Abstract

Non-abrasive iron-based grinding diamond wheels, lacking abrasive particles, negate the concern of detached passivated abrasives scratching the polished surface. During the Electrolytic In-Process Dressing (ELID) polishing process, α-Fe2O3 particles form on the oxide film surface of the iron-based grinding diamond wheel devoid of abrasives. These particles assume the role of the grinding diamond wheel for polishing. Therefore, the ELID electrolytic performance and the oxide film formation performance of the non-abrasive iron-based grinding diamond wheel significantly influence the formation of α-Fe2O3 particles and the subsequent ELID polishing performance. Our studies investigating the ELID dressing behavior of the non-abrasive iron-based grinding diamond wheel have analyzed the influence mechanism of the electric field, flow field, and pulse energy on its ELID dressing. Moreover, the roundness of the ELID dressing grinding diamond wheel, oxide film properties, and α-Fe2O3 particle content were measured, and plate glass was polished using the ELID non-abrasive iron-based grinding diamond wheel. The results illustrate that the non-abrasive iron-based grinding diamond wheel exhibits excellent ELID dressing performance. The diamond wheel’s roundness is less than 0.001 mm, the oxide film uniformly covers the surface, the content of α-Fe2O3 particles is evenly distributed, and the surface accuracy of the polished plate glass is approximately 0.5 nm. These findings provide a compelling case for the continued use and development of grainless iron-based grinding diamond wheels in precision grinding operations.

1. Introduction

As early as the 1980s, cast-iron-bonded grinding diamond wheels with micro-scaled powders were innovatively fabricated by T. Nakagawa [1,2,3]. However, due to their small pores, which were easily blocked and caused passivation, these fine-grain, cast-iron-bonded grinding diamond wheels proved difficult to popularize and apply in common grinding processes of that era [4,5,6,7]. To address the issue of abrasive passivation, significant progress has been made in achieving nano-level surface quality by applying the ELID grinding method to sharpen the abrasives (H.Ohmori). As a result, Electrolytic In-Process Dressing (ELID) grinding is gaining increasing attention in the field of ultra-precision machining [8,9,10].

Though conducted at the nanoscopic scale, ELID grinding often results in deep scratches on finely ground surfaces. Even a minor scratch on a highly precise nanoscale surface can be catastrophic or irreparable. Researchers have identified a root cause of these surface scratches. They found that passivated abrasive particles detach and fall into the electrolyte. When this electrolyte participates in the grinding processes, these abrasive particles cause secondary scratches on the surfaces, leading to defects.

In recent years, innovative diamond wheel designs have been proposed to supersede traditional hard cast-iron-bonded diamond wheels [11], including porous metal-bonded grinding diamond wheels [12,13,14,15], iron–resin-bonded diamond wheels [16,17,18,19], conductive rubber diamond wheels [20,21,22,23], and plant–carbon-bonded grinding diamond wheels [24,25,26,27], multi-layer brazed coarse-grained diamond wheel [28,29,30]. Researchers have also combined PELID and 3D printing techniques to manufacture new grinding diamond wheels [31,32,33]. These advanced bonded diamond wheels are effective in achieving higher surface quality and broadening the application fields for ELID grinding due to their ability to attain higher grain density and avoid agglomeration compared to the traditional sintering technique. Indeed, these new grinding diamond wheels mitigate the scratches on finely ground surfaces, but they do not eliminate all scratches.

Although significant progress has been made in achieving high precision and high-quality machining surfaces in ELID grinding, avoiding secondary scratches caused by passivated abrasive particles remains a challenge. This paper introduces a novel iron-based grinding diamond wheel devoid of abrasive particles. This non-abrasive particle diamond wheel is manufactured to form an iron oxide film as the primary component on the surface through the ELID electrolysis process [34]. Notably, the oxide film generates α-Fe2O3 on the surface of the iron-based grinding diamond wheels via an electrochemical reaction under high grinding temperatures. Large quantities of α-Fe2O3 particles are favorable, serving as an excellent agent for polishing in place of abrasive particles. Due to the absence of abrasive particles, our new diamond wheels address the issue of passivating particles that may detach and scratch the processed surface [35,36].

The non-abrasive iron-based grinding diamond wheel introduced in this study represents an initial development, making it crucial to understand its electrolysis process, oxidation film formation, and oxide film performance. We examine the impact of the oxide film’s characteristics and its composition, properties, iron group content, and α-Fe2O3 particle conversion on the polishing performance of ELID. Our focus is on the electrolysis mechanism of the non-abrasive iron-based grinding diamond wheel, discussing the decisive factors that differentiate non-abrasive diamond wheels from other iron-based grinding diamond wheels. The mechanical properties of the oxide film were tested by polishing plate glass using the electrolyzed, non-abrasive iron-based grinding wheel. The polished surface of the plate glass was measured and compared with the polishing results obtained using abrasive iron-based grinding wheels.

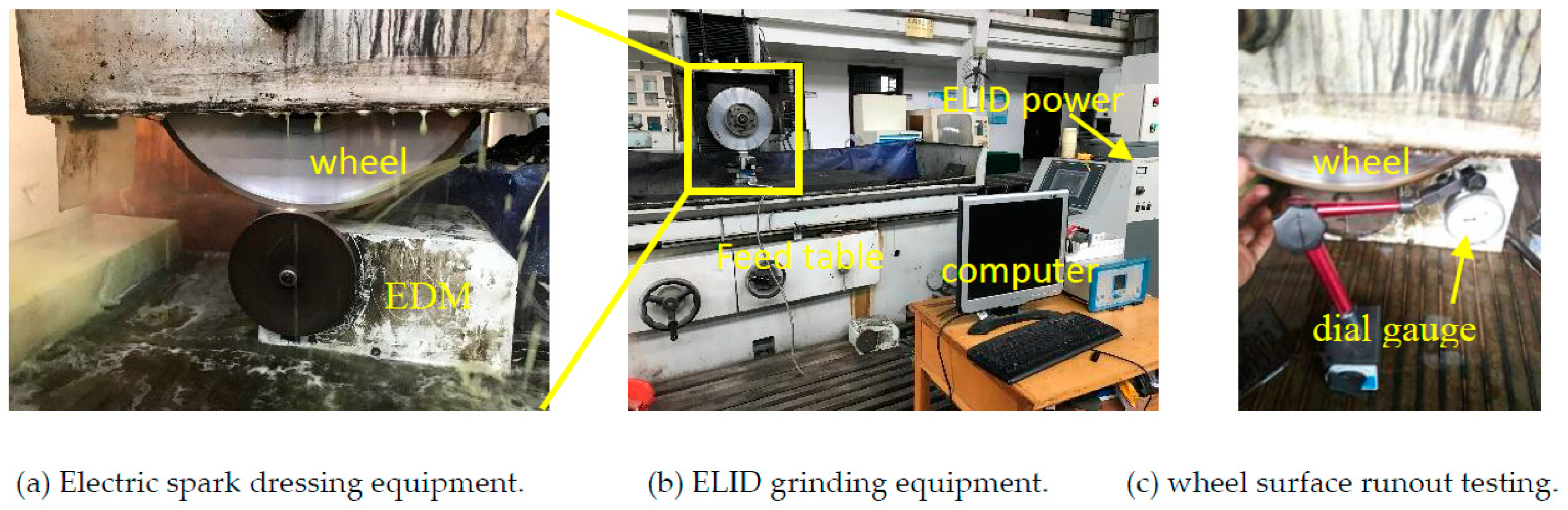

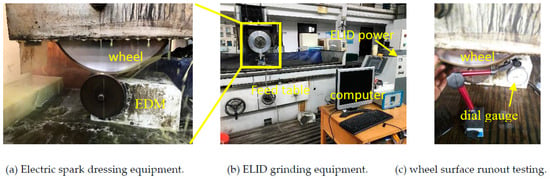

2. Experimental Setup

We have employed a surface grinding machine, the MM7140 (Hangzhou Machine Tool Factory, Zhejiang, China), equipped with an ELID electrolysis system. The homemade electrolyte used is of the HDMY-50 type, diluted at a ratio of 1:50, to implement the Electric Discharge Machining (EDM) dressing of the non-abrasive iron-based grinding diamond wheel. The selected abrasive wheel is a W1.5 iron-based bond diamond wheel with a particle size of 1.5 μm and a concentration of 100%. The non-abrasive wheel consists of 60–80% α-Fe powder, 10–30% copper powder, 1–10% tin powder, 1–10% nickel powder, and 1–10% graphite. Bumps on the grinding diamond wheel, located near the EDM dressing cathode, were preferentially removed. The uniform distribution of electric sparks across the diamond wheel’s circumference indicated that the grinding diamond wheel was dressed uniformly. The circumference of the grinding diamond wheel post-EDM dressing ranged within 0.001 mm, as measured by a dial gauge. Grinding equipment is as shown in Figure 1. (1) Firstly, place the EDM spark erosion shaping system on the workbench and adjust the discharge gap between the grinding wheel and the EDM electrode to 0.5–1 mm. Allow the grinding wheel to uniformly discharge along its entire circumference. This indicates the completion of the grinding wheel EDM spark shaping. (2) Secondly, affix a dial indicator to the workbench, align the pointer with the surface of the grinding wheel, and rotate the grinding wheel. Measure the roundness of the grinding wheel after EDM spark shaping and transfer the roundness data to the computer for storage. (3) Lastly, connect the grinding wheel to the ELID (Electrolytic In-Process Dressing) power supply for electrolysis. After electrolyzing for 50–100 min, follow step (2) to measure the roundness of the grinding wheel. After the grinding process, the mechanical properties of the oxide layer on the non-abrasive iron-based grinding diamond wheels are measured using a nanoindentation instrument. CSM instrument (Swiss CSM Instrument Company, Geneva, Switzerland), SA UNHT-type ultra-nanoindentation instrument with a displacement resolution of 0.01 nm, a maximum indentation depth of 500 μm, a maximum load of 500 mN, and a load resolution of 50 nN. It used a Berkovich diamond indenter. The experiment was conducted in an ultra-clean environment with a cleanliness level of 10,000, with the ambient atmosphere being air and the temperature maintained at 24 ± 0.5 °C. The approach distance ranged from 1000 nm to 0.01 mm, with an approach speed of 2500 nm/min and a retract speed of 2000 nm/min. The loading time was 30 s, the unloading time was 30 s, and there was a 5 s pause between tests. The test was repeated 5 times, and the mechanical properties were calculated using the Oliver and Pharr method.

Figure 1.

ELID grinding equipment, electric spark dressing, and runout measurement.

ELID pre-electrolysis was conducted on the non-abrasive iron-based grinding diamond wheel for 50–100 min to observe the formation of the oxide film on the surface. When the electric current was maintained under 1–2 A, and the oxide film was uniformly generated, it signified that the ELID electrolysis of the grinding diamond wheel was complete. The roundness of the grinding diamond wheel following the electrolytic process should be less than 0.001 mm. Plate glass manufactured by China Luoyang Float Glass Group Co., Ltd., Luoyang, China, was ground using electroplated abrasive wheels, including abrasive W1.5 iron-based wheels and non-abrasive iron-based wheels. The grinding parameters were as follows: wheel speed at 1500 rpm, grinding depth ranging from 0.001 to 0.01 mm, and a feed rate between 200 and 350 mm/min. Surface roughness and microstructure were measured using an atomic force microscope, and a comparison was made between the two. The atomic force microscope is a Veeco Corporation’s model multimode nanoscope 3a, operating in contact mode with a contact-based measurement method.

