Hemp Biomass as a Raw Material for Sustainable Development

Abstract

:1. Introduction

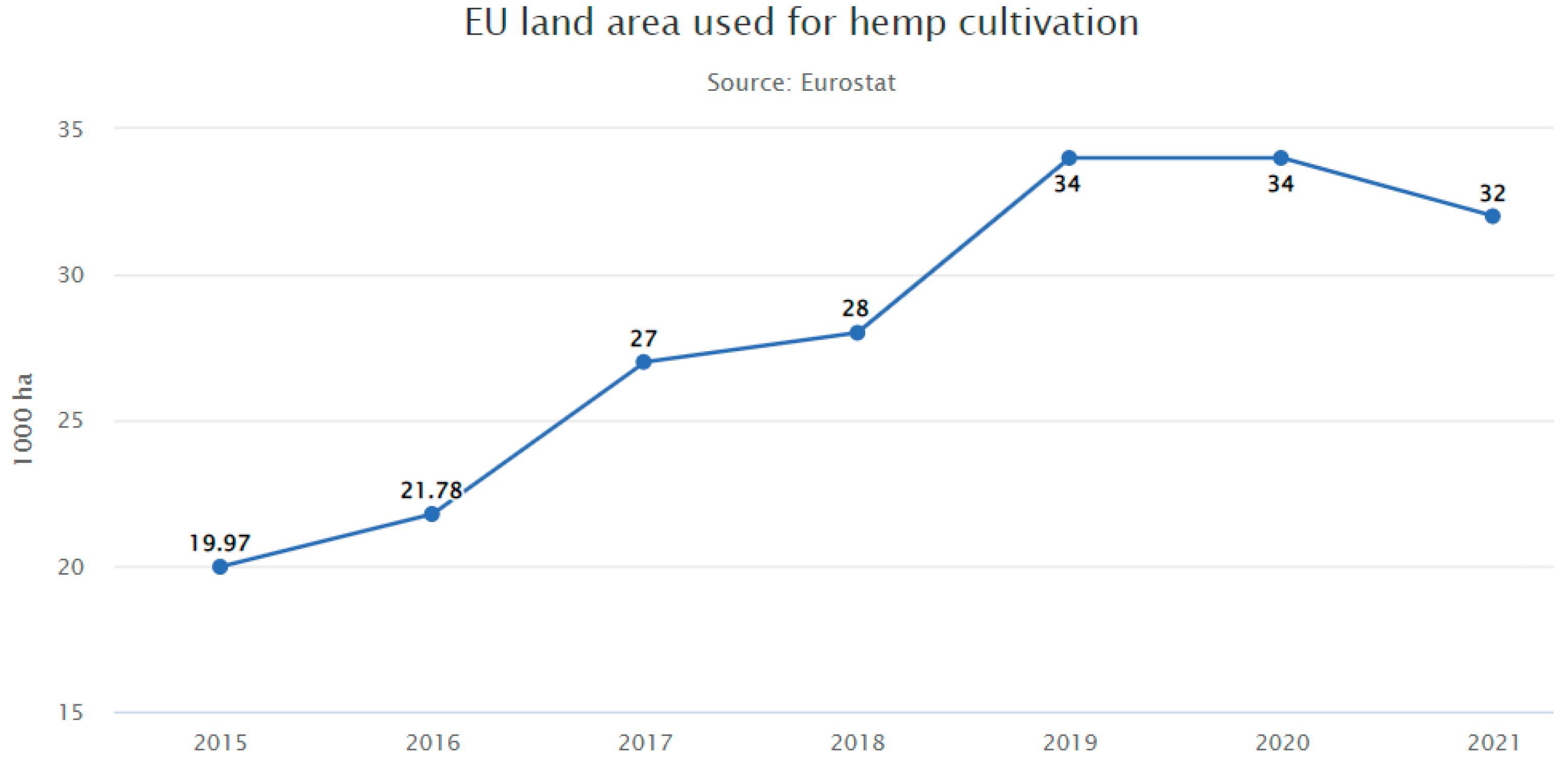

2. Hemp Cultivation in Terms of Achieving the Goals of the European Green Deal

3. Cultivation of Industrial Hemp

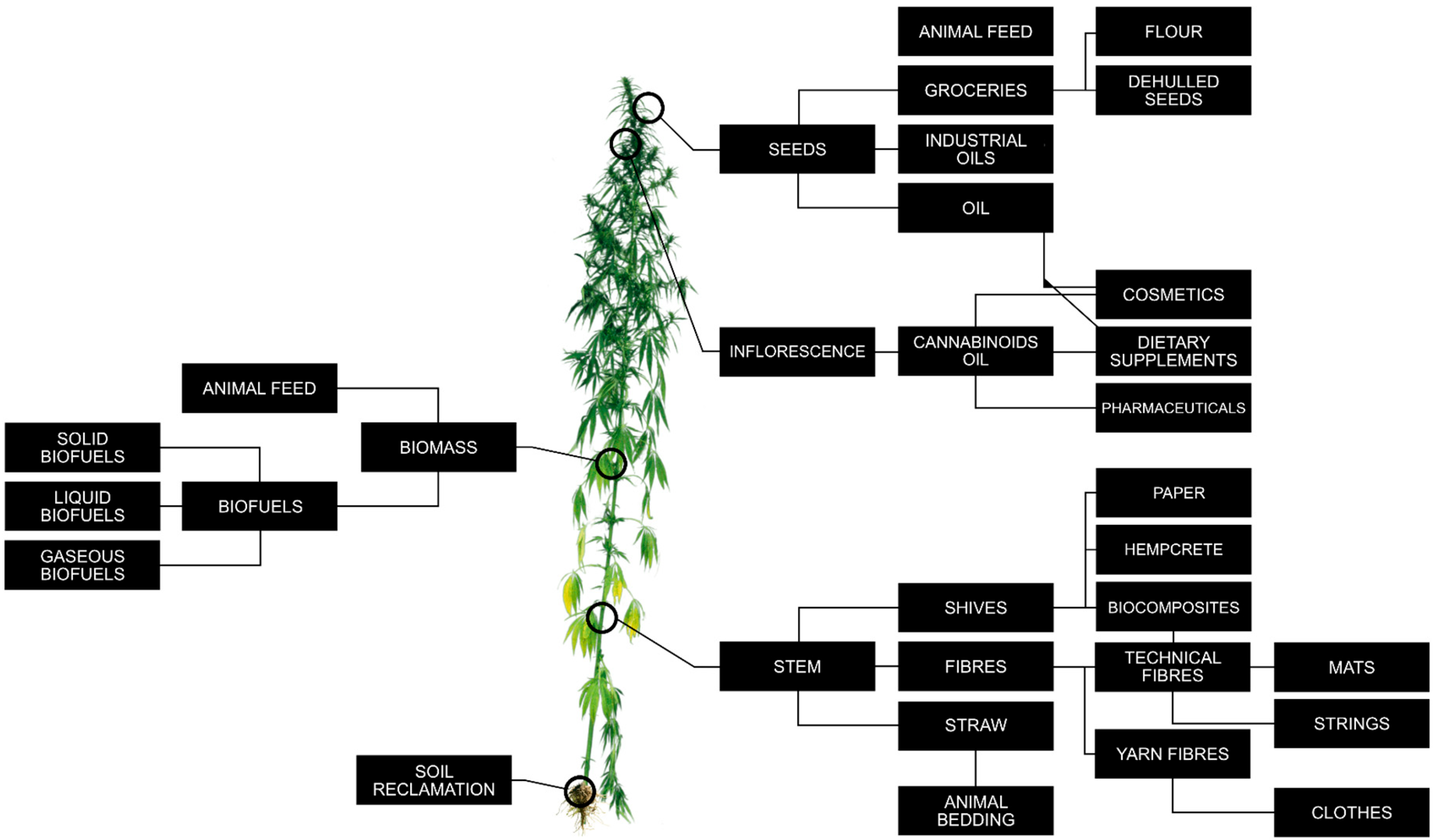

4. Various Uses of Industrial Hemp

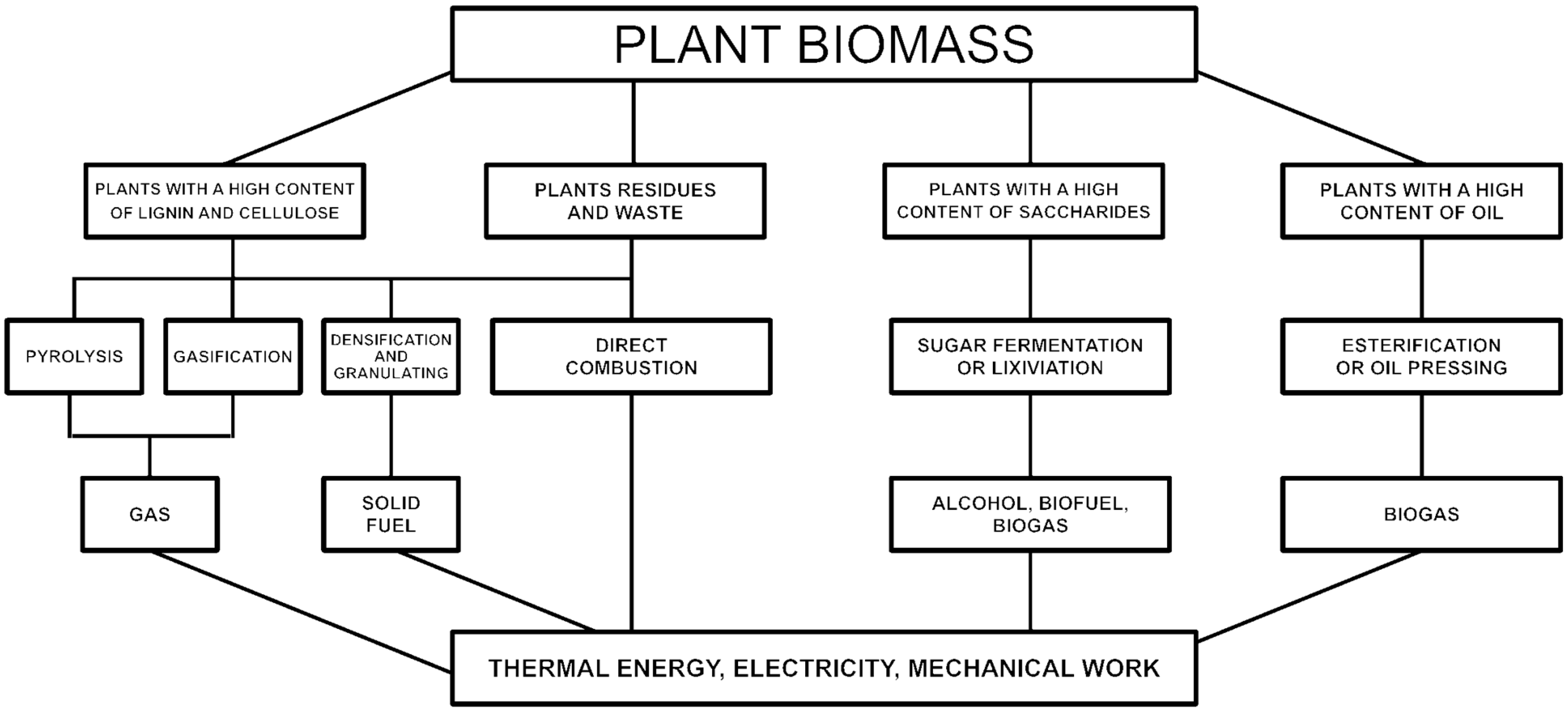

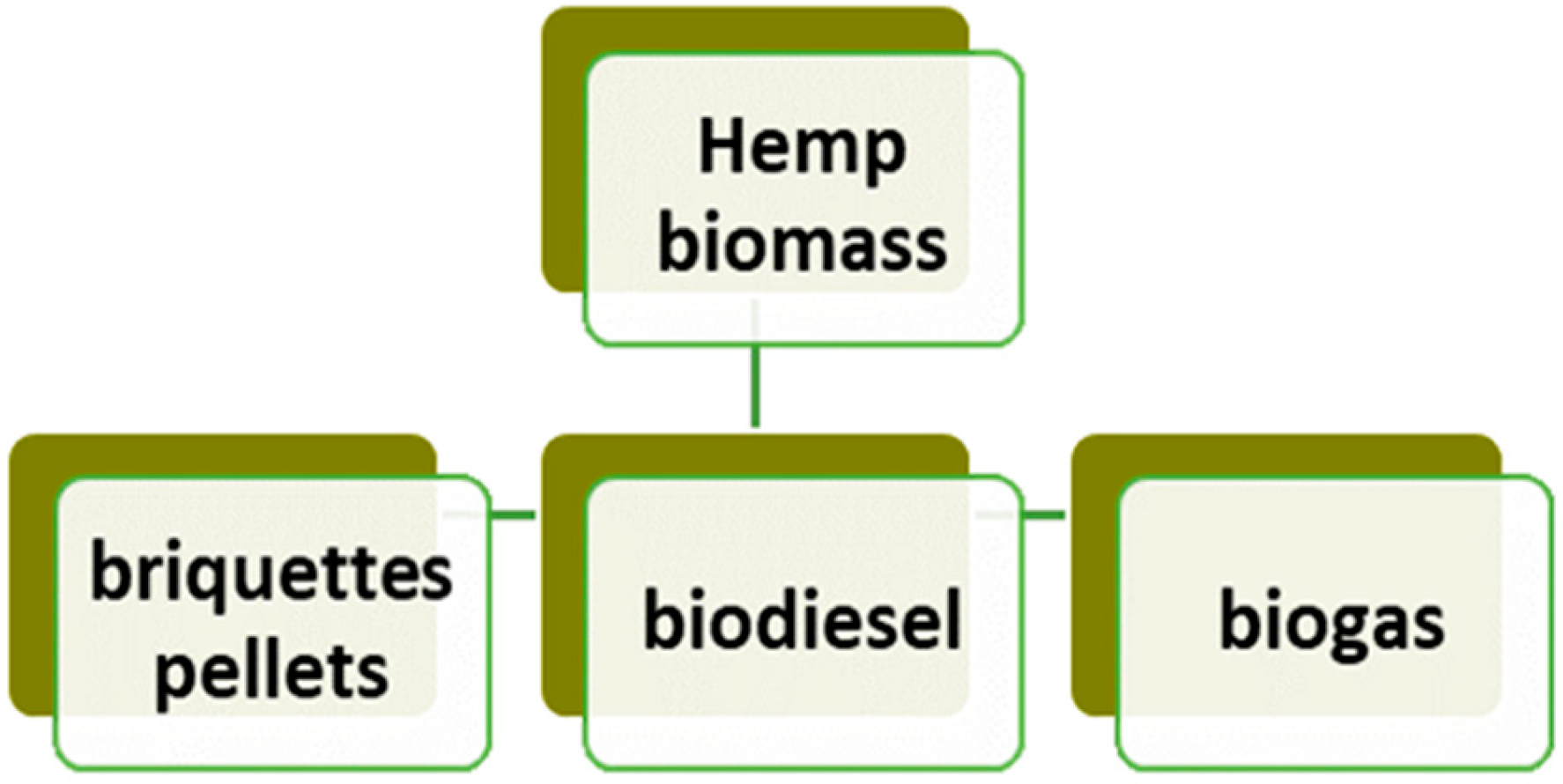

5. The Use of Hemp Biomass for Biofuels Production

6. Social and Economic Aspects of Hemp Cultivation

7. Current Problems in the Hemp Industry

