Semi-Analytical Prediction of Ground Surface Heave Induced by Shield Tunneling Considering Three-Dimensional Space Effect

Abstract

:1. Introduction

2. Problem Description

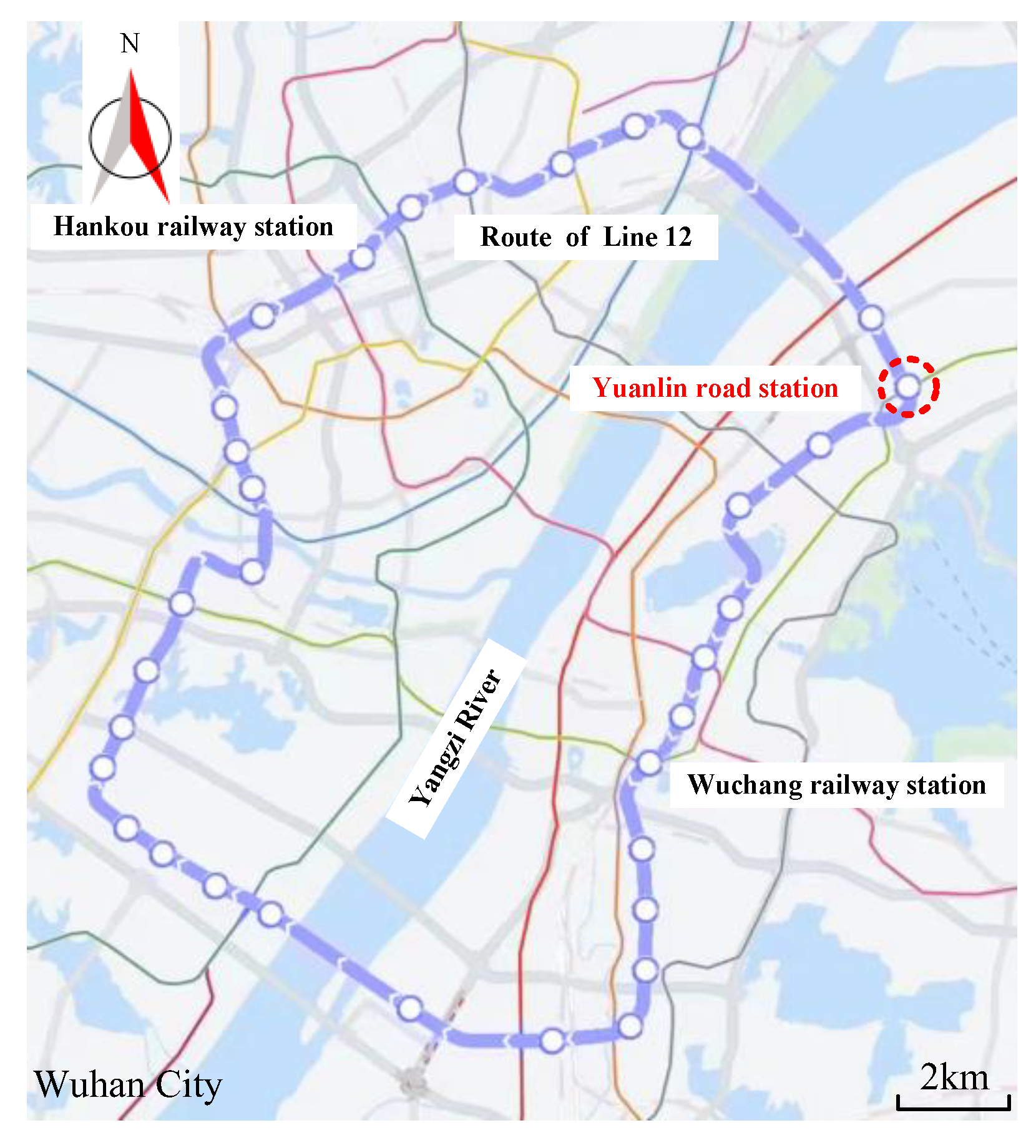

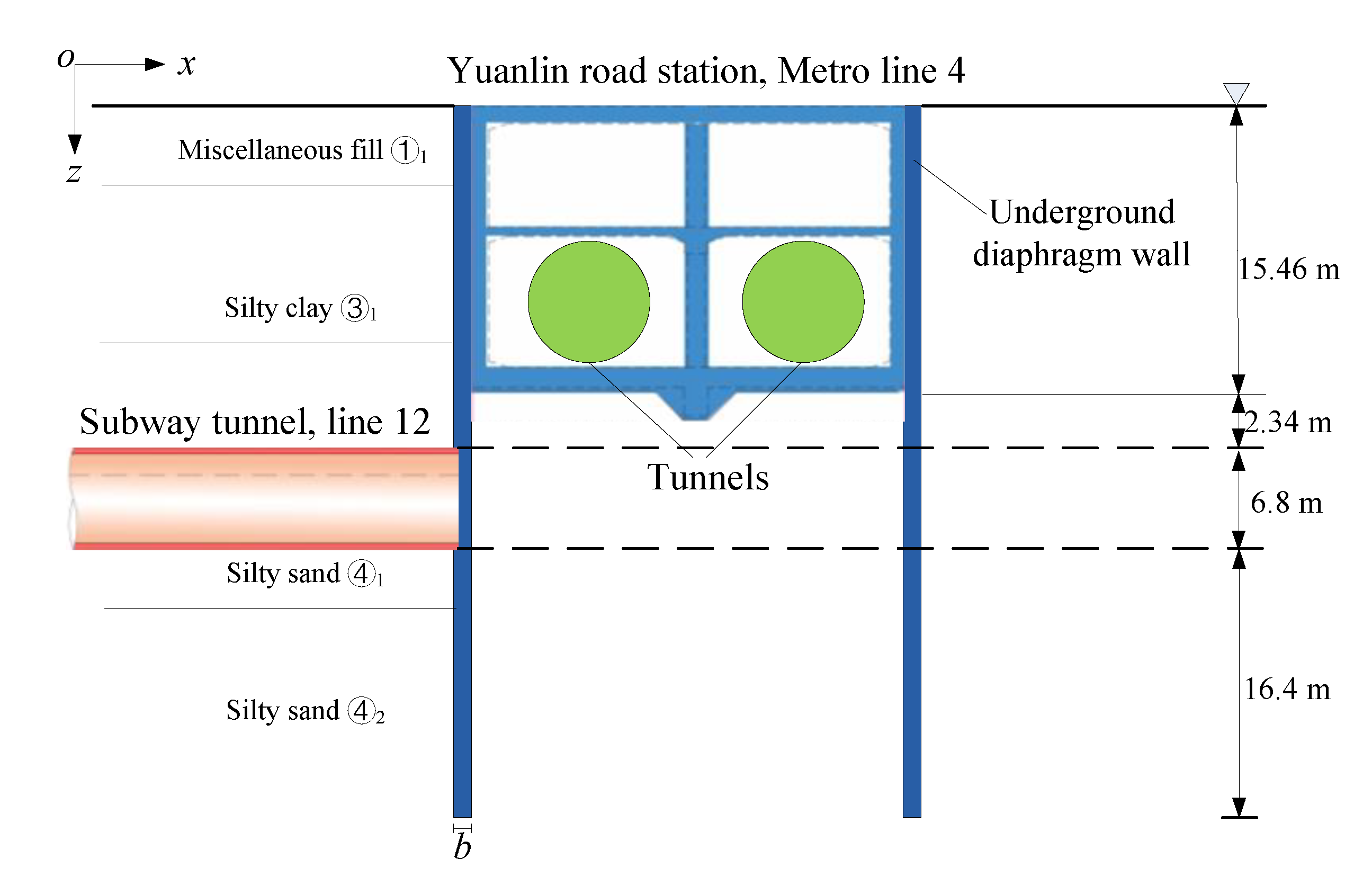

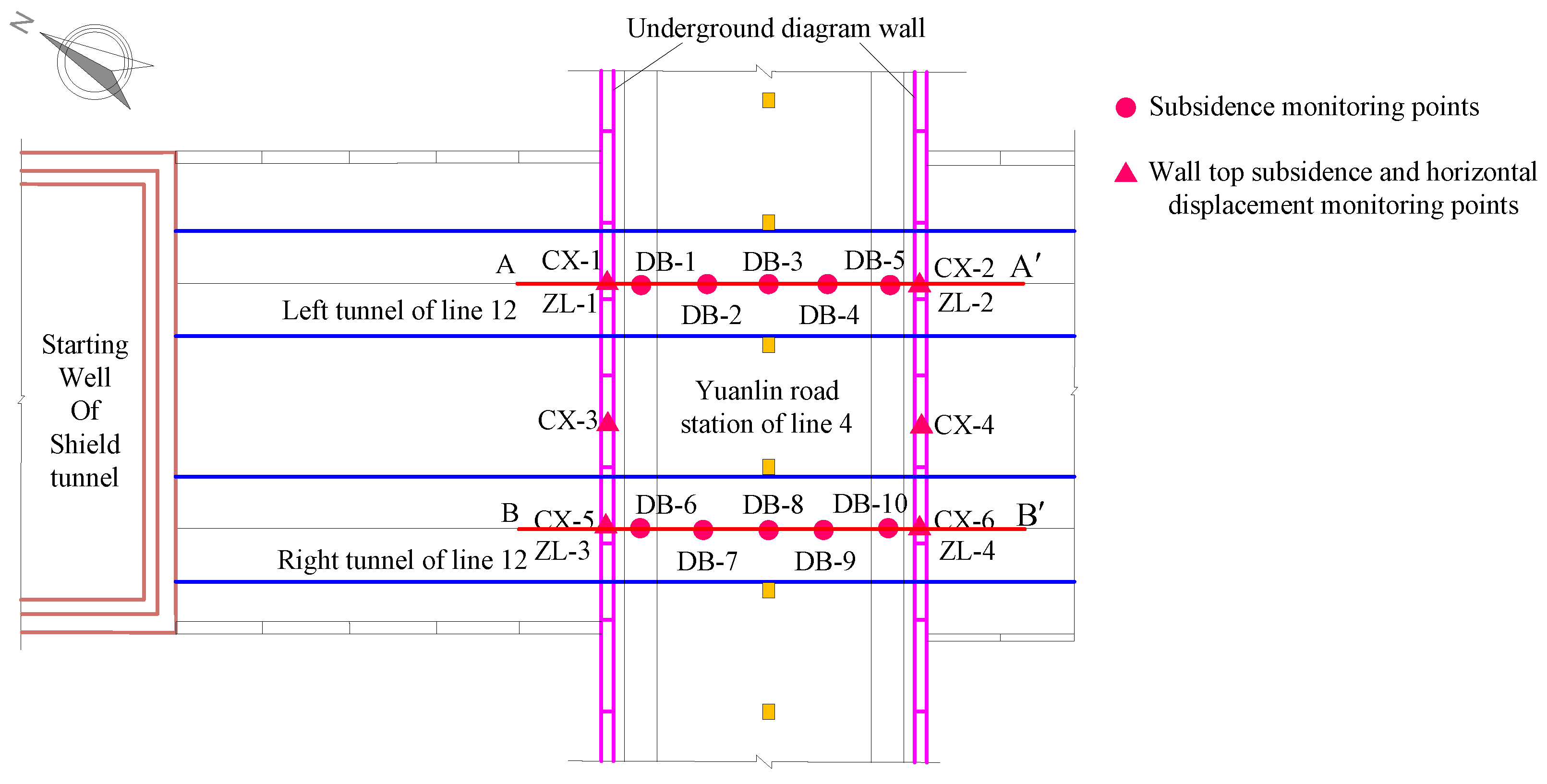

2.1. Engineering Background

2.2. Engineering Geological Conditions

