Investigation of Rock Joint and Fracture Influence on Delayed Blasting Performance

Abstract

:1. Introduction

2. Current Status of Blasting on Fractured Rock Mass

3. Change in Stress Field in Fractured Rock Due to Blasting

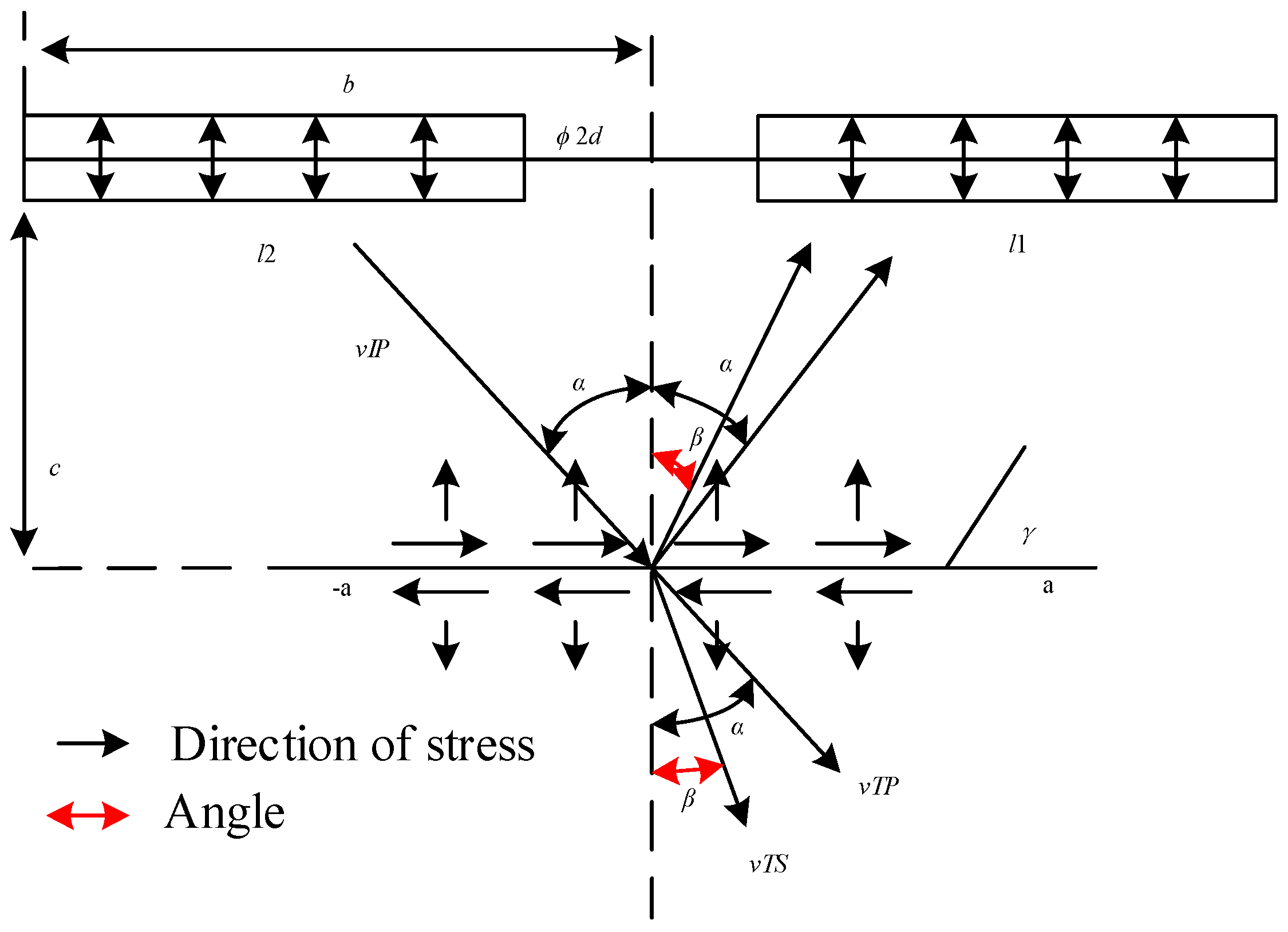

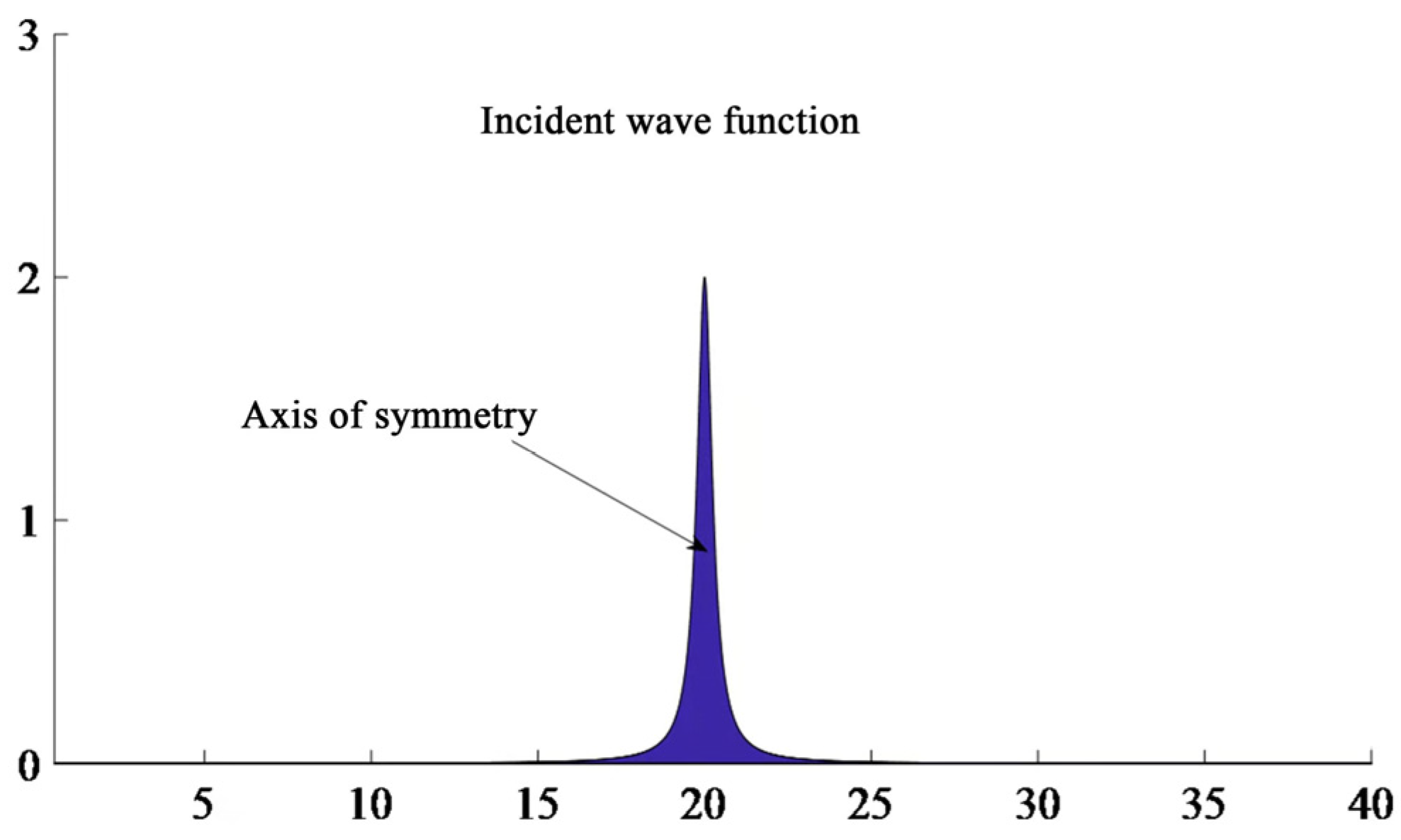

3.1. Attenuation of Stress Wave in Fractured Rock Mass

3.2. Constitutive Model of Fractured Rock Mass Blasting

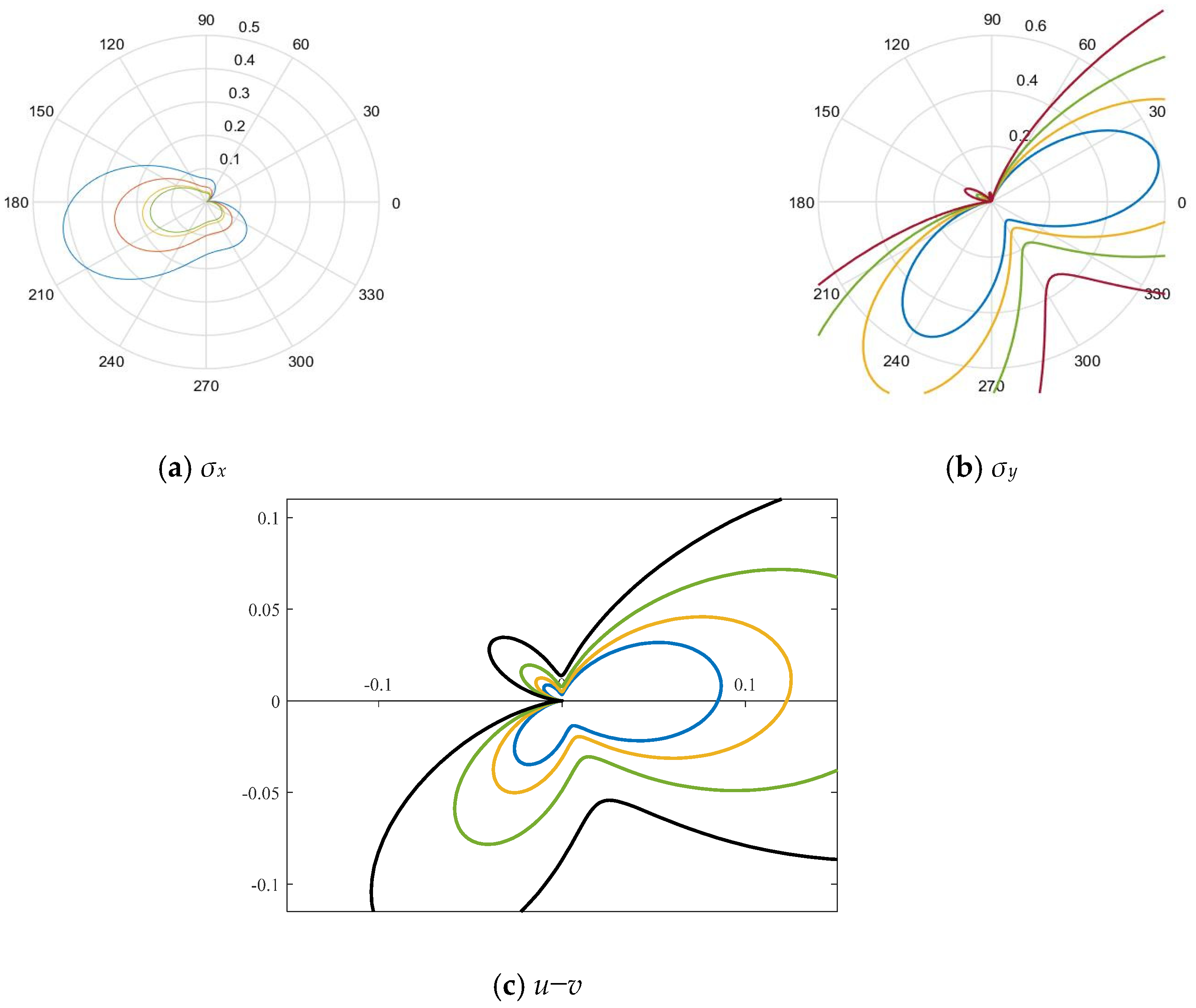

4. Analysis of Stress and Displacement Distribution around Joints

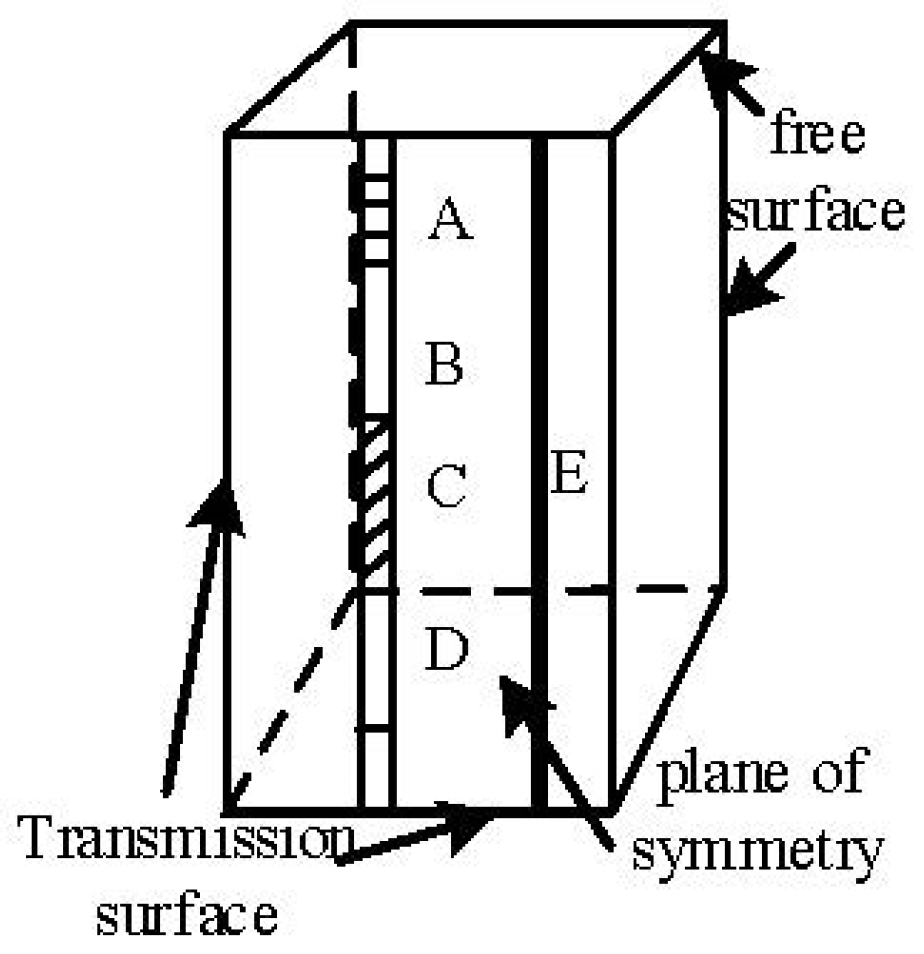

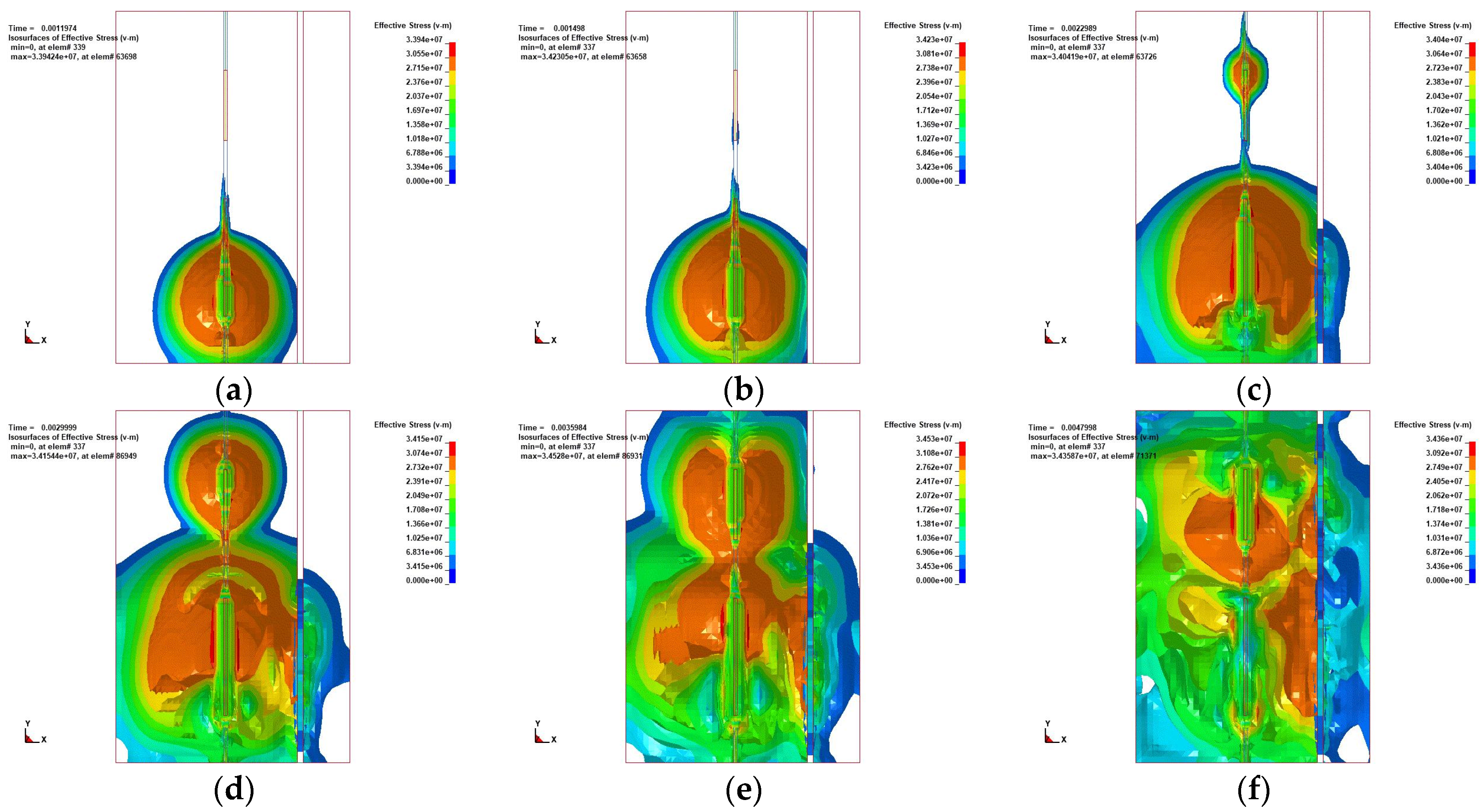

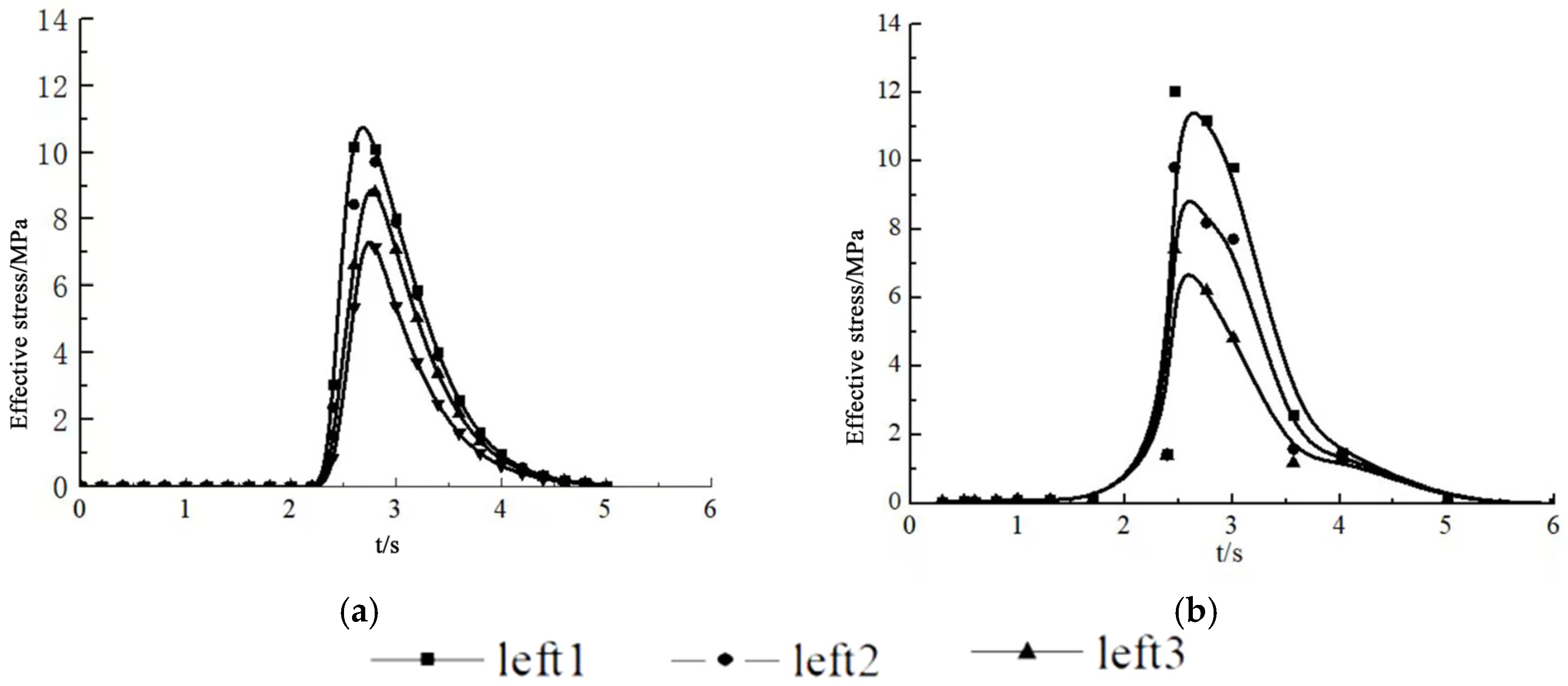

