Abstract

Tomato ketchup is one of the most popular foods eaten all over the world. To improve the texture of these sauces, modified starches are used most commonly. This may be negatively assessed by consumers. The solution to this problem could be the use of legume flours, as beyond thickening potential, they are recognized as plant foods of high nutritional value. The aim of the work was to estimate the applicability of pulse flour as a texture-forming agent for ketchup. A comprehensive assessment of the quality of ketchup was made, both in terms of sensory properties and instrumentally analyzed physicochemical features: acidity, color, texture, rheological properties, and dynamics of water molecules using the LF NMR method. It was stated that pulse flours are suitable for use as forming agents for ketchup, although they have slightly weaker thickening properties with a consistency index ranging from 5.06–6.82 Pa·sn, compared to acetylated distarch adipate (19.48 Pa·sn). Texture, which is the most important parameter for consumer acceptance of ketchup, can be successfully analyzed using instrumental methods. Firmness ranged from 0.51 N for lentil and pea-fortified ketchup to 0.55 N for the lupine variant. Ketchup thickened with different pulses and flours reveals slightly different individual sensory characteristics, so it makes it possible to create a new gamut of healthy tomato sauces. The highest overall sensory score was attributed accordingly to lentils (6.9), lupine (6.2), chickpeas (6.1), and peas (5.8).

1. Introduction

Tomato ketchup is one of the most popular foods eaten all over the world. It is a simple dish, just a sauce consisting of tomatoes, sucrose, vinegar, salt, and various species. It may also contain various types of texturizing agents such as pectin or xanthan and specially modified starches. Ketchup is often recognized as a condiment for snacks but just as often is eaten as a component of various foods such as pasta, pizza, etc. It has a large share of market sales. Moreover, further growth in its consumption, estimated to be 2.64% annually, is predicted in the period from 2021 to 2025 [1,2,3,4]. This popularity of ketchup is not only due to the fact that it improves the taste of popular dishes and snacks but also that consumers are aware of the pro-health activity of tomatoes [5]. Ketchup, as a tomato-based product, is nutritionally considered a source of valuable carotenoids, mainly lycopene, which reveals a potent antioxidative, hypolipidemic, and antidiabetic activity. The intake of this phytochemical is related to a lower threat of insulin resistance and metabolic syndrome. Moreover, it has been proven using in vivo studies that consumption of ketchup itself may improve blood glucose metabolism due to the beneficial regulatory effects in energy metabolism in hepatocytes [6,7].

Physicochemically, ketchup is a complex type of dispersed system. It may be considered as a suspension in which tomato pulp and spices are insoluble solids dispersed in the colloid aqueous phase containing water-soluble substances such as salt, sugar, and organic acids as well as polysaccharide macromolecules, e.g., starch. All these components contribute to the ketchup texture, the decisive factor for consumer acceptance of this food product. Both the degree of fragmentation of solid particles (mainly tomato pulp) and the broadly understood physicochemical properties of thickening hydrocolloids are important [3,8]. Rheological properties, that are strongly related to texture, of ketchup are mainly controlled by rheological properties of dispersing phase, i.e., colloidal system containing hydrocolloids, salt, sugar, and acids [9]. Hence, a proper choice of thickener is one of the most important challenges determining competitiveness in the food market. However, as modern consumers are more and more aware of the relationship between high quality nutrition and health there is a need for new thickeners that beyond its viscosity are also a source of health-promoting substances [10]. Application of flours obtained from legume seeds could be a good solution [11,12].

Legume seeds are a rich source of plant protein [13]. They also contain a lot of other nutritionally valuable components such as fat, slowly digestible carbohydrates, vitamins, minerals, and certain phytochemicals revealing pro-health activity. It should be, however, emphasized that legume seeds differ significantly in composition [14,15,16]. The most popular pulses, i.e., peas and beans are quite similar to each other as they rich in carbohydrates (above 60%) and low in fats (1–2%). The protein content is high (two to three times higher) compared to cereal grains, but the lowest among legumes and is close to 20%. Lupine is distinguished by a very high, similar to meat products, protein content. It is even higher than in soybean, used for oil extraction and production of vegetable protein preparations, and amounts of 44% [11,17,18,19]. Pulses phytochemicals include polyphenols, phytosterols, saponins, etc. reveal antioxidant activity and thus contribute in decreasing the risk of various non-communicable diseases such as diabetes, hypertension, cardiovascular diseases or cancer. Starch contained in pulses contains more amylose than popular commercial starches that results in slowing down of its digestion and lowering the glycemic index. Lupine is distinguished by a particularly high biological activity, however for a long time it was used mainly for animal nutrition due to the high content of anti-nutritional substances, mainly alkaloids. However, many years of breeders’ efforts resulted in so called sweet varieties meeting high requirements regarding the quality of lupine seeds.

