Construction Quality of Prefabricated Buildings Using Structural Equation Modeling

Abstract

1. Introduction

2. Overview of the Quality of Fabricated Buildings

2.1. Construction Technology and Materials of Fabricated Buildings

2.2. Advanced Technical Means to Improve the Quality of Fabricated Buildings

2.3. Factors Influencing the Quality of Fabricated Buildings

3. Materials and Methods

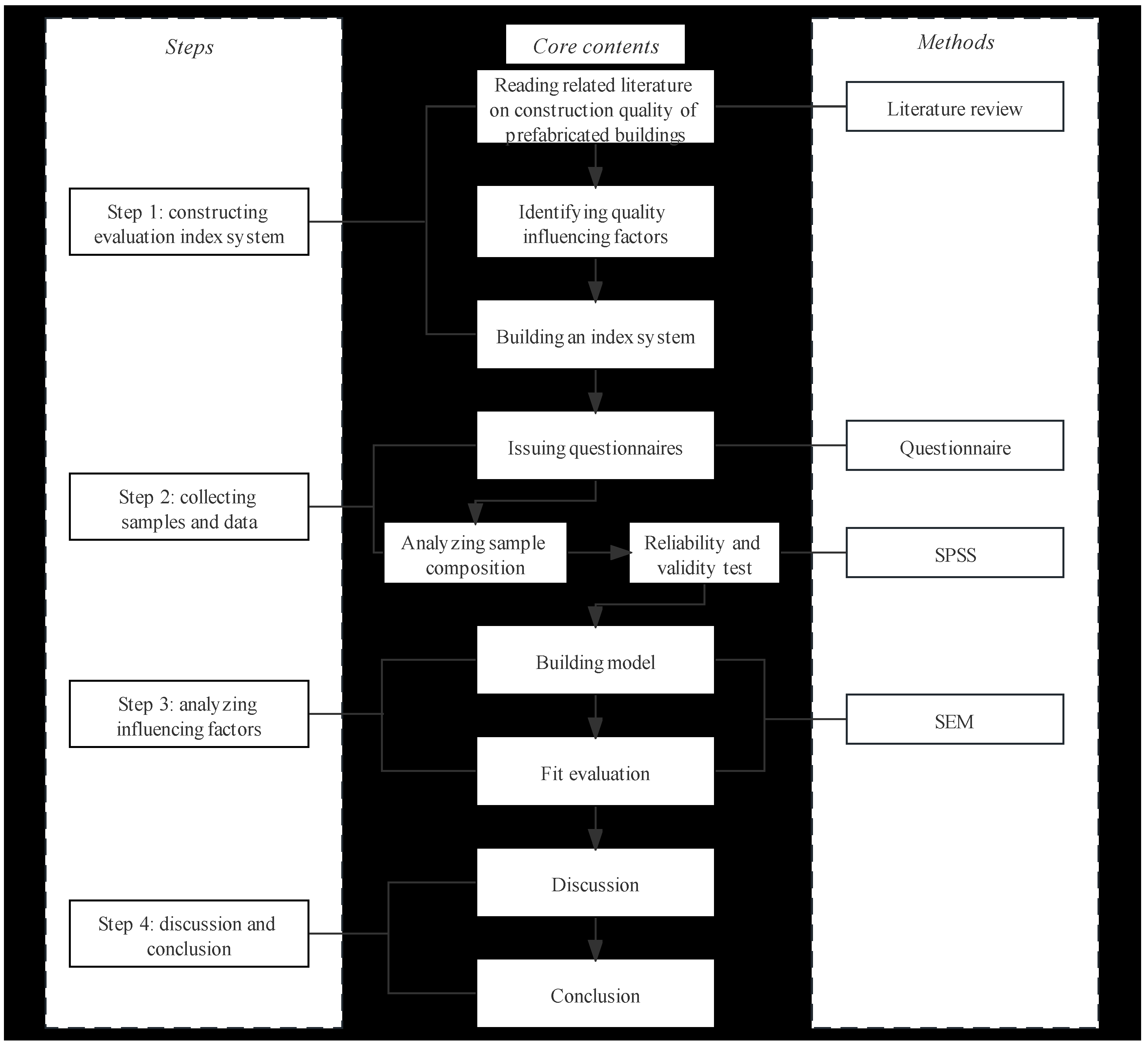

3.1. Study Process

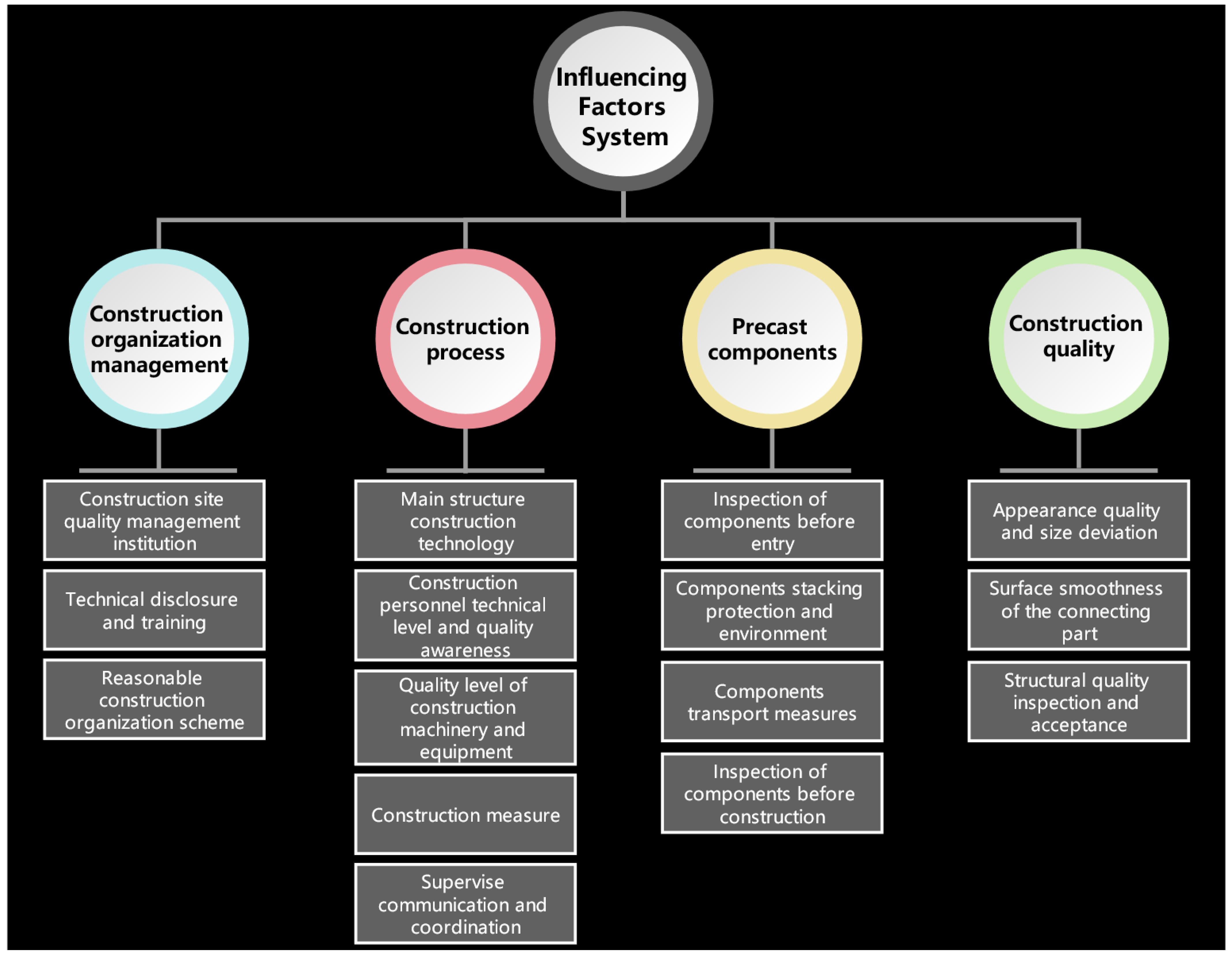

3.2. Introduction to the List of Influencing Factors

3.2.1. Principles of Constructing a List of Influencing Factors

3.2.2. Steps in Constructing a List of Influencing Factors

3.3. Samples and Data Collection

3.4. Introduction of the Reliability and Validity Tests

3.5. Introduction of SEM

4. Result

4.1. Reliability and Validity Tests

4.2. Model Building and Identification

4.2.1. Model Correction

4.2.2. Confirmatory Factor Analysis (CFA)

5. Discussion

6. Conclusions

6.1. Measures

- Deploying relevant standards and norms is essential to establishing an effective quality management system and ensuring adequate attention to structural quality by site managers and construction personnel.

