Abstract

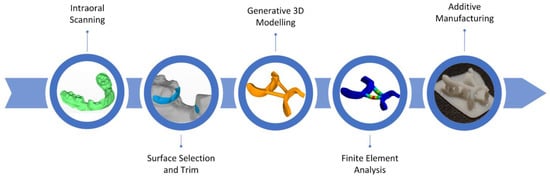

Primary dentition is crucial in influencing the emergence of permanent teeth. Premature primary tooth loss can result in undesired tooth motions and space loss in the permanent dentition. Typically, fixed or removable dental appliances are adopted to maintain edentulous space until the eruption of permanent teeth. However, traditional space maintainers have limitations in terms of variability in tooth anatomy, potential allergic reactions in some individuals (i.e., nickel sensitivity), difficulties in maintaining oral hygiene, and patient acceptance. The present study introduces a fully digital framework for the design and manufacturing of customized pediatric unilateral space maintainers using generative algorithms. The proposed approach overcomes the current challenges by using a biocompatible resin material and optimizing the device’s size, design, and color. The methodology involves intraoral scanning, surface selection, and trim, generative 3D modeling, finite element analysis (FEA), and additive manufacturing (AM) through vat photopolymerization. FEA results demonstrate the device’s mechanical performance and reliability, while additive manufacturing ensures design freedom, high resolution, surface finishing, dimensional accuracy, and proper fit. The mechanical interlocking system facilitates easy and effective positioning of the device. This digital approach offers the potential for wider usage of space maintainers and can be further validated through experimental assessments and clinical studies.

1. Introduction and Background

Primary teeth, particularly the first and second primary molars, play an important role in maintaining vertical space because they not only allow proper positioning and occlusion of permanent molars but also guide the correct eruption of the corresponding permanent teeth. Thus, maintaining these teeth in position improves esthetics, mastication, and speech [].

Premature loss of posterior primary teeth, both upper and lower, can lead to undesirable tooth movements resulting in space loss in the permanent dentition. This can have side effects on the developing occlusion, including crowding, impaction or ectopic eruption, over-eruption of unopposed teeth, and center-line discrepancies []. Ectopic eruption of permanent teeth or premature primary tooth loss due to caries and/or trauma may result in undesirable primary and permanent tooth movements, loss of space between permanent teeth, extrusion of teeth without an antagonist, and mesialization or distalization of teeth adjacent to the gap, resulting in a loss of arch length, crowding, and impaction of permanent teeth [,]. The space maintainer can also be used in the case of permanent tooth agenesis when it is not possible to close the space through orthodontic therapy, allowing future management of space. To ensure the proper development of occlusion, which is a key responsibility of pediatric dentists and orthodontists, it is important to understand both the factors that contribute to improper occlusion development and the complications arising from arch space loss.

When early loss of primary teeth occurs, the clinician should conduct a thorough clinical and/or radiographic examination to determine the need for intervention. If intervention is necessary, the clinician must decide whether to use fixed or removable space maintainers based on the specific case. Space Maintenance can be defined as the provisional cementation of an appliance whose main goal is to control and prevent the loss of space []. These devices prevent space loss by occupying it in different ways depending on the design, so that when the permanent teeth erupt, there will be no crowding, impaction, or ectopic eruption, and no mesial drifting []. When designing a specific space maintainer, it is important to consider several key factors, including the type of maintainer, recommended usage guidelines, aesthetic requirements, and the effectiveness of maintaining cleanliness [,].

Different types of space maintainers have been designed in the last three decades and can be found in the literature. Although these space maintainers are classified as fixed or removable space maintainers, they are all used to prevent loss of space [,]. The type of appliance is determined by several factors, including the stage of dental development, the number of lost teeth, the occlusion, the dental arch involved, the child’s age, and his/her ability to cooperate []. Pediatric dentists have used and recommended conventional metal space maintainers in the form of a band cemented to the tooth distal to the space and a horizontal loop that maintains the space by resting on the tooth mesial to the space (Figure 1).

Figure 1.

Conventional unilateral (band-and-loop) metal space maintainer.

However, conventional metal space maintainers incur some drawbacks, particularly in terms of their design and manufacture []. Researchers observed a correlation between space maintainers and a higher periodontal index score, which is associated with an increased risk of oral cavity bacteria growth [,,]. Additionally, nickel is a common and severe allergen, and nickel sensitivity was found to be higher in children who had intraoral devices that contained nickel []. The use of a stainless-steel alloy or a biocompatible material is then recommended in the production of the appliance to prevent any health concerns, especially for young patients. Additionally, the great variability of the anatomy of primary teeth can lead to longer chair time for the selection of the appropriate bands, and their adaptation to the teeth is not always perfect.

