Abstract

This paper studies the problem of planning and scheduling in selective maintenance tasks of mission requirements and the health condition of the fleet. In order to deal with the problems of high maintenance cost and long time consumption in maintenance systems, a two-stage fleet maintenance optimization method is proposed. Firstly, a selective maintenance model of fleets based on age reduction is established to maximize the probability of completing the next mission and minimize the maintenance cost. Secondly, a multiobjective sparrow search algorithm is designed to solve the maintenance planning problem in the first stage, and a nondominated solution set of maintenance strategies satisfying the mission constraint is obtained. In the second stage, the simulated annealing algorithm is used to schedule the maintenance task and obtain the minimum maintenance hours required by the maintenance strategy. An example analysis of a vehicle fleet is launched to prove the effectiveness of this method. In a word, this method not only meets the mission requirements but also achieves the purpose of reducing maintenance cost and maintenance hours, which can provide reference for other types of equipment maintenance.

1. Introduction

Equipment maintenance is a key segment to ensure high-tech equipment exerts its ability. With the development of information technology and the increase in mission requirements, fleet operation mode has been regarded as an important development direction in the future of the fields of aerospace, transportation, military and so on. Equipment maintenance also presents new characteristics such as complexity, networking and flexibility. Therefore, the maintenance of equipment is very important in the operation stage [1]. Many studies have shown that maintenance planning is a key factor affecting maintenance efficiency in equipment maintenance support tasks [2].

In recent years, researchers have conducted studies on maintenance planning methods focusing on areas such as reliability modeling, mission profiling, and resource requirements. Claudio Alvarez et al. [3] presented a stochastic dynamic programming model for a condition-based maintenance application, which allows preventive maintenance measures to be taken by allowing nonperiodic inspections. Ming-Yi You [4] considered three types of product lifetime probabilistic models, proposing a generalized hybrid maintenance policy for maintenance scheduling with the help of both time-based maintenance and condition-based maintenance techniques. Tao Jiang et al. [5] developed a new selective maintenance model for systems that execute multiple consecutive missions. In each break, multiple optional maintenance actions, from perfect replacements down to imperfect and minimal repairs, can be chosen for each component. Peilong Yuan et al. [6] considered carrier aircraft support operations which should satisfy serial and parallel constraint relationships, presenting a periodic and event-driven rolling horizon scheduling strategy. This strategy adjusts the baseline scheduling in a reasonable computational time and avoids the unnecessary scheduling. Zhengang Guo et al. [7,8] managed to reduce the waiting time, makespan and electricity consumption in complex and customized manufacturing by proposing a self-adaptive collaboration control method.

By monitoring the health condition of each key component in complex equipment in real time, judging whether the system has a symptom of failure based on the understanding of failing mechanism and evaluating the approximate occurrence time of system failure, the maintenance team can make flexible maintenance arrangements according to the health status of the system and make adequate preparations before maintenance tasks. Scheduled maintenance and other maintenance strategies do not consider the dynamic change in equipment health condition, and some key components cannot be properly maintained, resulting in a waste of maintenance resources and mission risks. Therefore, the condition-based maintenance strategy based on real-time monitoring and evaluation of equipment health condition has been gradually focused on [9,10]. Marco Koopmans et al. [11] studied the condition-based maintenance strategy for industrial facilities consisting of multiple units working in parallel. Weikai Wang et al. [12] constructed a condition-based maintenance model based on piecewise deterministic Markov process and considered the imperfect maintenance of units with natural degradation.

According to the degree of repair, maintenance strategies can be divided into perfect maintenance, minimal maintenance, imperfect maintenance, etc. [13] Among them, the imperfect maintenance cannot make the system as good as a new one, but its health condition can be rendered better than before. Li Yang et al. [14] proposed a two-stage preventive maintenance policy that considered imperfect maintenance, and the defect will finally be removed by replacement in the second stage. Yuling Liu et al. [15] established a fleet-level selective imperfect maintenance model and proposed a maintenance strategy optimization method based on evolutionary copetition game theory. Wanqing Cheng et al. [16] simultaneously considered three maintenance behaviors: no maintenance, imperfect maintenance and replacement. They proposed an imperfect model by introducing the degradation ratio that follows the beta distribution and used the MDP method to solve the optimal maintenance problem.

In a group of vehicles with different models and different health conditions, there is a problem that the objective to minimize the maintenance resources, such as maintenance hours and spare components, conflicts with the objective to maximize the maintenance achievement. In this condition, selective maintenance planning (SMP) comes into being. SMP employs different maintenance strategies for different equipment in the fleet, enabling the fleet to meet the mission requirements while consuming as little maintenance resources as possible. In recent years, selective maintenance planning has attracted more and more attention in the field of equipment maintenance. Shahraki et al. [17] conducted a study on selective maintenance planning for multistate systems, considering random dependent components and imperfect maintenance, and proposed a multiobjective optimization model considering two objective functions, including the expected value and variance of the system reliability. Yu Liu et al. [18] proposed a sequential planning method for selective maintenance of multistate systems, considering the limited time available for maintenance task between continuous tasks, so as to maximize the probability of the system successfully completing the next mission. Wenbin Cao et al. [19] summarized a set of criteria considered in selective maintenance optimization into three categories: system characteristics, maintenance characteristics and mission profile characteristics. Based on these criteria, a comprehensive literature review of selective maintenance is made, and it is pointed out that selective maintenance modeling considering different task profiles is a kind of problem worth paying attention to.

For the selective maintenance decision problem of a complex equipment system, after the establishment of the mathematical model of the problem, it is necessary to select the appropriate algorithm to optimize the mathematical model, so as to optimize the decision objectives while satisfying the constraint, such as the minimum system failure and maintenance cost, the maximum system reliability or availability, etc. Heuristic algorithms are commonly used in maintenance modeling problems, including Tabu search algorithm [20], genetic algorithm [21], ant colony algorithm (ACO) [18], simulated annealing algorithm [22] (SA), etc. At present, most maintenance decision-solving methods of equipment systems take a single variable as the optimization objective, and after obtaining the maintenance strategy, other indicators are not considered to evaluate the strategy, so that the decision plan ignores some aspects of the requirements, resulting in the reduction in mission capability or the waste of maintenance resources. Therefore, considering multiple indexes in maintenance tasks to make decisions and taking a reasonable way to evaluate the decision scheme is the focus of the current research on maintenance decision-solving methods. Xu, E.B et al. [23] established a three-objective selective maintenance model for series–parallel systems and used an improved NSGA-III evolutionary algorithm to solve the problem. NSGA-III reserves some dominated points near reference points instead of only reserving nondominated points in NSGA-II, which contributes to keep the diversity of the population.

