Effect of Type of Flour and Microalgae (Chlorella vulgaris) on the Rheological, Microstructural, Textural, and Sensory Properties of Vegan Muffins

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Dough Preparation and Baking

2.3. Rheological Properties of Dough

2.4. Water Content and Activity, Muffin Crumb Color

2.5. 2D and 3D Microstructure Examination of Muffin Crumb

2.6. Muffin Crumb Texture Examination

2.7. Sensorial Evaluation

2.8. Statistical Analysis

3. Results

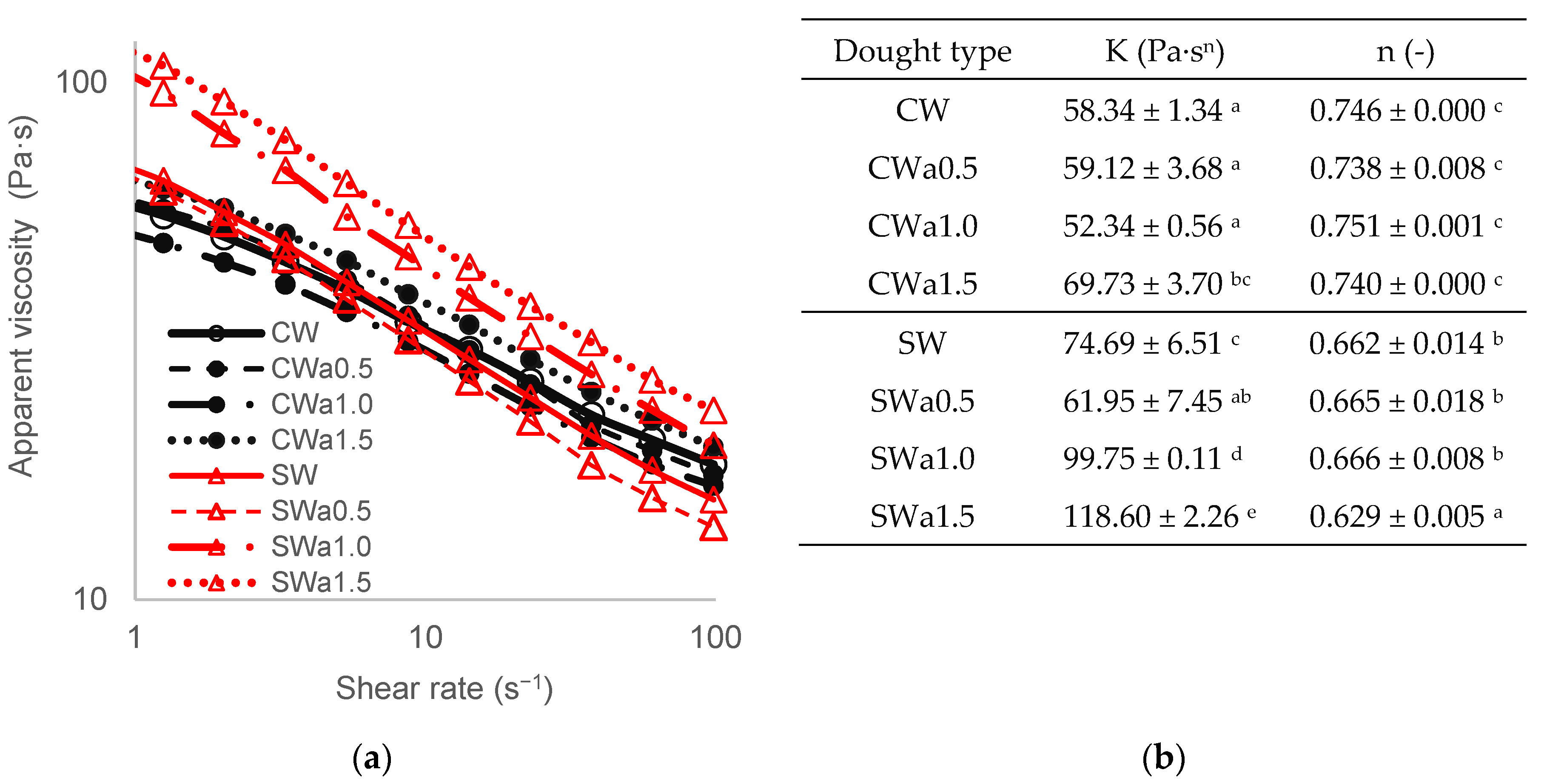

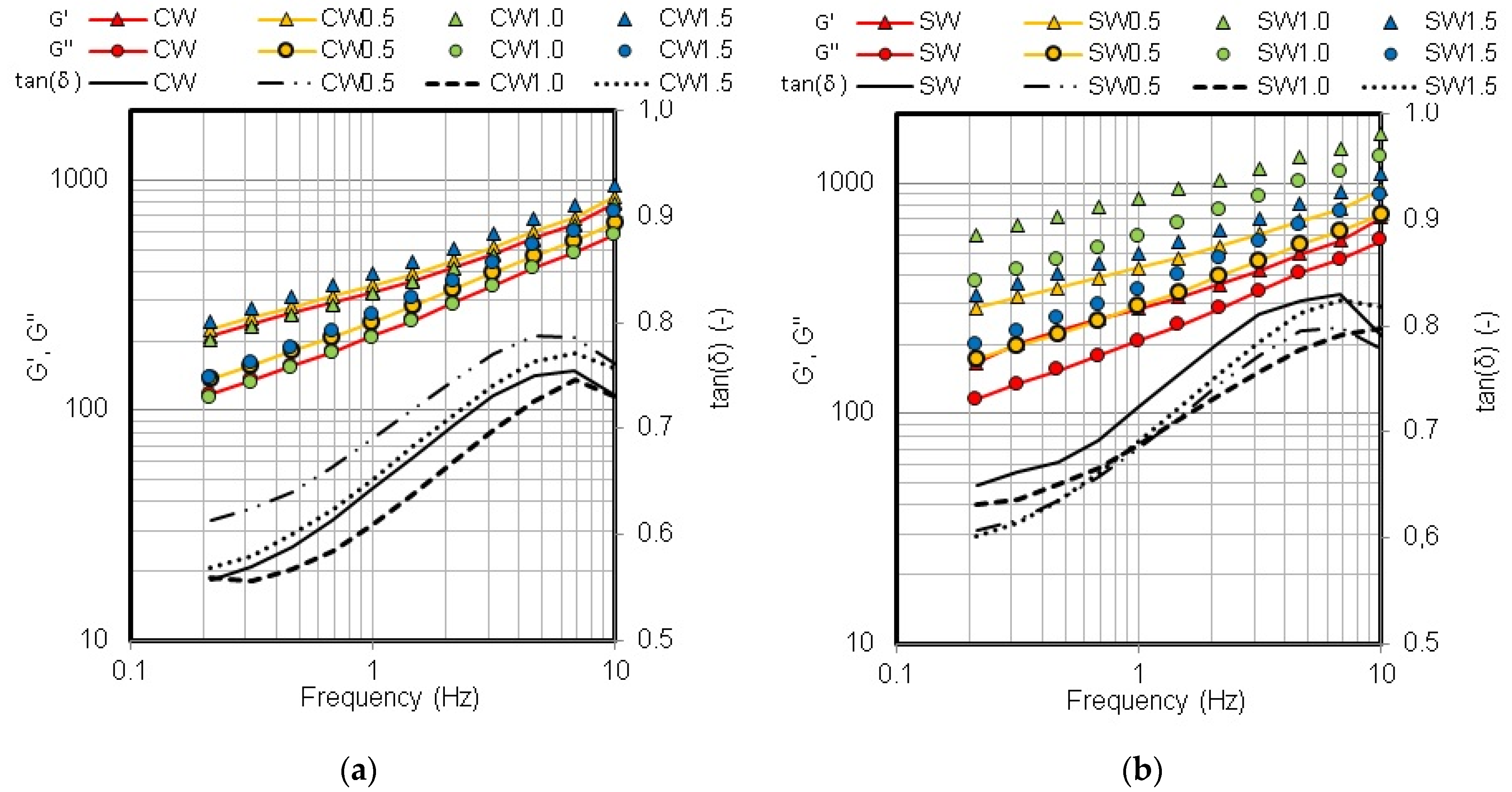

3.1. Rheological Properties of Dough

3.2. Water Content, Water Activity (aw), and Muffin Crumb Color

3.3. Two- and Three-Dimensional Microstructure of Muffin Crumb