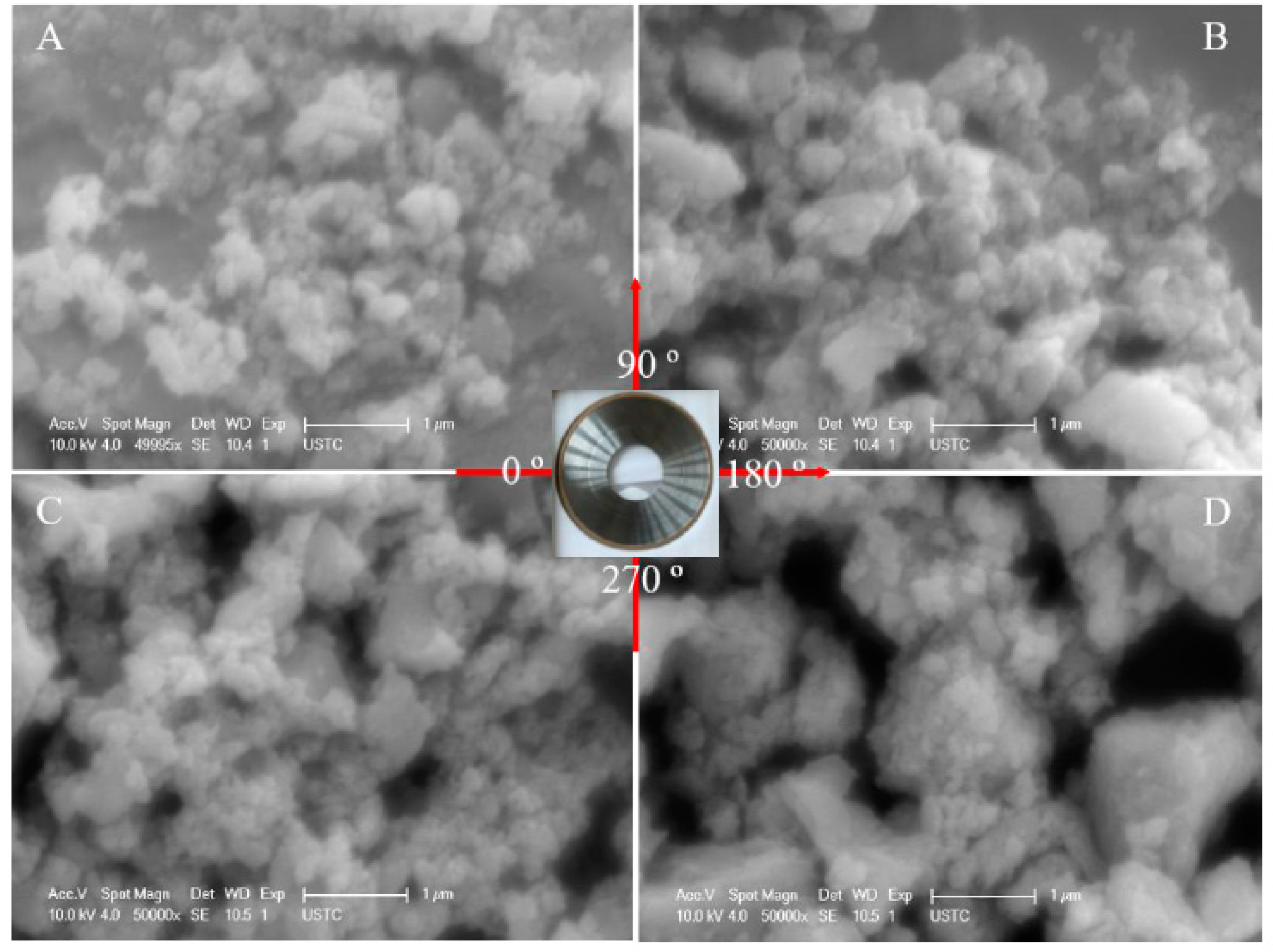

A SEM microscope (NoVaTM Nano SEM 250, FEI Company, Hillsboro, OR, USA) was utilized in the experiment to measure the morphology and distribution of the oxide film on different parts of the grinding diamond wheel (0°, 90°, 180°, and 270°, respectively). The scanning electron microscope is of SEM model NoVaTM Nano SEM 430. The experimental conditions are detailed in Table 1.

Table 1.

ELID dressing conditions.

3. Results

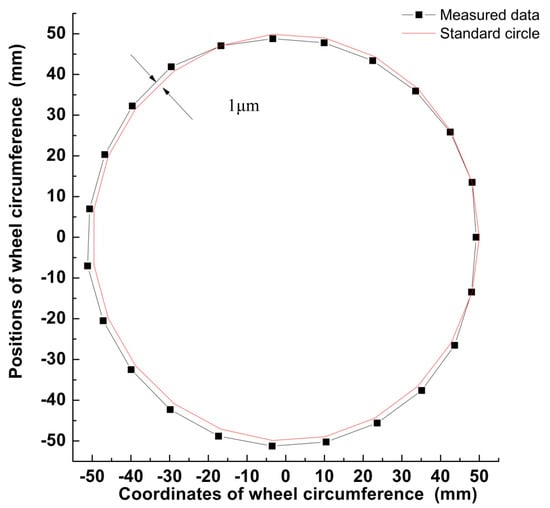

3.1. Roundness of Grinding Diamond Wheels

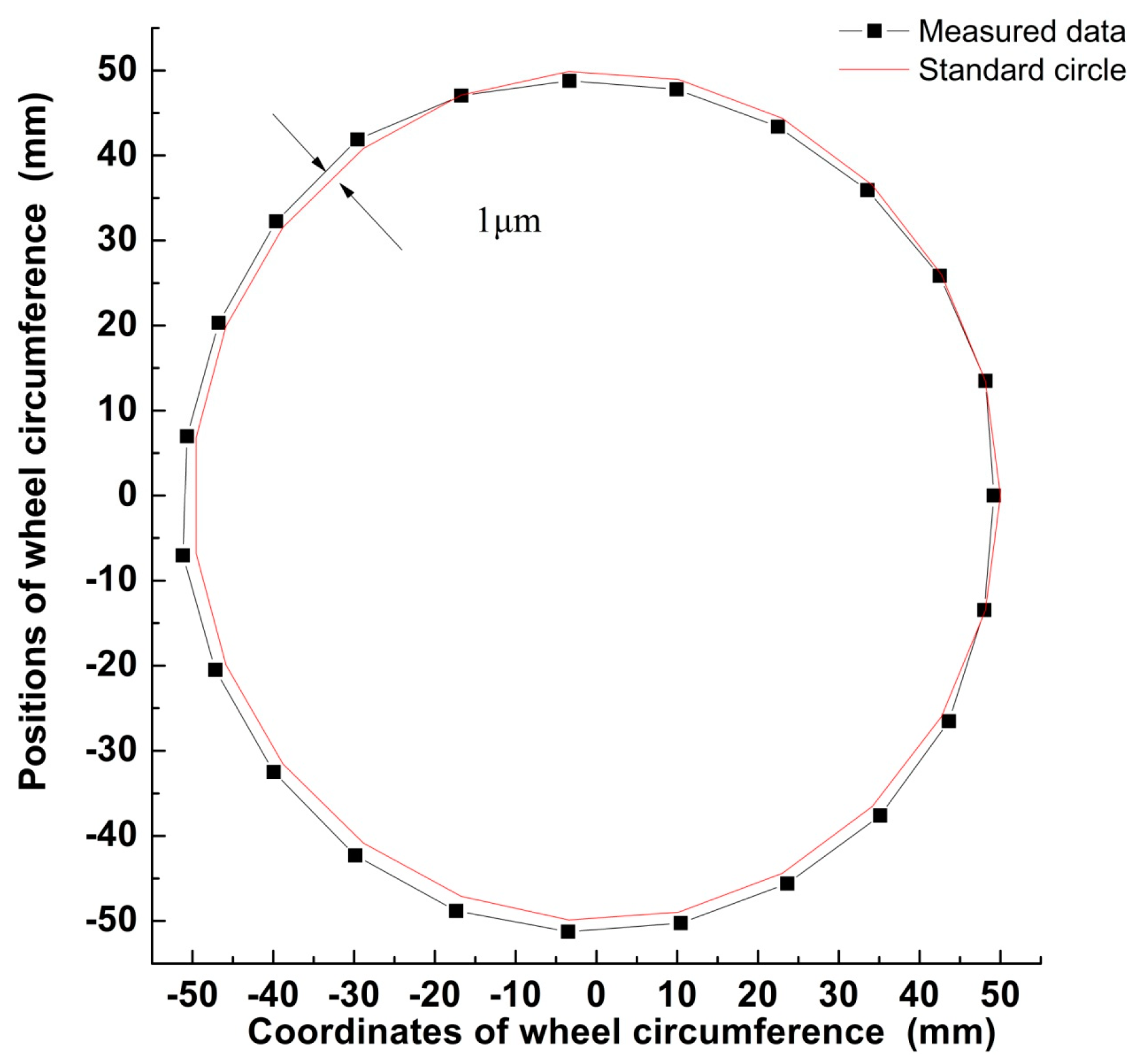

The diamond wheel’s roundness is of paramount importance, as it directly influences the grinding system’s runout. Therefore, maintaining the grinding diamond wheel’s roundness within a specified limit of 0.001 mm is crucial. Typically, the iron-based grinding diamond wheel is shaped using electric spark trimming. This technique makes use of pulse energy to erode non-round convex points on the diamond wheel’s surface. As a result, the surface of the grinding diamond wheel progressively approximates a standard circle. This process not only refines the diamond wheel’s shape but also significantly enhances the precision and effectiveness of the grinding process. By ensuring the exactness of the diamond wheel’s roundness, the grinding system can perform more efficiently, providing higher accuracy in the final product.

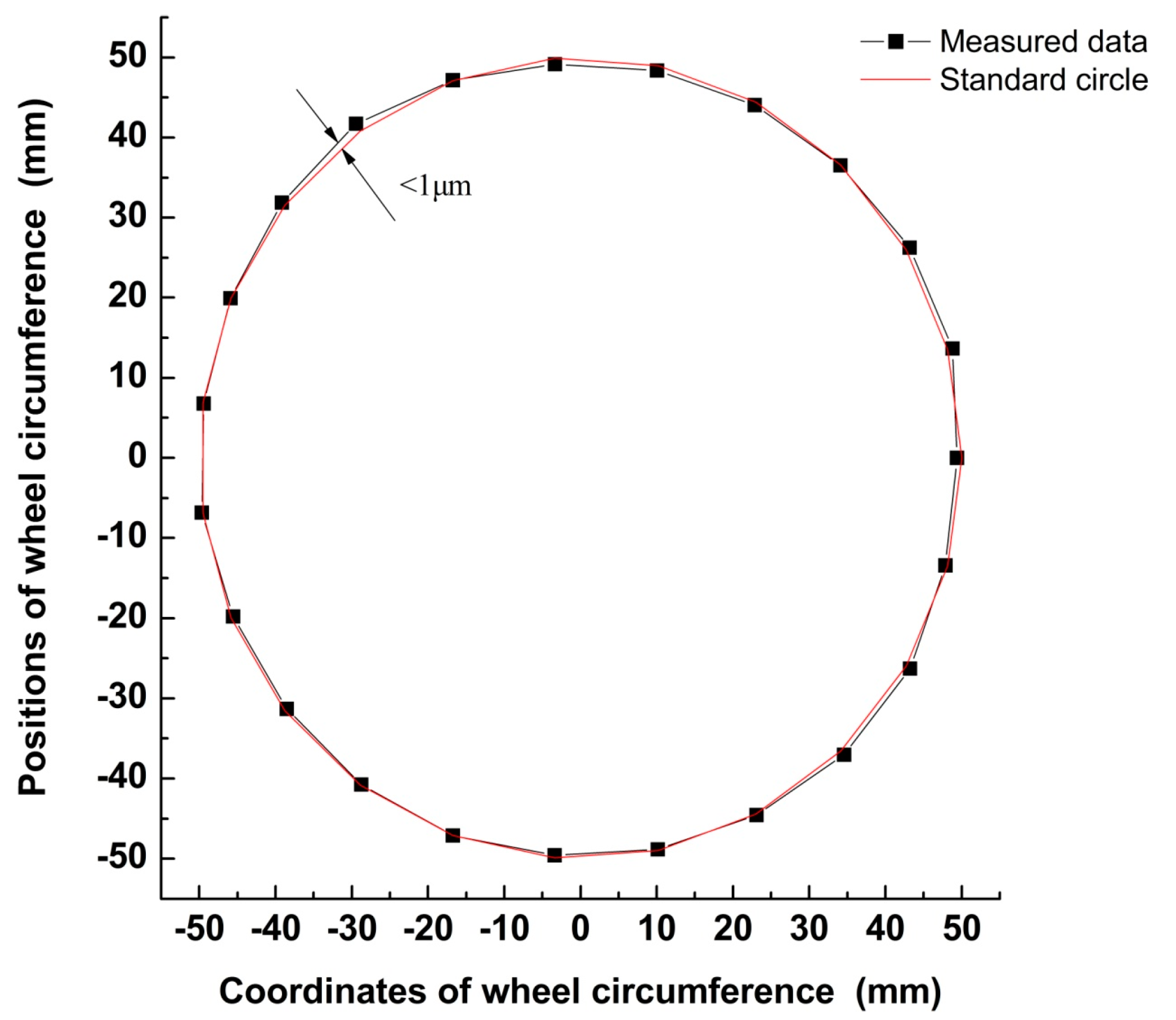

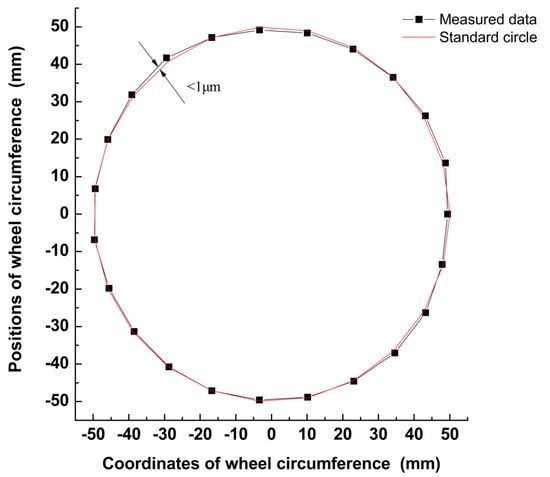

The non-abrasive iron-based grinding diamond wheel exhibits a roundness of approximately 0.001 mm following EDM dressing (shown in Figure 2). However, Figure 3 demonstrates that the roundness of the grinding diamond wheel was further refined to less than 0.001 mm post-ELID electrolytic dressing. Notably, during the ELID electrolytic dressing process, the bumps on the diamond wheel were preferentially subjected to electrolysis following EDM dressing. This resulted in the grinding diamond wheel surface approximating a standard circle. Therefore, our experimental study suggests that ELID electrolytic dressing can enhance the accuracy achieved by EDM dressing.

