Experimental Research into the Ultrasonic P-Wave Velocity of Coal Slime Based Backfill Material

Abstract

:1. Introduction

2. Experimental Procedures

2.1. Characteristics of Experimental Raw Materials

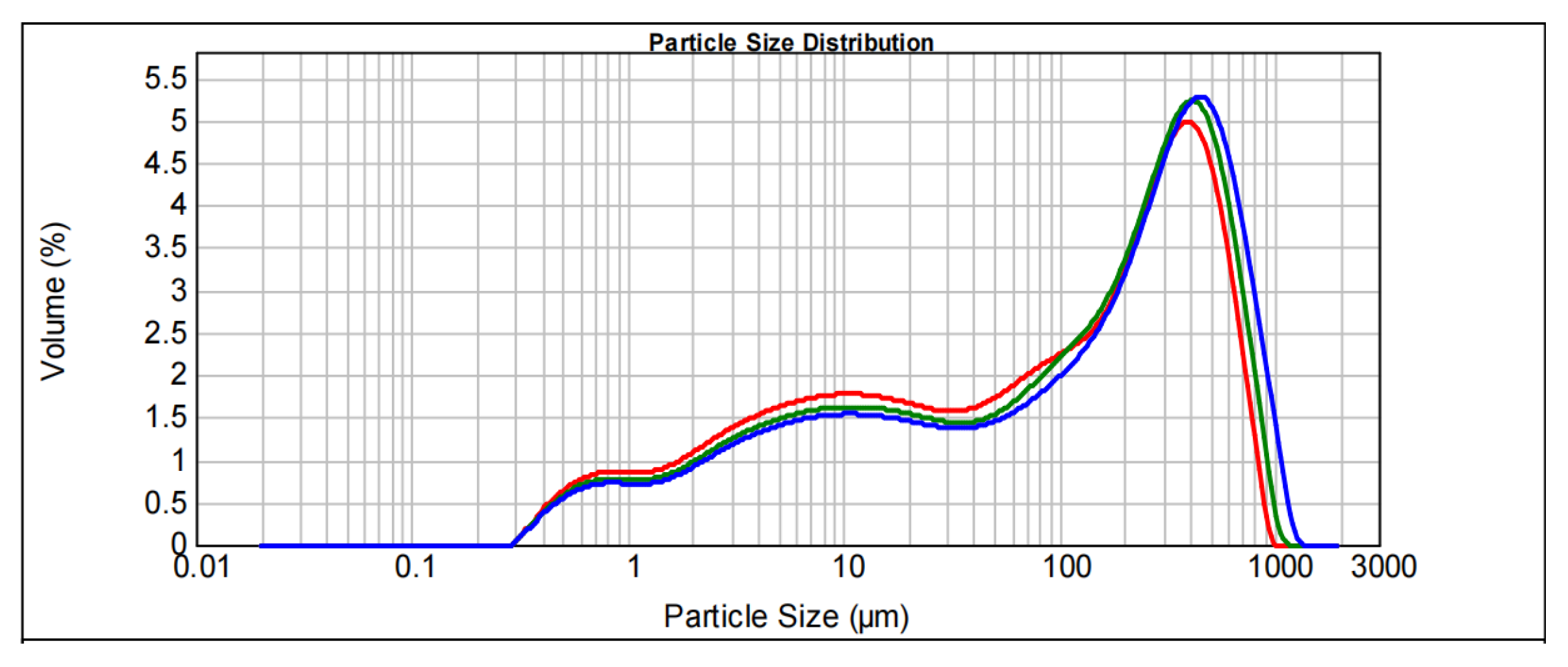

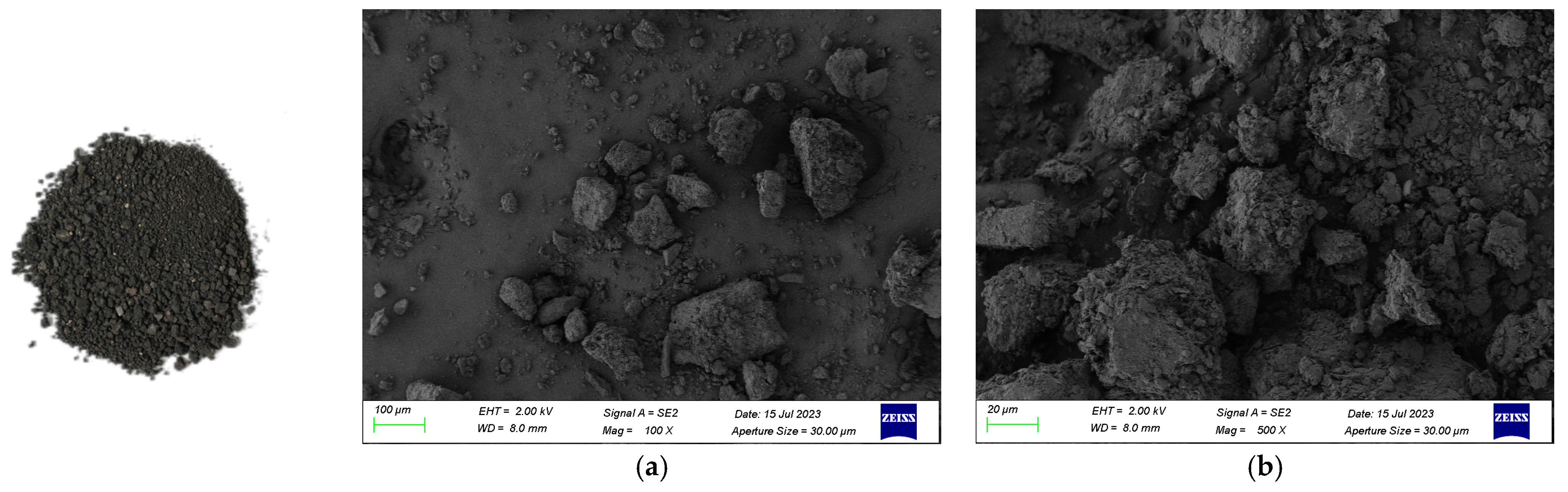

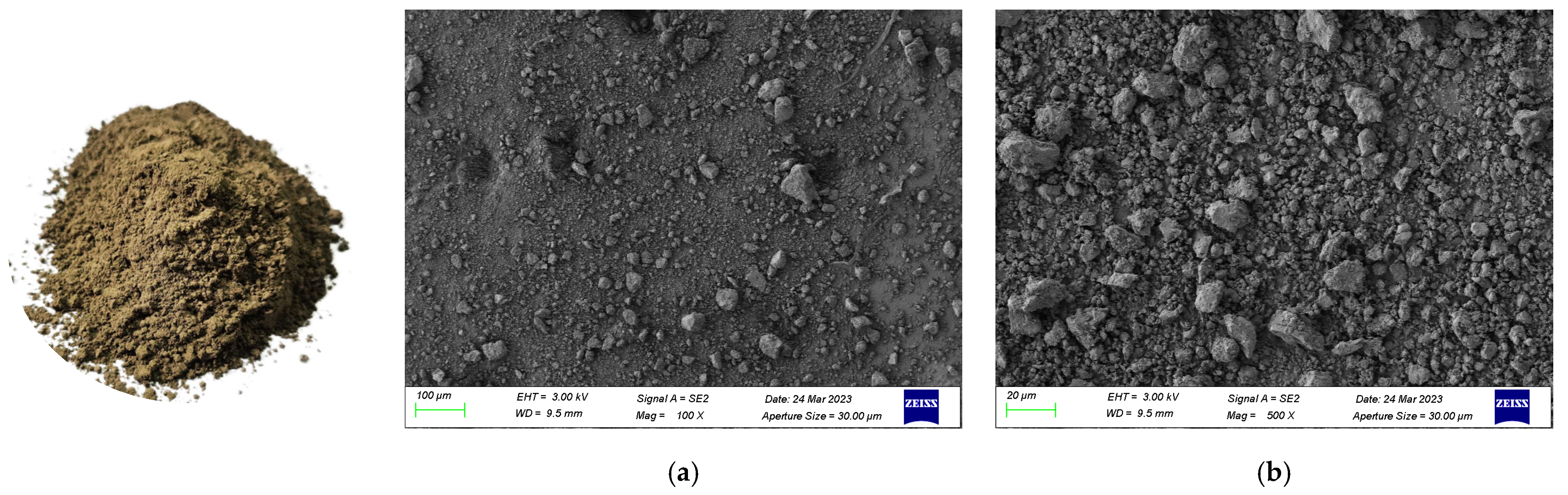

2.1.1. Coal Slime