5. Analysis of Blasting Simulation

6. Conclusions

- (1)

- By constructing a nonlinear joint blasting model and introducing the detonation wave propagation velocity simplification into the vibration velocity of the incident particle at the joint interface, the incident P-wave incident joint is obtained. The peak value is at 3.0 s with a peak vibration velocity of 0.33 m/s; the S-wave reflected from the joint interface is first reflected backward and then forward. The peak vibration velocity of the particle is 0.027 m/s.

- (2)

- By combining with the relevant theories of stress and displacement field at the crack end of type I and II cracks, it is obtained that the joint presents asymmetric characteristics around the stress field. The end σx is positive in the direction of 0°–330° subject to tensile stress, whereas σy is positive in the direction of 0°–180° under tensile stress; the longitudinal stress σy of the joint is low around the compressive stress distribution area. At this point, the rock material does not fail, and the stress concentration appears in the lower-right position. The lateral displacement of the joint ends is significantly affected by the stress components in both directions.

- (3)

- Based on the analysis results of ANSYS, it is found that the intensity of the shock wave after detonation is greater than the strength of the rock. Then, the sub-layer shock wave supplements the energy of the shock wave that is not enough to break the rock and induces further cracking. Based on the analysis results on the attenuation of detonation wave energy, the stress exhibits a decreasing trend in the process. By constructing a variation diagram of the peak effective stress, it is found that the peak value first increases to 10–12 MPa and then shows a downward trend.