Digital space maintainers, instead, leverage intraoral scanners as a foundational element. Although an intraoral scan or impression sent to the technician to create a patient-specific space maintainer is an extra step in the workflow, it yields highly personalized results and substantially reduces the need for post-treatment interventions and modifications. Consequently, treatment times are shortened, also enabling clinicians to adopt a more child-friendly and child-oriented approach []. Personalization improves the adaptability of the space maintainer while also providing better hygiene for the area and reducing the bulkiness of the appliance, thus increasing patient comfort.

In recent years, scientific research has oriented towards the digitalization of the design process of space maintainers with the aim of improving the patients’ acceptance of the treatments. There are a few examples of solutions adopting computer-aided design/computer-aided manufacturing (CAD/CAM) technologies in pediatric dentistry [,]. These works usually adopt a 3D intraoral scanner to acquire the anatomy of the child’s dentition and dedicated software to model a band-and-loop space maintainer. An example of this approach can be found in studies by Lee [] and Khanna et al. []. In Lee [], the space maintainer has been designed by the Dental System (3Shape) software, adapting the pre-defined “crown” function and bridging the teeth using connectors. Then, the space maintainer was manufactured by a 5-axis milling machine starting from a zirconia block. Khanna and colleagues [] designed the appliance with the DentalCAD 2.2 Valletta (Exocad) software and used a micro laser sintering technology with a titanium-based powdered material for its manufacturing. The integration of digital design with additive manufacturing allows to produce space maintainers in virtually any shape or form. Personalized design through digital scans and three-dimensional modelling software enables us to create space maintainers that precisely fit patient’s teeth, optimizing adaptability and effectiveness. This customization reduces the risk of displacement or discomfort compared to non-customized devices. Additionally, personalized design enhances patient compliance by creating more comfortable and less intrusive space maintainers, leading to better patient acceptance. Moreover, additive manufacturing offers greater design freedom and flexibility since it allows for the creation of complex geometries without the same limitations imposed by traditional manufacturing techniques. This freedom from constraints allows for greater innovation, improved adaptability, and enhanced performance of orthodontic devices []. In addition, the digital design process can be assisted by finite element analyses, which are perfectly suited to simulate both conventional and unusual loading conditions. It is crucial to ensure that the designed appliance is structurally capable of withstanding the forces and stresses encountered in the oral environment.

However, it is worth noting that digital approaches also entail certain limitations. A first shortcoming, for example, is given by the reliance on design software, which may have pre-defined functions or limitations that restrict the creation of free-form geometries. Many design software tools used in the orthodontic field are proprietary and may have specific constraints that limit the design possibilities. These software tools often provide a range of pre-defined shapes that guide the design process. While these functions can be useful for commonly used designs, they may not offer the same level of flexibility when it comes to creating complex, free-form geometries. This can restrict the exploration of innovative designs, characterized by unconventional shapes, that could potentially improve the adaptability or functionality of the space maintainer. Furthermore, while additive manufacturing reduces geometric constraints, it may also introduce alternative issues, including the choice of appropriate materials, printing resolution, post-processing treatments, structural integrity, and cost implications. Material extrusion technologies, for example, cannot print fine details with high surface quality, while micro laser sintering technologies are expensive solutions. In addition, parts manufactured by micro laser sintering also present lower surface finishing. A smooth surface finish, instead, is desirable to minimize potential irritation or discomfort in the oral cavity. For this reason, post-processing treatments such as sanding, polishing, or coating may be required to achieve the desired surface quality [].

The present work proposes a fully digital framework to produce customized pediatric unilateral space maintainers that address most of the above-described limitations. The procedure starts with an intraoral scanning of the dental anatomy and integrates generative 3D modeling, finite element analysis (FEA), and additive manufacturing. Generative algorithms are used to enhance flexibility in creating free-form geometries providing more freedom for designing complex shapes and structures. A finite element model has been developed to evaluate the structural behavior of the designed space maintainer. In particular, the finite element analysis has been conceived to simulate how an incorrect loading condition of the device could affect its functionality. Specifically, the analysis considered potential out-of-plane loading caused by external elements exerting pressure on the device during occlusion movement. Finally, the space maintainer has been additively manufactured by using a bio-compatible photosensitive resin and vat photopolymerization, specifically Digital Light Processing (DLP) technology. DLP 3D printers enable to produce high-resolution parts with fine details and smooth surface finishes. Also, they support a wide range of photopolymer materials specifically formulated for dental applications. These materials are biocompatible, ensuring they are safe to use in the patient’s mouth. They also offer various mechanical properties, such as flexibility, strength, and durability, allowing for customization based on the specific requirements of the space maintainer. The main aim of this study is to showcase the practical feasibility of a fully digital workflow in evaluating the mechanical behavior and producing orthodontic space maintainers prior to their implementation with patients.

2. Materials and Methods

The digital process of creating pediatric personalized space maintainers can be summarized in the schematic representation reported in Figure 2.