- Instituting an inspection and acceptance system, particularly for contractors, is vital. This involves establishing a quality acceptance system upon prefabricated components’ arrival at the construction site, followed by process and physical quality acceptance systems.

- Introducing pre-job technical training and delivery systems is crucial.

- Executing effective technical control encompasses appropriate lifting timing, machinery, equipment, and precise installation.

- Optimizing digital construction capabilities involves using BIM technology for assembly building models, enabling visualization and realistic quality simulation through modeling to identify latent quality issues on-site.

- Instituting an information collection system and deploying automated testing tools for construction site data collection, encompassing encountered quality issues, material dimensions, component quality, connections, etc. These data are integrated into a management platform to facilitate systematic analysis by technical personnel based on uploaded data and issues.

6.2. Further Action

- Explore the intrinsic connections among quality factors, refining the theoretical model.

- Develop a comprehensive strategy framework for enhancing quality in prefab construction.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Factors Influencing the Quality of Fabricated Buildings | |

|---|---|

| The lack of advanced tooling | Technology in the production phase |

| Insufficient involvement of all parts | Failure to use advanced mechanical equipment |

| Absence of effective communication channels | Immature quality management system |

| Lack of technical personnel | Inadequate quality inspection mechanism |

| The need for improvements in the industry environment | Inadequate pre-feasibility study and planning |

| Imperfect supply chain | Personnel training |

| Project participation by all parties | BIM technology |

| The supply capability of the component plant | Type of structure, contractor’s capability |

| Transportation of parts | Project quality planning |

| Project quality supervision | The absence of measures for transporting components |

| Project quality control | The substandard production quality inspection |

| The high rate of component rework | Drawing review |

| The absence of measures for stacking | The substandard skills of personnel |

| the lack of a clear basis for design | The lack of standardization in the production of components |

References

- Li, Z.D.; Zhen, Y.; Li, S.; Wu, H.; Zhao, Y.; Sun, L. Quality risk analysis and management of assembly building construction based on FAHP. J. Eng. Manag. 2022, 36, 113–118. [Google Scholar]

- Li, C.; Yao, H.; Jin, P. Identification and control of influencing factors of assembly building construction quality. Urban Build. Space 2022, 29, 356–357. [Google Scholar]

- Liu, X. Research on Evaluation and Application of Quality Influencing Factors in Assembly Building Construction Process. Master’s Thesis, Xihua University, Chengdu, China, 2020. [Google Scholar]

- Huang, W. Research on Assembly Building Construction Technology and Quality Control Methods. Master’s Thesis, Jiangsu University, Zhenjiang, China, 2022. [Google Scholar]

- Chang, C.G.; Wang, J.Y.; Li, H.X. Identification and control of quality factors in assembly building construction. J. Shenyang Univ. Archit. Soc. Sci. Ed. 2016, 18, 58–63. [Google Scholar]

- Kobayakawa, T.; Mihara, A.; Komatsu, Y. Construction Record on an office building with a composite Structure Composed of Precast Columns and Steel Beams. Concr. J. 1992, 30, 37–47. [Google Scholar] [CrossRef] [PubMed]

- Jian, B.L.; Qiao, Q.F.; Zheng, L.; Yan, W. Experimental study on seismic performance of T-shaped partly precast reinforced concrete shear wall with grouting sleeves. Struct. Des. Tall Spec. Build. 2019, 28, e1632. [Google Scholar]

- Shamim, A.S.; Jaffry, S.A.; Cui, C.Y. Investigation of glass-fibre-reinforced-polymer shells as formwork and reinforcement for concrete columns. Can. J. Civ. Eng. 2007, 34, 389–402. [Google Scholar]