The high nutritional value of pulses induced interest in using their flours as ingredients in various foods, mainly cereal-based products such as bread, cakes, or snacks [20,21,22,23]. Much less attention has been paid to the use of pulses in other food categories [12]. Modern consumers more and more often are looking for food of high nutritional quality, especially so-called clean-label products, i.e., those that contain no food additives. Therefore, replacing the modified starch with pulse flour could not only contribute to increasing the nutritional value of ketchup but also meet the requirements of conscious consumers. Therefore, the purpose of the work was to estimate the applicability of pulse flour as a texture-forming agent for ketchup.

2. Materials and Methods

2.1. Ketchup

Tomato ketchup was prepared in 200 g batches according to the recipe in accordance with the procedure of Śmigielska et al. [24]. The ketchup formulation consisted of 60 g of concentrated (30%) tomato puree, 25 g of sucrose, 12 g of spirit vinegar (10%), 6.5 g of flour, and 3 g of table salt. The ketchup was manufactured using Thermomix (TM6, Vorwerk, Wuppertal, Germany). Five different variants containing following thickeners were prepared: 1—acetylated distarch adipate (reference) (ZETPEZET, Piła, Poland), 2—lupine flour (Green Essence, Pyszyce, Poland), 3—pea flour (Crispy Natural, Kalisz, Poland), 4—chickpea flour (BIO PLANET, Leszno, Poland), 5—lentil flour (PRO-BIO, Staré Město, Czech Republic).

2.2. Titratable Acidity and pH

Titratable acidity and pH of ketchup were determined according to Pearson [25].

2.3. Color Measurements

Chroma Meter CR-310 (Konica Minolta Sensing Inc., Tokyo, Japan) was used for the color measurements of ketchup. Color parameters were expressed in CIE L*a*b* color space. Additionally, a/b ratio was calculated [26].

2.4. Universal Texture Profile

The universal texture profile was determined according to Lewandowicz et al. [27] with the assistance of TA.XT2 Texture Analyzer (Stable Micro Systems, Godalming, UK).

2.5. Rheological Properties

Rheological properties were determined using a RotoVisco1 rheometer (Haake Technik GmbH, Vreden, Germany) equipped with a Z20 DIN Ti coaxial measurement system. Flow curves were determined within 0.1–600 s−1 shear rate for increasing and decreasing shear speed, using the procedure described previously [27]. The obtained data were fitted to the Ostwald de Waele model using RheoWin 3.61 software.

2.6. Low Field NMR

NMR relaxation times were analyzed with a pulse NMR spectrometer PS15T operating at 15 MHz (Ellab, Poznań, Poland). The inversion–recovery (180-TI-90) pulse sequence was applied for measurements of the T1 relaxation times. The 180 pulse was 4.8 μs, the distance between RF pulses (TI) changed from 2 to 1800 ms, and the repetition time TR between sequences was 18 s.

Measurements of the spin–spin (T2) relaxation times were taken using the pulse train of the Carr–Purcell–Meiboom–Gill spin echoes (90-TE/2-(180)n). The echo time TE was 3 ms, and the number of the spin-echoes signal (n) was 50. The five accumulations of the spin-echo trains were used. The repetition time between pulse trains was 15 s.

2.7. Sensory Analysis

Quantitative Descriptive Analysis (QDA) was performed by a panel consisting of six persons trained according to the PN-ISO 8586:2023-10 [28] standard. The following distinctive features were analyzed: color, texture (consistency, smoothness, grainy), smell (tomato, vinegary, foreign), taste (tomato, vinegary, sour, sweet, foreign), and overall assessment. The intensity of distinctive features was assessed using a 10 cm linear scale with specific boundary terms.

2.8. Statistical Analysis

The statistical analyses were performed using Statistica 13.3 (TIBCO Software Inc., Palo Alto, CA, USA). One-way analysis of variance and Tukey’s post hoc test was performed to determine statistically homogenous subsets at α = 0.05. Principal component analysis (PCA) was performed based on the correlation matrix.

3. Results and Discussion

All analyzed ketchup revealed basic physicochemical properties typical for this class of products (Table 1). Moreover, the differences between the values of the analyzed parameters were smaller than those found for ketchup offered commercially by the largest producers [29]. The lowest pH value was found for ketchup containing modified starch, whereas the highest was for lentil flour. The pH values of commercial products reach even lower values, up to 3.4. The titratable acidity of the analyzed products also differed slightly. It was the lowest for ketchup with lupine flour and the highest for products containing flours of other pulses. In the case of commercial products, the variation in the acidity value is significantly greater and ranges from 0.83 to 1.64 1/100 g [29].

Table 1.

General characteristics of ketchup.