Therefore, aiming at the mission and reliability driven selective maintenance planning problem of a fleet, this paper establishes a phased solution framework to solve the problem. The main contributions of this paper are as follows: (1) A fleet-level selective maintenance decision model based on virtual age reduction theory is constructed. In the process of model establishment, the optimization objectives of cost and mission capability are both considered. (2) The two-stage problem-solving framework and the corresponding solution method are proposed. Considering the convergence speed of the algorithm and the process of the maintenance task, the problem is decomposed into two parts, including multiobjective optimization selective maintenance decision and maintenance scheduling based on maintenance hours. An MSSA heuristic algorithm and the SA algorithm are used to solve the problem.

The structure of this paper is as follows: In Section 2, a mathematical model for selective maintenance planning of a fleet is established. In Section 3, a framework for solving the model is proposed, and an MSSA algorithm and an SA algorithm are used to optimize the model. In Section 4, a case is selected to verify the above model and algorithm, and the results are analyzed. Finally, we summarize the content of this paper.

2. Equipment Group Maintenance Planning Model Based on Service Age Regression Model

2.1. Problem Description and Model Assumptions

Much research on maintenance planning often ignores the constraints of maintenance resources, such as maintenance time and maintenance team, and believes that multiple resources required by maintenance tasks are adequately available. However, maintenance tasks in the real world are often constrained by the limited resources [24]. Therefore, the problem of maintenance decision under limited maintenance resources has become the focus of research in the field of system support in recent years. Under the premise that various maintenance resources are subject to task constraints, this paper pays attention to the clustering characteristics of the fleet under maintenance, carries out research on the selective maintenance decision making of a fleet considering imperfect maintenance and provides an optimized maintenance strategy under the mission constraints.

In the equipment group maintenance planning model involved in this paper, it is considered that the equipment group and maintenance tasks meet the following assumptions:

Assumption 1.

The equipment cluster has several devices of the same model, all of which have the same system structure, are series–parallel systems and have the same number and type of components.

Assumption 2.

The maintenance cost of each component is related to the initial and postmaintenance state of the component, which can be measured by the component maintenance grade and replacement maintenance cost. The replacement maintenance cost of all components of the same model is the same.

Assumption 3.

The probability of the fleet to satisfy the requirement in the next mission given by the model is a value predicted according to the component state, without considering the influence of other environmental factors during the task.

Assumption 4.

Each process requires different maintenance team and equipment, and each group of maintenance team and equipment can only maintain one subsystem of the equipment at the same time.

2.2. Optimization Objective

2.2.1. The Probability of the Fleet to Satisfy the Requirement in the Next Mission

The mission satisfied capability of the fleet refers to the health condition that the fleet can keep during the mission. In the series–parallel system, as long as the failure probability of the equipment system during the mission is lower than the required level, the equipment system can be considered to have achieved the health condition required by the mission after maintenance. The performance of a component, subsystem or system can be described in a variety of ways. In the research aimed at maintenance planning, such performance can often be measured by a series of indicators, such as reliability, failure rate or mean time between failures. In this paper, it is assumed that the component lifetime model follows the two-parameter Weibull distribution in Equation (1):

where is the shape parameter and is the scale parameter.

Cassady et al. proposed the concept of conditional survival probability to describe the probability that a component does not fail in the duration of the mission [25]; that is, the probability that the components will still work normally when the task ends if the components work normally at the beginning of the task:

In this chapter, reliability is used to represent the probability that components work normally. When the task duration is , Equation (2) becomes

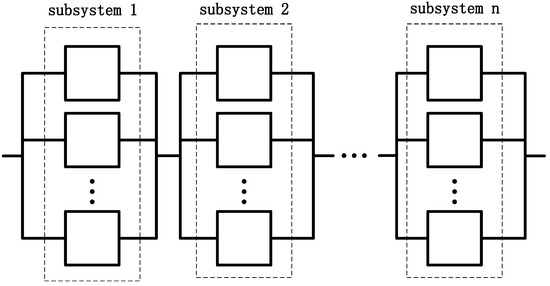

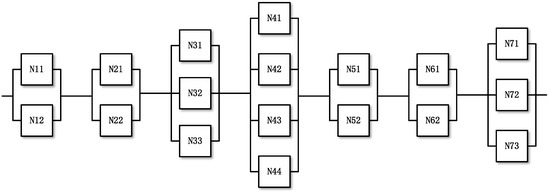

In the virtual service age model, the component failure rate is determined by the virtual service age rather than the actual working time. According to the system mission reliability model in Figure 1, the conditional survival probability of the fourth equipment in the equipment cluster can be expressed as

Figure 1.

Structure diagram of series–parallel system.

The mission satisfied capability of a single equipment system can be evaluated according to its reliability. However, the health condition of the fleet cannot be simply described by reliability, which can only be comprehensively evaluated according to the attributes of each equipment unit. In this section, a k-out-of-n system model is used to describe the mission satisfied capability of the fleet. It is believed that at any stage in the mission process, as long as the amount of failed equipment in the fleet remains below a certain level, the fleet can be regarded as able to successfully complete the mission objective. Therefore, the probability of the the amount of failed equipment kept at the required level can be regarded as the mission satisfied capability of the fleet. In this section, the k-out-of-n system model is combined with the survival probability of the equipment system mentioned above, and the relationship between the component health condition and the mission satisfied capability of the fleet is described by the method of universal generating function.

In the fleet described in this chapter, the state (failure or nonfailure) of component in the mission process is expressed by the binary variable . According to the survival probability defined in Equation (5), the mission performance of the fleet can be expressed by the following structure function:

Among them, the binary variable represents whether the health state of the equipment cluster meets the mission requirements. The structure function of the system indicates the relationship between the state of the system and the state of its components. For example, for the system formed by two components in series and parallel, their structural function can be expressed as

Assuming that the health states of all N components in the equipment cluster are independent of each other, the relationship between mission satisfied capability P of the fleet and health states of all components can be expressed in the form of universal generating function according to the structure functions:

Therefore, this section combines the method of universal generating function with the method of survival probability to describe the mission satisfied capability.

