Enhancing Energy Efficiency and Retention of Bioactive Compounds in Apple Drying: Comparative Analysis of Combined Hot Air–Infrared Drying Strategies

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experiments Setup

2.2. Details of the Experiment

2.3. Effective Moisture Diffusion Coefficient

- (a)

- Mass transfer of moisture inside the product continues only through diffusion.

- (b)

- The exit of moisture from the product is uniform.

- (c)

- External resistance against mass transfer is negligible.

- (d)

- Sample volume is constant during the drying process, and the effects of shrinkage are not taken into account.

- (e)

- The diffusion coefficient is constant.

- (f)

- (g)

- (h)

- (i)

2.4. Convective Mass Transfer

2.5. Activation Energy

2.6. Energy Efficiency

2.7. Measurement of Bioactive Compounds

2.7.1. Antioxidant Activity

2.7.2. Total Flavonoid Content (TFC)

2.7.3. Total Phenolic Content (TPC)

2.8. Uncertainty and Statistical Analysis

3. Results and Discussion

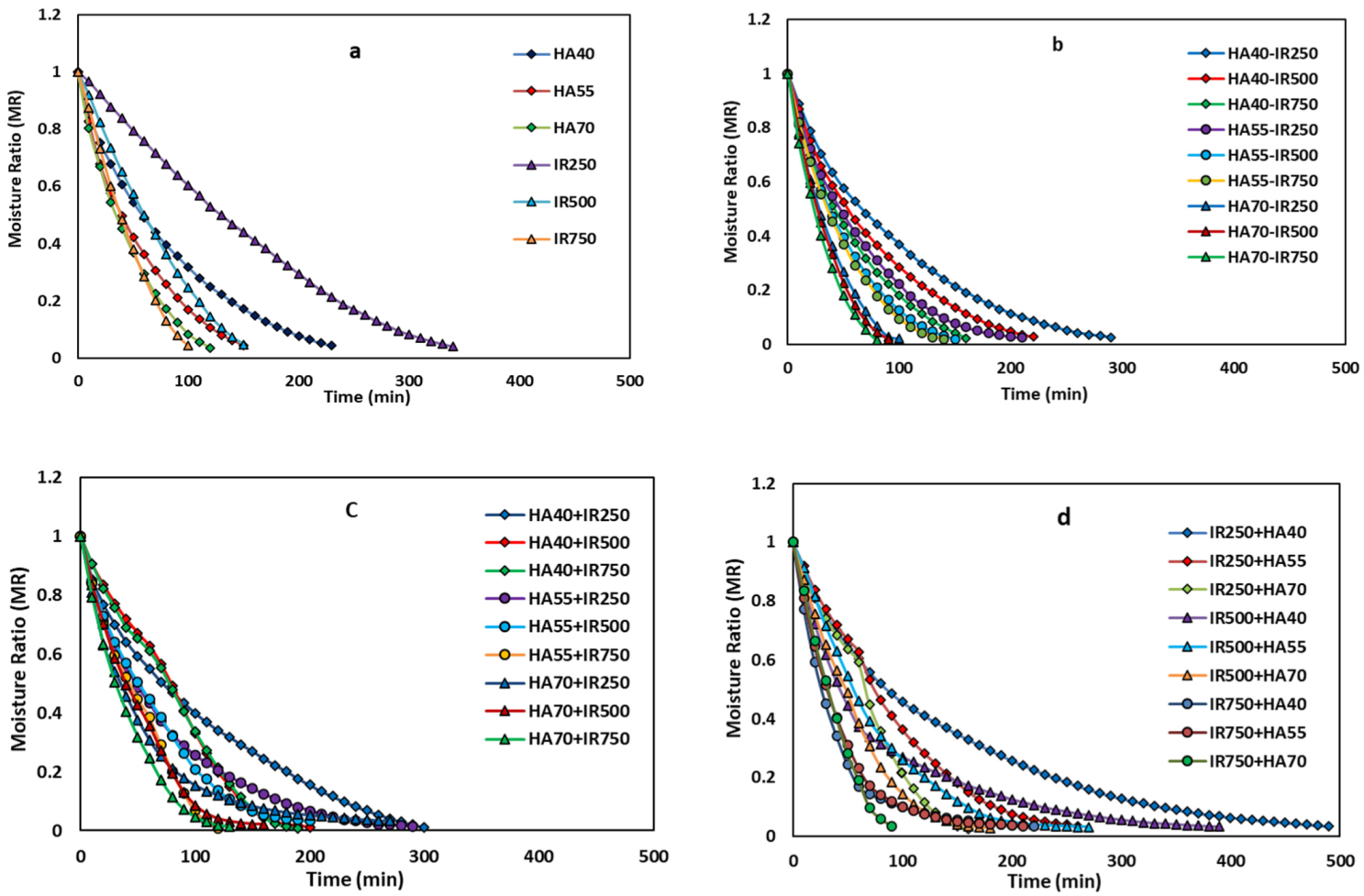

3.1. Investigation of Drying Kinetics in Different Strategies

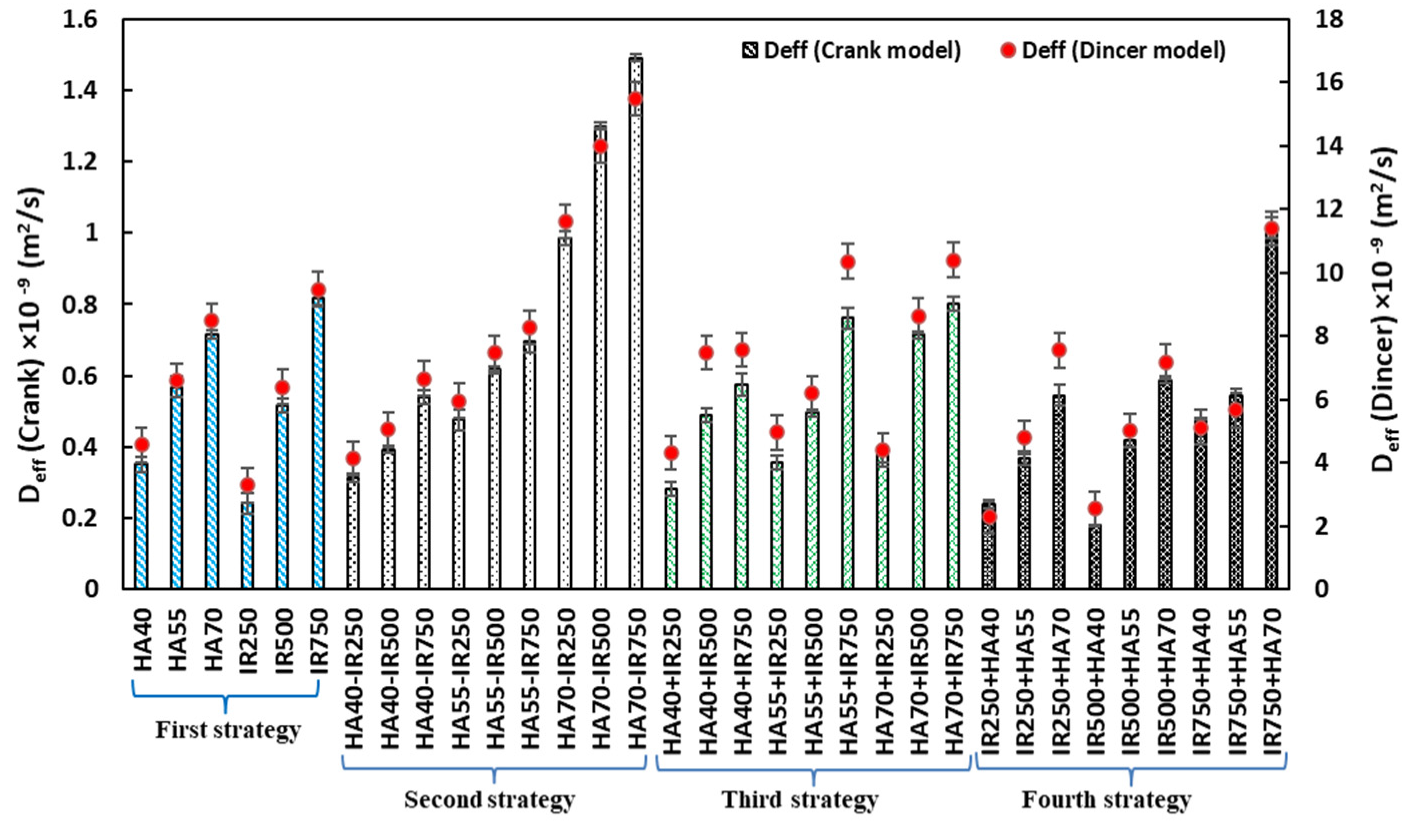

