Full Anchor Cable Support Mechanism and Application of Roadway with Thick Soft Rock Mass Immediate Roof

Abstract

:1. Introduction

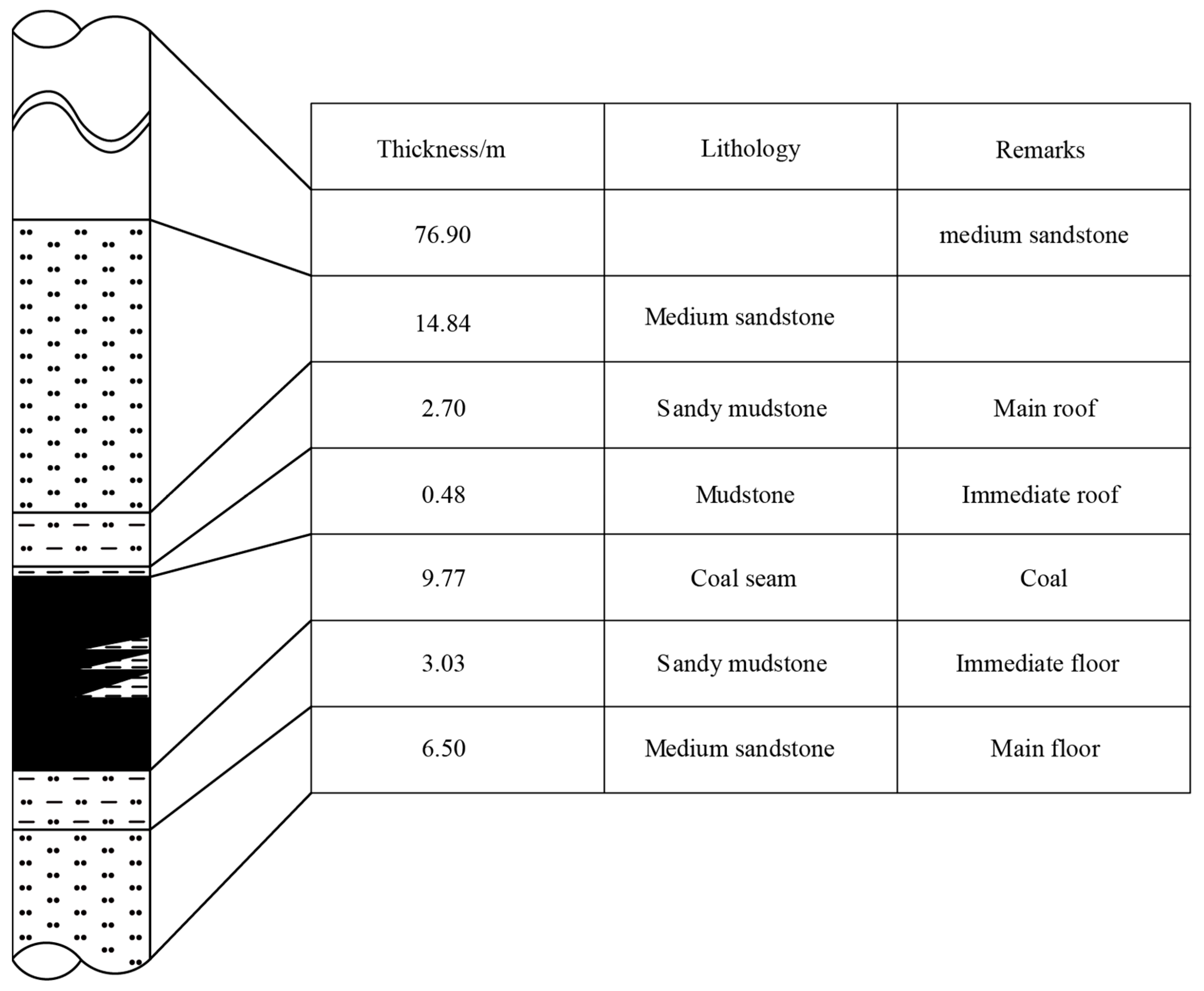

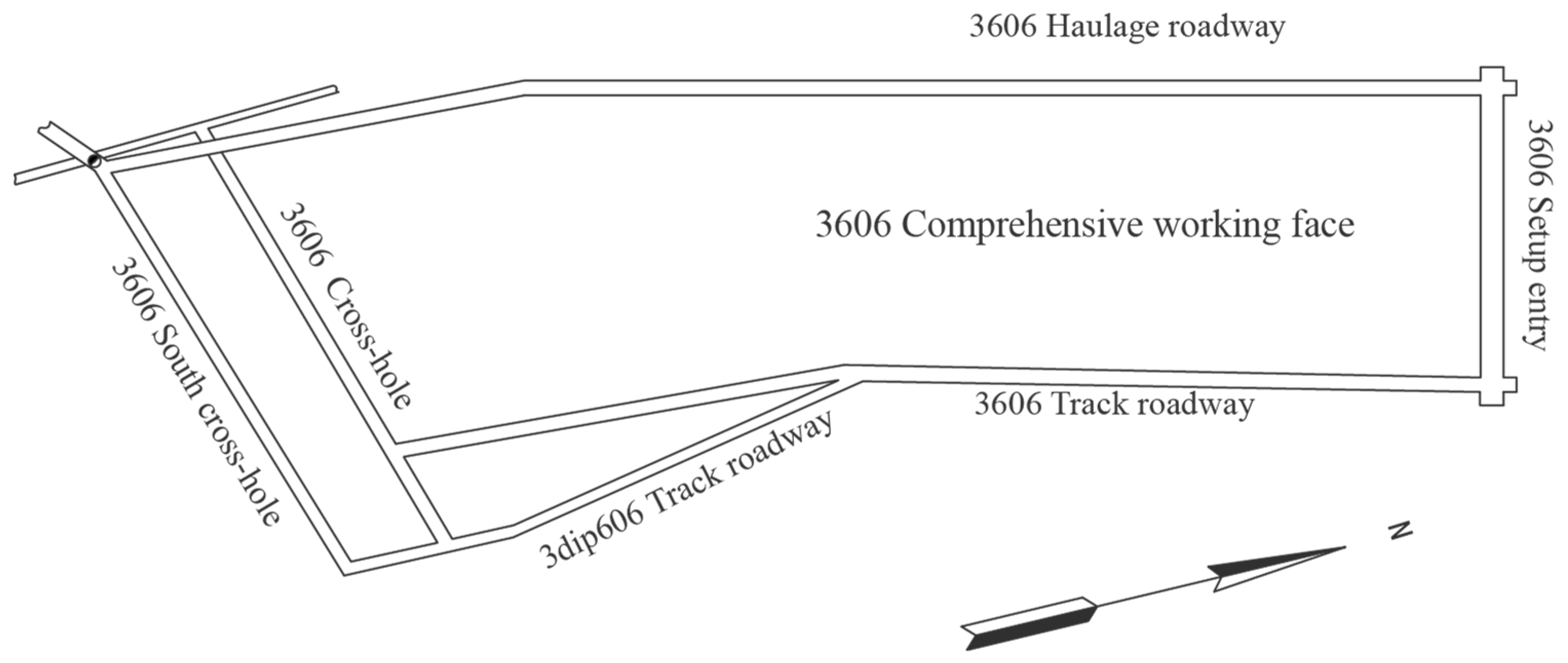

2. Site Geological and Engineering Characteristics