2.1.2. Characteristics of High-Water-Content Materials

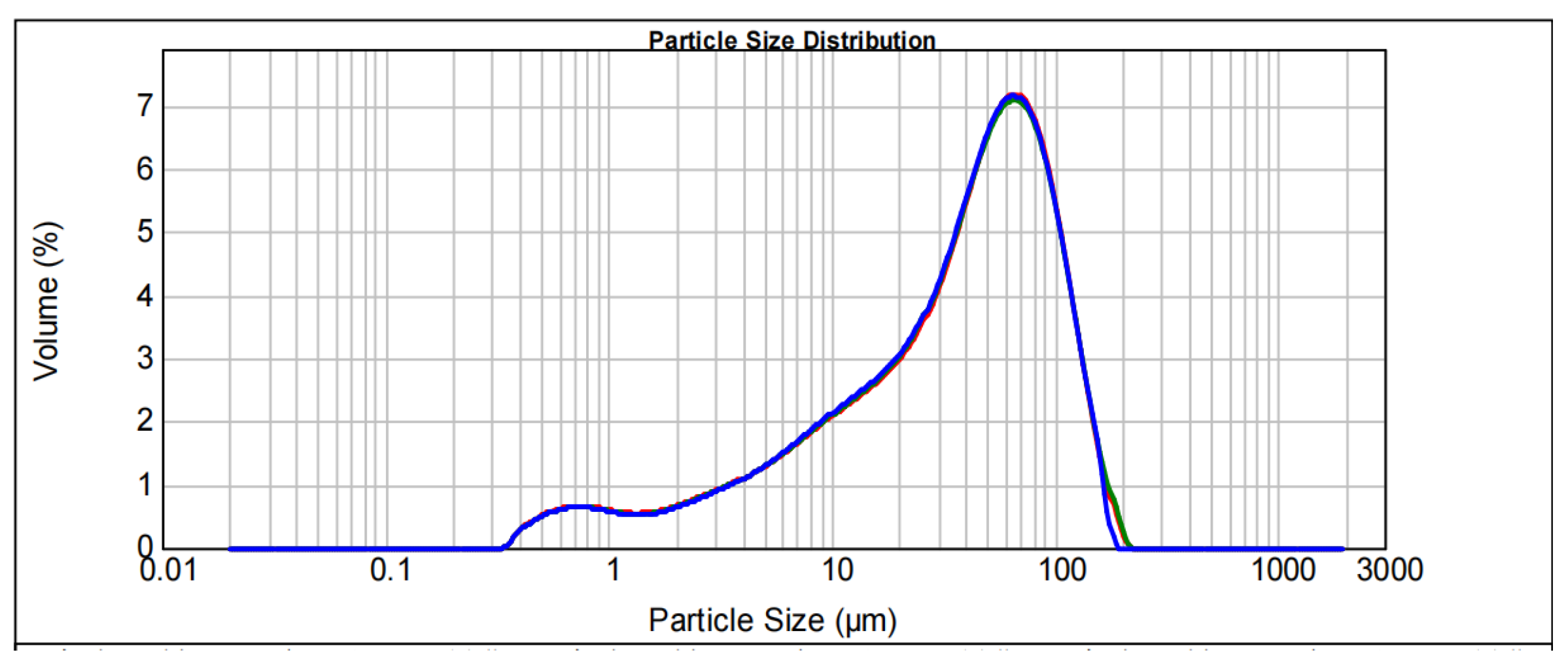

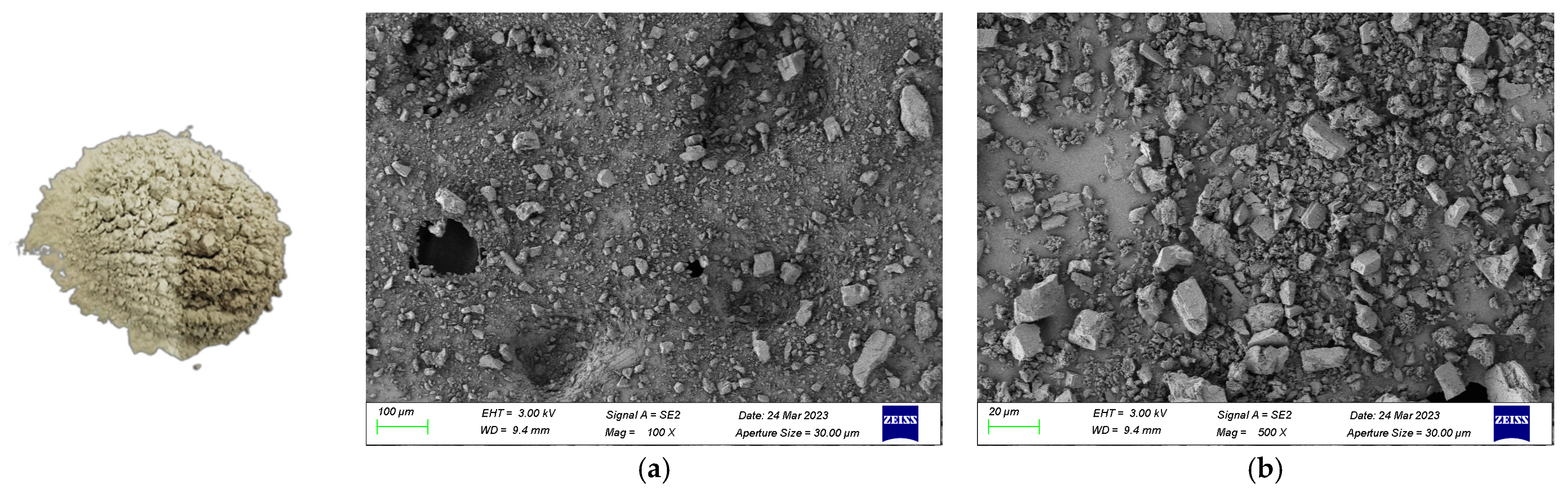

2.1.3. Characteristics of Cement

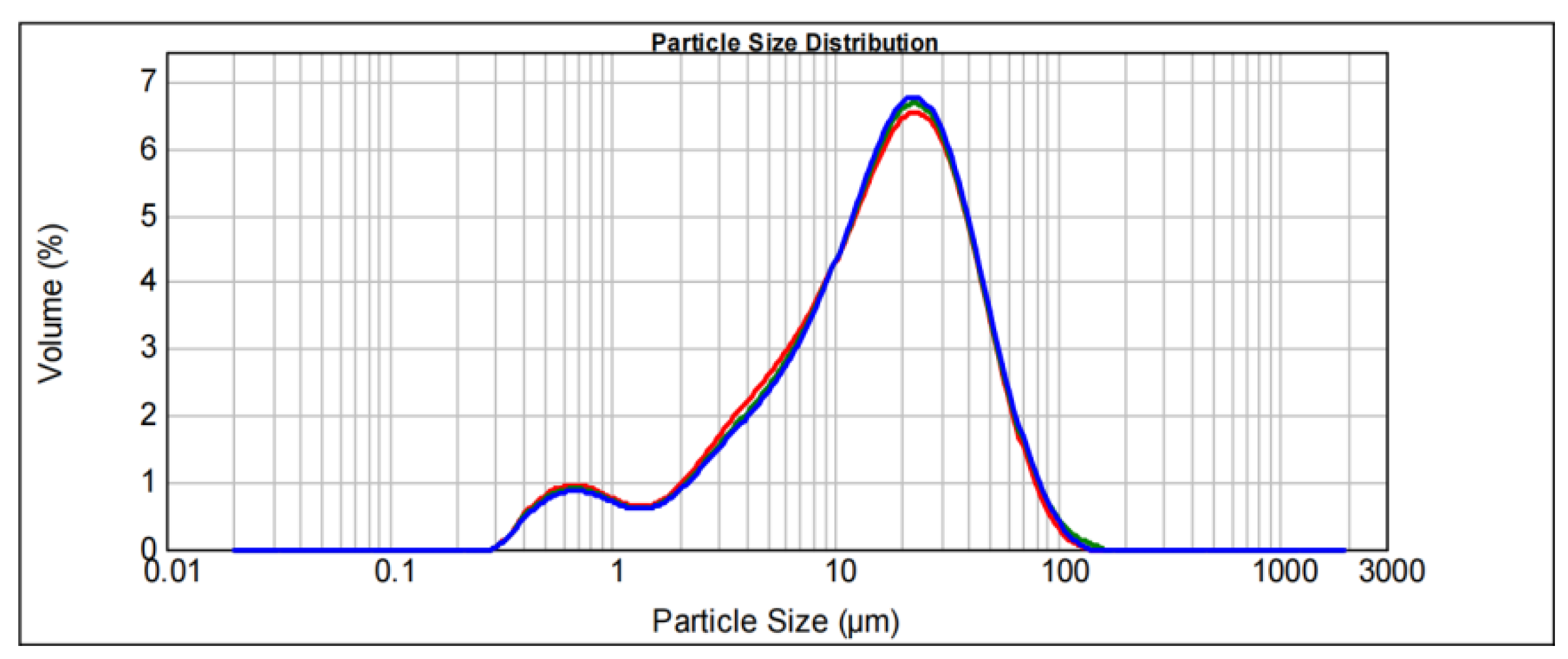

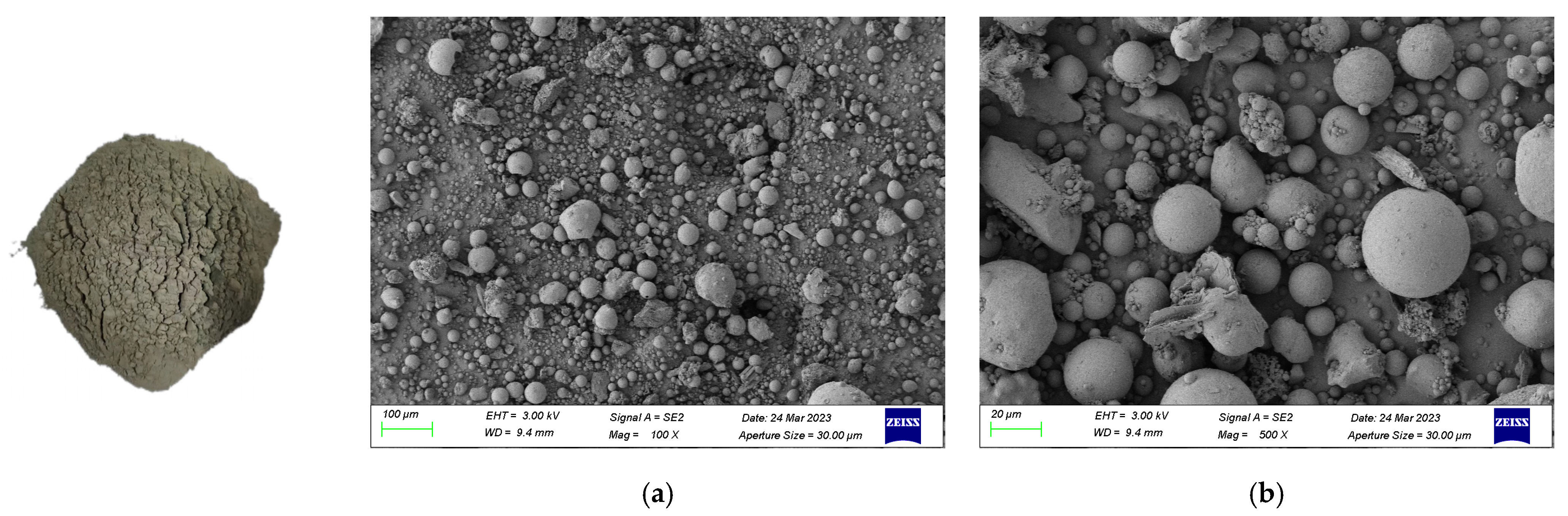

2.1.4. Characteristics of Fly Ash

2.2. Specimen Preparation Procedures

3. Orthogonal Test Schemes and Test Results

3.1. Orthogonal Design of Experiment

