Featured Application

The Intergovernmental Panel on Climate Change (IPCC)’s Sixth Assessment Report (AR6) recognizes the physico-chemical process known as carbonation. The present paper utilizes a way of calculating carbon dioxide uptake quickly and easily following the simplified methodology known as Tier 1 applied to the largest cement consumer in South America.

Abstract

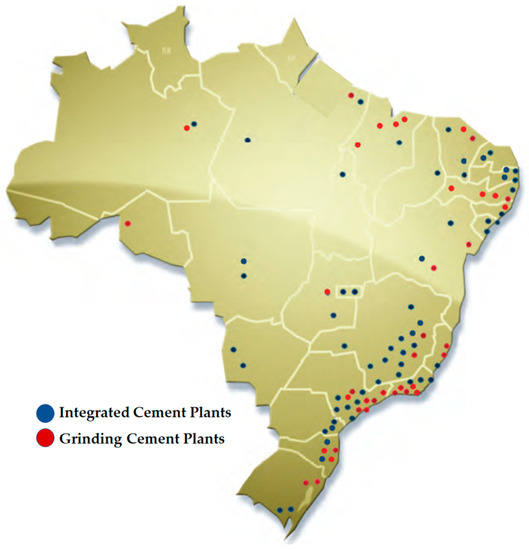

The worldwide cement industry plays an important role in addressing the climate change challenge. Brazil’s cement industry currently has 91 cement plants with an installed production capacity of 94 million tons per year and has started to calculate the net CO2 emissions to achieve a carbon-neutral cement sector by 2050. Accordingly, the carbon dioxide uptake due to mortar and concrete carbonation is subtracted from the carbon dioxide emitted by the chemical reaction for the calcination of lime, i.e., the calcination process performed during clinker production. Now-adays, the Intergovernmental Panel on Climate Change (IPCC) Guidelines for National Greenhouse Gas (GHG) Inventories to report the GHG emissions do not include any calculation procedure to consider the mortar and concrete carbonation. However, the Intergovernmental Panel on Climate Change (IPCC)’s Sixth Assessment Report (AR6) recognizes the physico-chemical process known as carbonation. Brazilian net carbon dioxide emissions of cements produced from 1990 to 2019 are estimated considering the carbon dioxide uptake during the service-life and end-of-life and secondary usage stages (Tier 1). This is a fundamental scientific and technological novelty that changes the current approach to estimate the carbon dioxide emissions due to the Portland cement clinker production. Even considering the relative novelty of this approach, it should be promoted in the future and included in the national inventory report (NIR). The carbon dioxide uptake by mortar and concrete carbonation for 30 years is about 140 million tons. Within this thirty-year period about 483 million tons have been released due to the calcination process.

1. Introduction

The international climate change context is undergoing increasingly rapid change, forcing citizens, industry, and countries to mitigate carbon dioxide ever more quickly if they do not want to be excluded from the developments that are shaping the world. Accordingly, the global cement industry is always looking for innovations to cut emissions.

Carbon dioxide uptake by concrete carbonation can help induce systemic changes by improving the assessment of anthropogenic carbon dioxide emissions. Such meaningful systemic changes will not have immediate results, but are expected to yield innovative products, production processes, and business models, i.e., low-carbon cements and concretes, carbon dioxide curing, circular business models, etc. All of these will be critically important for achieving transitions to net-zero carbon emissions.

1.1. International Climate Change Context

The Intergovernmental Panel on Climate Change (IPCC), which is the United Nations body for assessing the science and establishing policy-relevant facts related to climate change, has recently developed an analysis of key findings on the impact of the increase in CO2 emissions on climate change [1]. The IPCC’s Sixth Assessment Report examines the sources of global emissions and provides an updated assessment of the progress on climate change mitigation. As is the case with most environmental science research, assessing causality is a significant challenge, which in this instance is to determine the relationship between the impact of national climate commitments and long-term emissions goals outcomes. The IPCC’s Sixth Assessment Report (AR6) sets in its first part entitled “Climate Change 2021: The Physical Science Basis” [2] that “the uptake of CO2 in cement infrastructure (carbonation) offsets about one half of the carbon dioxide emissions from current cement production”. Furthermore, it is also mentioned that the carbon budget has been improved by adding a method for estimating the carbon dioxide emissions from cement production and the sink associated with mortar and concrete carbonation. Finally, in March 2023, the Intergovernmental Panel on Climate Change (IPCC) has considered the Synthesis Report, the closing chapter of the Sixth Assessment Report (AR6), at its 58th Plenary Session which was held in Interlaken, Switzerland. This Synthesis Report integrates all the findings collected in the six reports released by the IPCC during the Sixth Assessment Cycle which began in 2015, i.e., three Special Reports plus three Reports made by the IPCC Working Groups [3].

China has proposed a goal to achieve carbon neutrality by 2060 and Dinga and Wen [4] recognized that the cement paste in concrete can take up as much carbon dioxide emissions as that produced during calcination. Moreover, accounting for carbon dioxide due to carbonation could represent a significant impact in decarbonizing China’s cement industry. Considering 15% of the carbon dioxide uptake of all the carbon dioxide produced by calcination, carbonation will aid in reducing 8.8% of global emissions by 2060. Therefore, it is essential for China to add carbonation effects when constructing its carbon dioxide emission inventories for the cement industry. This approach is consistent with what is currently known regarding the carbon dioxide uptake by cement-based materials [5]. Summing up, achieving carbon neutrality in China’s Cement Industry by 2060 is possible under advanced and aggressive abatement scenarios.

Zhang and Wang [6] proposed to develop a multifaceted approach to reach carbon peaking in the cement industry, i.e., to achieve the point at which carbon dioxide emissions from the cement industry attain the highest level and then subsequently drop. Furthermore, the idea that the global cement industry has a huge potential to bring about changes to minimize global warming was supported.

1.2. General Background on the Carbonation as a Stage in the Decarbonization Roadmaps

Petroche and Ramírez [7] performed a life cycle assessment (LCA) based on Ecuadorian inventories to assess the environmental sustainability of the cement industry in Ecuador. They concluded that it could be applied to the broader Latin American region. Global Warming Potential (GWP) for clinker was 897 kg CO2/ton and 126–442 kg CO2/m3 for ready-mixed concrete. Nevertheless, they do not yet consider the concrete carbonation process in their life cycle assessment (LCA).

Hon Chung Lau [8] presented the decarbonization roadmaps for the ten ASEAN countries for the first time. Countries belonging to the Association of Southeast Asian Nations (ASEAN) are Brunei Darussalam, Burma, Cambodia, Indonesia, Laos, Malaysia, Philippines, Singapore, Thailand, and Vietnam. The ASEAN countries are rich in natural resources containing up to 20% of all known species of the world. The equator passes through both the north of Brazil and Indonesia. Thus, some climatic similarities between some regions of Brazil and the ASEAN countries can be found. However, the ASEAN area is facing a substantial increase in temperature and rainfall intensity and duration, with frequent floods, droughts, and fires.

Hon Chung Lau [8] highlighted that to decarbonize industries which require high-temperature heating such as the cement sector, hydrogen can be used. In addition, considering carbon capture and storage in the roadmap, it was mentioned in particular that there are 57 Gt of CO2 storage potential in Vietnam, Thailand, Philippines, and South Sumatra. Nevertheless, the roadmap has, unfortunately, not considered the cement-based materials’ carbonation yet.