2.2.2. Maintenance Cost of Equipment Group

The use of money represents the consumption of maintenance resources in maintenance tasks, including maintenance spare components, maintenance manpower, etc. In this section, the Kijima II model [26] is used to describe the impact of maintenance tasks on the mission capability of the equipment system. Maintenance activities will repair all the accumulated damage of the system, and the virtual age of the system will be reduced to a certain proportion.

where represents the virtual age of the system before the k-th maintenance task, and represents the virtual age of the system after the k-th maintenance task.

The maintenance work is divided into several levels, and then the maintenance cost required by the maintenance task of the equipment system at different levels is determined. In the series–parallel equipment system, the equipment is composed of several subsystems, and each subsystem is composed of several parallel components; then, the maintenance cost c associated with the maintenance of the level is

2.2.3. Constraints in the Maintenance Task

Similar to the maintenance cost, the maintenance hours of equipment are also related to the maintenance level of equipment. The calculation process of maintenance hours is as follows:

Maintenance time t associated with maintenance level is

The maintenance time of subsystem i in the equipment system is

The virtual age rollback factor is determined by the ratio of the invested maintenance cost to the replacement maintenance cost. Given the component maintenance grade f, the virtual age rollback factor can be expressed as

where is the virtual age improvement coefficient, which is determined according to the method based on the virtual age and remaining life of the system. The remaining life of components can be expressed as

Then, the virtual age improvement coefficient of components can be expressed as

In summary, the constraints considered in this paper include maintenance level, maximum maintenance time and minimum mission satisfied capability.

2.2.4. Optimization Model

Given the health condition of the fleet before the maintenance work and the mission requirements, the selective maintenance decision problem in this chapter can be described as follows: under the constraints of the next mission maintenance time and mission satisfied capability, the appropriate maintenance level is selected for each component in the system so as to maximize the task capability of the equipment system and minimize the maintenance cost. On this basis, a multiobjective dynamic programming model for the selective maintenance problem of equipment cluster is established, which can be expressed as

subject to

Among them, Equations (16) and (17), respectively, give the optimization objectives of maintenance cost and mission satisfied capability, and Equation (18) limits the selection range of the maintenance level. Equations (19) and (20) give the constraints of maintenance hours and mission satisfied capability.

3. Mission and Reliability Driven Fleet Selective Maintenance Planning Two-Stage Method

3.1. A Two-Stage Method Considering Multiple Optimization Objectives and Maintenance Time Constraints

The selective maintenance planning problem of fleet mentioned in this paper has the following characteristics: First, the available maintenance resources in the maintenance task are limited. Second, the repaired equipment should be able to meet the reliability requirements during the next mission. Due to the complexity of the equipment operating conditions, the initial health condition of the fleet is complex and changeable. Previously used time-based maintenance strategies did not take the dynamic perception of equipment conditions into account, so some inefficient support operations could be taken, while some key components could not properly be maintained, resulting in a waste of potential remaining useful life [27].

In this context, the main purpose of the fleet maintenance planning is to make a maintenance strategy which systematically considers the mission requirements and the limited maintenance resources within the required time and reduces the time and cost as much as possible. In addition, maintenance planning should be based on the health conditions of the fleet and the key components of each equipment, as well as the allocation of maintenance resources, such as tools and spare parts, to select the appropriate maintenance objects, maintenance methods and maintenance order.

The maintenance planning problem is a multiobjective optimization problem, and there are two optimization objectives: maintenance cost and mission satisfied capability. There are two methods to solve this kind of problem: One is to convert the multiobjective problem into a single-objective problem by weighting the optimization objective, but this method misses some important search regions in the solution space. The second is to find the nondominant solution set on the Pareto frontier of the problem and select the strategy according to the given rules. Due to the complexity of the application environment, it is unacceptable to simply transform the optimization objectives into a single-optimization objective, resulting in possible omissions. At the same time, in order to enhance the rate of convergence, we can reduce the complexity of the problem by dividing the solving process into two stages.

Therefore, a nondominated maintenance strategy solution set can be obtained by using a heuristic algorithm and Pareto nondominated sorting method to optimize two optimization objectives in the problem. Then, considering the different requirements on the minimum mission satisfied capability, the obtained nondominated solution set is divided into different intervals according to the task success rate, and several solutions with the highest fitness are selected as alternatives in each interval. According to the assumption, one group of maintenance equipment can only serve one equipment at the same time. Therefore, after the maintenance strategy of the fleet is determined, the planning of maintenance scheduling can be regarded as a flow shop scheduling problem with the goal of minimizing maintenance time.

According to the above analysis of the problem, the problem can be divided into two stages to solve in turn, and a series of solution sets can be obtained to strike a balance between the two optimization objectives of cost and equipment group task capability, with the corresponding minimized maintenance hours and the optimal maintenance schedule. The problem can be solved as follows:

The first stage of the problem aims to maximize the mission satisfied capability and minimize the maintenance cost, takes the total maintenance cost and the task success rate as constraints, completes the multiobjective selective maintenance decision, sorts and filters the resulting solution set and inputs the second stage of the problem.

The second stage of the problem can be classified as a job-shop scheduling problem. The N subsystems of each equipment in the fleet need to complete maintenance operations, that is, each equipment needs to go through N maintenance processes in turn.

The above two parts of the problem can be solved by heuristic algorithm, respectively, and a nondominated solution set aiming at maximizing mission satisfied capability and minimizing maintenance cost is obtained. The solution set is further evaluated by maintenance hours to obtain the best alternative maintenance strategy and the corresponding optimal maintenance schedule. Combined with other known information, maintenance support elements such as maintenance resources can also be given.

3.2. Algorithm Design

3.2.1. An Improved Sparrow Search Algorithm Used for Solving Selective Maintenance Planning

The sparrow search algorithm (SSA) is a swarm intelligent algorithm developed based on sparrows’ foraging and antipredation mechanism, proposed by Xue et al. [28], and it has attracted wide attention since it was proposed [29,30]. Li et al. compared the performance of this algorithm with some other typical swarm algorithms in recent years through a series of test functions and believed that this algorithm has great research and application potential [31].

