Risk Interdependency Network Model for the Cost and Time of Pile Installation in Saudi Arabia, Using Partial Least Squares Structural Equation Modeling

Abstract

:1. Introduction

2. Literature Review

2.1. Risks Associated with Pile Installation

2.2. Risk Assessment Methods

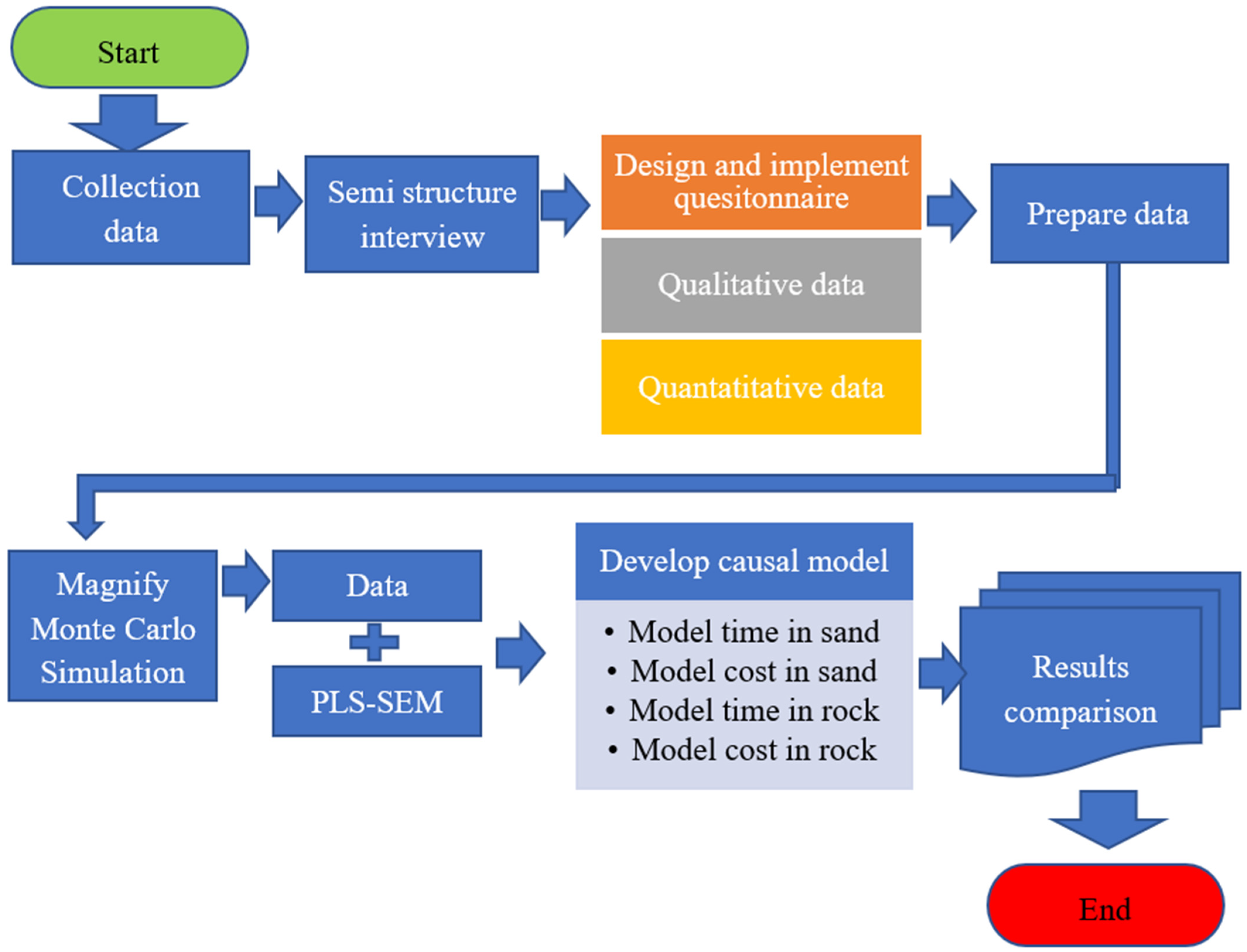

3. Research Methodology

3.1. Data Collection

3.2. Semi-Structured Interviews

3.3. Designing and Conducting the Survey of Experts

3.4. Data Preparation

3.5. Magnifying and Normalizing the Data Using a Monte Carlo Simulation

3.6. Developing an Interdependency Model Using a PLS-SEM

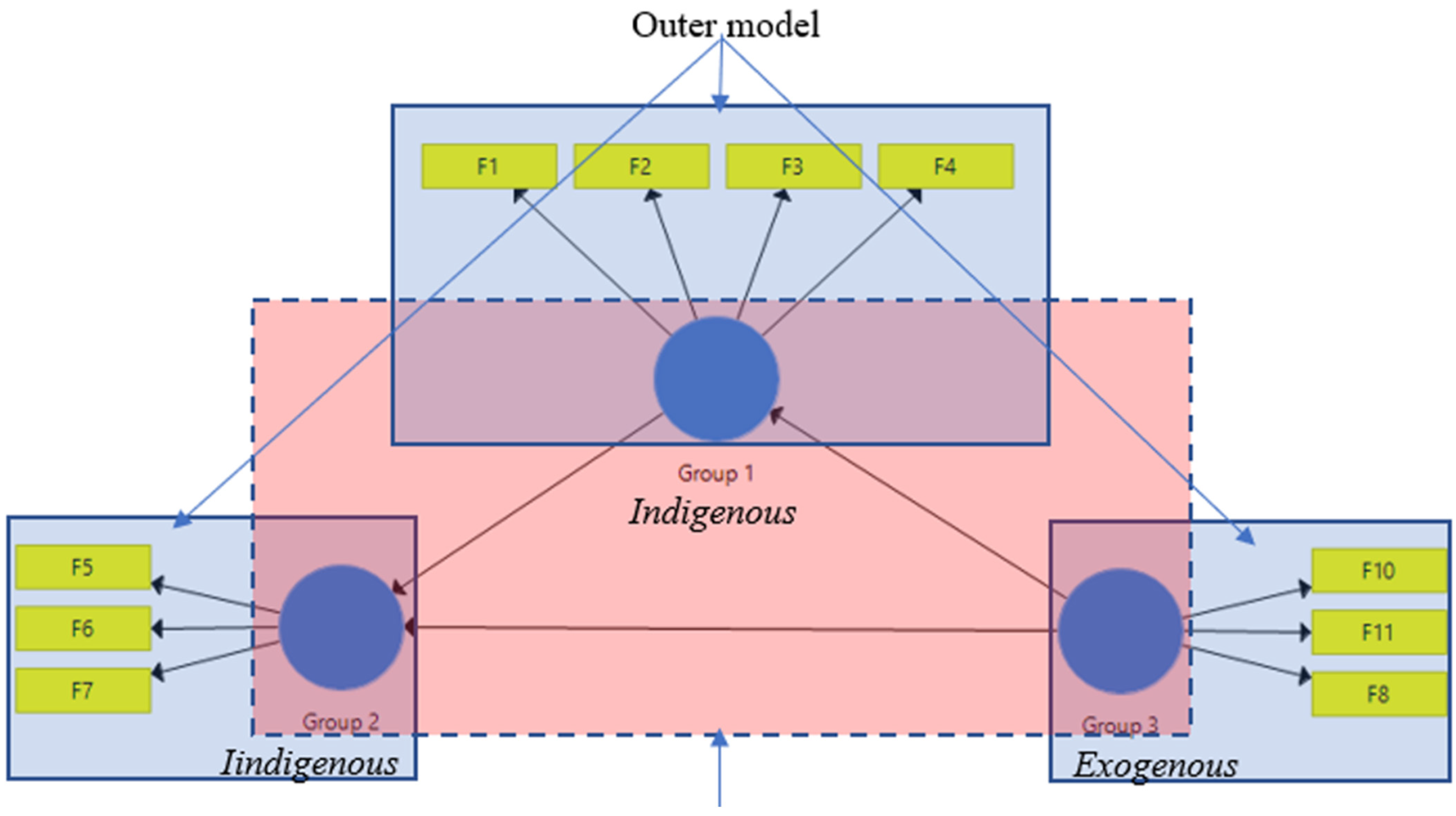

3.6.1. Information on the Components of a PLS-SEM

Outer Model Assessment

Inner Model Assessment

3.6.2. Establishing the Interdependency Model

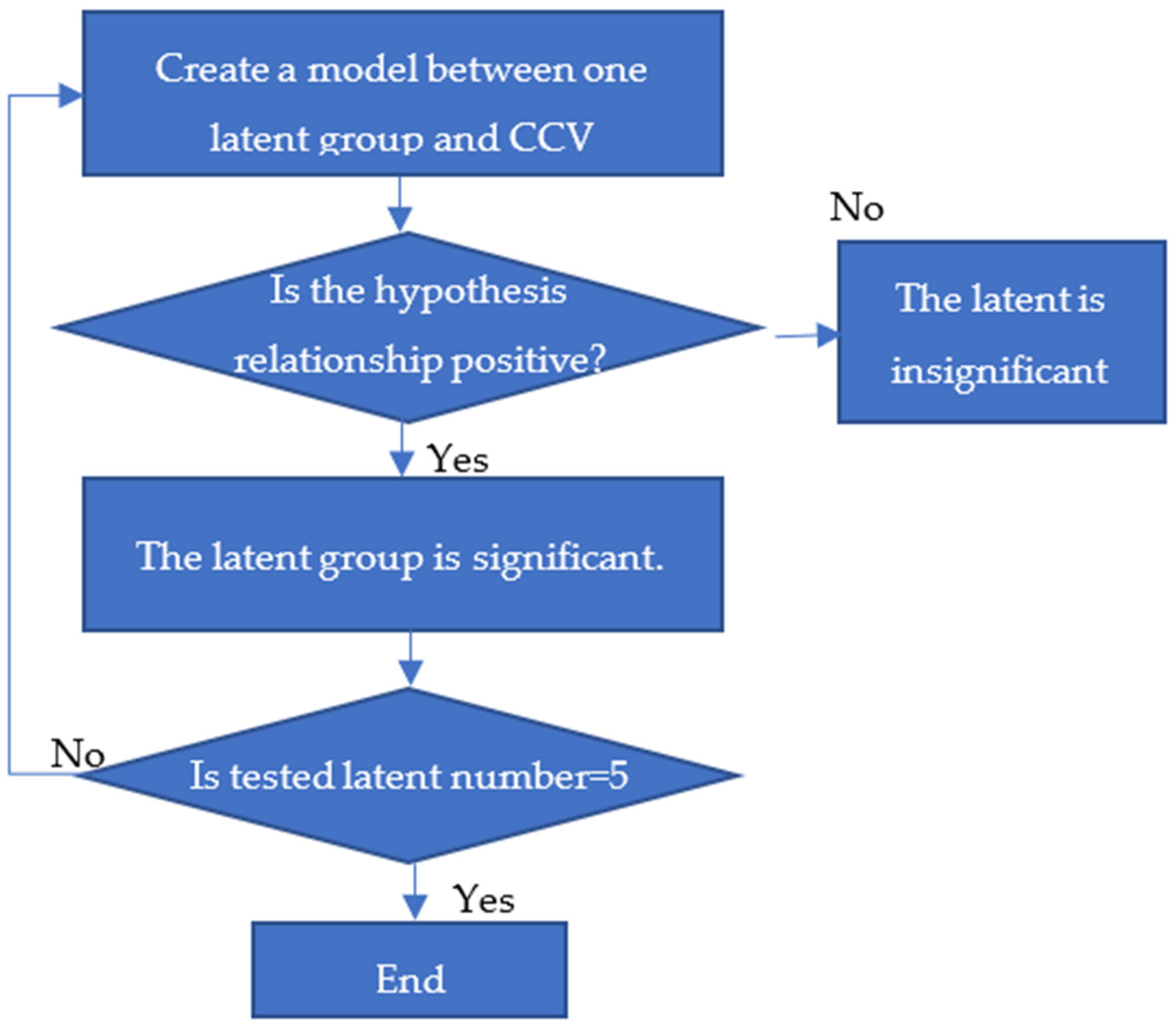

Phase One: Identify the Significant Groups