The technical and economic systems that serve to minimize waste and maximize the reuse of resources, material efficiency measures, biofuel substitution, renewable electricity usage, and carbon capture and storage are known as “the new circular economy paradigm”. Recent studies based on this paradigm have demonstrated that carbon dioxide emissions associated with Building Design + Construction and transport infrastructures can be lowered about 50% by 2030 and 90% by 2045 [9]. However, while concrete structures can uptake part of the embodied carbon dioxide if exposed to air, this is not considered in some recent studies [10]. By contrast, the same authors included concrete carbonation in the reference LCA study.

A limited number of reviews have been performed to shed light on the capacity of concrete for natural carbonation, carbonation curing, and mineral carbonation, which are either focused on one of these carbonation procedures or oriented to assess the impact of carbonation on the mechanical and durable properties of the concretes [11].

Accelerated carbonation as an effective approach for reducing the carbon footprint in cement-based materials has been widely researched. With regard to the selection of carbon dioxide utilization products, three criteria are assessed for each product: technology readiness level (TRL), carbon dioxide uptake potential, and energy demand. The technology readiness level (TRL) definitions of the different technological routes were provided in the Horizon 2020 Work Programme [12]. Carbonated concrete and aggregates production via carbon dioxide mineralization is at TRL 9 “actual system proven in operational environment”. Some examples are Solidia Cement™ and CarbonCure™ to produce carbonated cement by carbon dioxide curing technology and Carbon8 for carbonated aggregates [13].

Sereng et al. [14] studied accelerated carbonation on recycled concrete aggregates (RCAs) and recorded a mean value of CO2 uptake of about 15–20 g/kg RCA. In addition, accelerated carbonation reduced by 67% the water absorption coefficient, decreasing the total porosity as a result of the capillary pores clogging. By contrast, RCA microporosity is increased as a result of the C-S-H gel decalcification. In particular, Bretti and Ceseri [15] modeled the effects of climate change on the porosity of Portland cement paste. Guo et al. [16] found that the carbon dioxide uptake per mass of cement paste reached 22–26% after a 28-day carbon dioxide curing. Also, the total porosity decreased as a result of the reduction in the pores volume with diameters less than 50 nm.

Silva et al. [17] found promising results in the cement paste powder generated in the recycling process of concrete, which is a material composed mainly of hydrated cement, and was subjected to carbonation. Hu et al. [18] found that the addition of polypropylene fibers enhanced the CO2 uptake of cement-based materials subjected to the CO2-curing process. According to Xuan et al. [19], the use of eggshell powder added to the Portland cement under carbonation-curing conditions improved the mechanical characteristics and durability of the cement-based materials. Furthermore, Wang and Wang [20] reported that the use of biochar with LC3 binders could enhance the environmental benefits of Portland cement.

Alimi et al. [21] assessed the impact of cement kiln dust (CKD) on the carbon dioxide uptake of concrete. Two CKDs with different fineness were used as a cement constituent (0–60%) in two mortar mixes (water/binder ratios of 0.5 and 0.425). Mortar specimens were subjected to accelerated carbonation curing for 12 h. The global carbon dioxide uptake in CKD mixes was less than those of the control mixes. However, the relative carbon dioxide uptake, given as a percentage of the cement content, was higher in mixes made with the finer CKD at the higher water/binder ratio. Accordingly, it was concluded that the replacement of cement by CKD promoted a reduction in the carbon dioxide uptake of mortars.

Merino-Lechuga et al. [22] studied the effect of accelerated carbonation on the properties of precast concretes made with natural and recycled aggregates. Natural aggregates were replaced by recycled aggregates and two carbonation conditions were used: accelerated carbonation (5% CO2) and natural carbonation (atmospheric carbon dioxide). The accelerated carbonation increased the density, the compressive strength, and the carbon dioxide capture, which was 525% higher compared to curing under natural carbonation. Therefore, carbon curing is a promising technology to mitigate the effects of climate change. Consequently, the effective CO2 sink process of precast concrete elements was suggested.

AzariJafari et al. [23] evaluated the carbon dioxide uptake of the U.S. pavement network for 30 years (2020–2050) during its use and end-of-life stage. Their study showed that 5.8 million tons of carbon dioxide can be taken up by concrete pavements in the U.S. Furthermore, stockpiling the crushed concrete at the end-of-life period could raise the carbon uptake to 11.8 million tons for 30 years (2020–2050). Therefore, concrete stockpiling is a cost-effective method of carbon dioxide abatement ($25–$100/ton of carbon dioxide).

By contrast, Huovila et al. [24] forgot the beneficial effect of concrete carbonation and albedo in their critical review on carbon-neutral cities. In the target category of “built environment and community structure”, the use of recycled materials in infrastructure is mentioned as an action. Nevertheless, in the target category of “carbon sinks, sequestration and biodiversity”, the authors included “Increasing carbon stock of forest and other green areas in city area”, but omitted the reference to the high albedo of the concrete pavements, which has been studied extensively in several cities [25,26], and also did not discuss concrete carbonation. Since cities have geographically bounded areas, which restrict the potential for development of land-based carbon sequestration, a more significant role for other types of carbon dioxide uptake is expected, such as the use of some carbonatable cement-based materials. Furthermore, the use of materials of high albedo in buildings and pavements should be taken into account.

Younsi [27] compared the carbon dioxide uptake calculated with the standardized method described in the European Standard EN 16757 [28] to that calculated with the parameters measured experimentally. It was concluded that the predictions of the European Standard EN 16757 underestimate the carbonation rate, underestimate the carbonation degree (indoor exposure), and overestimate the carbonation degree (outdoor exposure). Accordingly, several adjustments to the parameters given in the European Standard EN 16757 were recommended.

In addition, Younsi et al. [29] studied the carbon dioxide uptake of several types of Portland cement concretes after a 10-year natural carbonation and compared the experimental results with the ones calculated by applying the EN 16757 procedure. The standard procedure underestimates the carbon dioxide uptake of concretes made with additions, mainly as a consequence of their carbonation depth underestimation, especially for concretes with a high ground granulated blast-furnace slag content [30].

Wang and Lee proposed an optimal slag-blended concrete mix design to mitigate the impact of global warming considering compressive strength and carbonation resistance [31].

Finally, it should be taken into account that the net carbon dioxide emissions increase as the compressive strength increases and the carbon dioxide uptake ratio increases [32].

The aim and novelty of this paper is to present, for the first time in the technical literature, a proper factual calculation of carbon removals in Brazil by the carbonation of cement-based materials.

The remainder of this paper is structured as follows: following the introduction, Section 2 presents an outlook of the Brazilian Cement Sector’s current situation; Section 3 provides an overview of the method to estimate the carbon dioxide removals due to carbonation; and Section 4 presents an analysis of the cement production and consumption in America and the carbonation results of Brazilian cement-based materials.

2. The Brazilian Cement Sector

Brazil counts 91 cement manufacturing plants (Figure 1) controlled by 23 industrial groups (Table 1) [33] with a capacity of 94 million tons of cement per year (2022) [33]. The cement production and cement sales were 65.8 and 64.7 million tons in 2021, respectively. Further, the apparent consumption was 64.395 million tons in 2021 (Figure 2). Infrastructure building, housing construction work, and property development contributed to the rise by 6.6% year-to-year from the 2020 cement consumption levels. By contrast, cement sales decreased by 3% year-to-year to 63.1 million tons in 2022, according to the Brazilian National Cement Industry Association (SNIC). This is due to the fact that dispatches dropped in the Southeast, Northeast, and South areas, although sales increased elsewhere in Brazil. In addition, exports fell to 0.40 million tons (2022) from 0.47 million tons (2021). However, the sales forecast for 2023 is an increase of 1%, which would result in a mass market close of up to 64 million tons [34].

