Influence of Warm Mix Asphalt Additives on the Physical Characteristics of Crumb Rubber Asphalt Binders

Abstract

:1. Introduction

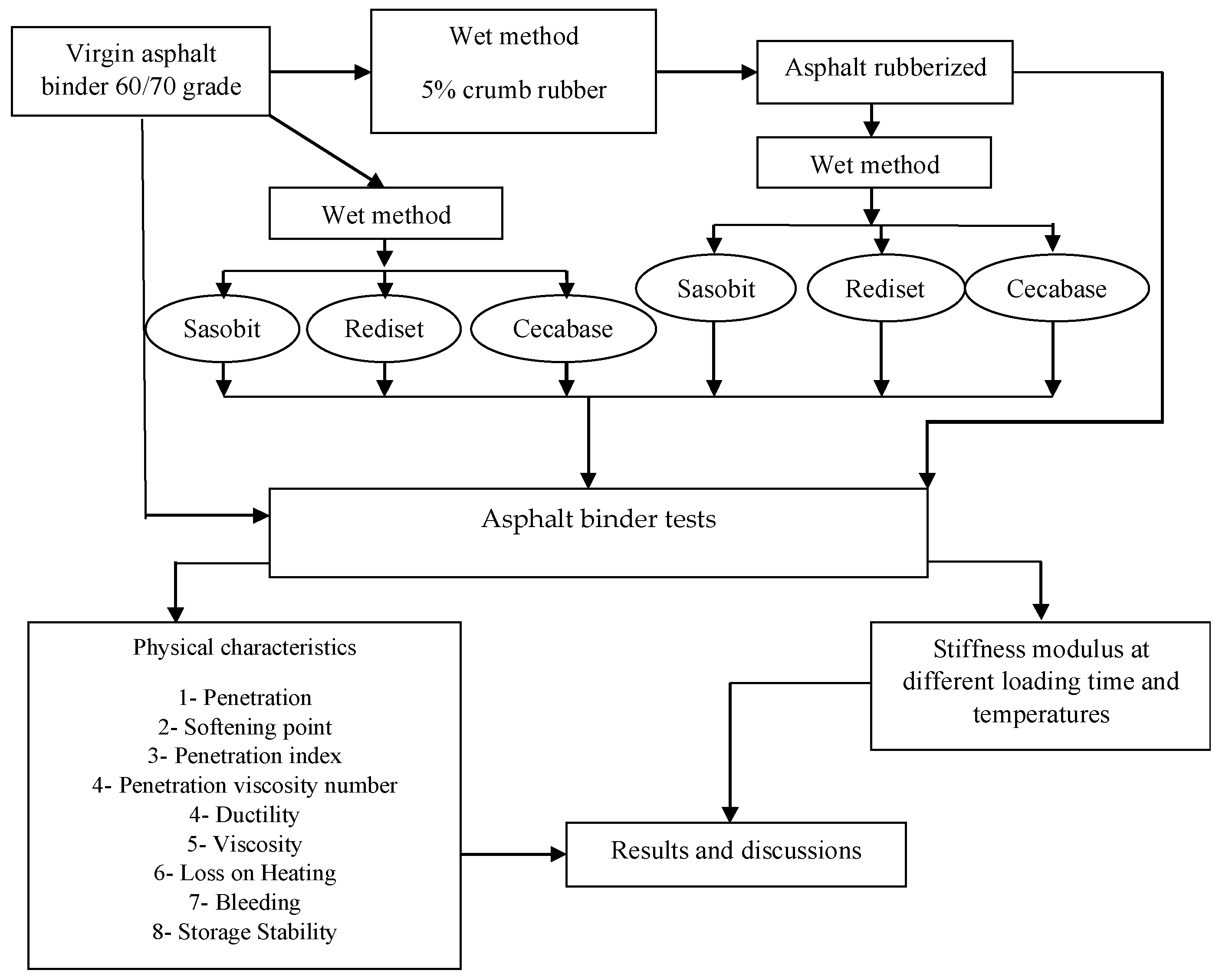

2. Material and Methods

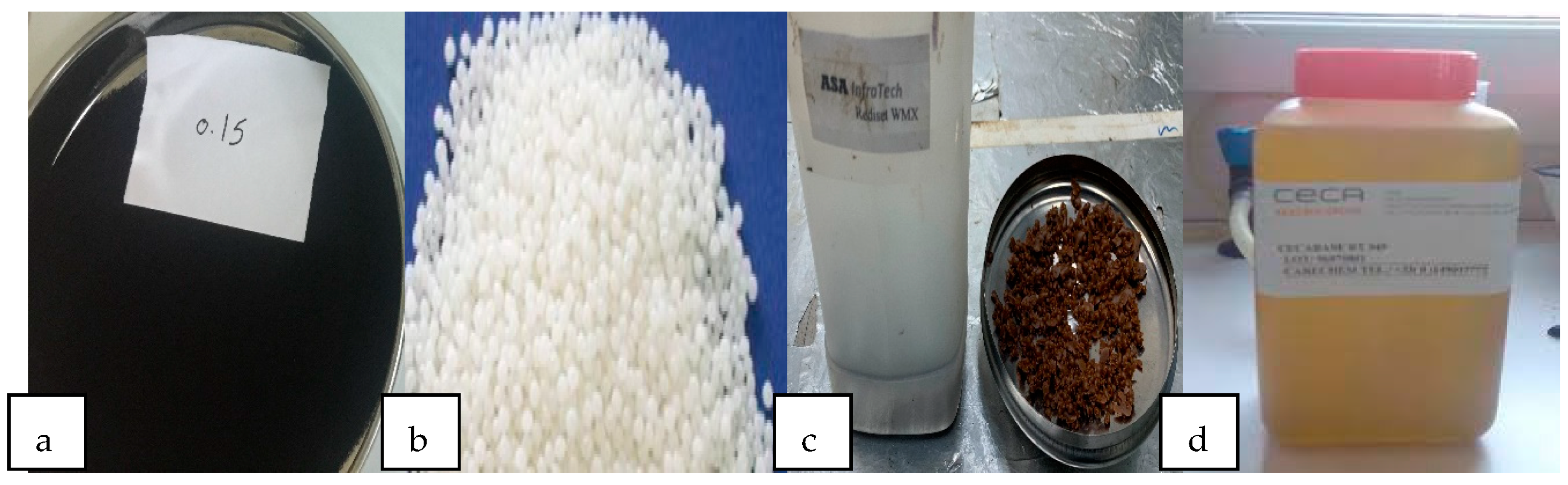

2.1. Asphalt Binder

2.2. Crumb Rubber

2.3. WMA Additives

2.3.1. Sasobit

2.3.2. Cecabase RT 975

2.3.3. Rediset WMX

2.4. Preparation of the CR Binders Containing the WMA Additives

2.5. Testing Program

3. Results and Discussion

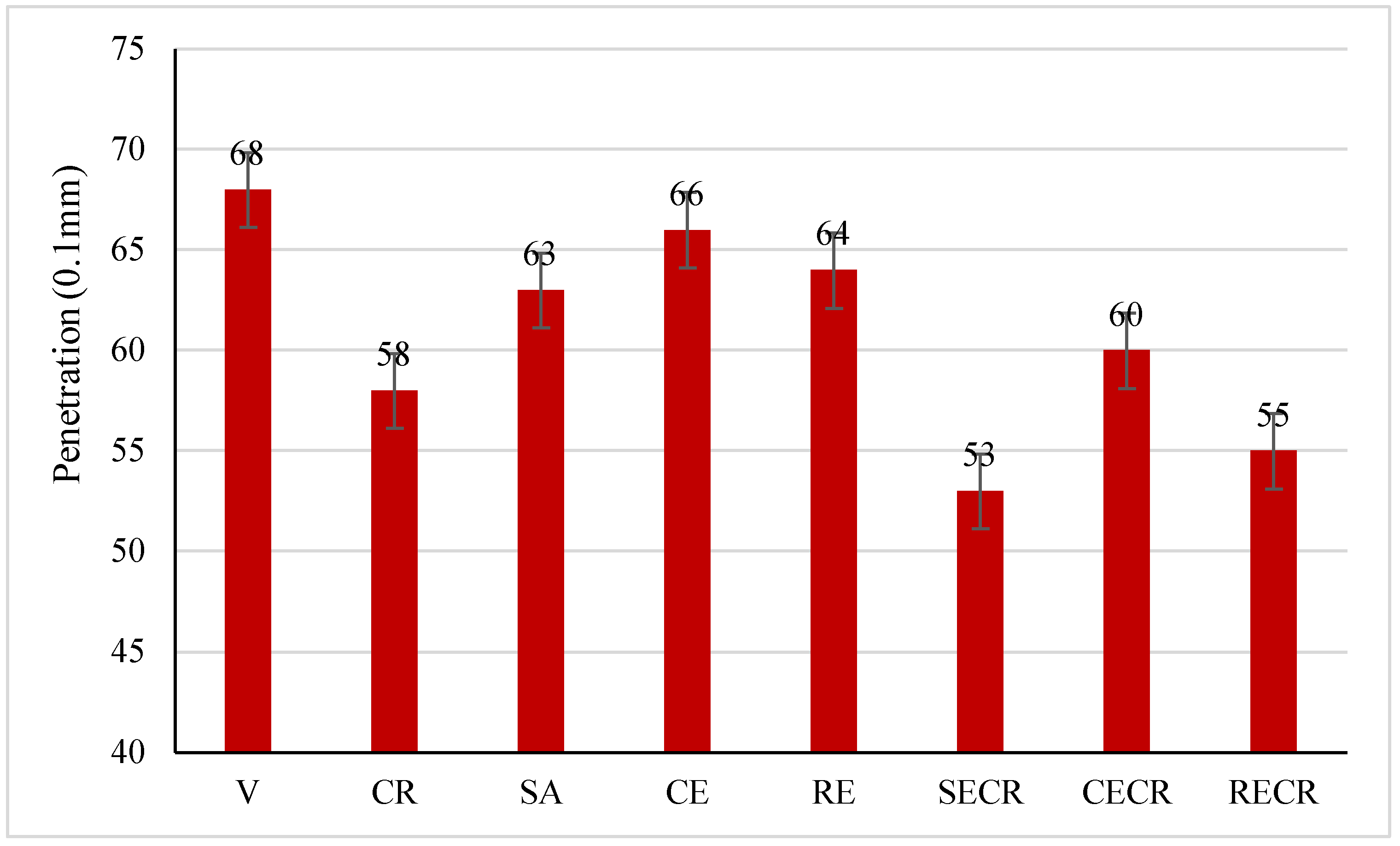

3.1. Penetration

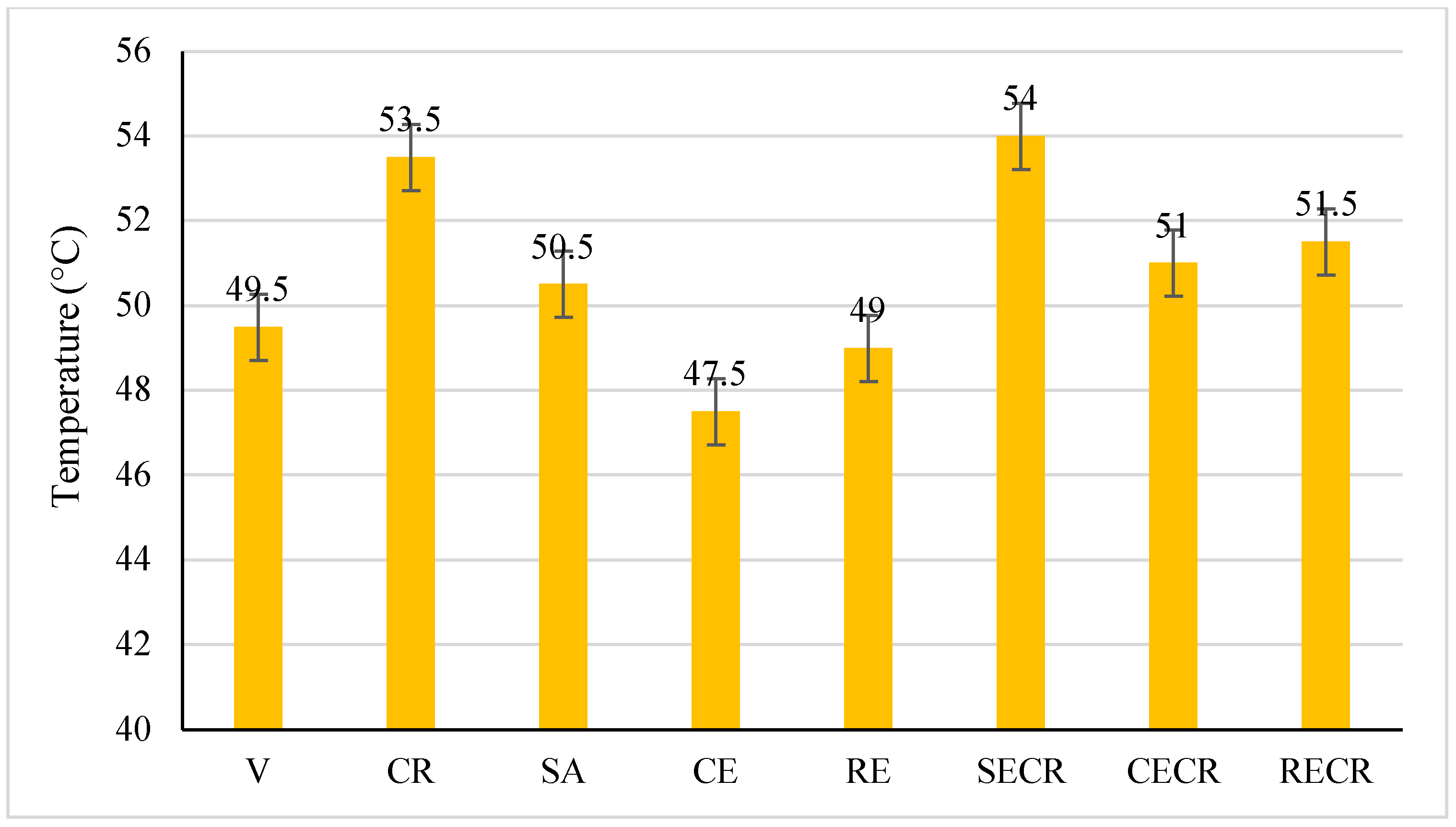

3.2. Softening Point

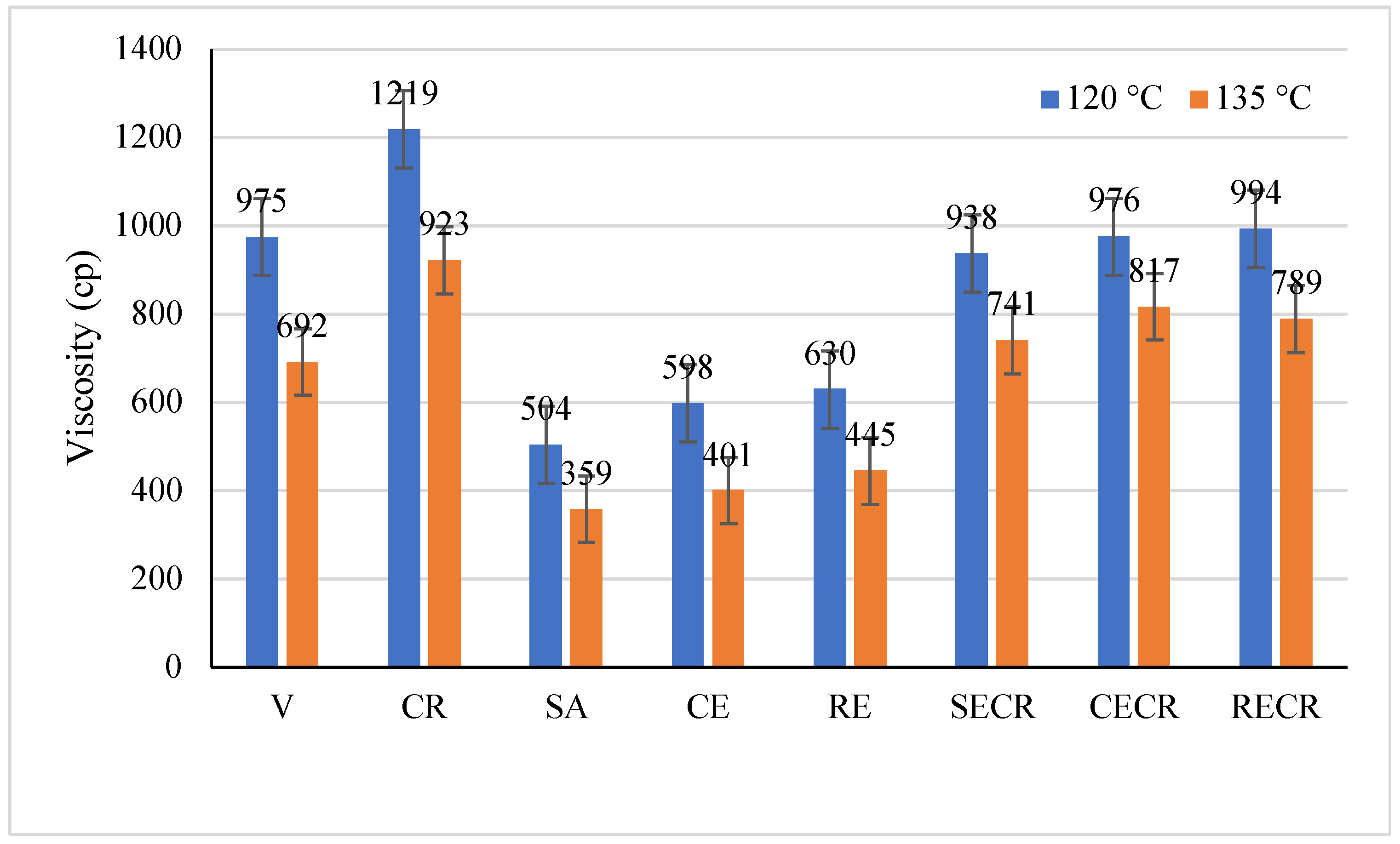

3.3. Viscosity

3.4. Temperature Susceptibility

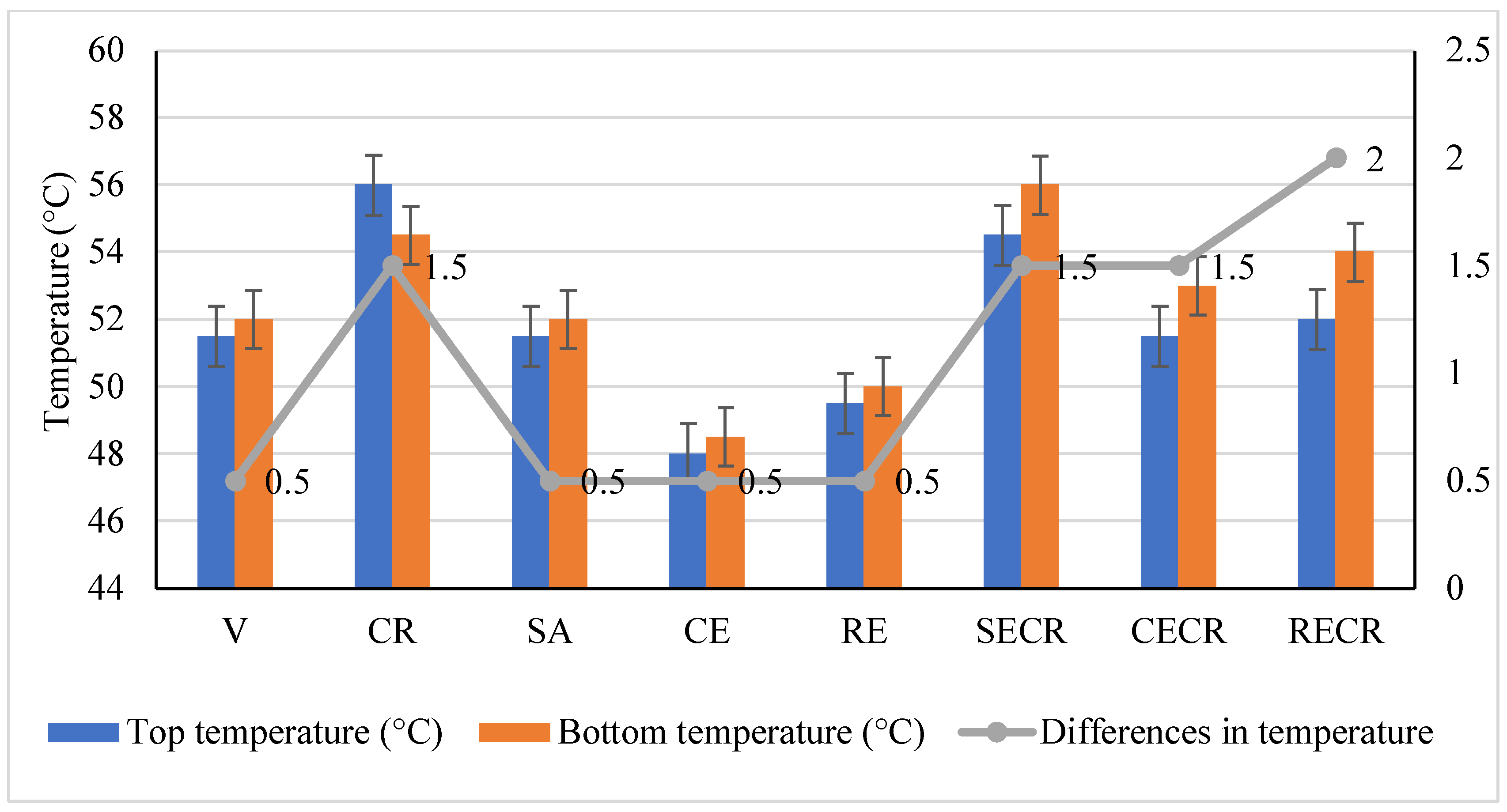

3.5. Storage Stability

3.6. Ductility

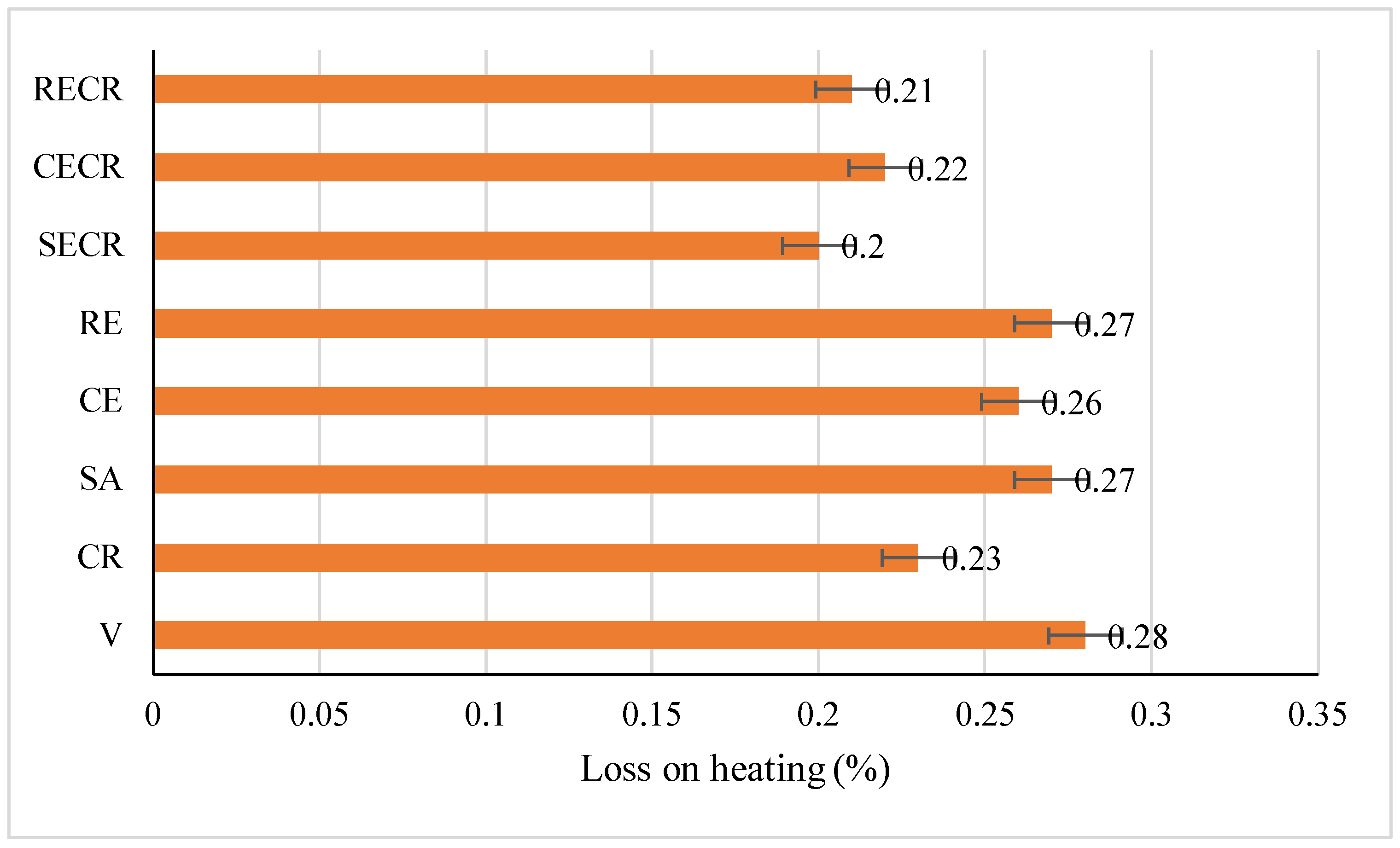

3.7. Loss on Heating

3.8. Stiffness Modulus

4. Conclusions

- Enhanced asphalt binders, resulting from modifications, display increased levels of hardness. Notably, the binder that underwent modification through the introduction of crumb rubber and Sasobit showcases the most pronounced hardness.