Higher variability between the analyzed ketchup was observed in relation to their color parameters (Table 1). These differences are important as it is postulated that for the quality of tomato products (not just ketchup itself), lightness and a/b ratio are most indicative [26]. The darkest was the control sample, containing modified starch. The L* values increased in a series of ketchup containing sequentially pea, lupine, chickpea, and lentil flour. Nevertheless, these differences were not very large. Similar values of lightness have been reported by Ahouagi et al. [2] for ketchup containing small amounts of strawberry pulp. However, also significantly higher L* values of about 50 have been reported [26]. These differences may result both from the quality of tomatoes used to make the ketchup as well as from the difference in production technology. The changes in a* parameter relative to the green-red (magenta) color axis follow the pattern found for lightness. The highest shift towards a green hue for the reference sample was observed. Then, the series of increasing values of parameter a* follows that of the L* parameter. In contrast, many differences in b* parameter, relative to the blue-yellow opposite colors axis, were observed. The sample containing pea flour showed the highest shift towards blue. The control sample was similar. Much more yellowish, with b* parameter above 13, were samples containing other pulses flours. As a consequence, a huge difference in the values of the a/b ratio was observed. For tomato products, the a/b ratio should be at least 1.8 [26]. This requirement is met for the reference sample containing modified starch, significantly exceeded for the sample containing pea flour, and below the limit for the other ketchup. Similar observations were made for tomato pulp powder as a thickening agent. Too much addition of this thickener reduces the a/b ratio below the recommended value [26].

The texture is considered a crucial parameter in the consumer acceptability of ketchup [30]. However, the precise definition of texture is difficult, which implies multiplicity and diversity of methods for its assessment. Among the instrumental methods, the Texture Profile Analysis (TPA) should be mentioned primarily. It was originated by Surmacka-Szczesniak and is still being developed [31]. The parameters of the TPA of analyzed ketchup are presented in Table 2. Firmness, adhesiveness, and gumminess are parameters for which significant differences were observed. In comparison, cohesiveness and springiness were almost of the same value for all samples. Ketchup thickened with pulses flours showed similar firmness values as those reported by Ahouagi et. al, while the sample containing modified starch showed twice the value of this parameter [2].

Table 2.

Universal texture profile analysis of analyzed ketchup.

Despite the popularity of the apparatus for analyzing the TPA profile, it is difficult to compare the data obtained. This phenomenon is due to the possibility of applying different probes and different parameters of texture analysis by different research groups. Therefore, to evaluate the texture of ketchup, rheological methods are used more often [4]. Such an approach provides better reproducibility of the results, especially if rheometers are used, i.e., apparatus with a defined and controlled shear rate [32]. The highest values of the consistency index were found for ketchup thickened with modified starch (Table 3). Samples containing pulse flours showed significantly lower K values, the smallest for peas and then in sequence for lupine, lentil, and chickpea. These data are consistent with those reported by Juszczak et al. for ketchup thickened with different modified starches [4]. Flow behavior index values showed much less variation. Its values below 1 mean that the apparent viscosity of all ketchup decreases with increasing shear rate. Moreover, all samples revealed rheopexy (antithixotropy). This phenomenon indicates that fluid reveals a time-dependent increase in viscosity by shearing. It means that ketchup, when shaken, would be fluid at first, becoming more viscous as the shaking continued. Rheopexy was considered a rather rare phenomenon, especially if not accompanied by thinning under an increasing shear rate. However, it is observed more and more often for different dispersed systems [33,34,35]. It is also believed that the relationship between thixotropy and rheopexy is complicated. Moreover, it has been stated that the thixotropic behavior of starch dispersion can change into rheopectic behavior by changing concentration or shear rate [36].

Table 3.

Ostwald de Waele equation coefficients for analyzed ketchup.

Low-field nuclear magnetic resonance (LF NMR) is a method designed to study the dynamics of protons [37,38]. However, there has been a growing interest in applying this method to food studies in recent years [39,40,41,42]. This is possible as in food, the process of nuclear relaxation of both water and fat molecules is observed. As a result of measurements in the water system, the values of spin-lattice relaxation time T1 and spin-spin relaxation time T2 are recorded. T1 is related to the ratio of free to entrapped water, whereas T2 to water molecules dynamics. The spin-lattice relaxation time is affected by many factors, e.g., temperature, resonant frequency, or the presence of macromolecules, and it is always longer than T2. This means that in the presence of large molecules (for example, starch), the rotation of water molecules is slowed down; thus, the relaxation time is shortened [43]. By incorporation of fats into the biopolymer solution and formation of a two-phase system, for example, in emulsions, each of the relaxation times separate into two components. This means that there are two fractions of protons relaxing at different rates in the system. Moreover, the chemical exchange between these fractions of protons is much slower than the relaxation time. The long components (T12 and T22) reflect the relaxation processes of the fraction of protons mainly associated with starch paste [44]. By the analyses of ketchup employing the LF NMR method (Table 4), no splitting of relaxation times into two components was observed. This is despite the fact that ketchup is considered to be a complex two-phase system [4]. This observation proves that potato pulp particles suspended in a solution of low molecular mass components of ketchup did not form a phase in which proton relaxation proceeds differently than in the liquid phase. The spin-lattice relaxation time of ketchup containing acetylated distarch adipate is significantly lower than that of all others. Starch is a biopolymer of extremely high molecular mass, and its modification consists of cross-linking that additionally increases the size of its macromolecules [27]. Protein molecules have a much smaller molar mass, and starches of other plant species have a lower molar mass than the E 1422 starch used in this study [45]. The values of the spin-lattice relaxation times were less diversified, with the highest value observed for ketchup-containing pea flour (Table 4). Mean correlation time τc, which describes the time for a molecule to rotate by 1 radian, also showed a large variation, and its lowest value was observed for ketchup containing modified starch.