Figure 2.

The digital design process of the personalized space maintainers.

2.1. Anatomical Data Acquisition

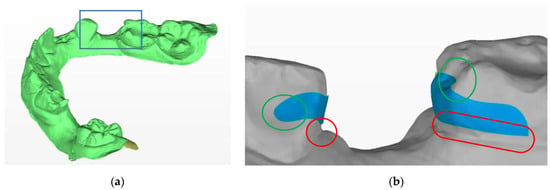

The starting point of the process consists of performing an intraoral scan of the child’s dentition. This procedure allows digital capture of the shape of gum and teeth by a digital dental scanner []. This approach has witnessed a significant increase in terms of diffusion and adoption among dentists in recent years []. One of its advantages is that the resulting output consists of a 3D mesh of the patient’s mouth, that can be subsequently exported in a .stl file (Figure 3a).

Figure 3.

Initial teeth surface elaboration: (a) 3D intraoral scan of the child’s dentition and (b) selection of a portion of the two teeth that are required to be maintained at a certain distance.

After the completion of the 3D scanning process, the subsequent step involves identifying and selecting the specific surfaces of the teeth model that require to be kept at a specified distance. The complete scan is imported in MeshLab, and the teeth portion, adjacent to the edentulous space that must be preserved, is selected, and then trimmed. To prevent interference between the appliance and the patient’s chewing, the selected areas should maintain specified distances from the gingiva in the lower zone and the occlusal plane in the upper zone. Figure 3b shows an example of this selection for the space between the primary mandibular canine and the primary mandibular second molar.

It is relevant to notice that, compared to the traditional solutions, the selection proposed in this work offers two advantages. By selecting a small partial surface on the mesial, distal, vestibular, and lingual teeth areas, which does not interfere with the child’s mastication, mechanical locking of the space maintainer is achieved (highlighted in green in Figure 3b), preventing it from dropping significantly lower. Additionally, maintaining a distance from the teeth–gum border (highlighted in red in Figure 3b) significantly reduces the risk of gum irritation and plaque formation in that area.

2.2. Generative Design

Based on the previous step’s selections, a manifold model must be created for 3D printing. The digital approach and additive manufacturing technology enable the production of custom space maintainers with innovative shapes, while adhering to medical limits and requirements. In this regard, the generative design approach was used to explore multiple solutions.

The generative design utilizes computer algorithms and artificial intelligence to automatically explore and produce multiple design alternatives. It generates innovative and optimized solutions to complex problems in fields like engineering, architecture, and product design. By setting constraints, goals, and parameters, the algorithm iteratively evaluates numerous design possibilities, uncovering solutions not readily apparent to human designers. Techniques like parametric modeling, genetic algorithms, machine learning, and optimization are employed to identify efficient designs. This methodology yields groundbreaking outcomes with enhanced efficiency, cost-effectiveness, and performance, while minimizing material usage and time expenditures [].

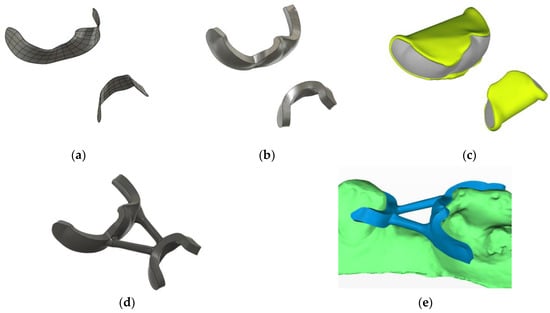

Figure 4 illustrates the main phases of the process using the software Autodesk Fusion 360. Initially, the meshes of the two input parts are converted into T-Spline surfaces, as shown in Figure 4a, and thickened by 1 mm in the normal direction, as shown in Figure 4b. These two solid borders represent the crucial connection between the space maintainer and the child’s teeth; thus, their shape and thickness must be preserved. Generative design algorithms can be guided by an initial design, but this may lead to bias, causing the algorithm to favor outcomes aligned with the proposed preferences and restrict the exploration of diverse possibilities. To prevent such influence on the results, it was decided to avoid providing an initial design to the algorithm.

Figure 4.

Generative design main steps: (a) T-Spline surfaces generated from the portions of the intraoral 3D scan, (b) manifold thickened bodies, (c) volumes to be avoided during the procedure highlighted in yellow, (d) output from the generative design and (e) digital model of the space maintainer on the mesh of the 3D scan.