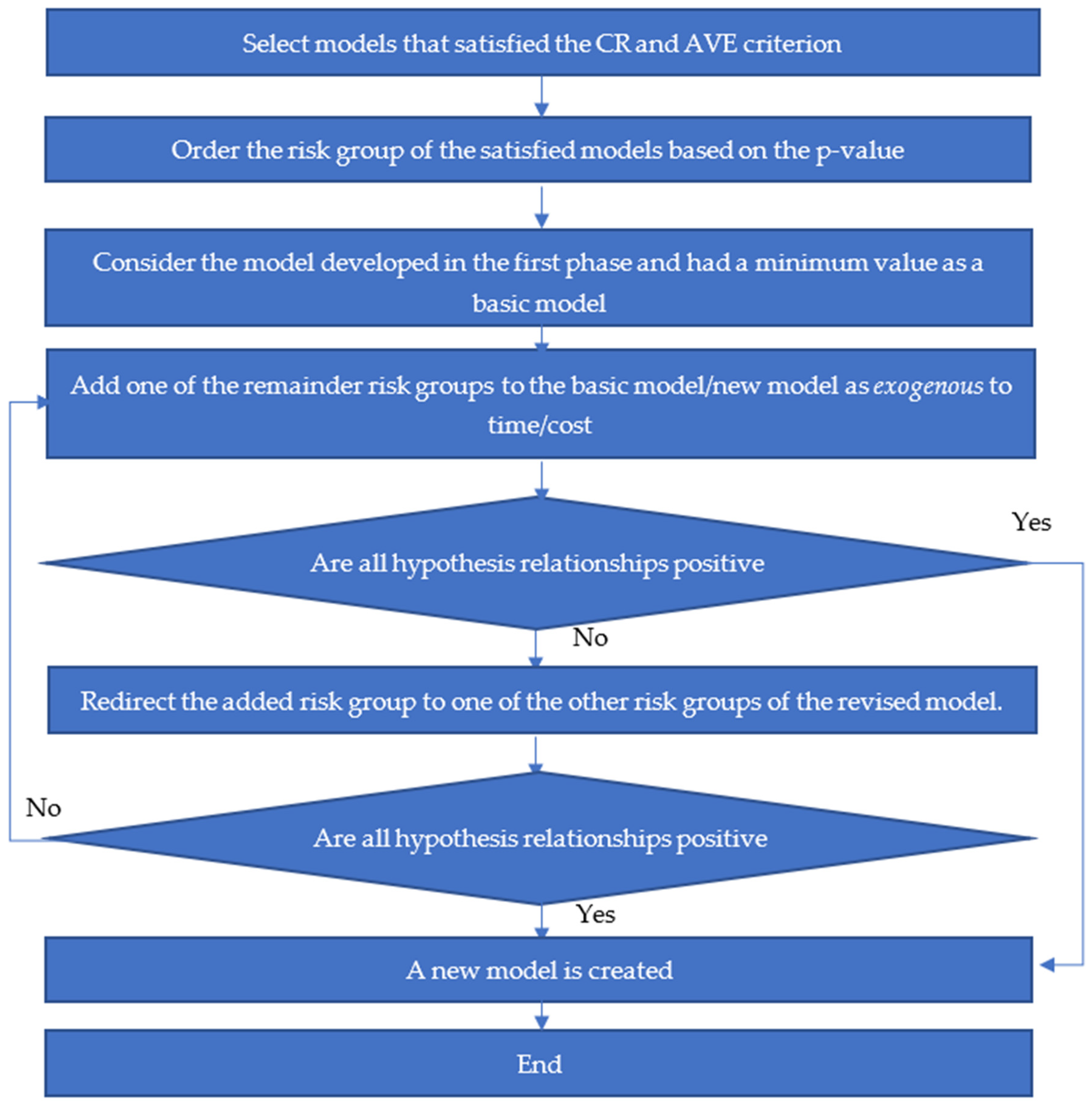

Phase Two: Merge the Significant Risk Groups into One Model

4. Results and Discussion

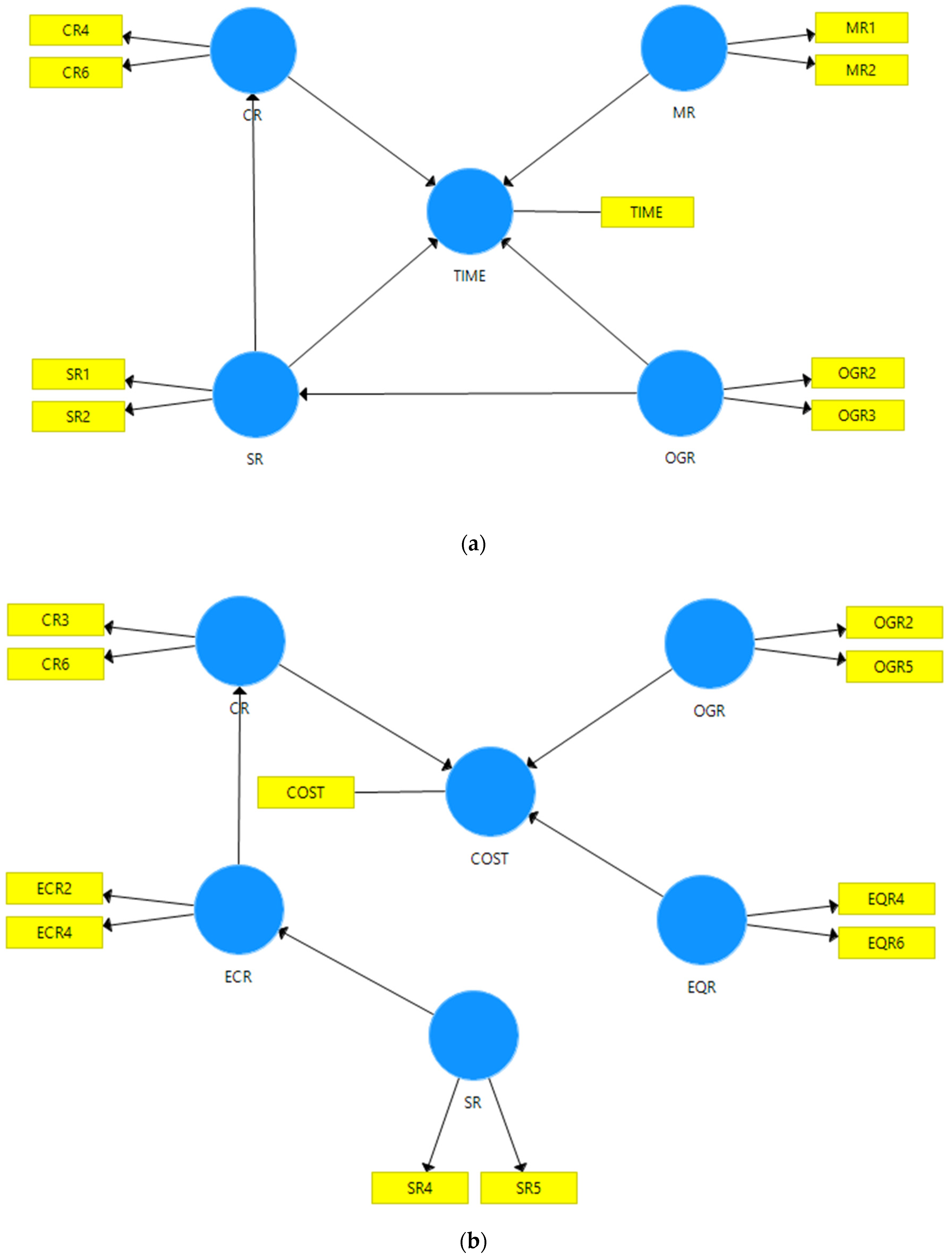

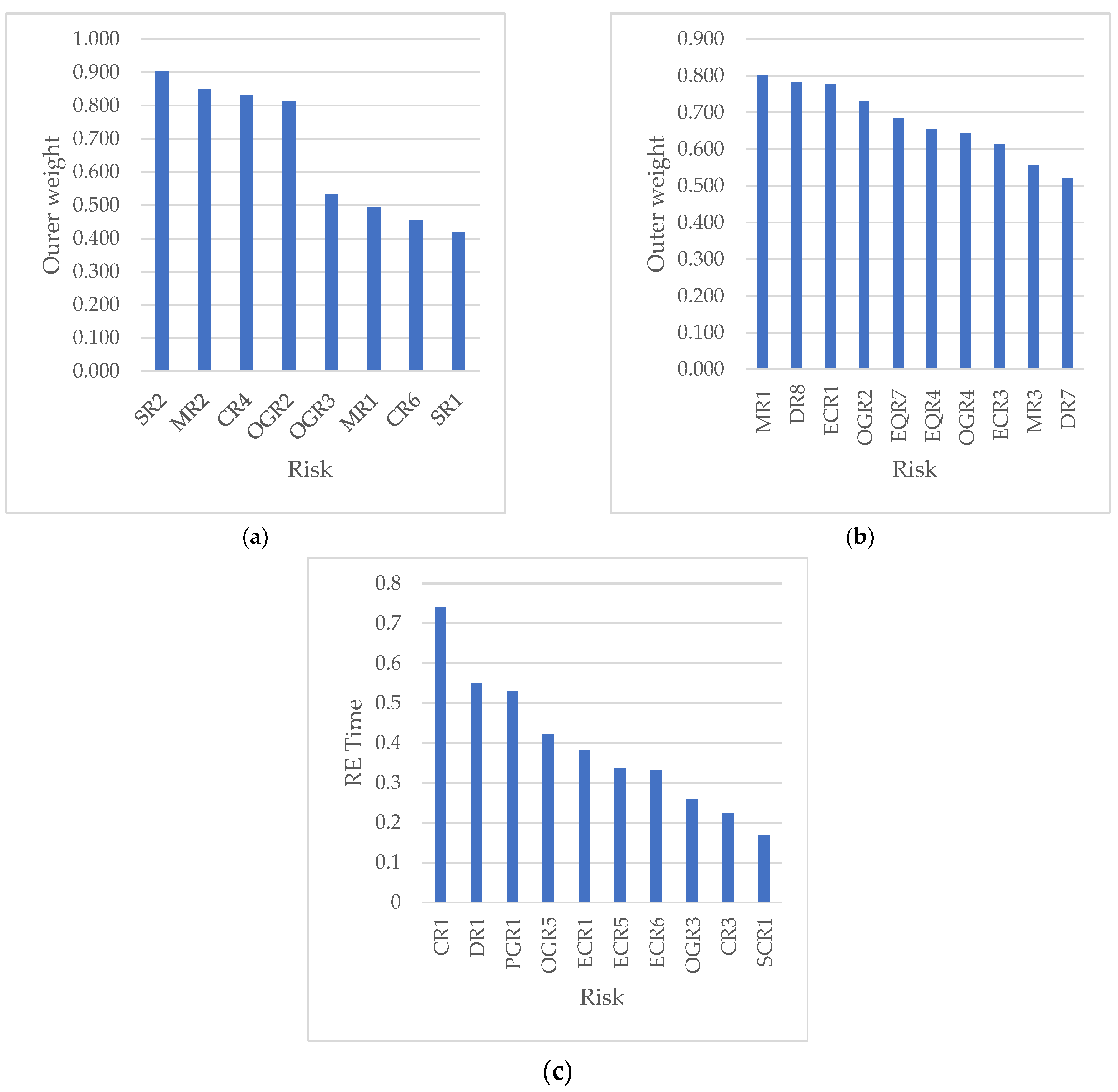

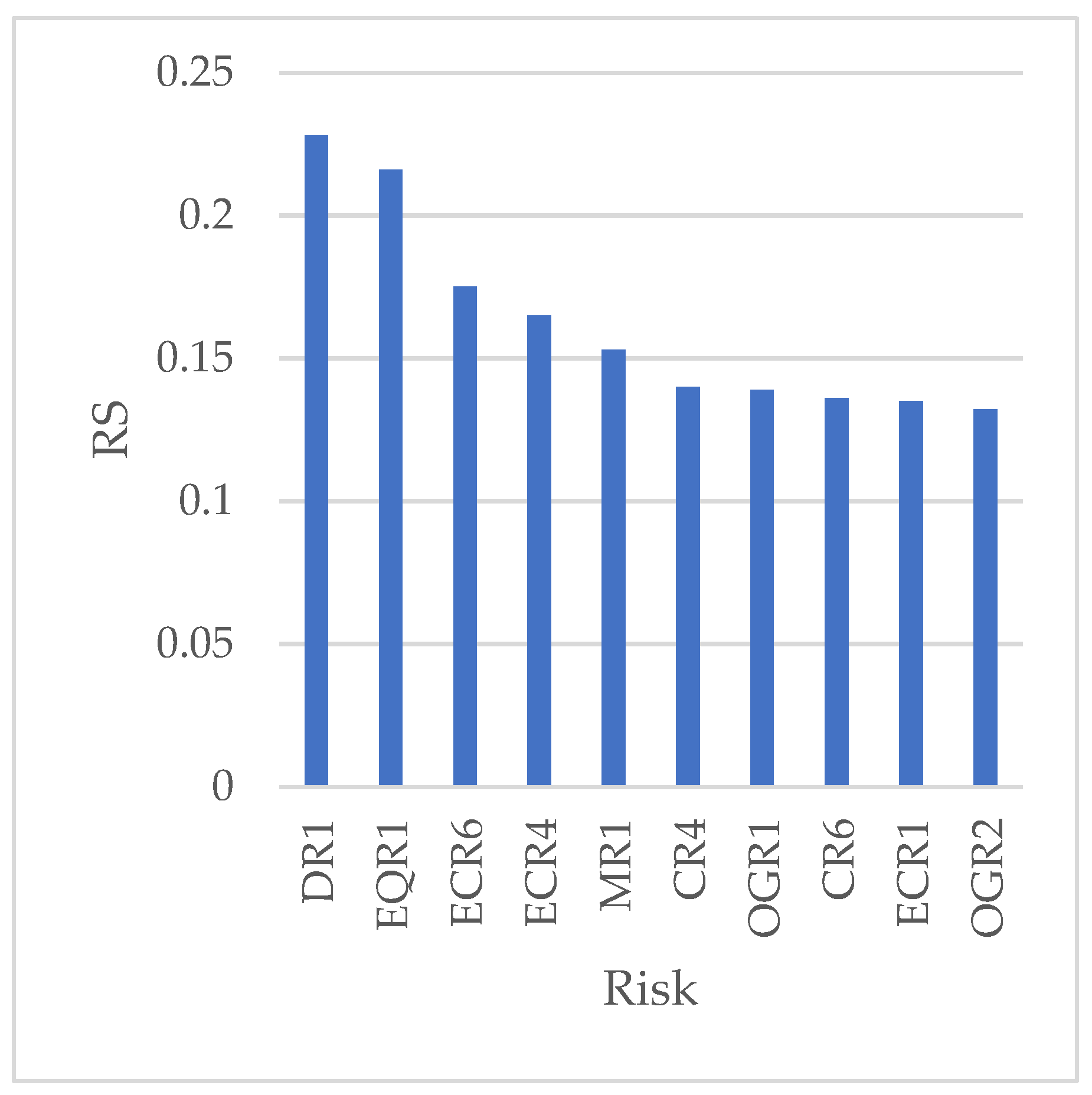

4.1. Risk Interdependency Model in Sand

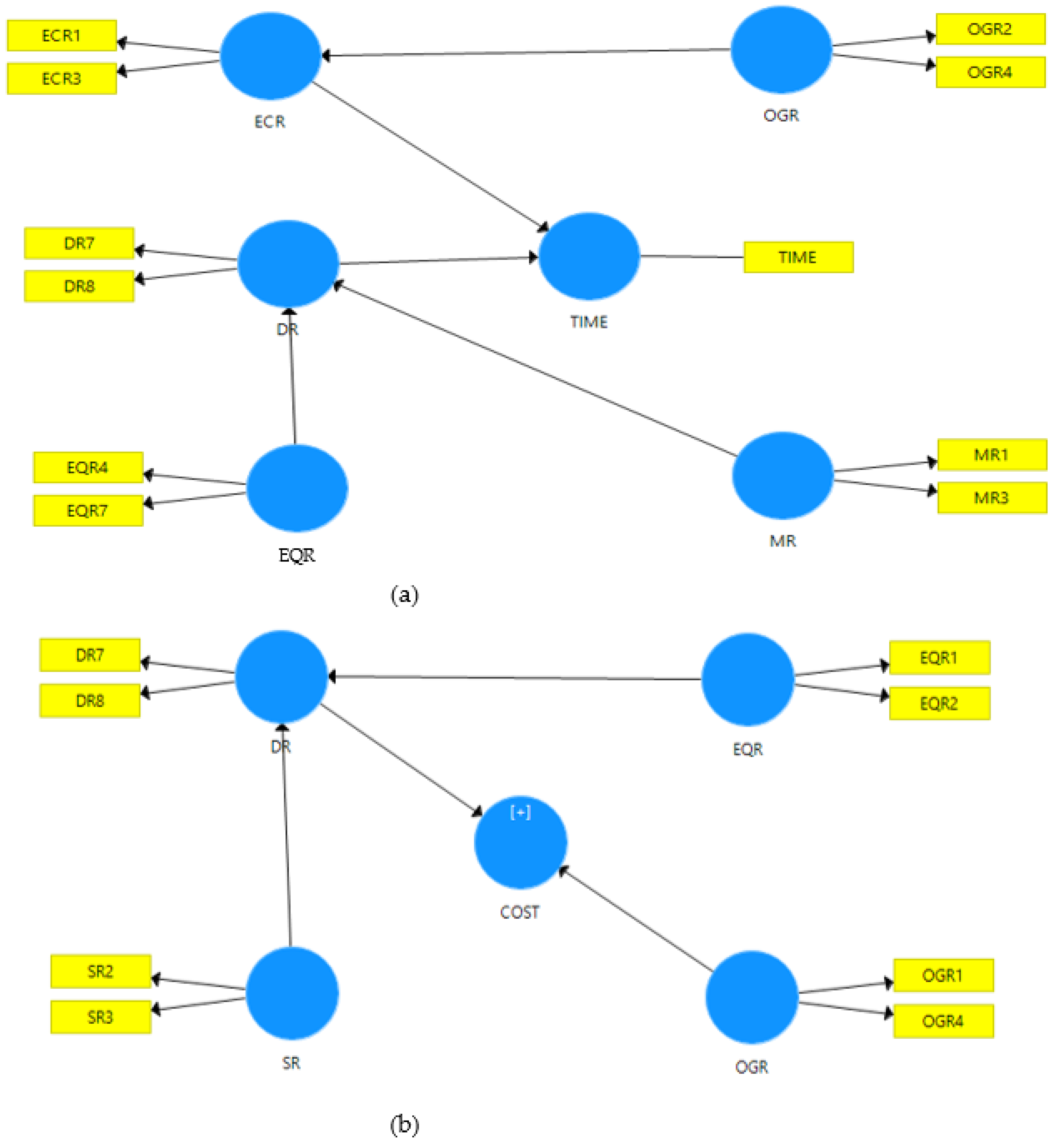

4.2. Risk Interdependency Model in Rock

5. Conclusions

6. Recommendation for Further Studies

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| ER1 | ER2 | DR1 | DR2 | DR3 | DR4 | DR5 | DR6 | DR7 | DR8 | MR1 | MR2 | MR3 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Expert 1 | 0.25 | 0.09 | 0.35 | 0.49 | 0.25 | 0.35 | 0.21 | 0.35 | 0.25 | 0.35 | 0.35 | 0.49 | 0.49 |

| Expert 2 | 0.35 | 0.35 | 0.45 | 0.21 | 0.35 | 0.27 | 0.21 | 0.35 | 0.09 | 0.35 | 0.21 | 0.45 | 0.27 |