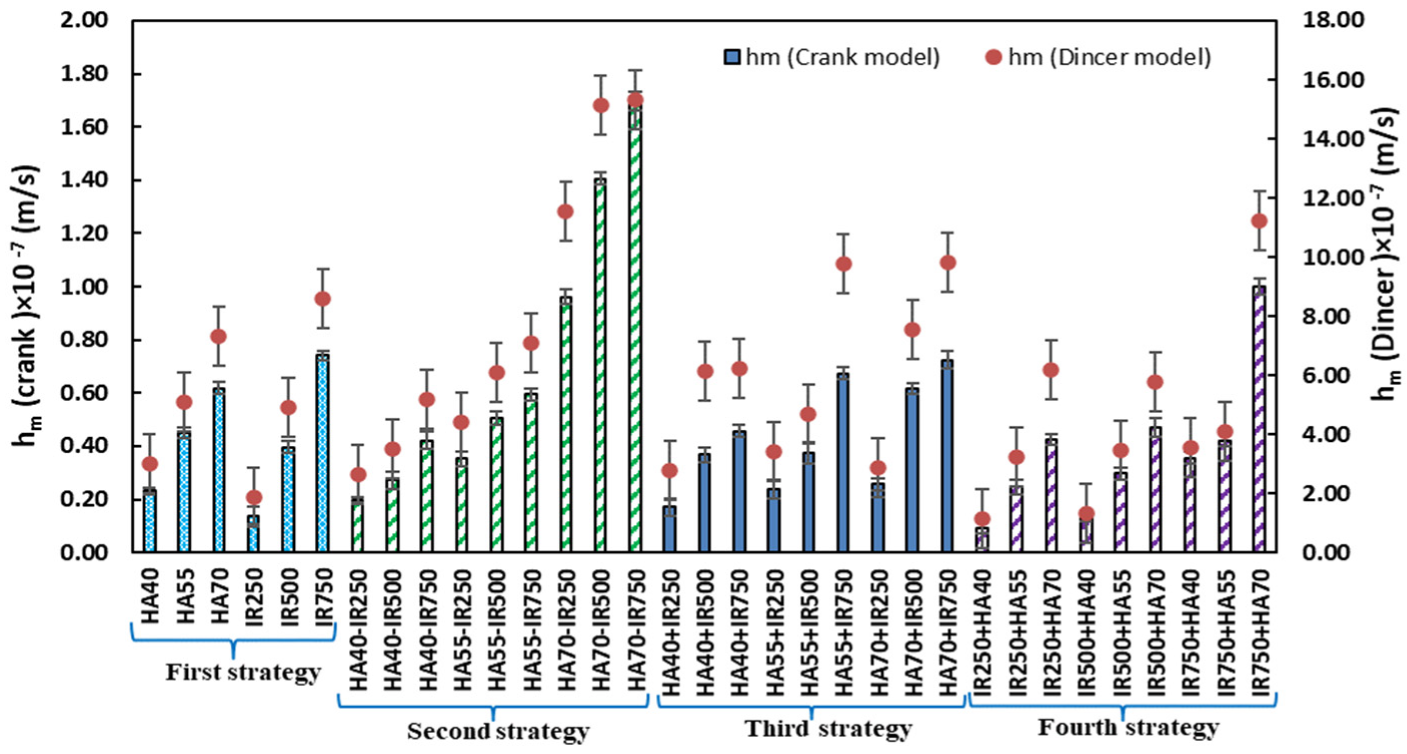

3.2. Investigation of Internal and External Mass Transfer in Different Strategies

3.3. Calculation of Activation Energy

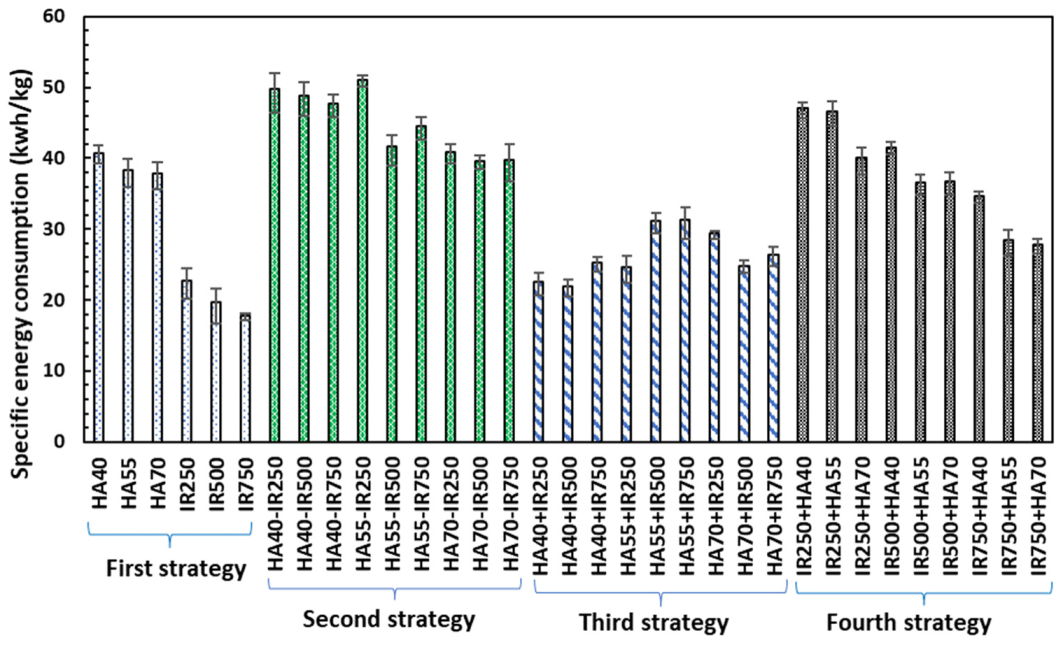

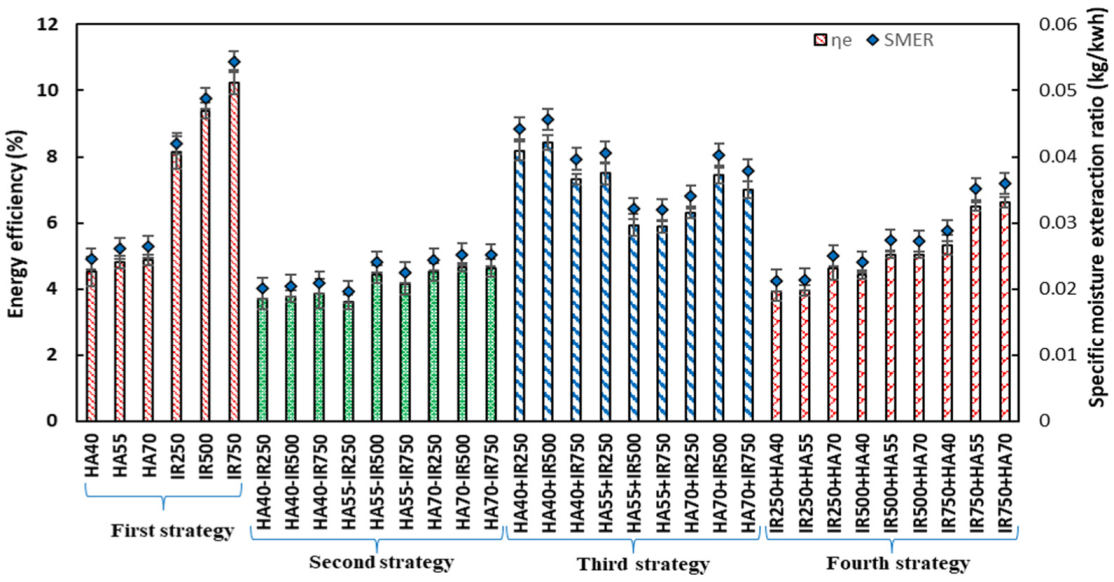

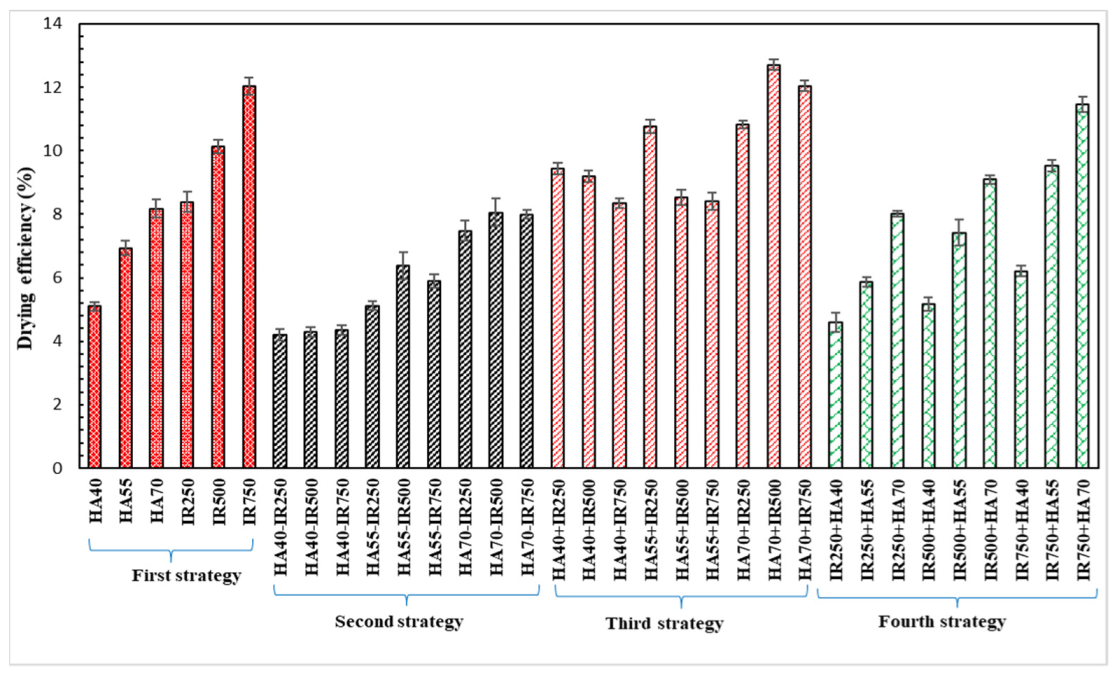

3.4. Energy Parameters in Different Strategies

3.5. Bioactive Compounds

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| Bim | Biot number | Qw | Energy required for extraction of moisture (kj) |

| Cm | Specific heat of sample (kj/kg °C) | Qm | Energy required for heating of sample (kJ) |

| DE | Drying efficiency (%) | R | Constant of gases (kJ/mol k) |

| Deff | Effective diffusivity (m2/s) | S | Drying rate constant (1/s) |

| Di | Dincer number | SEC | Specific energy consumption (kWh/kg) |

| Ec | Activation energy of convective mass transfer (kJ/mol) | SMER | Specific moisture extraction ratio (kg/kWh) |

| Ed | Activation energy of diffusion (kJ/mol) | T | Drying air temperature (°C) |

| Ec total | Total energy consumption (kWh) | Tm1 | Initial temperature of sample (°C) |

| G | Lag factor | Tm2 | Final temperature of sample (°C) |

| hfg | Latent heat of sample (kJ/kg) | t | Drying time (h) |

| hm | Convective mass transfer (m/s) | u | Velocity of drying air (m/s) |

| k | Function of effective diffusivity | wn | The uncertainties in the independent variables |

| L | Thickness of product (m) | WR | The total uncertainty (%) |

| M | Moisture content (%) | mp | Moisture content of sample (%) |

| MR | Moisture ratio | x | Characteristic dimension (m) |

| M0 | Initial moisture content (%) | zn | Independent variables |

| Me | Equilibrium moisture content (%) | µ1 | Function of Biot number |

| mi | Initial weight of sample (g) | ɳe | Energy efficiency (%) |

| mf | Final weight of sample (g) |

References

- Özdemir, Y.; Sayin, E.O.; Kurultay, Ş. Latest apple drying technologies: A Review. Int. J. Agric. Nat. Sci. 2009, 2, 43–46. [Google Scholar]

- Rajoriya, D.; Shewale, S.R.; Bhavya, M.; Hebbar, H.U. Far infrared assisted refractance window drying of apple slices: Comparative study on flavour, nutrient retention and drying characteristics. Innov. Food Sci. Emerg. Technol. 2020, 66, 102530. [Google Scholar] [CrossRef]