Figure 1.

Brazilian integrated and grinding cement plants (2022).

Table 1.

Cement Plants in Brazil (Data from: http://snic.org.br/fabricas-localizacoes.php, accessed on 10 January 2023.

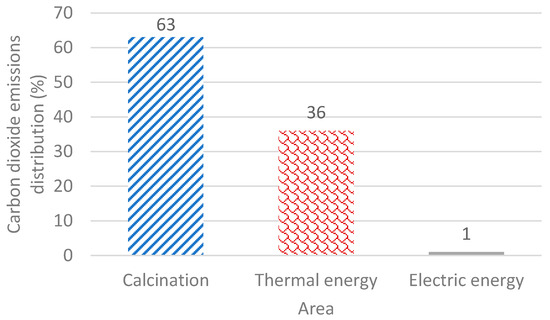

Figure 2.

Carbon dioxide emissions broken down by area by the cement production in Brazil (2022) «source: author original».

Cement manufacturing starts with clinker production in kilns. This stage is the time when direct carbon dioxide emissions occur. Normally, from 30% to 40% of the direct carbon dioxide emissions result from the combustion of fuels and the remaining 60–70% are intrinsic to the chemical process involved in the conversion of limestone to calcium oxide in the formation of clinker (calcination). About 5% of carbon dioxide emissions occur indirectly, primarily because of the electrical consumption by the factory.

In Brazil, fuels combustion represents 36% of the global carbon dioxide emissions, whereas calcination contributes another 63% to the carbon dioxide emissions (Figure 2). In addition, electrical energy contributes approximately one per cent to the global emissions, since renewable sources currently have the largest share in electric power capacity in Brazil (74%).

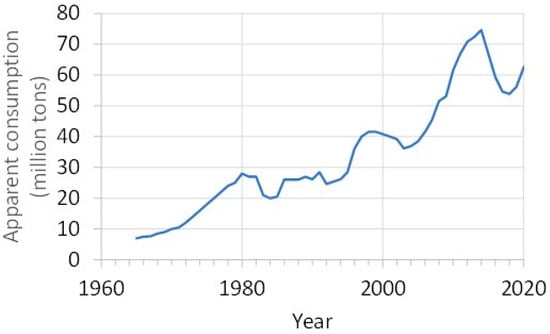

The period of time between 1965 and 1981 was called the Brazilian economic miracle, while the 1981–2003 period entailed market consolidation with cement consumption ranging from 20 to 40 million tons of cement (Figure 3). From 2003 until 2014, a sharp growth was observed, i.e., from about 35 to around 70 million tons. Later, after a decrease in four years, between 2015 and 2018, there was a rise in the apparent consumption up to values of about 65 million tons (Figure 3).

Figure 3.

Apparent consumption in Brazil from 1965 to 2022 (million tons per annum) «source: author original».

2.1. The Brazilian Cement Industry’s Potential for Reducing Carbon Dioxide Emissions by 2050

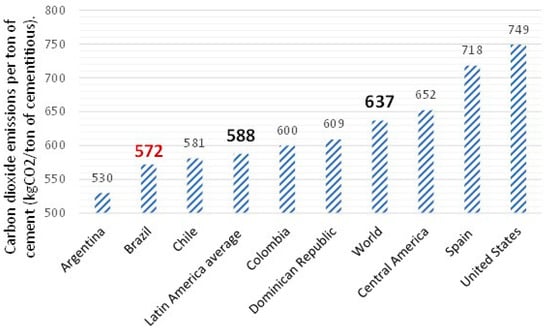

As a developing country, Brazil has a significant infrastructure program to be implemented in the wake of the increase in population and urbanization patterns. Therefore, the demand for cement in the coming decades will rise. The energy-intensive and emission-intensive cement industry would thus be obliged to limit the emission of greenhouse gases. The cement industry globally accounts for approximately 7.4% (2.9 Gtons in 2016) [35] of all anthropogenic carbon dioxide emissions. By contrast, this share is about 2.6% in Brazil because of a set of actions that the Brazilian cement sector has been implementing for years. Consequently, Brazil is one of the countries worldwide that emits the lowest amount of carbon dioxide per ton of cement. Figure 4 shows a comparison of the carbon dioxide emissions per ton of cement (2015) between Brazil (572 kg CO2/ton of cementitious) and some other countries. The Latin American and world average in 2015 were 588 and 637 kg CO2/ton of cementitious, respectively.

Figure 4.

Comparison of the carbon dioxide emissions per ton of cement in some countries (kgCO2/ton of cement) «source: author original».

The Brazilian cement sector has developed a Cement Technology Roadmap presenting some alternatives for mitigating carbon dioxide emissions from the national industry in the short- and long-term, and for the commitment of reducing carbon dioxide [36]. Accordingly, the Brazilian cement sector has committed to a 34% reduction in carbon dioxide emissions due to the cement production, to 375 kg/ton of cement by 2050 from 564 kg/ton of cement recorded in 2019.

2.2. The Brazilian Cement Sector Roadmap

Brazilian cement production expanded at rates well above 273 per cent between 1990 and 2014, i.e., from 26 million to 71 million tons. By contrast, global carbon dioxide emissions increased by 223% over this period. This result was mostly due to the 18% reduction in carbon dioxide emissions intensity from 700 kg CO2/ton cement to 564 kg CO2/ton cement over this period. Accordingly, the Brazilian cement industry has one of the lowest worldwide levels of specific carbon dioxide emissions, on account of mitigation measures implemented by the Brazilian industry over recent decades [36].

One of the main mitigation measures is the increase in cement constituents, such as limestone and calcined clay, to partially replace the clinker in the final blended cement. It is expected there will be a sharp clinker/cement ratio reduction from 67% (2014) to 52% in 2050, allowing for significant CO2 emissions reduction (290 million tons in the period). Therefore, the carbon dioxide mitigation due to the clinker substitution will represent a 69% decrease.

The average thermal consumption and electricity consumption in Brazil is 3.5 GJ/t of clinker and 113 kWh/t of cement, respectively (Table 2). Although significant changes in cement production energy intensity are not expected by 2030, the replacement of obsolete installations with new lines according to the best available technologies (BATs) might start after 2030 in order to reach figures of 3.2 GJ/t of clinker and 91 kWh/t cement by 2050. These measures will lead to a cumulative carbon dioxide depletion of 38 million tons by 2050 (9% of the Brazilian industry mitigation).

Table 2.

Key indicators for the Brazilian cement industry by 2030 and 2050 within the 2 °C scenario.

With regard to the substitution rate with alternative fuels (% of thermal substitution), some regional differences have been observed in Brazil. Therefore, the range of substitution could be 30–40% and 50–60% for 2030 and 2050, respectively. Consequently, the carbon dioxide mitigation due to the increase in alternative fuel’s usage is about 13%.

Finally, Carbon Capture, Usage, and Storage (CCUS) technologies will play a key role in decarbonization in the Brazilian cement sector and in addressing the challenge of global climate change. It is expected to reach a cumulative reduction of 38 million tons of carbon dioxide (9% of the Brazilian industry mitigation).