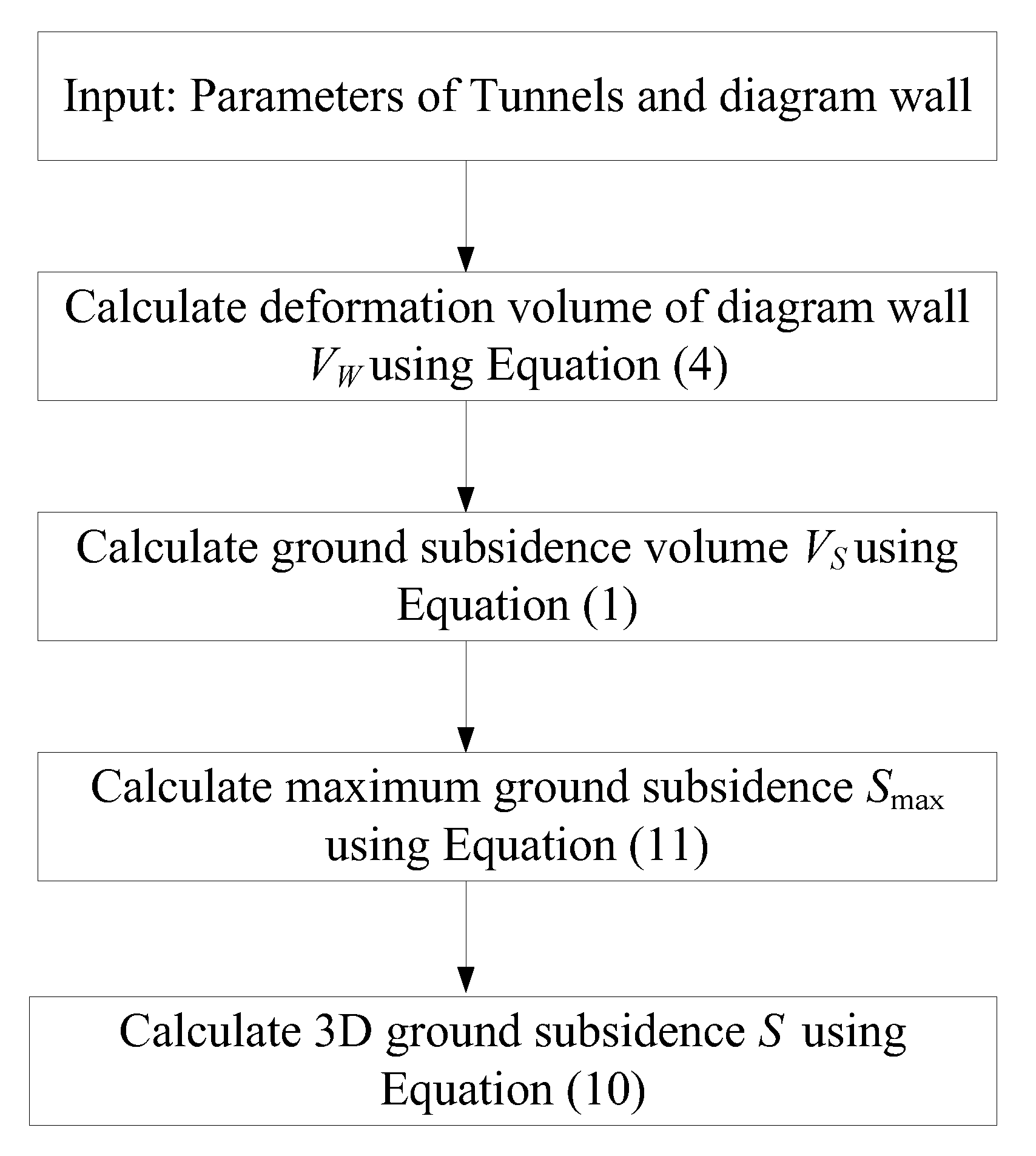

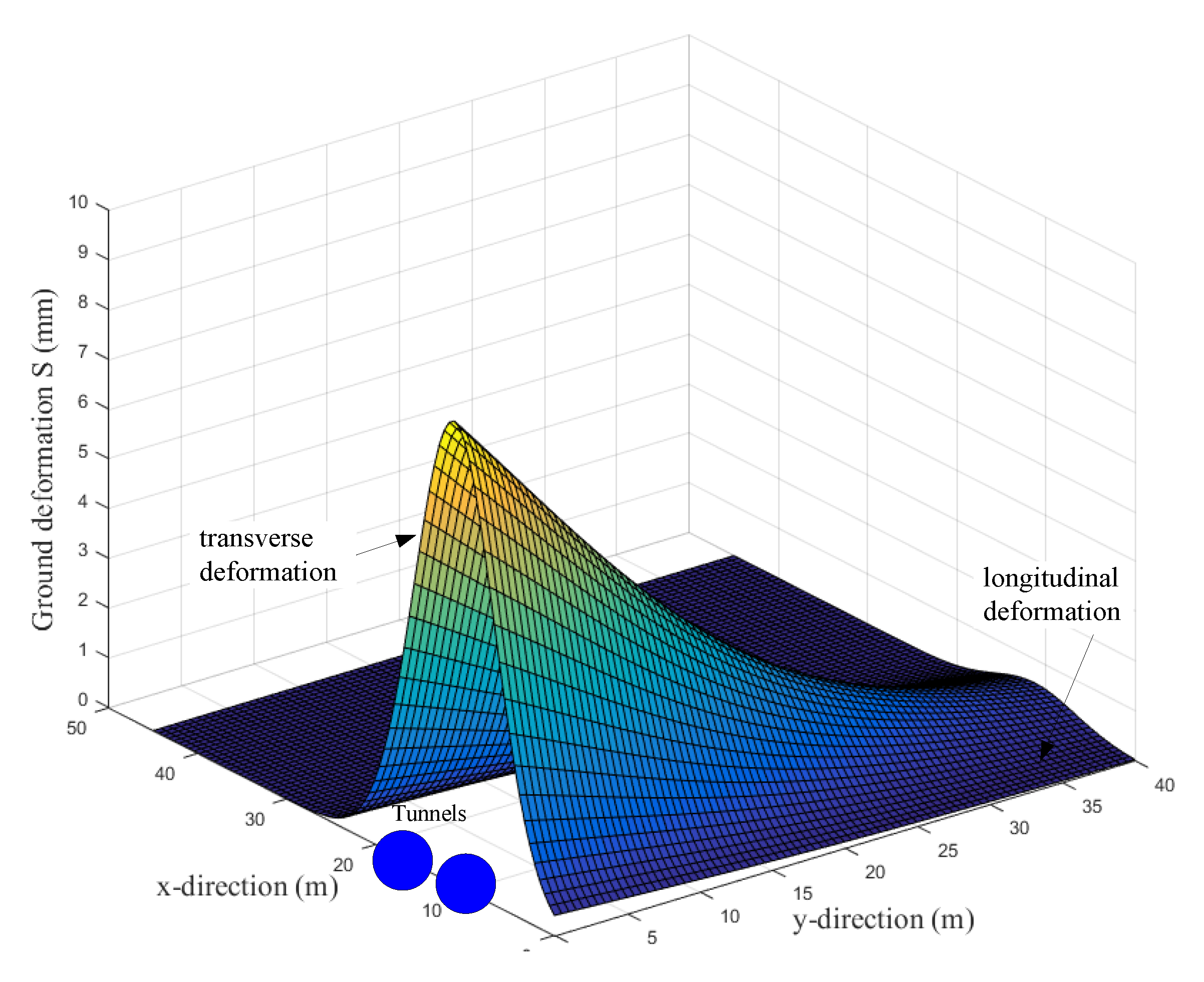

3. Prediction Method of Ground Heave Considering the 3D Space Effect

3.1. Basic Assumptions

- (1)

- The diaphragm wall is a linear elastic material, and underground water is not considered.

- (2)

- Under the process of tunneling, the soil volume behind the underground diaphragm wall remains constant.

- (3)