3.4. Muffin Crumb Texture

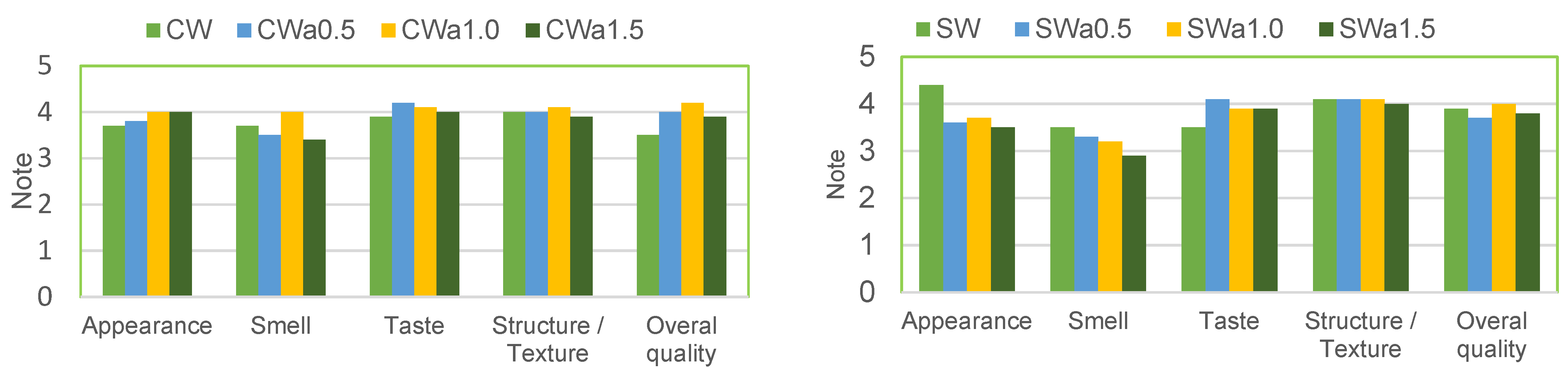

3.5. Sensorial Evaluation of Vegan Muffins

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| CW | Common wheat flour |

| SW | Whole spelt flour (50%), and wheat flour (50%), Microalgae addition: a0.5, a1.0, and a1.5% |

| G′ | Elastic modulus |

| G″ | Viscous modulus |

| tgδ | Loss angle |

| aw | Water activity |

| τ | Shear stress (Pa) |

| γ | Shear rate (s−1) |

| K | Consistency coefficient (Pa·sn) |

| n | Flow behavior index |

| r2 | Determination coefficient |

| L* | Lightness |

| a* | Redness |

| b* | Yellowness |

| C* | Chroma |

| hab | Hue |

References

- Available online: https://www.fao.org/fileadmin/templates/wsfs/docs/Issues_papers/HLEF2050_Global_Agriculture.pdf (accessed on 1 June 2023).

- Batista, A.P.; Gouveia, L.; Bandarra, N.; Franco, J.M.; Raymundo, A. Comparison of microalgal biomass profiles as novel functional ingredient for food products. Algal Res. 2013, 2, 164–173. [Google Scholar] [CrossRef] [Green Version]

- Barka, A.; Blecker, C. Microalgae as a potential source of single-cell proteins. Biotechnol. Agron. Soc. Environ. 2016, 20, 427–436. [Google Scholar] [CrossRef]

- Ramírez-Rodrigues, M.M.; Estrada-Beristain, C.; Metri-Ojeda, J.; Pérez-Alva, A.; Baigts-Allende, D.K. Spirulina platensis protein as sustainable ingredient for nutritional food products development. Sustainability 2021, 13, 6849. [Google Scholar] [CrossRef]