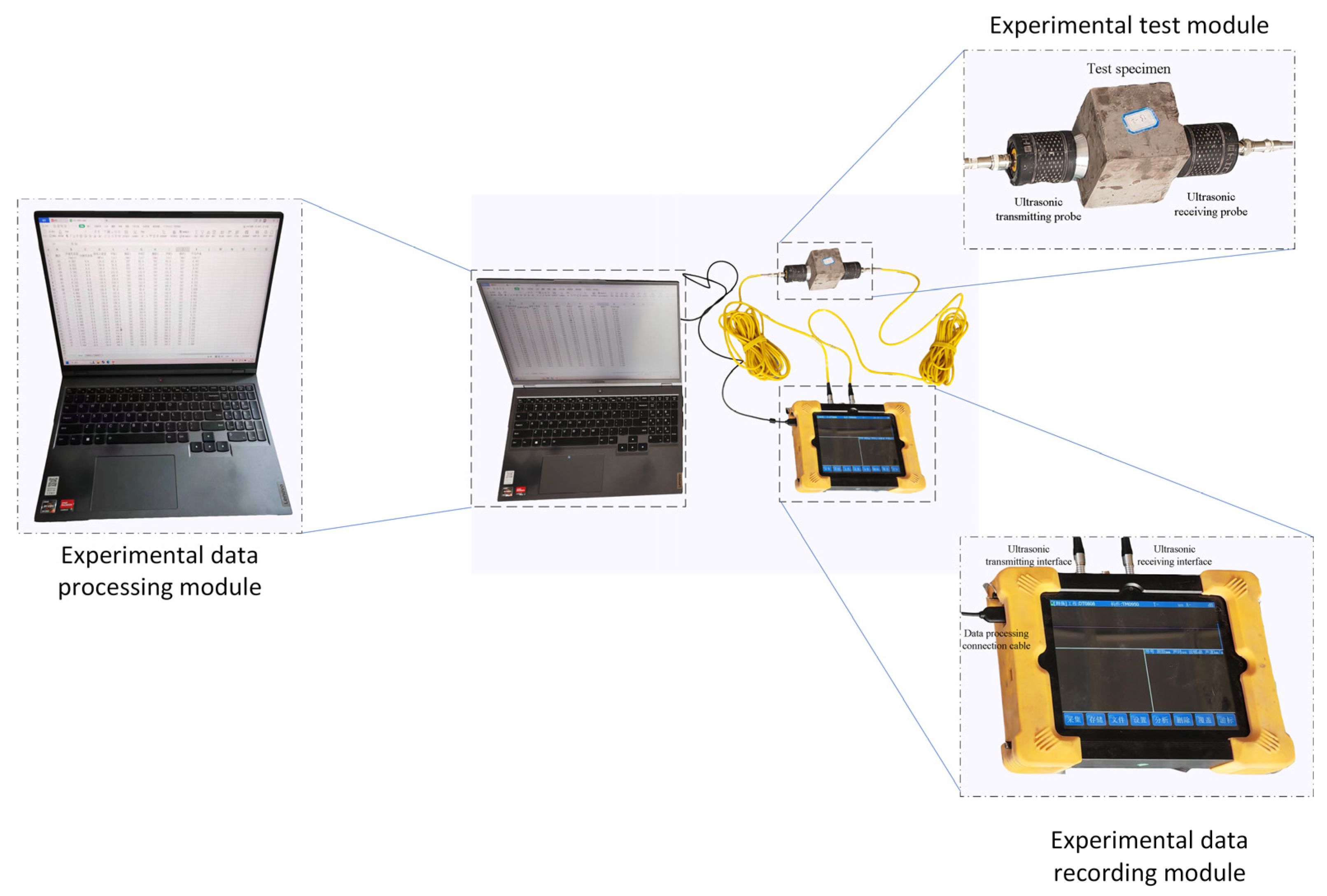

3.2. Ultrasonic Experimental Design

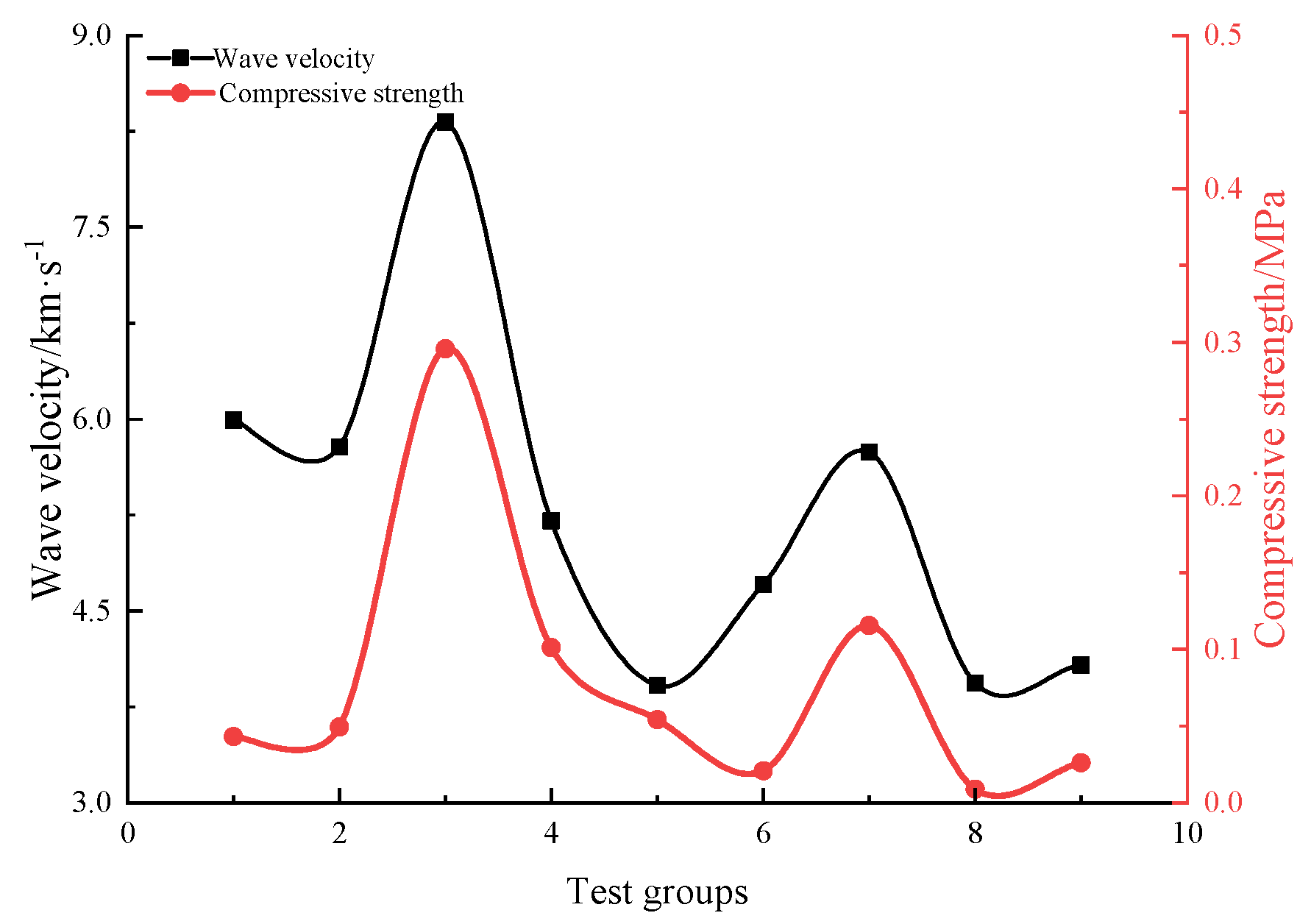

3.3. Experimental Data and Analysis

4. Correlation between Strength and P-Wave Velocity

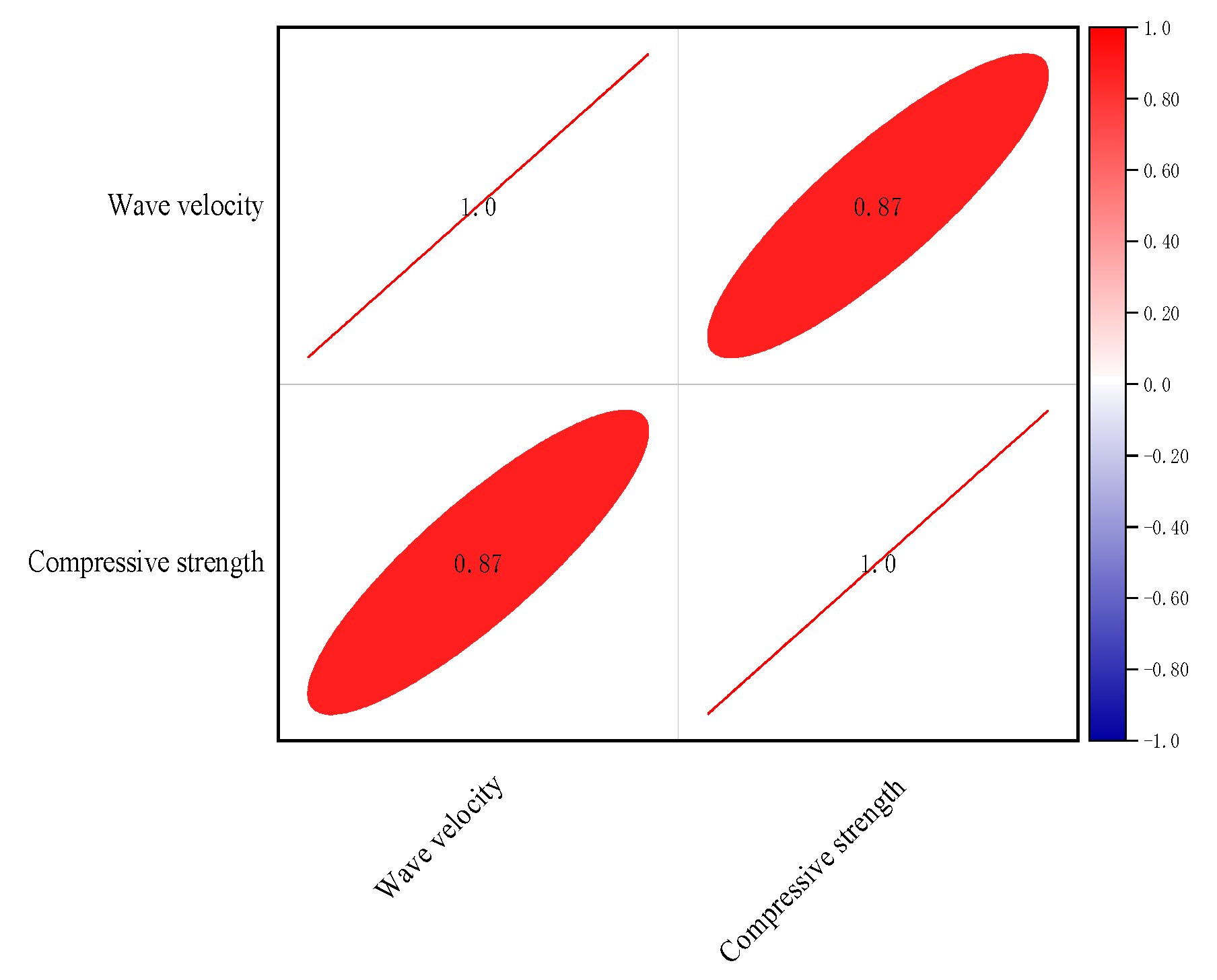

4.1. Correlation between Compressive Strength and P-Wave Velocity

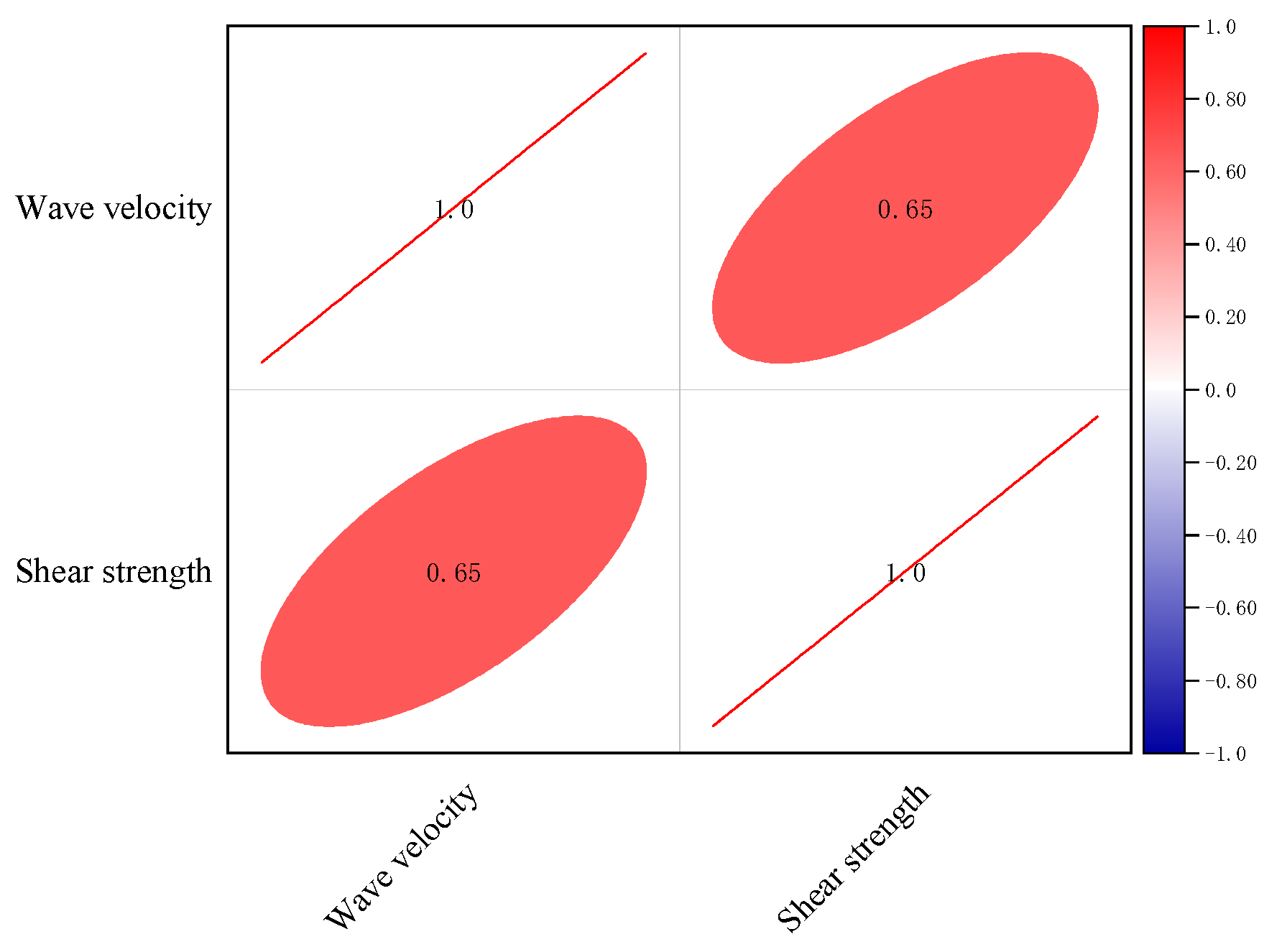