8. Summary and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Visković, J.; Zheljazkov, V.D.; Sikora, V.; Noller, J.; Latković, D.; Ocamb, C.M.; Koren, A. Industrial Hemp (Cannabis sativa L.) Agronomy and Utilization: A Review. Agronomy 2023, 13, 931. [Google Scholar] [CrossRef]

- Hesami, M.; Pepe, M.; Baiton, A.; Salami, S.A.; Jones, A.M.P. New insight into ornamental applications of cannabis: Perspectives and challenges. Plants 2022, 11, 2383. [Google Scholar] [CrossRef] [PubMed]

- Hesami, M.; Pepe, M.; Baiton, A.; Jones, A.M.P. Current status and future prospects in cannabinoid production through in vitro culture and synthetic biology. Biotechnol. Adv. 2022, 62, 108074. [Google Scholar] [CrossRef] [PubMed]

- Johnson, R. Defining hemp: A fact sheet. Congr. Res. Serv. 2019, 44742, 1–12. [Google Scholar]

- Grzebisz, W. (Ed.) Produkcja roślinna. In Technologie Produkcji Roślinnej. Rolnictwo; Hortpress: Warszawa, Poland, 2015; pp. 280–288. [Google Scholar]

- Karus, M.; Vogt, D. European hemp industry: Cultivation, processing and product lines. Euphytica 2004, 140, 7–12. [Google Scholar] [CrossRef]

- European Commission. Available online: https://agriculture.ec.europa.eu/farming/crop-productions-and-plant-based-products/hemp_en (accessed on 4 May 2023).