Additionally, it was essential to define a volume to be excluded during the automatic generative process to prevent interference with the actual oral cavity. Therefore, a mesh was created to cover the internal space and the lateral sides of each thickened element, highlighted in yellow in Figure 4c. The load is applied to the internal surface of the molar tooth, while the other internal surface is fixed in space. The load’s direction aligns with a line connecting the centers of mass of the two solid borders. Another design criterion is the adoption of additive manufacturing as the production technology, with a minimum element thickness of 1 mm. The optimization objectives focus on reducing mass while maintaining a minimum factor of safety equal to 2. A factor of safety refers to an additional margin of strength or performance that is intentionally incorporated into the generated design solutions. It serves to enhance the reliability and robustness of the final design by providing a safety margin against uncertainties and unexpected conditions. The factor of safety is used to ensure that the selected design, among those generated, has a higher capacity to handle loads or stresses than the predicted maximum operational demands. It is typically expressed as a ratio, representing the factor by which the predicted maximum load or stress is multiplied to determine the final design’s capacity.

The generative design produces multiple shapes, but the selected one, shown in Figure 4d, strikes the best tradeoff between mass reduction and strength. Adjustments to the output are easily made due to the T-Spline nature of the body. Figure 4e displays the space maintainer model placed on the intraoral scan of the child.

2.3. Finite Element Analysis

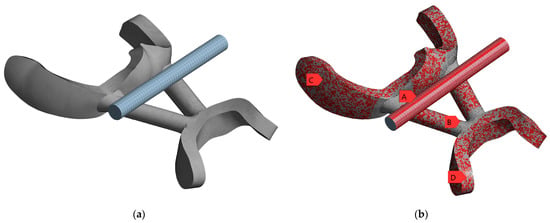

Finite element analyses were performed by Ansys 2022 software to simulate a bending test on the space maintainer. The aim was to evaluate its mechanical behavior under static structural conditions, considering large displacements and elastic-plastic material properties. The purpose of the finite element analysis is to simulate the impact of unforeseen loading on the functionality of the device. Specifically, the analysis considers the possibility of out-of-plane loading, which could occur if external elements exert pressure on the device during occlusion movement. Practically, this loading condition was simulated using a rigid pin to emulate a bending test. The material properties used in the analysis were determined through experimental tensile tests. The linear-elastic behavior was modeled through Young’s modulus E of and a Poisson’s ratio () of , while the plastic material behavior was implemented by means of a multilinear isotropic hardening model, as presented in Table 1.

Table 1.

Elastic-plastic material properties for “OD-Clear MF Bio monomer free” resin.

A three-dimensional finite element model was created to simulate the teeth space maintainer, as illustrated in Figure 5. The geometry was discretized using brick elements with quadratic shape functions and a nominal dimension of 0.1 mm. The model consisted of 191,081 nodes and 108,912 elements, determined through a convergence study. Convergence criteria ensured that the maximum von Mises stress differed by less than 3% between successive mesh iterations. To simulate the bending test, appropriate boundary conditions were applied. A fixed support boundary condition was used to represent the contact between the space maintainer and the adjacent teeth (C and D surfaces of Figure 5). It is worth noting that constraints C and D were intended to model the cementation process between the device and the patient’s teeth. Furthermore, a rigid cylindrical pin simulated the applied force caused by the external object. A frictionless contact formulation between the space maintainer and the pin was employed (A and B surfaces of Figure 5), eliminating the need for a friction coefficient. The finite element analysis assessed the mechanical response of the teeth space maintainers under bending conditions, yielding stress and displacement distributions that offer valuable insights into their behavior. Detailed results will be presented and discussed in a subsequent section, providing a comprehensive understanding of the space maintainer’s performance.

Figure 5.

Finite element model: (a) mesh of the rigid pin and the teeth space maintainer and (b) surfaces employed for the boundary condition application.

2.4. Additive Manufacturing

Vat technology additive manufacturing, specifically the DLP technique, was adopted to fabricate the space maintainer. This method uses a DLP or a Liquid Crystal Display (LCD) projector to emit ultraviolet (UV) light, thus curing and solidifying a liquid photosensitive photopolymer. Each digital image produced via the projector or LCD screen determines the all-at-once curing of a complete slice. Therefore, the printing speed is determined by the vertical axis (z-axis) length rather than the dimensions on the x and y planes. DLP was chosen due to its high resolution and accuracy, making it one of the most effective additive technologies for polymers. It easily achieves layer thicknesses of 50 microns, and offers a range of biocompatible, orthodontic, and dental resins []. The Anycubic Photon Mono SE 3D printing machine, equipped with a 6-inch monochrome LCD display, was used, and Photon Workshop V2.1.23 software was utilized for setting the printing parameters. Table 2 provides details on the adopted main parameters.

Table 2.

Main printing parameters adopted.

The space maintainer was printed parallel to the build platform, positioned at a distance of 4 mm, and appropriately supported. The adopted resin, “OD-Clear MF Bio monomer free”, supplied by 3Dresyns company, exhibits excellent biocompatibility with minimal risks of residuals or by-products released by saliva. In addition, the manufacturer reports remarkable mechanical properties, such as a flexural strength exceeding 110 MPa, an elastic modulus ranging from 2 to 3 GPa, and a tensile strength exceeding 50 MPa []. These properties are crucial for space maintainers, ensuring the prevention of unexpected fractures.