- All rubberized asphalt binders modified with warm mix asphalt (WMA) techniques manifest elevated values of softening points in comparison to the original asphalt binder. Among these alternatives, the rubberized asphalt binder that incorporates Sasobit stands out with the highest softening point.

- The penetration index, penetration viscosity number, and loss on heating of crumb rubber with WMA additives closely resemble those of the virgin asphalt binder.

- The modified asphalt binders exhibit commendable stability over the course of storage.

- With the exception of the rubberized asphalt binder adjusted with Rediset, all other modified asphalt binders adhere to the criteria set by the ductility test.

- All pairings of rubberized asphalt binder and WMA additives contribute to the reduction of viscosity values. Notably, the rubberized asphalt binder with Sasobit showcases superior workability compared to its counterparts employing alternative WMA additives.

- Among the assortment of asphalt binders, the combination that involves crumb rubber and Sasobit-modified binder presents the highest stiffness modulus values under conditions of intermediate and high temperatures.

- When subjected to lower temperatures and briefer loading periods, the blend of Rediset and crumb rubber produces the most significant stiffness modulus values.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Fakhri, M.; Javadi, S.; Sedghi, R.; Arzjani, D.; Zarrinpour, Y. Effects of deicing agents on moisture susceptibility of the WMA containing recycled crumb rubber. Constr. Build. Mater. 2019, 227, 116581. [Google Scholar] [CrossRef]

- Pouranian, M.R.; Shishehbor, M. Sustainability Assessment of Green Asphalt Mixtures: A Review. Environments 2019, 6, 73. [Google Scholar] [CrossRef]

- Rahman, M.T.; Mohajerani, A.; Giustozzi, F. Recycling of Waste Materials for Asphalt Concrete and Bitumen: A Review. Materials 2020, 13, 1495. [Google Scholar] [CrossRef] [PubMed]