- Zhao, X.; Wei, X.; Guo, Y.; Qiu, C.; Long, S.; Wang, Y.; Qiu, H. Industrial Hemp—An Old but Versatile Bast Fiber Crop. J. Nat. Fibers 2022, 19, 6269–6282. [Google Scholar] [CrossRef]

- Karche, T.; Singh, M.R. The application of hemp (Cannabis sativa L.) for a green economy: A review. Turk. J. Bot. 2019, 43, 710–723. [Google Scholar] [CrossRef]

- European Industrial Hemp Association. Available online: www.eiha.org (accessed on 29 November 2022).

- European Commission. A European Green Deal. Available online: https://commission.europa.eu/strategy-and-policy/priorities-2019-2024/european-green-deal_en (accessed on 4 May 2023).

- Cierpucha, W. (Ed.) Technologia Uprawy i Przetwórstwa Konopi Włóknistych; Instytut Włókien Naturalnych i Roślin Zielarskich: Poznań, Poland, 2013; pp. 22–31. [Google Scholar]

- Burczyk, H.; Frankowski, J. Henola—Polska odmiana konopi oleistych. Zag. Doradz. Rol. 2018, 93, 89–101. [Google Scholar]

- Wójtowicz, A.; Strażyński, P.; Mrówczyński, M. (Eds.) Metodyka Integrowanej Ochrony Konopi Dla Doradców; Instytut Ochrony Roślin—Państwowy Instytut Badawczy: Poznań, Poland, 2018. [Google Scholar]

- The Ministry of Agriculture and Rural Development. Available online: https://www.gov.pl/web/rolnictwo/wyszukiwarka-srodkow-ochrony-roslin---zastosowanie (accessed on 8 May 2023).

- Kaniewski, R.; Pniewska, I.; Kubacki, A.; Strzelczyk, M.; Chudy, M.; Oleszak, G. Konopie siewne (Cannabis sativa L.)—Wartościowa roślina użytkowa i lecznicza. Post. Fitoter. 2017, 18, 139–144. [Google Scholar] [CrossRef]

- Research Centre for Cultivar Testing. Available online: www.coboru.pl (accessed on 16 December 2022).

- Buchwald, W.; Silska, G.; Mańkowska, G.; Forycka, A. Stan ochrony bioróżnorodności roślin włóknistych i zielarskich w Polsce, Len i Konopie. Biul. Inf. Pol. Izby Lnu I Konopi 2015, 24, 16–20. [Google Scholar]

- Mańkowska, G.; Strybe, M.; Chudy, M.; Luwańska, A.; Baraniecki, P. Ocena cech użytkowych wybranych odmian konopi Cannabis sativa L., zgromadzonych w Instytucie Włókien Naturalnych i Roślin Zielarskich w 2008 roku. Zesz. Probl. Post. Nauk Rol. 2010, 555, 529–536. [Google Scholar]

- Burczyk, H.; Oleszak, G. Oilseed hemp (Cannabis sativa L. var. oleifera) grown for seeds, oil and biogas. Probl. Inż. Rol. 2016, 24, 109–116. [Google Scholar]

- Schumacher, A.G.D.; Pequito, S.; Pazour, J. Industrial hemp fiber: A sustainable and economical alternative to cotton. J. Clean. Prod. 2020, 268, 122180. [Google Scholar] [CrossRef]

- Zimniewska, M. Hemp Fibre Properties and Processing Target Textile: A Review. Materials 2022, 15, 1901. [Google Scholar] [CrossRef] [PubMed]

- Gedik, G.; Avinc, O. Hemp Fiber as a Sustainable Raw Material Source for Textile Industry: Can We Use Its Potential for More Eco-Friendly Production? In Sustainable Textiles: Production, Processing, Manufacturing & Chemistry. Sustainability in the Textile and Apparel Industry; Muthu, S., Gardetti, M., Eds.; Springer: Cham, Switzerland, 2020; pp. 87–110. [Google Scholar] [CrossRef]

- Farinon, B.; Molinari, R.; Costantini, L.; Merendino, N. The Seed of Industrial Hemp (Cannabis sativa L.): Nutritional Quality and Potential Functionality for Human Health and Nutrition. Nutrients 2020, 12, 1935. [Google Scholar] [CrossRef] [PubMed]

- Leonard, W.; Zhang, P.; Ying, D.; Fang, Z. Hempseed in food industry: Nutritional value, health benefits, and industrial applications. Compr. Rev. Food Sci. Food Saf. 2020, 19, 282–308. [Google Scholar] [CrossRef] [PubMed]

- Pei, L.; Luo, Y.; Gu, X.; Wang, J. Formation, Stability and Properties of Hemp Seed Oil Emulsions for Application in the Cosmetics Industry. Tenside Surfactants Deterg. 2021, 57, 451–459. [Google Scholar] [CrossRef]