3. Full Anchor Cable Support Mechanism for the Immediate Roof of a Thick Soft Rock Mass Roadway

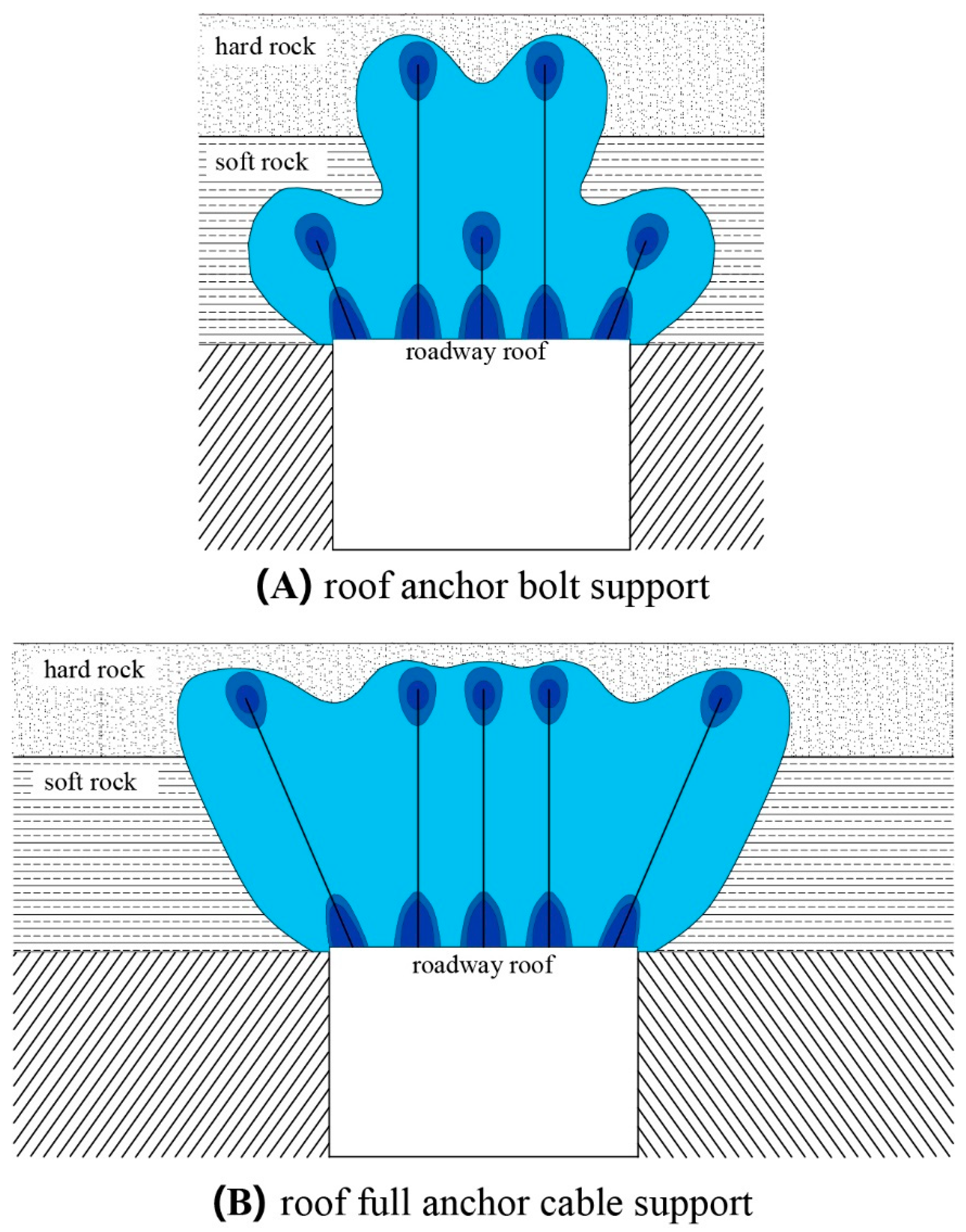

3.1. Support Mechanism Analysis

3.2. Supporting Effect Numerical Simulation Analysis

