Gluten-Free Cookies Enriched with Baobab Flour (Adansonia digitata L.) and Buckwheat Flour (Fagopyrum esculentum)

Abstract

:Featured Application

Abstract

1. Introduction

2. Materials and Methods

2.1. Preparation of Composite Flours

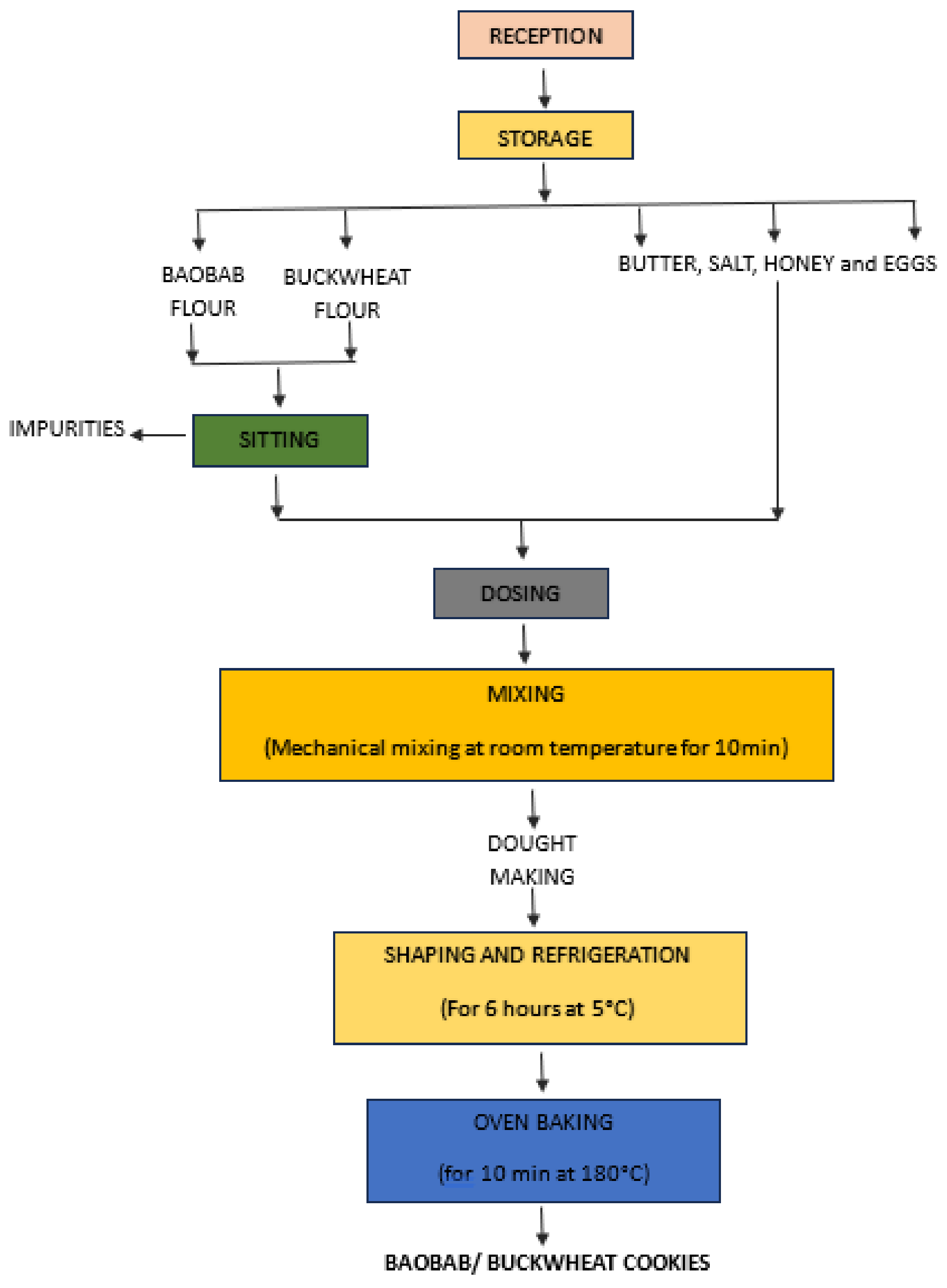

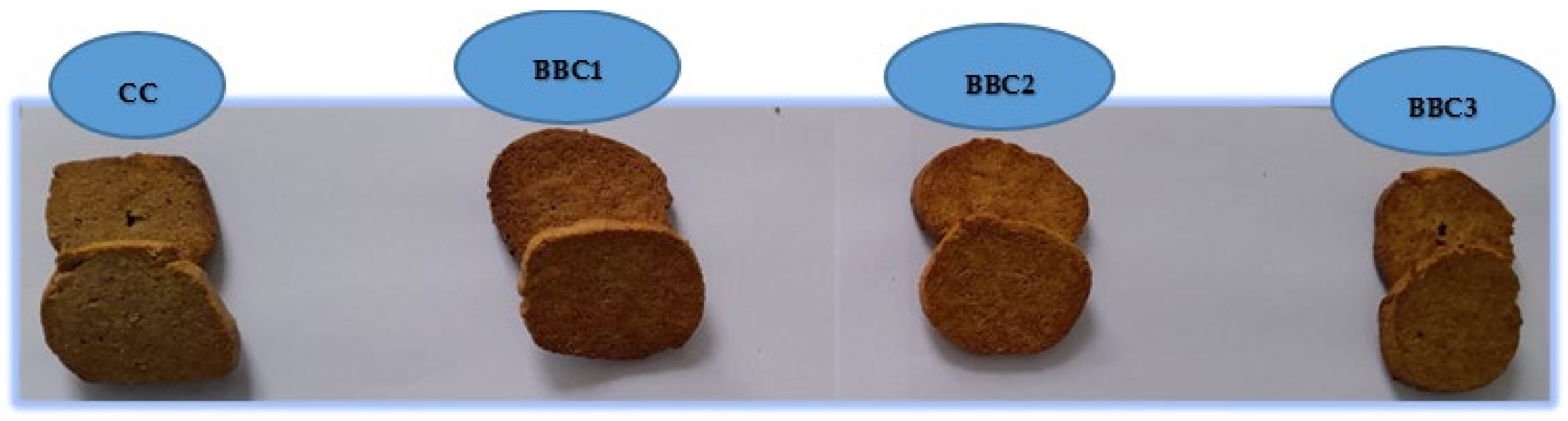

2.2. Cookie Preparation

2.3. Determination of Proximate Composition

2.4. Macro- and Micro-Elements

2.5. Phytochemical Profile

2.5.1. Preparation of Alcoholic Extracts

2.5.2. Evaluation of Total Phenolic Content (TPC)

2.5.3. Determination of Total Flavonoid Content (TFC)

2.5.4. Antioxidant Activity (AA)

2.5.5. Determination of Individual Polyphenols via LC-MS

2.6. Sensory Analysis

2.7. Statistical Analysis

3. Results and Discussion

3.1. Proximate Composition of Composite Flours and Cookies

3.2. Macro- and Micro-Element Composition of Composite Flours and Cookies

3.3. Phytochemical Profile of Composite Flours and Cookies

3.4. Individual Polyphenols of Composite Flours and Cookies Determined via LC-MS

3.5. Sensory Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lee, C.J.; Moon, T.W. Structural characteristics of slowly digestible starch and resistant starch isolated from heat–moisture treated waxy potato starch. Carbohydr. Polym. 2005, 125, 200–205. [Google Scholar] [CrossRef]

- Xu, J.; Zhang, Y.; Wang, W.; Li, Y. Advanced properties of gluten-free cookies, cakes, and crackers: A review. Trends Food Sci. Technol. 2020, 103, 200–213. [Google Scholar] [CrossRef]