- Bernaert, N.; Van Droogenbroeck, B.; Van Pamel, E.; De Ruyck, H. Innovative refractance window drying technology to keep nutrient value during processing. Trends Food Sci. Technol. 2019, 84, 22–24. [Google Scholar] [CrossRef]

- Motevali, A.; Younji, S.; Chayjan, R.A.; Aghilinategh, N.; Banakar, A. Drying kinetics of dill leaves in a convective dryer. Int. Agrophys. 2013, 27, 39. [Google Scholar] [CrossRef] [Green Version]

- Abbaszadeh, A.; Motevali, A.; Ghobadian, B.; Khoshtaghaza, M.H.; Minaei, S. Effect of air velocity and temperature on energy and effective moisture diffusivity for russian olive (Elaeagnusan gastifolial L.) in thin-layer drying. Iran. J. Chem. Chem. Eng.-Int. Engl. Ed. 2012, 31, 65–69. [Google Scholar]

- Raghavi, L.; Moses, J.; Anandharamakrishnan, C. Refractance window drying of foods: A review. J. Food Eng. 2018, 222, 267–275. [Google Scholar] [CrossRef]

- Motevali, A.; Minaei, S. Effects of microwave pretreatment on the energy and exergy utilization in thin-layer drying of sour pomegranate arils. Chem. Ind. Chem. Eng. Q. 2012, 18, 63–72. [Google Scholar] [CrossRef]

- EL-Mesery, H.S.; Kamel, R.M.; Emara, R.Z. Influence of infrared intensity and air temperature on energy consumption and physical quality of dried apple using hybrid dryer. Case Stud. Therm. Eng. 2021, 27, 101365. [Google Scholar] [CrossRef]

- Calín-Sánchez, Á.; Lipan, L.; Cano-Lamadrid, M.; Kharaghani, A.; Masztalerz, K.; Carbonell-Barrachina, Á.A.; Figiel, A. Comparison of traditional and novel drying techniques and its effect on quality of fruits, vegetables and aromatic herbs. Foods 2020, 9, 1261. [Google Scholar] [CrossRef]

- Chasiotis, V.; Tzempelikos, D.; Filios, A. Assessment of constant and time-varying temperature schemes on the convective drying characteristics of hemp leaves. Case Stud. Therm. Eng. 2021, 26, 101098. [Google Scholar] [CrossRef]

- Joardder, M.U.; Karim, M. Drying kinetics and properties evolution of apple slices under convective and intermittent-MW drying. Therm. Sci. Eng. Prog. 2022, 30, 101279. [Google Scholar] [CrossRef]

- Shewale, S.R.; Rajoriya, D.; Hebbar, H.U. Low humidity air drying of apple slices: Effect of EMR pretreatment on mass transfer parameters, energy efficiency and quality. Innov. Food Sci. Emerg. Technol. 2019, 55, 1–10. [Google Scholar] [CrossRef]

- Motevali, A.; Minaei, S.; Khoshtagaza, M.H. Evaluation of energy consumption in different drying methods. Energy Convers. Manag. 2011, 52, 1192–1199. [Google Scholar] [CrossRef]

- Motevali, A.; Minaei, S.; Khoshtaghaza, M.H.; Amirnejat, H. Comparison of energy consumption and specific energy requirements of different methods for drying mushroom slices. Energy 2011, 36, 6433–6441. [Google Scholar] [CrossRef]

- Motevali, A.; Tabatabaee Koloor, R. A comparison between pollutants and greenhouse gas emissions from operation of different dryers based on energy consumption of power plants. J. Clean. Prod. 2020, 259, 120963. [Google Scholar] [CrossRef]

- Kumar, P.; Singh, D. Advanced technologies and performance investigations of solar dryers: A review. Renew. Energy Focus 2020, 35, 148–158. [Google Scholar] [CrossRef]

- Sadin, R.; Chegini, G.-R.; Sadin, H. The effect of temperature and slice thickness on drying kinetics tomato in the infrared dryer. Heat Mass Transf. 2014, 50, 501–507. [Google Scholar] [CrossRef]

- Younis, M.; Abdelkarim, D.; El-Abdein, A.Z. Kinetics and mathematical modeling of infrared thin-layer drying of garlic slices. Saudi J. Biol. Sci. 2018, 25, 332–338. [Google Scholar] [CrossRef]

- Şevik, S.; Aktaş, M.; Dolgun, E.C.; Arslan, E.; Tuncer, A.D. Performance analysis of solar and solar-infrared dryer of mint and apple slices using energy-exergy methodology. Sol. Energy 2019, 180, 537–549. [Google Scholar] [CrossRef]

- Samadi, S.H.; Loghmanieh, I. Evaluation of energy aspects of apple drying in the hot-air and infrared dryers. Energy Res. J. 2013, 4, 30–38. [Google Scholar] [CrossRef]

- Rahmanian-Koushkaki, H.; Nourmohamadi-Moghadami, A.; Zare, D.; Karimi, G. Experimental and theoretical investigation of hot air-infrared thin layer drying of corn in a fixed and vibratory bed dryer. Eng. Agric. Environ. Food 2017, 10, 191–197. [Google Scholar] [CrossRef]

- Witrowa-Rajchert, D.; Bawoł, A.; Czapski, J.; Kidoń, M. Studies on drying of purple carrot roots. Dry. Technol. 2009, 27, 1325–1331. [Google Scholar] [CrossRef]

- Ciurzynska, A.; Trusinska, M.; Rybak, K.; Wiktor, A.; Nowacka, M. The Influence of Pulsed Electric Field and Air Temperature on the Course of Hot-Air Drying and the Bioactive Compounds of Apple Tissue. Molecules 2023, 28, 2970. [Google Scholar] [CrossRef] [PubMed]

- Cruz, A.C.; Guiné, R.P.; Gonçalves, J.C. Drying kinetics and product quality for convective drying of apples (cvs. Golden Delicious and Granny Smith). Int. J. Fruit Sci. 2015, 15, 54–78. [Google Scholar] [CrossRef]

- Onwude, D.I.; Hashim, N.; Abdan, K.; Janius, R.; Chen, G. The effectiveness of combined infrared and hot-air drying strategies for sweet potato. J. Food Eng. 2019, 241, 75–87. [Google Scholar] [CrossRef]

- Kim, S.S.; Bhowmik, S.R. Effective moisture diffusivity of plain yogurt undergoing microwave vacuum drying. J. Food Eng. 1995, 24, 137–148. [Google Scholar] [CrossRef]

- Rafiee, S.; Keyhani, A.; Jafari, A. Modeling effective moisture diffusivity of wheat (Tajan) during air drying. Int. J. Food Prop. 2008, 11, 223–232. [Google Scholar] [CrossRef]

- Okos, M.; Narsimhan, G.; Singh, R.K.; Weitnauer, A. Handbook of Food Engineering; CRC Press: Boca Raton, FL, USA, 1992. [Google Scholar]

- Yağcioğlu, A.; Demir, V.; Günhan, T. Effective moisture diffusivity estimation from drying data. Tarım Mak. Bilim. Derg. 2007, 3, 249–256. [Google Scholar]