| Expert 3 | 0.09 | 0.27 | 0.05 | 0.01 | 0.01 | 0.35 | 0.27 | 0.09 | 0.15 | 0.05 | 0.21 | 0.27 | 0.35 |

| Expert 4 | 0.15 | 0.35 | 0.21 | 0.09 | 0.15 | 0.25 | 0.35 | 0.35 | 0.35 | 0.35 | 0.35 | 0.35 | 0.35 |

| Expert 5 | 0.21 | 0.15 | 0.21 | 0.03 | 0.35 | 0.25 | 0.35 | 0.09 | 0.35 | 0.05 | 0.03 | 0.35 | 0.15 |

| Expert 6 | 0.21 | 0.25 | 0.49 | 0.15 | 0.25 | 0.35 | 0.21 | 0.25 | 0.25 | 0.25 | 0.21 | 0.21 | 0.35 |

| Expert 7 | 0.09 | 0.35 | 0.81 | 0.63 | 0.35 | 0.63 | 0.63 | 0.81 | 0.81 | 0.63 | 0.63 | 0.63 | 0.81 |

| Expert 8 | 0.01 | 0.07 | 0.27 | 0.05 | 0.25 | 0.03 | 0.05 | 0.05 | 0.09 | 0.09 | 0.03 | 0.05 | 0.15 |

| Expert 9 | 0.25 | 0.15 | 0.45 | 0.09 | 0.25 | 0.21 | 0.49 | 0.21 | 0.15 | 0.15 | 0.09 | 0.35 | 0.25 |

| Expert 10 | 0.09 | 0.49 | 0.25 | 0.09 | 0.49 | 0.49 | 0.49 | 0.25 | 0.25 | 0.25 | 0.09 | 0.09 | 0.09 |

| Expert 11 | 0.15 | 0.15 | 0.35 | 0.15 | 0.49 | 0.25 | 0.15 | 0.01 | 0.25 | 0.21 | 0.81 | 0.01 | 0.01 |