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Bao, S. Study on the Change Law of Stress and Displacement at the End of Finite-Length Joints with Oblique Incidence of Stress Waves. Master’s Thesis, Liaoning University of Engineering and Technology, Fuxin, China, 2017. [Google Scholar]

- Song, L.; Yan, Y.; Han, B.; Shao, Z. Theoretical study on the propagation characteristics of longitudinal waves in nonlinear deformation joints. Chin. J. Appl. Mech. 2012, 29, 133–140+236. [Google Scholar]

- Zhao, A.; Feng, C.; Guo, R.; Li, S.; Jia, J. Research on the influence of joint properties on stress wave propagation and blasting effect. Chin. J. Rock Mech. Eng. 2018, 37, 2027–2037. [Google Scholar]

- Gao, Q.; Lu, W.; Leng, Z.; Wang, Y.; Sun, P.; Chen, M. Research on the regulation of blasting energy transmission in the blasting position in the hole in rock blasting. Chin. J. Geotech. Eng. 2020, 42, 2050–2059. [Google Scholar]

- Leng, Z.; Fan, Y.; Lu, W.; Zhou, J. Analysis of explosion energy transmission and rock breaking effect under the condition of double-point blasting in the hole. Chin. J. Rock Mech. Eng. 2019, 38, 2451–2462. [Google Scholar]

- Wu, H.; Gong, M. Calculation and application of hole-by-hole blasting vibration synthesis based on the actual delay range of the detonator. Blasting Vib. 2019, 39, 02520201–02520212. [Google Scholar]