- Gong, D.; Sun, L.; Li, X.; Zhang, W.; Zhang, D.; Cai, J. Micro/Nanofabrication, Assembly, and Actuation Based on Microorganisms: Recent Advances and Perspectives. Small Struct. 2023, 2200356. [Google Scholar] [CrossRef]

- Andrade, L.M.; Andrade, C.J.; Dias, M.; Nascimento, C.A.O.; Mendes, M.A. Chlorella and Spirulina microalgae as sources offunctional foods, nutraceuticals, and food supplements; an overview. MOJ Food Process. Technol. 2018, 6, 45–58. [Google Scholar] [CrossRef] [Green Version]

- Batista, A.P.; Niccolai, A.; Fradinho, P.; Fragoso, S.; Bursic, I.; Rodolfi, L. Microalgae biomass as an alternative ingredient in cookies: Sensory, physical and chemical properties, antioxidant activity and in vitro digestibility. Algal Res. 2017, 26, 161–171. [Google Scholar] [CrossRef]

- Batista, A.P.; Niccolai, A.; Bursic, I.; Sousa, I.; Raymundo, A.; Rodolfi, L.; Biondi, N.; Tredici, M.R. Microalgae as functional ingredients in savory food products: Application to wheat crackers. Foods 2019, 8, 611. [Google Scholar] [CrossRef] [Green Version]

- Lucas, B.F.; Morais, M.G.D.; Santos, T.D.; Costa, J.A.V. Spirulina for snack enrichment: Nutritional, physical and sensory evaluations. LWT Food Sci. 2018, 90, 270–276. [Google Scholar] [CrossRef]

- Lucas, B.F.; da Rosa, A.P.C.; de Carvalho, L.F.; de Morais, M.G.; Santos, T.D.; Costa, J.A.V. Snack bars enriched with Spirulina for schoolchildren nutrition. Food Sci. Technol. 2020, 40 (Suppl. S1), 146–152. [Google Scholar] [CrossRef] [Green Version]

- De Marco Rodríguez, E.; Steffolani, M.E.; Martínez, C.S.; León, A.E. Effects of Spirulina biomass on the technological and nutritional quality of bread wheat pasta. LWT Food Sci. 2014, 58, 102–108. [Google Scholar] [CrossRef]

- Różyło, R.; Hameed Hassoon, W.; Gawlik-Dziki, U.; Siastała, M.; Dziki, D. Study on the physical and antioxidant properties of gluten-free bread with Brown algae. CyTA J. Food 2017, 15, 196–203. [Google Scholar] [CrossRef] [Green Version]

- Merchant, R.E.; Phillips, T.W.; Udani, J. Nutritional supplementation with Chlorella pyrenoidosa lowers serum methylmalonic acid in vegans and vegetarians with a suspected vitamin B₁₂ deficiency. J. Med. Food 2015, 18, 1357–1362. [Google Scholar] [CrossRef] [PubMed]

- Baixauli, R.; Sanz, T.; Salvador, A.; Fiszman, S.M. Muffins with resistant starch: Baking performance in relation to the rheological properties of the batter. J. Cereal Sci. 2008, 47, 502–509. [Google Scholar] [CrossRef]

- Sanz, T.; Salvador, Ć.A.; Fiszman, Ć.S.M. Evaluation of four types of resistant starch in muffin baking performance and relationship with batter rheology. Eur. Food Res. Technol. 2008, 227, 813–819. [Google Scholar] [CrossRef]

- Rajiv, J.; Soumya, C.; Indrani, D.; Venkateswara Rao, G. Effect of replacement of wheat flour with finger millet flour (Eleusine coracana) on the batter microscopy, rheology and quality characteristics of muffins. J. Texture Stud. 2011, 42, 478–489. [Google Scholar] [CrossRef]