- Manychova, M.; Fuciman, O.; Pazdera, L. An Initial Investigation on the Potential Applicability of Non-Destructive Methods to Assessing Joint Condition in Prefabricated Structures. Solid State Phenom. 2016, 258, 489–492. [Google Scholar]

- Michael, J.L. Prefabricated brick wall panels: Economy or nightmare? Archit. Res. Q. 1999, 3, 351–360. [Google Scholar]

- Xin, Q.W.; Jian, F.L.; Zhou, P.K.; Yun, L.C.; Shimin, Z. Research on the Key Technique for the Integral Moulding of the Formwork for Plate or Box Beam Steel Cage. In Proceedings of the PEEE 2016: 2nd Annual International Conference on Power Engineering and Energy, Environment (PEEE 2016), Singapore, 18–19 January 2016. [Google Scholar]

- Xu, Z.L.; Yang, Z.; Xu, Y.S.; Fang, Z.Z.; Stilla, U. Geometric Modeling and Surface-Quality Inspection of Prefabricated Concrete Components Using Sliced Point Clouds. J. Constr. Eng. Manag. 2022, 148, 04022087. [Google Scholar] [CrossRef]

- Norman, M.; Terrence, F.; Ghassan, A. A Virtual Environment for the Design and Simulated Construction of Prefabricated Buildings. Virtual Real. 2003, 6, 244–256. [Google Scholar]

- Heryl, S.; Alan, R.; Ngoc, T. Linear Scheduling and 4D Visualization. J. Comput. Civ. Eng. 2008, 22, 192–205. [Google Scholar]

- Ali, A. RFID-Assisted Lifeeyele Managment of Building Componentsusing BIM Data. In Proceedings of the 26th International Symposium on Automation and Robotics in Construction (Isarc 2009), Austin, TX, USA, 24–27 June 2009; pp. 109–116. [Google Scholar]

- Opitz, F.; Windisch, R.; Scherer, R.J. Integration of document-and model-based building information project management support. Procedia Eng. 2014, 85, 403–411. [Google Scholar] [CrossRef]

- Cai, Z.L.; Zhang, J.C.; Chen, Z.R. Exploration on the Integration of Integrated Design and Construction of Prefabricated Assembly from the Perspective of EPC Management. Sci. Discov. 2022, 10, 4. [Google Scholar]

- Mahdi, S.; Arash, S.; Mohammad, N.; Carl, S.; Hamid, N. Automating measurement process to improve quality management for piping fabrication. Structures 2015, 3, 71–80. [Google Scholar]

- Heng, L.; Guo, H.L.; Martin, S.; Huang, T.; Chan, K.Y.N.; Greg, C. Rethinking prefabricated construction management using the VP-based IKEA model in Hong Kong. Constr. Manag. Econ. 2011, 29, 233–245. [Google Scholar]

- Alistair, G.F. Management of Prefabrication for Complex Cladding: Case Study. J. Archit. Eng. 1997, 3, 60–69. [Google Scholar]

- Faridah, I.; Norazian, M.Y.; Har, E.A.B. Management Factors for Successful IBS Projects Implementstion. Procedia-Soc. Behav. Sci. 2012, 68, 99–107. [Google Scholar]

- Izatul, l.J.; Faridah, I.; Arniatul, A.M. Issues in Managing Construction Phase of IBS Projects. Procedia-Soc. Behav. Sci. 2013, 101, 81–89. [Google Scholar]

- Mohammad, F.M. Construction Environment: Adopting IBS Construction Approach Towards Achieving Sustainable Development. Procedia-Soc. Behav. Sci. 2013, 85, 8–15. [Google Scholar] [CrossRef][Green Version]

- Zhang, X.L.; Martin, S.; Peng, Y. Exploring the chsllenges to industrialized residential building in China. Habitat Int. 2014, 41, 176–184. [Google Scholar] [CrossRef]

- Kraus, M. Hygrothermal Analysis of Indoor Environment of Residential Prefabricated Building. IOP Conf. Ser. Mater. Sci. Eng. 2017, 245, 042071. [Google Scholar] [CrossRef]