Table 4.

LF NMR study results.

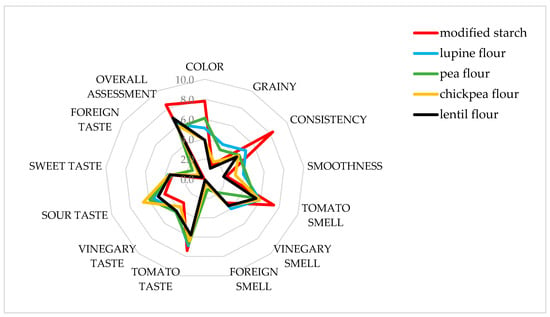

The above-presented results of instrumental measured parameters of ketchup are an important indicator of their quality. Moreover, they are precisely repeatable and make it possible to find out the causes of observed phenomena. However, for consumer acceptability, sensory properties are of crucial importance. The most important sensory features of ketchup, apart from the appropriate flavor and texture, are intense red color, appropriate consistency, sweet tomato, and spicy taste [46]. The sensory profile of the analyzed samples is presented in Figure 1. It comprised, apart from the parameters analyzed with instrumental methods, several features that could be assessed only by a panel of specialists with appropriate sensory sensitivity. They include grainy, smoothness, and consistency, as well as different tastes (tomato, vinegar, sour, sweet, and foreign) and different smells (tomato, vinegar, sour, and foreign). The grainy of the evaluated products meant a structure similar to porridge, granularity. Ketchup with lupine and pea flour showed relatively high, but still moderate, grainy. The others, including the control sample, were characterized by small grainy. Smoothness is an attribute that gives the impression of delicacy, softness, and velvety on the tongue. The variability of ketchup smoothness was similar. The most smooth were ketchup with E1422 and lentil flour, whereas the least smooth with pea and lupine flour. With regard to the flavor, it is worth emphasizing that all ketchup did not reveal any foreign smell or taste. Moreover, all ketchup had the same slight sweetness (sweet taste). As for the most distinctive tomato flavor—the reference sample stood out from the others with the most intense tomato smell. The other ketchup revealed slightly less intensively of that feature. The tomato taste of all ketchup also differed only slightly, with the most intense for the reference sample and the least intense for that containing lentil flour. There were only slight differences in the sour and vinegar taste as well as vinegar smell assessment. It corresponds to the small differences in values of pH and titratable acidity of ketchup presented in Table 1. However, it should be mentioned that there was more significant diversity in flavor features stated by the sensory panel than in pH and titratable acidity values. Consistency was also subject to sensory evaluation. This parameter could be classified as characterizing the texture of the product. Ketchup containing modified starch stood out with the highest consistency. This observation corresponds both to the highest firmness (parameter of universal texture profile) and the highest consistency index derived from the Ostwald de Waele equation. This observation contradicts the theorem postulated in the literature about the impossibility of evaluating the texture of products with instrumental methods [30]. Color is also an important feature determining consumer acceptance. However, in contrast to texture, including rheological parameters, it is difficult to find a simple correlation between sensory and instrumental analysis as regards the color rated as the best was the ketchup containing modified starch (Figure 1). However, this sample was not distinguished by any of the parameters of CIE L*a*b* color space presented in Table 1. However, the a/b ratio is higher for the control sample than for ketchup with lupine, chickpea, and lentil flours. Nevertheless, its greatest value was recorded for ketchup with pea flour. Moreover, control ketchup only meets the requirement presented in the work by Farahanky et al. [26]. This phenomenon might be related to a large color shift towards blue for ketchup with pea flour, which resulted in a worse consumer acceptance of this product. This suggests that when evaluating the sensory qualities, it is important to balance individual product features, and the use of specific numerical parameters should be approached critically.

Figure 1.

Characteristics of the sensory profile of analyzed ketchup.

The overall assessment of the products, defined as a general impression determining the comprehensive sensory quality of the product, taking into account all the features and their mutual harmonization, was found to be highest for the control sample. The other ketchup was rated slightly lower, with small differences between the lowest rated sample containing pea flour and the best sample, within pulses thickened ketchup, containing chickpea flour.

