Experimental Study on Permeability Evolution of Sandstone during Triaxial Compression Damage

Abstract

:1. Introduction

2. Test Principle and Method

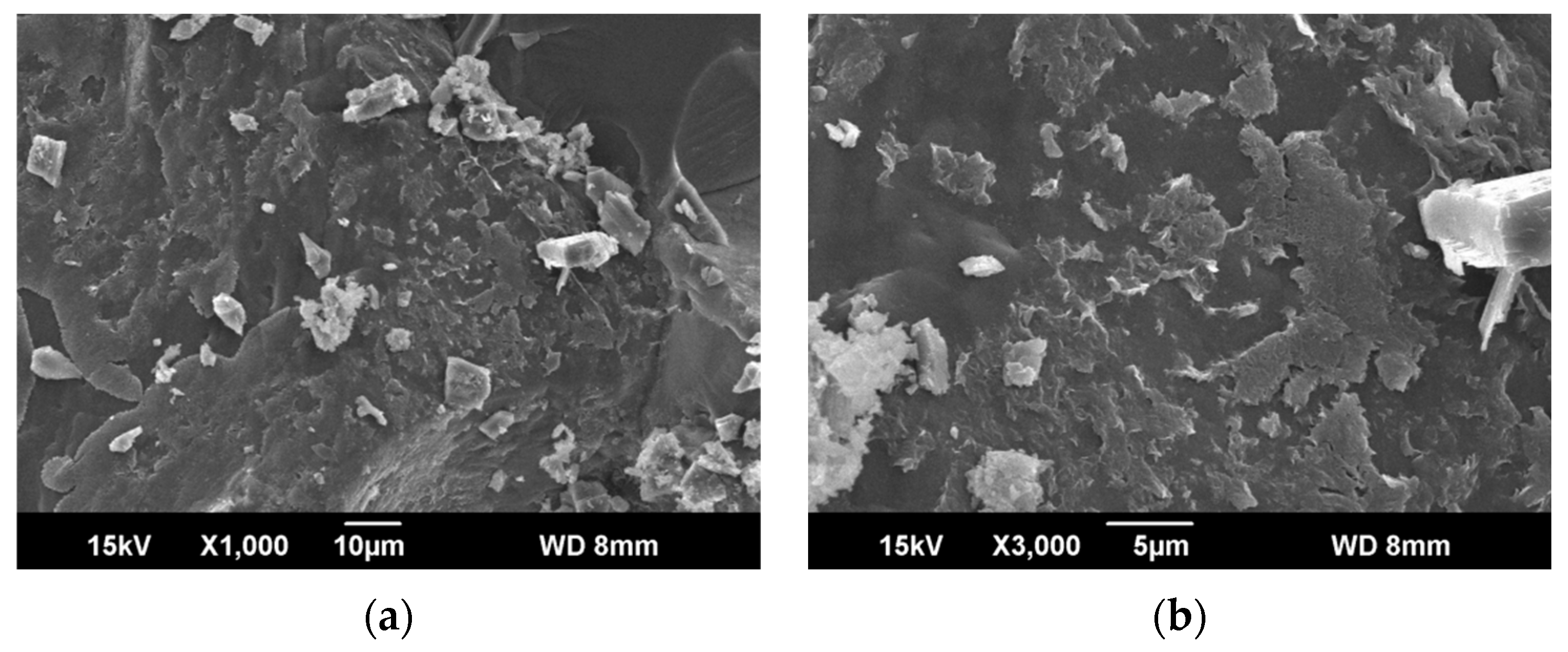

2.1. The Preparation of Tested Sample

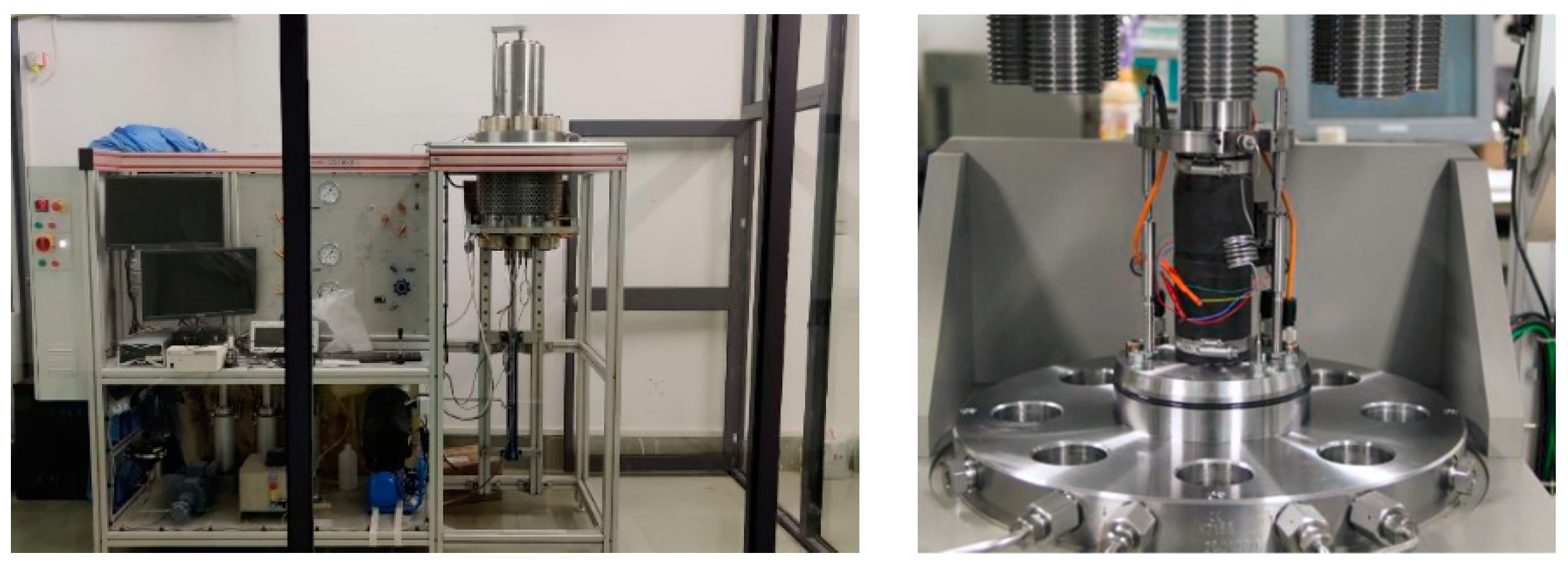

2.2. Test Equipment

2.3. Experimental Principle

2.4. Test Programme and Steps

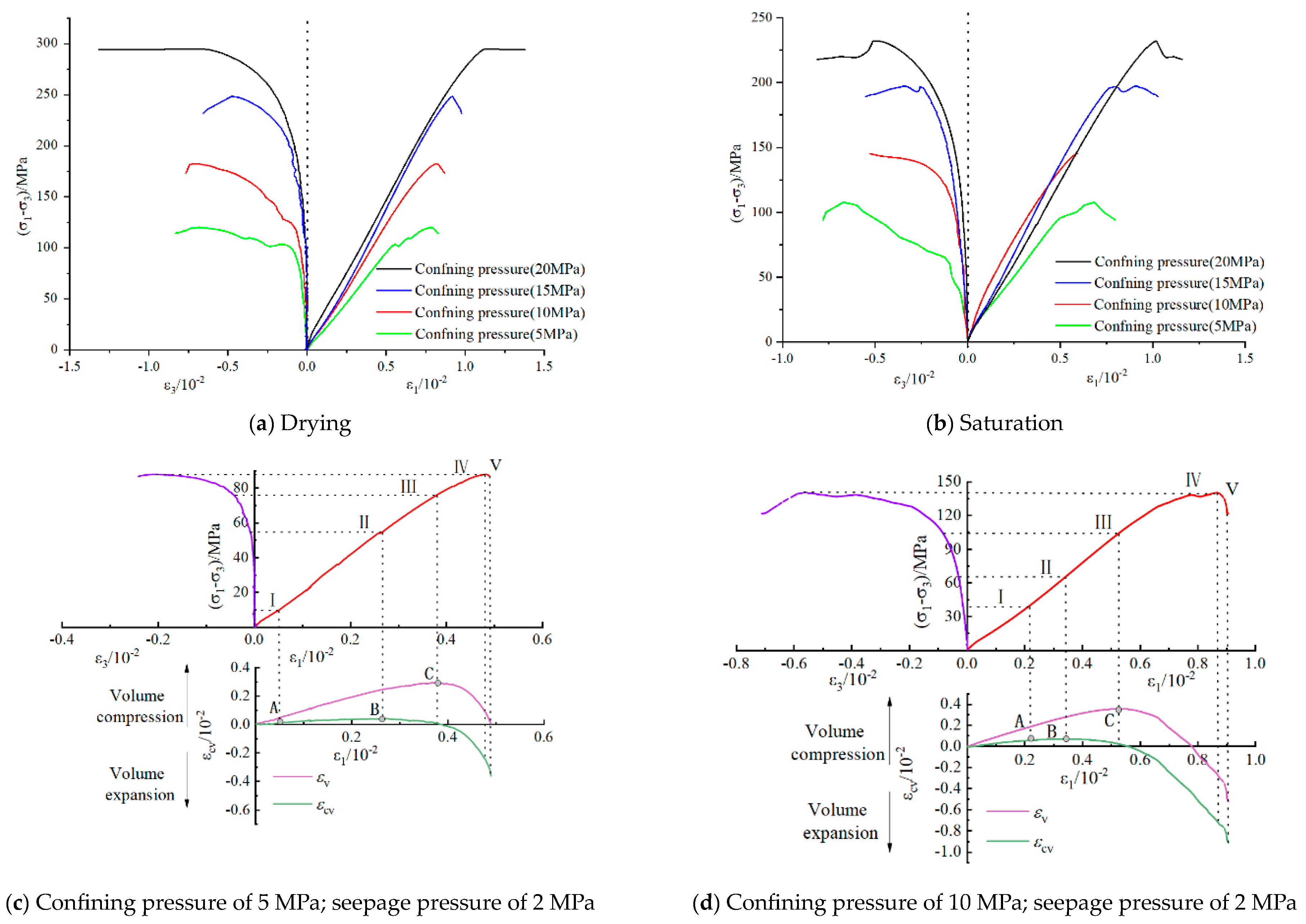

- Under dry conditions, the uniaxial compressive strength of sandstone was determined to be 48.24 MPa, accompanied by a modulus of elasticity measuring 13.22 GPa and a Poisson’s ratio of 0.25. Conversely, when subjected to saturated conditions, the sandstone exhibited a reduced uniaxial compressive strength of 38.76 MPa, coupled with a modulus of elasticity of 15.42 GPa and a Poisson’s ratio slightly increased to 0.26.

- The sandstone underwent triaxial compression tests in both dry and saturated states, along with different gradients of confining pressure, which provided a blank control group for the subsequent hydromechanical tests under saturation conditions. The following four gradients of confining pressure were utilized: 5, 10, 15, and 20 MPa.

- Hydromechanical tests were carried out on sandstone, encompassing various magnitudes of confining pressure gradients and seepage pressure gradients. Confining pressure gradients of 5, 10, 15, and 20 MPa were established, while seepage pressure gradients of 2, 4, and 8 MPa were implemented, the test programme is shown in Table 2. The ensuing hydromechanical test procedures were executed according to the subsequent steps:

- Firstly, the sandstone was secured in the triaxial pressure chamber and then the installation of the circumferential and axial sensors began in sequence.

- Secondly, the confining pressure was applied to the sandstone automatically using a control system, gradually ramping it up from 0 MPa to the designated target value at a controlled rate of 1 MPa/min. Following the stabilization of the confining pressure, the seepage pressure was applied from the upper chamber, incrementally increasing from 0 MPa to the intended value at a controlled pace of 1 MPa/min. It is important to note that the seepage pressure within the lower chamber was maintained at atmospheric pressure throughout this process.

- Thirdly, subsequent to achieving the targeted seepage pressure and ensuring its stability, the next step is to proceed to apply the deviatoric stress. This should be executed by applying a loading rate of 0.01 mm/min until the point of specimen failure is reached.