In this section, a multiobjective sparrow search algorithm (MSSA) is proposed to solve the multiobjective selective maintenance model. The original sparrow search algorithm is mainly aimed at a single-objective optimization problem. In the process of swarm position update, some solutions with poor fitness will jump directly near the optimal position, which will accelerate the convergence rate of the algorithm but also affect the global search ability of the algorithm, easily resulting in local optimal. In order to improve the algorithm and make it more suitable for the multiobjective selective maintenance model designed in this paper, this section improves the position update rules of the sparrow search algorithm, introducing the NSGA-II nondominated sorting method [32]. The improved algorithm is introduced as follows:

- (1)

- Coding method

A reasonable coding method is very important for the process of optimizing the algorithm to solve the problem. In this paper, component-based coding is adopted, and each component’s maintenance level in the maintenance strategy corresponds to a code. The dimension of the population is equal to the total number of components in the system, and the position information of each dimension is equal to the maintenance-level code of the components. In this coding way, the solution space of the maintenance planning problem can correspond to the search space of the sparrow search algorithm, and then the search is carried out through the location update process.

- (2)

- Nondominant sorting method

In the process of location updating, the sparrow search algorithm needs to sort the population according to fitness. Since the problem involved in this paper is a multiobjective optimization problem, there is no fixed fitness calculation method. One way to solve this problem is to use NSGA-II nondominated sorting method to divide sparrow populations.

The main steps of this sorting method are as follows: First, each individual in the population is compared with other individuals, and all the other individuals that dominate the individual are recorded. Then, all nondominant individuals are included in Pareto’s optimal frontier, that is, the first nondominant level. These individuals are then removed from the dominant records of the remaining individuals, the nondominant individuals of the remaining individuals are included in the second nondominant class and so on, until all individuals are included in a nondominant class. In this way, the operation rules of the original algorithm can be simulated by the operation of different non-dominant-level individuals.

- (3)

- Nondominated solution set update strategy

After Pareto frontier solutions are obtained by nondominated sorting, these solutions should be input into external files and saved. Because swarm intelligence algorithm usually has a large number of iterations, the number of Pareto frontier solutions output by the algorithm is large, and these solutions cannot all be kept, so there is usually a capacity limit of external files. The NSGA-II algorithm adopts the crowding ranking method to protect the diversity of solutions in external files so as to ensure that the distribution of the output solution set of the algorithm is sufficiently dispersed in the target space [29].

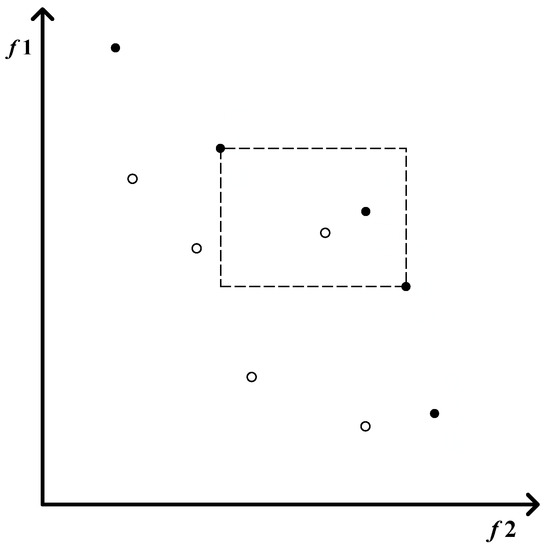

Crowding is a number that measures how close a solution is to its neighbors in the solution set. As shown in Figure 2, in which the solid points represent nondominant solutions and the hollow points represent general solutions, crowding can be defined as a normalized estimate of the perimeter of a rectangle composed of vertices with two adjacent solutions on either side of that point. Assuming that the coordinates of the solutions on both sides of the solution set are and , respectively, and in a certain dimension, define the normalized length of the rectangle formed by the i-th solution in this dimension direction as

Figure 2.

Crowding calculation method.

The sum of the normalized lengths of the rectangle in all dimensions is the crowding of the i-th solution in the solution set.

In this way, the update strategy of the external file of the algorithm can be expressed as follows: when the algorithm completes a position update, it compares the nondomination rank of the solution of the external file input with the solution in the file, deletes the dominated solution and then retains the solution with low density in the external file.

- (4)

- Location update procedure

Step 1: Initialize the population

Set the sparrow population size n and the maximum number of iterations itermax. According to the above coding method, the population is initialized, and the position coordinates of each dimension are randomly assigned to each individual within the constraint range of maintenance level as follows:

where X is the coordinates matrix of the population, and any individual i in any dimension j coordinates satisfies .

After initialization, the population was sorted by the fast nondominated sorting method. Then, according to Equations (8) and (10), the fitness of each individual in the population in the two objectives of mission capability and maintenance cost is given, respectively.

Step 2: Producer location update

In the sparrow search algorithm, when the alarm value is less than the safety threshold, the producers will search according to Equation (23):

where Q is a random variable subject to normal distribution, represents the position of the i sparrow in dimension j and represents the safety threshold; is the maximum number of iterations of the algorithm.

Since the power of the exponential function in Equation (23) is always less than 0, this step can be regarded as an operation to gradually converge the discoverer individual to the origin of coordinates. This operation is not conducive to the global search ability of the algorithm, so the method of making the coordinates increase in random proportion is adopted instead. At this point, the location update rule for the producer becomes

where represents the early warning value of individual sparrows.

Since the maintenance level can only be an integer, and there are upper and lower bound constraints, the producer should be integer-processed after updating the above rules, and the coordinates that exceed the constraints should be reset to the value closest to the value that obeys the constraints. After the location update is completed, the population is redivided by the nondominated sorting method, and the scrounger location update process is started.

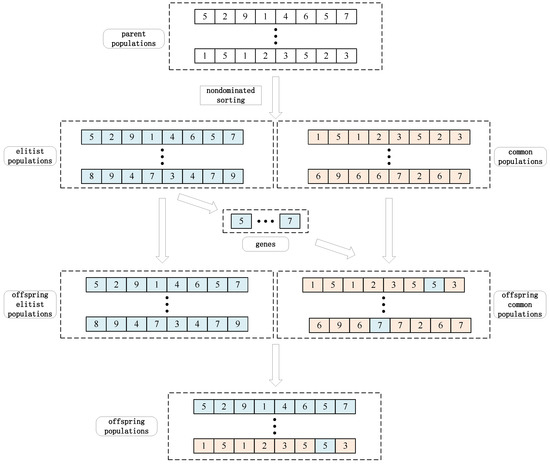

Step 3: Scrounger location update

In the scrounger location updating stage of the sparrow search algorithm, individuals with better fitness will jump near the producer, which reduces the global search ability of the algorithm. Since the problem model under consideration is discrete, this chapter combines the characteristics of genetic algorithm and adopts the mechanism of elitist to strengthen the local search ability of the algorithm. In this case, the position update rule in the accession stage can be described as the dynamic update process shown in Figure 3.