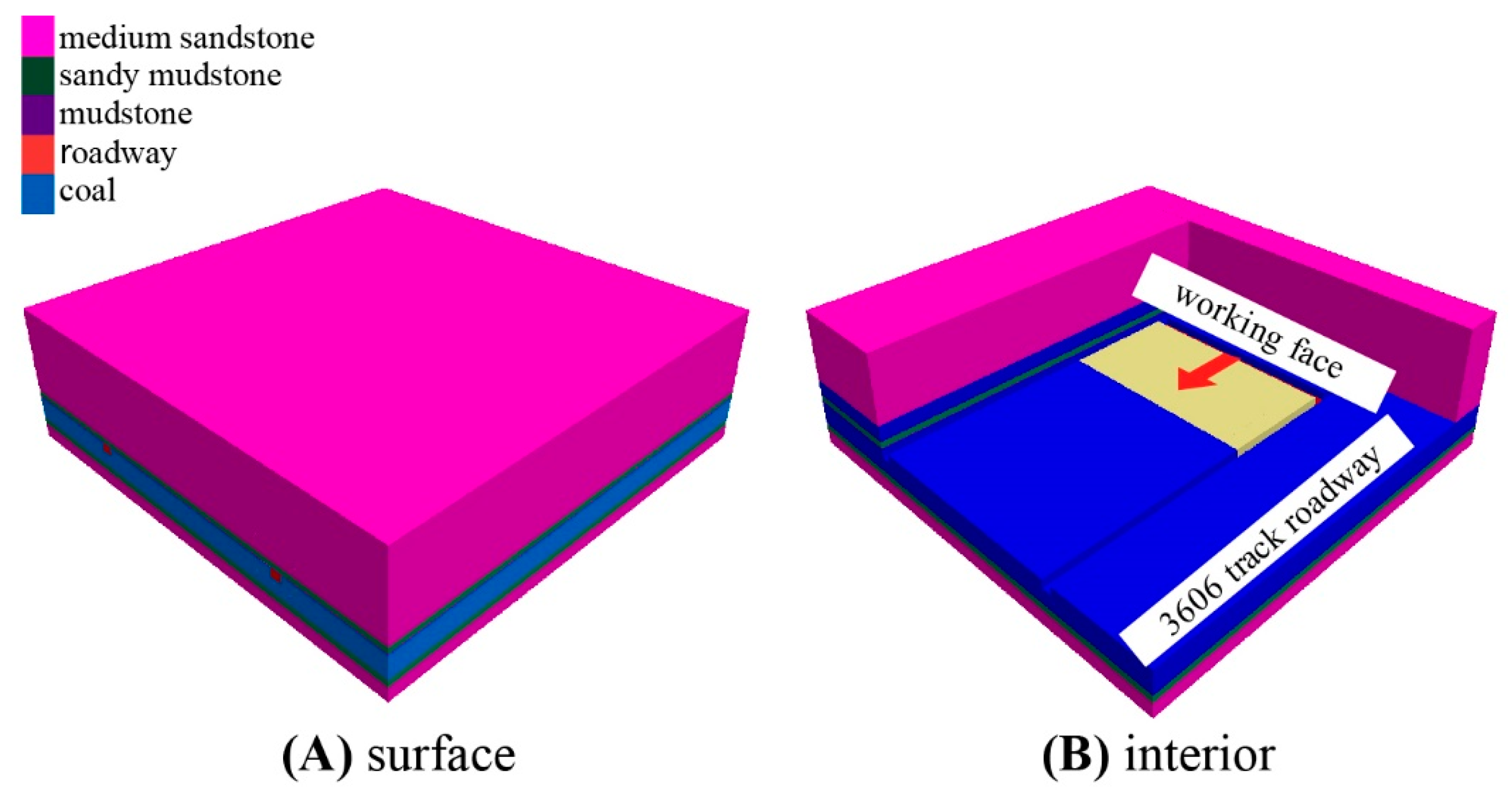

3.2.1. Numerical Simulation Calculation Model

- (1) Model

| Type | Density (kg·m−3) | Elastic Modulus (GPa) | Poisson’s Ratio | Internal Friction Angle (°) | Cohesion (MPa) | Tensile Strength (MPa) |