3. Analysis of Test Results

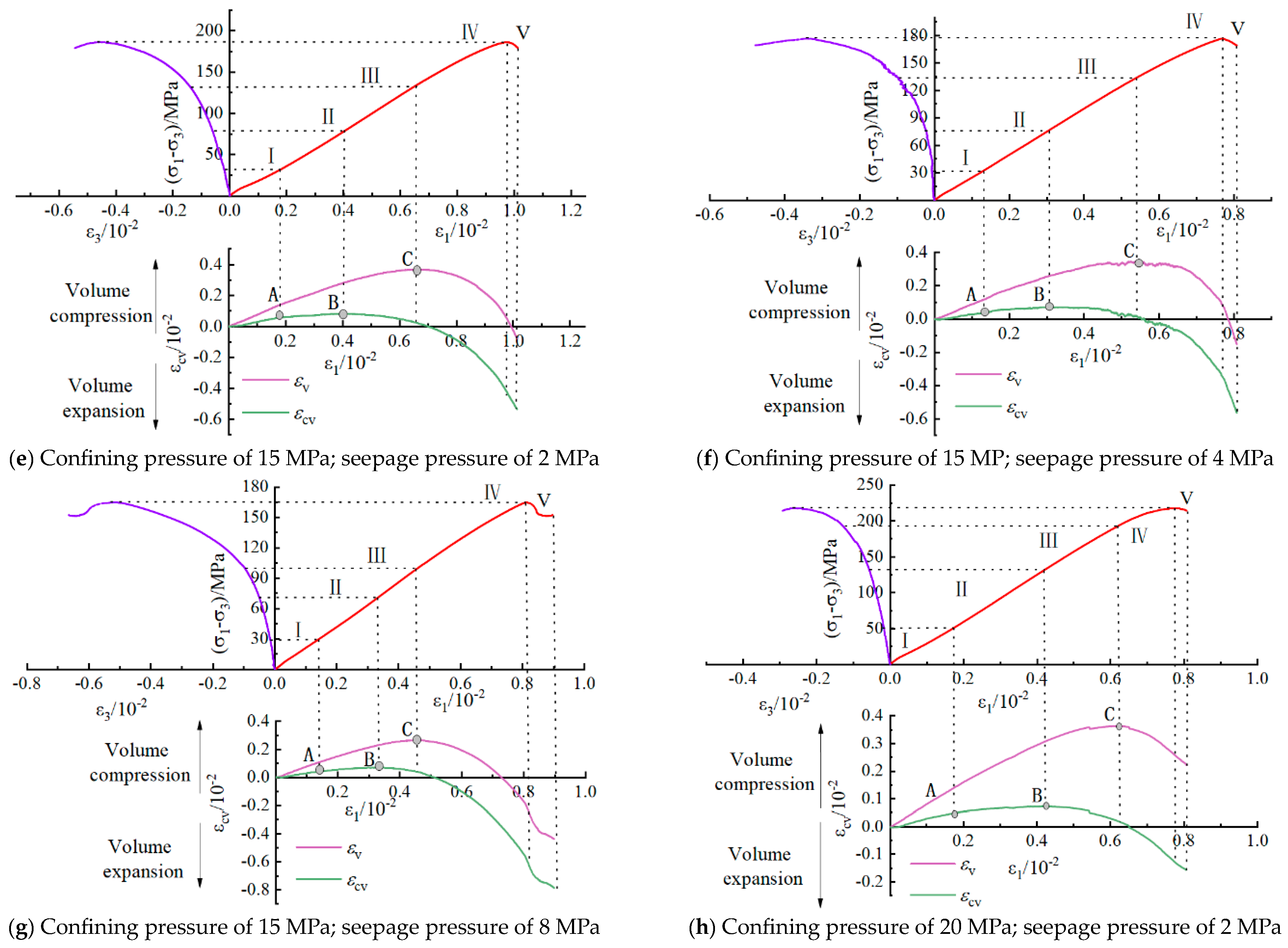

3.1. Stress–Strain Curve and Damage Characterization

- Stage I (microcrack closure stage): The internal primary pores and microcracks are closed in a compression manner, which is mainly the deformation of the weakest portion of the rock’s internal bearing capacity, and the deviatoric stress–axial strain curve at this stage has no obvious upward-concave characteristics. The relationship between deviatoric stress and axial strain appears as an approximately linear trend, characterized by an upper limit stress value which corresponds to the rock’s crack closure stress .

- Stage II (linear elastic deformation stage): As deviatoric stress progressively escalates, the primary pores and microcracks within the rock continue to close and compact. During this phase, the stress–axial strain curve maintains a linear trend, with the upper stress limit signifying the onset of rock fracturing.

- Stage III (stable crack expansion stage): The deviatoric stress–axial strain curve maintains an approximate linear pattern. However, the deviatoric stress–circumferential strain curve begins to exhibit nonlinear behavior as new cracks emerge within the specimen and gradually propagate in a stable fashion. The upper stress limit aligns with the crack damage stress.

- Stage IV (cracks non-stationary expansion stage): The microfracture increases rapidly, and progressive damage occurs within the rock sample. As the volumetric strain enters an expansion phase, the stress–strain curve demonstrates pronounced nonlinearity. The upper stress value in this context corresponds to the peak strength of the sandstone .

- Stage V (post-peak strain and damage stage): At the point where the deviatoric stress reaches its maximum, the internal structure undergoes complete disruption. Fissures rapidly propagate, culminating in the formation of a macroscopic fracture surface. The overall deformation is primarily characterized by shear-slip damage along this fracture surface. Subsequently, stress diminishes progressively with the augmentation of strain.