4.2. Correlation between Shear Strength and Ultrasonic P-Wave Velocity

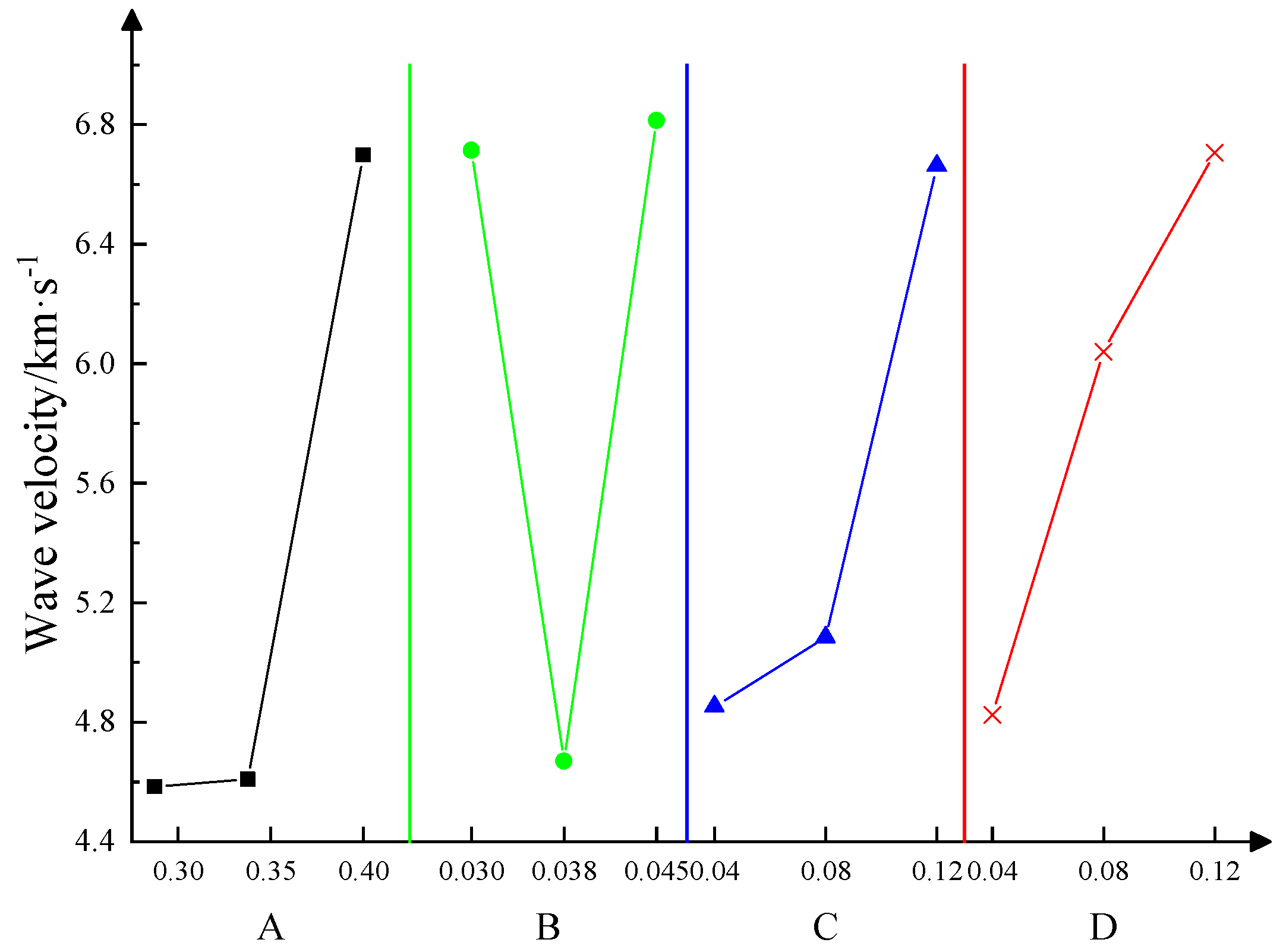

5. Influences of Mix Proportions of Materials on the Ultrasonic P-Wave Velocity

6. Parametric Analysis Model of Ultrasonic P-Wave Velocity

6.1. Variation of Characteristic Parameters under the Influences of Single Factors

6.2. Parametric Predictive Model

6.3. Establishment of the Predictive Model

6.4. Verification of the Synthetic Forecasting Model

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, D.D. Study and Application of Mechanical Properties of Coal Slime Foundation Pre-Filling Cement Materials. Master’s Thesis, Hunan University of Science and Technology, Xiangtan, China, 2022. [Google Scholar]

- Wang, X.J.; Zeng, J.; Qin, Y.H.; Li, C.L. Experimental study on filling mass measurement based on acoustic wave velocity. J. Sci. Technol. Eng. 2007, 23, 6180–6181+6186. [Google Scholar]

- Mu, G.C.; Deng, F.; Lai, Z.H. Study on the relationship between the strength of cemented backfill and ultrasonic wave velocity. J. Chem. Miner. Proc. 2020, 49, 1–3+53. [Google Scholar]