- Hwang, B.G.; Shan, M.; Looi, K.Y. Key constraints and mitigation strategies for prefabricated prefinished volumetric construction. J. Clean. Prod. 2018, 183, 183–193. [Google Scholar] [CrossRef]

- Li, D.Z.; Li, X.; Feng, H.B. ISM-based relationship among critical factors that affect the choice of prefabricated concrete buildings in China. Int. J. Constr. Manag. 2019, 22, 977–992. [Google Scholar] [CrossRef]

- Chang, Y.F.; Hiroaki, I. Fuzzy Multiple Criteria Decision Making Approach to Assess the Project Quality Management in Project. Procedia Comput. Sci. 2013, 22, 928–936. [Google Scholar] [CrossRef]

- Bai, S.; Zhang, Y.K.; Han, F.; Kou, Q.X.; Yang, X.T. Research on structural analysis and countermeasures of assembly building quality factors based on ISM analysis. Liaoning Econ. 2016, 8, 32–35. [Google Scholar]

- Gong, Y.C. Analysis of factors affecting the quality of assembly building construction and control measures. Doors Windows 2017, 155+157. [Google Scholar]

- Kang, B.F. Research on the analysis of factors affecting the quality of assembly building construction and optimization of control measures. Residence 2018, 3. [Google Scholar]

- Hua, G.H. Factors affecting the quality of assembly building construction and response measures. Urban Constr. Theory Res. Electron. Ed. 2019, 106. [Google Scholar]

- Wei, Q. Factors affecting the quality of assembly building construction and control measures. Green Build. Mater. 2020, 208–209. [Google Scholar]

- LI, X.J.; Zhang, Z.; Xie, W.J.; Liu, Y.S. Research on factors affecting construction quality control of assembled building projects. J. Eng. Manag. 2021, 35, 119–124. [Google Scholar]

- Chen, R.F.; Jiang, A.; Dong, Y.C.; Xiong, Q.W.; Lu, Y.R. Research on the construction and application of quality risk assessment model for assembly building construction. J. Railw. Sci. Eng. 2021, 18, 2788–2796. [Google Scholar]

- Shi, L.K.; Shang, Y.L. Research on construction quality risk analysis and management of precast assembled concrete residential projects. Concrete 2021, 101–104. [Google Scholar]

- Wang, Q.K.; Zhu, K.; Guo, P.W.; Guo, Z.; Zhang, B. Safety risk assessment of assembly building construction based on interaction matrix-fuzzy cognitive map. J. Saf. Environ. 2021, 1–11. [Google Scholar]

- Qi, B.K.; Li, C.F. Research on the establishment of assembly building construction quality assessment index system and assessment method. Constr. Technol. 2014, 43, 20–24. [Google Scholar]

- Liu, G.C.; Wen, Z.D.; Shen, J.; An, L.; Liang, Y. Research on the influence factors of assembly concrete building quality based on factor analysis. Constr. Econ. 2019, 40, 97–101. [Google Scholar]

- Faridah, I.; Har, E.A.B.; Mohd, A.M. Factors towards site management improvement for IBS construction. Procedia-Soc. Behav. Sci. 2013, 85, 43–50. [Google Scholar]

- Liang, X.C. Quality management system and strategy of assembly building project under EPC style. Constr. Econ. 2020, 41, 73–78. [Google Scholar]

- Wang, J.W.; Pan, Z.Y.; Wan, J.; Tian, M.Y.; Liu, S. Safety risk analysis of assembly building lifting construction based on STPA and fuzzy BN. China Saf. Prod. Sci. Technol. 2022, 18, 12–19. [Google Scholar]

- Zhang, K.; Cai, J.S.; Huang, Q.Y. Research on the interrelationship of factors influencing the quality of assembled buildings. Constr. Econ. 2021, 42, 95–98. [Google Scholar]

- Li, Y.; Li, F.; Zou, Y.; Ma, X.Y.; Lv, Z.Y. Safety and quality assessment of precast assembled concrete building construction. Constr. Technol. 2016, 47, 305–309. [Google Scholar]

- Sun, Y.F.; Wu, X.; He, M.L.; Cong, X.H. Research on the whole process quality management of assembly building based on BIM+IoT technology. Constr. Econ. 2021, 42, 58–61. [Google Scholar]