Figure 3.

Location update rule of MSSA user phase.

The sparrow populations are divided into elitist populations composed of first and second nondominant individuals and common populations composed of residual individuals. The elitist population is retained in the process of location update, and the individuals of the common population randomly acquire the genes of the elitist population in some dimensions to replace their own genes. After that, the progeny population is outputted, the population is redivided by the fast nondominated sorting method, the external file is updated and the alert location is updated.

Step 4: Watcher location update

A watcher is a proportion of individuals randomly selected from the population. Similar to the scrounger position update stage, the watcher adopts the location update method based on genetic algorithm. The sparrow in a better position will move to the individual in a worse position in the population, while the sparrow in a worse position will move to the less crowded position in the external file. The position update rule of the watcher becomes

where represents the location of a common population individual, represents a location recorded in an external file and represents a random integer between .

The population is then redivided by using the nondominated sorting method, the external file is updated and the second step is returned until the predetermined number of iterations is reached.

The overall processes of the proposed multiobjective sparrow search algorithm is summarized into Algorithm 1.

| Algorithm 1: The framework of MSSA | |

| Input: | |

| N: population of sparrows | |

| iterm: maximum iterations | |

| Output: | |

| nondominated solution set | |

| 1: | Initialize a population of N sparrows and define its relevant parameters |

| 2: | while iter < iterm do |

| 3: | rank the population with nondominated sorting approach; |

| 4: | for condition do |

| 5: | Using Equation (24) update the producers’ location; |

| 6: | set producers’ location as integer |

| 7: | Sort the population with nondominated sorting approach; |

| 8: | Genetic recombination between elitist swarms and basic swarms; |

| 9: | Sort the population with nondominated sorting approach; |

| 10: | Save the nondominated solution to the external archive; |

| 11: | Using Equation (25) update the guards’ location; |

| 12: | Sort the population with nondominated sorting approach; |

| 13: | Save the nondominated solution to the external archive; |

| 14: | iter = iter + 1; |

| 15: | Sort the external archive with crowding distance; |

| 16: | return nondominated solution set. |

3.2.2. A Simulated Annealing Algorithm Used to Solve Maintenance Scheduling

Since the maintenance scheduling of fleet is a sequential process, the efficiency of maintenance tasks can be further improved by reasonable maintenance scheduling. In this section, the SA algorithm is used to further optimize the maintenance schedule to minimize the maintenance time corresponding to the maintenance plan.

SA [33] is a local search algorithm that introduces the concept of annealing in solids. This algorithm can reduce the complexity of the algorithm and avoid the shortcoming of the traditional local search algorithm which converges to the local optimal solution quickly by making an annealing schedule of the temperatures and length of times for which the system is to be evolved. In this section, SA is used to calculate the minimum maintenance time of a known maintenance plan, and the most appropriate maintenance strategy is selected according to the maintenance time.

The purpose of maintenance scheduling optimization is to minimize the total maintenance time of the fleet through a reasonable scheduling scheme on the basis of an optimized maintenance plan. According to the analysis of known conditions, the input of the problem is a fleet to be repaired and the maintenance time required under the corresponding maintenance level, and the output is the maintenance sequence and the total maintenance time of the fleet.

represents the time when the i component completes maintenance on the j maintenance equipment, and represents the time required for the i component to complete maintenance on the j maintenance equipment, then

where represents the time when the j subsystem of the i equipment completes maintenance, and represents the time required for the j subsystem of the i equipment to be repaired.

If the maintenance schedule is given, the total maintenance time to complete the maintenance according to the schedule can be obtained by the iterative calculation of the above equations. After the input data, a maintenance schedule is randomly generated, and its total maintenance time is calculated. Then, a new schedule is generated by a displacement, and whether it is accepted or not is judged according to the acceptance rule, which changes with the temperature. Eventually the algorithm converges to a solution with a minimized total maintenance time. If represents the total maintenance time of the maintenance schedule generated after the disturbance, represents the total maintenance time of the original maintenance schedule, and T is the current temperature; then, the acceptance rule can be expressed by Equation (30):

where is a random number between 0 and 1.

The operation steps of the maintenance scheduling algorithm are as follows:

Step 1: Input the calculation data, including the number of equipment n, the number of maintenance processes m and the maintenance time of each maintenance;

Step 2: Initialize the temperature and the annealing coefficient and randomly generate a maintenance schedule that meets the constraints as the initial solution;

Step 3: Start the cooling cycle and perform several displacements at each temperature. The specific displacement rule is to randomly exchange the maintenance order of two components;

Step 4: After each displacement, calculate the total maintenance time corresponding to the new solution according to the Equations (26)–(29), and then perform the acceptance judgment according to the admission rules described in Equation (30);

Step 5: After the temperature gradually drops to the preset value of 0.1, jump out of the annealing cycle;

Step 6: Repeat the above steps several times to explore the algorithm performance under different initial conditions;

Step 7: Find the minimum total maintenance time and output the corresponding maintenance schedule.

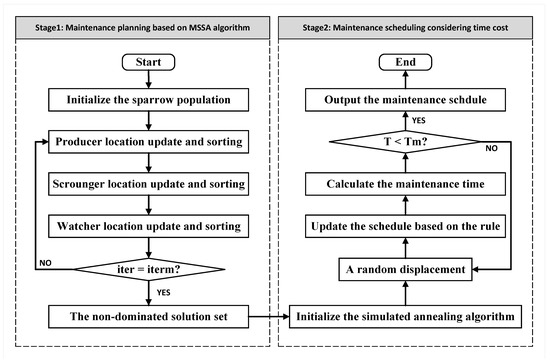

3.3. Process of Selective Maintenance Planning for Equipment Cluster Based on Two-Stage Algorithm Driven by Task and Reliability

According to the solution framework shown in Section 3.1, this paper establishes a two-stage algorithm-based selective maintenance planning method process for equipment clusters driven by tasks and reliability, which mainly includes the following three steps:

Step 1: Analyze the structure of the equipment system to determine the reliability indicators of the components in the system and the maintenance hours and costs required for different maintenance strategies. The virtual age model is used to describe the effects of maintenance activities on the health state of components in each equipment system of the mission profile and to determine the survival probability of the components in the mission.