- Caputa, J.; Nikiel-Loranc, A. Zastosowanie oleju konopnego w kosmetologii. Kosmetol. Estet. 2019, 4, 461–463. [Google Scholar]

- Eržen, M.; Košir, I.J.; Ocvirk, M.; Kreft, S.; Čerenak, A. Metabolomic Analysis of Cannabinoid and Essential Oil Profiles in Different Hemp (Cannabis sativa L.) Phenotypes. Plants 2021, 10, 966. [Google Scholar] [CrossRef]

- Orlando, G.; Adorisio, S.; Delfino, D.; Chiavaroli, A.; Brunetti, L.; Recinella, L.; Leone, S.; D’Antonio, M.; Zengin, G.; Acquaviva, A.; et al. Comparative Investigation of Composition, Antifungal, and Anti-Inflammatory Effects of the Essential Oil from Three Industrial Hemp Varieties from Italian Cultivation. Antibiotics 2021, 10, 334. [Google Scholar] [CrossRef]

- Karas, J.A.; Wong, L.J.M.; Paulin, O.K.A.; Mazeh, A.C.; Hussein, M.H.; Li, J.; Velkov, T. The Antimicrobial Activity of Cannabinoids. Antibiotics 2020, 9, 406. [Google Scholar] [CrossRef] [PubMed]

- Kaniewski, R.; Pniewska, I.; Świejkowski, M. Możliwości wykorzystania olejków eterycznych, ze szczególnym uwzględnieniem olejku konopnego, jako substancji aktywnych i środków konserwujących kosmetyki. Post. Fitoter. 2016, 17, 125–129. [Google Scholar]

- Loiacono, S.; Crini, G.; Chanet, G.; Raschetti, M.; Placet, V.; Morin-Crini, N. Metals in aqueous solutions and real effluents: Biosorption behavior of a hemp-based felt. J. Technol. Biotechnol. 2018, 93, 2592–2601. [Google Scholar] [CrossRef]

- Liu, J.; Zhang, C.; Tao, B.; Beckerman, J. Revealing the roles of biomass components in the biosorption of heavy metals in wastewater by various chemically treated hemp stalks. J. Taiwan Inst. Chem. Eng. 2023, 143, 104701. [Google Scholar] [CrossRef]

- Liu, J.; Beckerman, J. Application of sustainable biosorbents from hemp for remediation copper(II)-containing wastewater. J. Environ. Chem. Eng. 2022, 10, 107494. [Google Scholar] [CrossRef]

- Małachowska, E.; Przybysz, P.; Dubowik, M.; Kucner, M.; Buzała, K. Comparison of papermaking potential of wood and hemp cellulose pulps. For. Wood Technol. 2015, 91, 134–137. [Google Scholar]

- Naithani, V.; Tyagi, P.; Jameel, H.; Lucia, L.A.; Pal, L. Ecofriendly and Innovative Processing of Hemp Hurds Fibers for Tissue and Towel Paper. BioResources 2020, 15, 706–720. [Google Scholar] [CrossRef]

- Hryniewicz, M.; Borek, K.; Mazur, K.; Konieczna, A.; Motyka, J.; Rutkowski, M.; Rutkowski, T.; Nazaruk, M.; Koperski, B.; Koperski, W.; et al. Wykorzystanie paździerza konopnego jako zamiennika mieszanki kruszywowej w mieszance betonowej do produkcji prefabrykatów betonowych. Inżynieria Mater. 2022, 43, 23–25. [Google Scholar] [CrossRef]

- Pietruszka, B.; Gołębiewski, M. Właściwości wyrobów budowlanych na bazie konopi. Prz. bud. 2019, 90, 139–141. [Google Scholar]

- Arrigoni, A.; Pelosato, R.; Meliá, P.; Ruggieri, G.; Sabbadini, S.; Dotelli, G. Life cycle assessment of natural building materials: The role of carbonation, mixture components and transport in the environmental impacts of hempcrete blocks. J. Clean. Prod. 2017, 149, 1051–1061. [Google Scholar] [CrossRef]

- Drug Prevention Act of March 24 2022 [Ustawa z dn. 24 Marca 2022 o Zmianie Ustawy o Przeciwdziałaniu Narkomani (Dz. U. z 2022 r. poz. 763)]. Available online: https://isap.sejm.gov.pl/isap.nsf/DocDetails.xsp?id=WDU20220000763 (accessed on 27 March 2023).

- Pollio, A. The name of Cannabis: A short guide for nonbotanists. Cannabis Cannabinoid Res. 2016, 1, 234–238. [Google Scholar] [CrossRef] [PubMed]

- Hillig, K.W. Genetic evidence for speciation in Cannabis (Cannabaceae). Genet. Resour. Crop Evol. 2005, 52, 161–180. [Google Scholar] [CrossRef]

- Russo, E.B. Taming THC: Potential cannabis synergy and phytocannabinoid-terpenoid entourage effects. Br. J. Pharmacol. 2011, 163, 1344–1364. [Google Scholar] [CrossRef]

- Mechtler, K.; Bailer, J.; De Hueber, K. Variations of Δ9-THC content in single plants of hemp varieties. Ind. Crops Prod. 2004, 19, 19–24. [Google Scholar] [CrossRef]

- Weissman, A. On the definition of cannabinoids: Botanical? chemical? pharmacological? J. Clin. Pharmacol. 1981, 21, 159S–165S. [Google Scholar] [CrossRef]