- Li, T.Z.H.; You, S.Y. Analysis of quality influencing factors of assembled buildings based on Apriori. J. Tongji Univ. Nat. Sci. Ed. 2022, 50, 147–152. [Google Scholar]

- Wu, S.; Berjian, W. Quality evaluation of structural component construction of assembled buildings. Build. Constr. 2013, 35, 116–117+123. [Google Scholar]

- Qi, B.K.; Wang, D.; Bai, S.; Jin, l.C. Prefabricated assembly building construction common quality problems and preventive measures. Constr. Econ. 2016, 37, 28–30. [Google Scholar]

- Liu, D. Safety construction management of assembled concrete building. Build. Constr. 2016, 38, 991–992. [Google Scholar]

- Yuan, L. Analysis of factors influencing the quality of assembly building construction and control measures. Sci. Technol. Econ. Guide 2017, 218–219. [Google Scholar]

- Chen, W.; Fu, J.; Xiong, F.G.; Yang, J. Gray clustering measurement model for construction safety of assembly building project. China J. Saf. Sci. 2016, 26, 70–75. [Google Scholar]

- Li, Q.N.; Chen, W.Q. Safety evaluation of assembly building construction based on entropy modified BWM. J. Saf. Environ. 2020, 1–11. [Google Scholar]

- Gala, K.; Peng, Y.F.; Guo, B.R. Quality traceability and monitoring of assembly building components based on Bayesian network. J. Shenyang Univ. Archit. Soc. Sci. Ed. 2019, 21, 257–263. [Google Scholar]

- Yu, Y.Q.; Xiao, M.; Wang, Z. Technical standards for assembled concrete buildings. Constr. Sci. Technol. 2022, 448, 48–51. [Google Scholar]

- Li, X.J.; Wang, C.; Kassem, M.A.; Zhang, Z. Safety Risk Assessment in Urban Public Space Using Structural Equation Modelling. Appl. Sci. 2022, 12, 12318. [Google Scholar] [CrossRef]

- Wu, M. Structural Equation Modeling: Operation and Application of AMOS; Chongqing University Press: Chongqing, China, 2010. [Google Scholar]

- Guo, E.J. A Study on Factors Affecting the Construction Quality of Prefabricated Buildings and Quality Improvement Strategies. Master’s Thesis, Tianjin University, Tianjin, China, 2019. [Google Scholar]

| Principles | Contents |

|---|---|

| Systematic | The construction materials of fabricated buildings are prefabricated and transported to the site for lifting and connection. The factors that influence the quality of later construction must be systematically considered for the links before lifting the components. |

| Objective | The purpose of identifying quality impact factors for fabricated building construction is to allow contractors to quickly screen for matching quality impact factors while being objective. |

| Independence | The identified impact factor indicators should be independent of each other as far as possible to avoid similarity, overlap, and crossover in their meaning. |

| Targeted | This study focused on the quality of the construction of fabricated buildings. Hence, this study differs from the main structural implementation phase of traditional building construction and must have some relevance. |

| Qualitative quantitative combination | Some quality aspects can be measured using specific quality acceptance values, while others must be judged in the context of actual conditions and the practical experience of fabrication engineering professionals. Hence, a combination of qualitative and quantitative analysis is required. |

| Influencing Factors of the Construction Quality | References |

|---|---|

| Q1 Construction site quality management institution | [5,23,35,36,37,38,39,40] |

| Q2 Technical delivery and training | [29,35,38,41,42,43,44] |

| Q3 Reasonable construction organization scheme | [24,35,45,46,47,48,49,50] |

| Q4 Main structure construction technology | [36,37,39,41,42,44,50,51] |

| Q5 Construction personnel’s technical level of quality awareness | [22,29,36,40,42,43,47,49,52] |

| Q6 Construction machinery and equipment quality level | [5,22,44,45,46,49,52] |