Figure 2.

Roundness of non-abrasive wheels after EDM dressing.

Figure 3.

Roundness of non-abrasive wheels after ELID electrolytic dressing.

3.2. Electrolytic Uniformity

In the context of ELID electrolysis, the grinding diamond wheel’s roundness is heavily impacted by the uniformity of the oxide film generated on the diamond wheel’s surface post-trimming by an electric spark. An uneven distribution of the oxide film can easily compromise the roundness of the grinding diamond wheel. As such, ensuring the uniformity of ELID electrolysis on the grinding diamond wheel is of critical importance [37,38,39,40,41].

Bader Alqahtani conducted a study investigating the effects of voltage, electrode gap, and electrolyte flow rate on the oxide film’s uniformity. The research revealed that the oxide film distribution on the grinding diamond wheel surface was far from uniform, being more concentrated at the edge, reaching up to 140 μm, and less so in the middle, peaking at 50 μm. This uneven distribution is believed to be caused by factors such as an inconsistent power supply voltage, irregular electrolyte erosion, and non-uniform electrode gaps. It is, therefore, evident that the irregular distribution of the oxide film resulting from uneven electrolysis can lead to significant roundness errors in the grinding diamond wheel, with deviations reaching as high as 90 μm [42].

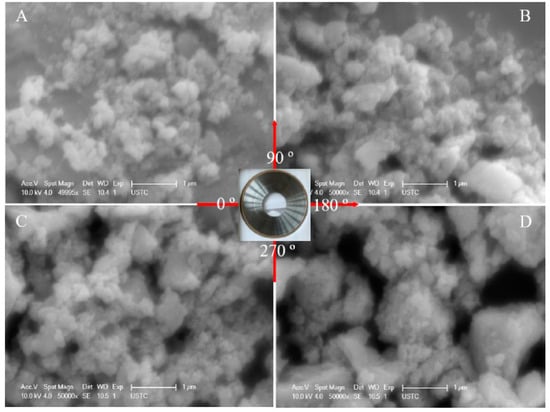

Under stable micro-second pulses, the oxide films were uniformly formed by the electrolysis process. The current of each pulse remained consistent, and the pulse energy was uniformly distributed. With an optimal circumferential speed of grinding, the uniformity of the oxide film was further enhanced. The morphology of the oxide film on the diamond wheel surface following ELID electrolysis is depicted in Figure 4, captured using SEM microscopy. As evident from Figure 4, the distribution of oxide particles across the entire circumference of the diamond wheel (the testing positions are at 0°, 90°, 180°, and 270° on the surface of the grinding wheel, respectively) fell within the expected range and covered the diamond wheel’s surface evenly, satisfying the uniformity requirements for oxide films post-electrolytic process.

Figure 4.

SEM micrographs of oxide films on non-abrasive grinding wheel surfaces distributed around the circumference: (A) 0°, (B) 90°, (C) 180°, and (D) 270°.

3.3. α-Fe2O3 Particle Content in Oxide Films

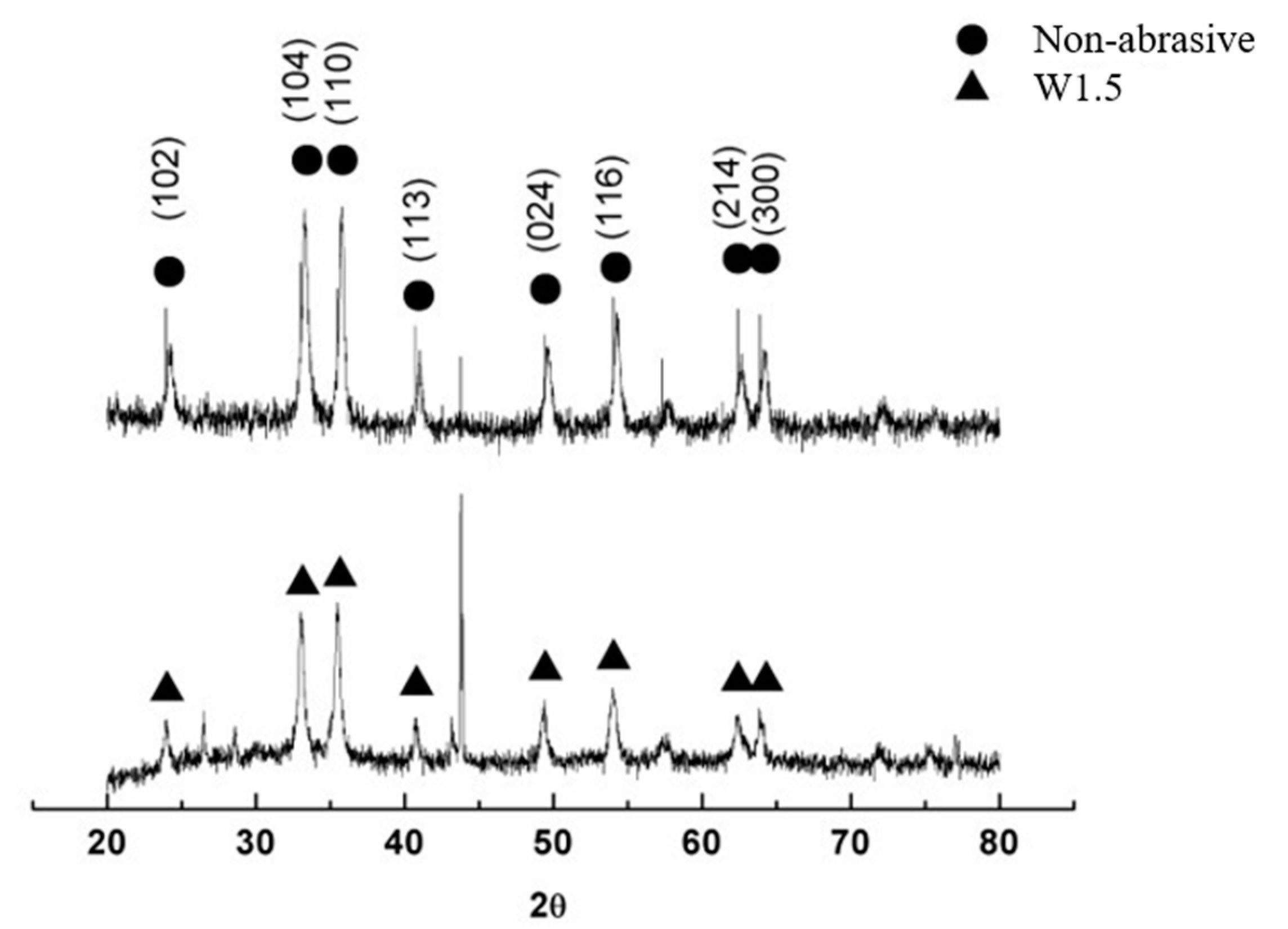

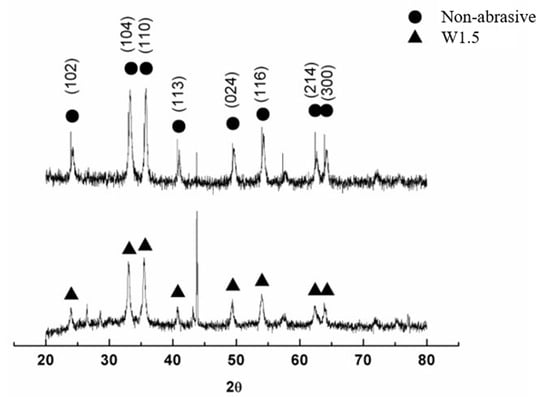

After drying the grinding diamond wheels, oxide film powders were collected from their surfaces. The grinding contact zone temperature was simulated using an XRD temperature (Bruker D8 Advance, Brucker AG, Berlin, Germany) variable tester to analyze the content of α-Fe2O3 particles. The α-Fe2O3 particle contents in oxide films on both the W1.5 iron-based grinding diamond wheel (with a particle size of 1.5 μm) and the non-abrasive particle diamond wheel were measured using XRD diffractometry, as depicted in Figure 5.

Figure 5.

Content of α-Fe2O3 particles in oxide films for non-abrasive iron-based wheel and W1.5 wheel.

As observed from Figure 5, the diffraction peak intensity of α-Fe2O3 on the non-abrasive iron-based grinding diamond wheel is approximately 1–2 times greater than that of the W1.5 iron-based grinding diamond wheel. A qualitative estimation suggests that the α-Fe2O3 content on the non-abrasive grinding diamond wheel is 1–2 times higher than on the W1.5 iron-based grinding diamond wheel. These results indicate that the non-abrasive grinding diamond wheel surface contains more α-Fe2O3 particles, making it better suited for ELID polishing.