3. Method to Estimate the Carbon Dioxide Removals Due to Carbonation

Within the Intergovernmental Panel on Climate Change (IPCC) reporting, a Tier represents the level of methodological complexity utilized to estimate greenhouse gas emissions for a specific source. Accordingly, Tier 1 is the basic methodology designed for all categories and ready to be used. Consequently, it is feasible for all countries. The 2006 IPCC Guidelines for National Greenhouse Gas (GHG) Inventories to report the GHG emissions give guidance on the choice of the most suitable method to estimate calcination emissions during the clinkerization process, based on national circumstances, and on how to estimate calcination carbon dioxide emissions at each Tier [37].

The Tier 1 methodology followed in the present study utilizes a generalized carbon dioxide uptake factor as shown in Equations (1) and (2). These equations consider the carbon dioxide uptake by mortars and concrete during their whole service life cycles.

Tier 1 is a basic adjustment method to obtain a removal estimate as described in the 1996 IPCC Guidelines [37]. This method is applicable if activity data are available from national sources. The Intergovernmental Panel on Climate Change (IPCC) Tier 1 approach, in which default values are used, is a simple procedure and can be considered as a first step to estimate the carbon dioxide uptake by cement-based materials (mortars and concretes).

There is no country in South America where Tier 1 is currently used. It is therefore of great importance to begin the expeditious implementation of this basic method in the zone.

Based on the studies found in the literature [38,39], we have considered the carbon dioxide uptake in the use stage (20%), during the end-of-life (2%), and for the secondary use (1%).

Carbon dioxide uptake = (0.20 + 0.02 + 0.01) × CO2 emissions from calcination

Carbon dioxide uptake = 0.23 × national CO2 emissions from calcination

It is well-known that mortars used for rendering applications will carbonate more rapidly than concretes, i.e., rendering mortars will remove carbon dioxide in a short period of time.

Accordingly, when a high proportion of the cement consumption is used as mortar, i.e., more than 10% but less than 30% (10%–30%), for the carbon dioxide uptake a correction factor should be applied as follows (Equation (3)). The source of the coefficients given in this Equation is the study entitled “CO2 Uptake in Cement-Containing Products. In Background and Calculation Models for IPCC Implementation” [39].

where the mortar factor is the percentage for rendering the mortar of the total clinker usage. This value will be 10 when the rendering mortar factor is below 10% and 30 when this value is above 30%.

Carbon dioxide uptake = ((0.20 + 0.02 + 0.01) + (0.0115 (mortar factor − 10))) × CO2 emissions from calcination

Summing up, in the last Equation, carbon dioxide uptake can be assessed as a four-terms equation, corresponding to the service life period (20%), end-of-life (2%), secondary use (1%), and then is broadened with an additional term for the mortar. The reason for this is because of the great difference between mortar and concrete regarding the carbonation rate as explained below.

According to Leemann et al. [40], the carbonation resistance in mortar and concrete is mainly governed by the carbon dioxide buffer capacity per volume of cement paste. In addition, the (water/CaOreactive) ratio is an indicator to evaluate such carbonation resistance. This indicates that the higher the cement content in the mortar or concrete, the better the carbonation resistance; and the lower the water/CaOreactive ratio, the better the carbonation resistance.

Masonry mortars usually are made with high water/cement ratios (w/c about 0.60), whereas concretes normally are made with lower w/c ratios [41], as low as 0.45 in some cases depending on the exposure class [42,43]. Furthermore, when the water-to-cement ratio is increased, the capillary porosity is increased. Capillary porosity is the main factor negatively affecting the compressive strength of cement-based materials, in addition to the carbon dioxide coefficient.

The minimum cement content in concrete for the exposure class XC 1 is 260 kg/m3 (C20/25 concrete with 20–25 N/mm2), while for the exposure class XA 1 is 360 kg/m3 (C35/45 concrete with 35–45 N/mm2) [41]. By contrast, there are different grades of cement mortar (M0.5–M7.5), which is the minimum required for 28-days compressive strength (0.5–7.5 N/mm2). The ratio of cement to sand ranges generally from 1:3 to 1:8 for the mortar to be workable and strong. Proportions of the Portland cement mortar for masonry work with brick/stone as the structural unit range from 1:3 to 1:6 (cement:sand); for architectural work it is about 1:6 and for flooring work the cement:sand proportions range from 1:4 to 1:8. Similar proportions can be found in the American Standard Specification for Mortar Cement [44]. It is essential to point out that mortar involves, first and foremost, the use of low-clinker cements. For instance, the clinker content in European masonry cements must be greater than or equal to 25% (MC5) or to 40% for the rest of the masonry cements (MC12.5–MC22.5) [45], leading to a low carbon dioxide buffer capacity.

Accordingly, this indicates that concrete even with a low cement content exhibits a better carbonation resistance than masonry mortars. With regard to the clinker content in Portland cements commonly used in structural concrete, this value can total up to 95% [46].

Concrete is a very strong structural building material composed of water, cement, and sand just like mortar. Nevertheless, concrete also has some coarse aggregates that makes it stronger and more durable than mortar. Mortar, which is composed of water, cement, and sand, has a higher water-to-cement ratio than concrete and, therefore, a higher capillary porosity. Mortar is used as the glue to hold bricks, blocks, etc., together, whereas concrete is mainly used for structural elements.

The main factor influencing carbonation is the pore system which affects the carbon dioxide diffusivity through the mortar and concrete. The carbonation rate is controlled by the penetration of carbon dioxide into their pore structure by diffusion. Therefore, the pore size distribution influences the rate of transport. Factors affecting the diffusion rate include the type and amount of cement, the porosity of the mortar or concrete, and the curing conditions, among other factors [47]. The decrease in the capillary porosity, achieved by lowering the water-to-cement ratio, further decreases the carbonation rate. Therefore, a linear relationship between porosity and accelerated carbonation has been found [48]. In addition, adequate curing conditions are required to avoid this unwanted effect [47]. Most of the worldwide concrete design guides include the minimum conditions for the curing of concretes but not for mortars [42].

Kim [49] highlighted the latest breakthroughs in cement and concrete research, including novel strategies for lowering carbon dioxide emissions in Portland cement production, such as the development of new building materials [50], and the development of mathematical modeling of the reliability of new composite materials [51]. Furthermore, it is necessary to highlight the importance of the prediction of the performance properties and reliability of new building materials [52]. For instance, AL-Kharabsheh et al. [50] suggested the partial replacement of Portland cement clinker in cement with wooden ash and studied its effect on concrete compressive strength and durability, concluding that 10% is the optimum replacement.

The calculation is based on carbon dioxide emissions from the calcination for clinker consumed within the country, rather than clinker produced within the country. To obtain clinker consumption data, the clinker production data were adjusted for imports and exports. Hence, a workbook was prepared including the following data inputs:

- Brazilian Portland cement clinker production

- Calcination emissions from Brazilian cement clinker production

- Imported cement/clinker (as ktonnes of clinker)

- Exported cement/clinker (as ktonnes of clinker)

- Percentage of Brazilian clinker used in mortar for rendering

This method has been applied to the cements produced in Brazil from 1990 to 2019, independently of their final use.