- Bilema, M.; Aman, M.Y.; Hassan, N.A.; Memon, Z.A.; Omar, H.A.; Yusoff, N.I.M.; Milad, A. Mechanical Performance of Reclaimed Asphalt Pavement Modified with Waste Frying Oil and Crumb Rubber. Materials 2021, 14, 2781. [Google Scholar] [CrossRef]

- Cheng, Y.; Chai, C.; Liang, C.; Chen, Y. Mechanical Performance of Warm-Mixed Porous Asphalt Mixture with Steel Slag and Crumb-Rubber–SBS Modified Bitumen for Seasonal Frozen Regions. Materials 2019, 12, 857. [Google Scholar] [CrossRef]

- Bilema, M.; Aman, Y.B.; Hassan, N.A.; Al-Saffar, Z.; Ahmad, K.; Rogo, K. Performance of Aged Asphalt Binder Treated with Various Types of Rejuvenators. Civ. Eng. J. 2021, 7, 502–517. [Google Scholar] [CrossRef]

- Tahmoorian, F.; Samali, B.; Yeaman, J.; Crabb, R. The Use of Glass to Optimize Bitumen Absorption of Hot Mix Asphalt Containing Recycled Construction Aggregates. Materials 2018, 11, 1053. [Google Scholar] [CrossRef]