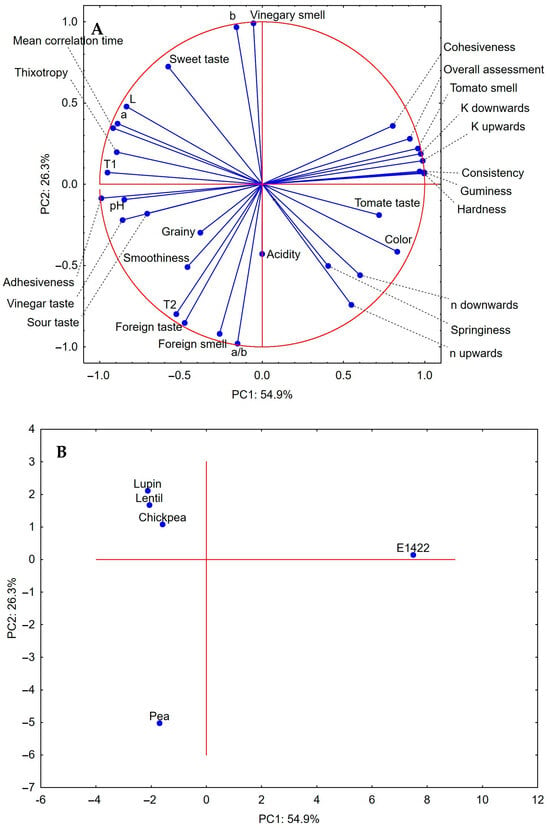

PCA analysis (Figure 2) was carried out to verify which factors determine the consumer acceptability of ketchup. The two principal components (factors 1 and 2) explain 81.27% of the total variance. The most noteworthy of the results presented in Figure 2A is the close correlation between consistency assessed during sensory study and firmness and gumminess examined instrumentally. Additionally, the consistency index analyzed using a rheometer with a defined and controlled shear rate reveals a pretty good correlation with the texture parameters. This means that contrary to the statement of Tauferova et al. [29] that the texture of products cannot be assessed instrumentally, such a procedure may be recommended. Moreover, the total assessment of ketchup reveals a high positive correlation with the above-mentioned texture parameters and also with cohesiveness and tomato smell. On the contrary, sour and vinegar taste, as well as adhesiveness, contribute to the negative assessment of ketchup. Vinegary smell, sweet taste, springiness, and flow behavior index seem to have little importance for consumer evaluation. Grainy, smoothness, titratable acidity, as well as foreign smell and taste, have a small but negative impact on the perception of ketchup. Regarding color, PCA analysis shows that sensory evaluation of this parameter is less important for the perception of the quality of ketchup than texture and tomato taste. Lightness, as well as a color parameter evaluated instrumentally, has a rather small but negative impact on consumer evaluation. Parameter b and a/b ratio seem to have even lesser effect. This may seem surprising in the context of a paper by Farahnaky et al. [26]. However, their work related to tomato products in general and not to ketchup specifically, which may explain this discrepancy. Spin-lattice relaxation time and mean correlation time revealed a negative correlation with the overall assessment of ketchup. This means that products in which water molecules reveal lower dynamics (stronger entrapped) are rated better. Spin-spin relaxation time is less important.

Figure 2.

Principal Components Analysis of the results of sensory analysis (color, consistency, grainy, smoothness, tomato taste, tomato smell, vinegary taste, vinegary smell, foreign taste, foreign smell, sour taste, sweet taste, overall assessment) and instrumental analyses (pH, titratable acidity, L {lightness}, a {green/magenta ratio}, b {blue/yellow ratio}, Firmness, Adhesiveness, Cohesiveness, Springiness, Gumminess, K up {consistency index up}, K down {consistency index down}, n up {flow behavior index up}, n down {flow behavior index down}, thixotropy, T1 {spin-lattice relaxation time}, T2 {spin-spin relaxation time}, mean correlation time. (A) loadings plot; (B) score plot.

The PCA score plot (Figure 2B) highlights the similar properties of ketchup containing lupin, lentil, and chickpea flours. In contrast, products containing pea flour and modified starch were proven to have more unique characteristics. The differences between ketchup containing pulse flour and that with E 1422 appear to be mainly due to differences in texture. The uniqueness of ketchup containing pea flour lies in differences in other features, mainly in color. Summing up, ketchup thickened with chickpea, pea, lentil, soy, or lupine flour reveals good sensory properties; however, they differ significantly in texture and rheological properties. This may open the possibility of creating a whole branch of healthy tomato sauce.