| Q7 Construction measure | [5,35,36,37,40,47,51] |

| Q8 Supervise communication and coordination | [22,29,38,42,43,44,46,50] |

| Q9 Component incoming acceptance | [5,24,35,46,47,49,51] |

| Q10 Component stacking protection and environment | [36,39,44,45,46,48,51] |

| Q11 Component transportation measures | [24,29,37,39,43,44,50,52] |

| Q12 Pre-construction inspection of the components | [5,29,36,37,41,49,52] |

| Q13 Appearance quality and dimensional deviation | [23,35,42,47,50,52,53] |

| Q14 Surface flatness of connection parts | [24,29,43,44,45,47,51,52,53] |

| Q15 Structural quality acceptance | [5,23,39,41,42,46,48,51] |

| Basic Information | Type | Quantity | Proportion |

|---|---|---|---|

| Work unit type | Government-related units | 15 | 2.83% |

| Colleges and universities | 49 | 9.24% | |

| Real estate development enterprises | 103 | 19.43% | |

| Component supplier enterprises | 24 | 4.52% | |

| Building construction enterprises | 196 | 37% | |

| Supervisory units | 132 | 24.90% | |

| Other (graduate students) | 11 | 2.08% | |

| Years of work/research in a prefabricated building | Less than 1 | 96 | 18.11% |

| 1–3 | 297 | 56.04% | |

| 4–5 | 128 | 24.15% | |

| Over 5 | 9 | 1.70% | |

| Degree of understanding the construction quality of a prefabricated building | Very well known | 102 | 19.25% |

| Fairly well known | 135 | 25.47% | |

| Generally know | 164 | 30.94% | |

| Very little | 73 | 13.77% | |

| Do not know | 56 | 10.57% |

| Fit Index | Standard | |||

|---|---|---|---|---|

| Relative-fit index | Root mean square error of approximation | RMSEA | <0.0.8 | Qualified |

| Goodness of fit | GFI | >0.9 | Qualified | |

| Absolute-fit index | Chi-square degree of freedom ratio | Χ2/df | ≤3.00 | Qualified |

| Comparative fit index | CFI | >0.9 | Qualified | |

| Normed fit index | NFI | >0.9 | Qualified | |

| Incremental fit index | IFI | >0.9 | Qualified | |

| Tucker–Lewis index | TLI | >0.9 | Qualified | |

| Adjusted goodness of fit index | AGFI | >0.9 | Qualified |

| Latent Variable | Index | CITC | Cronbach’s α Coefficient | |

|---|---|---|---|---|

| F1: Construction organization management | Q1 | 0.818 | 0.957 | 0.882 |

| Q2 | 0.806 | 0.957 | ||

| Q3 | 0.629 | 0.961 | ||

| F2: Construction process | Q4 | 0.82 | 0.957 | 0.962 |

| Q5 | 0.835 | 0.957 | ||

| Q6 | 0.824 | 0.957 | ||

| Q7 | 0.831 | 0.957 | ||

| Q8 | 0.787 | 0.958 | ||

| F3: Precast component | Q9 | 0.769 | 0.958 | 0.878 |

| Q10 | 0.638 | 0.96 | ||

| Q11 | 0.681 | 0.96 | ||

| Q12 | 0.587 | 0.961 | ||

| F4: Construction quality inspection | Q13 | 0.89 | 0.956 | 0.947 |

| Q14 | 0.87 | 0.956 | ||

| Q15 | 0.828 | 0.957 | ||

| Total | 0.961 |

| Kaiser–Meyer–Olkin value | 0.95 | |

| Bartlett sphere test | Approximate chi-square | 6598.803 |

| df | 105 | |

| p value (Sig.) | 0 | |

| Fit Index | Pre-Correction | Pre-Result | After-Correction | After-Result |

|---|---|---|---|---|

| RMSEA | 0.075 | Match | 0.064 | Match |

| GFI | 0.913 | Match | 0.931 | Match |

| Χ2/df | 3.238 | Mismatch | 2.662 | Match |

| CFI | 0.971 | Match | 0.979 | Match |

| NFI | 0.959 | Match | 0.967 | Match |

| IFI | 0.972 | Match | 0.979 | Match |

| TLI | 0.964 | Match | 0.974 | Match |

| AGFI | 0.876 | Mismatch | 0.91 | Match |

| Variable | Variable | Unstandardized Path Coefficient | Standard Error | CR Value | p Value | Standardized Path Coefficient | |