- Wang, M.; Zhang, L.; Li, A.; Irfan, M.; Du, Y.; Di, W. Comparative pyrolysis behaviors of tire tread and side wall from waste tire and characterization of the resulting chars. J. Environ. Manag. 2019, 232, 364–371. [Google Scholar] [CrossRef]

- Dong, R.; Zhao, M.; Tang, N. Characterization of crumb tire rubber lightly pyrolyzed in waste cooking oil and the properties of its modified bitumen. Constr. Build. Mater. 2019, 195, 10–18. [Google Scholar] [CrossRef]

- Thives, L.P.; Pais, J.C.; Pereira, P.A.A.; Palha, C.A.O.F.; Trichês, G. Contribution of Asphalt Rubber Mixtures to Sustainable Pavements by Reducing Pavement Thickness. Materials 2022, 15, 8592. [Google Scholar] [CrossRef]

- Presti, D.L. Recycled Tyre Rubber Modified Bitumens for road asphalt mixtures: A literature review. Constr. Build. Mater. 2013, 49, 863–881. [Google Scholar] [CrossRef]

- Caltrans & CIWMB Partnered Research. Guide, Asphalt Rubber Usage. “Caltrans”; State of California Department of Transportation: Sacramento, CA, USA, 2003; pp. 94612–95819.