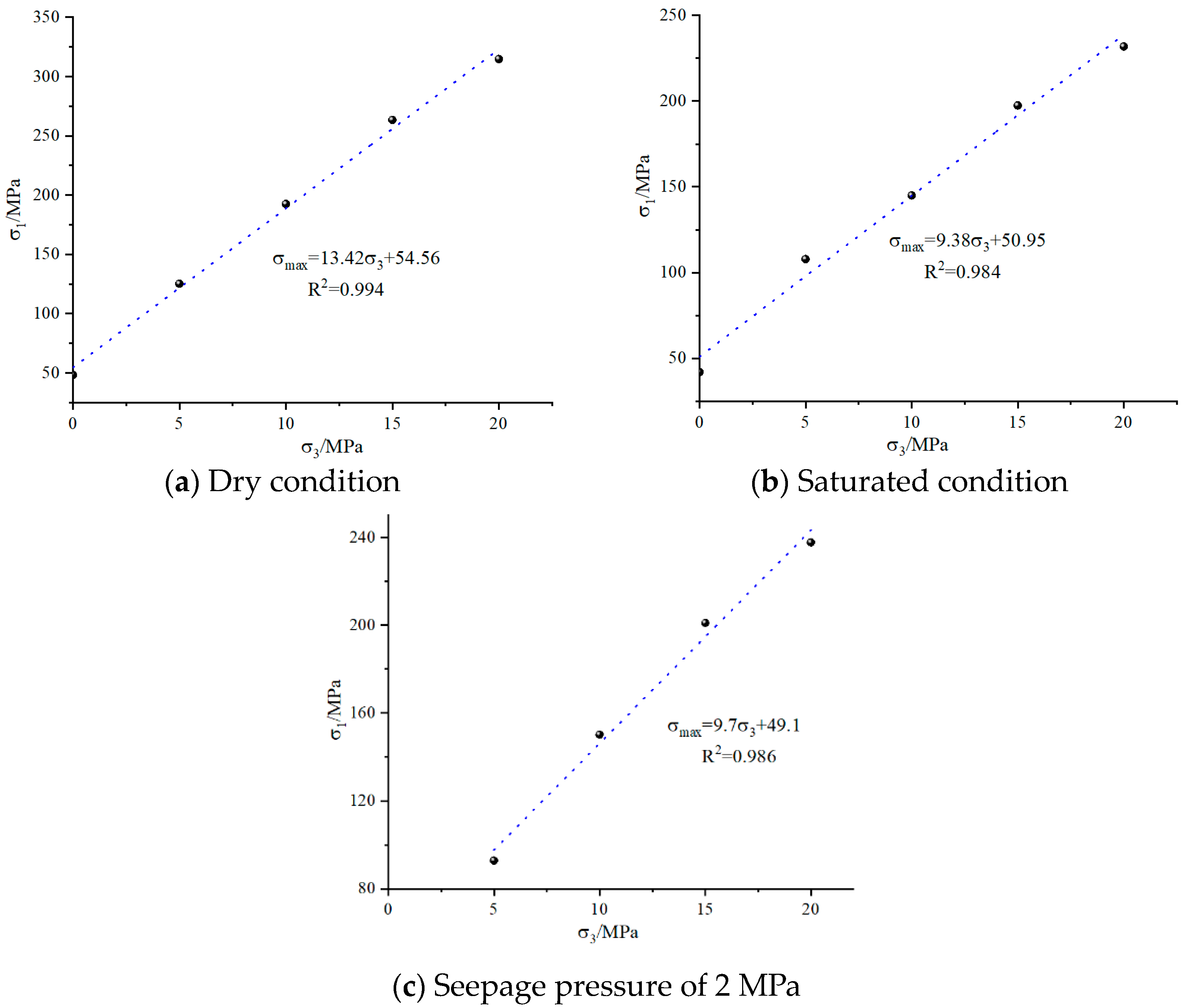

3.2. Strength Characteristics

3.3. Permeability Characteristics

3.3.1. Relationship between Permeability and Axial Stress–Strain

- (1)

- With the initial loading of deviatoric stress, the combined effect of confining pressure and deviatoric stress leads to further closure of pores and micro-fractures within the rock. As new fluid flow pathways have yet to establish, a gradual decrease in permeability ensues until the point of minimum permeability Kmin becomes evident.

- (2)

- During the linear elastic deformation stage, the sandstone approaches an elastic behaviour, where the fracture aperture remains approximately unchanged or slightly decreases. Fluid flow channels remain relatively constant or narrow in width, leading to a near-constant or slightly reduced permeability.

- (3)

- In the phase of stable crack propagation, the newly formed fractures within the sandstone have minimal aperture and connectivity. The rock undergoes a shift from volume compression to volume expansion. This phase corresponds to the maximum volumetric compression point permeability Kc, where the inhibitory effect of confining pressure weakens and permeability gradually increases.

- (4)

- During the phase characterized by unstable crack propagation, the interconnection of internal fractures intensifies, thereby leading to a substantial augmentation in the count of fluid flow pathways and the rapid escalation of permeability. The permeability Ks is observed at the peak stress point. Upon complete failure of the sandstone, macroscopic interconnected fractures form, leading to shear failure along these interconnected fractures, resulting in the maximum permeability Kmax.