- Pasban, A.; Sadrnia, H.; Mohebbi, M.; Shahidi, S.A. Spectral method for simulating 3D heat and mass transfer during drying of apple slices. J. Food Eng. 2017, 212, 201–212. [Google Scholar] [CrossRef]

- Beigi, M. Energy efficiency and moisture diffusivity of apple slices during convective drying. Food Sci. Technol. 2016, 36, 145–150. [Google Scholar] [CrossRef] [Green Version]

- Mohammadi, I.; Tabatabaekoloor, R.; Motevali, A. Effect of air recirculation and heat pump on mass transfer and energy parameters in drying of kiwifruit slices. Energy 2019, 170, 149–158. [Google Scholar] [CrossRef]

- Darvishi, H.; Mohamamdi, P.; Azadbakht, M.; Farhudi, Z. Effect of different drying conditions on the mass transfer characteristics of kiwi slices. J. Agric. Sci. Technol. 2018, 20, 249–264. [Google Scholar]

- Naseri, M.; Rasoli Sharabiani, V.; Taghinezhad, E.; Kaveh, M. Design and Construction of Combined Fluid Bed Dryer with Infrared, Microwave and Hot Air Heat Sources; University of Mohaghegh Ardabili: Ardabil, Iran, 2021. [Google Scholar]

- Guiné, R.P.; Lima, M.J. Study of the drying kinetics and calculation of mass transfer properties in hot air drying of Cynara cardunculus. Open Agric. 2020, 5, 740–750. [Google Scholar] [CrossRef]

- Dincer, I.; Dost, S. A modelling study for moisture diffusivities and moisture transfer coefficients in drying of solid objects. Int. J. Energy Res. 1996, 20, 531–539. [Google Scholar] [CrossRef]

- Dincer, I.; Hussain, M. Development of a new Bi–Di correlation for solids drying. Int. J. Heat Mass Transf. 2002, 45, 3065–3069. [Google Scholar] [CrossRef]

- Motevali, A.; Minaei, S.; Banakar, A.; Ghobadian, B.; Khoshtaghaza, M.H. Comparison of energy parameters in various dryers. Energy Convers. Manag. 2014, 87, 711–725. [Google Scholar] [CrossRef]

- Ebrahimzadeh, M.A.; Nabavi, S.F.; Nabavi, S.M. Antioxidant activity of leaves and inflorescence of Eryngium Caucasicum Trautv at flowering stage. Pharmacogn. Res. 2009, 1, 435–439. [Google Scholar]

- Chang, C.C.; Yang, M.H.; Wen, H.M.; Chern, J.C. Estimation of total flavonoid content in proplis by two complementary colorimetric methods. Food Drug Anal. 2002, 10, 178–182. [Google Scholar]

- Slinkard, K.; Singleton, V.L. Total phenol analysis: Automation and comparison with manual methods. Am. J. Enol. Vitic. 1977, 28, 49–55. [Google Scholar] [CrossRef]

- Gaikwad, P.S.; Sunil, C.; Negi, A.; Pare, A. Effect of microwave assisted hot-air drying temperatures on drying kinetics of dried black gram papad (Indian snack food): Drying characteristics of black gram papad. Appl. Food Res. 2022, 2, 100144. [Google Scholar] [CrossRef]

- Taghinezhad, E.; Rasooli Sharabiani, V.; Kaveh, M. Modeling and optimization of hybrid HIR drying variables for processing of parboiled paddy using Response Surface Methodology. Iran. J. Chem. Chem. Eng. 2019, 38, 251–260. [Google Scholar]

- Chen, X.D. A discussion on a generalized correlation for drying rate modeling. Dry. Technol. 2005, 23, 415–426. [Google Scholar] [CrossRef]

- Guiné, R.; Barroca, M.J. Estimation of the diffusivities and mass transfer coefficients for the drying of D. Joaquina pears. In Proceedings of the World Congress of Engineering—The 2013 International Conference of Systems Biology and Bioengineering, London, UK, 3–5 July 2013. [Google Scholar]

- Ramírez, C.; Astorga, V.; Nuñez, H.; Jaques, A.; Simpson, R. Anomalous diffusion based on fractional calculus approach applied to drying analysis of apple slices: The effects of relative humidity and temperature. J. Food Process Eng. 2017, 40, e12549. [Google Scholar] [CrossRef]

| Instrument | Specification | Uncertainty |

|---|---|---|

| Centrifugal fan | Range 0–252 m3/h, 51 W-0.23 A | - |

| Infrared lamp | 250 W, 220–230 V, 125 × 185 mm | - |

| Wattmeter | Range 0–9999 w | ±1 W |

| Thermometer | Range −10–50 °C | ±1 °C |

| Temperature sensor | Range 0–900 °C | ±1 °C |

| Moisture sensor | Range 0–100% RH | ±2% |

| Digital balance | Range 0–600 g | ±0.01 g |

| Investigated Research | Products | System Type | Drying Condition | Calculation Model | De (m2/s) | hm (m/s) |

|---|---|---|---|---|---|---|

| [21] | Apple | HA, IR | T → 90–150 °C P → 0.22–0.49 W/Cm2 | Crank, 1975 | 3.49 × 10−7–5.10 × 10−7 | _ |

| [25] | Tomato | IR | T → 60–80 °C P → constant | Crank, 1975 | 1.90 × 10−9–4.46 × 10−9 | _ |

| [45] | Pears | HA | T → 60, 70 °C | Dincer and Hussain, 2002 | 8.60 × 10−10–11.85 × 10−10 | 5.37 × 10−8–8.38 × 10−8 |

| [31] | Apple | HA | T = 50–70 °C | Crank, 1975 | 1.28 × 10−9–6.75 × 10−9 | _ |

| [24] | Corn | HA, IR | T = 40–60 °C P = 1000–3000 W/m2 | Crank, 1975 | 0.61 × 10−8–5.55 × 10−8 | _ |

| [46] | Apple | HA | T = 30–50 °C | Crank, 1975 | 5.59 × 10−12–2.55 × 10−11 | _ |

| [34] | Kiwi | HA | T = 50–80 °C | Dincer and Dost, 1995 | 0.16 × 10−8–1.45 × 10−8 | 1.93 × 10−7–4.95 × 10−7 |

| [35] | Sweet potato | HA, IR | T = 50–70 °C P = 1100 W/m2 | Crank, 1975 | 8.4 × 10−9–2.4 × 10−8 | _ |

| [26] | Garlic slices | IR | P = 0.075–0.3 W/Cm2 | Crank, 1975 | 5.83 × 10−11–7.66 × 10−10 | _ |

| [33] | Kiwi | HA | T = 45–65 °C | Crank, 1975; Dincer and Dost, 1995 | 1.83 × 10−9–5.37 × 10−9 1.94 × 10−9–6.79 × 10−9 | 1.95 × 10−7–6.85 × 10−7 2.11 × 10−7–8.55 × 10−7 |

| [17] | Apple | HA | T = 40 °C | Dincer and Dost, 1995 | 1.22 × 10−9–1.80 × 10−9 3.83 × 10−10–5.76 × 10−10 | _ |

| [20] | Mint and apple | Solar HA, IR | T= collector temperature P = 100 W/m2 | Dincer and Hussain, 2002 | 3.27 × 10−11–4.09 × 10−11 | 1.21 × 10−8–1.54 × 10−8 |