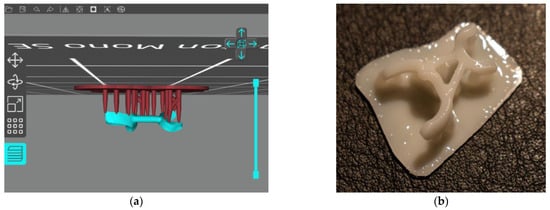

Figure 6 shows the manufacturing process of the space maintainer, from creating the printing file to its fabrication. Finally, the generated supports are mechanically removed at the end of the procedure by using a standard plier.

Figure 6.

Three-dimensional printing process: (a) printing file after the supports’ creation and (b) manufactured space maintainer.

3. Results

3.1. Finite Element Analysis Results

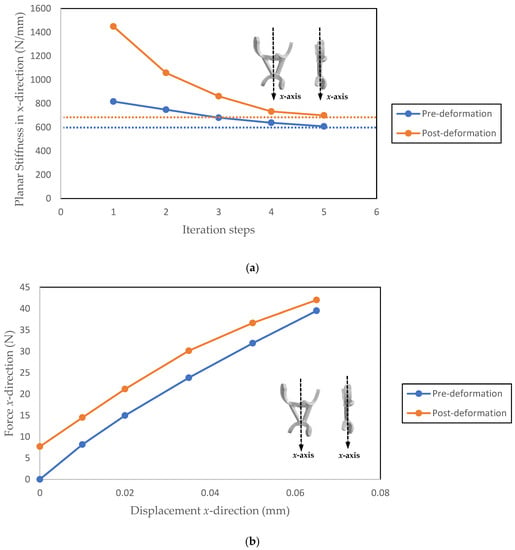

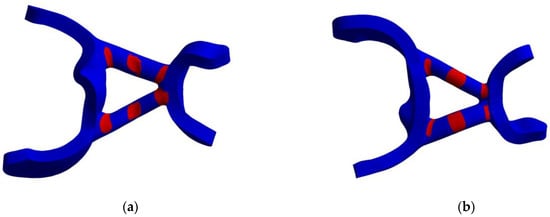

Finite element analysis was used to evaluate the planar stiffness (x-direction stiffness) of the space maintainer before and after undergoing severe plastic deformation in the bending test (Figure 7) caused by an external element pushing during the occlusion movement. Planar stiffness is a crucial parameter defining the component’s behavior when in use, since it is the main parameter that defines the device’s functionality during operation. The quantification of planar stiffness involved calculating the reaction force at a specific displacement of boundary condition D (Figure 7). The results in Figure 7 depict the magnitude of planar stiffness during successive iteration steps, where displacement in the simulation increases. The decreasing trend of planar stiffness primarily arises from the elastic-plastic response and the consideration of large displacements. However, as displacements become larger, the gradient of planar stiffness decreases, reaching a plateau typically observed around the fourth and fifth iteration steps. Overall, there is a slight increase in stiffness after plastic deformation (referred to as post-deformation) compared to the pre-deformation state. Nevertheless, this increase is not significant and can be attributed to the residual stress state resulting from the plastic deformation process. Figure 8 provides visual representations, including top and bottom views, of the extensively plasticized region within the simulated space maintainer. The highlighted red areas indicate regions that underwent significant plastic deformation, surpassing a plastic equivalent strain value of 0.1 mm/mm.

Figure 7.

Planar stiffness: (a) space maintainer stiffness pre- and post-plastic deformation and (b) force vs. displacement curve pre- and post-plastic deformation. Dashed lines represent the planar stiffness plateau reached during the simulation.

Figure 8.

The plastic region in red (i.e., equivalent plastic strain > 0.1 mm/mm) after bending test: (a) top view, (b) bottom view.

The findings indicate that the planar stiffness remained relatively constant before and after the occurrence of plastic deformation, suggesting a consistent response attributable to the elastic-perfectly plastic material behavior exhibited by the “OD-Clear MF Bio monomer free” resin. This consistency implies that the space maintainer can maintain its structural integrity and functional properties, even when subjected to severe plastic deformation.