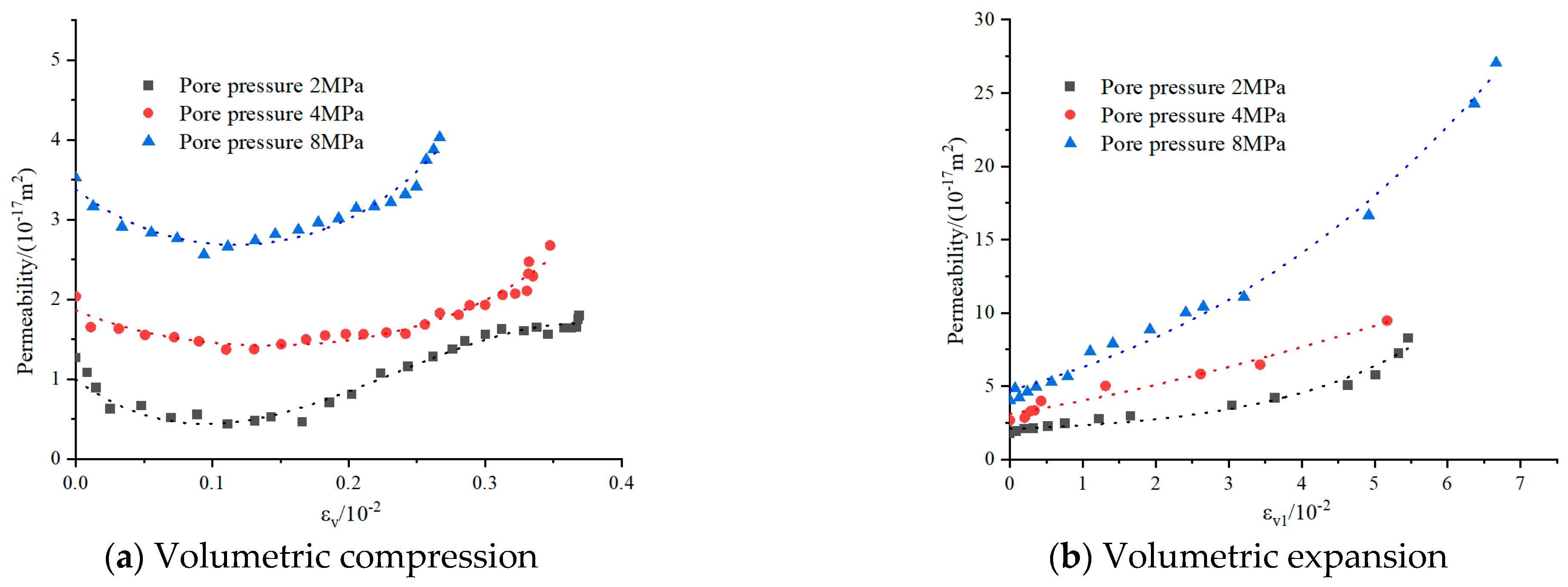

3.3.2. Relationship between Permeability and Volumetric Strain

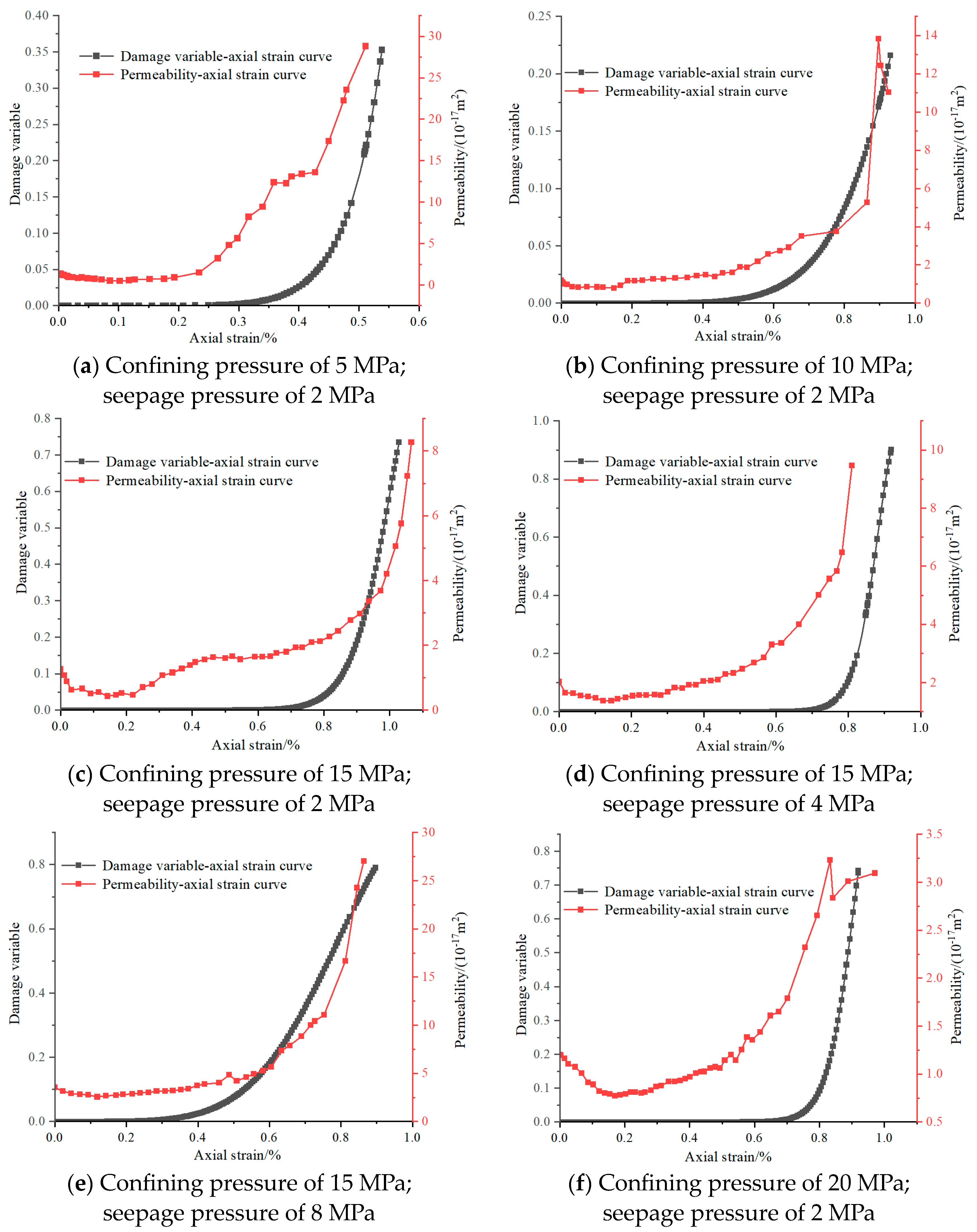

3.4. Analysis of Rock Damage Evolution

4. Conclusions

- (1)