- Pacher, P.; Batkai, S.; Kunos, G. The endocannabinoid system as an emerging target of pharmacotherapy. Pharmacol. Rev. 2006, 58, 389–462. [Google Scholar] [CrossRef]

- Di Marzo, V.; Bifulco, M.; De Petrocellis, L. The endocannabinoid system and its therapeutic exploitation. Nat. Rev. Drug Discov. 2004, 9, 771–784. [Google Scholar] [CrossRef] [PubMed]

- McGilveray, I. Pharmacokinetics of Cannabinoids. Pain Res. Manag. 2005, 10 (Suppl. A), 15A–22A. [Google Scholar] [CrossRef]

- Blessing, E.M.; Steenkamp, M.M.; Manzanares, J.; Marmam, C.R. Cannabidiol as potential treatment for anxiety disorders. Neurotherapeutics 2015, 12, 825–836. [Google Scholar] [CrossRef]

- Zuardi, A.W.; Crippa, J.A.D.S.; Hallac, J.E.C.; Moreira, F.A.; Guimaraes, F.S. Cannabidol, a Cannabis sativa constituent as an antipsychotic drug. Braz. J. Med. Biol. Res. 2006, 39, 421–429. [Google Scholar] [CrossRef]

- Baron, E.P. Comprehensive review of medicinal marijuana, cannabinoids and therapeutic implication in medicine and headache: What a long, strange trip it’s been…. Headache 2015, 55, 885–916. [Google Scholar] [CrossRef]

- Fernandez-Ruiz, J.; Hernandez, M.; Ramos, J.A. Cannabinoid-dopamine interaction in the pathophysiology of treatment of CNS disorders. CNC Neurosci. Ther. 2010, 16, e72–e91. [Google Scholar] [CrossRef]

- Abrams, D.I. The Therapeutic Effect of Cannabis and Cannabinoids: An Update from the Nationlal Academic of Science, Engineering and Medicine Report. Eur. J. Intern. Med. 2018, 49, 7–11. [Google Scholar] [CrossRef]

- Amar, M.B. Cannabinoids in Medicine: A review of their therapeutic potential. J. Ethnopharmacol. 2006, 105, 1–25. [Google Scholar] [CrossRef] [PubMed]

- Crini, G.; Lichtfouse, E.; Chanet, G.; Morin-Crini, N. Applications of hemp in textiles, paper industry, insulation and building materials, horticulture, animal nutrition, food and beverages, nutraceuticals, cosmetics and hygiene, medicine, agrochemistry, energy production and environment: A review. Environ. Chem. Lett. 2020, 18, 1451–1476. [Google Scholar] [CrossRef]

- Small, E.; Marcus, D. Hemp: A new crop with new uses for North America. In Trends in New Crops and New Uses; Janick, J., Whipkey, A., Eds.; ASHS Press: Alexandria, Egypt, 2002; pp. 284–326. [Google Scholar]

- Cherney, J.H.; Small, E. Industrial Hemp in North America: Production, Politics and Potential. Agronomy 2016, 6, 58. [Google Scholar] [CrossRef]

- Chandra, S.; Lata, H.; Khan, I.A.; ElSohly, M.A. Cannabis sativa L.: Botany and horticulture. In Cannabis Sativa L.-Botany and Biotechnology; Springer: Berlin/Heidelberg, Germany, 2017; pp. 79–100. [Google Scholar]

- Modi, A.A.; Shahid, R.; Saeed, M.U.; Younas, T. Hemp is the Future of Plastics. 3rd International Conference on Advances on Clean Energy Research. E3S Web Conf. 2018, 51, 03002. [Google Scholar] [CrossRef]

- Beluns, S.; Gaidukovs, S.; Platnieks, O.; Grase, L.; Gaidukova, G.; Thakur, V.K. Sustainable hemp-based bioplastics with tunable properties via reversible thermal crosslinking of cellulose. Int. J. Biol. Macromol. 2023, 242, 125055. [Google Scholar] [CrossRef]

- Nabels-Sneiders, M.; Platnieks, O.; Grase, L.; Gaidukovs, S. Lamination of Cast Hemp Paper with Bio-Based Plastics for Sustainable Packaging: Structure-Thermomechanical Properties Relationship and Biodegradation Studies. J. Compos. Sci. 2022, 6, 246. [Google Scholar] [CrossRef]

- Khattab, M.M.; Dahman, Y. Production and recovery of poly-3-hydroxybutyrate bioplastics using agro-industrial residues of hemp hurd biomass. Bioprocess Biosyst. Eng. 2019, 42, 1115–1127. [Google Scholar] [CrossRef]

- Sabu, T.; Shumilova, A.A.; Kiselev, E.G.; Baranovsky, S.V.; Vasiliev, A.D.; Nemtsev, I.V.; Petrovich Kuzmin, A.; Sukovatyi, A.G.; Pai Avinash, R.; Volova, T.G. Thermal, mechanical and biodegradation studies of biofiller based poly-3-hydroxybutyrate biocomposites. Int. J. Biol. Macromol. 2020, 155, 1373–1384. [Google Scholar] [CrossRef]

- Masnadi, M.S.; Grace, J.R.; Bi, X.T.; Lim, C.J.; Ellis, N. From fossil fuels towards renewables: Inhibitory and catalytic effects on carbon thermochemical conversion during co-gasification of biomass with fossil fuels. Appl. Energy 2015, 140, 196–209. [Google Scholar] [CrossRef]