- Green, P.H.; Cellier, C. Celiac disease. N. Engl. J. Med. 2007, 357, 1731–1743. [Google Scholar] [CrossRef]

- Leonard, M.M.; Sapone, A.; Catassi, C.; Fasano, A. Celiac disease and nonceliac gluten sensitivity: A review. JAMA 2017, 318, 647–656. [Google Scholar] [CrossRef]

- Di Cairano, M.; Galgano, F.; Tolve, R.; Caruso, M.C.; Condelli, N. Focus on gluten-free biscuits: Ingredients and issues. Trends Food Sci. Technol. 2018, 81, 203–212. [Google Scholar] [CrossRef]

- Sakač, M.; Torbica, A.; Sedej, I.; Hadnađev, M. Influence of breadmaking on antioxidant capacity of gluten-free bread based on rice and buckwheat flours. Food Res. Int. 2011, 44, 2806–2813. [Google Scholar] [CrossRef]

- Huda, M.N.; Lu, S.; Jahan, T.; Ding, M.; Jha, R.; Zhang, K.; Zhang, W.; Georgiev, M.I.; Park, S.U.; Zhou, M. Treasure from the garden: Bioactive compounds of buckwheat. Food Chem. 2021, 335, 127653. [Google Scholar] [CrossRef] [PubMed]

- Ikeda, K. Buckwheat composition, chemistry, and processing. Adv. Food Nutr. Res. 2002, 44, 395–434. [Google Scholar]

- Wu, N.N.; Tian, X.H.; Liu, Y.X.; Li, H.H.; Liang, R.P.; Zhang, M.; Liu, M.; Wang, L.P.; Zhai, X.T.; Tan, B. Cooking quality, texture and antioxidant properties of dried noodles enhanced with tartary buckwheat flour. Food Sci. Technol. Res. 2017, 23, 783–792. [Google Scholar] [CrossRef]

- De Francischi, M.L.P.; Salgado, J.; Da Costa, C.P. Immunological analysis of serum for buckwheat fed celiac patients. Mater. Veg. 1994, 46, 207–211. [Google Scholar] [CrossRef]