- Bilema, M.; Aman, M.; Hassan, N.; Haloul, M.; Modibbo, S. Influence of crumb rubber size particles on moisture damage and strength of the hot mix asphalt. Mater. Today Proc. 2021, 42, 2387–2391. [Google Scholar] [CrossRef]

- Milad, A.; Ahmeda, A.G.F.; Taib, A.M.; Rahmad, S.; Solla, M.; Yusoff, N.I.M. A review of the feasibility of using crumb rubber derived from end-of-life tire as asphalt binder modifier. J. Rubber Res. 2020, 23, 203–216. [Google Scholar] [CrossRef]

- Attia, M.; Abdelrahman, M. Enhancing the performance of crumb rubber-modified binders through varying the interaction conditions. Int. J. Pavement Eng. 2009, 10, 423–434. [Google Scholar] [CrossRef]

- Wang, H.; Liu, X.; Erkens, S.; Skarpas, A. Experimental characterization of storage stability of crumb rubber modified bitumen with warm-mix additives. Constr. Build. Mater. 2020, 249, 118840. [Google Scholar] [CrossRef]

- Airey, G.; Rahman, M.; Collop, A.C. Crumb Rubber and Bitumen Interaction as a Function of Crude Source and Bitumen Viscosity. Road Mater. Pavement Des. 2011, 5, 453–475. [Google Scholar] [CrossRef]

- Ozturk, H.I.; Kamran, F. Laboratory evaluation of dry process crumb rubber modified mixtures containing Warm Mix Asphalt Additives. Constr. Build. Mater. 2019, 229, 116940. [Google Scholar] [CrossRef]

- Caputo, P.; Abe, A.A.; Loise, V.; Porto, M.; Calandra, P.; Angelico, R.; Rossi, C.O. The Role of Additives in Warm Mix Asphalt Technology: An Insight into Their Mechanisms of Improving an Emerging Technology. Nanomaterials 2020, 10, 1202. [Google Scholar] [CrossRef]

- Woszuk, A.; Franus, W. A Review of the Application of Zeolite Materials in Warm Mix Asphalt Technologies. Appl. Sci. 2017, 7, 293. [Google Scholar] [CrossRef]

- Bilema, M.A.; Aman, M.Y.; Hassan, N.A.; Ahmad, K.A.; Elghatas, H.M.; Radwan, A.A.; Shyaa, A.S. Moisture Sensitivity of Crumb Rubber Modified Modifier Warm Mix Asphalt Additive for Two Different Compaction Temperatures. IOP Conf. Ser. Earth Environ. Sci. 2018, 140, 012072. [Google Scholar] [CrossRef]

- Williams, B.A.; Willis, J.R.; Shacat, J. Asphalt Pavement Industry Survey on Recycled Materials and Warm-Mix Asphalt Usage: 2019; NAPA: Greenbelt, MD, USA, 2020. [Google Scholar]

- Cheng, D.; Hicks, R.; Teesdale, T. Assessment of Warm Mix Technologies for Use with Asphalt Rubber Paving Applications. Mater. Sci. 2011. [Google Scholar]

- Rubio, M.C.; Martínez, G.; Baena, L.; Moreno, F. Warm mix asphalt: An overview. J. Clean. Prod. 2012, 24, 76–84. [Google Scholar] [CrossRef]

- Moreno, F.; Sol, M.; Martín, J.; Pérez, M.; Rubio, M.C. The effect of crumb rubber modifier on the resistance of asphalt mixes to plastic deformation. Mater. Des. 2013, 47, 274–280. [Google Scholar] [CrossRef]

- Leng, Z.; Yu, H.; Zhang, Z.; Tan, Z. Optimizing the mixing procedure of warm asphalt rubber with wax-based additives through mechanism investigation and performance characterization. Constr. Build. Mater. 2017, 144, 291–299. [Google Scholar] [CrossRef]

- Oliveira, J.R.M.; Silva, H.M.R.D.; Abreu, L.P.F.; Fernandes, S.R.M. Use of a warm mix asphalt additive to reduce the production temperatures and to improve the performance of asphalt rubber mixtures. J. Clean. Prod. 2013, 41, 15–22. [Google Scholar] [CrossRef]

- Ameri, M.; Yazdipanah, F.; Yengejeh, A.R.; Afshin, A. Production temperatures and mechanical performance of rubberized asphalt mixtures modified with two warm mix asphalt (WMA) additives. Mater. Struct. 2020, 53, 113. [Google Scholar] [CrossRef]

- Turbay, E.; Martinez-Arguelles, G.; Navarro-Donado, T.; Sánchez-Cotte, E.; Polo-Mendoza, R.; Covilla-Valera, E. Rheological Behaviour of WMA-Modified Asphalt Binders with Crumb Rubber. Polymers 2022, 14, 4148. [Google Scholar] [CrossRef]

- Wang, T.; Yang, R.; Li, A.; Chen, L.; Zhou, B. Effects of Sasobit and Its Adding Process on the Performance of Rubber Asphalt. Chem. Eng. Trans. 2016, 51, 181–186. [Google Scholar] [CrossRef]

- Sesay, T.; You, Q.; Chuan, J.; Qiao, H.; Zhang, H.; Tian, S. High and intermediate temperature performance of warm asphalt rubber containing conventional warm mix additives and novel chemical surfactant. Constr. Build. Mater. 2023, 394, 132214. [Google Scholar] [CrossRef]

- BILEMA, M.A.; Aman, M.Y.; Hassan, N.A.; Al-Saffar, Z.; Rogo, K.; Abdullah, N.F.A. Influence of crumb rubber incorporating different warm mix asphalt additives on the mechanical performance of the WMA mixture. J. Rehabil. Civ. Eng. 2021, 9, 1–11. [Google Scholar] [CrossRef]