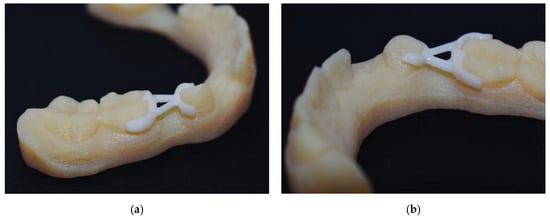

3.2. Additively Manufactured Space Maintainer

Figure 9 displays the final manufactured space maintainer that replace a missing primary first molar after the removal of supports. It is appropriately fitted to the teeth model for which it was designed. Figure 9a presents the buccal side of the maintainer, while Figure 9b shows the lingual side. Both images demonstrate the proper fit of the device on the teeth, with the lateral elements wrapping around the adjacent teeth without any clearance or interference, which could induce a deformation of the appliance. The images highlight the high accuracy, precise geometry, and overall excellent quality of the space maintainer. Minimal stratification, typical of additive manufacturing, is observed, and only partial residues of the mechanically removed supports are visible. Furthermore, upon fitting the space maintainer, it is evident that the appliance lies below the tooth surfaces, allowing unobstructed occlusion during biting, as intended during the design phase. Lastly, the space maintainer stops before reaching the gum area, fulfilling the goal of maintaining a distance from the teeth–gum border.

Figure 9.

Space maintainer fitted to the model of the teeth on which it was created: (a) buccal side and (b) lingual side. This case refers to the replacement of a primary first molar.

4. Discussion

This study presents a digital framework for designing customized pediatric unilateral space maintainers using intraoral scanning, generative algorithms, and additive manufacturing. The digital approach offers several advantages over traditional methods of space maintainer design and fabrication. Conventional appliances, produced manually in dental laboratories, often exhibit imperfect fitting and prolonged chair time for band selection due to the wide anatomical variability of primary teeth. Moreover, the use of materials like nickel in these devices can lead to allergies, and their larger size and geometry pose a risk of bacterial growth and hinder oral hygiene. Normally, space maintainers increase the plaque retention rate in the area of their positioning, and patients must be especially careful in the oral hygiene of this area [,]. Furthermore, fitting issues and pinching can arise, presenting challenges for pediatric dentists in their management, and can also be uncomfortable for the child. Therefore, the development of a fully digital workflow is aimed at addressing these concerns and improving patient acceptance, health, and comfort. The use of intraoral scanning ensures an accurate representation of the patient’s teeth, reducing the risk of improper fit and interference with mastication. Because of the accurate reconstruction of the patient’s teeth, the selection of the 3D model of the patient’s dentition of specific surfaces is possible. This allows us to maintain a certain distance from the teeth–gum border (as highlighted in Figure 3b). The high customization level helps to optimize cleaning, prevent gum irritation and plaque formation, also ensuring mechanical locking of the space maintainer, and reduces the risk of interference with mastication. The generative design was demonstrated to be effective in the exploration of different solutions and the creation of customized geometries, leading to a small overall size, better adaptation to the patient’s dentition, and enhanced effectiveness of the space maintainer. The finite element analysis was demonstrated to be valuable in assessing the effect of a bending loading condition on the planar stiffness of the appliance. This scenario could occur when an external element, such as food, applies pressure on the device during occlusion movement, potentially resulting in significant plastic deformation of the material. The simulations indicated that despite experiencing unusual loading conditions, the planar stiffness of the device remains relatively unchanged, ensuring its functionality is maintained.

The implementation of the DLP 3D printing process facilitated the use of a biocompatible resin with a tooth-like color. This, along with the small size of the device, could be useful in enhancing patient acceptance of orthodontic therapy. The dimensional accuracy and surface finish of the printed space maintainer proved adequate to allow its proper fit on the corresponding dental structures (as evidenced in Figure 9). At the same time, the designed distance from the teeth–gum border was maintained, which is supposed to improve dental hygiene. Moreover, the 3D printed space maintainer can be bonded through adhesive cementation by treating the tooth substrate with an etch and rinse adhesive system and applying a 10 methacryloyloxydecyl dihydrogen phosphate (MDP) primer on the appliance substrate. The space maintainer can be securely cemented using dual-cure cement. Due to its precise fit and adherence to tooth anatomy, the space for cement application is minimal, making it ideal for adhesive cementation. Undoubtedly, all space maintainers carry a risk of debonding. However, in this particular case, the space maintainer features a custom design and offers the potential for adhesive bonding, which could be advantageous when compared to conventional space maintainers. Cost implications of the proposed digital workflow are expected to be comparable to custom-made maintainers, with potential cost savings if 3D printing is conducted in-house. In addition, leveraging the expertise of clinicians who are already proficient in additive manufacturing, the application of these technologies for the manufacturing of 3D printed space maintainers would prove valuable in both primary care settings and dental hospitals/universities where these technologies have already been implemented. This study acknowledges that it is focused on an in vitro investigation and emphasizes the need for future in vivo studies. These studies will evaluate the acceptance of the device, debonding rate, plaque accumulation, and anatomical characteristics of teeth adjacent to the space. In vivo studies will provide a comprehensive understanding of the strengths and limitations of space maintainer designs. These studies will enable the evaluation of various designs for the first primary molar and second primary molar, encompassing both maxillary and mandibular regions. Furthermore, the studies will take into account the effects on patients’ oral health status, including factors such as caries risk and oral hygiene level.