- Baral, A.; Guha, G.S. Trees for carbon sequestration or fossil fuel substitution: The issue of cost vs. carbon benefit. Biomass Bioenergy 2004, 27, 41–55. [Google Scholar] [CrossRef]

- Gustavsson, L.; Börjesson, P.; Johansson, B.; Svenningsson, P. Reducing CO2 emissions by substituting biomass for fossil fuels. Energy 1995, 20, 1097–1113. [Google Scholar] [CrossRef]

- Lam, H.L.; Varbanov, P.; Klemeš, J. Minimising carbon footprint of regional biomass supply chains. Resour. Conserv. Recycl. 2010, 54, 303–309. [Google Scholar] [CrossRef]

- Hillier, J.; Hawes, C.; Squire, G.; Hilton, A.; Wale, S.; Smith, P. The carbon footprints of food crop production. Int. J. Agric. Sustain. 2009, 7, 107–118. [Google Scholar] [CrossRef]

- Grzybek, A.; Gradziuk, P.; Kowalczyk, K. Słoma: Energetyczne Paliwo; Wydawnictwo Wieś Jutra: Warszawa, Poland, 2001; pp. 66–70. [Google Scholar]

- Mańkowski, J.; Kołodziej, J.; Baraniecki, P. Energetyczne wykorzystanie biomasy z konopi uprawianych na terenach zrekultywowanych. Chemik 2014, 68, 901–902. [Google Scholar]

- Frankowski, J.; Sieracka, D. Possibilities of Using Waste Hemp Straw for Solid Biofuel Production. Environ. Sci. Proc. 2021, 4, 9018. [Google Scholar] [CrossRef]

- Niedziółka, I.; Szpryngiel, M.; Kachel-Jakubowska, M.; Kraszkiewicz, A.; Zawiślak, K.; Sobczak, P.; Nadulski, R. Assesment of the energrtic and mechanical properties od pellets produced from agricultural biomass. Renew. Energ. 2015, 76, 312–317. [Google Scholar] [CrossRef]

- Borkowska, H.; Molas, R. Yield comparison of four lignocellulosic perennial energy crop species. Biomass Bioenergy 2013, 51, 145–153. [Google Scholar] [CrossRef]

- Karpenstein-Machan, M. Sustainable cultivation concepts for domestic energy production from biomass. Crit. Rev. Plant Sci. 2001, 20, 1–14. [Google Scholar] [CrossRef]

- Rasi, S.; Veijanen, A.; Rintala, J. Trace compounds of biogas from different biogas production plants. Energy 2007, 32, 1375–1380. [Google Scholar] [CrossRef]

- Prade, T.; Svensson, S.E.; Mattsson, J.E. Energy balances for biogas and solid biofuel production from industrial hemp. Biomass Bioenergy 2012, 40, 36–52. [Google Scholar] [CrossRef]

- Demirbas, A. Competitive liquid biofuels from biomass. Appl. Energy 2011, 88, 17–28. [Google Scholar] [CrossRef]

- Act on Biocomponents and Liquid Biofuels of 25 August 2006 [Ustawa z dn. 25 Sierpnia 2006 r. o Biokomponentach i Biopaliwach Ciekłych (Dz. U. 2006 nr 169 poz. 1199)]. Available online: https://isap.sejm.gov.pl/isap.nsf/DocDetails.xsp?id=wdu20061691199 (accessed on 27 March 2023).

- Casas, A.; Ruiz, J.R.; Ramos, M.J.; Perez, A. Efects of triacetin on biodiesel quality. Energy Fuel 2010, 24, 4481–4489. [Google Scholar] [CrossRef]

- Perez, A.; Casas, A.; Fernandez, C.M.; Ramos, M.J.; Rodrigez, L. Winterization of peanut biodiesel to improve cold flow properties. Biosour. Technol. 2010, 101, 7375–7381. [Google Scholar] [CrossRef]

- Zucaro, A.; Fiorentino, G.; Ulgiati, S. Constraints, impacts and benefits of lignocellulose conversion pathways to liquid biofuels and biochemicals. In Lignocellulosic Biomass to Liquid Biofuels; Academic Press: Cambridge, MA, USA, 2020; pp. 249–282. [Google Scholar] [CrossRef]

- Szambelan, K.; Szwengiel, A.; Nowak, J.; Jeleń, H.; Frankowski, J. Low-waste technology for the production of bioethanol from sorghum grain: Comparison of Zymomonas mobilis and Saccharomyces cerevisiae in fermentation with stillage reusing. J. Clean. Prod. 2022, 352, 131607. [Google Scholar] [CrossRef]

- Arun, N.; Dalai, A.K. Enviromental and socioeconomic impact assestment of biofuels from lignocellulosic biomass. In Lignocellulosic Biomass to Liquid Biofuels; Academic Press: Cambridge, MA, USA, 2020; pp. 283–299. [Google Scholar] [CrossRef]

- Sharma, N.; Sharma, N. Second generation bioethanol production from lignocellulosic waste and its future perspective. A revive. Internat. J. Curr. Microbiol. Appl. Sci. 2018, 7, 1285–1290. [Google Scholar] [CrossRef]

- Singh, R.S.; Pandey, A.; Gnansounou, E. (Eds.) Biofuels: Production and Future Perspective; CRC Press: Boca Raton, FL, USA, 2016; p. 578. [Google Scholar]

- Parvez, A.M.; Lewis, J.D.; Afzal, M.T. Potential of industrial hemp (Cannabis sativa L.) for bioenergy production in Canada: Status, challenges and outlook. Renew. Sustain. Energy Rev. 2021, 141, 110784. [Google Scholar] [CrossRef]