- Hamzah, M.O.; Golchin, B.; Jamshidi, A.; Chailleux, E. Evaluation of Rediset for use in warm-mix asphalt: A review of the literatures. Int. J. Pavement Eng. 2014, 16, 809–831. [Google Scholar] [CrossRef]

- Vaitkus, A.; Čygas, D.; Laurinavičius, A.; Perveneckas, Z. Analysis and Evaluation of Possibilities for the Use of Warm Mix Asphalt in Lithuania. Balt. J. Road Bridge Eng. 2009, 4, 80–86. [Google Scholar] [CrossRef]

- Hurley, G.C.; Prowell, B.D. Evaluation of Sasobit® for Use in Warm Mix Asphalt. NCAT Rep. 2005, 5, 1–27. [Google Scholar]

- Abdullah, M.E.; Zamhari, K.A.; Buhari, R.; Abu Bakar, S.K.; Kamaruddin, N.H.M.; Nayan, N.; Hainin, M.R.; Hassan, N.A.; Hassan, S.A.; Yusoff, N.I.M. Warm Mix Asphalt Technology: A Review. J. Teknol. 2014, 71, 39–52. [Google Scholar] [CrossRef]

- Bilema, M.A.M.; Aman, M.Y.; Ahmad, K.A. Investigating the rheological and physical properties for unaged of crumb rubber-modified binders containing warm mix asphalt additive. In Proceedings of the 1st Global Civil Engineering Conference 1, Kuala Lumpur, Malaysia, 25–28 July 2017; Springer: Singapore, 2019; Volume 9, pp. 1389–1400. [Google Scholar] [CrossRef]

- Van Poel, C.D. A general system describing the visco-elastic properties of bitumens and its relation to routine test data. J. Appl. Chem. 1954, 4, 221–236. [Google Scholar] [CrossRef]

- Abatech Inc. Available online: https://www.abatech.com/ (accessed on 12 August 2023).

- Mashaan, N.S.; Ali, A.H.; Karim, M.R.; Abdelaziz, M. Effect of crumb rubber concentration on the physical and rheological properties of rubberised bitumen binders. Int. J. Phys. Sci. 2011, 6, 684–690. Available online: http://www.academicjournals.org/IJPS (accessed on 17 July 2021).

- Awazhar, N.A.; Khairuddin, F.H.; Rahmad, S.; Fadzil, S.M.; Omar, H.A.; Yusoff, N.I.M.; Badri, K.H. Engineering and leaching properties of asphalt binders modified with polyurethane and Cecabase additives for warm-mix asphalt application. Constr. Build. Mater. 2020, 238, 117699. [Google Scholar] [CrossRef]

- Mohamed, M.; Zumrawi, E. Effect of Crumb Rubber Modifiers (CRM) on Characteristics of Asphalt Binders in Sudan. Int. J. Mater. Sci. Appl. 2017, 6, 1. [Google Scholar] [CrossRef]

- Kök, B.V.; Yilmaz, M.; Akpolat, M. Evaluation of the conventional and rheological properties of SBS + Sasobit modified binder. Constr. Build. Mater. 2014, 63, 174–179. [Google Scholar] [CrossRef]

- Akpolat, M.; Akpolat, M. Investigation of rutting, fatigue and cracking resistance parameters of CR modified warm asphalt binders compare with SBS modified binders. Rev. Construcción 2022, 21, 309–328. [Google Scholar] [CrossRef]

- Bilema, M.; Aman, M.Y.; Hassan, N.A.; Al-Saffar, Z.; Mashaan, N.S.; Memon, Z.A.; Milad, A.; Yusoff, N.I.M. Effects of Waste Frying Oil and Crumb Rubber on the Characteristics of a Reclaimed Asphalt Pavement Binder. Materials 2021, 14, 3482. [Google Scholar] [CrossRef]

- Sengoz, B.; Isikyakar, G. Analysis of styrene-butadiene-styrene polymer modified bitumen using fluorescent microscopy and conventional test methods. J. Hazard. Mater. 2008. [Google Scholar] [CrossRef] [PubMed]

- Veeraiah, H.K.; Nagabhushanarao, S.S. Effect of optimized short-term aging temperature on rheological properties of rubberized binders containing warm mix additives. Constr. Build. Mater. 2020, 261, 120019. [Google Scholar] [CrossRef]

- Li, M.; Lv, A.; Ran, J.; Li, Q. Testing and Evaluation of Sasobit on the Performances of Asphalt Rubber. In ICCTP 2011: Towards Sustainable Transportation Systems, Proceedings of the 11th International Conference of Chinese Transportation Professionals, Nanjing, China, 14–17 August 2011; ASCE: Reston, VA, USA, 2011; pp. 3502–3509. [Google Scholar] [CrossRef]

- Mashaan, N.S.; Karim, M.R. Investigating the rheological properties of crumb rubber modified bitumen and its correlation with temperature susceptibility. Mater. Res. 2013. [CrossRef]

- Sedaghat, B.; Taherrian, R.; Hosseini, S.A.; Mousavi, S.M. Rheological properties of bitumen containing nanoclay and organic warm-mix asphalt additives. Constr. Build. Mater. 2020, 243, 118092. [Google Scholar] [CrossRef]