| [32] | Cynara cardunculus | HA | T = 35–65 °C | Crank, 1975; Dincer and Hussain, 2002 | 2.78 × 10−9–1.40 × 10−8 1.92 × 10−10–1.2033 × 10−9 | _ |

| This study | Apple | HA, IR HA–IR HA+IR IR+HA | T = 40–70 °C P = 250–750 W/m2 | Crank, 1975; Dincer and Hussain, 2002 | 1.8 × 10−10–1.49 × 10−9 4.39 × 10−9–1.55 × 10−8 | 9.28 × 10−9–1.7 × 10−7 2.86 × 10−7–1.53 × 10−6 |

| Dincer Model | Crank Model | |||||||

|---|---|---|---|---|---|---|---|---|

| Treatment | G | S | R2 | DI | BI | Slop (k) | Intercept | R2 |

| HA40 | 1.07 > 1 | 2.16 × 10−4 | 0.994 | 1.16 × 106 | 0.132 | 2.16 × 10−4 | 0.070 | 0.989 |

| HA55 | 1.1 > 1 | 3.29 × 10−4 | 0.993 | 7.60 × 105 | 0.155 | 3.50 × 10−4 | 0.157 | 0.984 |

| HA70 | 1.21 > 1 | 4.41 × 10−4 | 0.981 | 5.67 × 105 | 0.173 | 4.41 × 10−4 | 0.187 | 0.976 |

| IR250 | 1.39 > 1 | 1.49 × 10−4 | 0.947 | 1.68 × 106 | 0.115 | 1.49 × 10−4 | 0.326 | 0.953 |

| IR500 | 1.34 > 1 | 3.18 × 10−4 | 0.95 | 7.86 × 105 | 0.153 | 3.18 × 10−4 | 0.296 | 0.951 |

| IR750 | 1.36 > 1 | 5.03 × 10−4 | 0.944 | 4.97 × 105 | 0.182 | 5.03 × 10−4 | 0.307 | 0.951 |

| HA40–IR250 | 1.09 > 1 | 1.93 × 10−4 | 0.993 | 1.30 × 106 | 0.127 | 1.93 × 10−4 | 0.083 | 0.989 |

| HA40–IR500 | 1.1 > 1 | 2.42 × 10−4 | 0.993 | 1.03 × 106 | 0.138 | 2.42 × 10−4 | 0.092 | 0.986 |

| HA40–IR750 | 1.14 > 1 | 3.33 × 10−4 | 0.989 | 7.51 × 105 | 0.156 | 3.33 × 10−4 | 0.132 | 0.979 |

| HA55–IR250 | 1.13 > 1 | 2.93 × 10−4 | 0.991 | 8.53 × 105 | 0.148 | 2.93 × 10−4 | 0.118 | 0.990 |

| HA55–IR500 | 1.14 > 1 | 3.80 × 10−4 | 0.989 | 6.58 × 105 | 0.163 | 3.80 × 10−4 | 0.128 | 0.985 |

| HA55–IR750 | 1.19 > 1 | 4.29 × 10−4 | 0.984 | 5.83 × 105 | 0.171 | 4.29 × 10−4 | 0.173 | 0.980 |

| HA70–IR250 | 1.37 > 1 | 6.40 × 10−4 | 0.961 | 3.91 × 105 | 0.199 | 6.08 × 10−4 | 0.258 | 0.950 |

| HA70–IR500 | 1.42 > 1 | 8.01 × 10−4 | 0.97 | 3.12 × 105 | 0.216 | 8.01 × 10−4 | 0.350 | 0.930 |

| HA70–IR750 | 1.24 > 1 | 6.31 × 10−4 | 0.956 | 3.96 × 105 | 0.198 | 9.19 × 10−4 | 0.215 | 0.959 |

| HA40+IR250 | 1.27 > 1 | 2.02 × 10−4 | 0.972 | 1.24 × 106 | 0.129 | 1.73 × 10−4 | 0.078 | 0.968 |

| HA40+IR500 | 1.97 > 1 | 3.86 × 10−4 | 0.834 | 6.48 × 105 | 0.164 | 3.54 × 10−4 | 0.559 | 0.877 |

| HA40+IR750 | 1.94 > 1 | 3.81 × 10−4 | 0.832 | 6.56 × 105 | 0.164 | 3.02 × 10−4 | 0.390 | 0.899 |

| HA55+IR250 | 1.05 > 1 | 2.37 × 10−4 | 0.997 | 1.05 × 106 | 0.137 | 2.20 × 10−4 | 0.039 | 0.997 |

| HA55+IR500 | 1.18 > 1 | 3.06 × 10−4 | 0.981 | 8.17 × 105 | 0.151 | 3.06 × 10−4 | 0.166 | 0.985 |

| HA55+IR750 | 1.7 > 1 | 5.58 × 10−4 | 0.893 | 4.48 × 105 | 0.189 | 4.69 × 10−4 | 0.335 | 0.894 |

| HA70+IR250 | 0.665 | 2.07 × 10−4 | 0.957 | 1.21 × 106 | 0.130 | 2.33 × 10−4 | 0.282 | 0.975 |

| HA70+IR500 | 1.37 > 1 | 5.61 × 10−4 | 0.958 | 4.46 × 105 | 0.189 | 4.94 × 10−4 | 0.171 | 0.977 |

| HA70+IR750 | 1.33 > 1 | 4.51 × 10−4 | 0.967 | 5.54 × 105 | 0.174 | 4.40 × 10−4 | 0.262 | 0.960 |

| IR250+HA40 | 0.943 | 1.12 × 10−4 | 0.994 | 2.23 × 106 | 0.103 | 1.11 × 10−4 | −0.067 | 0.998 |

| IR250+HA55 | 1.27 > 1 | 2.29 × 10−4 | 0.970 | 1.09 × 106 | 0.135 | 2.26 × 10−4 | 0.228 | 0.986 |

| IR250+HA70 | 1.62 > 1 | 3.85 × 10−4 | 0.875 | 6.49 × 105 | 0.164 | 3.36 × 10−4 | 0.342 | 0.931 |

| IR500+HA40 | 0.695 | 1.00 × 10−4 | 0.919 | 2.50 × 106 | 0.099 | 1.46 × 10−4 | −0.312 | 0.985 |

| IR500+HA55 | 1.06 > 1 | 2.41 × 10−4 | 0.996 | 1.04 × 106 | 0.138 | 2.58 × 10−4 | 0.142 | 0.994 |

| IR500+HA70 | 1.24 > 1 | 3.64 × 10−4 | 0.974 | 6.87 × 105 | 0.161 | 3.62 × 10−4 | 0.207 | 0.987 |

| IR750+HA40 | 0.576 | 2.46 × 10−4 | 0.919 | 1.02 × 106 | 0.139 | 2.95 × 10−4 | −0.365 | 0.945 |

| IR750+HA55 | 0.701 | 2.76 × 10−4 | 0.970 | 9.06 × 105 | 0.145 | 3.34 × 10−4 | −0.146 | 0.980 |

| IR750+HA70 | 1.39 > 1 | 6.26 × 10−4 | 0.939 | 3.99 × 105 | 0.197 | 6.26 × 10−4 | 0.329 | 0.959 |

| Crank Diffusion | Dincer Diffusion | Crank Convection | Dincer Convection | |||||