- Bianchi, F.; Cervini, M.; Giuberti, G.; Rocchetti, G.; Lucini, L.; Simonato, B. Distilled grape pomace as a functional ingredient in vegan muffins: Effect on physicochemical, nutritional, rheological and sensory aspects. Int. J. Food Sci. Technol. 2022, 57, 4847–4858. [Google Scholar] [CrossRef]

- Shewry, P.R.; Hey, S.J. The contribution of wheat to human diet and health. Food Energy Secur. 2015, 4, 178–202. [Google Scholar] [CrossRef]

- Pruska-Kędzior, A.; Kędzior, Z.; Klockiewicz-Kaminska, E. Comparison of viscoelastic properties of gluten from spelt and common wheat. Eur. Food Res. Technol. 2008, 227, 199–207. [Google Scholar] [CrossRef]

- Frakolaki, G.; Giannou, V.; Topakas, E.; Tzia, C. Chemical characterization and breadmaking potential of spelt versus wheat flour. J. Cereal Sci. 2018, 79, 50–56. [Google Scholar] [CrossRef]

- Sinkovič, L.; Tóth, V.; Rakszegi, M.; Pipan, B. Elemental composition and nutritional characteristics of spelt flours and wholemeals. J. Elementol. 2023, 28, 27–39. [Google Scholar] [CrossRef]

- Marcet, I.; Collado, S.; Paredes, B.; Díaz, M. Rheological and textural properties in a bakery product as a function of the proportions of the egg yolk fractions: Discussion and modelling. Food Hydrocoll. 2015, 54, 119–129. [Google Scholar] [CrossRef]

- Marzec, A.; Kowalska, J.; Domian, E.; Galus, S.; Ciurzyńska, A.; Kowalska, H. Characteristics of dough rheology and the structural, mechanical, and sensory properties of sponge cakes with sweeteners. Molecules 2021, 26, 6638. [Google Scholar] [CrossRef] [PubMed]

- Shih, Y.T.; Wang, W.; Hasenbeck, A.; Stone, D.; Zhao, Y. Investigation of physicochemical, nutritional, and sensory qualities of muffins incorporated with dried brewer’s spent grain flours as a source of dietary fiber and protein. J. Food Sci. 2020, 85, 3943–3953. [Google Scholar] [CrossRef] [PubMed]

- Čáslavková, P.; Bednářová, M.; Ošťádalová, M.; Štarha, P.; Bednář, J.; Pokorná, J.; Tremlová, B.; Řezačová Lukášková, Z. Colour change of bakery products influenced by used additions. Acta Vet. Brno 2014, 83, 111–120. [Google Scholar] [CrossRef] [Green Version]

- Goswami, D.; Gupta, R.K.; Mridula, D.; Sharma, M.; Tyagi, S.K. Barnyard millet based muffins: Physical, textural and sensory properties. LWT Food Sci. 2015, 64, 374–380. [Google Scholar] [CrossRef]

- Bruker. Morphometric Parameters Measured by SkyscanTM CT-analyser Sofware. In Bruker-MicroCTCT-Analyser: Morphometric Parameters in 3D and 2D; Bruker: Billerica, MA, USA, 2008; pp. 1–49. [Google Scholar]

| Muffin Type | Water Content (%) | Water Activity (-) | ||

|---|---|---|---|---|

| CW | 25.68 ± 0.93 d | 0.889 ± 0.005 cd | ||

| CWa0.5 | 24.40 ± 0.09 c | 0.875 ± 0.013 abc | ||

| CWa1.0 | 23.99 ± 0.21 c | 0.860 ± 0.022 ab | ||

| CWa1.5 | 22.51 ± 0. 23 a | 0.845 ± 0.013 a | ||

| SW | 25.48 ± 0.30 d | 0.888 ± 0.003 cd | ||

| SWa0.5 | 24.25 ± 0.19 c | 0.895 ± 0.003 de | ||

| SWa1.0 | 23.20 ± 0.26 b | 0.908 ± 0.004 e | ||

| SWa1.5 | 22.53 ± 0.35 a | 0.923 ± 0.003 f | ||

| ANOVA | ||||

| Factor | F | p | F | p |

| Flour type (X) | 3.9 | 0.059 | 83.1 | <0.001 |

| Microalgae addition (Y) | 81.8 | <0.001 | 0.2 | 0.881 |

| X × Y | 1.5 | 0.231 | 19.0 | <0.001 |

| Muffin Type | L* | a* | b* | C* | hab (o) | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| CW | 70.20 ± 1.74 g | −0.66 ± 0.22 g | 19.03 ± 0.62 e | 19.04 ± 0.62 de | 91.95 ± 0.68 a | |||||