4. Results and Discussion

Brazil covers more than 8.5 million km2; therefore, it is the fifth-largest country on the planet. It is subdivided into five geographic regions following the criteria of similarity in social, economic, physical, and cultural aspects, which are named North (N), Northeast (NE), Center-West (CW), Southeast (SE) and South (S). Nevertheless, Brazil has one of the lowest levels of emission intensity across the world as a result of the actions resulting from the various sectoral policies implemented throughout the time period (Figure 2). For instance, electrical energy only contributes 1% of global greenhouse gas emissions in Brazil (Figure 2), since renewable sources currently have a significant share in electric power capacity (74%).

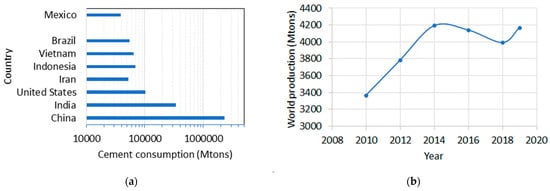

In economic terms, Brazil has held onto seventh place in cement consumption in 2020 in spite of the economic impact of the COVID-19 pandemic (Figure 5). In addition, the United States is the third- and Mexico is the fourteenth-largest worldwide cement consumer, whereas Mexico is the third-largest cement consumer in America.

Figure 5.

World production and consumption: (a) the world’s seven dominant consumers plus Mexico (14th); (b) world cement consumption (Mtons) «source: author original».

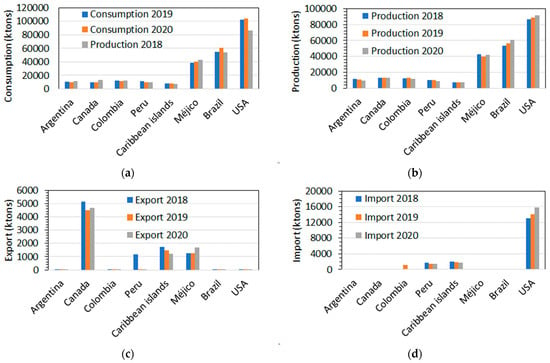

Brazil, located in South America, is the second-largest cement producer in America and the seventh in the world (Figure 6a). As shown in Figure 6b, the cement consumption keeps growing in Brazil and the U.S.. However, most countries in South America present different market developments. Cement sales skyrocketed in Brazil through the COVID-19 pandemic, due to relatively weak lockdown measures compared to other countries.

Figure 6.

Production and consumption parameters of the American main cement producers: (a) consumption 2018–2020; (b) production 2018–2020; (c) export 2018–2020; (d) import 2018–2020 «source: author original».

Mexico’s rebound in 2020 should have been greater and the Canadian cement consumption maintains its customary level.

Over in Peru, cement dispatches nearly doubled to 6.42 million tons in the first half of 2021 from 3.33 million tons in the same period in 2020. This rebound is attributed to the sales of bagged cement to the self-construction and public sector. In addition, imports (cement and clinker), from Vietnam, Japan, and Indonesia, nearly doubled from 0.76 Mt in the first half of 2019 to 1.4 million tons in the first half of 2021. We also highlight the fact that reported sales rebounded stronger than in Colombia and Argentina.

In Colombia, cement sales rose by 34% year-to-year to 6.20 million tons in the first half of 2021 from 4.61 million tons in the same period in 2020.

With regard to the Argentinian data, Portland cement sales grew by 44% to 5.52 million tons in the first half of 2021 from 3.83 million tons in the same period in 2020. Cement demand in Argentina in 2021 increased sharply. For instance, Loma Negra, a subsidiary of InterCement (Brazil), reported an increase in cement sales volumes of around 3.5%, probably due to the recovery of bulk cement sales, which were negatively affected by the COVID-19 pandemic restrictions in 2020. In 2022, the Argentinian cement market continued to consolidate its recovery from the COVID-19 pandemic. The main source of GHG emissions in Argentina comes from cement production, which represented 21% of emissions in 2016 (4.13 Mt CO2eq per year). Recently, significant actions have been undertaken to lower the clinker factor from 0.70 to 0.65, which will allow for the switch from 547 kg CO2/t of cement (2019) to 502 kg CO2/t of cement [53].

In conclusion, it has been noted that a significant recovery occurred in the larger cement-producing countries in America in 2021. It should be noted that Mexico, Colombia, Chile, and Argentina already use carbon pricing mechanisms, but they are not yet used in Brazil (under consideration in 2023) [54].

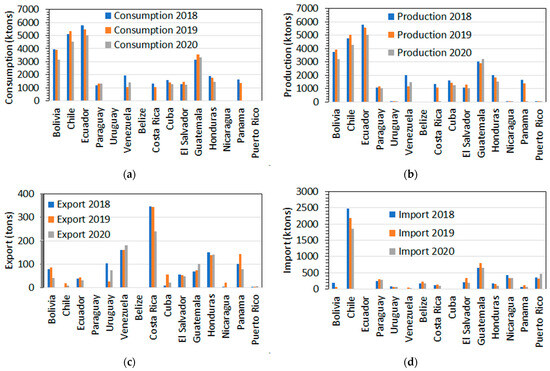

Figure 7 shows the cement consumption, production, export, and import figures of fifteen minor American cement producers. Bolivia, Chile, Ecuador, Costa Rica, Cuba, El Salvador, Guatemala, and Honduras reported that their cement volumes fell in 2020. Their cement production also fell, because the measures necessary to contain COVID-19 triggered an economic downturn. At this point, there was great uncertainty. However, it is expected to reset these parameters to their normal levels in 2023.

Figure 7.

Production and consumption parameters of the America minor cement producers: (a) consumption 2018–2020; (b) production 2018–2020; (c) export 2018–2020; (d) import 2018–2020 «source: author original».

The main cement production and consumption in the group of the minor cement producers is found in Ecuador, Chile, Bolivia, and Guatemala, in that order (Figure 7). By contrast, Costa Rica is the country that is now exporting more than the rest of the South American countries.

Brazil exported 0.12 million tons of cement in 2018 and Paraguay was the largest recipient of Brazilian exports at 0.092 million tons of cement, followed by Bolivia at 0.023 million tons. This value increased up to 0.15 million tons of cement in 2019 and 0.27 in 2020. Paraguay imported 0.14 and 0.31 million tons in 2018 and 2019, respectively. However, the upward trend stopped as a direct consequence of the slowdown in construction activity due to the COVID-19 pandemic restrictions. Bolivia’s cement demand fell in 2020 as a result of the COVID-19 pandemic (from 3.94 in 2028 to 3.17 million tons in 2020 and zero in 2021 and 2022).

Finally, it is noticeable that Chile is the largest importer of cement in comparison with the rest of the American minor cement producers (Figure 7). Chile, with more than 6500 km of Pacific coastline, is one of the countries with the longest coastline in the world, where a large population is concentrated from north to south. This fact justifies the seaborne imports from Asian countries. In 2011, imports only amounted 0.4 million tons, but one year later the imports increased sharply up to 1.8 million tons. Imports increased steadily and significantly during the period considered, with a maximum value of 3.15 million tons in 2015. Today Chile’s imports account for 2.82 million tons (2022).