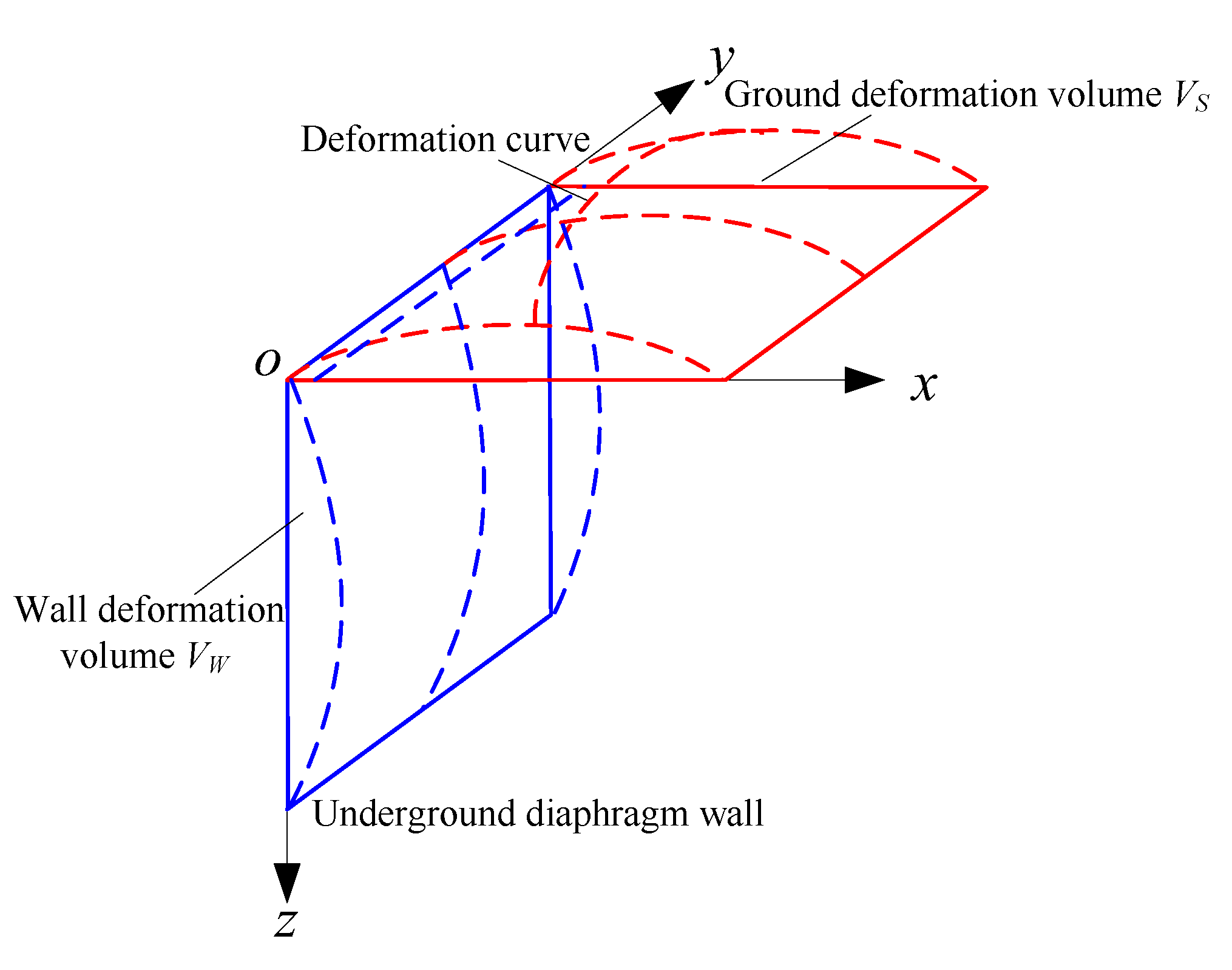

- Ground heave is induced by lateral deformation of the underground diaphragm wall, which is shown in Figure 3.

- (4)

- Diaphragm wall deformation volume VW has a proportional relationship with deformation volume VS.

- (5)

- In order to simplify the calculation, the weighted average method is used to homogenize multilayer soils.

- (6)

- The diaphragm wall follows Kirchhoff plate theory [39]. The reason is that the ratio of width and depth of the wall is 1.2 m/41 m, which far less than 1/5. Hence, this wall is a typical Kirchhoff plane.

- (7)

- Due to high strength of the diaphragm wall, only elastic deformation is considered in the wall, which is widely adopted. Additionally, the diaphragm wall is considered as an isotropic material.