| Expert 12 | 0.01 | 0.01 | 0.25 | 0.09 | 0.09 | 0.01 | 0.09 | 0.25 | 0.25 | 0.01 | 0.25 | 0.49 | 0.49 |

| CR1 | CR2 | CR3 | CR4 | CR5 | CR6 | CR7 | CR8 | CR9 | CR10 | SCR1 | SCR2 | SCR3 | |

| Expert 1 | 0.35 | 0.15 | 0.09 | 0.09 | 0.25 | 0.35 | 0.45 | 0.35 | 0.35 | 0.45 | 0.25 | 0.15 | 0.09 |

| Expert 2 | 0.45 | 0.63 | 0.35 | 0.63 | 0.25 | 0.35 | 0.21 | 0.21 | 0.35 | 0.45 | 0.35 | 0.45 | 0.45 |

| Expert 3 | 0.15 | 0.35 | 0.35 | 0.45 | 0.09 | 0.35 | 0.09 | 0.15 | 0.27 | 0.03 | 0.25 | 0.63 | 0.25 |

| Expert 4 | 0.21 | 0.25 | 0.25 | 0.35 | 0.45 | 0.35 | 0.63 | 0.15 | 0.63 | 0.35 | 0.15 | 0.63 | 0.25 |

| Expert 5 | 0.35 | 0.49 | 0.15 | 0.35 | 0.35 | 0.09 | 0.21 | 0.03 | 0.21 | 0.21 | 0.35 | 0.05 | 0.21 |

| Expert 6 | 0.05 | 0.25 | 0.09 | 0.21 | 0.25 | 0.25 | 0.01 | 0.09 | 0.25 | 0.15 | 0.09 | 0.35 | 0.25 |