|---|---|---|---|---|---|---|---|---|

| Ed | R2 | Ed | R2 | Ec | R2 | Ec | R2 | |

| HA | 21.32346 | 0.969 | 18.43989 | 0.993 | 29.31768 | 0.9699 | 26.41749 | 0.993 |

| HA–IR250 | 33.95466 | 0.967 | 30.56418 | 0.963 | 46.69389 | 0.967 | 43.86018 | 0.962 |

| HA–IR500 | 35.43384 | 0.972 | 30.23178 | 0.974 | 48.72153 | 0.972 | 43.51947 | 0.9738 |

| HA–IR750 | 30.01572 | 0.94 | 24.87183 | 0.913 | 41.15943 | 0.908 | 31.97688 | 0.931 |

| df | AA | TPC | TFC | Deff | Hm | ɳe | DE | SEC | |

|---|---|---|---|---|---|---|---|---|---|

| S | 2 | 3.73 ** | 62.71 ** | 91.53 ** | 5.55 × 10−19 ** | 8.53 × 10−15 ** | 62.01 ** | 113.06 ** | 2333.73 ** |

| T | 2 | 0.90 ** | 40.31 ** | 27.68 ** | 1.45 × 10−18 ** | 2.13 × 10−14 ** | 4.32 ** | 68.70 ** | 379.06 ** |

| I | 2 | 0.18 ns | 0.46 ns | 0.52 ns | 9.21 × 10−19 ** | 1.14 × 10−14 ** | 0.61 ** | 12.19 ** | 69.09 ** |

| S*T | 4 | 0.73 ** | 71.58 ** | 54.31 ** | 3.24 × 10−19 ** | 5.66 × 10−15 ** | 5.93 ** | 1.09 ** | 225.52 ** |

| S*I | 4 | 0.29 ** | 5.55 ** | 2.37 ** | 1.53 × 10−20 ** | 1.56 × 10−16 ** | 1.18 ** | 14.90 ** | 61.23 ** |

| T*I | 4 | 0.25 * | 5.07 ** | 7.54 ** | 2.65 × 10−20 ** | 7.24 × 10−16 ** | 0.64 ** | 2.31 ** | 13.60 ** |

| S*T*I | 8 | 0.36 ** | 5.07 ** | 6.168 ** | 1.69 × 10−20 ** | 2.82 × 10−16 ** | 0.78 ** | 1.38 ** | 25.61 ** |

| Error | 54 | 0.06 | 0.18 | 0.24 | 3.88 × 10−20 | 7.35 × 10−18 | 0.06 | 0.05 | 0.42 |

| Treatment | TPC (mg GAE/g) | TFC (mg CE/g) | AA (%) |

|---|---|---|---|

| HA40 | 15.70 ± 0.52 | 12.52 ± 0.69 | 67.72 ± 0.11 |

| HA55 | 11.42 ± 0.45 | 10.14 ± 0.41 | 68.01 ± 0.03 |

| HA70 | 9.18 ± 0.11 | 7.67 ± 0.32 | 68.26 ± 0.09 |

| IR250 | 21.84 ± 0.15 | 21.64 ± 0.83 | 68.44 ± 0.11 |

| IR500 | 18.37 ± 0.36 | 17.81 ± 0.65 | 68.39 ± 0.04 |

| IR750 | 7.04 ± 0.04 | 5.44 ± 0.21 | 68.23 ± 0.06 |

| HA40–IR250 | 6.71 ± 0.12 | 5.07 ± 0.23 | 67.53 ± 0.08 |

| HA40–IR500 | 6.05 ± 0.04 | 4.33 ± 0.17 | 67.36 ± 0.07 |

| HA40–IR750 | 6.16 ± 0.03 | 4.45 ± 0.11 | 67.36 ± 0.1 |

| HA55–IR250 | 5.61 ± 0.23 | 3.83 ± 0.08 | 66.50 ± 0.03 |

| HA55–IR500 | 6.49 ± 0.18 | 4.82 ± 0.10 | 66.51 ± 0.05 |

| HA55–IR750 | 5.61 ± 0.19 | 3.83 ± 0.14 | 66.50 ± 0.08 |

| HA70–IR250 | 5.50 ± 0.06 | 3.71 ± 0.09 | 66.50 ± 0.09 |

| HA70–IR500 | 4.25 ± 0.08 | 4.58 ± 0.18 | 67.88 ± 0.03 |

| HA70–IR750 | 8.50 ± 0.24 | 7.17 ± 0.34 | 67.39 ± 0.04 |

| HA40+IR250 | 10.46 ± 0.16 | 9.40 ± 0.22 | 67.42 ± 0.04 |

| HA40+IR500 | 7.52 ± 0.25 | 6.06 ± 0.20 | 67.38 ± 0.09 |

| HA40+IR750 | 7.36 ± 0.29 | 5.44 ± 0.26 | 67.38 ± 0.05 |

| HA55+IR250 | 11.85 ± 0.12 | 10.26 ± 0.29 | 67.44 ± 0.03 |

| HA55+IR500 | 13.80 ± 0.17 | 12.37 ± 0.25 | 67.04 ± 0.03 |

| HA55+IR750 | 15.14 ± 0.19 | 14.10 ± 0.28 | 67.06 ± 0.06 |

| HA70+IR250 | 3.56 ± 0.02 | 3.65 ± 0.21 | 67.35 ± 0.02 |

| HA70+IR500 | 7.46 ± 0.15 | 5.69 ± 0.22 | 66.95 ± 0.07 |

| HA70+IR750 | 3.14 ± 0.19 | 5.00 ± 0.24 | 68.02 ± 0.07 |

| IR250+HA40 | 7.35 ± 0.20 | 5.56 ± 0.12 | 67.72 ± 0.08 |

| IR250+HA55 | 5.54 ± 0.24 | 3.59 ± 0.32 | 67.69 ± 0.05 |

| IR250+HA70 | 6.99 ± 0.11 | 5.32 ± 0.09 | 67.72 ± 0.07 |

| IR500+HA40 | 6.99 ± 0.13 | 5.32 ± 0.15 | 67.72 ± 0.08 |

| IR500+HA55 | 6.33 ± 0.09 | 4.58 ± 0.18 | 67.71 ± 0.09 |

| IR500+HA70 | 4.00 ± 0.02 | 4.20 ± 0.06 | 68.19 ± 0.07 |

| IR750+HA40 | 7.66 ± 0.22 | 6.06 ± 0.11 | 67.81 ± 0.04 |

| IR750+HA55 | 7.33 ± 0.24 | 5.69 ± 0.13 | 67.81 ± 0.08 |

| IR750+HA70 | 6.44 ± 0.09 | 4.70 ± 0.07 | 67.79 ± 0.02 |

| S | T | I | AA | TPC | TFC | Deff | hm | ɳe | DE | SEC |

|---|---|---|---|---|---|---|---|---|---|---|

| HA–IR | 40 | 250 | 67.53 bcde | 6.71 fghi | 5.07 ghijk | 3.13 × 10−10 n | 1.98 × 10−8 mn | 4.19 m | 4.19 m | 49.77 b |