|---|---|---|---|---|---|---|

| medium sandstone | 2631 | 2.76 | 0.20 | 44.1 | 10.67 | 4.52 |

| sandy mudstone | 233 | 1.05 | 0.28 | 38.7 | 2.83 | 1.13 |

| mudstone | 2116 | 0.70 | 0.27 | 29.3 | 2.31 | 0.47 |

| coal | 1382 | 0.89 | 0.31 | 32.4 | 3.01 | 0.64 |

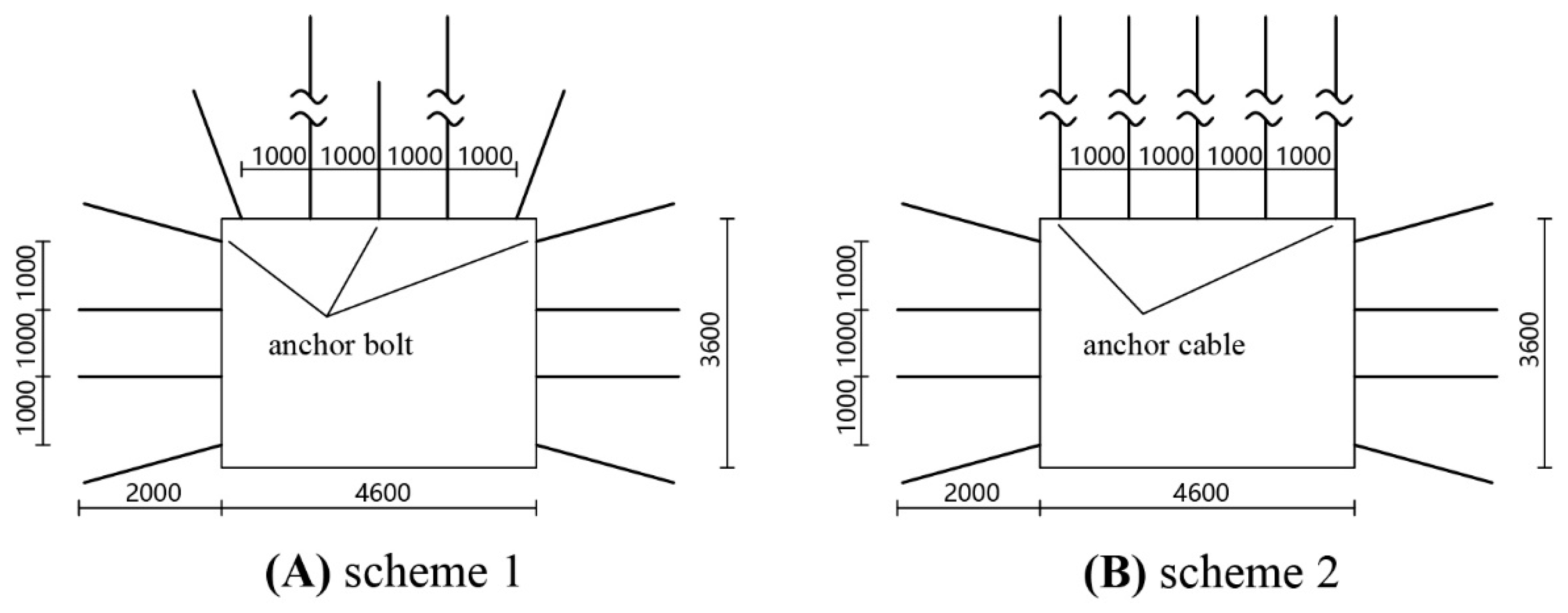

- (2) Simulation program

3.2.2. Analysis of Failure Effect

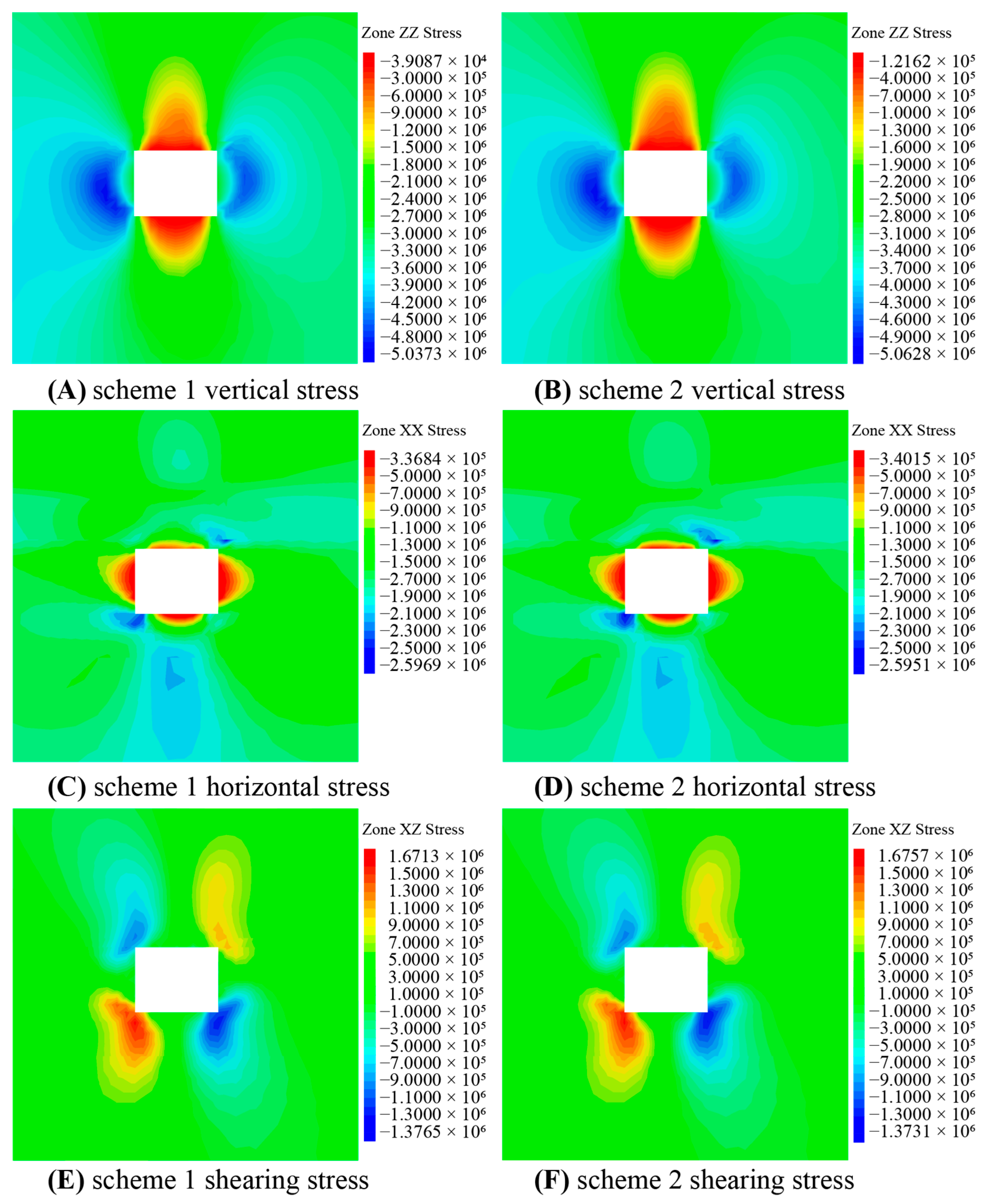

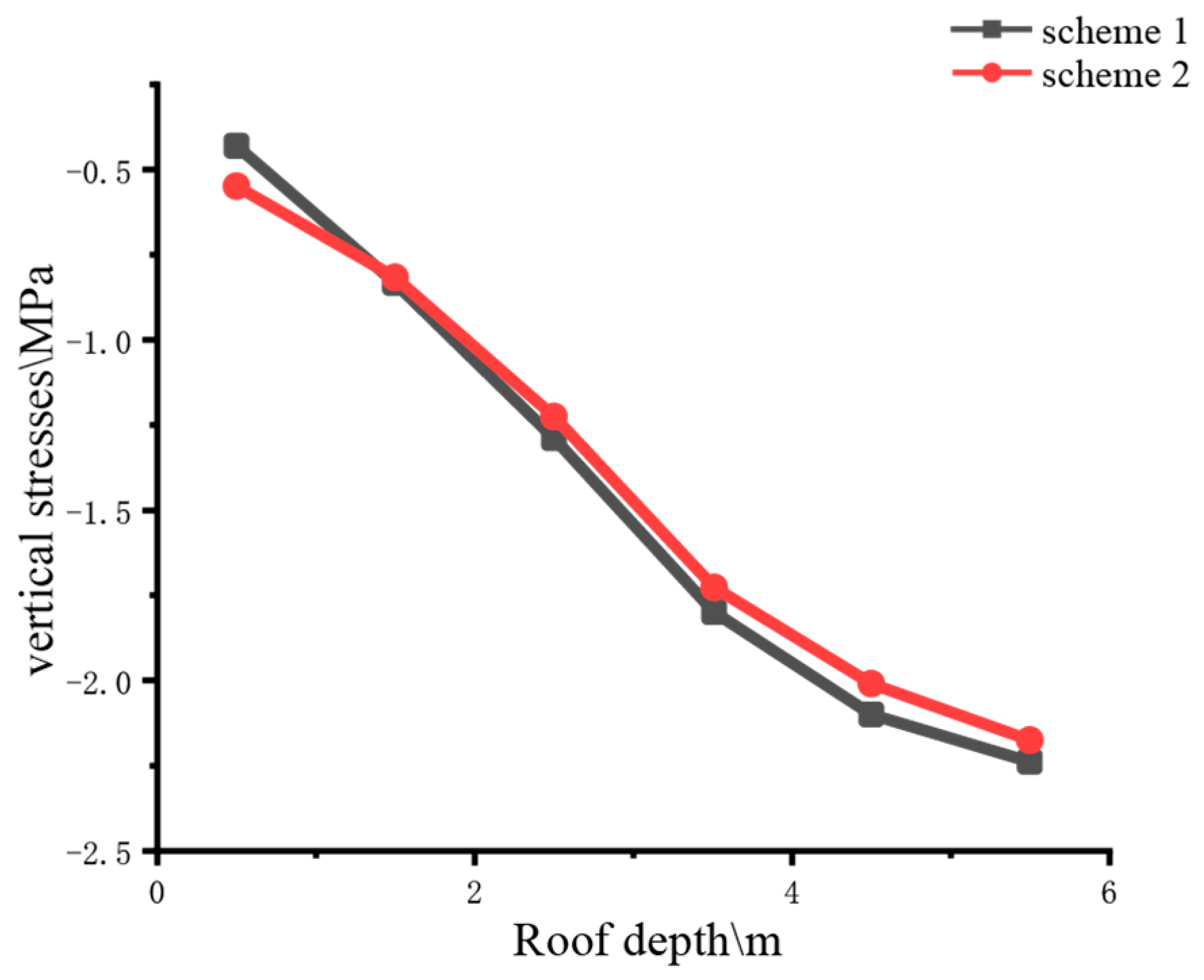

- (1) Analysis of stress variation law