|---|---|---|---|---|---|---|---|

| Factor 2 | ← | Factor 1 | 0.936 | 0.056 | 16.754 | *** | 0.738 |

| Factor 3 | ← | Factor 1 | 0.718 | 0.063 | 11.337 | *** | 0.686 |

| Factor 3 | ← | Factor 2 | 0.122 | 0.047 | 2.577 | 0.01 | 0.148 |

| Factor 4 | ← | Factor 3 | 0.217 | 0.045 | 4.824 | *** | 0.217 |

| Factor 4 | ← | Factor 1 | 0.54 | 0.055 | 9.825 | *** | 0.517 |

| Factor 4 | ← | Factor 2 | 0.24 | 0.031 | 7.746 | *** | 0.291 |

| Q1 | ← | Factor 1 | 1 | 0.928 | |||

| Q2 | ← | Factor 1 | 1.064 | 0.034 | 31.592 | *** | 0.924 |

| Q3 | ← | Factor 1 | 0.822 | 0.047 | 17.537 | *** | 0.7 |

| Q9 | ← | Factor 3 | 1 | 0.92 | |||

| Q10 | ← | Factor 3 | 0.829 | 0.042 | 19.612 | *** | 0.768 |

| Q11 | ← | Factor 3 | 0.908 | 0.045 | 20.363 | *** | 0.784 |

| Q12 | ← | Factor 3 | 0.801 | 0.045 | 17.81 | *** | 0.725 |

| Q8 | ← | Factor 2 | 1 | 0.888 | |||

| Q7 | ← | Factor 2 | 1.06 | 0.027 | 39.007 | *** | 0.929 |

| Q6 | ← | Factor 2 | 1.042 | 0.035 | 29.737 | *** | 0.931 |

| Q5 | ← | Factor 2 | 1.087 | 0.036 | 30.477 | *** | 0.94 |

| Q4 | ← | Factor 2 | 0.865 | 0.035 | 24.906 | *** | 0.864 |

| Q13 | ← | Factor 4 | 1 | 0.887 | |||

| Q14 | ← | Factor 4 | 1.037 | 0.034 | 30.409 | *** | 0.938 |

| Q15 | ← | Factor 4 | 1.009 | 0.032 | 31.504 | *** | 0.951 |

| Latent Variable | AVE Value of the Mean Variance Extraction | CR Value of the Combined Reliability |

|---|---|---|

| Factor 1 | 0.735 | 0.891 |

| Factor 2 | 0.830 | 0.961 |

| Factor 3 | 0.644 | 0.878 |

| Factor 4 | 0.857 | 0.947 |

| Latent Variable | Latent Variable | Standardized Direct Effects | Standardized Indirect Effects | Standardized Total Effects | |

|---|---|---|---|---|---|

| Factor 2 | ← | Factor 1 | 0.738 | 0.738 | |

| Factor 3 | ← | Factor 1 | 0.686 | 0.109 | 0.795 |

| Factor 4 | ← | Factor 1 | 0.517 | 0.387 | 0.904 |

| Factor 3 | ← | Factor 2 | 0.148 | 0.148 | |

| Factor 4 | ← | Factor 2 | 0.291 | 0.032 | 0.323 |

| Factor 4 | ← | Factor 3 | 0.217 | 0.217 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chai, Y.; Liang, X.; Liu, Y. Construction Quality of Prefabricated Buildings Using Structural Equation Modeling. Appl. Sci. 2023, 13, 9629. https://doi.org/10.3390/app13179629

Chai Y, Liang X, Liu Y. Construction Quality of Prefabricated Buildings Using Structural Equation Modeling. Applied Sciences. 2023; 13(17):9629. https://doi.org/10.3390/app13179629

Chicago/Turabian StyleChai, Ying, Xiufeng Liang, and Yi Liu. 2023. "Construction Quality of Prefabricated Buildings Using Structural Equation Modeling" Applied Sciences 13, no. 17: 9629. https://doi.org/10.3390/app13179629

APA StyleChai, Y., Liang, X., & Liu, Y. (2023). Construction Quality of Prefabricated Buildings Using Structural Equation Modeling. Applied Sciences, 13(17), 9629. https://doi.org/10.3390/app13179629