| Properties | Sasobit | Cecabase RT 975 | Rediset WMX |

|---|---|---|---|

| Appearance at 25 °C | Pastille flakes | Liquid | Pastilles |

| Density at 25 °C (g/cm3) | 0.9 | 0.997 | 0.55 |

| Color | Off-white | Dark amber liquid | Light brown |

| Melting point (°C) | 100–120 | - | 80–90 |

| Flash point (°C) | 285 | ˃200 | 253 |

| Binder | ID | Asphalt Binder (%) | Crumb (%) | Warm Mix Additive (%) |

|---|---|---|---|---|

| Virgin 60/70 | V | 100 | - | - |

| Crumb rubber | CR | 100 | 5 | - |

| Sasobit | SA | 100 | - | 1.5 |

| Cecabase | CE | 100 | - | 0.44 |

| Rediset | RE | 100 | - | 1.5 |

| Sasobit + crumb rubber | SECR | 100 | 5 | 1.5 |

| Cecabase + crumb rubber | CECR | 100 | 5 | 0.44 |

| Rediset + crumb rubber | RECR | 100 | 5 | 1.5 |

| Asphalt Binder Test (Unit) | Test Standard | Specification |

|---|---|---|

| Penetration at 25 °C (0.1 mm) | ASTM D5 | 60–70 |

| Softening point (°C) | ASTM D36 | 48–52 |

| Penetration index | - | −2 to 2 |

| Penetration viscosity number | - | - |

| Storage stability (°C) | ASTM D5892 | <2.2 |

| Ductility at 25 °C (cm) | ASTM D113 | Min. 100 |

| Loss on heating (%) | AASHTO T240 | Max. 1.00 |

| Viscosity at 120 and 135 °C (cp) | ASTM D4402 | - |

| Stiffness modulus (MPa) | - | - |

| ID | PI | PVN |

|---|---|---|

| V | −0.54 | −0.06 |

| CR | 0.04 | 0.39 |

| SA | −0.49 | −0.92 |

| CE | −1.17 | −0.69 |

| RE | −0.83 | −0.59 |

| SECR | −0.02 | 0.004 |

| CECR | −0.48 | 0.23 |

| RECR | −0.62 | 0.07 |

| Asphalt ID | Stiffness (MPa) at Loading Time: 10 (s) | ||

|---|---|---|---|

| High Temperature | Intermediate Temperature | Low Temperature | |

| V | 0.01 | 0.04 | 0.31 |

| CR | 0.01 | 0.06 | 0.43 |

| SA | 0.01 | 0.05 | 0.36 |

| CE | 0.00 | 0.03 | 0.31 |

| RE | 0.01 | 0.04 | 0.34 |

| SECR | 0.01 | 0.07 | 0.49 |

| CECR | 0.01 | 0.05 | 0.39 |

| RECR | 0.01 | 0.06 | 0.44 |

| Asphalt ID | Stiffness (MPa) at Loading Time 5 (s) | ||

| High Temperature | Intermediate Temperature | Low Temperature | |

| V | 0.01 | 0.07 | 0.47 |

| CR | 0.02 | 0.11 | 0.7 |

| SA | 0.01 | 0.08 | 0.54 |

| CE | 0.01 | 0.06 | 0.48 |

| RE | 0.01 | 0.07 | 0.5 |

| SECR | 0.02 | 0.13 | 0.83 |

| CECR | 0.01 | 0.09 | 0.61 |

| RECR | 0.02 | 0.1 | 0.73 |

| Asphalt ID | Stiffness (MPa) at Loading Time: 1 (s) | ||

| High Temperature | Intermediate Temperature | Low Temperature | |

| V | 0.05 | 0.32 | 1.48 |

| CR | 0.07 | 0.37 | 1.93 |

| SA | 0.05 | 0.31 | 1.71 |

| CE | 0.04 | 0.24 | 1.7 |

| RE | 0.05 | 0.28 | 1.71 |

| SECR | 0.08 | 0.42 | 2.51 |

| CECR | 0.06 | 0.34 | 1.87 |

| RECR | 0.07 | 0.38 | 2.35 |

| Asphalt ID | Stiffness (MPa) at Loading Time: 0.5 (s) | ||

| High Temperature | Intermediate Temperature | Low Temperature | |

| V | 0.08 | 0.42 | 2.58 |

| CR | 0.13 | 0.56 | 3.48 |

| SA | 0.09 | 0.47 | 3.09 |

| CE | 0.07 | 0.4 | 3.23 |

| RE | 0.08 | 0.43 | 3.16 |

| SECR | 0.15 | 0.67 | 4.17 |

| CECR | 0.1 | 0.49 | 3.45 |

| RECR | 0.11 | 0.58 | 4.11 |

| Asphalt ID | Stiffness (MPa) at Loading Time: 0.1 (s) | ||

| High Temperature | Intermediate Temperature | Low Temperature | |

| V | 0.3 | 1.23 | 7.81 |

| CR | 0.42 | 1.64 | 9.24 |

| SA | 0.35 | 1.44 | 8.67 |

| CE | 0.26 | 1.31 | 9.93 |

| RE | 0.3 | 1.39 | 9.43 |

| SECR | 0.46 | 1.88 | 11.04 |

| CECR | 0.37 | 1.57 | 9.17 |

| RECR | 0.41 | 1.8 | 11.31 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bilema, M.; Wah Yuen, C.; Alharthai, M.; Hazim Al-Saffar, Z.; Oleiwi Aletba, S.R.; Md Yusoff, N.I. Influence of Warm Mix Asphalt Additives on the Physical Characteristics of Crumb Rubber Asphalt Binders. Appl. Sci. 2023, 13, 10337. https://doi.org/10.3390/app131810337

Bilema M, Wah Yuen C, Alharthai M, Hazim Al-Saffar Z, Oleiwi Aletba SR, Md Yusoff NI. Influence of Warm Mix Asphalt Additives on the Physical Characteristics of Crumb Rubber Asphalt Binders. Applied Sciences. 2023; 13(18):10337. https://doi.org/10.3390/app131810337

Chicago/Turabian StyleBilema, Munder, Choon Wah Yuen, Mohammad Alharthai, Zaid Hazim Al-Saffar, Salam Ridha Oleiwi Aletba, and Nur Izzi Md Yusoff. 2023. "Influence of Warm Mix Asphalt Additives on the Physical Characteristics of Crumb Rubber Asphalt Binders" Applied Sciences 13, no. 18: 10337. https://doi.org/10.3390/app131810337

APA StyleBilema, M., Wah Yuen, C., Alharthai, M., Hazim Al-Saffar, Z., Oleiwi Aletba, S. R., & Md Yusoff, N. I. (2023). Influence of Warm Mix Asphalt Additives on the Physical Characteristics of Crumb Rubber Asphalt Binders. Applied Sciences, 13(18), 10337. https://doi.org/10.3390/app131810337