- Baljeet, S.Y.; Ritika, B.Y.; Roshan, L.Y. Studies on functional properties and incorporation of buckwheat flour for biscuit making. Int. Food Res. J. 2010, 17, 395–434. [Google Scholar]

- Mohajan, S.; Munna, M.M.; Orchy, T.N.; Hoque, M.M.; Farzana, T. Buckwheat flour fortified bread. Bangladesh J. Sci. Ind. Res. 2019, 54, 347–356. [Google Scholar] [CrossRef]

- Brites, L.T.G.F.; Rebellato, A.P.; Meinhart, A.D.; Godoy, H.T.; Pallone, J.A.L.; Steel, C.J. Technological, sensory, nutritional and bioactive potential of pan breads produced with refined and whole grain buckwheat flours. Food Chem. 2022, 13, 100243. [Google Scholar] [CrossRef] [PubMed]

- Bączek, N.; Jarmułowicz, A.; Wronkowska, M.; Haros, C.M. Assessment of the glycaemic index, content of bioactive compounds, and their in vitro bioaccessibility in oat-buckwheat breads. Food Chem. 2020, 330, 127199. [Google Scholar] [CrossRef]

- Choy, A.L.; Morrison, P.D.; Hughes, J.G.; Marriott, P.J.; Small, D.M. Quality and antioxidant properties of instant noodles enhanced with common buckwheat flour. J. Cereal Sci. 2013, 57, 281–287. [Google Scholar] [CrossRef]

- Lin, L.Y.; Liu, H.M.; Yu, Y.W.; Lin, S.D.; Mau, J.L. Quality and antioxidant property of buckwheat enhanced wheat bread. Food Chem. 2009, 112, 987–991. [Google Scholar] [CrossRef]

- Antoniewska, A.; Rutkowska, J.; Pineda, M.M.; Adamska, A. Antioxidative, nutritional and sensory properties of muffins with buckwheat flakes and amaranth flour blend partially substituting for wheat flour. LWT 2018, 89, 217–223. [Google Scholar] [CrossRef]

- Farzana, T.; Hossain, F.B.; Abedin, M.J.; Afrin, S.; Rahman, S.S. Nutritional and sensory attributes of biscuits enriched with buckwheat. J. Agric. Food Res. 2022, 10, 100394. [Google Scholar] [CrossRef]

- De Caluwé, E.; Halamouá, K.; Van Damme, P. Adansonia digitata L.—A review of traditional uses, phytochemistry, and pharmacology. Afr. Focus. 2010, 23, 11–51. [Google Scholar] [CrossRef]

- Buchmann, C.; Prehsler, S.; Hartl, A.; Vogl, C.R. The importance of baobab (Adansonia digitata L.) in rural West African subsistence—Suggestion of a cautionary approach to international market export of baobab fruits. Ecol. Food Nutr. 2010, 49, 145–172. [Google Scholar] [CrossRef]

- Gebauer, J.; Luedeling, E. A note on baobab (Adansonia digitata L.) in Kordofan, Sudan. Genet. Resour. Crop Evol. 2013, 60, 1587–1596. [Google Scholar] [CrossRef]

- Ajayi, I.A.; Dawodu, F.A.; Oderinde, R.A.; Egunyomi, A. Fatty acid composition and metal content of Adansonia digitata seeds and seed oil. Riv. Ital. Delle Sostanze Grasse 2003, 80, 41–44. [Google Scholar]

- Asogwa, I.S.; Ibrahim, A.N.; Agbaka, J.I. African baobab: Its role in enhancing nutrition, health, and the environment. Trees For. People 2021, 3, 100043. [Google Scholar] [CrossRef]

- Namratha, V.; Sahithi, P. Baobab: A review about “the tree of life”. Int. J. Adv. Herb. Sci. Technol. 2015, 1, 20–26. [Google Scholar]

- Dossa, S.; Negrea, M.; Cocan, I.; Berbecea, A.; Obistioiu, D.; Dragomir, C.; Alexa, E.; Rivis, A. Nutritional, Physico-Chemical, Phytochemical, and Rheological Characteristics of Composite Flour Substituted by Baobab Pulp Flour (Adansonia digitata L.) for Bread Making. Foods 2023, 12, 2697. [Google Scholar] [CrossRef] [PubMed]

- Barakat, H. Nutritional and Rheological Characteristics of Composite Flour Substituted with Baobab (Adansonia digitata L.) Pulp Flour for Cake Manufacturing and Organoleptic Properties of Their Prepared Cakes. Foods 2021, 10, 716. [Google Scholar] [CrossRef] [PubMed]

- Cissé, I.; Montet, D.; Reynes, M.; Danthu, P.; Yao, B.; Boulanger, R. Biochemical and nutritional properties of baobab pulp from endemic species of Madagascar and the African mainland. Afr. J. Agric. Res. 2013, 8, 6046–6054. [Google Scholar]

- Burlando, B.; Verotta, L.; Cornara, L.; Bottini-Massa, E. Herbal Principles in Cosmetics: Properties and Mechanisms of Action; CRC Press: Boca Raton, FL, USA, 2010. [Google Scholar]