| CW0.5 | 59.91 ± 1.90 e | −5.04 ± 0.35 c | 18.73 ± 0.95 de | 19.40 ± 0.91 e | 105.07 ± 1.34 e | |||||

| CW1.0 | 55.36 ± 0.93 c | −5.91 ± 0.33 b | 18.13 ± 0.60 bc | 19.07 ± 0.65 de | 108.02 ± 0.69 f | |||||

| CW1.5 | 51.46 ± 1.14 b | −6.22 ± 0.41 a | 17.82 ± 0.62 c | 18.88 ± 0.70 d | 109.18 ± 0.78 g | |||||

| SW | 63.01 ± 1.75 f | 3.54 ± 0.40 h | 18.56 ± 0.57 d | 18.90 ± 0.59 d | 259.24 ± 1.11 h | |||||

| SW0.5 | 57.26 ± 1.71 d | −1.60 ± 0.36 f | 18.16 ± 0.44 c | 18.24 ± 0.45 c | 94.99 ± 1.09 b | |||||

| SW1.0 | 52.13 ± 1.08 b | −2.98 ± 0.30 e | 17.50 ± 0.30 b | 17.75 ± 0.31 b | 99.61 ± 0.94 c | |||||

| SW1.5 | 49.57 ± 1.05 a | −3.99 ± 0.22 d | 16.81 ± 0.70 a | 17.28 ± 0.69 a | 103.34 ± 0.81 d | |||||

| ANOVA | ||||||||||

| Factor | F | p | F | p | F | p | F | p | F | p |

| Flour type (X) | 263.1 | <0.001 | 3637.5 | <0.001 | 45.5 | <0.001 | 110.0 | <0.001 | 55819 | <0.001 |

| Microalgae addition (Y) | 919.5 | <0.001 | 3131.0 | <0.001 | 44.2 | <0.001 | 16.2 | <0.001 | 57274 | <0.001 |

| X × Y | 26.2 | <0.001 | 60.8 | <0.001 | 1.5 | 0.227 | 10.0 | <0.001 | 84054 | <0.001 |

| Muffin Type | 2D Microstructure (n = 541) | 3D Microstructure (n = 2) | ||||||

|---|---|---|---|---|---|---|---|---|

| Closed Porosity (%) | Open Porosity (%) | Average Pores Area (Mm2) | Total Porosity (%) | Percent Object Volume (%) | Number of Pores | Structure Mode Index (-) | Structure Thickness (Mm) | |

| CW | 33.84 ± 6.59 cd | 44.67 ± 10.24 b | 0.24 ± 0.06 g | 64.34 b | 35.66 b | 3036 a | −4.33 | 0.122 c |

| CWa0.5 | 37.17 ± 6.13 e | 39.56 ± 8.46 a | 0.16 ± 0.06 d | 62.95 a | 37.05 b | 3955 b | −3.71 | 0.108 a |

| CWa1.0 | 37.48 ± 7.81 e | 38.86 ± 10.04 a | 0.13 ± 0.04 b | 63.00 a | 37.00 b | 5234 d | −3.71 | 0.102 a |

| CWa1.5 | 33.41 ± 6.19 c | 48.98 ± 11.42 c | 0.20 ± 0.06 f | 67.08 c | 32.92 a | 3376 a | −4.36 | 0.118 c |

| SW | 28.14 ± 6.19 b | 56.43 ± 11.04 e | 0.17 ± 0.07 e | 69.45 d | 30.55 a | 3407 a | −4.37 | 0.117 c |