Step 2: According to the logical relationship of the components in the equipment system, the mission reliability of the equipment system is obtained, the mission satisfied capability of the fleet is determined by combining the survival probability of the components in the task, and a multiobjective selective maintenance model of the fleet is established with the goal of maximizing the mission satisfied capability and minimizing the maintenance cost.

Step 3: Taking the maintenance cost and the mission satisfied capability of the fleet in the mission profile as objectives, the multiobjective selective maintenance model is solved by using the multiobjective sparrow search algorithm, and a series of nondominated maintenance strategy solution sets are obtained. With the maintenance time as the target, the SA algorithm is used to optimize the solution set of the maintenance strategy and obtain the maintenance schedule with the shortest maintenance time in the next mission.

In conclusion, the selective maintenance planning algorithm flow of the two-stage equipment group is shown in Figure 4.

Figure 4.

Selective maintenance planning algorithm flow of the two-stage equipment group.

In this section, several fleets composed of certain vehicle equipment systems are taken as examples, and the selective maintenance planning method of the fleet based on the two-stage algorithm proposed in this chapter is verified and analyzed. Assume that the mission requires that all subsystems work properly and that subsystems fail independently of each other. As the actual structure of the equipment system is complex and there are many components, for the sake of simplicity, each subsystem can be regarded as a structure composed of several key components in parallel, and the system reliability block diagram is shown in Figure 5.

Figure 5.

The vehicle system reliability block diagram.

4. Case Verification and Result Analysis

4.1. Case Verification

As shown in the figure, the equipment system consists of seven subsystems in series, each component in the system can be regarded as a multistate component with independent failure condition, and its mission capability is determined by the mission reliability of each subsystem. Table 1 lists the relevant parameters of various components in the system, including the shape parameter of the Weibull life distribution, scale parameter , virtual age improvement factor m, maintenance cost corresponding to replacement and maintenance (unit: yuan) and maintenance time (unit: min). The duration of the next mission is set to min, and the maximum maintenance level is set to 15. Assume that the fleet consists of four vehicles of the same model.

Table 1.

Parameters of various components in the system.

In order to make a selective maintenance decision on the fleet, the maintenance decision model is used to describe the problem, and the multiobjective sparrow search algorithm is used to solve the problem. The sparrow population size is set to 400, the maximum number of iterations is set to 1000 and the maintenance cost is capped at 35,000 yuan. After maintenance, the lower limit of the mission satisfied capability of the fleet is 0.7, and the upper limit of the storage of external files of the algorithm is 60.

Some specific parameter settings are as follows: The safety threshold of the producers is set to 0.9. The mission duration is 12. The size of the sparrow population is 400. The maximum iteration of MSSA is 1000. The annealing rate is 0.99. The initial temperature and final temperature of SA are 1000 and 1, respectively.

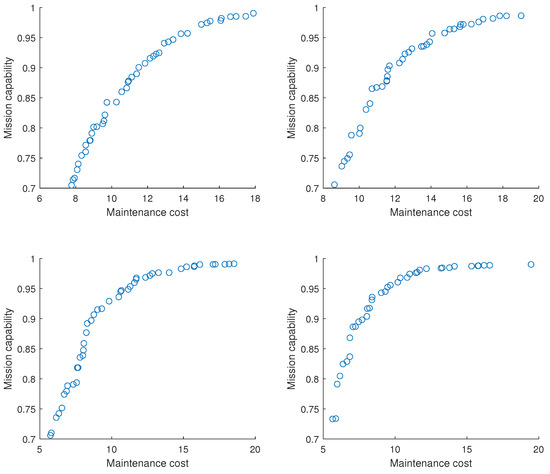

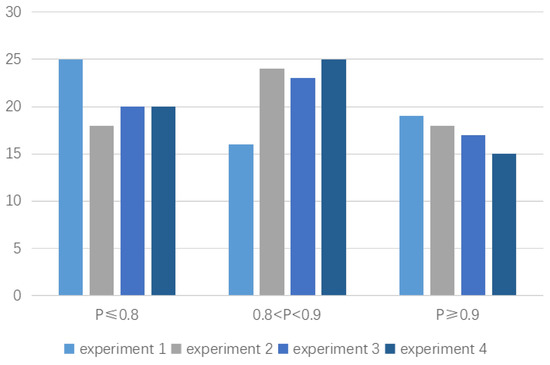

In this section, multiple tests are conducted on the equipment system under different initial health conditions, and the nondominated solution set is shown in Figure 6. Then, the optimal maintenance schedule and maintenance time corresponding to these strategies are obtained by SA algorithm. On this basis, the target space is divided into several parts according to the maintenance cost index, and the maintenance plan is determined according to the shortest maintenance time in each part.

Figure 6.

Nondominated solution set in four simulation experiments.

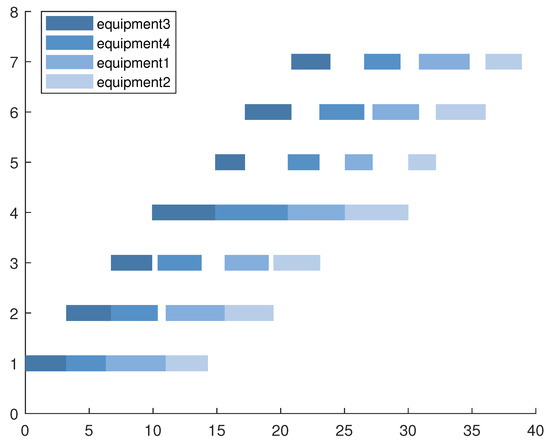

Table 2 shows several plans selected by evaluating the maintenance time, as well as the corresponding maintenance cost, task capability, maintenance time and maintenance schedule of these options. The Gantt chart of the maintenance schedule of Option 1 is shown in Figure 7. It can be seen that the mission satisfied capability of the fleet has a high correlation with the maintenance cost, and the maintenance hours between different schemes are similar after optimizing the maintenance schedule.

Table 2.

Options selected after evaluation of maintenance hours.

Figure 7.

The Gantt chart of maintenance schedule.

Figure 8 shows the distribution of the nondominated solution set obtained from the four tests in Figure 6 in terms of the mission satisfied capability dimension. It can be seen that the nondominated solution set obtained by the algorithm proposed in this section is evenly distributed in the target space.