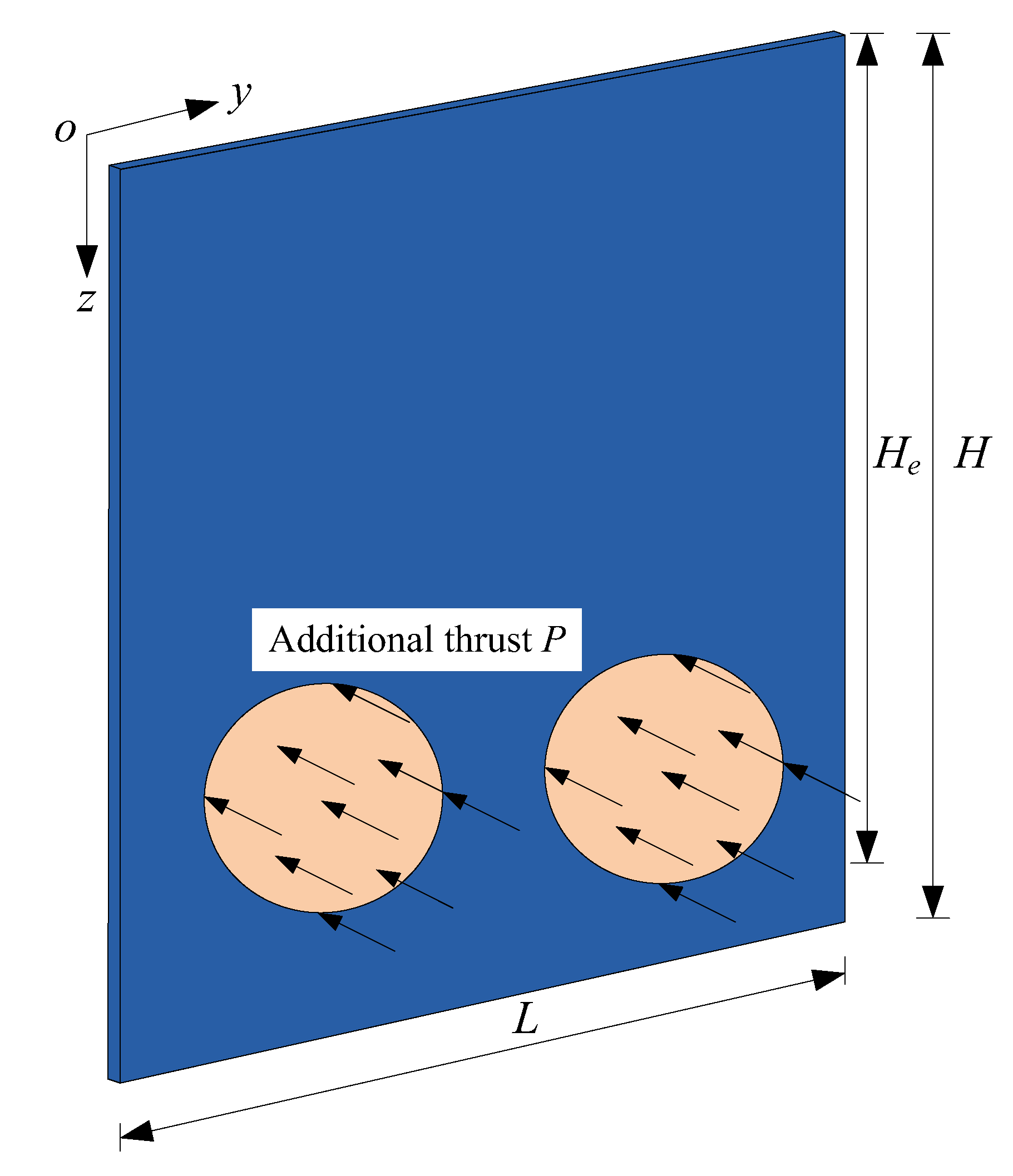

3.2. Deformation Volume of Diaphragm Wall

3.3. Ground Deformation Volume

3.4. Deformation Calculation

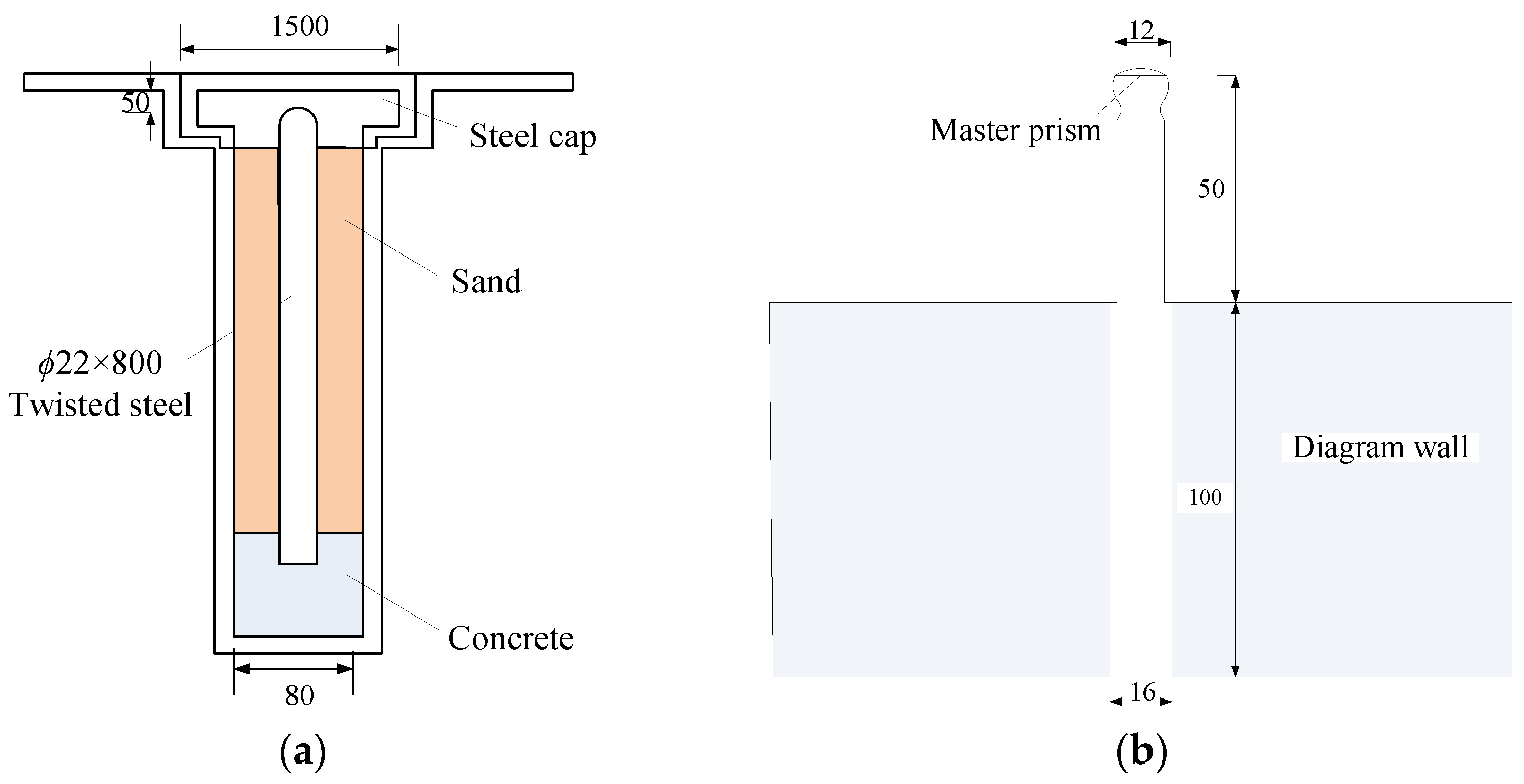

4. Field Monitoring Setting

5. Results and Discussion

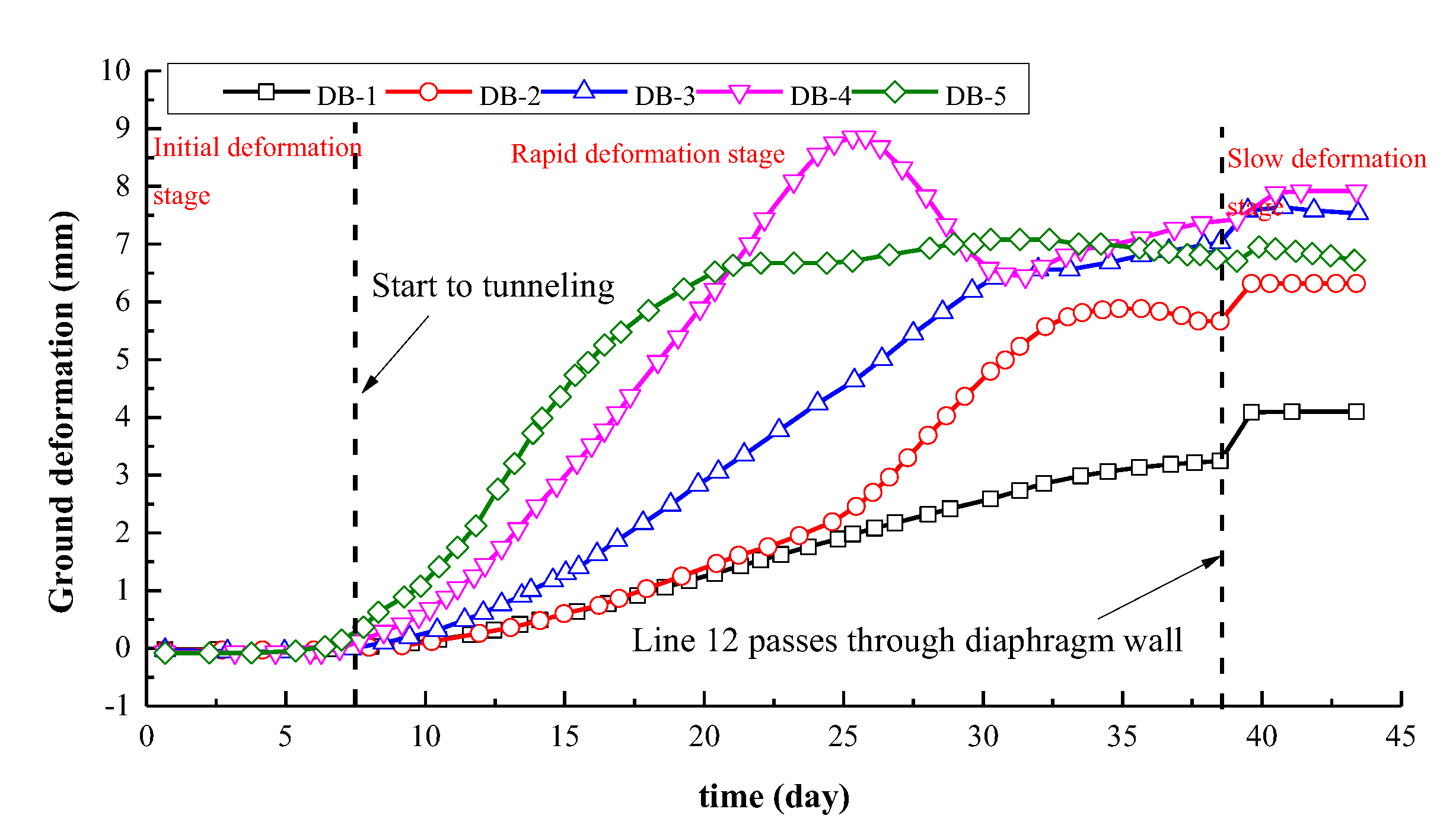

5.1. Field Monitoring Results