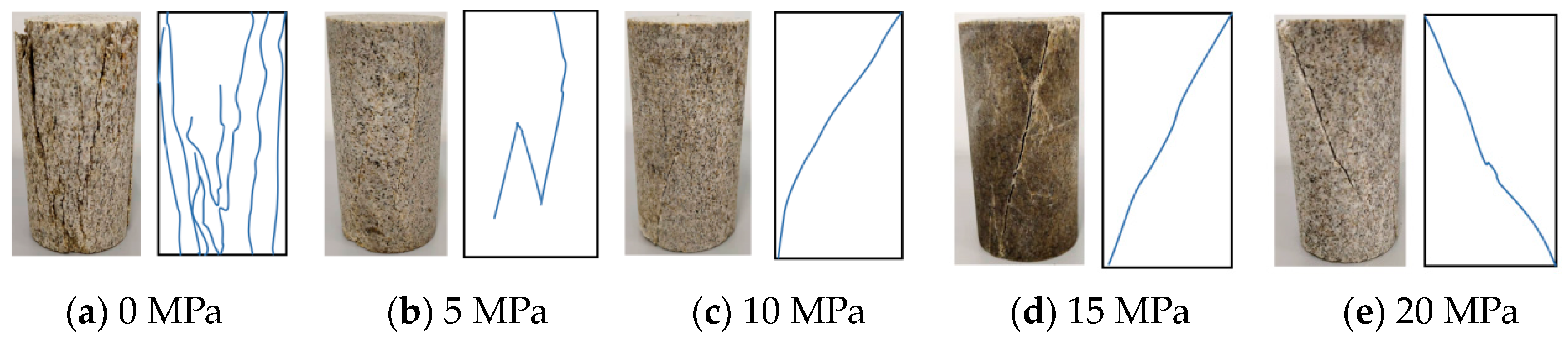

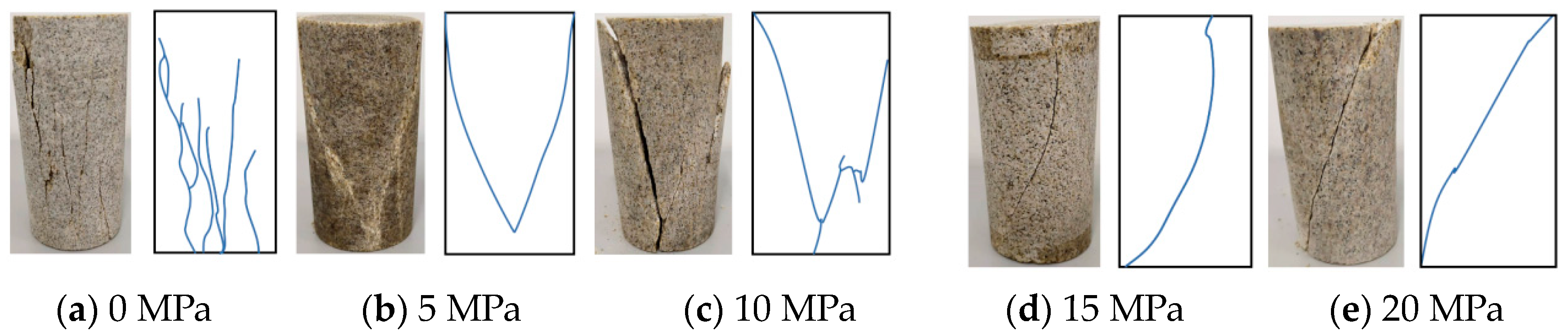

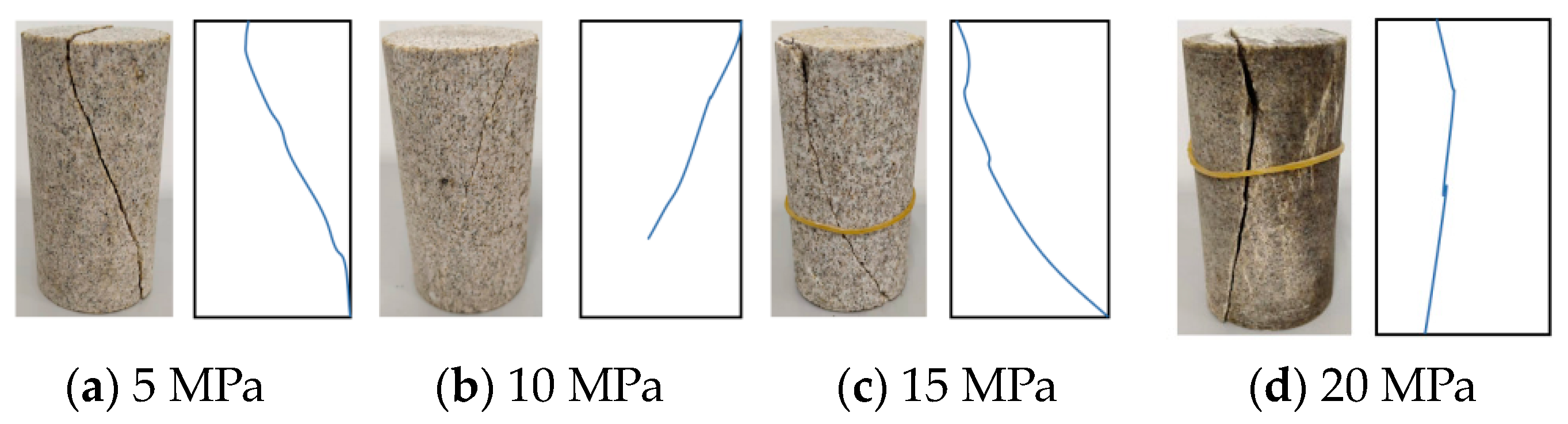

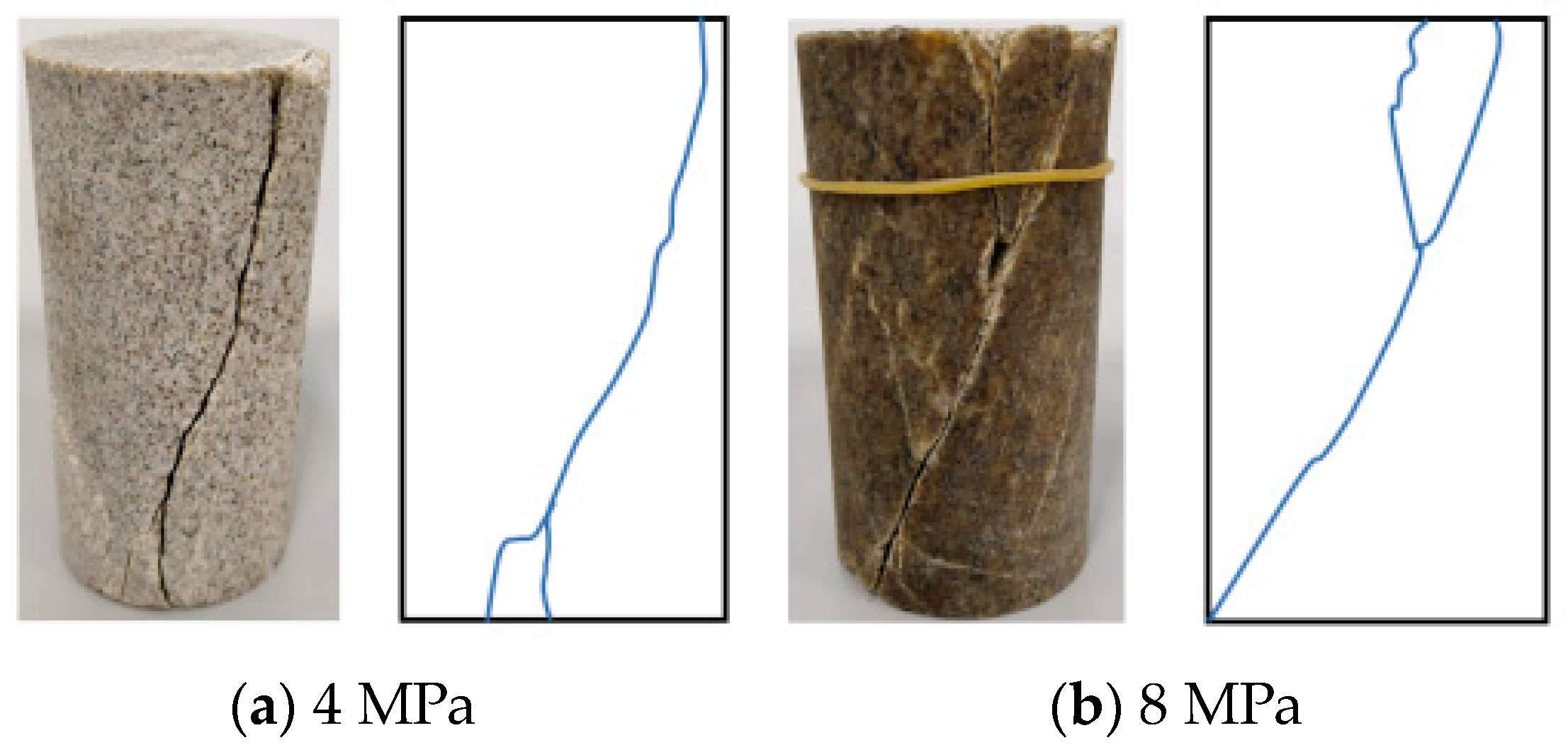

- Different stress thresholds correspond to distinct stages of rock deformation, namely the micro-fracture closure stage, linear elastic deformation stage, stable crack expansion stage, crack non-stationary expansion stage, and post-peak strain and damage stage. Under dry conditions, with increasing confining pressure, the failure mode shifts from macroscopic multi-crack failure to shear failure. In saturation conditions, the predominant failure mode is inclined plane shear failure.

- (2)

- Throughout the rock specimen’s deformation and failure process, the evolution of sandstone permeability exhibits four characteristic stages: gradual decrease, steady development, gradual increase, and rapid growth. This pattern correlates well with the micro-fracture closure, linear elastic deformation, crack development and expansion, and post-peak strain and failure stages. Key permeability values increase as pore pressure increases, but decrease as confining pressure increases. The permeability kcc can be approximated as the minimum permeability kmin.

- (3)

- The permeability adheres to a distinct four-stage pattern of gradual decrease, steady development, gradual increase, and rapid growth. This trend corresponds to the four phases of slow volumetric compression, rapid volumetric compression, rapid volumetric expansion, and slow volumetric expansion observed during rock deformation. The correlation between permeability and volumetric strain during the compression and expansion stages can be adequately described by the corresponding equations.

- (4)

- The propagation of internal cracks in sandstone under different conditions leads to evolving fracture damage. A correlation curve depicting the relationship between permeability and the damage variable was constructed, shedding light on the underlying mechanisms that govern the evolution of permeability in response to alterations in rock damage.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Xie, H.P.; Wang, J.H.; Shen, B.H.; Liu, J.-Z. New idea of coal mining: Scientific mining and sustainable mining capacity. Meitan Xuebao/J. China Coal Soc. 2012, 37, 1069–1079. [Google Scholar]

- Liang, Y. Scientific conception of precision coal mining. J. China Coal Soc. 2017, 42, 1–7. [Google Scholar]

- Jeanpert, J.; Iseppi, M.; Adler, P.M.; Genthon, P.; Sevin, B.; Thovert, J.-F.; Dewandel, B.; Join, J.-L. Fracture controlled permeability of ultramafic basement aquifers. Inferences from the Koniambo massif, New Caledonia. Eng. Geol. 2019, 256, 67–83. [Google Scholar] [CrossRef]