- Brendler, T.; Eloff, J.N.; Gurib-Fakim, A.; Phillips, L.D. (Eds.) African Herbal Pharmacopoeia, Association for African Medicinal Plants Standards (AAMPS); Graphics Press Ltd.: Baie du Tombeau, Mauritius, 2010; Volume 289. [Google Scholar]

- Tsetegho Sokeng, A.J.; Sobolev, A.P.; Di Lorenzo, A.; Xiao, J.; Mannina, L.; Capitani, D.; Daglia, M. Metabolite characterization of powdered fruits and leaves from Adansonia digitata L. (baobab): A multi-methodological approach. Food Chem. 2019, 272, 93–108. [Google Scholar] [CrossRef]

- Chadare, F.; Linnemann, A.; Hounhouigan, J.; Nout, M.; Van Boekel, M. Baobab food products: A review on their composition and nutritional value. Crit. Rev. Food Sci. Nutr. 2009, 49, 254–274. [Google Scholar] [CrossRef]

- Gebauer, J.; El Siddig, K.; Ebert, G. Baobab (Adansonia digitata L.): A review on a multipurpose tree with promising future in the Sudan. Gartenbauwissenscha 2002, 67, 155–160. [Google Scholar]

- Diop, A.; Sakho, M.; Dornier, M.; Cisse, M.; Reynes, M. Le baobab africain (Adansonia digitata L.): Principales caractéristiques et utilisations. Fruits 2005, 61, 55–69. [Google Scholar] [CrossRef]

- Mounjouenpou, P.; Ngono Eyenga, S.N.N.; Kamsu, E.J.; Kari, P.B.; Ehabe, E.E.; Ndjouenkeu, R. Effect of fortification with baobab (Adansonia digitata L.) pulp flour on sensorial acceptability and nutrient composition of rice cookies. Sci. Afr. 2018, 1, e00002. [Google Scholar] [CrossRef]

- ISO 2171; Determination of Ash Content by Incineration in Cereals, Pulses, and Derived Products, 4th ed. International Standard ISO: London, UK, 2017; p. 11.

- No. 110/1.ICC; ICC Standard Methods of the International Association for Cereal Science and Technology. ICC: Vienna, Austria, 2003.

- Association of Official Analytical Chemists (AOAC). Official Methods of Analysis of AOAC International, 17th ed.; AOAC International: Gaithersburg, MD, USA, 2000. [Google Scholar]

- Plustea, L.; Negrea, M.; Cocan, I.; Radulov, I.; Tulcan, C.; Berbecea, A.; Popescu, I.; Obistioiu, D.; Hotea, I.; Suster, G. Lupin (Lupinus sPP.)-Fortified Bread: A Sustainable, Nutritionally, Functionally, and Technologically Valuable Solution for Bakery. Foods 2022, 11, 2067. [Google Scholar] [CrossRef]

- Danciu, C.; Muntean, D.; Alexa, E.; Farcas, C.; Oprean, C.; Zupko, I.; Bor, A.; Minda, D.; Proks, M.; Buda, V.; et al. Phytochemical Characterization and Evaluation of the Antimicrobial, Antiproliferative and Pro-Apoptotic Potential of Ephedra alata Decne. Hydroalcoholic Extract against the MCF-7 Breast Cancer Cell Line. Molecules 2019, 24, 13. [Google Scholar] [CrossRef] [PubMed]

- Obistioiu, D.; Cocan, I.; Tîrziu, E.; Herman, V.; Negrea, M.; Cucerzan, A.; Neacsu, A.G.; Cozma, A.L.; Nichita, I.; Hulea, A. Phytochemical Profile and Microbiological Activity of Some Plants Belonging to the Fabaceae Family. Antibiotics 2021, 10, 662. [Google Scholar] [CrossRef]

- Cocan, I.; Cadariu, A.-I.; Negrea, M.; Alexa, E.; Obistioiu, D.; Radulov, I.; Poiana, M.-A. Investigating the Antioxidant Potential of Bell Pepper Processing By-Products for the Development of Value-Added Sausage Formulations. Appl. Sci. 2022, 12, 12421. [Google Scholar] [CrossRef]

- Ciulca, S.; Roma, G.; Alexa, E.; Radulov, I.; Cocan, I.; Madosa, E.; Ciulca, A. Variation of Polyphenol Content and Antioxidant Activity in Some Bilberry (Vaccinium myrtillus L.) Populations from Romania. Agronomy 2021, 11, 2557. [Google Scholar] [CrossRef]

- ISO 6658:2017; Sensory Analysis—Methodology—Overall Guidelines. ISO: Geneva, Switzerland, 2017.