Figure 8.

The distribution of the nondominated solution set.

The simulation analysis process in the above case analysis is completed based on the matlab platform, running on a PC configured with Intel(R) Core(TM) i7-9750H CPU and Windows 10 operating system.

4.2. Result Analysis

Combined with the operation results of the above example, it can be concluded that the selective maintenance planning of the fleet under the age reduction model in this paper has the following characteristics:

- (1)

- Fleet mission satisfied capability has a high correlation with the cost of maintenance tasks invested, and the benefit of unit maintenance cost invested decreases with the increase in fleet mission satisfied capability. The mission satisfied capability of the equipment cluster is determined by the health status of each equipment unit. The higher mission satisfied capability has higher requirements on the health status of each equipment; so, it needs to invest a lot in maintenance costs. In the case of a high requirement of mission satisfied capability and sufficient budget, more cost should be invested in exchange for higher mission success rate. In the case of low mission satisfied capability requirements and tight budgets, maintenance strategies with slightly lower mission satisfied capability can be selected to reduce costs.

- (2)

- There is little difference in maintenance hours corresponding to different maintenance strategies. Since a reasonable maintenance schedule is established to maximize the use of maintenance time, when the fixed maintenance hours are longer than the hours associated with the maintenance level, the corresponding maintenance hours of different maintenance strategies are not different; so, the maintenance hours can be considered as a supernumerary optimization objective.

In summary, the two-stage selective maintenance planning algorithm for the fleet proposed in this chapter can quickly solve the nondominated solution set that is evenly distributed in the target space, evaluate the solution set and give the maintenance schedule with the shortest maintenance time so as to provide the mission and health condition driven decision scheme and its theoretical basis for the selective maintenance task of a fleet.

5. Conclusions

Based on the maintenance planning problem of fleets driven by mission and reliability, this paper studies the selective maintenance decision-making method considering the health conditions of the fleet and the requirements of missions. Firstly, a selective maintenance model based on virtual age reduction is established according to the problem background, and then a phased problem-solving framework is presented. Finally, a multiobjective optimization algorithm is used to solve the model, and a maintenance strategy solution set satisfying the mission requirements is given. The specific work is summarized as follows:

- (1)

- A selective maintenance decision model of fleets based on virtual age reduction was constructed. In the process of model establishment, the traditional research structure of “unit–system” in maintenance planning was extended to the three-level research structure of “unit–system–fleet”, considering the cooperation of different equipment in missions. Based on the Kijima II imperfect maintenance model, this model uses virtual age to evaluate the health condition of equipment. A cost-based maintenance evaluation method is proposed considering the service age improvement coefficient, and the mission satisfied capability of a fleet is described by the survival probability.

- (2)

- The two-stage problem-solving framework of “decision–evaluation” and the corresponding solution method were proposed. The problem is decomposed into two parts: the multiobjective optimization decision of mission satisfied capability and maintenance cost and the strategy evaluation based on maintenance hours considering the convergence rate of the algorithm so as to simplify the difficulty of solving the problem. Based on the sparrow search algorithm, the discrete and multiobjective improvement is made, and the NSGA-II nondominated sorting method and elitist strategy are integrated so that the solution set of nondominated maintenance strategy distributed uniformly in the target space can be quickly obtained. Then, the SA algorithm is used to evaluate the maintenance strategy and give the corresponding optimal maintenance schedule and the minimized maintenance time so as to obtain a series of optimal maintenance strategies that satisfy the mission requirements.

- (3)

- In terms of the application of the method, we verified the case of a vehicle fleet, established its selective maintenance decision model and solved it by using the two-stage algorithm proposed in this chapter. A series of selective maintenance schemes of the vehicle fleet uniformly distributed in the target space were obtained, and the effectiveness of the method was verified. The above research methods can be applied to the dynamic selective maintenance decision problem of repairable fleets driven by mission and reliability, optimize maintenance task planning, reduce maintenance cost, improve availability and mission success probability and provide guidance for other similar problems.

However, fleets in the real world commonly consist of different types of units. In terms of future directions, a fleet with lager size and different types of vehicles can be take into consideration, which will increase the size of the problem. In addition, future research can focus on the maintenance planning of fleets in multiwave missions and consider the dynamic changes in factors such as task requirements and maintenance resources so as to achieve the optimal performance of the fleet in the overall task.

Author Contributions

Conceptualization, Q.C. and X.Y.; methodology, Q.C., P.W. and X.Y.; software, P.W. and L.Y.; validation Q.C. and P.W.; formal analysis, L.Y. and J.W.; investigation P.W., L.Y. and J.W.; resources Q.C. and L.Y.; data curation L.Y. and J.W.; writing—original draft preparation, P.W. and L.Y.; writing—review and editing, Q.C. and J.W.; project administration, Q.C. and X.Y. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

All datasets are publicly available.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Verhoeff, M.; Verhagen, W.J.C. Component Maintenance Planning Optimization in Defense Aviation. Aerospace 2023, 10, 255. [Google Scholar] [CrossRef]

- De Jonge, B.; Scarf, P.A. A review on maintenance optimization. Eur. J. Oper. Res. 2020, 285, 805–824. [Google Scholar] [CrossRef]

- Álvarez, C.; López-Campos, M.; Stegmaier, R.; Mancilla-David, F.; Schurch, R.; Angulo, A. A Condition-Based Maintenance Model Including Resource Constraints on the Number of Inspections. IEEE Trans. Reliab. 2020, 59, 1165–1176. [Google Scholar] [CrossRef]

- You, M.-Y. A generalized three-type lifetime probabilistic models-based hybrid maintenance policy with a practical switcher for time-based preventive maintenance and condition-based maintenance. Proc. Inst. Mech. Eng. Part J. Process. Mech. Eng. 2019, 233, 1231–1244. [Google Scholar] [CrossRef]

- Jiang, T.; Liu, Y. Selective maintenance strategy for systems executing multiple consecutive missions with uncertainty. Reliab. Eng. Syst. Saf. 2020, 193, 106632. [Google Scholar] [CrossRef]

- Yuan, P.; Han, W.; Su, X.; Liu, J.; Song, J. A Dynamic Scheduling Method for Carrier Aircraft Support Operation under Uncertain Conditions Based on Rolling Horizon Strategy. Appl. Sci. 2018, 8, 1546. [Google Scholar] [CrossRef]