- Beckel, E.; Oyler, K.; Mehta, N.; Khatri, N.; Marin, J.; Shah, A.; Cordaro-Gioia, E.; Decker, R.; Grau, H.; Stec, D. Primary explosive processing in the resonant acoustic mixer. Propellants Explos. Pyrotech. 2021, 46, 697–704. [Google Scholar] [CrossRef]

- Babanouri, N.; Abdolahpour, M.; Dehghani, H. Modeling blast-induced fragmentation of jointed rock mass using voronoi discrete-element method. Int. J. Geomech. 2020, 20, 04020117. [Google Scholar] [CrossRef]

- Han, D.Y.; Yang, H. Effects of tensile stresses on wave propagation across stylolitic rock joints. Int. J. Rock Mech. Min. Sci. 2021, 139, 104617. [Google Scholar] [CrossRef]

- Chai, S.B.; Wang, H.; Yu, L.Y.; Shi, J.H. Experimental study on static and dynamic compression mechanical properties of filled rock joints. Lat. Am. J. Solids Struct. 2020, 17, e264. [Google Scholar] [CrossRef]

- Lak, M.; Marji, M.F.; Bafghi, A.R.Y.; Abdollahipour, A. Discrete element modeling of explosion-induced fracture extension in jointed rock masses. J. Min. Environ. 2019, 10, 125–138. [Google Scholar]

- Dong, Q.; Li, X.P.; Huang, J.H. Model test study on cylindrical blasting stress wave propagation across jointed rock mass with different initial stresses. Adv. Civ. Eng. 2020, 8, 8881302. [Google Scholar] [CrossRef]

- Dunlop, E.C.; Salmachi, A.; McCabe, P.J. Investigation of increasing hydraulic fracture conductivity within producing ultra-deep coal seams using time-lapse rate transient analysis: A long-term pilot experiment in the Cooper Basin, Australia. Int. J. Coal Geol. 2020, 220, 103363. [Google Scholar] [CrossRef]

- Huang, L.; Liu, J.; Zhang, F.; Dontsov, E.; Damjanac, B. Exploring the influence of rock inherent heterogeneity and grain size on hydraulic fracturing using discrete element modeling. Int. J. Solids Struct. 2019, 176–177, 207–220. [Google Scholar] [CrossRef]

- Wang, X.; Cai, M. A comprehensive parametric study of grain-based models for rock failure process simulation. Int. J. Rock Mech. Min. Sci. 2019, 115, 60–76. [Google Scholar] [CrossRef]

- Chen, J.; Liu, P.; Zhao, H.; Zhang, C.; Zhang, J. Analytical studying the axial performance of fully encapsulated rock bolts. Eng. Fail. Anal. 2021, 128, 105580. [Google Scholar] [CrossRef]

- Chen, J.; Zhao, H.; He, F.; Zhang, J.; Tao, K. Studying the performance of fully encapsulated rock bolts with modified structural elements. Int. J. Coal Sci. Technol. 2021, 8, 64–76. [Google Scholar] [CrossRef]

- Chen, J.; Zhao, Y.; Zhao, H.; Zhang, J.; Zhang, C.; Li, D. Analytic study on the force transfer of full encapsulating rockbolts subjected to tensile force. Int. J. Appl. Mech. 2021, 13, 2150097. [Google Scholar] [CrossRef]

- He, Q.; Lei, Z.; Li, Y. Simulating Hydraulic Fracture Re-orientation from Oriented Perforations in Heterogeneous Rocks with An Improved Discrete Element Method. Rock Mech. Rock Eng. 2021, 54, 2859–2879. [Google Scholar] [CrossRef]

- Cai, R.; Li, Y.; Zhang, C. Damage assessment of prefabricated prestressed channel slab under plane charge blast. Eng. Struct. 2021, 246, 113021. [Google Scholar] [CrossRef]

- Wu, S.; Li, J.; Guo, J.; Shi, G.; Gu, Q.; Lu, C. Stress corrosion cracking fracture mechanism of cold-drawn high-carbon cable bolts. Mater. Sci. Eng. A 2020, 769, 138479. [Google Scholar] [CrossRef]