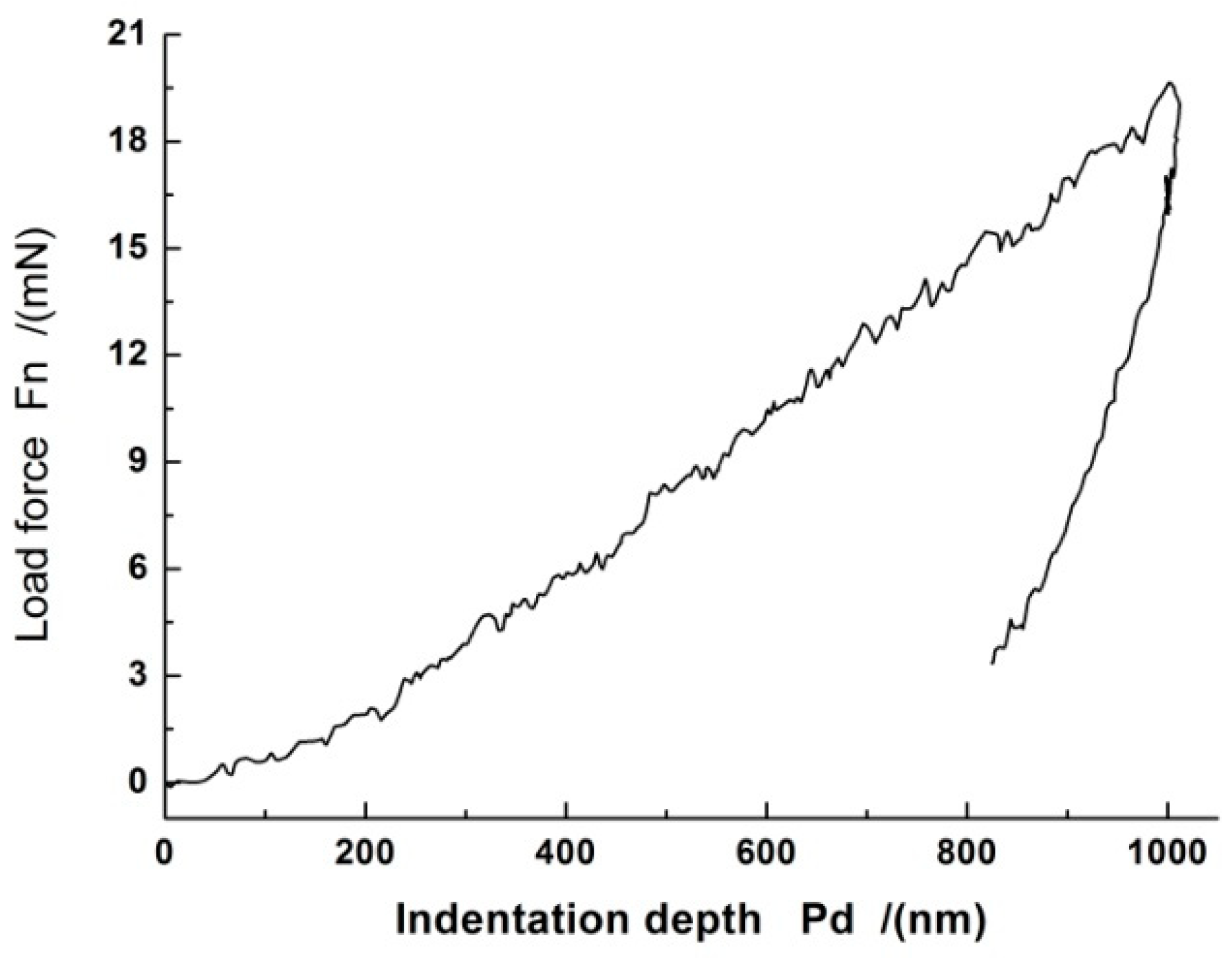

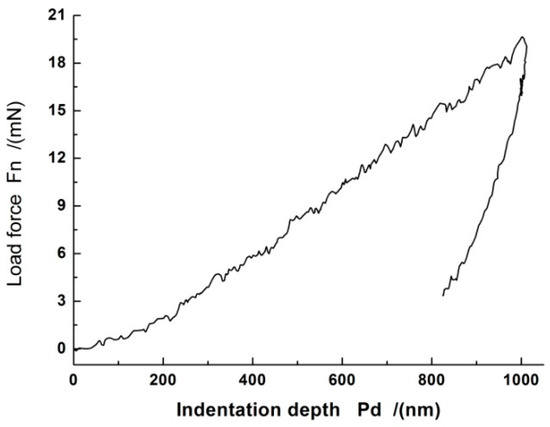

3.4. Mechanical Properties of Oxide Layer

The oxide layer covering the surface of the iron-based grinding diamond wheel after electrolysis, which lacks abrasive particles, mainly consists of various iron oxide compounds. On the other hand, the oxide layer generated after electrolysis of the iron-based grinding diamond wheel with abrasive particles contains these abrasive particles. Therefore, the mechanical properties of the oxide layer on the non-abrasive iron-based grinding diamond wheels are expected to differ from those of the oxide layer on the iron-based grinding diamond wheel with abrasive particles. To address this, the mechanical properties of the oxide layer on the iron-based grinding diamond wheel without abrasive particles were measured using a nanoindentation instrument. The measurement range was set at 0.001 mm to 0.01 mm for displacement, with a loading rate of 2500 nm/min. The load–displacement curve is presented in Figure 6. Figure 6 shows the load–displacement curve for a nanohardness test with a displacement of 0.001 mm. As seen in Figure 6, at the maximum displacement of 0.001 mm, the maximum load is 21 mN. The load–displacement curve exhibits several small fluctuations, indicating localized collapse of the oxide film during deformation, which is attributed to the porous and loose structure of the oxide film. The trends of the load–displacement curves for the remaining displacements (maximum displacements of 0.002, 0.005, and 0.01 mm) are consistent.

Figure 6.

Load–displacement curve from nanoindentation testing of the oxide layer on the iron-based grinding wheel without abrasive particles.