- Cheng, A.P.; Dong, F.S.; Zhang, Y.S.; Wang, P.; Dai, S.Y. Cemented filling body wave—Density double parameters strength prediction model the study. J. Metal Mine 2019, 517, 26–31. [Google Scholar]

- Ercikdi, B.; Yılmaz, T.; Külekci, G. Strengthand ultrasonic properties of cemented paste backfill. J. Ultrasonics 2014, 54, 195–204. [Google Scholar] [CrossRef] [PubMed]

- Gao, H.; Hao, W.X.; Li, L.; Wang, J.L.; Sun, J.H. Experimental study on working stress state detection of concrete by ultrasonic method. J. Build. Sci. 2017, 33, 94–99. [Google Scholar]

- Gao, H.; Hao, W.X.; Bi, C.K.; Sun, J.H. Experimental study on combined ultrasonic and acoustic emission characteristics of concrete under uniaxial loading. J. Agric. Univ. Hebei 2017, 40, 119–123. [Google Scholar]

- Xu, X.L.; Zhang, R.; Dai, F.; Yu, B.; Gao, M.Z. Experimental study on the influence of coal and rock characteristics on ultrasonic wave velocity. J. China Coal Soc. 2015, 40, 793–800. [Google Scholar]

- Li, S.H. Study on Strength and Acoustic Characteristics of Stratified Cemented Backfill. Master’s Thesis, Jiangxi University of Science and Technology, Ganzhou, China, 2021. [Google Scholar]

- Cheng, A.P.; Zhang, Y.S.; Dai, S.Y.; Dong, F.S. Ultrasonic wave velocity damage evolution test of cemented backfill. J. Metal Mine 2018, 507, 41–46. [Google Scholar]

- Yu, K.P.; Ren, F.Y.; Liu, D. Study on ultrasonic test and compressive strength test of cemented backfill. J. Min. Res. Dev. 2020, 40, 38–42. [Google Scholar]

- Yilmaz, T.; Ercikdi, B. Predicting the uniaxial compressive strength of cemented paste backfill from ultrasonic pulsevelocity test. J. Nondestruct. Test. Eval. 2016, 31, 247–266. [Google Scholar] [CrossRef]

- Trtnik, G.; Kavčič, F.; Turk, G. Prediction of concrete strength using ultrasonic pulse velocity and artificialneural networks. J. Ultrasonics 2009, 499, 53–60. [Google Scholar] [CrossRef] [PubMed]

- Wang, Q. Bearing Performance Characterization and Prediction of Lane Side Filling Concrete Based on Ultrasonic Wave. Master’s Thesis, Xi’an University of Science and Technology, Xi’an, China, 2022. [Google Scholar]

- Feng, G.R.; Li, Q.D.; Qi, T.Y.; Guo, Y.X.; Ran, H.Y. Evaluation of static anti-segregation performance of gangue by ultrasonic method. J. Min. Saf. Eng. 2019, 37, 1231–1237. [Google Scholar]

- Wu, J.Y. Macro and Micro Mechanical Properties and Creep Model of Cemented Backfill. Ph.D. Thesis, China University of Mining and Technology, Xuzhou, China, 2020. [Google Scholar]

- Xu, M.F.; Gao, Y.T.; Jin, A.B.; Zhou, Y.; Guo, L.J. Strength prediction of cemented backfill based on ultrasonic wave velocity and BP neural network. J. Chin. J. Eng. 2016, 38, 1059–1068. [Google Scholar]

- Chandrappa, A.K.; Biligiri, K.P. Influence of mix parameters on pore properties and modulus of pervious concrete: An application of ultrasonic pulse velocity. J. Mater. Struct. 2016, 49, 5255–5271. [Google Scholar] [CrossRef]

- Wang, X.P.; Liu, S.R.; Yang, J.J.; Wang, Z.Z.; Rong, H.; Zhang, L. Experimental study on the relationship between ultrasonic wave velocity and compressive strength of concrete. J. Concrete 2015, 12, 34–37. [Google Scholar]

- Cheng, Z.X.; Xu, Y.F.; Wang, Y.X. Development of the strength by ultrasonic method. J. Huazhong Univ. Sci. Technol. 2003, 20, 95–98. [Google Scholar]

- Zheng, B.C.; Zhou, H.Q.; He, R.J. Experimental study on the filling material of coal gangue paste. J. Min. Saf. Eng. 2006, 4, 460–463. [Google Scholar]

- Shi, J.W.; Wei, Z.J.; Liu, Q.L.; Li, Y.Y.; Chen, J.T. Study on the ratio optimization of filling materials for coal mine safety mining based on orthogonal test. J. Chin. J. Saf. Sci. 2011, 21, 111–115. [Google Scholar]

- Sun, Q.W.; Zhu, H.; Cui, Z.L. Study on the preparation and properties of fly ash-gangue based cement filling material. J. Chin. J. Saf. Sci. 2012, 22, 74–80. [Google Scholar]

- Si, Y.C. Research on resource utilization of coal slime in Binxian County. J. Chem. Eng. 2022, 36, 87–90. [Google Scholar]

- Wang, Q.F.; Xie, W.; Zheng, Y.Y. Effect of Composition on basic properties of high-water materials. J. Sichuan Build. Mater. 2016, 42, 3–4. [Google Scholar]

- Feng, G.M.; Ding, Y.; Zhu, H.J. Experimental study on ultra-high water filling material and its structure for mining. J. China Univ. Min. Technol. 2010, 39, 813–819. [Google Scholar]

- Feng, G.M. Research and Application of Ultra-High Water Filling Materials and Filling Mining. Ph.D. Thesis, China University of Mining and Technology, Xuzhou, China, 2009. [Google Scholar]

- Li, H.G.; Wang, J.; Liu, K. Study on the relationship between longitudinal wave velocity and mechanical properties of overlying rock in Shendong Mining area. J. Min. Res. Dev. 2023, 8, 113–119. [Google Scholar]

- Zhao, M.J.; Wu, D.L. Ultrasonic classification and strength prediction of engineering rock mass. Chin. J. Rock Mech. Eng. 2000, 1, 89–92. [Google Scholar]