- Wu, S.; Ramandi, H.L.; Hagan, P.C.; Crosky, A.; Saydam, S. Mineralogically influenced stress corrosion cracking of rockbolts and cable bolts in underground mines. Int. J. Rock Mech. Min. Sci. 2019, 119, 109–116. [Google Scholar] [CrossRef]

- Wu, S.; Zhang, X.; Li, J.; Wang, Z. Investigation for influences of seepage on mechanical properties of rocks using acoustic emission technique. Geofluids 2020, 1155, 10–19. [Google Scholar] [CrossRef]

- Henry, J. Explosive Dynamics and Its Applications; Xiong, J., Ed.; Science Press: Beijing, China, 1981. [Google Scholar]

- Gao, Q.; Lu, W.; Leng, Z. Research on the control effect of the initiation position in the hole on the energy transmission of the explosion in rock blasting. Chin. J. Rock Eng. 2020, 42, 2050–2059. [Google Scholar]

- Zhang, P.; Bai, R.; Sun, X. A Study of Millisecond Blasting on High Bench at Barun Iron Ore Operation. Geofluids 2021, 13, 3645438. [Google Scholar] [CrossRef]

- Han, Z.; Li, D.Y.; Tao, Z.; Zhu, Q.; Ranjith, P.G. Experimental study of stress wave propagation and energy characteristics across rock specimens containing cemented mortar joint with various thickness. Int. J. Rock Mech. Min. Sci. 2020, 131, 104352. [Google Scholar] [CrossRef]

- Shu, P.-Y.; Lin, C.-Y.; Li, H.-H.; Cheng, T.-W.; Ueng, T.-H.; Wang, T.-T. Dynamic response of rock containing regular sawteeth joints under various loading rates and angles of application. Appl. Sci. 2020, 10, 5204. [Google Scholar] [CrossRef]

- Hu, Y.G.; Yang, Z.W.; Huang, S.L.; Lu, W.B.; Zhao, G. A new safety control method of blasting excavation in high rock slope with joints. Rock Mech. Rock Eng. 2020, 53, 3015–3029. [Google Scholar] [CrossRef]

- Zhu, J.B.; Li, Y.S.; Peng, Q.; Deng, X.F.; Gao, M.Z.; Zhang, Z.J. Stress wave propagation across jointed rock mass under dynamic extension and its effect on dynamic response and supporting of underground opening. Tunn. Undergr. Space Technol. Inc. Trenchless Technol. Res. 2021, 108, 103648. [Google Scholar] [CrossRef]

| Density (g/cm3) | Young’s Modulus (MPa) | Poisson’s Ratio | Compressive Strength (MPa) | Tangent Modulus (MPa) |

|---|---|---|---|---|

| 1.85 | 1.2 | 0.38 | 0.8 | 0.1 |

| Density (g/cm3) | Young’s Modulus (×104 MPa) | Poisson’s Ratio | Tensile Strength (MPa) | Compressive Strength (MPa) |

|---|---|---|---|---|

| 2.43 | 5 | 0.26 | 5 | 130 |

| Density (g/cm3) | Blasting Speed (cm/us) | Blasting Pressure (GPa) | A | B | R1 | w | R2 |

|---|---|---|---|---|---|---|---|

| 1.20 | 0.40 | 50 | 2.14 × 1011 | 1.82 × 108 | 4.15 | 0.3 | 0.95 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, P.; Bai, R.; Sun, X.; Wang, T. Investigation of Rock Joint and Fracture Influence on Delayed Blasting Performance. Appl. Sci. 2023, 13, 10275. https://doi.org/10.3390/app131810275

Zhang P, Bai R, Sun X, Wang T. Investigation of Rock Joint and Fracture Influence on Delayed Blasting Performance. Applied Sciences. 2023; 13(18):10275. https://doi.org/10.3390/app131810275

Chicago/Turabian StyleZhang, Pengfei, Runcai Bai, Xue Sun, and Tianheng Wang. 2023. "Investigation of Rock Joint and Fracture Influence on Delayed Blasting Performance" Applied Sciences 13, no. 18: 10275. https://doi.org/10.3390/app131810275

APA StyleZhang, P., Bai, R., Sun, X., & Wang, T. (2023). Investigation of Rock Joint and Fracture Influence on Delayed Blasting Performance. Applied Sciences, 13(18), 10275. https://doi.org/10.3390/app131810275