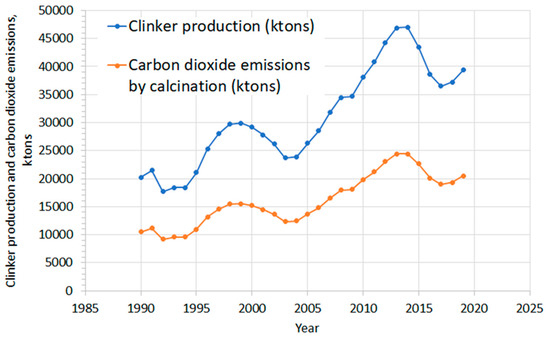

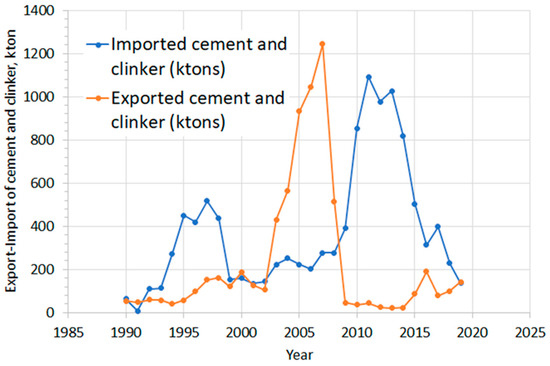

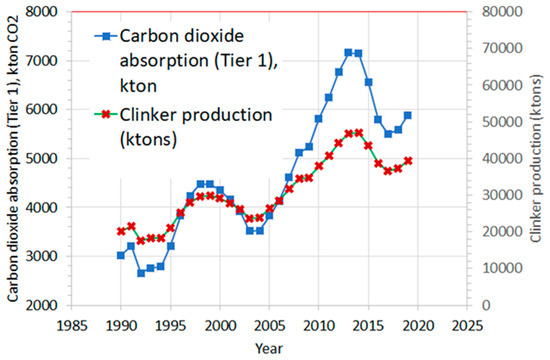

Figure 8 shows the clinker production and carbon dioxide emissions in Brazil between 1990 to 2019; whereas Figure 9 gives the clinker exported and imported in the same period. As expected, clinker production growth follows the same trend as the increased carbon dioxide emissions by calcination. From 1990 to 2005, both lines are relatively parallel. Nevertheless, the slope between 2005 and 2015 is double for the clinker production growth compared to the carbon dioxide emissions by calcination. This fact can be explained by the increase in the substitution rate with alternative fuels (% of thermal substitution) from 0% to 14.8% in 2014 (Table 2). This represents a carbon dioxide mitigation of about 7%. From 2015 up to now, both lines in Figure 8 become parallel again. This is because technical improvements were slowed down during this period of time.

Figure 8.

Clinker production and carbon dioxide emissions, ktons, between 1990 to 2019 «data source: National Cement Industry Association (SNIC)».

Figure 9.

Clinker exported and imported, ktons, between 1990 to 2019 «source: author original».

Clinker production increased from 20 million tons in 1990 to 47 million tons in 2015. That is, the clinker production doubled in 25 years (between 1990 to 2019) (Figure 8). Currently, the clinker imported and exported is lower than 200,000 tons with maximum values in 2007 (exported: 1244 ktons) and 2011 (imported: 1091 ktons).

Finally, Figure 10 presents the estimated results of carbon dioxide absorption considering the Tier 1 methodology described in the experimental part (Equations (1) and (2)). As expected, the carbon dioxide uptake follows the same trend as the clinker consumption. Therefore, a peak of carbon dioxide uptake of 7 million tons could be attributed to the clinker production of 2014.

Figure 10.

Carbon dioxide absorption (Tier 1), kton CO2 «source: author original».

The carbon dioxide absorption between 2013 and 2014 is much higher than the clinker production due to the influence of the clinker imported on the Portland cement production and, therefore, on the mortar and concrete exposed to the atmosphere to be carbonated. The maximum import amount was 1.03 million tons in 2013, while the maximum clinker production was 47 million tons in 2014.

According to Wang [55], the type of the concrete elements and the size of the crushed concrete impact the carbon dioxide uptake rate; however, these parameters do not change the total carbon dioxide uptake ratio. By contrast, it should be considered that as the compressive strength increases, as a result of using a higher content of clinker, the net carbon dioxide emissions increase [32].

This carbon dioxide absorption by the cement-based materials manufactured with this clinker will be performed during the service-life of the mortars and concrete structures. The total amount uptake from 1990 to 2019 during the service-life was 125 million tons, whereas during the secondary use and end-of-life it was 5 and 10 million tons, respectively.

Currently, the Brazilian Carbon Neutrality Roadmap does not consider the carbon uptake as a lever to contribute to climate change mitigation [36]. However, the carbon dioxide absorption due to the carbonation process could be implemented in order to help the Brazilian cement industry to reach the net-zero carbon dioxide emissions goal.

5. Conclusions

The Intergovernmental Panel on Climate Change (IPCC)’s Sixth Assessment Report (AR6) recognizes the physico-chemical process known as carbonation. Accordingly, the aim and novelty of this paper is to present, for the first time in the technical literature, a proper factual calculation of carbon removals by the cement-based materials carbonation in Brazil, which is the largest cement producer in South America. This procedure can generally be performed in the rest of the countries of America.

Following the expected data of clinker production, export, import, and apparent consumption recorded in the present paper and the results obtained by applying the methodology named Tier 1 to estimate the carbon uptake of cement-based materials produced in Brazil from 1990 to 2019, the following conclusions can be extracted:

- Brazil is the seventh worldwide cement producer and is one with the lowest kgCO2/ton of cement ratio as a consequence of the low electrical impact (1%) in the cement production, low clinker factor (0.67 in 2014 and 0.59, data estimated for 2030), and alternative fuels usage (15% in 2014 and 35%, data estimated for 2030).

- The carbon dioxide uptake by mortar and concrete carbonation for 30 years (from 1990 to 2019) is about 140 million tons. Within this twenty-year period about 483 million tons have been released due to the calcination process.

- Based on this data, the carbon dioxide uptake during the service-life, end-of-life and secondary usage stages can be given as follows:

- 125 million tons during the service-life;

- 5 million tons during secondary use; and

- 10 million tons during end-of-life.

- These values correspond to the 20%, 2%, and 1% of the carbon dioxide emitted by the calcination, respectively.

In addition, the carbon dioxide uptake should be implemented in the Brazilian Carbon Neutrality Roadmap, which is the tool to set out the Brazilian cement industry’s target to achieve net-zero carbon dioxide emissions along the cement and concrete value chain.

Author Contributions

Conceptualization, J.H.d.S.R. and M.Á.S.; methodology, M.Á.S.; software, J.H.d.S.R. and M.Á.S.; validation, G.V., A.Z., P.M., J.H.d.S.R. and M.Á.S.; formal analysis, G.V., A.Z., P.M., J.H.d.S.R. and M.Á.S.; investigation, G.V., A.Z., P.M., J.H.d.S.R. and M.Á.S.; data curation, G.V., A.Z., P.M., J.H.d.S.R. and M.Á.S.; writing—original draft preparation, J.H.d.S.R. and M.Á.S.; writing—review and editing, J.H.d.S.R. and M.Á.S.; supervision, J.H.d.S.R. and M.Á.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

We would like to express our profound gratitude to the National Cement Industry Association (SNIC) and the Brazilian Portland Cement Association (ABCP) from Brazil and to all the individuals who have kindly collaborated with us.

Conflicts of Interest

The authors declare no conflict of interest.

References

- The Intergovernmental Panel on Climate Change. 2006 IPCC Guidelines for National Greenhouse Gas Inventories; IPCC Guidelines Volume 3. Chapter 3 Industrial Processes. IPCC Good Practice Guidance and Uncertainty Management in National Greenhouse Gas Inventories 3.1; Eggleston, H.S., Buendia, L., Miwa, K., Ngara, T., Tanabe, K., Eds.; IGES: Fukuoka, Japan. Available online: https://www.ipcc-nggip.iges.or.jp/public/gp/english/3_Industry.pdf (accessed on 15 February 2023).