- Guo, Z.; Zhang, Y.; Zhao, X.; Song, X. A timed colored petri net simulation-based self-adaptive collaboration method for production-logistics systems. Appl. Sci. 2017, 7, 235. [Google Scholar] [CrossRef]

- Guo, Z.; Zhang, Y.; Zhao, X.; Song, X. CPS-based self-adaptive collaborative control for smart production-logistics systems. IEEE Trans. Cybern. 2020, 51, 188–198. [Google Scholar] [CrossRef]

- Keizer, M.C.O.; Flapper, S.D.P.; Teunter, R.H. Condition-based maintenance policies for systems with multiple dependent components: A review. Eur. J. Oper. Res. 2017, 261, 405–420. [Google Scholar] [CrossRef]

- Ali, A.; Abdelhadi, A. Condition-Based Monitoring and Maintenance: State of the Art Review. Appl. Sci. 2022, 12, 688. [Google Scholar]

- Koopmans, M.; De Jonge, B. Condition-based maintenance and production speed optimization under limited maintenance capacity. Comput. Ind. Eng. 2023, 179, 109155. [Google Scholar] [CrossRef]

- Wang, W.; Chen, X. Piecewise deterministic Markov process for condition-based imperfect maintenance models. Reliab. Eng. Syst. Saf. 2023, 236, 109271. [Google Scholar]

- Pham, H.; Wang, H. Imperfect maintenance. Eur. J. Oper. Res. 1996, 94, 425–438. [Google Scholar]

- Yang, L.; Ye, Z.S.; Lee, C.G.; Yang, S.F.; Peng, R. A two-phase preventive maintenance policy considering imperfect repair and postponed replacement. Eur. J. Oper. Res. 2019, 274, 966–977. [Google Scholar] [CrossRef]

- Liu, Y.; Guo, P.; Zhang, C. Fleet-Level Selective Dispatch and Imperfect Maintenance Strategy Optimization Based on Evolutionary Co-Petition Game Theory. IEEE Access 2020, 8, 148689–148701. [Google Scholar] [CrossRef]

- Cheng, W.; Zhao, X. Maintenance Optimization for Dependent Two-Unit Systems Considering Stochastic Degradation and Imperfect Maintenance. In Proceedings of the 2022 IEEE 22nd International Conference on Software Quality, Reliability, and Security Companion (QRS-C), Guangzhou, China, 30 March 2023. [Google Scholar]

- Shahraki, A.F.; Yadav, O.P.; Vogiatzis, C. Selective maintenance optimization for multi-state systems considering stochastically dependent components and stochastic imperfect maintenance actions. Reliab. Eng. Syst. Saf. 2020, 196, 106738. [Google Scholar]

- Liu, Y.; Chen, Y.; Jiang, T. On sequence planning for selective maintenance of multi-state systems under stochastic maintenance durations. Eur. J. Oper. Res. 2018, 268, 113–127. [Google Scholar] [CrossRef]

- Cao, W.; Jia, X.; Hu, Q.; Zhao, J.; Wu, Y. A literature review on selective maintenance for multi-unit systems. Qual. Reliab. Eng. Int. 2018, 34, 824–845. [Google Scholar] [CrossRef]

- Lust, T.; Roux, O.; Riane, F. Exact and heuristic methods for the selective maintenance problem. Eur. J. Oper. Res. 2009, 197, 1166–1177. [Google Scholar] [CrossRef]

- Vu, H.C.; Do, P.; Barros, A.; Bérenguer, C. Maintenance grouping strategy for multi-component systems with dynamic contexts. Reliab. Eng. Syst. Saf. 2014, 132, 233–249. [Google Scholar] [CrossRef]

- Duan, C.; Deng, C.; Gharaei, A.; Wu, J.; Wang, B. Selective maintenance scheduling under stochastic maintenance quality with multiple maintenance actions. Int. J. Prod. Res. 2018, 56, 7160–7178. [Google Scholar] [CrossRef]

- Xu, E.B.; Yang, M.S.; Li, Y.; Gao, X.Q.; Wang, Z.Y.; Ren, L.J. A multi-objective selective maintenance optimization method for series-parallel systems using NSGA-III and NSGA-II evolutionary algorithms. Adv. Prod. Eng. Manag. 2021, 16, 372–384. [Google Scholar]

- Urbani, M.; Brunelli, M.; Punkka, A. An approach for bi-objective maintenance scheduling on a networked system with limited resources. Eur. J. Oper. Res. 2023, 305, 101–113. [Google Scholar]

- Maillart, L.M.; Cassady, C.R.; Rainwater, C.; Schneider, K. Selective Maintenance Decision-Making Over Extended Planning Horizons. IEEE Trans. Reliab. 2009, 58, 462–469. [Google Scholar]

- Kijima, M. Some results for repairable systems with general repair. J. Appl. Probab. 1989, 26, 89–102. [Google Scholar] [CrossRef]

- Kang, J.; Sobral, J.; Soares, C.G. Review of condition-based maintenance strategies for offshore wind energy. J. Mar. Sci. Appl. 2019, 18, 1–16. [Google Scholar]

- Xue, J.; Shen, B. A novel swarm intelligence optimization approach: Sparrow search algorithm. Syst. Sci. Control. Eng. 2020, 8, 22–34. [Google Scholar]

- Zhang, C.; Ding, S. A stochastic configuration network based on chaotic sparrow search algorithm. Knowl.-Based Syst. 2021, 220, 106924. [Google Scholar] [CrossRef]

- Zhang, Z.; Han, Y. Discrete sparrow search algorithm for symmetric traveling salesman problem. Appl. Soft Comput. 2022, 118, 108469. [Google Scholar]

- Li, Y.; Wang, S.; Chen, Q.; Wang, X. Comparative study of several new swarm intelligence optimization algorithms. Comput. Eng. Appl. 2020, 56, 1–12. [Google Scholar]

- Deb, K.; Pratap, A.; Agarwal, S.; Meyarivan, T. A fast and elitist multiobjective genetic algorithm: NSGA-II. IEEE Trans. Evol. Comput. 2002, 6, 182–197. [Google Scholar] [CrossRef]

- Kirkpatrick, S.; Gelatt, C.D., Jr.; Vecchi, M.P. Optimization by simulated annealing. Science 1983, 220, 671–680. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).