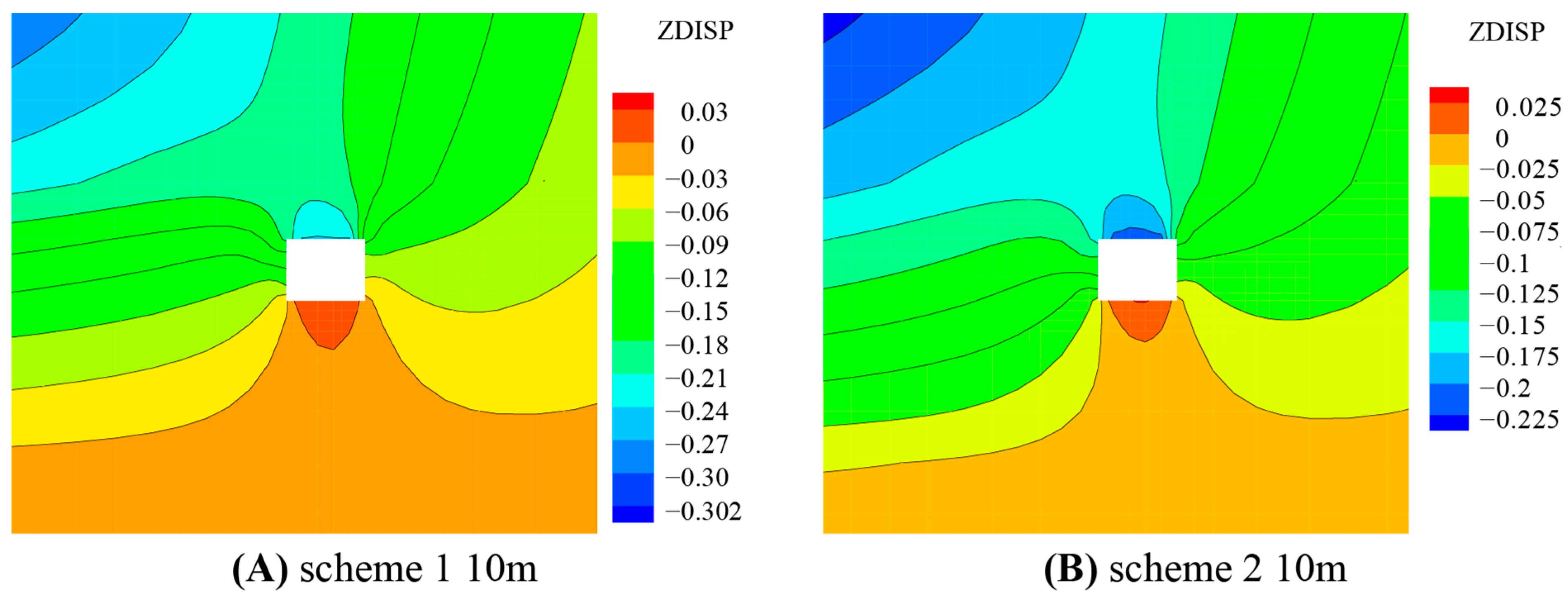

- (2) Analysis of deformation law and plastic development status of roof

4. Determination of Full Anchor Cable Support Parameters

4.1. Roadway Support Scheme Design