- IPCC. Climate Change 2021: The Physical Science Basis. Contribution of Working Group I to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change; Masson-Delmotte, V., Zhai, P., Pirani, A., Connors, S.L., Péan, C., Berger, S., Caud, N., Chen, Y., Goldfarb, L., Gomis, M.I., et al., Eds.; Cambridge University Press: Cambridge, UK; New York, NY, USA, 2021; p. 2391. Available online: https://report.ipcc.ch/ar6/wg1/IPCC_AR6_WGI_FullReport.pdf (accessed on 15 February 2023). [CrossRef]

- Intergovernmental Panel on Climate Change, 2023 (IPCC). AR6 Synthesis Report Climate Change 2023. Available online: https://www.ipcc.ch/assessment-report/ar6/ (accessed on 15 February 2023).

- Dinga, C.D.; Wen, Z. China’s green deal: Can China’s cement industry achieve carbon neutral emissions by 2060? Renew. Sustain. Energy Rev. 2022, 155, 111931. [Google Scholar] [CrossRef]

- Sanjuán, M.Á.; Andrade, C.; Mora, P.; Zaragoza, A. Carbon Dioxide Uptake by Mortars and Concretes Made with Portuguese Cements. Appl. Sci. 2020, 10, 646. [Google Scholar] [CrossRef]

- Zhang, G.-Y.; Wang, X.-Y. Carbon Peaking and Carbon Neutrality in the Cement-Based Materials. Materials 2023, 16, 4705. [Google Scholar] [CrossRef] [PubMed]

- Petroche, D.M.; Ramirez, A.D. The Environmental Profile of Clinker, Cement, and Concrete: A Life Cycle Perspective Study Based on Ecuadorian Data. Buildings 2022, 12, 311. [Google Scholar] [CrossRef]

- Lau, H.C. Decarbonization roadmaps for ASEAN and their implications. Energy Rep. 2022, 8, 6000–6022. [Google Scholar] [CrossRef]

- Karlsson, I.; Rootzén, J.; Toktarova, A.; Odenberger, M.; Johnsson, F.; Göransson, L. Roadmap for Decarbonization of the Building and Construction Industry—A Supply Chain Analysis Including Primary Production of Steel and Cement. Energies 2020, 13, 4136. [Google Scholar] [CrossRef]

- Karlsson, I.; Rootzén, J.; Johnsson, F.; Erlandsson, M. Achieving net-zero carbon emissions in construction supply chains—A multidimensional analysis of residential building systems. Dev. Built Environ. 2021, 8, 100059. [Google Scholar] [CrossRef]

- Kazemian, M.; Shafei, B. Carbon sequestration and storage in concrete: A state-of-the-art review of compositions, methods, and developments. J. CO2 Util. 2023, 70, 102443. [Google Scholar] [CrossRef]

- European Commission. HORIZON 2020. Work Programme 2014–2015. Annex G. Technology Readiness Levels (TRL). 2014. Available online: https://ec.europa.eu/research/participants/data/ref/h2020/wp/2014_2015/annexes/h2020-wp1415-annex-g-trl_en.pdf (accessed on 10 July 2023).

- Monteiro, J.; Roussanaly, S. CCUS scenarios for the cement industry: Is CO2 utilization feasible? J. CO2 Util. 2022, 61, 102015. [Google Scholar] [CrossRef]

- Sereng, M.; Djerbi, A.; Metalssi, O.O.; Dangla, P.; Torrenti, J.-M. Improvement of Recycled Aggregates Properties by Means of CO2 Uptake. Appl. Sci. 2021, 11, 6571. [Google Scholar] [CrossRef]

- Bretti, G.; Ceseri, M. Climate Change Effects on Carbonation Process: A Scenario-Based Study. Heritage 2023, 6, 236–257. [Google Scholar] [CrossRef]

- Guo, B.; Chu, G.; Yu, R.; Wang, Y.; Yu, Q.; Niu, D. Effects of sufficient carbonation on the strength and microstructure of CO2-cured concrete. J. Build. Eng. 2023, 76, 107311. [Google Scholar] [CrossRef]

- Silva, A.; Nogueira, R.; Bogas, A.; Wawrzyńczak, D.; Ściubidło, A.; Majchrzak-Kucęba, I. Parametric Study towards Optimization of a Short Duration Carbonation Process of Recycled Cement Paste. Materials 2022, 15, 6513. [Google Scholar] [CrossRef] [PubMed]

- Hu, L.; Chen, Z.; Hu, J. Carbon Sequestration, Mechanical Properties and Carbonation Kinetics of PP-Fiber-Reinforced Cement-Based Composites with CO2-Curing Treatment. Coatings 2022, 12, 1339. [Google Scholar] [CrossRef]

- Xuan, M.-Y.; Lin, R.-S.; Min, T.-B.; Wang, X.-Y. Carbonation treatment of eggshell powder concrete for performance enhancement. Constr. Build. Mater. 2023, 377, 130814. [Google Scholar] [CrossRef]

- Wang, Y.-S.; Wang, X.-Y. Multi-characterizations of the hydration, microstructure, and mechanical properties of a biochar–limestone calcined clay cement (LC3) mixture. J. Mater. Res. Technol. 2023, 24, 3691–3703. [Google Scholar] [CrossRef]

- Alimi, W.O.; Adekunle, S.K.; Ahmad, S.; Amao, A.O. Carbon dioxide sequestration characteristics of concrete mixtures incorporating high-volume cement kiln dust. Case Stud. Constr. Mater. 2022, 17, e01414. [Google Scholar] [CrossRef]

- Merino-Lechuga, A.M.; González-Caro, Á.; Fernández-Ledesma, E.; Jiménez, J.R.; Fernández-Rodríguez, J.M.; Suescum-Morales, D. Accelerated Carbonation of Vibro-Compacted Porous Concrete for Eco-Friendly Precast Elements. Materials 2023, 16, 2995. [Google Scholar] [CrossRef]

- AzariJafari, H.; Guo, F.; Gregory, J.; Kirchain, R. Carbon uptake of concrete in the US pavement network. Resour. Conserv. Recycl. 2021, 167, 105397. [Google Scholar] [CrossRef]

- Huovila, A.; Siikavirta, H.; Antuña-Rozado, C.; Rökman, J.; Tuominen, P.; Paiho, S.; Hedman, Å.; Ylén, P. Carbon-neutral cities: Critical review of theory and practice. J. Clean. Prod. 2022, 341, 130912. [Google Scholar] [CrossRef]

- Sanjuán, M.Á.; Morales, Á.; Zaragoza, A. Effect of Precast Concrete Pavement Albedo on the Climate Change Mitigation in Spain. Sustainability 2021, 13, 11448. [Google Scholar] [CrossRef]

- Sanjuán, M.Á.; Morales, Á.; Zaragoza, A. Precast Concrete Pavements of High Albedo to Achieve the Net “Zero-Emissions” Commitments. Appl. Sci. 2022, 12, 1955. [Google Scholar] [CrossRef]

- Younsi, A. Long-term carbon dioxide sequestration by concretes with supplementary cementitious materials under indoor and outdoor exposure: Assessment as per a standardized model. J. Build. Eng. 2022, 51, 104306. [Google Scholar] [CrossRef]

- EN 16757:2022; Sustainability of Construction Works—Environmental Product Declarations—Product Category Rules for Concrete and Concrete Elements. European Committee for Standardization (CEN): Brussels, Belgium, 2022.