- Giot, R.; Auvray, C.; Conil, N.; de La Vaissière, R. Multi-stage water permeability measurements on claystone by steady and transient flow methods. Eng. Geol. 2018, 247, 27–37. [Google Scholar] [CrossRef]

- Zhang, Y.; Ma, Y.; Hu, Z.; Lei, H.; Bai, L.; Lei, Z.; Zhang, Q. An experimental investigation into the characteristics of hydraulic fracturing and fracture permeability after hydraulic fracturing in granite. Renew. Energy 2019, 140, 615–624. [Google Scholar] [CrossRef]

- Ning, Z.; Xue, Y.; Li, Z.; Su, M.; Kong, F. Damage Characteristics of Granite Under Hydraulic and Cyclic Loading–Unloading Coupling Condition. Rock Mech. Rock Eng. 2022, 55, 1393–1410. [Google Scholar] [CrossRef]

- Peng, S.; Qu, H.; Luo, L. An experimental study on the penetrability of sedimentary rock during the complete stress strain path. J. China Coal Soc. 2000, 25, 113–116. [Google Scholar]

- Xiao, W.J.; Zhang, D.M.; Wang, X.J. Experimental study on progressive failure process and permeability characteristics of red sandstone under seepage pressure. Eng. Geol. 2020, 265, 105406. [Google Scholar] [CrossRef]

- Menezes, F.F. Anisotropy of volume change and permeability evolution of hard sandstones under triaxial stress conditions. J. Pet. Sci. Eng. 2019, 174, 921–939. [Google Scholar] [CrossRef]

- Xu, P.; Yang, S.Q. Permeability evolution of sandstone under short-term and long-term triaxial compression. Int. J. Rock Mech. Min. Sci. 2016, 85, 152–164. [Google Scholar] [CrossRef]

- Badrul Alam, A.K.M.; Niioka, M.; Fujii, Y.; Fukuda, D.; Kodama, J.-I. Effects of confining pressure on the permeability of three rock types under compression. Int. J. Rock Mech. Min. Sci. 2014, 65, 49–61. [Google Scholar] [CrossRef]

- Wang, H.L.; Xu, W.Y.; Yang, S.Q. Experimental investigation on permeability evolution law during course of deformation and failure of rock specimen. Chin. J. Rock Soil Mech. 2006, 27, 1703–1708. [Google Scholar]

- Wang, H.; Xu, W. Relationship Between Permeability and Strain of Sandstone During the Process of Deformation and Failure. Geotech. Geol. Eng. 2013, 31, 347–353. [Google Scholar] [CrossRef]

- Hu, D.W.; Zhou, H.; Zhang, F.; Shao, J.F. Evolution of poroelastic properties and permeability in damaged sandstone. Int. J. Rock Mech. Min. Sci. 2010, 47, 962–973. [Google Scholar] [CrossRef]

- Chen, X.; Tang, C.-A.; Yu, J.; Zhou, J.-F. Experimental investigation on deformation characteristics and permeability evolution of rock under confining pressure unloading conditions. J. Cent. South Univ. 2018, 25, 1987–2001. [Google Scholar] [CrossRef]

- Nguyen, V.H.; Gland, N.; Dautriat, J.; David, C.; Wassermann, J.; Guélard, J. Compaction, permeability evolution and stress path effects in unconsolidated sand and weakly consolidated sandstone. Int. J. Rock Mech. Min. Sci. 2014, 67, 226–239. [Google Scholar] [CrossRef]