4. Conclusions

Pulse flours are suitable for use as texture-forming agents for ketchup. They have slightly weaker thickening properties than acetylated distarch adipate, but they do not significantly change the sensory properties of ketchup. The texture of ketchup is the most important parameter for consumer acceptance of this product. It can be successfully analyzed using instrumental methods. For this purpose, both rheological methods and the analysis of the universal texture profile are useful. The low-field nuclear resonance method also proved useful for assessing the quality of ketchup, as the dynamics of water protons strongly correlate with the texture of ketchup. Instrumental analysis of the color of ketchup is less useful for assessing the quality of ketchup than the previously mentioned methods. As ketchup containing different flours reveals slightly different individual characteristics, it opens the possibility of creating the whole gamut of healthy tomato sauces. Nevertheless, lentil flour should be recommended as the thickener of the first choice due to better overall sensory assessment of the final product.

Author Contributions

Conceptualization, J.L.T.-B.; Data curation, J.L.T.-B. and M.K.; Funding acquisition, P.Ł.K.; Investigation, J.L.T.-B., J.L., P.J., P.Ł.K., K.Z. and H.M.B.; Methodology, J.L.T.-B., J.L., K.Z. and H.M.B.; Project administration, J.L.T.-B.; Resources, P.Ł.K.; Supervision, J.L.T.-B. and P.Ł.K.; Visualization, J.L.; Writing—original draft, J.L.T.-B., J.L. and P.Ł.K.; Writing—review and editing, J.L.T.-B., J.L., P.Ł.K. and M.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The datasets generated for this study are available on request to the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Shokraneh, N.; Alimi, M.; Shahidi, S.-A.; Mizani, M.; Bameni Moghadam, M.; Rafe, A. Textural and Rheological Properties of Sliceable Ketchup. Gels 2023, 9, 222. [Google Scholar] [CrossRef] [PubMed]

- Ahouagi, V.B.; Mequelino, D.B.; Tavano, O.L.; Garcia, J.A.D.; Nachtigall, A.M.; Vilas Boas, B.M. Physicochemical characteristics, antioxidant activity, and acceptability of strawberry-enriched ketchup sauces. Food Chem. 2021, 340, 127925. [Google Scholar] [CrossRef] [PubMed]

- Baeghbali, S.; Shahriari, S.; Pazuki, G. Effect of pressure homogenization and modified starch on the viscosity of ketchup: Experimental and modeling. J. Food Process Eng. 2021, 44, e13683. [Google Scholar] [CrossRef]

- Juszczak, L.; Oczadły, Z.; Gałkowska, D. Effect of Modified Starches on Rheological Properties of Ketchup. Food Bioprocess Technol. 2013, 6, 1251–1260. [Google Scholar] [CrossRef]

- Collins, E.J.; Bowyer, C.; Tsouza, A.; Chopra, M. Tomatoes: An Extensive Review of the Associated Health Impacts of Tomatoes and Factors That Can Affect Their Cultivation. Biology 2022, 11, 239. [Google Scholar] [CrossRef] [PubMed]

- Mirzaei, D.; Pedram Nia, A.; Jalali, M. Effect of inulin and date syrup from Kaluteh variety on the qualitative and microbial properties of prebiotic ketchup. J. Food Sci. Technol. 2021, 58, 4127–4138. [Google Scholar] [CrossRef]

- Jeong, J.H.; Lee, H.L.; Park, H.J.; Yoon, Y.E.; Shin, J.; Jeong, M.-Y.; Park, S.H.; Kim, D.; Han, S.-W.; Kang, C.-G.; et al. Effects of tomato ketchup and tomato paste extract on hepatic lipid accumulation and adipogenesis. Food Sci. Biotechnol. 2023, 32, 1111–1122. [Google Scholar] [CrossRef]

- Cai, X.; Du, X.; Zhu, G.; Cai, Z.; Cao, C. The use of potato starch/xanthan gum combinations as a thickening agent in the formulation of tomato ketchup. CyTA J. Food 2020, 18, 401–408. [Google Scholar] [CrossRef]

- Le Thanh-Blicharz, J.; Lewandowicz, J. Functionality of Native Starches in Food Systems: Cluster Analysis Grouping of Rheological Properties in Different Product Matrices. Foods 2020, 9, 1073. [Google Scholar] [CrossRef]

- Śmigielska, H.; Błaszczak, W.; Lewandowicz, G. Applicability of Food Grade Modified Starches as a Carrier of Microelements. Processes 2022, 10, 235. [Google Scholar] [CrossRef]

- Kumar, S.; Pandey, G. Biofortification of pulses and legumes to enhance nutrition. Heliyon 2020, 6, e03682. [Google Scholar] [CrossRef] [PubMed]

- Yazdanpanah, S.; Ansarifard, S.; Hasani, M. Development of Novel Gluten-Free Sausage Based on Chickpea, Corn Flour, and HPMC. Int. J. Food Sci. 2022, 2022, 3616887. [Google Scholar] [CrossRef] [PubMed]

- Semba, R.D.; Ramsing, R.; Rahman, N.; Kraemer, K.; Bloem, M.W. Legumes as a sustainable source of protein in human diets. Glob. Food Sec. 2021, 28, 100520. [Google Scholar] [CrossRef]