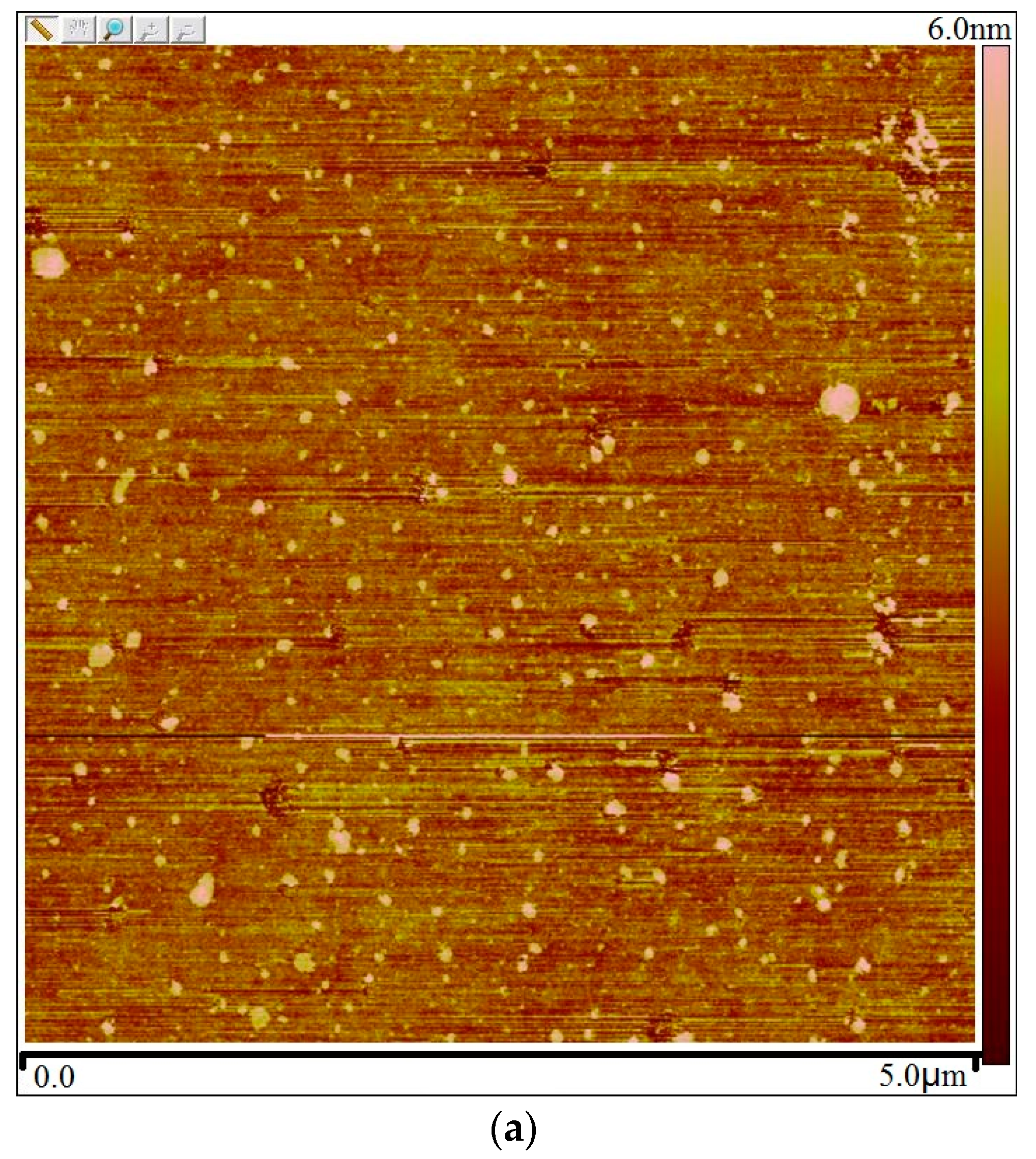

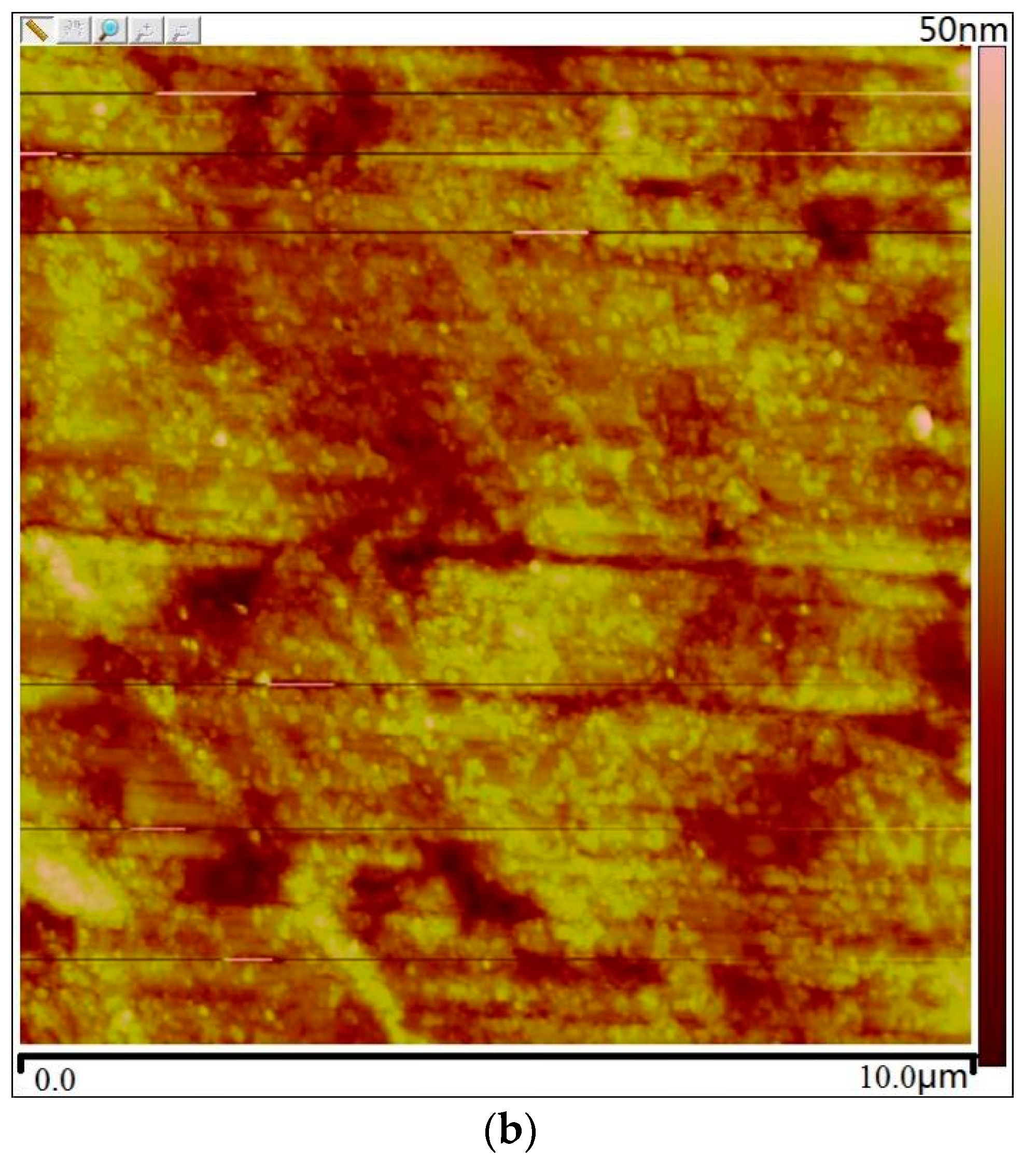

3.5. Polishing Experiments of Plate Glass

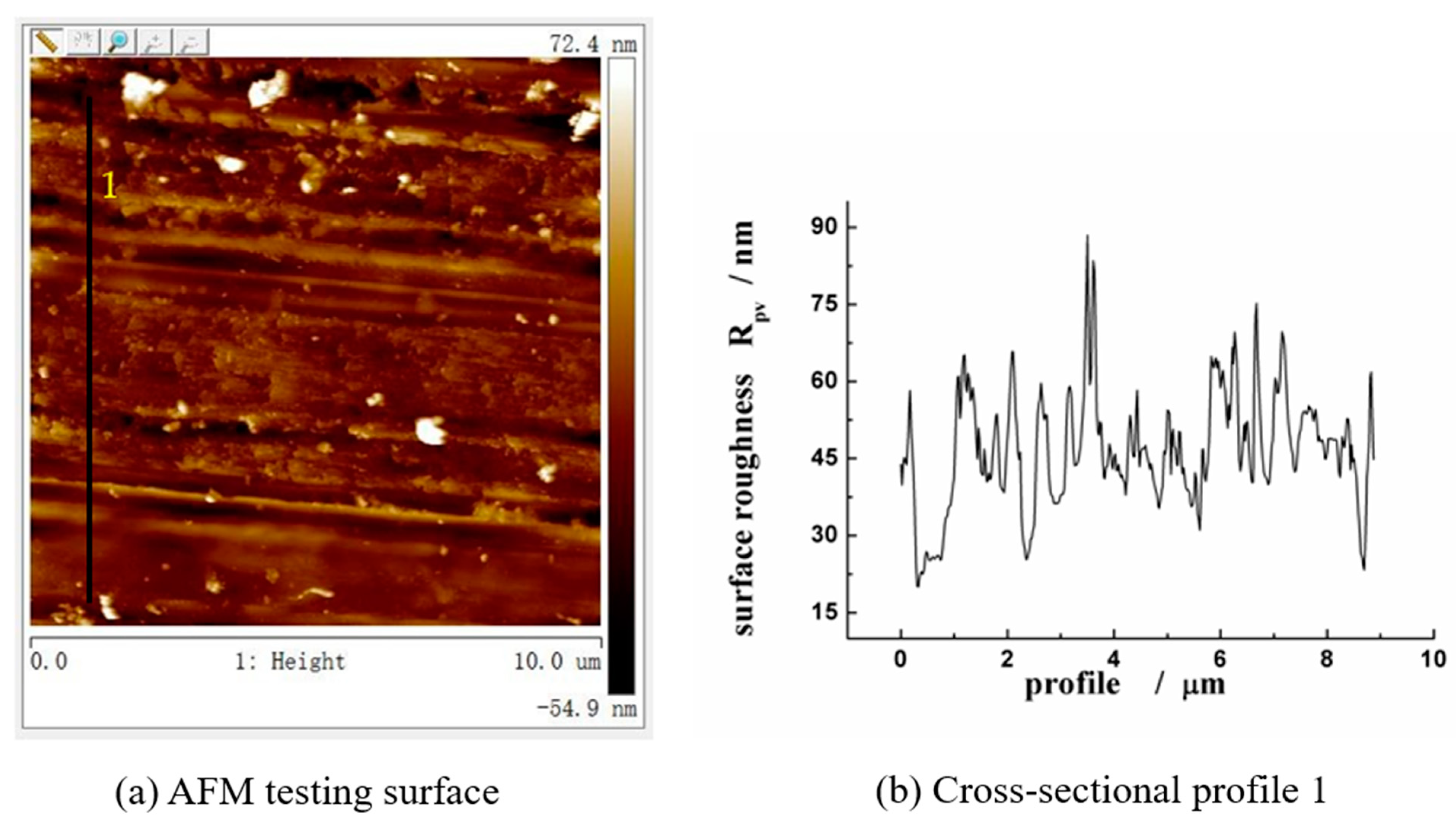

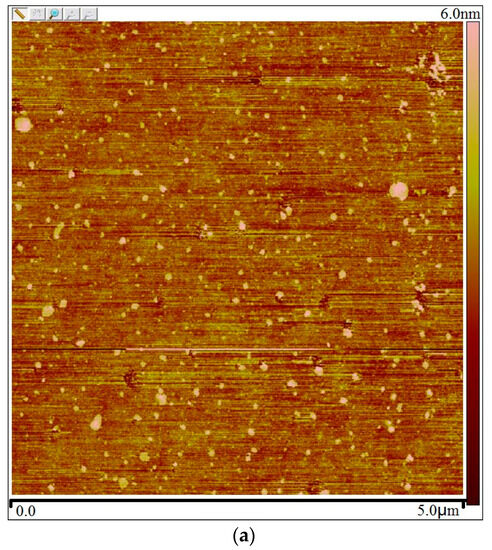

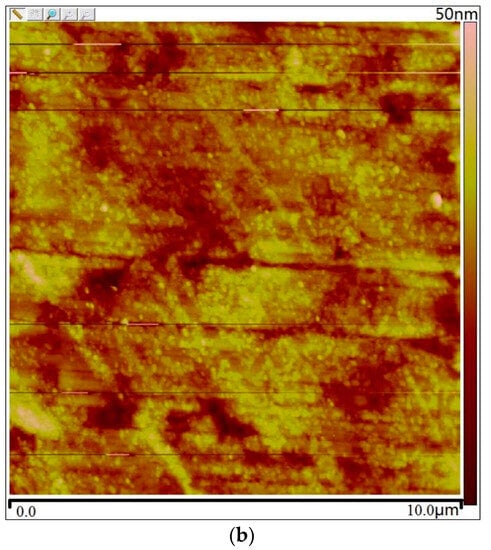

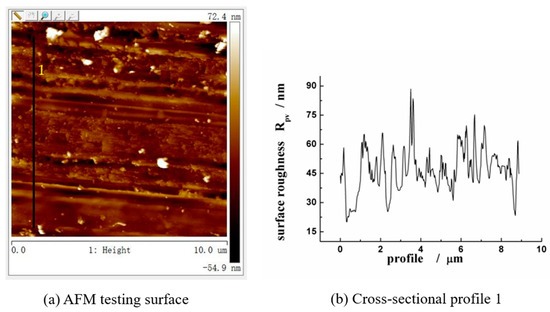

The ELID dressing technique was employed to polish plate glass using non-abrasive and W1.5 iron-based grinding diamond wheels. Subsequent evaluation of the polished surface was conducted using an atomic force microscope, as depicted in Figure 7a,b. In Figure 7a, within the parameters of the test range, no discernible scratches were identified, and the surface roughness, quantified as Ra, was a mere 0.5 nm. In Figure 7b, the discernible scratches were identified, and the surface roughness was Ra4.89 nm. It was conclusively demonstrated that the non-abrasive iron-based ELID grinding diamond wheel was capable of yielding superior polishing results.

Figure 7.

Surface morphology of a plate glass after ELID dressing measured by AFM. (a) AFM photo of plate glass by ELID grinding with non-abrasive wheel. (b) AFM photo of plate glass by ELID grinding with W1.5 wheel.

4. Discussion

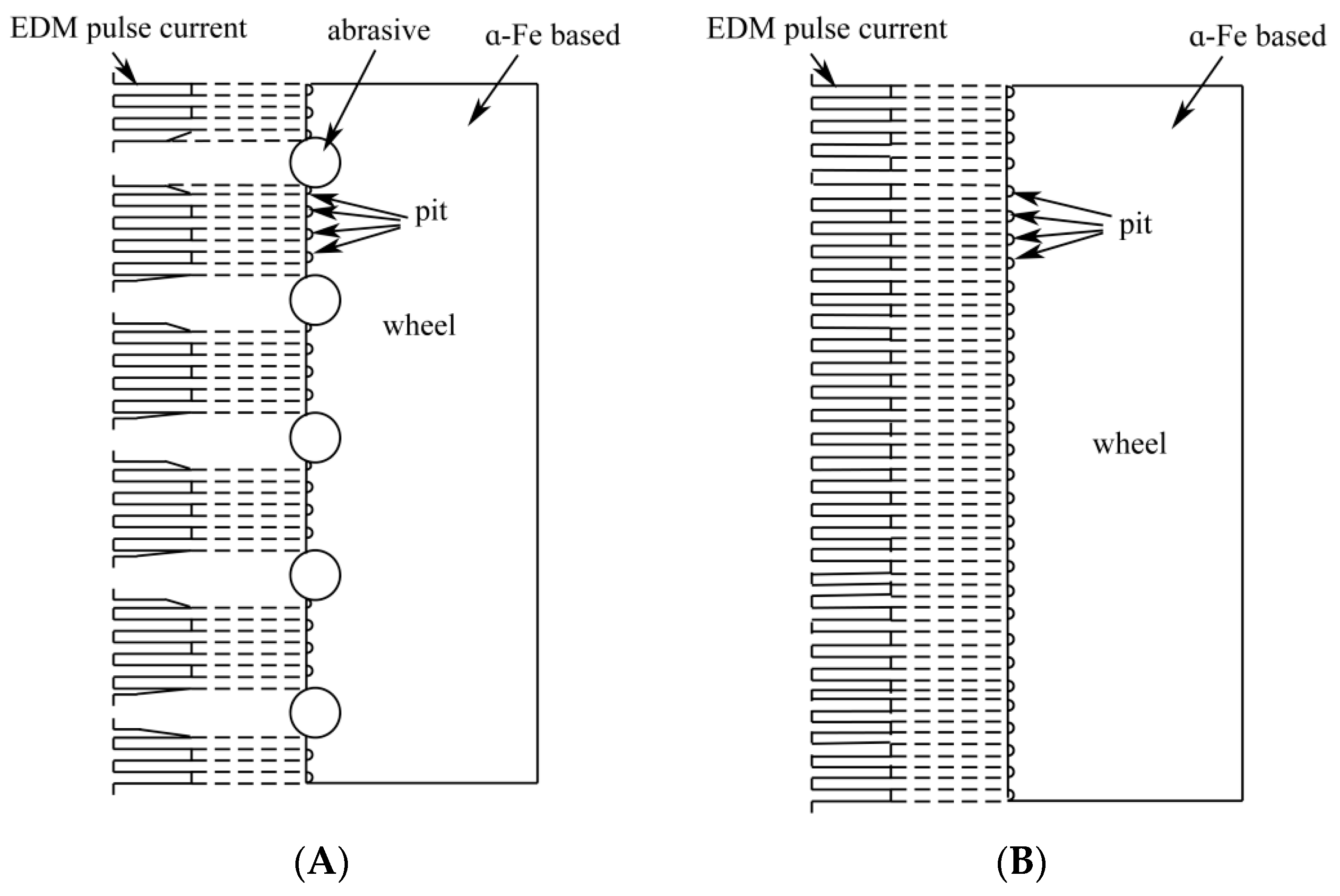

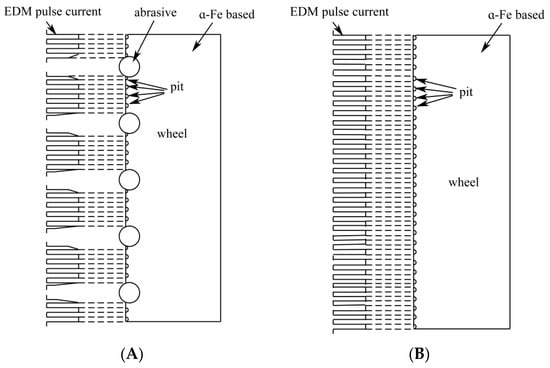

4.1. Spark Energy in EDM Dressing

Our tests were designed to distinguish and understand the effect of EDM dressing on both abrasive and non-abrasive diamond wheels. Figure 8 illustrates the EDM dressing of abrasive grinding diamond wheels and non-abrasive diamond wheels, respectively. Figure 8A shows the abrasive area, which is insulated and non-conductive. There are insulating and conductive areas on the grinding diamond wheel surface. During EDM dressing, the insulated area did not discharge, while the conductive area did, causing the EDM pulse energy in the insulation-conductive transition zone to jump from 0 to Ei. This resulted in the energy of the electric sparks being unstable in the transition area, leading to uneven etching of the convex points. Consequently, the surface roundness of the grinding diamond wheel obtained by EDM dressing was uneven.

Figure 8.

Schematic diagram of EDM dressing for (A) abrasive grinding wheel and (B) non-abrasive iron-based wheel.

This outcome was compared with the EDM dressing of non-abrasive iron-based grinding diamond wheels. Figure 8B shows that the spark energy of non-abrasive diamond wheels was uniform across all EDM areas, resulting in an even etching of the metal on the diamond wheel surface. Consequently, the surface roundness of non-abrasive iron-based grinding diamond wheels was uniform.

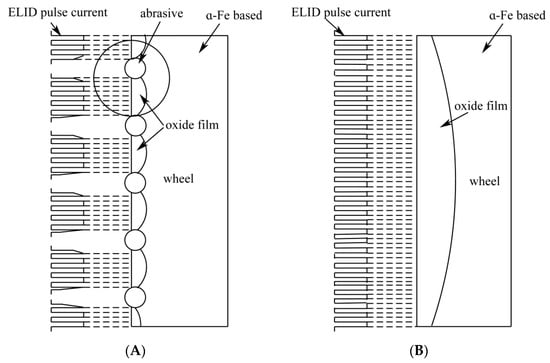

4.2. Effect of Electric Field Uniformity

The principle of EDM dressing underscores the necessity for uniform pulse energy and a consistent erosion rate to achieve a round surface on the grinding diamond wheel. As such, the uniform distribution of the electric field is an essential requirement.