5. Conclusions

The present study proposes a fully digital framework for creating pediatric unilateral space maintainers. The feasibility of integrating intraoral scanning, generative design, finite element analysis, and additive manufacturing to provide customized and personalized solutions was verified. The proposed methodology demonstrated to be a promising approach to improve patient-specific treatments with the aim of enhancing adaptability, hygiene, and patient comfort. While the proposed approach highlighted promising results in the design and manufacturing of space maintainers, clinical validation is necessary to evaluate its performance, efficacy, and patient satisfaction. Conducting comprehensive clinical trials would provide valuable insights into the effectiveness and acceptance of digitally designed and fabricated space maintainers in real-world scenarios. Considering the completely digital nature of this study, further investigations could be easily carried out by studying additional designs, thus providing insights into the areas where the appliance experiences the best performance.

Author Contributions

Conceptualization, F.T., A.C., B.A., A.P., L.L., E.C., G.D., M.R.G., A.V.R. and S.B.; methodology, F.T., A.C., B.A., A.P. and A.V.R.; validation, F.T., A.C. and B.A.; writing—original draft preparation, F.T., A.C., B.A. and L.L.; writing—review and editing, A.P., L.L., E.C., G.D. and M.R.G.; supervision, F.T., A.V.R. and S.B.; project administration, F.T. and A.C.; funding acquisition, F.T. All authors have read and agreed to the published version of the manuscript.

Funding

This work is supported by the Università di Pisa under the “PRA—Progetti di Ricerca di Ateneo” (Institutional Research Grants)—Project no. PRA_2022_23_ “Optimization of extrusion-based additive manufacturing for metallic and ceramic parts”.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Barbería, E.; Lucavechi, T.; Cárdenas, D.; Maroto, M. Free-end space maintainers: Design, utilization and advantages. J. Clin. Pediatr. Dent. 2007, 31, 5–8. [Google Scholar] [CrossRef] [PubMed]

- Bindayel, N.A. Clinical evaluation of short term space variation following premature loss of primary second molar, at early permanent dentition stage. Saudi Dent. J. 2019, 31, 311–315. [Google Scholar] [CrossRef]

- Tunison, W.; Flores-Mir, C.; El Badrawy, H.; Nassar, U.; El-Bialy, T. Dental Arch Space Changes Following Premature Loss of Primary First Molars: A Systematic Review. Pediatr. Dent. 2008, 30, 297–302. [Google Scholar] [PubMed]

- Watt, E.; Ahmad, A.; Adamji, R.; Katsimbali, A.; Ashley, P.; Noar, J. Space maintainers in the primary and mixed dentition—A clinical guide. Br. Dent. J. 2018, 225, 293–298. [Google Scholar] [CrossRef] [PubMed]

- Laing, E.; Ashley, P.; Naini, F.B.; Gill, D.S. Space maintenance. Int. J. Paediatr. Dent. 2009, 19, 155–162. [Google Scholar] [CrossRef]

- Mosharrafian, S.; Baghalian, A.; Hamrah, M.H.; Kargar, M. Clinical Evaluation for Space Maintainer after Unilateral Loss of Primary First Molar in the Early Mixed Dentition Stage. Int. J. Dent. 2021, 2021, 3967164. [Google Scholar] [CrossRef]

- Ahmad, A.J.; Parekh, S.; Ashley, P.F. Methods of space maintenance for premature loss of a primary molar: A review. Eur. Arch. Paediatr. Dent. 2018, 19, 311–320. [Google Scholar] [CrossRef]

- Law, C.S.; Fields, H. 26—Space Maintenance in the Primary Dentition. In Pediatric Dentistry, 6th ed.; Nowak, A.J., Christensen, J.R., Mabry, T.R., Townsend, J.A., Wells, M.H., Eds.; Elsevier: Philadelphia, PA, USA, 2019; pp. 379–385.e372. [Google Scholar]

- Ozkalayci, N.; Yetmez, M. New Design for an Adjustable Cise Space Maintainer. Biomed. Res. Int. 2018, 2018, 5434609. [Google Scholar] [CrossRef]

- Guo, H.; Wang, Y.; Zhao, Y.J.; Liu, H. Computer-aided design of polyetheretherketone for application to removable pediatric space maintainers. BMC Oral. Health 2020, 20, 201. [Google Scholar] [CrossRef]

- Srivastava, N.; Grover, J.; Panthri, P. Space Maintenance with an Innovative “Tube and Loop” Space Maintainer (Nikhil Appliance). Int. J. Clin. Pediatr. Dent. 2016, 9, 86–89. [Google Scholar]

- Arikan, V.; Kizilci, E.; Ozalp, N.; Ozcelik, B. Effects of Fixed and Removable Space Maintainers on Plaque Accumulation, Periodontal Health, Candidal and Enterococcus Faecalis Carriage. Med. Prin Pract. 2015, 24, 311–317. [Google Scholar] [CrossRef] [PubMed]