- Younsi, A.; Turcry, P.; Aït-Mokhtar, A. Quantification of CO2 uptake of concretes with mineral additions after 10-year natural carbonation. J. Clean. Prod. 2022, 349, 131362. [Google Scholar] [CrossRef]

- Witkowski, H.; Koniorczyk, M. The influence of pozzolanic additives on the carbonation rate and Life Cycle Inventory of concrete. Constr. Build. Mater. 2020, 254, 119301. [Google Scholar] [CrossRef]

- Wang, X.-Y.; Lee, H.-S. Effect of global warming on the proportional design of low CO2 slag-blended concrete. Constr. Build. Mater. 2019, 225, 1140–1151. [Google Scholar] [CrossRef]

- Wang, X.-Y. Simulation for optimal mixture design of low-CO2 high-volume fly ash concrete considering climate change and CO2 uptake. Cem. Concr. Compos. 2019, 104, 103408. [Google Scholar] [CrossRef]

- The National Cement Industry Union (SNIC). Available online: http://snic.org.br/fabricas-localizacoes.php (accessed on 15 February 2023).

- ICR Newsroom. Brazilian Cement Consumption down 3% in 2022. 2023. Available online: https://www.cemnet.com/News/story/174147/brazilian-cement-consumption-down-3-in-2022.html (accessed on 15 February 2023).

- Sanjuán, M.A.; Argiz, C.; Mora, P.; Zaragoza, A. Carbon Dioxide Uptake in the Roadmap 2050 of the Spanish Cement Industry. Energies 2020, 13, 3452. Available online: https://doi.org/10.3390/en13133452 (accessed on 15 February 2023). [CrossRef]

- SNIC. Cement Technology Roadmap—Carbon Emissions Reduction Potential in the Brazilian Cement Industry by 2050/Coordinated by Gonzalo Visedo and Marcelo Pecchio; SNIC: Rio de Janeiro, Brazil, 2019; p. 64. Available online: http://snic.org.br/assets/pdf/roadmap/cement-technology-roadmap-brazil.pdf (accessed on 15 February 2023).

- IPCC. 2006 IPCC Guidelines for National Greenhouse Gas Inventories, Prepared by the National Greenhouse Gas Inventories Programme; Eggleston, H.S., Buendia, L., Miwa, K., Ngara, T., Tanabe, K., Eds.; IPCC National Greenhouse Gas Inventories Programme, Technical Support Unit; IGES: Fukuoka, Japan, 2006; Available online: https://www.ipcc.ch/report/2006-ipcc-guidelines-for-national-greenhouse-gas-inventories/ (accessed on 15 February 2023).

- Sanjuán, M.Á.; Andrade, C.; Mora, P.; Zaragoza, A. Carbon Dioxide Uptake by Cement-Based Materials: A Spanish Case Study. Appl. Sci. 2020, 10, 339. [Google Scholar] [CrossRef]

- Stripple, H.; Ljungkrantz, C.; Gustafsson, T. CO2 Uptake in Cement-Containing Products. In Background and Calculation Models for IPCC Implementation, 2nd ed.; Report Number: B 2309; IVL Swedish Environmental Research Institute: Stockholm, Sweden, 2021; pp. 1–77. Available online: https://www.ivl.se/download/18.34244ba71728fcb3f3f8f9/1622457897161/B2309.pdf (accessed on 15 February 2023).

- Leemann, A.; Nygaard, P.; Kaufmann, J.; Loser, R. Relation between carbonation resistance, mix design and exposure of mortar and concrete. Cem. Concr. Compos. 2015, 62, 33–43. [Google Scholar] [CrossRef]

- EN 206:2013+A1:2016; Concrete—Specification, Performance, Production and Conformity. CEN: Brussels, Belgium, 2016.

- EN 1992-1-1; Eurocode 2: Design of Concrete Structures—Part 1-1: General Rules and Rules for Buildings. European Committee for Standardization (CEN): Brussels, Belgium, 2004.

- Schießl, P.; Bamforth, P.; Baroghel-Bouny, V.; Corley, G.; Faber, M.; Forbes, J.; Gehlen, C.; Helene, P.; Helland, S.; Ishida, T.; et al. Model Code for Service Life Design, Fib Bulletin No. 34, 1st ed.; International Federation for Structural Concrete (FIB): Lausanne, Switzerland, 2006; p. 116. Available online: https://www.fib-international.org/publications/fib-bulletins/model-code-for-service-life-design-pdf-detail.html (accessed on 28 July 2023).

- ASTM C1329/C1329M-23; Standard Specification for Mortar Cement. ASTM International: West Conshohocken, PA, USA, 2023.

- EN 413-1:2011; Masonry Cement—Part 1: Composition, Specifications and Conformity Criteria. European Committee for Standardization (CEN): Brussels, Belgium, 2011.

- EN 197-1:2011; Cement—Part 1: Composition, Specifications and Conformity Criteria for Common Cements. European Committee for Standardization (CEN): Brussels, Belgium, 2011.

- Singh, N.; Sharma, B.; Rathee, M. Carbonation resistance of blended mortars and industrial by-products: A brief review. Clean. Mater. 2022, 4, 100058. [Google Scholar] [CrossRef]

- Gonen, T.; Yazicioglu, S. The influence of compaction pores on sorptivity and carbonation of concrete. Constr. Build. Mater. 2007, 21, 1040–1045. [Google Scholar] [CrossRef]

- Kim, G. New Advances in Cement and Concrete Research. Materials 2023, 16, 4162. [Google Scholar] [CrossRef]

- AL-Kharabsheh, B.N.; Arbili, M.M.; Majdi, A.; Ahmad, J.; Deifalla, A.F.; Hakamy, A. A Review on Strength and Durability Properties of Wooden Ash Based Concrete. Materials 2022, 15, 7282. [Google Scholar] [CrossRef]

- Isametova, M.E.; Nussipali, R.; Martyushev, N.V.; Malozyomov, B.V.; Efremenkov, E.A.; Isametov, A. Mathematical Modeling of the Reliability of Polymer Composite Materials. Mathematics 2022, 10, 3978. [Google Scholar] [CrossRef]

- Yelemessov, K.; Sabirova, L.B.; Martyushev, N.V.; Malozyomov, B.V.; Bakhmagambetova, G.B.; Atanova, O.V. Modeling and Model Verification of the Stress-Strain State of Reinforced Polymer Concrete. Materials 2023, 16, 3494. [Google Scholar] [CrossRef]

- Gaspes, E.; Landauer, S.; García, A.B.; Pauels, N. Towards Resource Efficiency and Decarbonising Building Materials in Argentina, 1st ed.; Concrete and Cement Industry Sector: Autonomous City of Buenos Aires, Argentina, 2022; p. 87. Available online: https://www.giz.de/en/downloads/giz2022-en-argentina-resource-efficiency.pdf (accessed on 8 September 2023).

- Carbon Pricing. Available online: https://ourworldindata.org/carbon-pricing (accessed on 15 February 2023).

- Wang, X.-Y. CO2 uptake of slag-blended concrete. Environ. Sci. Pollut. Res. 2021, 28, 48890–48904. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).