| Expert 7 | 0.45 | 0.49 | 0.35 | 0.49 | 0.49 | 0.45 | 0.35 | 0.35 | 0.63 | 0.45 | 0.35 | 0.49 | 0.35 |

| Expert 8 | 0.05 | 0.05 | 0.03 | 0.05 | 0.09 | 0.07 | 0.09 | 0.09 | 0.05 | 0.03 | 0.05 | 0.03 | 0.09 |

| Expert 9 | 0.21 | 0.15 | 0.45 | 0.15 | 0.09 | 0.21 | 0.15 | 0.15 | 0.15 | 0.21 | 0.25 | 0.09 | 0.09 |

| Expert 10 | 0.35 | 0.25 | 0.25 | 0.25 | 0.25 | 0.09 | 0.09 | 0.09 | 0.25 | 0.25 | 0.25 | 0.15 | 0.25 |

| Expert 11 | 0.49 | 0.09 | 0.35 | 0.81 | 0.81 | 0.63 | 0.15 | 0.09 | 0.81 | 0.49 | 0.81 | 0.81 | 0.63 |

| Expert 12 | 0.25 | 0.09 | 0.25 | 0.49 | 0.09 | 0.09 | 0.09 | 0.25 | 0.49 | 0.09 | 0.25 | 0.01 | 0.25 |

| ER1 | ER2 | ER3 | ER4 | ER5 | ER6 | ER7 | ER8 | ER9 | PGR1 | PGR2 | ECR1 | ECR2 | |

| Expert 1 | 0.15 | 0.15 | 0.09 | 0.09 | 0.15 | 0.09 | 0.09 | 0.25 | 0.09 | 0.15 | 0.09 | 0.35 | 0.15 |

| Expert 2 | 0.21 | 0.35 | 0.45 | 0.45 | 0.45 | 0.21 | 0.21 | 0.45 | 0.15 | 0.45 | 0.35 | 0.45 | 0.35 |

| Expert 3 | 0.15 | 0.21 | 0.63 | 0.35 | 0.27 | 0.09 | 0.21 | 0.45 | 0.45 | 0.09 | 0.09 | 0.63 | 0.35 |

| Expert 4 | 0.25 | 0.15 | 0.15 | 0.15 | 0.25 | 0.15 | 0.25 | 0.49 | 0.35 | 0.63 | 0.25 | 0.45 | 0.25 |

| Expert 5 | 0.03 | 0.01 | 0.03 | 0.35 | 0.35 | 0.21 | 0.15 | 0.21 | 0.15 | 0.35 | 0.05 | 0.35 | 0.03 |

| Expert 6 | 0.25 | 0.25 | 0.35 | 0.25 | 0.25 | 0.15 | 0.35 | 0.35 | 0.15 | 0.27 | 0.35 | 0.35 | 0.25 |

| Expert 7 | 0.35 | 0.35 | 0.49 | 0.63 | 0.45 | 0.49 | 0.49 | 0.63 | 0.63 | 0.21 | 0.49 | 0.49 | 0.49 |

| Expert 8 | 0.03 | 0.09 | 0.03 | 0.05 | 0.05 | 0.03 | 0.03 | 0.25 | 0.25 | 0.09 | 0.09 | 0.15 | 0.09 |

| Expert 9 | 0.09 | 0.35 | 0.03 | 0.09 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.09 | 0.35 | 0.35 |

| Expert 10 | 0.25 | 0.25 | 0.25 | 0.09 | 0.25 | 0.09 | 0.09 | 0.09 | 0.09 | 0.25 | 0.25 | 0.25 | 0.09 |

| Expert 11 | 0.35 | 0.81 | 0.01 | 0.01 | 0.35 | 0.25 | 0.25 | 0.01 | 0.35 | 0.49 | 0.49 | 0.81 | 0.81 |

| Expert 12 | 0.25 | 0.25 | 0.09 | 0.09 | 0.09 | 0.25 | 0.25 | 0.09 | 0.25 | 0.25 | 0.25 | 0.09 | 0.09 |

| ECR3 | ECR4 | ECR5 | ECR6 | OGR1 | OGR2 | OGR3 | OGR4 | OGR5 | |||||

| Expert 1 | 0.09 | 0.25 | 0.25 | 0.25 | 0.25 | 0.15 | 0.21 | 0.09 | 0.15 | ||||

| Expert 2 | 0.35 | 0.25 | 0.25 | 0.15 | 0.27 | 0.45 | 0.15 | 0.35 | 0.35 | ||||

| Expert 3 | 0.35 | 0.15 | 0.21 | 0.05 | 0.35 | 0.63 | 0.35 | 0.63 | 0.45 | ||||

| Expert 4 | 0.25 | 0.63 | 0.35 | 0.35 | 0.35 | 0.07 | 0.25 | 0.35 | 0.25 | ||||

| Expert 5 | 0.03 | 0.15 | 0.05 | 0.15 | 0.21 | 0.21 | 0.05 | 0.21 | 0.21 | ||||

| Expert 6 | 0.15 | 0.25 | 0.15 | 0.21 | 0.35 | 0.45 | 0.35 | 0.15 | 0.21 | ||||

| Expert 7 | 0.49 | 0.49 | 0.45 | 0.35 | 0.63 | 0.63 | 0.63 | 0.81 | 0.63 | ||||

| Expert 8 | 0.15 | 0.09 | 0.05 | 0.03 | 0.05 | 0.15 | 0.15 | 0.15 | 0.09 | ||||

| Expert 9 | 0.15 | 0.15 | 0.15 | 0.09 | 0.35 | 0.15 | 0.15 | 0.35 | 0.15 | ||||

| Expert 10 | 0.09 | 0.25 | 0.09 | 0.09 | 0.09 | 0.09 | 0.09 | 0.09 | 0.09 | ||||

| Expert 11 | 0.09 | 0.81 | 0.09 | 0.09 | 0.01 | 0.49 | 0.49 | 0.63 | 0.15 | ||||

| Expert 12 | 0.01 | 0.09 | 0.25 | 0.09 | 0.01 | 0.09 | 0.09 | 0.09 | 0.01 | ||||

| SR1 | SR2 | SR3 | SR4 | SR5 | Cost/pile (SAR) | Duration/pile (hour) | |||||||

| Expert 1 | 0.25 | 0.63 | 0.15 | 0.09 | 0.09 | 0.17 | 0 | ||||||

| Expert 2 | 0.45 | 0.45 | 0.25 | 0.25 | 0.45 | 0.28 | 0.04 | ||||||

| Expert 3 | 0.25 | 0.35 | 0.27 | 0.15 | 0.15 | 0.08 | 0 | ||||||

| Expert 4 | 0.15 | 0.63 | 0.35 | 0.15 | 0.25 | 0.13 | 0 | ||||||

| Expert 5 | 0.21 | 0.35 | 0.35 | 0.15 | 0.35 | 0 | 0.4 | ||||||

| Expert 6 | 0.15 | 0.21 | 0.15 | 0.21 | 0.35 | 0.22 | 0.01 | ||||||

| Expert 7 | 0.63 | 0.63 | 0.63 | 0.49 | 0.63 | 0.97 | 0.64 | ||||||

| Expert 8 | 0.03 | 0.03 | 0.03 | 0.01 | 0.09 | 0.75 | 0.4 | ||||||

| Expert 9 | 0.45 | 0.35 | 0.25 | 0.15 | 0.09 | 1 | 1 | ||||||

| Expert 10 | 0.25 | 0.25 | 0.09 | 0.09 | 0.09 | 0.9 | 0.28 | ||||||

| Expert 11 | 0.15 | 0.15 | 0.49 | 0.49 | 0.35 | 0.88 | 0.82 | ||||||

| Expert 12 | 0.25 | 0.25 | 0.25 | 0.25 | 0.25 | 0.84 | 0.73 | ||||||

References

- Report Store. “Saudi Arabia Construction Market Size, Trend Analysis by Sector (Commercial, Industrial, Infrastruc-ture, Energy and Utilities, Institutional and Residential) and Forecast, 2023–2027”. June 2023. Available online: https://www.globaldata.com/store/report/saudi-arabia-construction-market-analysis/#:~:text=The%20Saudi%20Arabia%20construction%20market,Vision%202030'%20economic%20diversification%20plan (accessed on 4 April 2023).

- Mordor Intelligence. Saudi Arabia Construction Market—Growth, Trends, COVID-19 Impact, and Forecasts (2023–2028). Available online: https://www.mordorintelligence.com/industry-reports/saudi-arabia-construction-market (accessed on 7 February 2023).

- World Economic Outlook Database; International Monetary Funds: Washington, DC, USA, 2023.