- Zielińska-Dawidziak, M.; Tomczak, A.; Burzyńska, M.; Rokosik, E.; Dwiecki, K.; Piasecka-Kwiatkowska, D. Comparison of Lupinus angustifolius protein digestibility in dependence on protein, amino acids, trypsin inhibitors and polyphenolic compounds content. Int. J. Food Sci. Technol. 2019, 55, 2029–2040. [Google Scholar] [CrossRef]

- Tomczak, A.; Zielińska-Dawidziak, M.; Piasecka-Kwiatkowska, D.; Lampart-Szczapa, E. Blue lupine seeds protein content and amino acids composition. Plant Soil Environ. 2018, 64, 147–155. [Google Scholar] [CrossRef]

- Azarpazhooh, E.; Ahmed, J. Composition of Raw and Processed Dry Beans and Other Pulses. In Dry Beans and Pulses; Wiley: Hoboken, NJ, USA, 2022; pp. 129–157. [Google Scholar]

- Asif, M.; Rooney, L.W.; Ali, R.; Riaz, M.N. Application and Opportunities of Pulses in Food System: A Review. Crit. Rev. Food Sci. Nutr. 2013, 53, 1168–1179. [Google Scholar] [CrossRef] [PubMed]

- Pereira, A.; Ramos, F.; Sanches Silva, A. Lupin (Lupinus albus L.) Seeds: Balancing the Good and the Bad and Addressing Future Challenges. Molecules 2022, 27, 8557. [Google Scholar] [CrossRef]

- Bähr, M.; Fechner, A.; Hasenkopf, K.; Mittermaier, S.; Jahreis, G. Chemical composition of dehulled seeds of selected lupin cultivars in comparison to pea and soya bean. LWT Food Sci. Technol. 2014, 59, 587–590. [Google Scholar] [CrossRef]

- Paladugula, M.P.; Smith, B.; Morris, C.F.; Kiszonas, A. Incorporation of yellow pea flour into white pan bread. Cereal Chem. 2021, 98, 1020–1026. [Google Scholar] [CrossRef]

- Sopiwnyk, E.; Bourré, L.; Young, G.; Borsuk, Y.; Lagassé, S.; Boyd, L.; Sarkar, A.; Jones, S.; Dyck, A.; Malcolmson, L. Flour and bread making properties of whole and split yellow peas treated with dry and steam heat used as premilling treatment. Cereal Chem. 2020, 97, 1290–1302. [Google Scholar] [CrossRef]

- Rachwa-Rosiak, D.; Nebesny, E.; Budryn, G. Chickpeas—Composition, Nutritional Value, Health Benefits, Application to Bread and Snacks: A Review. Crit. Rev. Food Sci. Nutr. 2015, 55, 1137–1145. [Google Scholar] [CrossRef] [PubMed]

- Joshi, M.; Timilsena, Y.; Adhikari, B. Global production, processing and utilization of lentil: A review. J. Integr. Agric. 2017, 16, 2898–2913. [Google Scholar] [CrossRef]

- Śmigielska, H.; Lewandowicz, J.; Le Thanh-Blicharz, J. Effect of type 4 resistant starch on colour and rheological properties of tomato ketchup. Zywnosc Nauka Technol. Jakosc/Food Sci. Technol. Qual. 2013, 20, 137–149. [Google Scholar] [CrossRef]

- Pearson, D. Chemical Analysis of Foods, 7th ed.; Churchhill Livingstone: London, UK, 1976. [Google Scholar]

- Farahnaky, A.; Abbasi, A.; Jamalian, J.; Mesbahi, G. The use of tomato pulp powder as a thickening agent in the formulation of tomato ketchup. J. Texture Stud. 2008, 39, 169–182. [Google Scholar] [CrossRef]

- Lewandowicz, J.; Le Thanh-Blicharz, J.; Szwengiel, A. The Effect of Chemical Modification on the Rheological Properties and Structure of Food Grade Modified Starches. Processes 2022, 10, 938. [Google Scholar] [CrossRef]

- PN-EN ISO 8586:2023-10; Sensory Analysis—Selection and Training of Sensory Assessors. The Polish Committee for Standardization: Warsaw, Poland, 2023.

- Sharoba, A.M.; Senge, B.; El-Mansy, H.A.; Bahlol, H.E.; Blochwitz, R. Chemical, sensory and rheological properties of some commercial German and Egyptian tomato ketchups. Eur. Food Res. Technol. 2005, 220, 142–151. [Google Scholar] [CrossRef]

- Tauferova, A.; Tremlova, B.; Bednar, J.; Golian, J.; Zidek, R.; Vietoris, V. Determination of Ketchup Sensory Texture Acceptability and Examination of Determining Factors as a Basis for Product Optimization. Int. J. Food Prop. 2015, 18, 660–669. [Google Scholar] [CrossRef]

- Surmacka-Szczesniak, A. Classification of Textural Characteristics. J. Food Sci. 1963, 28, 385–389. [Google Scholar] [CrossRef]