4.2. Simulation Result Analysis

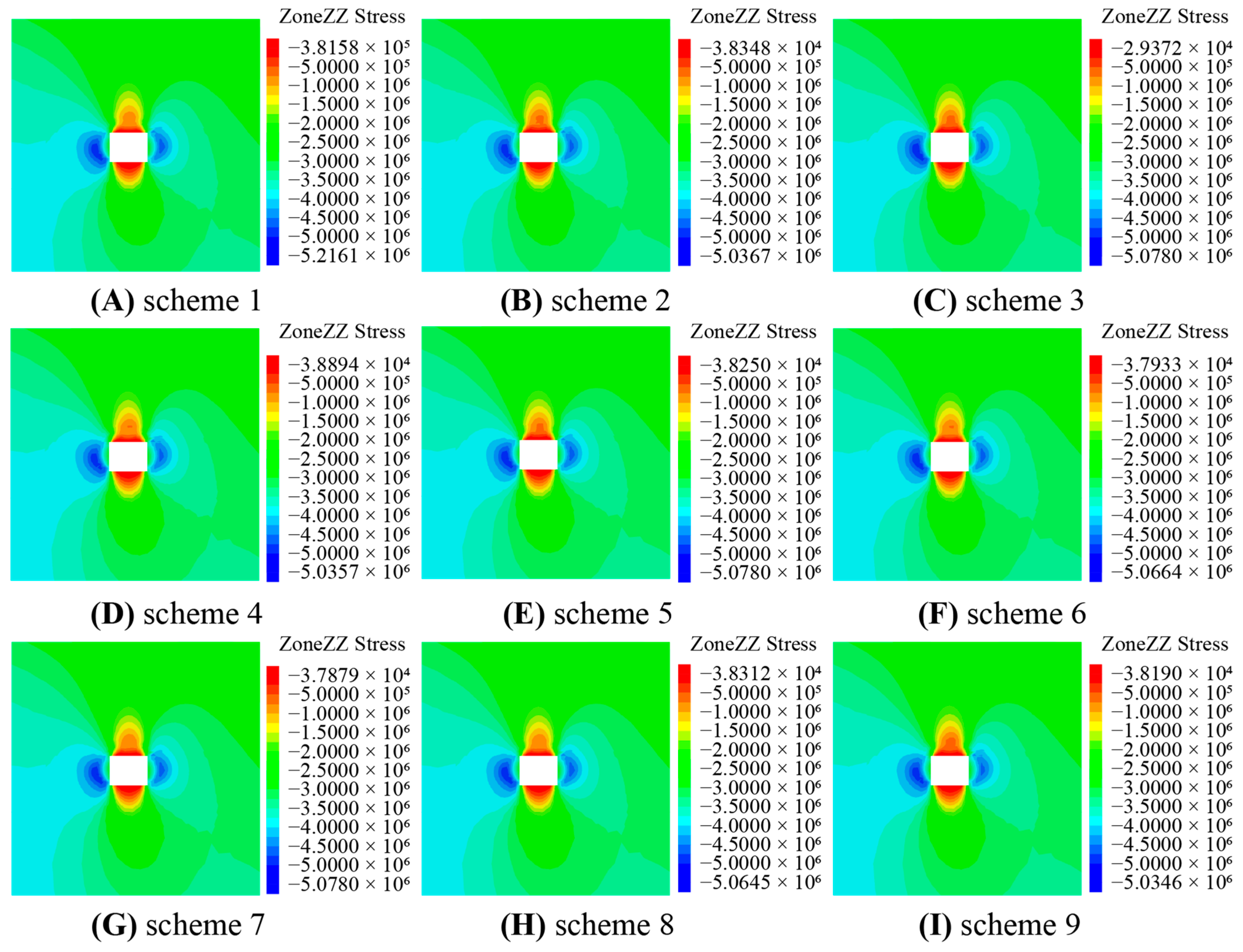

4.2.1. Surrounding Rock Stress Analysis

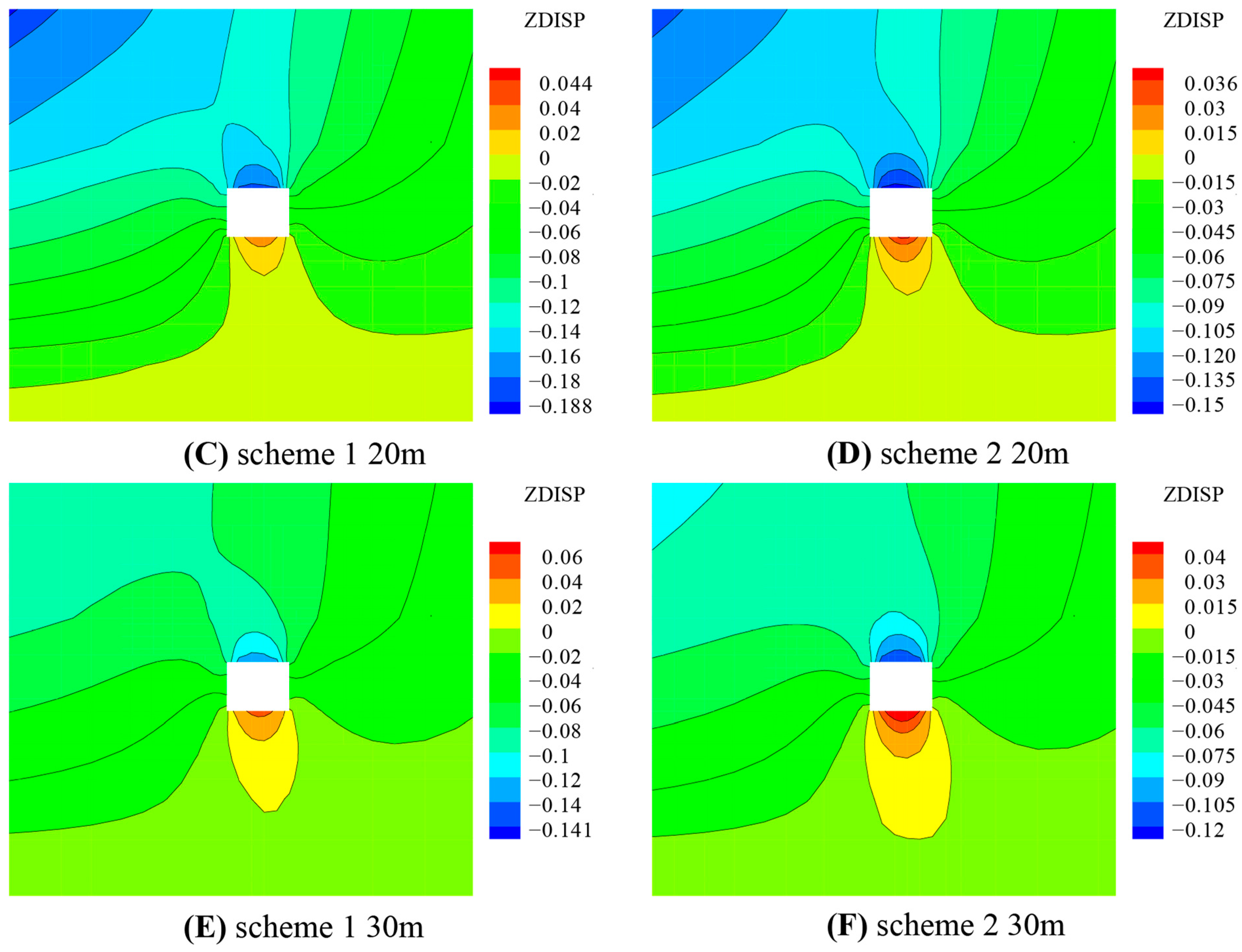

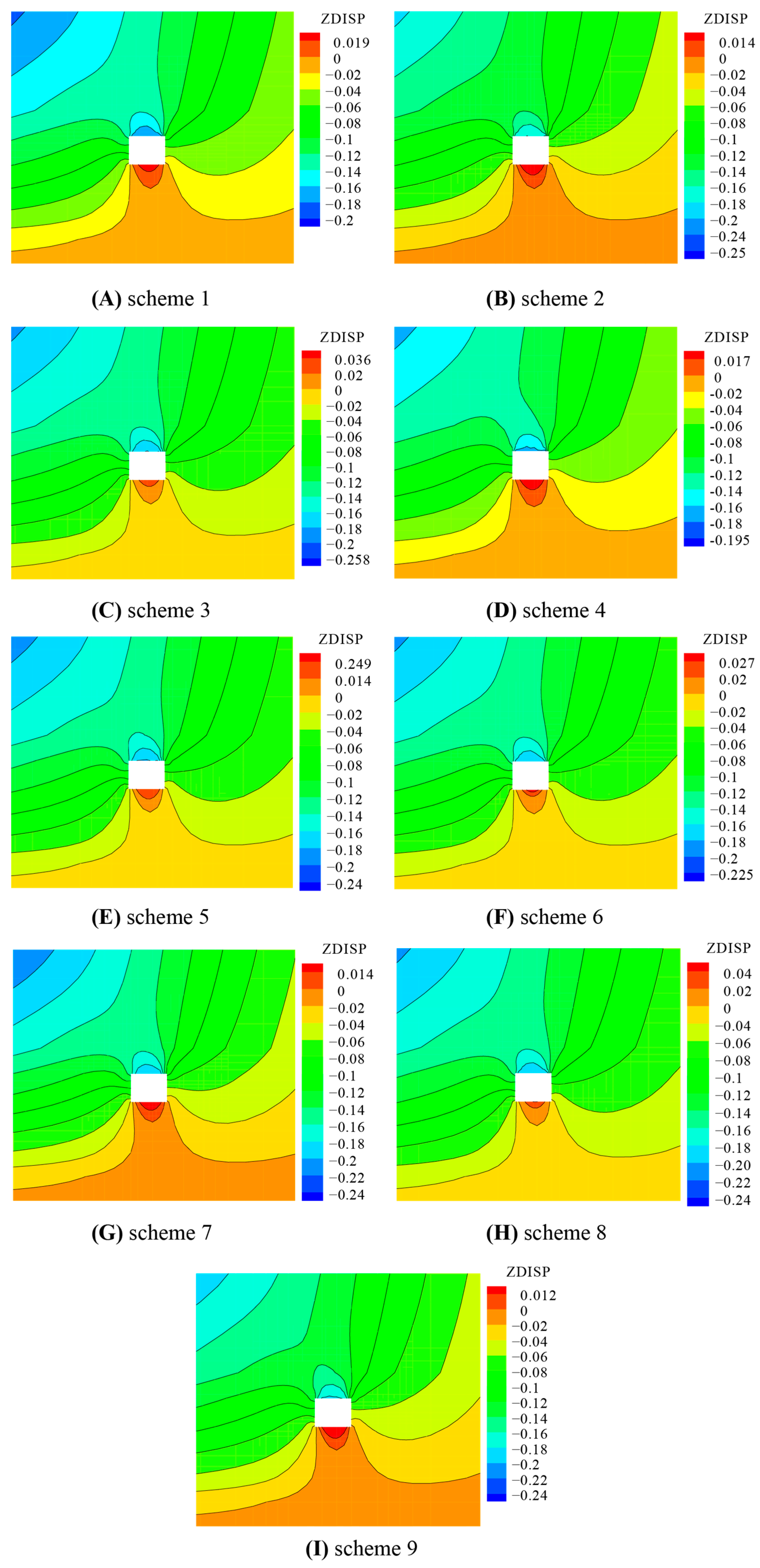

4.2.2. Surrounding Rock Displacement Analysis