5.2. Field Monitoring Results

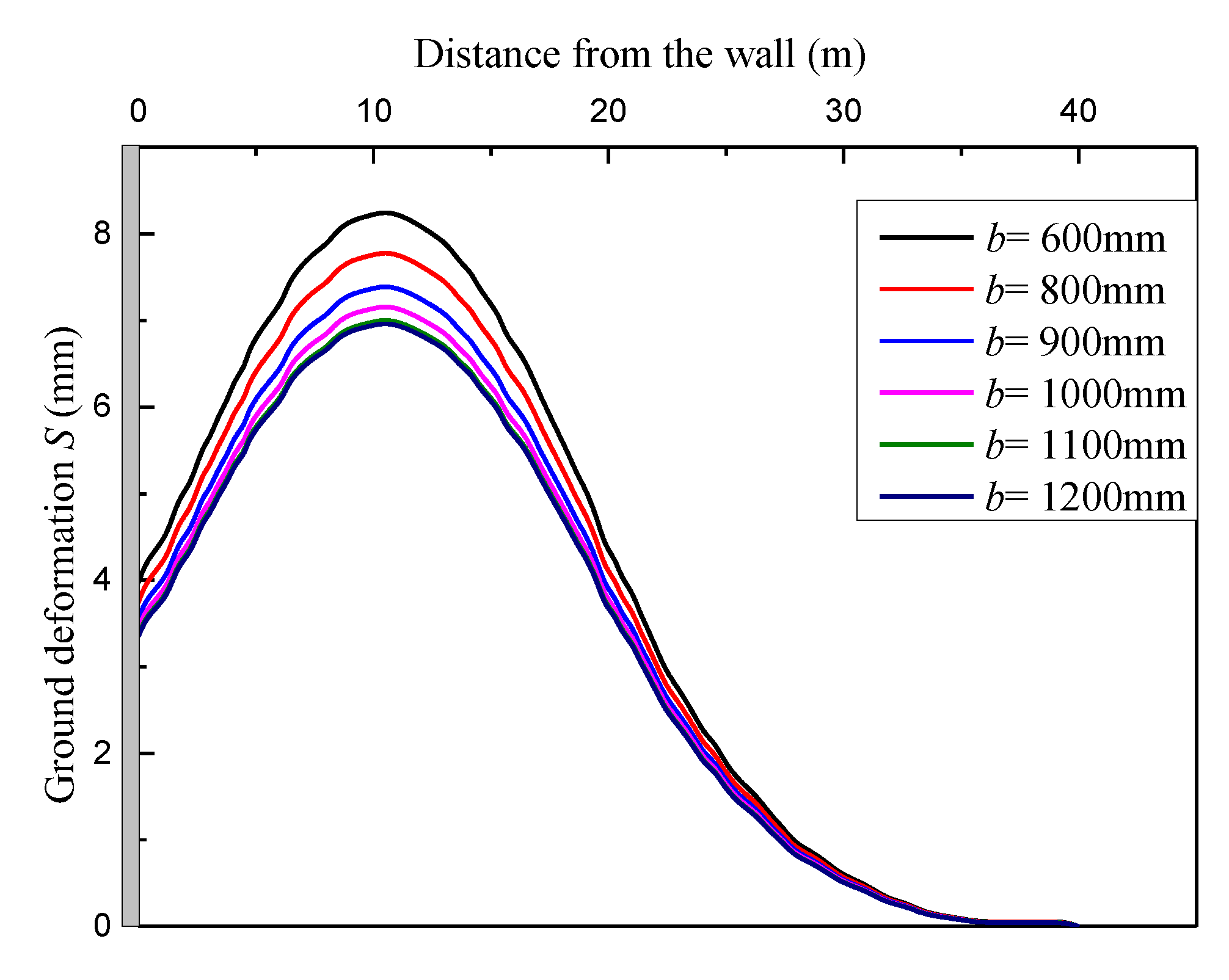

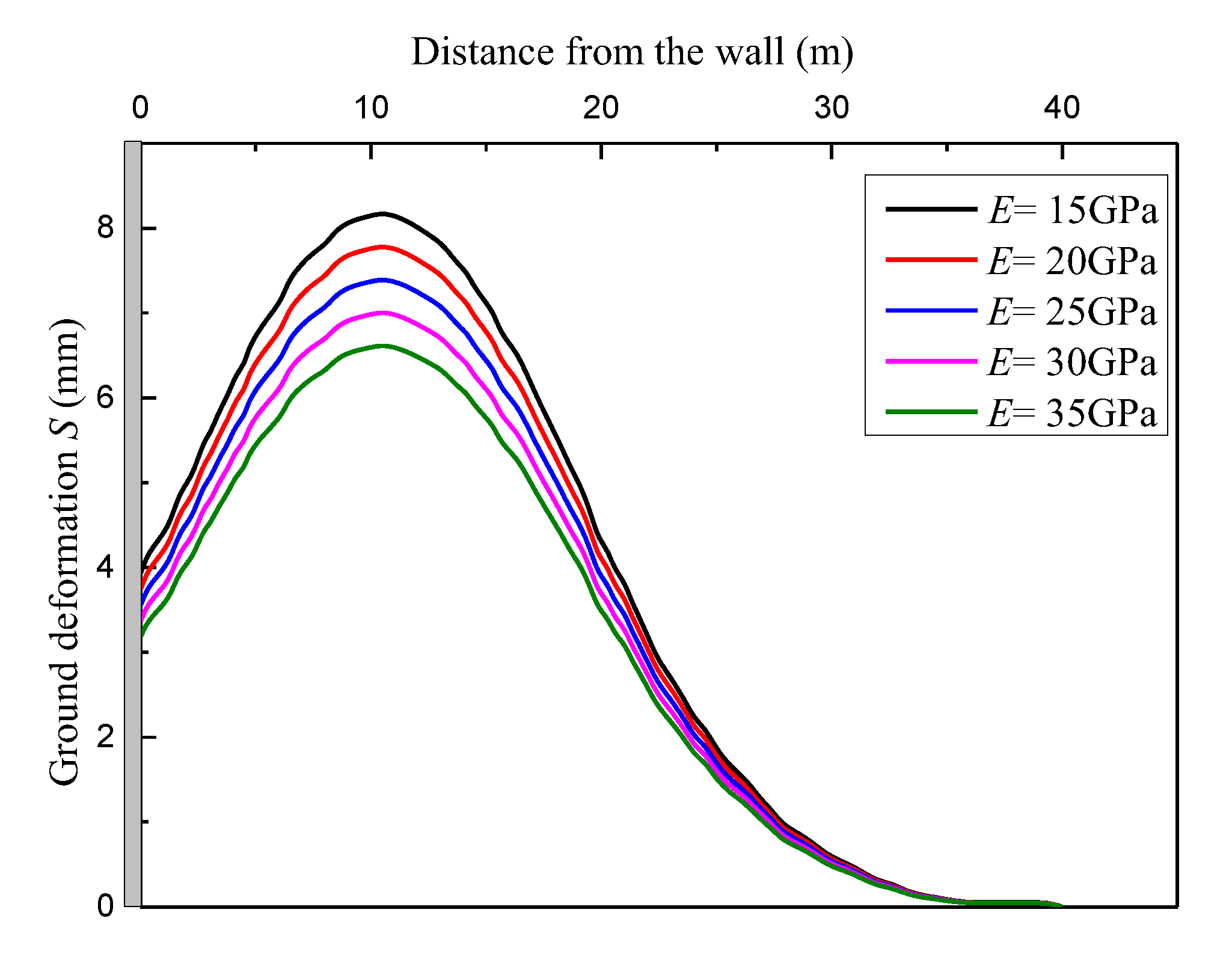

5.3. Parametric Study of Underground Diaphragm Wall

6. Conclusions and Discussion

- (1)

- The relationships between the deformation volume of the underground diaphragm wall and the ground deformation volume are first established. The deformation volume of the diaphragm wall is calculated using Kirchhoff plate theory, and the ground deformation volume is evaluated by the transverse deformation curve and longitudinal deformation curve. Further, the ground heave solutions at arbitrary position are obtained.