- Bhinder, S.; Kaur, A.; Singh, B.; Yadav, M.P.; Singh, N. Proximate composition, amino acid profile, pasting and process characteristics of flour from different Tartary buckwheat varieties. Food Res. Int. 2020, 130, 108946. [Google Scholar] [CrossRef]

- Lockett, C.; Calvert, C.; Grivetti, L. Energy and micronutrient composition of dietary and medicinal wild plants consumed during drought. Study of rural Fulani, Northeastern Nigeria. Int. J. Food Sci. Nutr. 2000, 51, 195–208. [Google Scholar]

- Murray, S.; Schoeninger, M.; Bunn, H.; Pickering, T.; MarIen, J. Nutritional composition of some wild plant foods and honey used by Hadza foragers of Tanzania. Food Compos. Anal. 2001, 14, 3–13. [Google Scholar] [CrossRef]

- Osman, M. Chemical and nutrient analysis of baobab (Adansonia digitata) fruit and seed protein solubility. Plant Foods Hum. Nutr. 2004, 59, 29–33. [Google Scholar] [CrossRef] [PubMed]

- Chopra, N.; Dhillon, B.; Puri, S. Formulation of buckwheat cookies and their nutritional, physical, sensory and microbiological analysis. Int. J. Adv. Biotechnol. Res. 2014, 5, 381–387. [Google Scholar]

- Stadlmayr, B.; Wanangwe, J.; Waruhiu, C.G.; Jamnadass, R.; Kehlenbeck, K. Nutritional composition of baobab (Adansonia digitata L.) fruit pulp sampled at different geographical locations in Kenya. J. Food Compos. Anal. 2020, 94, 103617. [Google Scholar] [CrossRef]

- Wardlaw, G.M.; Kessel, M.W. Perspectives in Nutrition, 5th ed.; McGraw-Hill Education: New York, NY, USA, 2002; pp. 162–452. [Google Scholar]

- Cozzolino, S.M.F. Biodisponibilidade de Nutrientes; Manole: Plovdiv, Bulgaria, 2009; p. 1172. [Google Scholar]

- Gupta, U.C.; Gupta, S.C. Sources and deficiency diseases of mineral nutrients in human health and nutrition: A review. Pedosphere 2014, 24, 13–38. [Google Scholar] [CrossRef]

- WHO Guidelines on Food Fortification with Micronutrients; WHO: Geneva, Switzerland, 2006; Available online: https://www.who.int/publications/i/item/9241594012 (accessed on 15 August 2023).

- World Health Organization (WHO). Guidelines: On Potassium Intake in Adults and Children Summary of Guidance. WHO/NMH/NHD/13.1; World Health Organization (WHO): Geneva, Switzerland, 2013; Available online: https://apps.who.int/iris/bitstream/handle/10665/85225/WHO_NMH_NHD_13.1_fre.pdf (accessed on 15 August 2023).

- EFSA Panel on Dietetic Products, Nutrition and Allergies. Scientific Opinion on the Tolerable Upper Intake Level of Calcium. EFSA J. 2012, 10, 2814. [Google Scholar]

- EFSA Panel on Dietetic Products, Nutrition and Allergies. Scientific Opinion on Dietary Reference Values for Magnesium. EFSA J. 2015, 13, 4186. [Google Scholar]

- Reena, R.; Lin, Y.T.; Shetty, K. Phenolics, their antioxidant and antimicrobial activity in dark germinated fenugreek sprouts in response to peptide and phytochemical elicitors. Asia Pac. J. Clin. Nutr. 2004, 13, 295–307. [Google Scholar]

- Balasundram, N.; Sundram, K.; Samman, S. Phenolic compounds in plants and agri-industrial by-products: Antioxidant activity, occurrence, and potential uses. Food Chem. 2006, 99, 191–203. [Google Scholar] [CrossRef]

- Balarabe, B.I.; Yunfeng, P.; Lihua, F.; Munir, A.D.; Mingming, G.; Donghong, L. Characterizing the phenolic constituents of baobab (Adansonia digitata) fruit shell by LC-MS/QTOF and their in vitro biological activities. Sci. Total Environ. 2019, 694, 133387. [Google Scholar]

- Şensoy, Í.; Rosen, R.T.; Ho, C.T.; Karwe, M.V. Effect of processing on buckwheat phenolics and antioxidant activity. Food Chem. 2006, 99, 388–393. [Google Scholar] [CrossRef]

- Chlopicka, J.; Pasko, P.; Gorinstein, S.; Jedryas, A.; Zagrodzki, P. Total phenolic and total flavonoid content, antioxidant activity and sensory evaluation of pseudocereal bread. LWT Food Sci. Technol. 2012, 46, 548–555. [Google Scholar] [CrossRef]

- Cook, N.C.; Samman, S. Flavonoids-chemistry, metabolism, cardioprotective effects, and dietary sources. J. Nutr. Biochem. 1996, 7, 66–76. [Google Scholar] [CrossRef]

- Dorota, D.-S.; Wieslaw, O. Effect of processing on the flavonoid content in buckwheat (Fagopyrum esculentum Moench) grain. J. Agric. Food Chem. 1999, 47, 4383–4387. [Google Scholar]

- Sun, T.; Ho, C.T. Antioxidant activities of buckwheat extracts. Food Chem. 2005, 90, 743–749. [Google Scholar] [CrossRef]