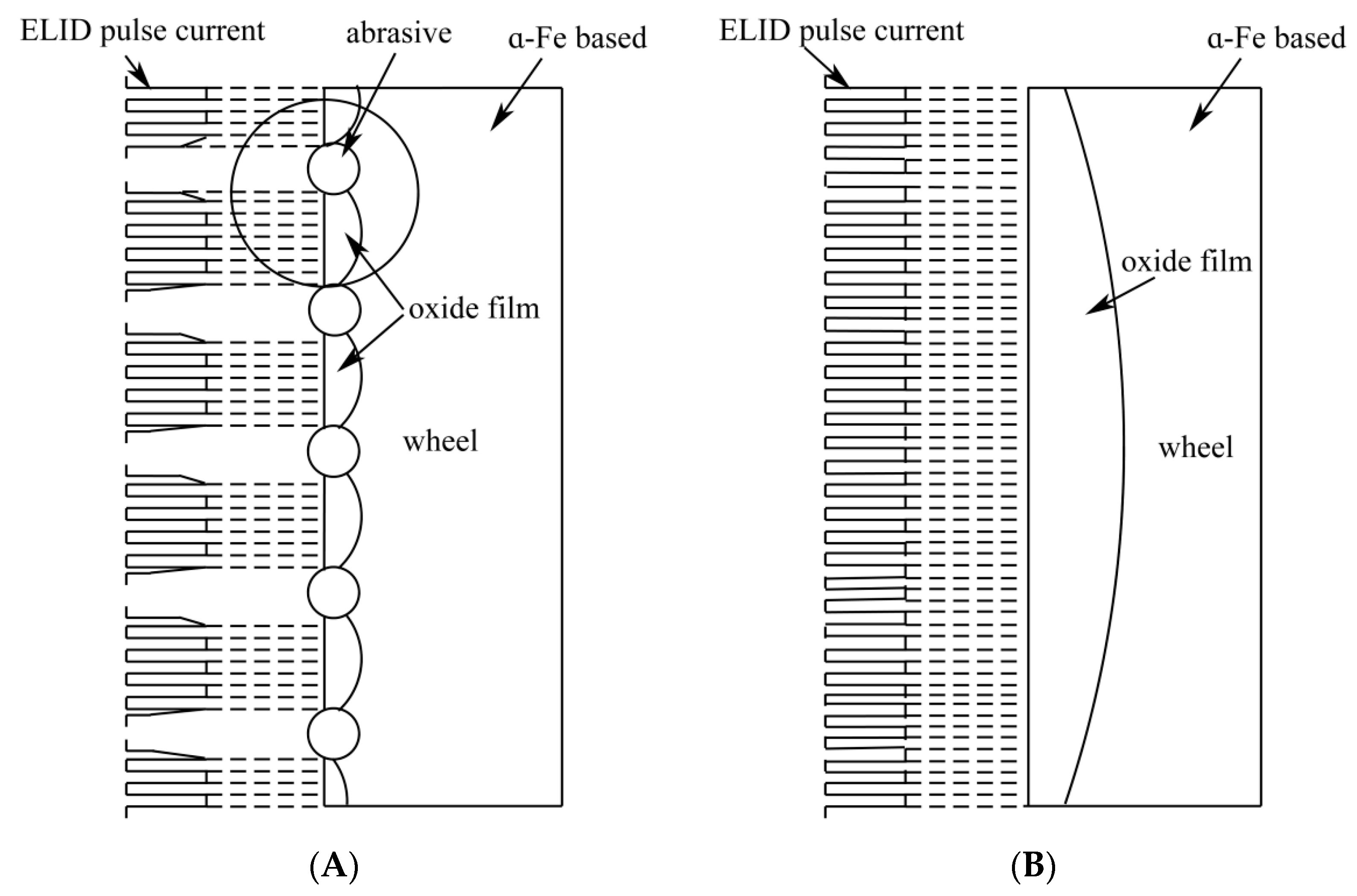

Figure 9A,B provide visual representations of ELID electrolysis of the abrasive grinding diamond wheel and the non-abrasive grinding diamond wheel, respectively, to underscore the differences between them. Given that the abrasive is insulated while the bonding agent is conductive, ELID electrolysis impacts both the insulating and conductive regions on the grinding diamond wheel surface. The principle of ELID electrolysis mirrors that of EDM dressing; both processes result in non-uniform electric field distribution. The current transitioned from 0 to i*, leading to an uneven roundness of the grinding diamond wheel surface produced by ELID electrolysis.

Figure 9.

ELID electrolytic dressing diagrams of (A) abrasive wheels and (B) non-abrasive wheels.

In contrast, non-abrasive iron-based grinding diamond wheels offer no obstructions throughout the entire electrolytic area. The oxide film generated by the electrolysis process was evenly distributed under a uniform electric field. As a result, the roundness of the non-abrasive grinding diamond wheel surface achieved by ELID electrolytic dressing was uniform, as depicted in Figure 9B.

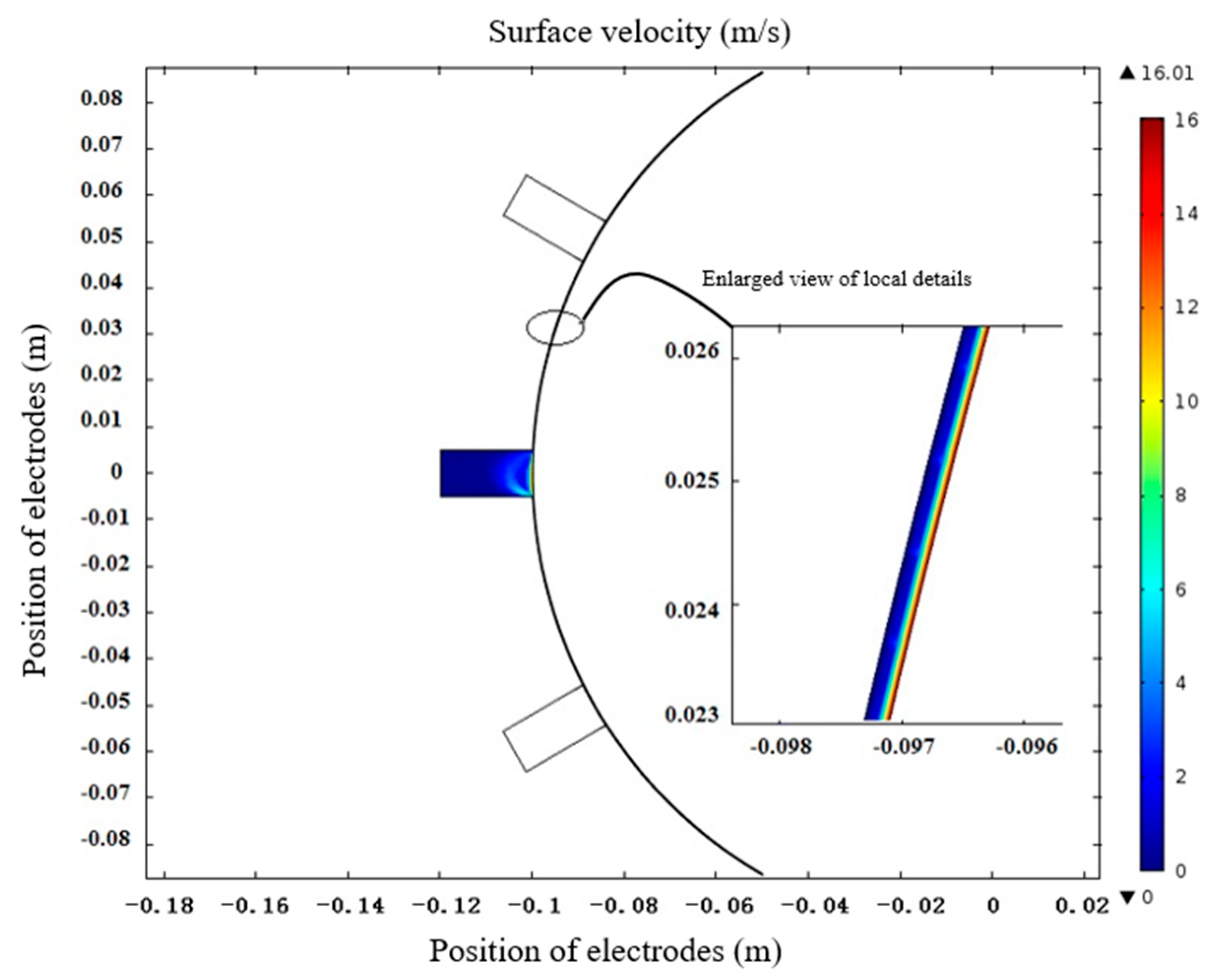

4.3. Effect of Flow Field Uniformity

Following the electrolytic principle of ELID (Electrolytic In-Process Dressing), achieving a round grinding diamond wheel post-electrolysis necessitates an even distribution of the oxide film, along with a uniform distribution of the flow field. A homogeneously distributed flow field ensures the even dispersion of the electric field. The flow state of the electrolyte between the grinding diamond wheel and the electrode greatly influences the electric field.

Therefore, precise control of the electrolyte’s flow state can enhance the uniformity of the electric field, promoting a more consistent distribution of the oxide film on the grinding diamond wheel surface. This uniformity, in turn, significantly improves the grinding diamond wheel’s roundness, leading to more precise and efficient grinding operations. This crucial understanding of the relationship between the electrolyte flow state, electric field, and diamond wheel roundness is a key factor in optimizing ELID electrolysis processes.

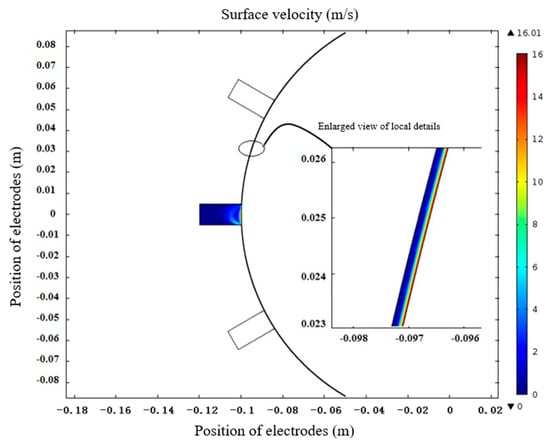

The distribution of the electrolyte between the grinding diamond wheel and the electrode significantly impacts the electric field. To analyze the flow field between the electrode and the grinding diamond wheel during ELID electrolysis, we applied a COMSOL simulation to non-abrasive grinding diamond wheels, as demonstrated in Figure 10. The effect of the flow field on abrasive grinding diamond wheels parallels that on non-abrasive grinding diamond wheels.

Figure 10.

COMSOL simulation of the flow field distribution by ELID electrolytic process.

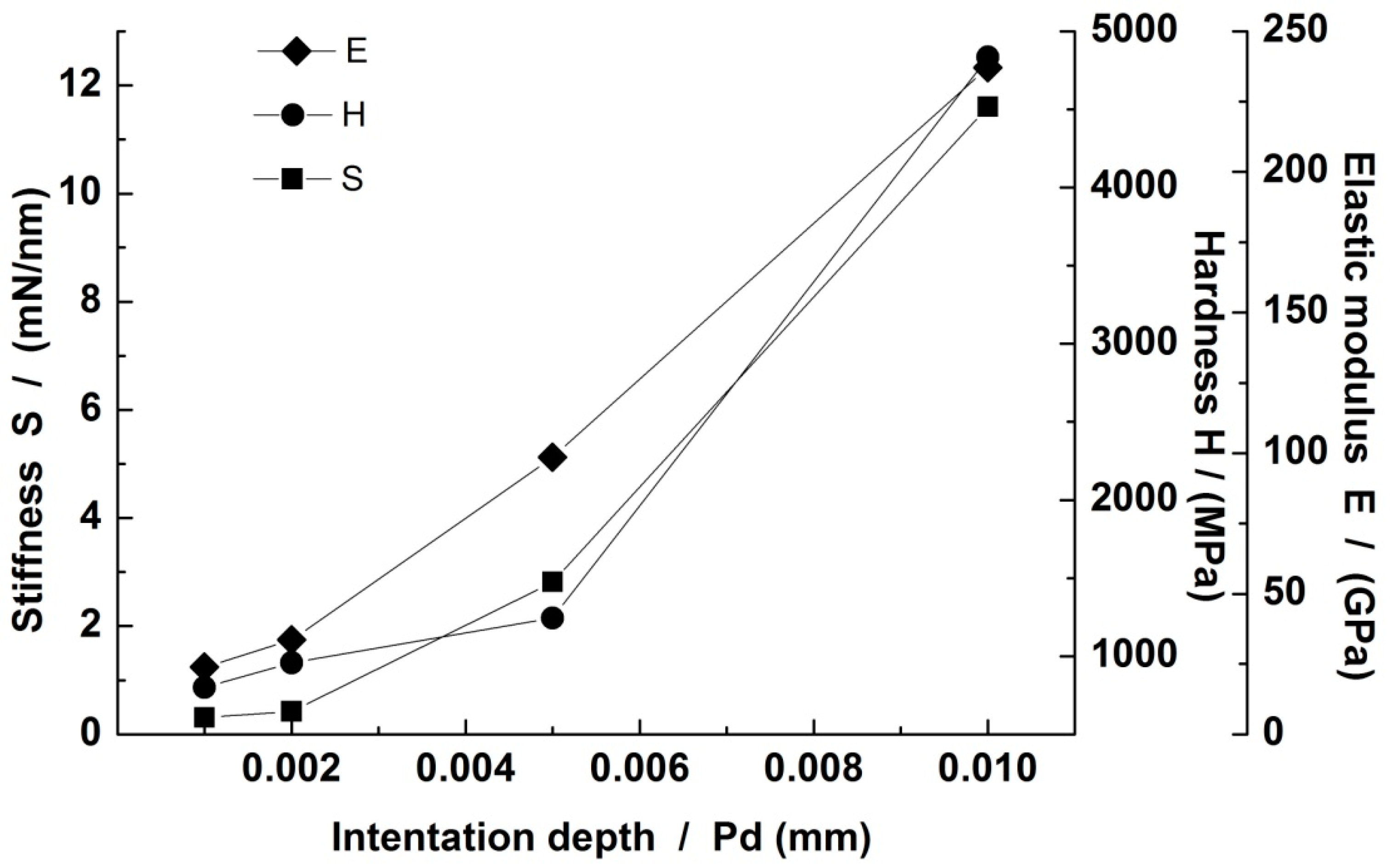

4.4. Influence of Oxide Layer Mechanical Properties

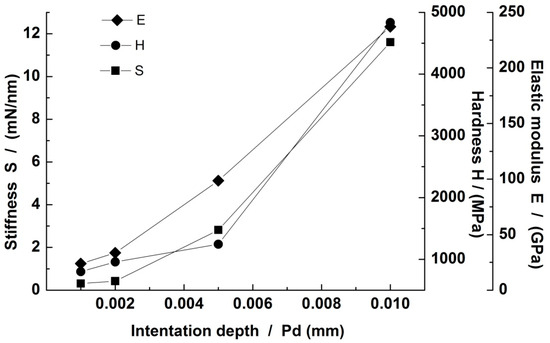

The variations of hardness (H), elastic modulus (E), and stiffness (S) of the oxide layer on the iron-based grinding diamond wheel without abrasive particles obtained from nanoindentation testing with respect to the depth of indentation are depicted in Figure 11. It can be observed from the graph that both hardness H and elastic modulus E, as well as stiffness S, increase with the increase in indentation depth. The hardness ranges from 800 to 4900 MPa, the elastic modulus ranges from 23 to 230 GPa, and the stiffness ranges from 0.3 to 11 mN/nm. At relatively shallow indentation depths, the influence of the grinding diamond wheel substrate is minimal, allowing the mechanical properties to be attributed mainly to the oxide layer. As the indentation depth increases, the influence of the grinding diamond wheel substrate becomes more pronounced, resulting in higher measured values of hardness, elastic modulus, and stiffness. When the maximum indentation depth of 0.01 mm is reached, the measured hardness, elastic modulus, and stiffness approach the performance indicators of the grinding diamond wheel substrate. Based on this, it can be inferred that the hardness of the oxide layer is 800 MPa, the elastic modulus is 23 GPa, and the stiffness is 0.3 mN/nm.