| SWa0.5 | 34.34 ± 7.43 d | 50.46 ± 9.80 d | 0.11 ± 0.05 a | 68.56 d | 31.44 a | 5896 e | −3.09 | 0.104 a |

| SWa1.0 | 36.80 ± 6.58 e | 43.64 ± 9.22 b | 0.14 ± 0.06 c | 65.35 b | 34.65 b | 4309 c | −3.43 | 0.105 a |

| SWa1.5 | 26.88 ± 5.36 a | 57.62 ± 5.43 f | 0.16 ± 0.06 d | 69.66 d | 30.34 a | 3691 a | −3.42 | 0.108 a |

| Muffin Type | Hardness (N) | Elasticity (-) | Cohesiveness (-) | Chewiness (-) | ||||

|---|---|---|---|---|---|---|---|---|

| CW | 62.55 ± 6.76 c | 0.85 ± 0.03 | 0.49 ± 0.04 | 25.85 ± 3.63 a | ||||

| CWa0.5 | 64.65 ± 8.28 d | 0.81 ± 0.04 | 0.46 ± 0.05 | 24.14 ± 2.71 a | ||||

| CWa1.0 | 62.17 ± 5.10 c | 0.82 ± 0.02 | 0.46 ± 0.04 | 23.41 ± 1.83 a | ||||

| CWa1.5 | 61.75 ± 5.86 c | 0.83 ± 0.02 | 0.46 ± 0.02 | 23.52 ± 2.08 a | ||||

| SW | 52.75 ± 5.10 a | 0.76 ± 0.06 | 0.42 ± 0.06 | 16.71 ± 2.77 b | ||||

| SWa0.5 | 57.41 ± 5.32 b | 0.76 ± 0.03 | 0.42 ± 0.05 | 18.16 ± 1.52 b | ||||

| SWa1.0 | 52.80 ± 4.33 a | 0.79 ± 0.03 | 0.45 ± 0.04 | 18.54 ± 1.33 b | ||||

| SWa1.5 | 52.25 ± 3.61 a | 0.77 ± 0.05 | 0.43 ± 0.05 | 17.12 ± 2.66 b | ||||

| ANOVA | ||||||||

| Factor | F | p | F | p | F | p | F | p |

| Flour type (X) | 100.97 | <0.001 | 3.27 | 0.072 | 2.93 | 0.088 | 82.50 | <0.001 |

| Microalgae addition (Y) | 4.28 | 0.006 | 1.48 | 0.221 | 0.61 | 0.609 | 1.02 | 0.387 |

| X × Y | 0.74 | 0.531 | 0.55 | 0.652 | 0.99 | 0.399 | 0.81 | 0.492 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Marzec, A.; Kramarczuk, P.; Kowalska, H.; Kowalska, J. Effect of Type of Flour and Microalgae (Chlorella vulgaris) on the Rheological, Microstructural, Textural, and Sensory Properties of Vegan Muffins. Appl. Sci. 2023, 13, 7632. https://doi.org/10.3390/app13137632

Marzec A, Kramarczuk P, Kowalska H, Kowalska J. Effect of Type of Flour and Microalgae (Chlorella vulgaris) on the Rheological, Microstructural, Textural, and Sensory Properties of Vegan Muffins. Applied Sciences. 2023; 13(13):7632. https://doi.org/10.3390/app13137632

Chicago/Turabian StyleMarzec, Agata, Patrycja Kramarczuk, Hanna Kowalska, and Jolanta Kowalska. 2023. "Effect of Type of Flour and Microalgae (Chlorella vulgaris) on the Rheological, Microstructural, Textural, and Sensory Properties of Vegan Muffins" Applied Sciences 13, no. 13: 7632. https://doi.org/10.3390/app13137632

APA StyleMarzec, A., Kramarczuk, P., Kowalska, H., & Kowalska, J. (2023). Effect of Type of Flour and Microalgae (Chlorella vulgaris) on the Rheological, Microstructural, Textural, and Sensory Properties of Vegan Muffins. Applied Sciences, 13(13), 7632. https://doi.org/10.3390/app13137632