- Bolang, A.S.L.; Rizal, M.; Nurkolis, F.; Mayulu, N.; Taslim, N.A.; Radu, S.; Samtiya, M.; Assa, Y.A.; Herlambang, H.A.; Pondagitan, A.S.; et al. Cookies rich in iron (Fe), folic acid, cobalamin (vitamin B12), and antioxidants: A novel functional food potential for adolescent with anemia. F1000Research 2023, 10, 1075. [Google Scholar] [CrossRef]

- Ngadiarti, I.; Nurkolis, F.; Handoko, M.N.; Perdana, F.; Permatasari, H.K.; Taslim, N.A.; Mayulu, N.; Wewengkang, D.S.; Noor, S.L.; Batubara, S.C.; et al. Anti-aging potential of cookies from sea grapes in mice fed on cholesterol- and fat-enriched diet: In vitro with in vivo study. Heliyon 2022, 8, e09348. [Google Scholar] [CrossRef] [PubMed]

- Tembo, D.T.; Holmes, M.J.; Marshall, L.J. Effect of thermal treatment and storage on bioactive compounds, organic acids and antioxidant activity of baobab fruit (Adansonia digitata) pulp from Malawi. J. Food Compos. Anal. 2017, 58, 40–51. [Google Scholar] [CrossRef]

- Lee, L.S.; Choi, E.J.; Kim, C.H.; Sung, J.M.; Kim, Y.B.; Seo, D.H.; Choi, H.W.; Choi, Y.S.; Kum, J.S.; Park, J.D. Contribution of flavonoids to the antioxidant properties of common and tartary buckwheat. J. Cereal Sci. 2016, 68, 181–186. [Google Scholar] [CrossRef]

- Schewe, T.; Sies, H. 82—Epicatechin and Its Role in Protection of LDL and Vascular Endothelium; Preedy, V.R., Ed.; Beer in Health and Disease Prevention; Academic Press: Cambridge, MA, USA, 2009; pp. 803–813. [Google Scholar]

- Sirotkin, A.V.; Kolesarova, A. Chapter 4—Plant Molecules and Their Influence on Health and Female Reproduction; Sirotkin, A.V., Kolesarova, A., Eds.; Environmental Contaminants and Medicinal Plants Action on Female Reproduction; Academic Press: Cambridge, MA, USA, 2022; pp. 245–399. [Google Scholar]

- Patel, K.; Patel, D.K. Chapter 26—The Beneficial Role of Rutin, A Naturally Occurring Flavonoid in Health Promotion and Disease Prevention: A Systematic Review and Update. In Bioactive Food as Dietary Interventions for Arthritis and Related Inflammatory Diseases, 2nd ed.; Watson, R.R., Preedy, V.R., Eds.; Academic Press: Cambridge, MA, USA, 2019; pp. 457–479. [Google Scholar]

| Samples | Ingredients | |||||

|---|---|---|---|---|---|---|

| Baobab Flour (g) | Buckwheat Flour (g) | Butter (g) | Salt (g) | Honey (g) | Eggs (pcs) | |

| CC | - | 340 | 200 | 0.5 | 200 | 2 |

| BBC1 | 34 | 306 | 200 | 0.5 | 200 | 2 |

| BBC2 | 68 | 272 | 200 | 0.5 | 200 | 2 |

| BBC3 | 102 | 238 | 200 | 0.5 | 200 | 2 |

| Parameters | Methods | Unit |

|---|---|---|

| Ash | ISO 2171/2007 [35] | % |

| Moisture | Standard Methods of the International Association for Cereal Science and Technology (2003) [36] | % |

| Protein | Standard Methods of the International Association for Cereal Science and Technology (2003) [36] | % |

| Fat | Association of Official Analytical Chemists [37] | |

| Carbohydrate | Carbohydrate content was calculated as the difference between 100 and the sum of moisture, ash, protein, and fat content [38] | g/100 g |

| Energy value | The energy value was obtained by summing 4 times the protein content, 4 times the carbohydrate content, and 9 times the fat content [38] | kcal/100 g |

| Samples | Nutritional Characteristics | |||||

|---|---|---|---|---|---|---|

| Moisture | Mineral Content | Proteins | Lipids | Carbohydrates | Energy Values | |

| (%) | (%) | (%) | (%) | (g/100 g) | (kcal/100 g) | |

| Composite flours | ||||||

| BWF | 10.13 ± 1.15 a | 1.66 ± 0.01 a | 12.63 ± 0.02 a | 3.19 ± 0.07 a | 72.38 ± 1.09 a | 368.79 ± 4.87 |

| BF | 13.79 ± 0.01 b | 4.00 ± 0.02 b | 4.31 ± 0.05 b | 1.56 ± 0.02 b | 76.34 ± 0.06 b | 336.62 ± 0.16 |

| BBF1 | 9.07 ± 0.06 c | 1.99 ± 0.02 c | 11.72 ± 0.03 c | 2.46 ± 0.02 c | 74.76 ± 0.09 c | 368.03 ± 0.20 |