- (2)

- The proposed method is verified by field measurements from Wuhan Metro tunnel cases from China. In general, a good agreement has been observed for shield excavation-induced ground heave profiles and the predictions are good for normalized ground heave profiles. The maximum error is 14.6%, which is acceptable. Hence, the proposed method can be used as a feasible approach for the estimation of deformations induced by shield excavations.

- (3)

- The parameters of underground diaphragm walls are studied using the proposed deformation calculation method to determine reasonable design schemes for underground diaphragm walls. The elastic modulus of diaphragm walls has significant effects on ground heaves, while the thickness and embedded ratio of diaphragm walls has limited effects on ground heaves. As elastic modulus and the thickness of diaphragm wall increase, the ground heaves gradually decrease. In addition, the effects of the embedded ratio show a positive correlation. However, when the thickness and embedded ratio reach a certain value, they have little effect on ground heaves.

- (4)

- The presence of underground water has non-ignorable influences on ground deformation. So a new ground heave prediction method should be derived considering underground water seepage in the future.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

References

- Schuster, M.; Kung, G.; Juang, C.; Hashash, Y. Simplified model for evaluating damage potential of buildings adjacent to a braced excavation. J. Geotech. Geoenviron. Eng. 2009, 135, 1823–1835. [Google Scholar] [CrossRef]

- Hsiao, E.; Schuster, M.; Juang, C.; Kung, G. Reliability analysis and updating of excavation-induced ground settlement for building serviceability assessment. J. Geotech. Geoenviron. Eng. 2008, 134, 1448–1458. [Google Scholar] [CrossRef]

- Fan, X.; Phoon, K.; Xu, C.; Tang, C. Closed-form solution for excavation-induced ground settlement profile in clay. Comput. Geotech. 2021, 137, 104266. [Google Scholar] [CrossRef]

- Cao, L.; Zhang, D.; Fang, Q. Semi-analytical prediction for tunnelling-induced ground movements in multi-layered clayey soils. Tunneling Undergr. Space Technol. 2020, 102, 103446. [Google Scholar] [CrossRef]

- Dalgoc, K.; Hendriks, M.; Ilki, A. Building response to tunneling and excavation-induced ground movements: Using transfer functions to review the limiting tensile strain method. Struct. Infrastruct. Eng. Maint. Manag. Life-Cycle Des. Perform. 2018, 14, 766–779. [Google Scholar] [CrossRef]

- Park, K. Elastic solution for the tunneling-induced ground movements in clays. Int. J. Geomech. 2004, 4, 310–318. [Google Scholar] [CrossRef]

- Bobet, A. Analytical solutions for shallow tunnels in saturated ground. J. Eng. Mech. 2001, 127, 1258–1266. [Google Scholar] [CrossRef]

- Fattah, M.; Shlash, K.; Salim, N. Prediction of settlement through induced by tunneling in cohesive ground. Acta Geotech. 2013, 8, 167–179. [Google Scholar] [CrossRef]

- Kong, F.; Lu, D.; Du, X.; Shen, C. Elastic analytical solution of shallow tunnel owing to twin tunnelling based on a unified displacement function. Appl. Math. 2019, 68, 422–442. [Google Scholar] [CrossRef]

- Mindlin, R. Force at a point in the interior of a semi-infinite solid. Physics 1936, 7, 195–202. [Google Scholar] [CrossRef]

- Timoshenko, S.; Goodier, J. Theory of Elasticity; McGraw-Hill Higher Education: New York, NY, USA, 1970. [Google Scholar]

- Sagaseta, C. Analysis of undrained soil deformation due to ground loss. Geotechnique 1987, 37, 301–320. [Google Scholar] [CrossRef]

- Verruijt, A. A complex variable solution for a deforming circular tunnel in an elastic half-plane. Int. J. Numer. Anal. Methods Geomech. 1997, 21, 77–89. [Google Scholar] [CrossRef]

- Peck, R. Deep excavation and tunneling in soft ground. In Proceedings of the 7th International Conference on Soil Mechanics and Foundation Engineering, State-of-the-Art, Mexico City, Mexico, 25–29 August 1969; pp. 225–290. [Google Scholar]

- Zhao, C.; Lavasan, A.; Barciaga, T. Mechanized tunneling induced ground movement and its dependency on the tunnel volume loss and soil properties. Int. J. Numer. Anal. Methods Geomech. 2019, 43, 781–800. [Google Scholar] [CrossRef]

- Moh, Z.; Ju, H.; Hwang, R. Ground movements around tunnels in soft ground. In Proceedings of the International Symposium on Geotechnical Aspects of Underground Construction in Soft Ground; Balkema: Rotterdam, The Netherlands, 1996; pp. 268–273. [Google Scholar]

- Atkinson, J.; Potts, D. Stability of a shallow circular tunnel in cohesionless soil. Geotechnique 1977, 27, 203–215. [Google Scholar] [CrossRef]

- Finno, R.; Blackburn, J.; Roboski, J. Three-dimensional effects for supported excavations in clay. J. Geotech. Geoenviron. Eng. 2007, 133, 30–36. [Google Scholar] [CrossRef]

- Liu, C.; Peng, Z.; Pan, L.; Pan, L.; Liu, H.; Yang, Y.; Chen, W. Influence of tunnel boring machine (TBM) advance on adjacent tunnel during ultra-rapid underground pass (URUP) tunneling: A case study and numerical investigation. Appl. Sci. 2020, 10, 3746. [Google Scholar] [CrossRef]

- Shah, R.; Lavasan, A.; Peila, D. Numerical study on backfilling the tail void using a two-component grout. J. Mater. Civ. Eng. 2018, 30, 4018003–40180011. [Google Scholar] [CrossRef]

- Fu, J. Modelling Ground Movement and Associated Building Response Due to Tunneling in Soils. Ph.D. Thesis, Technische Universitaet Bergakademie Freiberg, Freiberg, Germany, 2014. [Google Scholar]

- Franzius, J.; Potts, D. Influence of mesh geometry on three-dimensional finite-element analysis of tunnel excavation. Int. J. Geomech. 2005, 5, 256–266. [Google Scholar] [CrossRef]

- Wang, X.; Schmettow, T.; Chen, X.; Xia, C. Prediction of ground settlements induced by twin shield tunneling in rock and soil—A case study. Undergr. Space 2022, 7, 623–635. [Google Scholar] [CrossRef]

- Zhu, C. Surface settlement analysis induced by shield tunneling construction in the loess region. Adv. Mater. Sci. Eng. 2021, 2021, 5573372. [Google Scholar] [CrossRef]

- Jin, H.; Yuan, D.; Jin, D.; Wu, J.; Wang, X.; Han, B.; Mao, J. Shield kinematics and its influence on ground settlement in ultrasoft soil: A case study in Suzhou. Can. Geotech. J. 2022, 59, 1887–1900. [Google Scholar] [CrossRef]