- Das, L.; Liu, E.; Saeed, A.; Williams, D.W.; Hu, H.; Li, C.; Ray, A.E.; Shi, J. Industrial hemp as a potential bioenergy crop in comparison with kenaf, switchgrass and biomass sorghum. Bioresour. Technol. 2017, 244, 641–649. [Google Scholar] [CrossRef]

- Frankowski, J.; Wawro, A.; Batog, J.; Burczyk, H. New Polish Oilseed Hemp Cultivar Henola—Cultivation, Properties and Utilization for Bioethanol Production. J. Nat. Fibers 2022, 19, 7283–7295. [Google Scholar] [CrossRef]

- Wawro, A.; Batog, J.; Gieparda, W. Chemical and Enzymatic Treatment of Hemp Biomass for Bioethanol Production. Appl. Sci. 2019, 9, 5348. [Google Scholar] [CrossRef]

- Gomez, L.D.; Steele-King, C.G.; McQueen-Mason, S.J. Sustainable liquid biofuels from biomass: The writing’s on the walls. New Phytol. 2008, 178, 473–485. [Google Scholar] [CrossRef] [PubMed]

- Szulc, R.; Dach, J. (Eds.) Kierunki Rozwoju Ekoenergetyki w Polskim Rolnictwie; Polskie Towarzystwo Inżynierii Rolniczej w Krakowie: Kraków, Poland, 2014; pp. 5–13, 48–51, 72–86. [Google Scholar]

- Dach, J.; Jędruś, A.; Kowalik, I. Biofermentator do badań procesów rozkładu płynnych odpadów organicznych. J. Res. Appl. Agric. Eng. 2004, 49, 10–13. [Google Scholar]

- Mursec, B.; Vindis, P.; Janzekovic, M.; Brus, M.; Cus, F. Analysis of different substrates for processing into biogas. J. Achiev. Mater. Manuf. Eng. 2009, 37, 652–659. [Google Scholar]

- Frankowski, J.; Zaborowicz, M.; Dach, J.; Czekała, W.; Przybył, J. Biological Waste Management in the Case of a Pandemic Emergency and Other Natural Disasters. Determination of Bioenergy Production from Floricultural Waste and Modeling of Methane Production Using Deep Neural Modeling Methods. Energies 2020, 30, 3014. [Google Scholar] [CrossRef]

- Łochyńska, M.; Frankowski, J. The biogas production potential from silkworm waste. Waste Manag. 2018, 79, 564–570. [Google Scholar] [CrossRef] [PubMed]

- Ingrao, C.; Matarazzo, A.; Gorjian, S.; Adamczyk, J.; Failla, S.; Primerano, P.; Huisingh, D. Wheat-straw derived bioethanol production: A review of Life Cycle Assessments. Sci. Total Environ. 2021, 781, 146751. [Google Scholar] [CrossRef]

- Norouzi, O.; Hesami, M.; Pepe, M.; Dutta, A.; Jones, A.M.P. In vitro plant tissue culture as the fifth generation of bioenergy. Sci. Rep. 2022, 12, 5038. [Google Scholar] [CrossRef]

- Spychalski, G. Wybrane aspekty uprawy roślin włóknistych i zielarskich w wielkopolskim rolnictwie. Rocz. Nauk. Stowarzyszenia Ekon. Rol. I Agrobiznesu 2014, 16, 189–194. [Google Scholar]

- Józwiak, W.; Juźwiak, J. Rolnictwo wielostronne czy wyspecjalizowane? Wieś I Rol. 2007, 4, 9–20. [Google Scholar]

- Polityka Insight. Available online: www.politykainsight.pl/_resource/multimedium/20198941 (accessed on 7 December 2022).

- Pari, L.; Baraniecki, P.; Kaniewski, R.; Scarfone, A. Harvesting strategies of bast fiber crops in Europe and in China. Ind. Crops Prod. 2014, 68, 90–96. [Google Scholar] [CrossRef]

- Assirelli, A.; Dal Re, L.; Esposito, S.; Cocchi, A.; Santangelo, E. The Mechanical Harvesting of Hemp Using In-Field Stand-Retting: A Simpler Approach Converted to the Production of Fibers for Industrial Use. Sustainability 2020, 12, 8795. [Google Scholar] [CrossRef]

- Frankowski, J.; Zaborowicz, M.; Sieracka, D.; Łochyńska, M.; Czeszak, W. Prediction of the Hemp Yield Using Artificial Intelligence Methods. J. Nat. Fibers 2022, 19, 13725–13735. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sieracka, D.; Frankowski, J.; Wacławek, S.; Czekała, W. Hemp Biomass as a Raw Material for Sustainable Development. Appl. Sci. 2023, 13, 9733. https://doi.org/10.3390/app13179733

Sieracka D, Frankowski J, Wacławek S, Czekała W. Hemp Biomass as a Raw Material for Sustainable Development. Applied Sciences. 2023; 13(17):9733. https://doi.org/10.3390/app13179733

Chicago/Turabian StyleSieracka, Dominika, Jakub Frankowski, Stanisław Wacławek, and Wojciech Czekała. 2023. "Hemp Biomass as a Raw Material for Sustainable Development" Applied Sciences 13, no. 17: 9733. https://doi.org/10.3390/app13179733

APA StyleSieracka, D., Frankowski, J., Wacławek, S., & Czekała, W. (2023). Hemp Biomass as a Raw Material for Sustainable Development. Applied Sciences, 13(17), 9733. https://doi.org/10.3390/app13179733