Figure 11.

Mechanical properties of the iron-based grinding wheel without abrasive particles.

The authors previously conducted research on the mechanical properties of oxide films generated after Electrolytic In-Process Dressing (ELID) of abrasive-containing iron-based grinding diamond wheels. The obtained range for stiffness was 27–95 μN/nm [43]. In contrast, K. Fathima measured a stiffness value of 16.34 μN/nm for the oxide film on abrasive-containing grinding diamond wheels [44]. These values are of the same order of magnitude. Comparatively, the stiffness of the oxide film on non-abrasive iron-based grinding diamond wheels is significantly higher than that of abrasive-containing ones. As described in Section 4.2, during ELID electrolysis of abrasive-containing iron-based grinding diamond wheels, the presence of abrasive particles disrupts the uniformity of the electric field, leading to weaker oxide film properties. The oxide film becomes discontinuous and unevenly distributed. Conversely, when non-abrasive iron-based grinding diamond wheels undergo ELID electrolysis, the electric field remains uniform, resulting in better oxide film properties. The oxide film is continuous and evenly distributed. The oxide film on the surface of the grinding diamond wheel behaves like a spring. During ELID polishing, a certain “spring force” is applied to squeeze α-Fe2O3 particles within the oxide film onto the workpiece surface, thereby polishing the workpiece. Due to the uniform distribution and mechanical properties of the oxide film on non-abrasive iron-based grinding diamond wheels, α-Fe2O3 particles are uniformly squeezed onto the workpiece surface, leading to uniform polishing, where the material is evenly removed. Consequently, the polishing performance of non-abrasive iron-based grinding diamond wheel oxide films surpasses that of abrasive-containing ones.

4.5. Comparison of Microscopic Morphology in Plate Glass Polishing

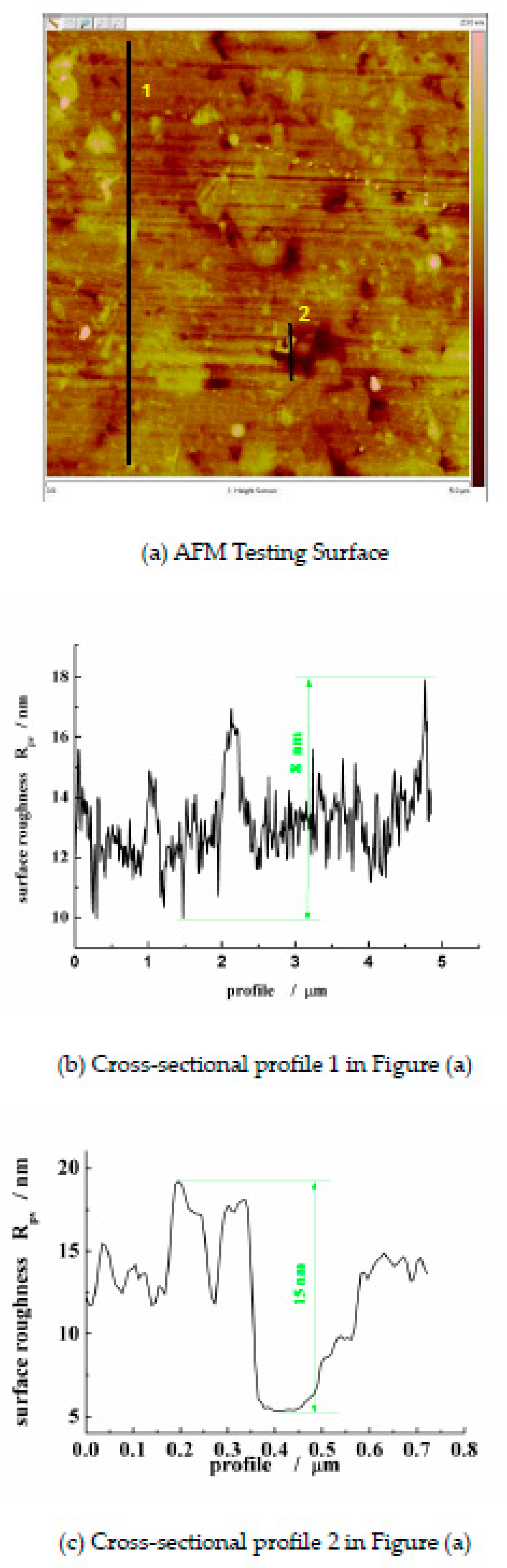

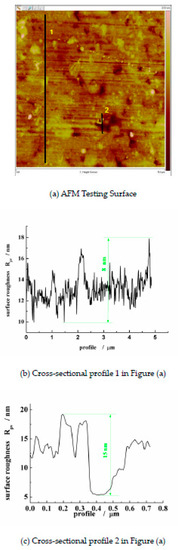

The W1.5 grinding diamond wheel and non-abrasive iron-based grinding diamond wheel were subjected to electrical discharge shaping using the ELID technique, followed by ELID electrolytic sharpening. Subsequently, both the shaped and sharpened W1.5 grinding diamond wheel and the non-abrasive iron-based grinding diamond wheel were employed for the polishing of plate glass. The polished surfaces of the plate glass were examined using Atomic Force Microscopy (AFM), and the results of AFM testing for the plate glass polished with the W1.5 grinding diamond wheel and non-abrasive iron-based grinding diamond wheel are shown in Figure 12 and Figure 13, respectively.

Figure 12.

AFM test image of plate glass ground with w1.5 iron-based grinding wheel.

Figure 13.

AFM test results for plate glass ground with a non-abrasive iron-based grinding wheel.

Figure 12 depicts the AFM microscopic morphology of plate glass polished with the W1.5 grinding diamond wheel. In Figure 12a, it is evident that the surface exhibits characteristics of plastic removal, with numerous plow furrows having widths of 1–2 μm and depths ranging from 20 to 30 nm. Figure 12b shows the contour of profile 1 from Figure 12a, revealing a local surface roughness Ra of 11 nm and a maximum peak-to-valley height Rpv of 75 nm. Based on the analysis of the mechanical properties of the oxide film in the previous section, it can be inferred that the formation of these deeper plow furrows is due to the presence of abrasive particles obstructing the current during the ELID electrolytic sharpening process. On the abrasive-containing grinding diamond wheel surface, a continuous current path cannot be established, causing interruptions in the sharpening process. As a result, the oxide film distribution becomes uneven, leading to non-uniform mechanical properties. This non-uniformity in the “spring force” of the oxide film results in uneven forces acting on the specimen surface. Consequently, variations in the depth of scratches formed on the specimen surface occur, where areas without oxide film coverage experience greater “spring force,” leading to deeper scratches. Conversely, areas covered by the oxide film experience weaker “spring force,” resulting in shallower scratches on the specimen.

Figure 13 represents the AFM microscopic morphology of plate glass polished with a non-abrasive grinding diamond wheel. In Figure 13a, it is apparent that the surface within the tested area exhibits characteristics of plastic removal. Figure 13b shows a local cross-sectional profile perpendicular to the grinding direction. The results of the profile test in the direction perpendicular to the grinding direction reveal a local surface roughness Ra of 2 nm and a maximum peak-to-valley height Rpv of 8 nm. There are no obvious deeper scratches observed. Figure 13c displays local pits, with depths of up to 15 nm, which are defects formed during the sintering process of the specimen. Based on the analysis of the mechanical properties of the oxide film in the previous section, it can be inferred that during electrolysis with the non-abrasive iron-based grinding diamond wheel, the absence of abrasives obstructs the current. As a result, the electrolytic sharpening process proceeds continuously, resulting in the formation of a well-performing oxide film. The oxide film is evenly distributed and possesses uniform mechanical properties, leading to excellent polishing performance. Material removal is uniform, resulting in an even distribution of scratches on the specimen surface with relatively shallow depths.

In summary, the analysis indicates that when using an abrasive-containing iron-based grinding diamond wheel for ELID grinding of plate glass, the plow furrows formed on the specimen surface exhibit non-uniform depths. On the other hand, when employing a non-abrasive iron-based grinding diamond wheel for ELID polishing of plate glass, the plow furrows on the specimen surface have uniform and shallow depths. This demonstrates that using a non-abrasive iron-based grinding diamond wheel for ELID polishing of plate glass achieves better polishing results. This is attributed to the uniformity of the oxide film generated during ELID electrolysis with the non-abrasive iron-based grinding diamond wheel. The oxide film possesses uniform mechanical properties, resulting in an even distribution of the “spring force” of the oxide film on the grinding diamond wheel surface. Consequently, the plow furrows formed on the specimen surface are also evenly distributed.

In fields such as optical lenses and computer chips, the precision of surface form for lenses and chip substrates needs to be in the nanometer range. Any significant scratches or defects can adversely affect the imaging quality of optical lenses and the photolithography, etching, and linewidth of computer chips. Ultimately, this can impact electronic transmission and, in severe cases, lead to product rejection. The application of non-abrasive iron-based grinding wheels successfully addresses the scratching issues caused by traditional abrasive grinding wheels, providing a new approach for the manufacturing of optical lenses and computer chip substrates.

The non-abrasive iron-based grinding wheel, due to its lack of abrasive particles, has a lower polishing efficiency compared to traditional grinding methods. However, when compared to other polishing methods, it exhibits higher efficiency. In ultra-precision polishing environments with good wheel electrolysis and film formation on the wheel surface, the non-abrasive iron-based grinding wheel’s polishing efficiency surpasses that of traditional methods. Nevertheless, it is important to note that this method generates metal ions during electrolysis, so its application in the chip industry should consider the potential introduction of metal contamination.

5. Conclusions

- (1)

- Both the EDM and ELID electrolytic dressing techniques have demonstrated superior roundness when applied to non-abrasive iron-based grinding diamond wheels, thereby ensuring the feasibility of ELID ultra-precision grinding. The electric field distribution in these non-abrasive iron-based grinding diamond wheels is more evenly dispersed and sensible compared to that in abrasive grinding diamond wheels;

- (2)

- Scanning Electron Microscopy (SEM) results, obtained from four uniformly distributed points around the circumference, confirmed the even distribution of the oxide film on the surface of the non-abrasive iron-based grinding diamond wheels;

- (3)

- Further analysis revealed that the content of α-Fe2O3 particles in the non-abrasive iron-based grinding diamond wheel was 1–2 times that found in the W1.5 iron-based grinding diamond wheel. This increased presence of α-Fe2O3 particles could be a contributing factor to the observed superior performance;

- (4)

- The surface precision achieved when using the non-abrasive iron-based grinding diamond wheel to polish plate glass was significantly enhanced. The surface roughness was measured to be Ra0.5 nm, and no apparent scratches were detected. This reaffirms the potential and effectiveness of non-abrasive iron-based grinding diamond wheels in achieving high-precision results in material processing;

- (5)

- The mechanical properties of the oxide layer on the iron-based grinding diamond wheel without abrasive particles were determined using a nanoindentation instrument, yielding a hardness (H) of 800 MPa, an elastic modulus (E) of 23 GPa, and a stiffness of 0.3 mN/nm;

- (6)

- In subsequent applications, it is possible to adjust the current and voltage during electrolysis to control the thickness of the oxide film formed on the grinding wheel’s surface. Furthermore, by tweaking the wheel formulation and grinding parameters, it is feasible to modify the content of α-Fe2O3 particles within the oxide film. Additionally, adjustments can be made to the mechanical properties of the oxide film on the grinding wheel’s surface. Therefore, the performance of the oxide film is subject to dynamic changes.

