech. Eng. 2015, 34, 2428–2435. [Google Scholar]

- Zhang, K.Z.; Xia, J.M. Weight-variable identification model of comprehensive evaluation on burst liability of coal. Chin. J. Rock Mech. Eng. 2004, 23, 3480–3483. [Google Scholar]

- Tan, Y.L.; Guo, W.Y.; Xin, H.Q.; Zhao, T.B.; Yu, F.H.; Liu, X.S. Key technology of rock burst monitoring and control in deep coal mining. J. Chin. Coal Soc. 2019, 44, 160–172. [Google Scholar]

- Mutke, G.; Dubiński, J.; Lurka, A. New criteria to assess seismic and rock burst hazard in coal mines. Arch. Min. Sci. 2015, 60, 743–760. [Google Scholar]

- China National Mine Safety Adminstration. Detailed Rules for Prevention and Control of Coal Mine Rock Burst; China Coal Industry Publishing House: Beijing, China, 2018. [Google Scholar]

- Xu, J.; Jiang, J.; Xu, N.; Liu, Q.; Gao, Y. A new energy index for evaluating the tendency of rockburst and its engineering application. Eng. Geol. 2017, 230, 46–54. [Google Scholar] [CrossRef]

- Gong, F.; Yan, J.; Li, X.; Luo, S. A peak-strength strain energy storage index for rock burst proneness of rock materials. Int. J. Rock Mech. Min. Sci. 2019, 117, 76–89. [Google Scholar] [CrossRef]

- Jiang, F.X.; Wang, J.C.; Sun, G.J.; Zhu, S.T. Engineering criterion of gob-side entry rock burst hazard in deep mining. J. Chin. Coal Soc. 2015, 40, 1729–1736. [Google Scholar]

- Yang, G.Y.; Jiang, F.X.; Li, L.; Li, N.L.; Liu, P. Engineering criterion study on coal mining rock burst hazard. J. Min. Saf. Eng. 2018, 35, 1200–1207. [Google Scholar]

- Gong, F.; Yan, J.; Luo, S.; Li, X. Investigation on the Linear Energy Storage and Dissipation Laws of Rock Materials Under Uniaxial Compression. Rock Mech. Rock Eng. 2019, 52, 4237–4255. [Google Scholar] [CrossRef]

- Zhang, S.P.; Zhao, J.; Li, S.D.; Zhou, T.; Cui, X.C.; Zhang, D.; Liang, J.Z.; Wang, G.A.; Zhu, S.T.; Sun, B. Study on impact risk assessment of isolated coal mass in roadway of thick coal seam in deep mine. J. Safe Sci. Technol. 2022, 18, 70–77. [Google Scholar]

- Fan, D.Y.; Liu, X.S.; Tan, Y.L.; Li, X.B.; Purev, L. Instability energy mechanism of super-large section crossing chambers in deep coal mines. Int. J. Min. Sci. Technol. 2022, 32, 1075–1086. [Google Scholar] [CrossRef]

- Wen, J.L.; Li, H.S.; Jiang, F.X.; Yu, Z.X.; Ma, H.T.; Yang, X.L. Rock burst risk evaluation based on equivalent surrounding rock strength. Int. J. Min. Sci. Technol. 2019, 29, 571–576. [Google Scholar] [CrossRef]

- Yang, H.Z.; Guo, Z.P.; Chen, D.Z.; Chen, D.Z.; Wang, C.; Zhang, F.Y.; Du, Z.W. Study on reasonable roadway position of working face under strip coal pillar in rock burst mine. Shock Vib. 2020, 2020, 8832791. [Google Scholar] [CrossRef]

- Qiu, P.Q.; Ning, J.G.; Wang, J.; Hu, S.C.; Li, Z. Mitigating rock burst hazard in deep coal mines insight from dredging concentrated stress: A case study. Tunn. Undergr. Space Technol. 2021, 115, 104060. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).