- Aziz, F.R. The Use of Simulation to Predict cfa Equipment Productivity; Alexandria University: Alexandria, Egypt, 2004. [Google Scholar]

- Hosny, H.E.; Ibrahim, A.H.; Fraig, R.F. Risk management framework for Continuous Flight Auger piles construction in Egypt. Alex. Eng. J. 2018, 57, 2667–2677. [Google Scholar] [CrossRef]

- Ehsan, N.; Mirza, E.; Alam, M.; Ishaqu, A. Notice of Retraction: Risk management in construction industry. In Proceedings of the 3rd International Conference on Computer Science and Information Technology, Chengdu, China, 9–11 July 2010. [Google Scholar]

- Choudhry, R.M.; Aslam, M.A.; Hinze, J.W.; Arain, F.M. Cost and Schedule Risk Analysis of Bridge Construction in Pakistan: Establishing Risk Guidelines. J. Constr. Eng. Manag. 2014, 140, 04014020. [Google Scholar] [CrossRef]

- Hosny, H.E.; Ibrahim, A.H.; Fraig, R.F. Cost analysis of continuous flight auger piles construction in Egypt. Alex. Eng. J. 2016, 55, 2709–2720. [Google Scholar] [CrossRef]

- Mata, P.; Silva, P.F.; Pinho, F.F.S. Risk Management of bored piling construction on sandy soils with real-time cost control. Infrastructures 2021, 6, 77. [Google Scholar] [CrossRef]

- Surenth, S.; Rajapakshe, R.M.P.P.V.; Muthumala, I.S.; Samarawickrama, M.N.C. Cost Forecasting Analysis on Bored and Cast-In-situ Piles in Sri Lanka: Case Study at Selected Pile Construction Sites in Colombo Metropolis Area. Eng. J. Inst. Eng. Sri Lanka 2019, 52, 57. [Google Scholar] [CrossRef]

- Zayed, T.M.; Halpin, D.W. Process versus Data Oriented Techniques in Pile Construction Productivity Assessment. J. Constr. Eng. Manag. 2004, 130, 490–499. [Google Scholar] [CrossRef]

- Zayed, T. Stochastic productivity assessment of continuous flight auger piles. Arch. Sci. Rev. 2009, 52, 17–27. [Google Scholar] [CrossRef]

- Zayed, T.M.; Halpin, D.W. Productivity and Cost Regression Models for Pile Construction. J. Constr. Eng. Manag. 2005, 131, 779–789. [Google Scholar] [CrossRef]

- Zayed, T.M.; Halpin, D.W. Pile Construction Productivity Assessment. J. Constr. Eng. Manag. 2005, 131, 705–714. [Google Scholar] [CrossRef]

- Al-Gahtani, K.; Alsanabani, N. Impact factors on time and cost in pile construction. Proc. Int. Struct. Eng. Constr. 2023, 10, 1. [Google Scholar] [CrossRef]

- Tsouvalas, A. Underwater noise emission due to offshore pile installation: A Review. Energies 2020, 13, 3037. [Google Scholar] [CrossRef]

- Juretzek, C.; Schmidt, B.; Boethling, M. Turning scientific knowledge into regulation: Effective measures for noise mitigation of pile driving. J. Mar. Sci. Eng. 2021, 9, 819. [Google Scholar] [CrossRef]

- White, D.; Finlay, T.; Bolton, M.; Bearss, G. Press-in piling: Ground vibration and noise during pile installation. In Deep Foundations 2002: An International Perspective on Theory, Design, Construction, and Performance; American Society of Civil Engineers: Reston, VA, USA, 2002; pp. 363–371. [Google Scholar]

- Zayed, T.M.; Halpin, D.W. Deterministic models for assessing productivity and cost of bored piles. Constr. Manag. Econ. 2005, 23, 531–543. [Google Scholar] [CrossRef]

- Mahamid, I.; Al-Ghonamy, A.; Aichouni, M. Factors affecting accuracy of pretender cost estimate: Studies of Saudi Arabia. Int. J. Appl. Eng. Res. 2014, 9, 21–36. [Google Scholar]

- Guan, L.; Abbasi, A.; Ryan, M.J. A simulation-based risk interdependency network model for project risk assessment. Decis. Support Syst. 2021, 148, 113602. [Google Scholar] [CrossRef]

- Wold, H. Model Construction and Evaluation When Theoretical Knowledge Is Scarce: Theory and Application of Partial Least Squares, In Evaluation of Econometric Models; Academic Press: Cambridge, MA, USA, 1980. [Google Scholar]

- Lohmöller, J.B.; Wold, H. Three-mode path models with latent variables and partial least squares (PLS) parameter estimation. In Proceedings of the European Meeting of the Psychometric Society, Groningen, The Netherlands, 19–21 June 1980. [Google Scholar]

- Hair, J.F.; Ringle, C.M.; Sarstedt, M. PLS-SEM: Indeed a Silver Bullet. J. Mark. Theory Pract. 2011, 19, 139–152. [Google Scholar] [CrossRef]

- Hair, J.F.; Ringle, C.M.; Sarstedt, M. Partial least squares structural equation modeling: Rigorous applications, better results and higher acceptance. Long Range Plann 2013, 46, 1–12. [Google Scholar] [CrossRef]

- Hair, J.F.; Risher, J.J.; Sarstedt, M.; Ringle, C.M. When to use and how to report the results of PLS-SEM. Eur. Bus. Rev. 2019, 31, 2–24. [Google Scholar] [CrossRef]

- Wang, P. PLS-SEM Model of Integrated Stem Education Concept and Network Teaching Model of Architectural Engineering Course. Math. Probl. Eng. 2022, 2022, 1–10. [Google Scholar] [CrossRef]

- Gamil, Y.; Rahman, I.A.; Nagapan, S.; Nasaruddin, N.A.N. Exploring the failure factors of Yemen construction industry using PLS-SEM approach. Asian J. Civ. Eng. 2020, 21, 967–975. [Google Scholar] [CrossRef]

- Carranza, R.; Díaz, E.; Martín-Consuegra, D.; Fernández-Ferrín, P. PLS–SEM in business promotion strategies. A multigroup analysis of mobile coupon users using MICOM. Ind. Manag. Data Syst. 2020, 120, 2349–2374. [Google Scholar] [CrossRef]

- Yusif, S.; Hafeez-Baig, A.; Soar, J.; Teik, D.O.L. PLS-SEM path analysis to determine the predictive relevance of e-Health readiness assessment model. Health Technol. 2020, 10, 1497–1513. [Google Scholar] [CrossRef]

- Kineber, A.F.; Siddharth, S.; Chileshe, N.; Alsolami, B.; Hamed, M.M. Addressing of Value Management Implementation Barriers within the Indian Construction Industry: A PLS-SEM Approach. Sustainability 2022, 14, 16602. [Google Scholar] [CrossRef]

- Guenther, P.; Guenther, M.; Ringle, C.M.; Zaefarian, G.; Cartwright, S. Improving PLS-SEM use for business marketing research. Ind. Mark. Manag. 2023, 111, 127–142. [Google Scholar] [CrossRef]

- Al-Mekhlafi, A.-B.A.; Othman, I.; Kineber, A.F.; Mousa, A.A.; Zamil, A.M.A. Modeling the Impact of Massive Open Online Courses (MOOC) Implementation Factors on Continuance Intention of Students: PLS-SEM Approach. Sustainability 2022, 14, 5342. [Google Scholar] [CrossRef]

- Su, C.-H.; Cheng, T.-W. A sustainability innovation experiential learning model for virtual reality chemistry laboratory: An empirical study with PLS-SEM and IPMA. Sustainability 2019, 11, 1027. [Google Scholar] [CrossRef]

- Duc, M.L.; Bilik, P.; Martinek, R. Analysis of Factors Affecting Electric Power Quality: PLS-SEM and Deep Learning Neural Network Analysis. IEEE Access 2023, 11, 40591–40607. [Google Scholar] [CrossRef]

- Alsugair, A.M. Cost Deviation Model of Construction Projects in Saudi Arabia Using PLS-SEM. Sustainability 2022, 14, 16391. [Google Scholar] [CrossRef]

- Mulcahy, R. Risk Management, Tricks of the Trade for Project Managers; RMC Pub.: Crowton, UK, 2019. [Google Scholar]

- Eldosouky, I.A.; Ibrahim, A.H.; Mohammed, H.E.-D. Management of construction cost contingency covering upside and downside risks. Alex. Eng. J. 2014, 53, 863–881. [Google Scholar] [CrossRef]

- Griffis, B.F.H.; Christodoulou, S.; Member, A. 44. Construction Risk Analysis Tool for Determining Liquidated Damages Insurance Premiums: Case Study. J. Constr. Eng. Manag. 2000, 126, 407–413. [Google Scholar] [CrossRef]

- Zayed, T. Assessment of Productivity for Concrete Bored Pile Construction. Ph.D. Thesis, Purdue University, West Lafayette, IN, USA, 2001. [Google Scholar]

- Chen, L.; Lu, Q.; Li, S.; He, W.; Yang, J. Bayesian Monte Carlo Simulation–Driven Approach for Construction Schedule Risk Inference. J. Manag. Eng. 2021, 37, 04020115. [Google Scholar] [CrossRef]