| 500 | 67.36 cdef | 6.05 ij | 4.33 klmno | 3.92 × 10−10 kl | 2.71 × 10−8 kl | 4.30 m | 4.30 m | 48.86 b | ||

| 750 | 67.36 cdef | 6.16 ij | 4.45 klmn | 5.40 × 10−10 i | 4.20 × 10−8 i | 4.35 m | 4.35 m | 47.74 c | ||

| 55 | 250 | 66.50 gi | 5.61 j | 3.83 mno | 4.75 × 10−10 j | 3.52 × 10−8 j | 5.12 l | 5.12 l | 51.04 a | |

| 500 | 66.51 h | 6.49 ghij | 4.82 hijkl | 6.16 × 10−10 g | 5.04 × 10−8 g | 6.38 j | 6.38 j | 41.59 e | ||

| 750 | 66.50 gi | 5.61 j | 3.83 mno | 6.96 × 10−10 f | 5.95 × 10−8 f | 5.88 k | 5.88 k | 44.52 d | ||

| 70 | 250 | 66.50 gi | 5.50 j | 3.71 no | 9.86 × 10−10 c | 9.61 × 10−8 c | 7.47 i | 7.47 i | 40.89 ef | |

| 500 | 67.88 abc | 4.25 k | 4.58 jklm | 1.29 × 10−9 b | 1.40 × 10−7 b | 8.05 h | 8.05 h | 39.65 g | ||

| 750 | 67.39 cdef | 8.50 e | 7.17 e | 1.49 × 10−9 a | 1.69 × 10−7 a | 7.99 h | 7.99 h | 39.81 fg | ||

| HA+IR | 40 | 250 | 67.42 cdef | 10.46 d | 9.40 d | 2.80 × 10−10 o | 1.70 × 10−8 no | 9.43 ef | 9.43 ef | 22.61 n |

| 500 | 67.38 cdef | 7.52 f | 6.06 f | 4.90 × 10−10 j | 3.67 × 10−8 j | 9.19 ef | 5.86 k | 21.91 n | ||

| 750 | 67.38 cdef | 7.36 fgh | 5.44 fghi | 5.74 × 10−10 hi | 4.57 × 10−8 hi | 8.34 gh | 8.34 gh | 25.22 m | ||

| 55 | 250 | 67.44 cdef | 11.85 c | 10.26 c | 1.80 × 10−10 q | 2.37 × 10−8 lm | 10.75 d | 10.75 d | 24.62 m | |

| 500 | 67.04 ef | 13.80 b | 12.37 b | 4.96 × 10−10 j | 3.74 × 10−8 j | 8.53 g | 8.53 g | 31.09 j | ||

| 750 | 67.06 ef | 15.14 a | 14.10 a | 7.61 × 10−10 e | 6.73 × 10−8 e | 8.39 gh | 8.39 gh | 31.30 j | ||

| 70 | 250 | 67.35 def | 3.56 kl | 3.65 no | 3.78 × 10−10 lm | 2.57 × 10−8 kl | 10.82 d | 10.82 d | 29.34 k | |

| 500 | 66.95 fg | 7.46 fg | 5.69 fg | 7.14 × 10−10 f | 6.16 × 10−8 f | 12.71 a | 12.71 a | 24.83 m | ||

| 750 | 68.02 ab | 3.14 l | 5.00 ghijkl | 8.01 × 10−10 d | 7.23 × 10−8 d | 12.04 b | 12.04 b | 26.36 l | ||

| IR+HA | 40 | 250 | 67.72 abcd | 7.35 fgh | 5.56 fgh | 2.36 × 10−10 p | 9.28 × 10−9 p | 4.59 m | 4.59 m | 47.00 c |

| 500 | 67.69 abcd | 5.54 j | 3.59 o | 3.66 × 10−10 lm | 2.46 × 10−8 l | 5.86 k | 9.19 ef | 46.64 c | ||

| 750 | 67.72 abcd | 6.99 fghi | 5.32 fghij | 5.45 × 10−10 i | 4.25 × 10−8 hi | 8.00 h | 8.00 h | 40.00 fg | ||

| 55 | 250 | 67.72 abcd | 6.99 fghi | 5.32 fghij | 3.57 × 10−10 m | 1.35 × 10−8 op | 5.15 l | 5.15 l | 41.57 e | |

| 500 | 67.71 abcd | 6.33 ij | 4.58 jklm | 4.18 × 10−10 k | 2.95 × 10−8 k | 7.41 i | 7.41 i | 36.57 h | ||

| 750 | 68.19 a | 4.00 kl | 4.20 lmno | 5.87 × 10−10 gh | 4.71 × 10−8 gh | 9.09 f | 9.09 f | 36.72 h | ||

| 70 | 250 | 67.81 abcd | 7.66 ef | 6.06 f | 4.78 × 10−10 j | 3.55 × 10−8 j | 6.20 jk | 6.20 jk | 34.67 i | |

| 500 | 67.81 abcd | 7.33 fgh | 5.69 fg | 5.42 × 10−10 i | 4.22 × 10−8 i | 9.52 e | 9.52 e | 28.47 k | ||

| 750 | 67.79 abcd | 6.44 hij | 4.70 ijkl | 1.01 × 10−9 c | 1.00 × 10−7 c | 11.46 c | 11.46 c | 22.70 n |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Teymori-Omran, M.; Askari Asli-Ardeh, E.; Taghinezhad, E.; Motevali, A.; Szumny, A.; Nowacka, M. Enhancing Energy Efficiency and Retention of Bioactive Compounds in Apple Drying: Comparative Analysis of Combined Hot Air–Infrared Drying Strategies. Appl. Sci. 2023, 13, 7612. https://doi.org/10.3390/app13137612

Teymori-Omran M, Askari Asli-Ardeh E, Taghinezhad E, Motevali A, Szumny A, Nowacka M. Enhancing Energy Efficiency and Retention of Bioactive Compounds in Apple Drying: Comparative Analysis of Combined Hot Air–Infrared Drying Strategies. Applied Sciences. 2023; 13(13):7612. https://doi.org/10.3390/app13137612

Chicago/Turabian StyleTeymori-Omran, Milad, Ezzatollah Askari Asli-Ardeh, Ebrahim Taghinezhad, Ali Motevali, Antoni Szumny, and Małgorzata Nowacka. 2023. "Enhancing Energy Efficiency and Retention of Bioactive Compounds in Apple Drying: Comparative Analysis of Combined Hot Air–Infrared Drying Strategies" Applied Sciences 13, no. 13: 7612. https://doi.org/10.3390/app13137612

APA StyleTeymori-Omran, M., Askari Asli-Ardeh, E., Taghinezhad, E., Motevali, A., Szumny, A., & Nowacka, M. (2023). Enhancing Energy Efficiency and Retention of Bioactive Compounds in Apple Drying: Comparative Analysis of Combined Hot Air–Infrared Drying Strategies. Applied Sciences, 13(13), 7612. https://doi.org/10.3390/app13137612