Author Contributions

Conceptualization, H.Z. and J.K.; writing—review and editing, D.V.A.; investigation, M.Z. All authors have read and agreed to the published version of the manuscript.

Funding

The project described was supported by Grant Number 51475147 from the National Science Foundation, China, and by the Programs for Science and Technology Development of Henan (222102520003). It was also funded by the Priority Academic Program Development of Jiangsu Higher Education Institutions (PAPD) and the Ministry of Science and Higher Education of the Russian Federation (grant No. FENU-2020-0020).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data is contained within the article.

Acknowledgments

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Nakagawa, T. Highly efficient and precise grinding using strongly bonded super abrasive wheel. Seisan-Kenkyu J. Inst. Ind. Sci. Univ. Tokyo 1988, 40, 3–8. [Google Scholar]

- Karikomi, K.; Hagiuda, Y.; Nakagawa, T. An improvement of self-dressing ability on the cast iron bonded diamond grinding wheel by mixing grass powder in it. J. Jpn. Soc. Precis. Eng. 1988, 4, 2002–2005. [Google Scholar]

- Karikomi, K.; Nakagawa, T. Creep feed grinding mechanism of fine ceramics by cast iron bonded diamond wheel. J. Jpn. Soc. Precis. Eng. 1988, 54, 2156–2162. [Google Scholar] [CrossRef]

- Yang, M.; Liu, C.; Guo, B.; Liu, K.; Tu, R.; Ohmori, H.; Zhang, S. Understanding of highly-oriented 3C-SiC ductile-brittle transition mechanism in ELID ultra-precision grinding. Mater. Charact. 2023, 203, 113136. [Google Scholar] [CrossRef]

- Ji, B.; Wu, H.; Yang, L.; Liu, C.; Cao, G.; Sun, H. Oxide film thickness and composite mechanical properties of an ultrasonic-assisted ELID cast-iron-bonded grinding wheel. Int. J. Adv. Manuf. Technol. 2023, 127, 3891–3904. [Google Scholar] [CrossRef]

- Zhou, H.; Guo, M.; Wang, X. Ultraprecision grinding of silicon wafers using a newly developed diamond wheel. Mater. Sci. Semicond. Process. 2017, 68, 238–244. [Google Scholar] [CrossRef]

- Wu, Q.; Zheng, W.; Deng, Z.; Zhao, H. Research status and perspectives of ELID grinding oxidation films. China Mech. Eng. 2018, 29, 2023–2030. [Google Scholar]

- Park, K.; Ohmori, H.; Nakagawa, T. Grinding of plastics and carbon fiber reinforced plastics (CFRP) with metal bonded grinding wheel of small diameter. J. Jpn. Soc. Grind. 1995, 39, 33–39. [Google Scholar]

- Ohmori, H. Electrolytic in-process dressing (ELID) grinding technique for ultra precision mirror surface machining. Int. J. Jpn. Soc. Precis. Eng. 1992, 25, 273. [Google Scholar]

- Omori, H.; Takahashi, I.; Nakagawa, T.; Hagiuda, Y.; Karikome, K. Development of ELID mirror surface grinding by cast iron bond grinding wheel. Mon. J. Inst. Ind. Sci. Univ. Tokyo 1997, 49, 339–341. [Google Scholar]

- Guan, J.; Yuan, Z.; Zhang, F.; Luan, D.; Cong, J.; Sun, X. Research on metal cement grinding wheel for ELID mirror grinding. J. Harbin Inst. Technol. 1998, 30, 90–93. [Google Scholar]

- Tian, C.; Wan, Y.; Li, X.; Rong, Y. Study on the additively manufactured porous metal-bonded grinding wheel designed by octahedron lattice structure. Int. J. Adv. Manuf. Technol. 2023, 125, 1743–1756. [Google Scholar] [CrossRef]

- Onishi, H.; Kobayashi, M.; Takata, A.; Ishizaki, K.; Shioura, T.; Kondo, Y.; Tukuda, A. Fabrication of new porous metal-bonded grinding wheel. J. Porous Mater. 1999, 4, 187–198. [Google Scholar] [CrossRef]

- Truong, S.; Isono, Y.; Tanaka, T. A study on the toughening of bond bridge of Ni-Cu-Sn alloy-development of porous metal bonded diamond wheel. J. Jpn. Soc. Precis. Eng. 1998, 64, 923–928. [Google Scholar] [CrossRef]

- Xiong, H.; Liu, M.; Xia, J. Study on grinding performance of porous metal bond diamond wheel manufactured with hollow sphere pore-forming agent. Diam. Abras. Eng. 2011, 31, 44–49. [Google Scholar]

- Itoh, N.; Ohmori, H.; Kasai, T.; Karaki-Doy, T.; Horio, K. Characteristics of ELID surface grinding by fine abrasive metal-resin bonded wheel. Int. J. Jpn. Soc. Precis. Eng. 1998, 32, 273–274. [Google Scholar]

- Maebayashi, N.; Itoh, N.; Ohmori, H.; Katoh, T.; Yamasaki, K.; Ohmiya, K. Development of metal-resin bonded wheel containing electro-conductive rubber balls using green sheets. Proc. JSPE Semest. Meet. 2016, 425–426. [Google Scholar] [CrossRef]

- Itoh, N.; Ohmori, H.; Kasai, T. Development of metal-resin bonded wheel using fine metal powder and its grinding performance. Int. J. Jpn. Soc. Precis. Eng. 1999, 33, 333–334. [Google Scholar]

- Itoh, N.; Ohmori, H.; Moriyasu, S. Finishing characteristics of brittle materials by ELID-lap grinding using metal-resin bonded wheels. Int. J. Mach. Tools Manuf. Des. Res. Appl. 1998, 38, 747–762. [Google Scholar] [CrossRef]

- Hasegawa, Y.; Horibe, T.; Itoh, N.; Ideue, T.; Takahashi, M.; Ohmori, H.; Katoh, T. Development of ELID grinding system for electro-conductive rubber bonded wheel using electrolyzed water: 2nd Grinding characteristics using coolant nozzle with electrolyzed water generator. Proc. JSPE Semest. Meet. 2013, 801–802. [Google Scholar] [CrossRef]

- Sakata, N.; Yamamoto, H.; Ohmori, H.; Itoh, N.; Inazawa, K. Effects of micro-bubble on ELID grinding performance using electro-conductive rubber bonded wheel. Proc. JSPE Semest. Meet. 2018, 13, 765–766. [Google Scholar] [CrossRef]

- Ezura, A.; Inazawa, K.; Omori, K.; Uehara, Y.; Itoh, N.; Ohmori, H. ELID mirror surface grinding for concave molds by conductive elastic wheel containing carbon black. Int. J. Autom. Technol. 2022, 16, 21–31. [Google Scholar] [CrossRef]

- Omiya, K.; Itoh, N.; Kasuga, H.; Ohmori, H.; Kato, T.; Maebayashi, N. ELID grinding performance using metal-resin bonded wheel conducting electro-conductive-rubber ball. Jpn. Soc. Mech. Eng. 2015, 23, 93–94. [Google Scholar]

- Hasegawa, Y. Development of eco-friendly ELID grinding wheel using plant carbon. J. Jpn. Soc. Abras. Technol. 2009, 53, 735. [Google Scholar]

- Huang, J.; Li, W. Study of electrolysis property of bamboo charcoal bonded grinding wheel. New Technol. New Process. 2011, 2, 57–59. [Google Scholar]

- Itoh, N.; Ohmori, H. Development of metal free conductive bonded diamond wheel for environmentally friendly electrolytic In-process Dressing (ELID) grinding. New Diam. Front. Carbon Technol. 2004, 14, 224–238. [Google Scholar]

- Nemoto, A. Development of R.B. ceramics bonded diamond wheel for eco-friendly ELID grinding. J. Jpn. Soc. Abras. Technol. 2004, 48, 578–579. [Google Scholar]

- Wu, Q.; Ouyang, Z.; Yang, H.; Song, K.; Deng, Z. Influence of carbon nanotubes on electrolytic dressing grinding performance of a multi-layer brazed coarse-grained diamond wheel. J. Mech. Eng. 2020, 56, 231–239. [Google Scholar]

- Wu, Q.; Wang, Y.; Zhao, H.; Zheng, W.; Deng, Z. Precision grinding of ultra-fine cemented carbide based on electrolytic in-process dressing of a multi-layer brazed diamond wheel. J. Mech. Eng. 2018, 54, 212–220. [Google Scholar] [CrossRef]

- Chen, J.; Huang, H.; Xu, X. An experimental study on the grinding of Alumina with a monolayer brazed diamond wheel. Int. J. Adv. Manuf. Technol. 2009, 41, 16–23. [Google Scholar] [CrossRef]

- Itoh, N.; Ohmori, H.; Kato, T.; Umezu, S.; Matsuzawa, T. Fabrication of grinding wheel using a combined system of PELID and 3D printer. J. Jpn. Soc. Abras. Technol. 2017, 61, 318–321. [Google Scholar]

- Yamada, N.; Itoh, N.; Mashiko, Y.; Omori, H.; Umezu, S.; Inazawa, K. Attempt of the inner structure grinding wheel by PELID and 3D Printer. Jpn. Soc. Precis. Eng. 2017, 2017, 381–382. [Google Scholar]

- Kashimura, S.; Inazawa, K.; Ohmori, H.; Itoh, N. Development of resin fibrous grinding wheels using twin nozzle PELID and analysis of their grinding performance. Int. J. Autom. Technol. 2021, 15, 49–56. [Google Scholar] [CrossRef]

- Kuai, J.; Zhang, J.; Ardashev, D.V.; Zhang, H. Properties of α-Fe2O3 in oxide film of α-Fe grinding wheel without abrasive particles. Ferroelectrics 2019, 548, 1–7. [Google Scholar] [CrossRef]

- Kuai, J. Grinding point-temperature model of ELID oxide film and its heat transfer and formation mechanism of α-Fe2O3. Nanomater. Energy 2017, 6, 1–6. [Google Scholar] [CrossRef]

- Kuai, J.; Ardashev, D.V.; Zhang, H. Study of α-Fe2O3 formation and its measurement in oxide films of wheel surface during ELID grinding process. Mod. Phys. Lett. B 2017, 31, 1750025. [Google Scholar] [CrossRef]

- Liu, Z.; Ren, C.; Zhao, K.; Chen, G.; He, C. Modeling of oxide-film thickness in electrolytic in-process dressing grinding with workpiece swing. Int. J. Adv. Manuf. Technol. 2022, 122, 1695–1718. [Google Scholar] [CrossRef]

- Lim, H.; Fathima, K.; Kumar, A.; Rahman, M. A fundamental study on the mechanism of electrolytic in-process dressing (ELID) grinding. Int. J. Mach. Tools Manuf. 2002, 42, 935–943. [Google Scholar] [CrossRef]

- Zhang, K.; Ren, C.; Yang, L.; Li, Q.; Jin, X. Precision internal grinding of bearing steel based on the state control of oxide layer with electrolytic in-process dressing. J. Mater. Process. Technol. 2012, 212, 1611–1621. [Google Scholar] [CrossRef]

- Zhang, J.; Yang, Y.; Zhang, X.; Guan, J.; Zheng, L.; Li, G. Experimental study on the characteristic and function of oxide film formed on grinding wheel in ELID precision grinding. Ind. Lubr. Tribol. 2020, 72, 549–555. [Google Scholar] [CrossRef]

- Chen, H.; Li, J. Anodic metal matrix removal rate in electrolytic in-process dressing I: Two-dimensional modeling. J. Appl. Phys. 2000, 87, 3151–3158. [Google Scholar] [CrossRef]

- Alqahtani, B.; Zhang, M.; Marinescu, I.; Bafakeeh, O.; Al Sofyani, S. Microscopic characterization and modeling of oxide layer for electrolytic in-process dressing (ELID) grinding with focus on voltage, electrode-wheel gap, and coolant flow. Int. J. Adv. Manuf. Technol. 2019, 105, 4853–4862. [Google Scholar] [CrossRef]

- Gui, J.; Zhang, F. Study on Calculation Model of Spring Stiffness of Passive Film for ELID Grinding. Tool Eng. 2008, 42, 29–32. [Google Scholar]

- Fathima, K.; Rahman, M.; Senthil Kumar, A.; Lim, H. Modeling of ultra precision ELID grinding. Trans. ASME J. Manu. Sci. Eng. 2007, 129, 296–302. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).