- Hair, F.J., Jr.; Sarstedt, M.; Hopkins, L.; Kuppelwieser, V.G. Partial least squares structural equation modeling (PLS-SEM): An emerging tool in business research. Eur. Bus. Rev. 2014, 26, 106–121. [Google Scholar] [CrossRef]

- Hair, F.J., Jr.; Sarstedt, M.; Ringle, C.M.; Gudergan, S.P. Advanced Issues in Partial Least Squares Structural Equation Modeling; saGe Publications: Thousand Oaks, CA, USA, 2017. [Google Scholar]

| Application | Purpose | Reference |

|---|---|---|

| Architectural Engineering | Learning teaching course | [27] |

| Construction engineering | Identifying the failure factors of the Yemen construction industry | [28] |

| Business | Planning business promotion strategies | [29] |

| Health care | find out the predictive relevance of the e-health readiness assessment approach. | [30] |

| Management | Analyze the implementation challenges for value management (VM) in construction projects. | [31] |

| Business | Enhancing the usage of the PLS-SEM for commercial marketing research | [32] |

| Education | Studying the impact of massive open online courses | [33] |

| Chemistry | Modeling for a virtual reality chemistry laboratory | [34] |

| Power | Analyzing factors influencing electric power quality | [35] |

| Construction engineering | Study the direct and indirect relationships among the group’s factors affecting the CCV | [36] |

| No. | Risk Name | Symbol | Risk Group | References |

|---|---|---|---|---|

| 1 | Natural disasters (earthquakes, floods, and hurricanes) | ER1 | External risks | [5] |

| 2 | Weather conditions (high/low temperatures, humidity, and rain) | ER2 | ||

| 3 | Improper and insufficient assessment of soil | DR1 | Design risks | [37] |

| 4 | Ambiguity in the purpose of the project | DR2 | ||

| 5 | The design requires innovative construction methods, equipment, or materials | DR3 | ||

| 6 | Changes in graphics, quantities, or methodology | DR4 | ||

| 7 | Incomplete information and design | DR5 | ||

| 8 | The length and diameter of the concrete pile | DR6 | ||

| 9 | The distance between the pile and the adjacent pile | DR7 | ||

| 10 | The nature of the project (piles for the foundations of a building and a bridge or piles supporting excavation walls) | DR8 | ||

| 11 | Poor communication between project stakeholders | MR1 | Management risks | [8] |

| 12 | Poor staff efficiency (delays in examination and testing, a delay in approving contractor submissions, ineffective decision making) | MR2 | ||

| 13 | Lack of quality management (planning, assurance, and control) | MR3 | ||

| 14 | Labor mistakes, rework, and idle times | CR1 | Construction risks | [38] |

| 15 | Manpower shortage | CR2 | ||

| 16 | Labor conflicts and disputes | CR3 | ||

| 17 | Safety issues | CR4 | ||

| 18 | Labor cost fluctuations | CR5 | ||

| 19 | Survey errors and site-handling mistakes | CR6 | ||

| 20 | The method of pouring concrete and its efficiency | CR7 | ||

| 21 | Waiting time for other operations (such as substrate axis adjustment). | CR8 | ||

| 22 | Crew experience | CR9 | ||

| 23 | A consultant’s requirement for concrete from a specific factory | CR10 | Identified by the experts | |

| 24 | Lack of management skills | SCR1 | Sub-contractor risks | [5] |

| 25 | Delay in the delivery of project requirements | SCR2 | ||

| 26 | Low credibility | SCR3 | ||

| 27 | Incidents with internal or external stakeholders | EQR1 | Equipment risks | [5] |

| 28 | Improper maintenance | EQR2 | ||

| 29 | Delays in the delivery of services and spare parts | EQR3 | ||

| 30 | The delay and/or failure of logistics services | EQR4 | ||

| 31 | The incompetence of operators | EQR5 | ||

| 32 | Drill type | EQR6 | ||

| 33 | The size of the withdrawal units | EQR7 | ||

| 34 | The number of pieces of equipment on site | EQR9 | Identified by the experts | |

| 35 | The size of the drilling machine | EQR9 | Identified by the experts | |

| 36 | Failure to obtain approvals or permits | PGR1 | Political and governmental risks | [38,39] |

| 37 | Import restrictions | PGR2 | ||

| 38 | Lack of funds: a lack of cash flow from the contractor | ECR1 | Economical risks | [5] |

| 39 | Rising maintenance expenses as a result of poor contractor servicing | ECR2 | ||

| 40 | Rising maintenance expenses as a result of poor supplier servicing | ECR3 | ||

| 41 | Inflation risk: unexpected price changes. | ECR4 | ||

| 42 | Economic crisis | ECR5 | ||

| 43 | Foreign exchange risks: unstable exchange rates, transfer restrictions, and supply and demand balance | ECR6 | ||

| 44 | Failure to finance the project | OGR1 | Owner generated risks | [5,40] |

| 45 | Unqualified owner representatives | OGR2 | ||

| 46 | The delay or refusal of compensation to the contractor | OGR3 | ||

| 47 | An owner’s ultra-standard expectations and requirements | OGR4 | ||

| 48 | A delay in or the inability of the owner to provide full possession of the site | OGR5 | ||

| 49 | Investigation samples do not cover the entire study area | SR1 | Site risks | [40] |

| 50 | Soil type | SR2 | ||

| 51 | Issues due to size limitations | SR3 | ||

| 52 | Space considerations at the construction site | SR4 | ||

| 53 | On-site infrastructure | SR5 |

| Option | Option Coding | Normalized Value |

|---|---|---|

| Very low | 1 | 0.1 |

| Low | 2 | 0.3 |

| Moderate | 3 | 0.5 |

| High | 4 | 0.7 |

| Very high | 5 | 0.9 |

| Model | Group | CMR | AVE | p-Value | Significant Factors |

|---|---|---|---|---|---|

| Model 1 | ER | 0.51 | 0.50 | 0.319 | ER1, ER2 |

| Model 2 | DR | 0.7 | 0.54 | 0.0593 | DR4, DR5 |

| Model 3 | MR | 0.67 | 0.52 | 0.001 | MR1, MR2 |

| Model 4 | CR | 0.71 | 0.56 | 0.007 | CR4, CR6 |

| Model 5 | SCR | 0.69 | 0.52 | 0.131 | SCR1, SCR2 |

| Model 6 | EQR | 0.69 | 0.52 | 0.067 | EQR2, EQR |

| Model 7 | PGR | 0.22 | 0.46 | 0.56 | PGR1, PGR2 |

| Model 8 | ECR | 0.67 | 0.53 | 0.30 | ECR5, ECR6 |

| Model 9 | OGR | 0.69 | 0.53 | 0.014 | OGR2, OGR3 |

| Model 10 | SR | 0.67 | 0.51 | 0.004 | SR1, SR2 |

| Group | CMR | AVE | p-Value | Significant Factors |

|---|---|---|---|---|

| ER | 0.65 | 0.55 | 0.687 | ER1, ER2 |

| DR | 0.7 | 0.55 | 0.277 | DR2, DR4 |

| MR | 0.69 | 0.53 | 0.613 | MR1, MR3 |

| CR | 0.72 | 0.58 | 0.015 | CR3, CR6 |

| SCR | 0.59 | 0.51 | 0.244 | SCR1, SCR2 |

| EAR | 0.68 | 0.53 | 0.05 | EQR4, EQ6 |

| PGR | 0.70 | 0.55 | 0.067 | PGR1, PGR2 |

| ECR | 0.66 | 0.51 | 0.04 | ECR2, ECR4 |

| OGR | 0.68 | 0.52 | 0.001 | OGR2, OGR2 |

| SR | 0.71 | 0.55 | 0.065 | SR4, SR5 |

| Group | CR | AVE | p-Value | Significant Factors |

|---|---|---|---|---|

| ER | 0.417 | 0.51 | 0.338 | ER1, ER2 |

| DR | 0.72 | 0.57 | 0.019 | DR7, DR8 |

| MR | 0.63 | 0.52 | 0.063 | MR1, MR3 |

| CR | 0.70 | 0.53 | 0.096 | CR1, CR8 |

| SCR | 0.66 | 0.51 | 0.106 | SCR1, SCR2 |

| EAR | 0.71 | 0.55 | 0.124 | EQR4, EQ6 |

| PGR | 0.039 | 0.53 | 0.425 | PGR1, PGR2 |

| ECR | 0.68 | 0.51 | 0.038 | ECR1, ECR3 |

| OGR | 0.68 | 0.52 | 0.001 | OGR2, OGR2 |

| SR | 0.71 | 0.55 | 0.065 | SR4, SR5 |

| Group | CR | AVE | p-Value | Significant Factors |

|---|---|---|---|---|

| ER | 0.66 | 0.049 | 0.687 | ER1, ER2 |

| DR | 0.73 | 0.57 | 0.277 | DR7, DR8 |

| MR | 0.68 | 0.53 | 0.613 | MR1, MR2 |

| CR | 0.72 | 0.54 | 0.015 | CR1, CR5 |

| SCR | 0.76 | 0.56 | 0.244 | SCR1, SCR2 |

| EAR | 0.64 | 0.606 | 0.05 | EQR1, EQ2 |

| PGR | 0.68 | 0.47 | 0.067 | PGR1, PGR2 |

| ECR | 0.68 | 0.52 | 0.04 | ECR1, ECR6 |

| OGR | 0.71 | 0.55 | 0.001 | OGR1, OGR4 |

| SR | 0.708 | 0.55 | 0.065 | SR2, SR3 |

| Time | Cost | ||||

|---|---|---|---|---|---|

| Risk Group | CMR | AVE | Risk Group | CMR | AVE |

| CR | 0.706 | 0.558 | CR | 0.736 | 0.583 |

| MR | 0.671 | 0.519 | ECR | 0.658 | 0.504 |

| OGR | 0.684 | 0.528 | EAR | 0.679 | 0.524 |

| SR | 0.642 | 0.504 | OGR | 0.676 | 0.515 |

| SR | 0.711 | 0.553 | |||

| Time | Cost | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| CR | ECR | EAR | OGR | SR | CR | ECR | EAR | OGR | SR | ||