- Gan, X.; Yu, J.; Gong, X.; Liu, N.; Zheng, D. Behaviours of existing shield tunnels due to tunneling underneath considering asymmetric ground settlements. Undergr. Space 2022, 7, 882–897. [Google Scholar] [CrossRef]

- Zhang, J.; Gao, Y.; Liu, X.; Zhang, Z.; Yuan, Y.; Mang, H. A shield tunneling for enlarging the diameter of existing tunnels: Experimental investigations. Tunneling Undergr. Space Technol. 2022, 128, 104605. [Google Scholar] [CrossRef]

- Liu, B.; Yu, Z.; Zhang, R.; Han, Y.; Wang, Z.; Wang, S. Effects of undercrossing tunneling on existing shield tunnels. Int. J. Geomech. 2021, 21, 1–12. [Google Scholar] [CrossRef]

- Lin, X.; Chen, R.; Wu, H.; Cheng, H. Deformation of behaviors of existing tunnels caused by shield tunneling undercrossing oblique angle. Tunneling Undergr. Space Technol. 2019, 89, 78–90. [Google Scholar] [CrossRef]

- Chakeri, H.; Hasanpour, R.; Hindistan, M. Analysis of interaction between tunnels in soft ground by 3D numerical modeling. Bull. Eng. Geol. Environ. 2011, 70, 439–448. [Google Scholar] [CrossRef]

- Klar, A.; Vorsster, T.; Soga, K.; Mair, R. Soil-pipe interaction due to tunnelling: Comparison between Winkler and elastic continuum solutions. Geotechnique 2005, 55, 461–466. [Google Scholar] [CrossRef]

- Zhang, H.; Huang, M. Geotechnical influence on existing subway tunnels induced by multiline tunneling in Shanghai soft soil. Comput. Geotech. 2014, 56, 121–132. [Google Scholar] [CrossRef]

- He, S.; Lai, J.; Wang, L.; Wang, K. A literature review on properties and applications of grouts for shield tunnel. Constr. Build. Mater. 2020, 239, 117782. [Google Scholar] [CrossRef]

- Zhao, Y.; Chen, X.; Hu, B.; Wang, P.; Li, W. Evolution of tunnel uplift induced by adjacent long and collinear excavation and an effective protective measure. Tunn. Undergr. Space Technol. 2023, 131, 104846. [Google Scholar] [CrossRef]

- Wei, G.; Qi, Y.; Chen, C.; Zhang, S.; Qian, C.; Zhou, J. Analysis of the protective effect of setting isolation piles outside the foundation pit on the underpass tunnel side. Transp. Geotech. 2022, 35, 100791. [Google Scholar] [CrossRef]

- Liang, X.; Ying, K.; Ye, F.; Su, E.; Xia, T.; Han, X. Selection of backfill grouting materials and ratios for shield tunnel considering stratum suitability. Constr. Build. Mater. 2022, 314, 125431. [Google Scholar] [CrossRef]

- Bowles, J. Foundation Analysis and Design; McGraw-Hill: New York, NY, USA, 1988. [Google Scholar]

- Qian, W.; Qi, T.; Zhao, Y.; Le, Y.; Yi, H. Deformation characteristics and safety assessment of a high-speed railway induced by undercutting metro tunnel excavation. J. Rock Mech. Geotech. Eng. 2019, 11, 88–98. [Google Scholar] [CrossRef]

- Simo, J.; Hughes, T. Interdisciplinary Applied Mathematics; Springer: Berlin/Heidelberg, Germany, 1998. [Google Scholar]

- Kung, G.; Juang, C.; Hsiao, E.; Hashash, Y. Simplified model for wall deflection and ground-surface settlement caused by braced excavation in clays. J. Geotech. Geoenviron. Eng. 2007, 133, 731–747. [Google Scholar] [CrossRef]

- Clough, G.; O’Rourke, T. Construction Induced Movements of Insitu Wall, Design and Performance of Earth Retaining Structure; ASCE: New York, NY, USA, 1990; pp. 439–470. [Google Scholar]

- Feng, C.; Zhang, D. The general deformation mode and its application of subway station foundation pit in sandy cobble stratum. Chin. J. Rock Mech. Eng. 2018, 37, 4395–4405. (In Chinese) [Google Scholar] [CrossRef]

- Huang, M.; Zhang, C.; Li, Z. A simplified analysis method for the influence of tunneling on ground piles. Tunn. Undergr. Space Technol. 2009, 125, 207–215. [Google Scholar] [CrossRef]

- Xiong, F.; Sun, H.; Zhang, Q.; Wang, Y.; Jiang, Q. Preferential flow in three-dimensional stochastic fracture networks: The effect of topological structure. Eng. Geol. 2022, 309, 106856. [Google Scholar] [CrossRef]

- Xiong, F.; Zhu, C.; Feng, G.; Zheng, J.; Sun, H. A three-dimensional coupled thermo-hydro model for geothermal development in discrete fracture networks of hot dry rock reservoirs. Gondwana Res. 2023, 122, 331–347. [Google Scholar] [CrossRef]

| Soil | Weight γ (kN/m3) | Bearing Capacity fak (kPa) | Friction Angle φ (°) | Modulus of Compression Es (MPa) | Poisson Ratio μ | Permeability Coefficient k (cm/s) |

|---|---|---|---|---|---|---|

| miscellaneous fill ①1 | 20.0 | - | 18 | - | 0.25 | 5.0 × 10−3 |

| silty clay ③1 | 19.1 | 123 | 11 | 4.5 | 0.3 | 3.5 × 10−3 |

| silty sand ④1 | 19.0 | 155 | 33.4 | 13.5 | 0.3 | 2.8 × 10−3 |

| silty sand ④2 | 19.5 | 206 | 35.2 | 18.6 | 0.3 | 3.1 × 10−3 |

| Modulus of Elasticity E (GPa) | Poisson Ratio μ | Friction Angle φ (°) | |

|---|---|---|---|

| Diaphragm wall | 20 | 0.1 | 50 |

| Equivalent soil | 12.2 | 0.3 | 25 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qi, J.; Zhang, G.; Jiao, Y.; Shen, L.; Zheng, F.; Zou, J.; Zhang, P. Semi-Analytical Prediction of Ground Surface Heave Induced by Shield Tunneling Considering Three-Dimensional Space Effect. Appl. Sci. 2023, 13, 11588. https://doi.org/10.3390/app132011588

Qi J, Zhang G, Jiao Y, Shen L, Zheng F, Zou J, Zhang P. Semi-Analytical Prediction of Ground Surface Heave Induced by Shield Tunneling Considering Three-Dimensional Space Effect. Applied Sciences. 2023; 13(20):11588. https://doi.org/10.3390/app132011588

Chicago/Turabian StyleQi, Jianfeng, Guohua Zhang, Yuyong Jiao, Luyi Shen, Fei Zheng, Junpeng Zou, and Peng Zhang. 2023. "Semi-Analytical Prediction of Ground Surface Heave Induced by Shield Tunneling Considering Three-Dimensional Space Effect" Applied Sciences 13, no. 20: 11588. https://doi.org/10.3390/app132011588

APA StyleQi, J., Zhang, G., Jiao, Y., Shen, L., Zheng, F., Zou, J., & Zhang, P. (2023). Semi-Analytical Prediction of Ground Surface Heave Induced by Shield Tunneling Considering Three-Dimensional Space Effect. Applied Sciences, 13(20), 11588. https://doi.org/10.3390/app132011588