| BBF2 | 9.23 ± 0.04 c,d | 2.22 ± 0.19 d | 11.13 ± 0.02 d | 2.29 ± 0.04 d | 75.13 ± 0.24 c,d | 365.65 ± 0.96 |

| BBF3 | 9.38 ± 0.03 d | 2.67 ± 0.01 e | 9.98 ± 0.03 e | 2.20 ± 0.02 d | 75.78 ± 0.01 d | 362.80 ± 0.12 |

| Cookies | ||||||

| CC | 10.58 ± 0.28 a | 1.10 ± 0.20 a | 8.27 ± 0.03 a | 22.96 ± 0.04 a | 57.09 ± 0.13 a | 468.05 ± 0.67 |

| BBC1 | 11.58 ± 0.01 b | 1.31 ± 0.04 b | 7.67 ± 0.03 b | 21.53 ± 0.08 b | 57.91 ± 0.04 a,b | 456.12 ± 0.56 |

| BBC2 | 12.05 ± 0.08 b,c | 1.42 ± 0.04 c | 7.00 ± 0.03 c | 20.78 ± 0.08 c | 58.75 ± 0.10 b,c | 450.05 ± 0.65 |

| BBC3 | 12.25 ± 0.12 c | 1.51 ± 0.03 d | 6.87 ± 0.10 c | 20.13 ± 0.07 d | 59.24 ± 0.05 c | 445.63 ± 0.55 |

| Samples | Macro- and Micro-Element Contents (mg/kg) | |||||||

|---|---|---|---|---|---|---|---|---|

| Fe | Zn | Ni | Cu | K | Mg | Ca | Mn | |

| Composite flours | ||||||||

| BF | 155.14 ± 2.95 a | 14.90 ± 0.01 a | 0.598 ± 0.002 a | 8.04 ± 0.05 a | 13,276.47 ± 174.00 a | 1066.73 ± 9.97 a | 1570.67 ± 29.67 a | 4.84 ± 0.05 a |

| BWF | 57.66 ± 0.16 b | 17.30 ± 0.11 b | 0.391 ± 0.01 b | 4.23 ± 0.02 b | 1255.35 ± 58.92 b | 287.82 ± 2.01 b | 181.55 ± 3.24 b | 10.65 ± 0.04 b |

| BBF1 | 71.65 ± 0.12 c,e | 14.12 ± 0.15 a,c | 0.412 ± 0.01 b | 4.46 ± 0.14 b,c | 1389.57 ± 36.28 a | 288.83 ± 0.48 b,c | 586.12 ± 2.62 c | 10.02 ± 0.12 b |

| BBF2 | 81.96 ± 0.07 d | 13.60 ± 0.34 c | 0.467 ± 0.001 c | 4.57 ± 0.12 c | 1640.07 ± 135.16 c | 322.78 ± 23.95 c,d | 628.74 ± 10.40 d | 9.10 ± 0.08 c |

| BBF3 | 89.03 ± 0.1 e | 12.30 ± 0.13 d | 0.516 ± 0.02 d | 4.88 ± 0.06 d | 2488.81 ± 435.58 d | 378.57 ± 9.07 d | 865.82 ± 9.28 e | 8.26 ± 0.05 c |

| Composite cookies | ||||||||

| CC | 29.99 ± 0.11 a | 7.09 ± 0.10 a | 0.175 ± 0.03 a | 3.18 ± 0.17 a | 951.30 ± 64.88 a | 272.42 ± 1.00 a | 144.13 ± 12.19 a | 6.51 ± 0.15 a |

| BBC1 | 33.02 ± 0.11 a,b | 6.91 ± 0.09 a | 0.243 ± 0.01 b | 3.34 ± 0.14 a,b | 1192.13 ± 127.20 b | 275.96 ± 4.55 a | 442.54 ± 8.15 b | 6.03 ± 0.22 a |

| BBC2 | 36.22 ± 0.18 b,c | 5.72 ± 0.12 b | 0.347 ± 0.02 c | 3.55 ± 0.05 b,c | 1386.30 ± 104.14 c | 293.20 ± 7.94 b | 572.73 ± 15.01 c | 5.16 ± 0.15 b |

| BBC3 | 39.99 ± 0.03 c | 5.37 ± 0.08 b | 0.382 ± 0.01 c | 3.88 ± 0.04 c | 2093.07 ± 38.86 d | 298.72 ± 15.19 b | 672.97 ± 38.99 d | 4.67 ± 0.06 c |

| Samples | Total Polyphenol Content (mg/100 g) | Total Flavonoid Content (mg/100 g) | Antioxidant Activity, DPPH (%) |