| CR | 0.747 | CR | 0.763 | ||||||||

| MR | 0.130 | 0.720 | ECR | 0.193 | 0.710 | ||||||

| OGR | 0.038 | 0.052 | 0.727 | EAR | 0.093 | 0.123 | 0.724 | ||||

| SR | 0.213 | 0.092 | 0.184 | 0.710 | OGR | 0.224 | 0.109 | 0.132 | 0.718 | ||

| SR | 0.140 | 0.152 | 0.121 | 0.132 | 0.744 | ||||||

| Time | Cost | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| CR | MR | OGR | SR | CR | ECR | EAR | OGR | SR | ||

| CR4 | 0.893 | 0.134 | −0.003 | 0.198 | CR3 | 0.743 | 0.168 | 0.083 | 0.215 | 0.094 |

| CR6 | 0.565 | 0.041 | 0.088 | 0.106 | CR6 | 0.783 | 0.128 | 0.061 | 0.131 | 0.119 |

| MR1 | 0.154 | 0.529 | 0.051 | 0.010 | ECR2 | 0.180 | 0.858 | 0.115 | 0.076 | 0.113 |

| MR2 | 0.064 | 0.870 | 0.032 | 0.102 | ECR4 | 0.076 | 0.523 | 0.047 | 0.086 | 0.110 |

| OGR2 | 0.007 | 0.033 | 0.846 | 0.161 | EQR4 | 0.096 | 0.107 | 0.853 | 0.054 | 0.076 |

| OGR3 | 0.060 | 0.048 | 0.584 | 0.100 | EQR6 | 0.026 | 0.065 | 0.566 | 0.167 | 0.111 |

| SR1 | 0.089 | 0.093 | 0.065 | 0.426 | OGR2 | 0.143 | 0.064 | 0.053 | 0.809 | 0.077 |

| SR2 | 0.195 | 0.059 | 0.174 | 0.908 | OGR5 | 0.189 | 0.098 | 0.153 | 0.613 | 0.122 |

| SR4 | 0.138 | 0.104 | 0.090 | 0.058 | 0.696 | |||||

| SR5 | 0.076 | 0.122 | 0.090 | 0.133 | 0.789 | |||||

| Time | Cost | ||||||

|---|---|---|---|---|---|---|---|

| Path | b | t-Value | p Values | Path | b | t-Value | p Values |

| CR → Time | 0.095 | 1.800 | 0.072 | CR → COST | 0.122 | 2.043 | 0.042 |

| MR → Time | 0.149 | 2.836 | 0.005 | ECR → CR | 0.193 | 2.419 | 0.016 |

| OGR → SR | 0.184 | 1.682 | 0.093 | EQR → COST | 0.095 | 1.696 | 0.091 |

| OGR → Time | 0.106 | 1.723 | 0.086 | OGR → COST | 0.174 | 3.416 | 0.001 |

| SR → CR | 0.213 | 1.694 | 0.091 | SR → ECR | 0.152 | 1.864 | 0.063 |

| SR → Time | 0.091 | 1.668 | 0.096 | ||||

| Time | Cost | ||||

|---|---|---|---|---|---|

| Risk Group | CMR | AVE | Risk Group | CMR | AVE |

| DR | 0.718 | 0.566 | DR | 0.724 | 0.569 |

| ECR | 0.673 | 0.510 | EAR | 0.689 | 0.474 |

| EAR | 0.714 | 0.556 | OGR | 0.710 | 0.558 |

| MR | 0.683 | 0.525 | SR | 0.710 | 0.550 |

| OGR | 0.691 | 0.528 | |||

| Time | Cost | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| DR | ECR | EAR | MR | OGR | DR | EAR | OGR | SR | ||

| DR | 0.752 | DR | 0.754 | |||||||

| ECR | 0.150 | 0.714 | EAR | 0.218 | 0.689 | |||||

| EAR | 0.204 | 0.111 | 0.745 | OGR | 0.203 | 0.098 | 0.747 | |||

| MR | 0.156 | 0.141 | 0.086 | 0.724 | SR | 0.208 | 0.034 | 0.051 | 0.742 | |

| OGR | 0.209 | 0.182 | 0.064 | 0.110 | 0.727 | |||||

| Time | Cost | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| DR | ECR | EAR | MR | OGR | DR | EAR | OGR | SR | ||

| DR7 | 0.630 | 0.073 | 0.115 | 0.050 | 0.138 | DR7 | 0.701 | 0.136 | 0.156 | 0.069 |

| DR8 | 0.857 | 0.143 | 0.184 | 0.165 | 0.175 | DR8 | 0.804 | 0.188 | 0.152 | 0.232 |

| ECR1 | 0.145 | 0.790 | 0.117 | 0.160 | 0.150 | EQR1 | 0.197 | 0.927 | 0.105 | 0.048 |

| ECR3 | 0.061 | 0.630 | 0.033 | 0.028 | 0.108 | EQR2 | 0.077 | 0.300 | −0.007 | −0.032 |

| EQR4 | 0.149 | 0.056 | 0.732 | 0.056 | 0.064 | OGR1 | 0.148 | 0.028 | 0.610 | −0.001 |

| EQR7 | 0.156 | 0.107 | 0.759 | 0.072 | 0.032 | OGR4 | 0.160 | 0.105 | 0.862 | 0.064 |

| MR1 | 0.131 | 0.136 | 0.072 | 0.831 | 0.090 | SR2 | 0.161 | 0.039 | 0.030 | 0.768 |

| MR3 | 0.091 | 0.058 | 0.051 | 0.599 | 0.068 | SR3 | 0.148 | 0.010 | 0.046 | 0.714 |

| OGR2 | 0.145 | 0.141 | 0.046 | 0.117 | 0.766 | |||||

| OGR4 | 0.159 | 0.124 | 0.047 | 0.038 | 0.685 | |||||

| Time | Cost | ||||||

|---|---|---|---|---|---|---|---|

| Path | b | t Value | p-Value | Path | b | t Value | p-Value |

| DR → TIME | 0.139 | 1.898 | 0.058 | DR → COST | 0.374 | 2.095 | 0.037 |

| ECR → TIME | 0.111 | 1.873 | 0.062 | EQR → DR | 0.211 | 1.713 | 0.087 |

| EQR → DR | 0.193 | 1.966 | 0.050 | OGR → Cost | 0.166 | 2.368 | 0.018 |

| MR → DR | 0.139 | 1.689 | 0.092 | SR → DR | 0.201 | 2.587 | 0.010 |

| OGR → ECR | 0.182 | 2.261 | 0.024 | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alsanabani, N.M.; Al-Gahtani, K.S.; Almohsen, A.S.; Alsharef, A. Risk Interdependency Network Model for the Cost and Time of Pile Installation in Saudi Arabia, Using Partial Least Squares Structural Equation Modeling. Appl. Sci. 2023, 13, 10886. https://doi.org/10.3390/app131910886

Alsanabani NM, Al-Gahtani KS, Almohsen AS, Alsharef A. Risk Interdependency Network Model for the Cost and Time of Pile Installation in Saudi Arabia, Using Partial Least Squares Structural Equation Modeling. Applied Sciences. 2023; 13(19):10886. https://doi.org/10.3390/app131910886

Chicago/Turabian StyleAlsanabani, Naif M., Khalid S. Al-Gahtani, Abdulmohsen S. Almohsen, and Abdullah Alsharef. 2023. "Risk Interdependency Network Model for the Cost and Time of Pile Installation in Saudi Arabia, Using Partial Least Squares Structural Equation Modeling" Applied Sciences 13, no. 19: 10886. https://doi.org/10.3390/app131910886

APA StyleAlsanabani, N. M., Al-Gahtani, K. S., Almohsen, A. S., & Alsharef, A. (2023). Risk Interdependency Network Model for the Cost and Time of Pile Installation in Saudi Arabia, Using Partial Least Squares Structural Equation Modeling. Applied Sciences, 13(19), 10886. https://doi.org/10.3390/app131910886