- Hosseinipour, Z.S.; Poorzandpoush, K.; Heidari, A.; Ahmadi, M. Assessment of Periodontal Parameters Following the Use of Fixed and Removable Space Maintainers in 6–12-Year Olds. Int. J. Clin. Pediatr. Dent. 2019, 12, 405–409. [Google Scholar] [CrossRef]

- Kundu, R.; Tripathi, A.M.; Jaiswal, J.N.; Ghoshal, U.; Palit, M.; Khanduja, S. Effect of fixed space maintainers and removable appliances on oral microflora in children: An in vivo study. J. Indian. Soc. Pedod. Prev. Dent. 2016, 34, 3–9. [Google Scholar] [CrossRef]

- Feasby, W.H.; Ecclestone, E.R.; Grainger, R.M. Nickel sensitivity in pediatric dental patients. Pediatr. Dent. 1988, 10, 127–129. [Google Scholar]

- Vandenberghe, B. The digital patient—Imaging science in dentistry. J. Dent. 2018, 74, S21–S26. [Google Scholar] [CrossRef] [PubMed]

- Dhanotra, K.G.; Bhatia, R. Digitainers—Digital Space Maintainers: A Review. Int. J. Clin. Pediatr. Dent. 2021, 14, S69. [Google Scholar]

- Zarean, P.; Zarean, P.; Sendi, P.; Neuhaus, K.W. Advances in the Manufacturing Process of Space Maintainers in Pediatric Dentistry: A Systematic Review from Traditional Methods to 3D-Printing. Appl. Sci. 2023, 13, 6998. [Google Scholar] [CrossRef]

- Lee, J.H. Fully digital workflow for the fabrication of a tooth-colored space maintainer for a young patient. J. Esthet. Restor. Dent. 2023, 35, 561–566. [Google Scholar] [CrossRef]

- Khanna, S.; Rao, D.; Panwar, S.; Pawar, B.A.; Ameen, S. 3D Printed Band and Loop Space Maintainer: A Digital Game Changer in Preventive Orthodontics. J. Clin. Pediatr. Dent. 2021, 45, 147–151. [Google Scholar] [CrossRef] [PubMed]

- Tamburrino, F.; Barone, S.; Paoli, A.; Razionale, A.V. Post-processing treatments to enhance additively manufactured polymeric parts: A review. Virtual Phys. Prototyp. 2021, 16, 218–251. [Google Scholar] [CrossRef]

- Tamburrino, F.; Aruanno, B.; Razionale, A.V.; Barone, S.; Martini, M.; Bordegoni, M. A Digital Process for Manufacturing Customized Trays for Dental-Whitening Treatments. Processes 2022, 10, 1232. [Google Scholar] [CrossRef]

- Al-Hassiny, A.; Végh, D.; Bányai, D.; Végh, A.; Géczi, Z.; Borbély, J.; Hermann, P.; Hegedüs, T. User Experience of Intraoral Scanners in Dentistry: Transnational Questionnaire Study. Int. Dent. J. 2023; in press, corrected proofs. [Google Scholar] [CrossRef]

- Krish, S. A practical generative design method. Comput.-Aided Des. 2011, 43, 88–100. [Google Scholar] [CrossRef]

- Andjela, L.; Abdurahmanovich, V.M.; Vladimirovna, S.N.; Mikhailovna, G.I.; Yurievich, D.D.; Alekseevna, M.Y. A review on Vat Photopolymerization 3D-printing processes for dental application. Dent. Mater. 2022, 38, E284–E296. [Google Scholar] [CrossRef] [PubMed]

- 3Dresyn OD-Clear MF Bio Monomer Free. Available online: https://www.3dresyns.com/products/3dresyn-od-clear-mf-bio-monomer-free-for-ultra-safe-night-guards-surgical-guides (accessed on 7 June 2023).

- Chi, M.H.; Qi, M.L.; Lan, A.; Wang, P.; Weir, M.D.; Melo, M.A.; Sun, X.L.; Dong, B.; Li, C.Y.; Wu, J.L.; et al. Novel Bioactive and Therapeutic Dental Polymeric Materials to Inhibit Periodontal Pathogens and Biofilms. Int. J. Mol. Sci. 2019, 20, 278. [Google Scholar] [CrossRef]

- Qi, M.L.; Chi, M.H.; Sun, X.L.; Xie, X.J.; Weir, M.D.; Oates, T.W.; Zhou, Y.M.; Wang, L.; Bai, Y.X.; Xu, H.H.K. Novel nanomaterial-based antibacterial photodynamic therapies to combat oral bacterial biofilms and infectious diseases. Int. J. Nanomed. 2019, 14, 6937–6956. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).