|---|---|---|---|

| Flours | |||

| BWF | 283.87 ± 0.06 a | 125.36 ± 1.12 a | 79.72 ± 0.01 a |

| BF | 629.7 ± 0.35 b | 213.13 ± 0.08 b | 86.62 ± 0.04 a,b |

| BBF1 | 292.35 ± 0.35 a,c | 181.03 ± 0.12 c | 81.56 ± 0.19 b |

| BBF2 | 311.62 ± 0.78 c,d | 194.94 ± 1.78 d | 83.11 ± 0.02 b |

| BBF3 | 320.12 ± 2.07 d | 209.28 ± 0.85 b | 84.78 ± 0.01 b |

| Cookies | |||

| CC | 226.34 ± 0.75 a | 102.96 ± 4.07 a | 76.33 ± 0.07 a |

| BBC1 | 250.06 ± 1.17 b | 135.74 ± 3.10 b | 78.74 ± 0.03 a,b |

| BBC2 | 252.74 ± 0.15 b | 140.44 ± 0.81 b,c | 80.32 ± 0.03 b,c |

| BBC3 | 285 ± 32.82 c | 147.69 ± 2 c | 82.52 ± 0.07 c,d |

| Samples | ||||||

|---|---|---|---|---|---|---|

| Epicatechin (mg/kg) | Cafeic Acid (mg/kg) | Rutin (mg/kg) | Rosmarinic Acid (mg/kg) | Resveratrol (mg/kg) | Quercitin (mg/kg) | |

| Composite flours | ||||||

| BWF | 90.03 ± 0.21 a | 17.57 ± 0.93 a | 246.93 ± 0.75 a | 68.13 ± 0.60 a | 126.30 ± 1.67 a | 15.80 ± 0.44 a |

| BF | 158.6 ± 0.46 b | 17.67 ± 1.01 a | nd * | 67.93 ± 0.57 a | 141.73 ± 0.57 b | 16.10 ± 0.61 a |

| BBF1 | 106.63 ± 0.21 c | 17.63 ± 0.15 a | 145.80 ± 0.56 b,c | 68.00 ± 0.50 a | 128.50 ± 1.14 a | 15.90 ± 0.10 a |

| BBF2 | 109.23 ± 0.04 c | 17.64 ± 0.15 a | 137.60 ± 0.61 c,d | 68.01 ± 0.61 a | 129.90 ± 0.10 a,c | 15.91 ± 0.08 a |

| BBF3 | 121.18 ± 0.73 d | 17.64 ± 0.14 a | 122.20 ± 0.02 d | 68.00 ± 0.05 a | 132.20 ± 0.02 c | 16.05 ± 0.13 a |

| Cookies | ||||||

| CC | nd | 17.80 ± 0.1 a | 259.57 ± 0.40 a | 68.0 ± 0.53 a | 116.53 ± 0.55 a | 15.90 ± 0.10 a |

| BBC1 | 92.55 ± 0.05 a | 17.75 ± 0.04 a | 151.40 ± 0.18 b | 67.97 ± 0.15 a | 121.31 ± 0.45 b | 15.94 ± 0.19 a |

| BBC2 | 99.79 ± 0.52 b | 17.77 ± 0.04 a | 140.98 ± 0.28 b | 67.83 ± 0.06 a | 124.12 ± 0.64 c | 16.20 ± 0.13 b |

| BBC3 | 108.59 ± 0.62 c | 17.77 ± 0.03 a | 130.47 ± 0.51 b | 67.83 ± 0.12 a | 126.98 ± 0.25 c | 16.26 ± 0.09 b |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dossa, S.; Dragomir, C.; Plustea, L.; Dinulescu, C.; Cocan, I.; Negrea, M.; Berbecea, A.; Alexa, E.; Rivis, A. Gluten-Free Cookies Enriched with Baobab Flour (Adansonia digitata L.) and Buckwheat Flour (Fagopyrum esculentum). Appl. Sci. 2023, 13, 12908. https://doi.org/10.3390/app132312908

Dossa S, Dragomir C, Plustea L, Dinulescu C, Cocan I, Negrea M, Berbecea A, Alexa E, Rivis A. Gluten-Free Cookies Enriched with Baobab Flour (Adansonia digitata L.) and Buckwheat Flour (Fagopyrum esculentum). Applied Sciences. 2023; 13(23):12908. https://doi.org/10.3390/app132312908

Chicago/Turabian StyleDossa, Sylvestre, Christine Dragomir, Loredana Plustea, Cosmin Dinulescu, Ileana Cocan, Monica Negrea, Adina Berbecea, Ersilia Alexa, and Adrian Rivis. 2023. "Gluten-Free Cookies Enriched with Baobab Flour (Adansonia digitata L.) and Buckwheat Flour (Fagopyrum esculentum)" Applied Sciences 13, no. 23: 12908. https://doi.org/10.3390/app132312908

APA StyleDossa, S., Dragomir, C., Plustea, L., Dinulescu, C., Cocan, I., Negrea, M., Berbecea, A., Alexa, E., & Rivis, A. (2023). Gluten-Free Cookies Enriched with Baobab Flour (Adansonia digitata L.) and Buckwheat Flour (Fagopyrum esculentum). Applied Sciences, 13(23), 12908. https://doi.org/10.3390/app132312908