- Yang, T.; Wang, P.; Wang, S.; Liu, H. Experimental Study on Shear-Seepage Coupling Characteristics of Single Fractured Rock Mass Under Cyclic Loading and Unloading. Rock Mech. Rock Eng. 2023, 56, 2137–2156. [Google Scholar] [CrossRef]

- Wang, C.; Zhao, Y.; Ning, L.; Bi, J. Permeability evolution of coal subjected to triaxial compression based on in-situ nuclear magnetic resonance. Int. J. Rock Mech. Min. Sci. 2022, 159, 105213. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhou, H.; Zhong, J.; Liu, D. Study on the relation between damage and permeability of sandstone at depth under cyclic loading. Int. J. Coal Sci. Technol. Engl. Ed. 2019, 6, 479–492. [Google Scholar] [CrossRef]

- Zou, H.; Liu, J.F.; Yu, B.; Zhou, Z.-W. Experimental study on mechanical and permeability properties of sandstone with different granularities. Chin. J. Geotech. Eng. 2015, 37, 1462–1468. [Google Scholar]

- Gao, C.; Xie, L.Z.; Xie, H.P.; He, B.; Li, C.B.; Wang, J.; Luo, Y. Coupling between the statistical damage model and permeability variation in reservoir sandstone: Theoretical analysis and verification. J. Nat. Gas Sci. Eng. 2016, 37, 375–385. [Google Scholar] [CrossRef]

- Chen, Y.; Xu, J.; Cao, Q.; Rao, H.; Cui, M.; Zhang, Q. Experimental Study on Mechanical and Strain Localisation Behaviour of Sandstone Under Seepage–Stress Coupling. Rock Mech. Rock Eng. 2023. [Google Scholar] [CrossRef]

- Martin, C.D.; Chandler, N.A. The progressive fracture of Lac du Bonnet granite. Int. J. Rock Mech. Min. Sci. Geomech. 1994, 31, 643–659. [Google Scholar] [CrossRef]

- Li, G.; Zhu, D.R.; Yao, H.Y.; Pan, P.Z.; Zhou, Y.X.; Wang, R. Loading and unloading test on fracture characteristics of marble after heating. Chin. J. Hefei Univ. Technol. Nat. Sci. Ed. 2016, 39, 109–114+133. [Google Scholar]

- Yang, H.Q.; Liu, J.F.; Wong, N.Y. Influence of petroleum on the failure pattern of saturated pre-cracked and intact sandstone. Bull. Eng. Geol. Environ. 2017, 77, 767–774. [Google Scholar] [CrossRef]

- Zhang, J.W.; Song, Z.X.; Fan, W.B.; Huang, D. Experimental study on mechanical behavior and permeability characteristics of sandstone under stress-seepage coupling. Chin. J. Rock Mech. Eng. 2019, 38, 1364–1372. [Google Scholar]

- Zhang, L.M.; Jiang, S.Q.; Yu, J. Experimental Research into the Evolution of Permeability of Sandstone under Triaxial Compression. Energies 2020, 13, 5065. [Google Scholar] [CrossRef]

| O | Si | Fe | K | C | Ca |

|---|---|---|---|---|---|

| 47.7% | 30.2% | 6.01% | 3.81% | 2.28% | 1.02% |

| Seepage Pressure/MPa | Confining Pressure/MPa |

|---|---|

| 2 | 5, 10, 15, 20 |

| 4 | 15 |

| 8 | 15 |

| Seepage Pressure/MPa | Condition | Cohesion/MPa | The Angle of Internal Friction/° |

|---|---|---|---|

| / | Dry | 7.4 | 59.5 |

| 0 | Saturated | 8.3 | 53.8 |

| 2 | Saturated | 7.9 | 54.4 |

| Seepage Pressure/MPa | Confining Pressure/MPa | K0 | Kmin | Kc | Kz | Ks | Kmax |

|---|---|---|---|---|---|---|---|

| 2 | 5 | 1.37 | 0.48 | 12.3 | 17.3 | 23.5 | 28.8 |

| 10 | 1.21 | 0.79 | 1.89 | 3.75 | 5.27 | 13.8 | |

| 2 | 15 | 1.27 | 0.43 | 1.79 | 3.36 | 3.68 | 8.26 |

| 4 | 2.03 | 1.37 | 2.67 | 5.56 | 5.83 | 9.46 | |

| 8 | 3.52 | 2.56 | 4.03 | 11.1 | 16.6 | 27.1 | |

| 2 | 20 | 1.20 | 0.77 | 1.43 | 3.09 | 2.32 | 3.23 |

| Seepage Pressure/MPa | Confining Pressure/MPa | Kcc/(10−17/m2) | Kci/(10−17/m2) |

|---|---|---|---|

| 2 | 5 | 0.53 | 3.22 |

| 10 | 1.17 | 1.32 | |

| 2 | 15 | 0.49 | 1.46 |

| 4 | 1.37 | 1.73 | |

| 8 | 2.64 | 3.11 | |

| 2 | 20 | 0.78 | 0.99 |

| Item | Confining Pressure | Seepage Pressure | Volumetric Compression Stage | Volumetric Expansion Stage |

|---|---|---|---|---|

| 1 | 15 | 2 | (R2 = 0.992) | (R2 = 0.963) |

| 2 | 15 | 4 | (R2 = 0.986) | (R2 = 0.945) |

| 3 | 15 | 8 | (R2 = 0.981) | (R2 = 0.980) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wei, L.; Lin, Z.; Long, H.; Ye, Q. Experimental Study on Permeability Evolution of Sandstone during Triaxial Compression Damage. Appl. Sci. 2023, 13, 11579. https://doi.org/10.3390/app132011579

Wei L, Lin Z, Long H, Ye Q. Experimental Study on Permeability Evolution of Sandstone during Triaxial Compression Damage. Applied Sciences. 2023; 13(20):11579. https://doi.org/10.3390/app132011579

Chicago/Turabian StyleWei, Lide, Zhinan Lin, Haifeng Long, and Qiongyao Ye. 2023. "Experimental Study on Permeability Evolution of Sandstone during Triaxial Compression Damage" Applied Sciences 13, no. 20: 11579. https://doi.org/10.3390/app132011579

APA StyleWei, L., Lin, Z., Long, H., & Ye, Q. (2023). Experimental Study on Permeability Evolution of Sandstone during Triaxial Compression Damage. Applied Sciences, 13(20), 11579. https://doi.org/10.3390/app132011579