- You, M.Q.; Su, C.D.; Li, X.S. Study on the relationship between mechanical properties of damaged rock samples and longitudinal wave velocity. Chin. J. Rock Mech. Eng. 2008, 3, 458–467. [Google Scholar]

| Cad | Had | Nad | St, ad | Oad |

|---|---|---|---|---|

| 38.29 | 2.88 | 0.25 | 0.20 | 8.03 |

| SiO2 | Al2O3 | CaO | Fe2O3 | K2O | MgO | Na2O | TiO2 |

|---|---|---|---|---|---|---|---|

| 59.68 | 17.58 | 2.37 | 4.10 | 1.96 | 1.18 | 1.22 | 1.51 |

| SiO2 | Al2O3 | Fe2O3 | SO3 | TiO2 | K2O | Na2O | CaO | MgO |

|---|---|---|---|---|---|---|---|---|

| 11.85 | 29.73 | 42.52 | 2.55 | 2.93 | 6.92 | 1.00 | 0.34 | 0.05 |

| CaO | Al2O3 | Fe2O3 | SO3 | SiO2 | MgO | K2O | Na2O |

|---|---|---|---|---|---|---|---|

| 31.32 | 1.34 | 0.50 | 37.05 | 4.42 | 2.97 | 0.26 | 0.08 |

| SiO2 | Al2O3 | Fe2O3 | CaO | MgO | SO3 | K2O | Na2O | TiO2 |

|---|---|---|---|---|---|---|---|---|

| 22.5 | 5.3 | 4.7 | 61.7 | 2.1 | 2.2 | 0.8 | 0.4 | 0.3 |

| SiO2 | Al2O3 | Fe2O3 | CaO | MgO | SO3 | K2O | Na2O | TiO2 |

|---|---|---|---|---|---|---|---|---|

| 55.8 | 22.1 | 11.9 | 3.4 | 2.3 | 3.2 | 0.6 | 0.3 | 0.4 |

| Levels | A. Mass Concentration of Coal Slime (A) | B. Content of High-Water-Content Material (B/A) | C. Cement Content (C/A) | D. Content of Fly Ash (D/A) |

|---|---|---|---|---|

| 1 | 0.4000 | 0.0300 | 0.04 | 0.04 |

| 2 | 0.3375 | 0.0375 | 0.08 | 0.08 |

| 3 | 0.2875 | 0.0450 | 0.12 | 0.12 |

| Measurement point spacing (mm) | 70.7 | Sampling period (us) | 0.50 |

| Distance measurement increment (mm) | 0 | Zero sound correction (us) | 12.50 |

| Emission voltage (V) | 500 | Aggregate | none |

| Test surface | Side | Ultrasonic frequency (Hz) | 50 K |

| Test Groups | Influencing Factors | Test Results | |||||

|---|---|---|---|---|---|---|---|

| A | B | C | D | Wave Velocity/km·s−1 | Compressive Strength/MPa | Shear Strength/MPa | |

| 1 | 0.400 | 0.0300 | 0.04 | 0.04 | 5.992 | 0.107 | 0.056 |

| 2 | 0.400 | 0.0375 | 0.08 | 0.08 | 5.783 | 0.161 | 0.095 |

| 3 | 0.400 | 0.0450 | 0.12 | 0.12 | 8.319 | 0.234 | 0.369 |

| 4 | 0.3375 | 0.0300 | 0.08 | 0.12 | 5.205 | 0.247 | 0.109 |

| 5 | 0.3375 | 0.0375 | 0.12 | 0.04 | 3.916 | 0.086 | 0.043 |

| 6 | 0.3375 | 0.0450 | 0.04 | 0.08 | 4.706 | 0.076 | 0.052 |

| 7 | 0.2875 | 0.0300 | 0.12 | 0.08 | 5.741 | 0.115 | 0.139 |

| 8 | 0.2875 | 0.0375 | 0.04 | 0.12 | 3.936 | 0.102 | 0.036 |

| 9 | 0.2875 | 0.0450 | 0.08 | 0.04 | 4.076 | 0.105 | 0.033 |

| Factor | Ultrasonic P-Wave Velocity/km·s−1 | |||

|---|---|---|---|---|

| A | B | C | D | |

| k1 | 6.698 | 5.646 | 4.878 | 4.661 |

| k2 | 4.609 | 4.545 | 5.021 | 5.410 |

| k3 | 4.584 | 5.700 | 5.992 | 5.820 |

| R | 2.114 | 1.155 | 1.114 | 1.159 |

| Source of Variation | Sum of Squared Deviations | Degree of Freedom | Variance | F-Value | Fα 2 | Significant Level |

|---|---|---|---|---|---|---|

| A | 8.8312 | 2 | 4.4156 | 3.884 | F0.01(2,6) = 10.925 F0.05(2,6) = 5.143 F0.1(2,6) = 3.463 F0.25(2,6) = 1.762 | 1* |

| B | 2.5488 | 2 | 1.2744 | |||

| C | 2.2027 | 2 | 1.1013 | |||

| Error e | 2.0701 | 2 | 1.0351 | |||

| Correction error e | 6.8216 | 6 | 1.1369 | |||

| Sum | 15.653 |

| Factor | Index | Fit Relation | General Formula | Degree of Fit R2 |

|---|---|---|---|---|

| Mass concentration of coal slime(PA) | Wave velocity | 0.99 | ||

| High-water content(PB) | Wave velocity | 0.99 | ||

| Cement content(PC) | Wave velocity | 0.99 | ||

| Fly ash content(PD) | Wave velocity | 0.99 |

| The Specimen Number | A. Mass Concentration of Coal Slime | B. Content of High-Water-Content Material | C. Cement Content | D. Content of Fly Ash |

|---|---|---|---|---|

| C1 | 0.35 | 0.037 | 0.06 | 0.10 |

| C2 | 0.31 | 0.039 | 0.07 | 0.11 |

| C3 | 0.32 | 0.041 | 0.10 | 0.05 |

| The Specimen Number | Materials | Wave Velocity/km·s−1 |

|---|---|---|

| C1 | Predicted value | 4.133 |

| Experimental value | 4.324 | |

| Error/% | 4.413% | |

| C2 | Predicted value | 3.965 |

| Experimental value | 4.231 | |

| Error/% | 6.270% | |

| C3 | Predicted value | 3.891 |

| Experimental value | 4.051 | |

| Error/% | 3.950% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

An, B.; Cui, C.; Ren, J.; Wang, D.; Wang, J.; Yi, Q. Experimental Research into the Ultrasonic P-Wave Velocity of Coal Slime Based Backfill Material. Appl. Sci. 2023, 13, 11043. https://doi.org/10.3390/app131911043

An B, Cui C, Ren J, Wang D, Wang J, Yi Q. Experimental Research into the Ultrasonic P-Wave Velocity of Coal Slime Based Backfill Material. Applied Sciences. 2023; 13(19):11043. https://doi.org/10.3390/app131911043

Chicago/Turabian StyleAn, Baifu, Chenghao Cui, Jinfang Ren, Dongda Wang, Jiale Wang, and Qiaomei Yi. 2023. "Experimental Research into the Ultrasonic P-Wave Velocity of Coal Slime Based Backfill Material" Applied Sciences 13, no. 19: 11043. https://doi.org/10.3390/app131911043

APA StyleAn, B., Cui, C., Ren, J., Wang, D., Wang, J., & Yi, Q. (2023). Experimental Research into the Ultrasonic P-Wave Velocity of Coal Slime Based Backfill Material. Applied Sciences, 13(19), 11043. https://doi.org/10.3390/app131911043