- Małyszek, Z.; Makowska, A.; Smentek, J.; Kubiak, P.; Le Thanh-Blicharz, J.; Lewandowicz, G. Assessment of factors determining accuracy in measuring rheological properties of modified starches. Zywn. Nauk. Technol. Jakosc/Food. Sci. Technol. Qual. 2015, 22, 160–175. [Google Scholar] [CrossRef]

- Xu, X.; Zhang, D.; Tong, S.; Liu, F.; Wei, W.; Liu, Z. Experimental study on shear viscosity and rheopexy of Escherichia coli suspensions. Rheol. Acta 2022, 61, 271–280. [Google Scholar] [CrossRef]

- Kaveh, Z.; Azadmard-Damirchi, S.; Yousefi, G.; Hosseini, S.M.H. Effect of different alcoholic-alkaline treatments on physical and mucoadhesive properties of tapioca starch. Int. J. Biol. Macromol. 2020, 153, 1005–1015. [Google Scholar] [CrossRef] [PubMed]

- Zhao, H.; Zhang, K. The structure recovery capacity of highly concentrated emulsions under shear flow via studying their rheopexy. J. Dispers. Sci. Technol. 2018, 39, 970–976. [Google Scholar] [CrossRef]

- Dewar, R.J.; Joyce, M.J. The thixotropic and rheopectic behaviour of maize starch and maltodextrin thickeners used in dysphagia therapy. Carbohydr. Polym. 2006, 65, 296–305. [Google Scholar] [CrossRef]

- Ezeanaka, M.C.; Nsor-Atindana, J.; Zhang, M. Online Low-field Nuclear Magnetic Resonance (LF-NMR) and Magnetic Resonance Imaging (MRI) for Food Quality Optimization in Food Processing. Food Bioprocess Technol. 2019, 12, 1435–1451. [Google Scholar] [CrossRef]

- Kamal, T.; Cheng, S.; Khan, I.A.; Nawab, K.; Zhang, T.; Song, Y.; Wang, S.; Nadeem, M.; Riaz, M.; Khan, M.A.U.; et al. Potential uses of LF-NMR and MRI in the study of water dynamics and quality measurement of fruits and vegetables. J. Food Process. Preserv. 2019, 43, e14202. [Google Scholar] [CrossRef]

- Li, R.; Xia, Z.; Li, B.; Tian, Y.; Zhang, G.; Li, M.; Dong, J. Advances in Supercritical Carbon Dioxide Extraction of Bioactive Substances from Different Parts of Ginkgo biloba L. Molecules 2021, 26, 4011. [Google Scholar] [CrossRef]

- Resende, M.T.; Osheter, T.; Linder, C.; Wiesman, Z. Proton Low Field NMR Relaxation Time Domain Sensor for Monitoring of Oxidation Stability of PUFA-Rich Oils and Emulsion Products. Foods 2021, 10, 1385. [Google Scholar] [CrossRef] [PubMed]

- Brosio, E.; Gianferri, R.R. Low-resolution NMR—An analytical tool in foods characterization and traceability. In Basic NMR in Foods Characterization; Brosio, E., Ed.; Research Signpost: Kerala, India, 2009; pp. 9–37. ISBN 978-81-308-0303-6. [Google Scholar]

- Abrami, M.; Chiarappa, G.; Farra, R.; Grassi, G.; Marizza, P.; Grassi, M. Use of low-field NMR for the characterization of gels and biological tissues. ADMET DMPK 2018, 6, 34. [Google Scholar] [CrossRef]

- Makowska, A.; Dwiecki, K.; Kubiak, P.; Baranowska, H.M.; Lewandowicz, G. Polymer-Solvent Interactions in Modified Starches Pastes–Electrokinetic, Dynamic Light Scattering, Rheological and Low Field Nuclear Magnetic Resonance Approach. Polymers 2022, 14, 2977. [Google Scholar] [CrossRef]

- Małyszek, Z.; Lewandowicz, J.; Le Thanh-Blicharz, J.; Walkowiak, K.; Kowalczewski, P.Ł.; Baranowska, H.M. Water Behavior of Emulsions Stabilized by Modified Potato Starch. Polymers 2021, 13, 2200. [Google Scholar] [CrossRef] [PubMed]

- Hedley, C.L. Carbohydrates in Grain Legume Seeds: Improving Nutritional Quality and Agronomic Characteristics; CABI Publishing: Wallingrod, UK, 2000; ISBN 978-0-85199-467-3. [Google Scholar]

- Bannwart, G.C.M.D.C.; Bolini, H.M.A.; Toledo, M.C.D.F.; Kohn, A.P.C.; Cantanhede, G.C. Evaluation of Brazilian light ketchups II: Quantitative descriptive and physicochemical analysis. Ciência Tecnol. Aliment. 2008, 28, 107–115. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).