4.2.3. Surrounding Rock Plastic Zone Analysis

4.3. Determine the Support Scheme

5. Field Application and Effect Evaluation

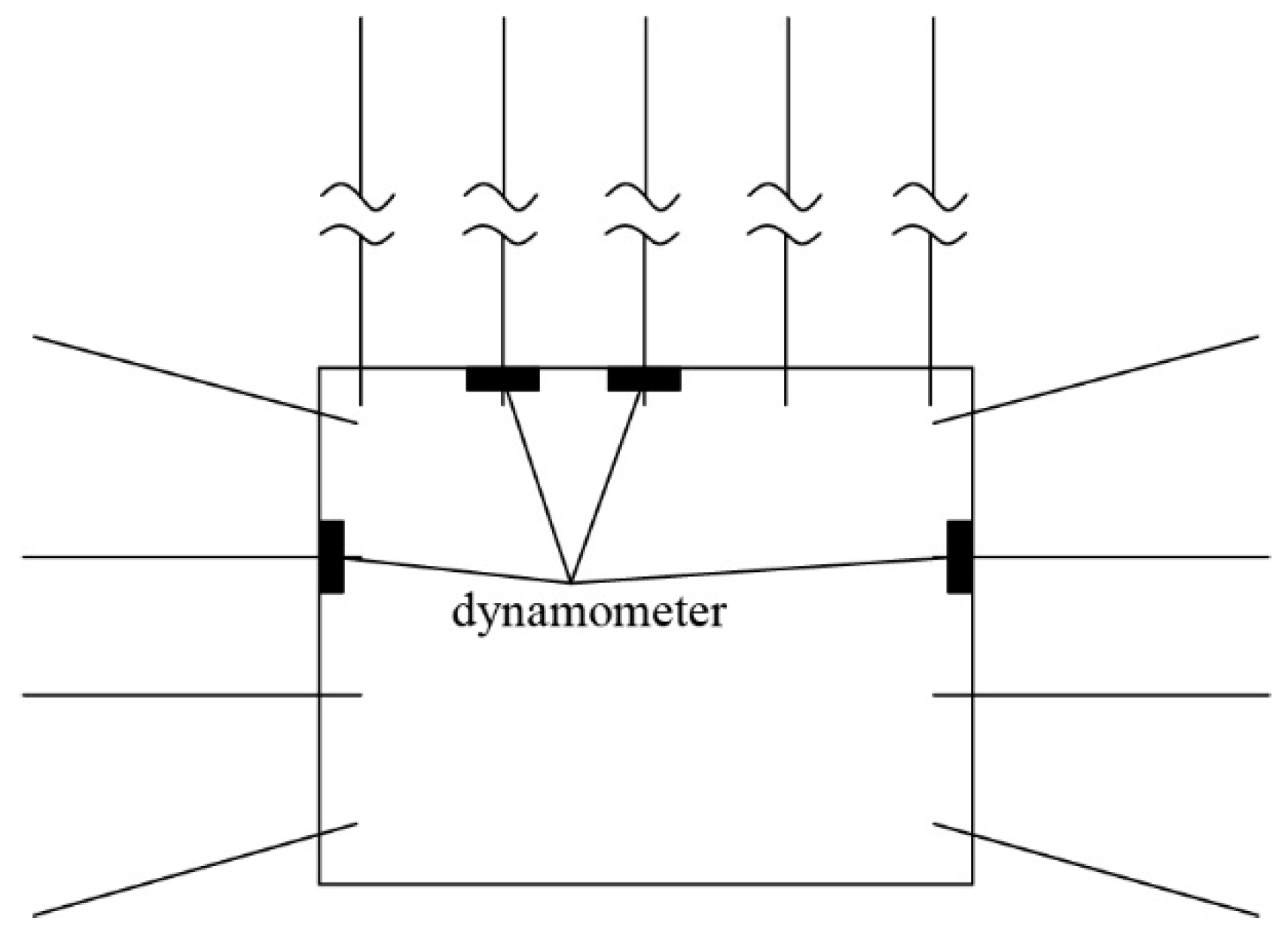

5.1. Monitoring Program

5.2. Analysis of Mine Pressure Appearance

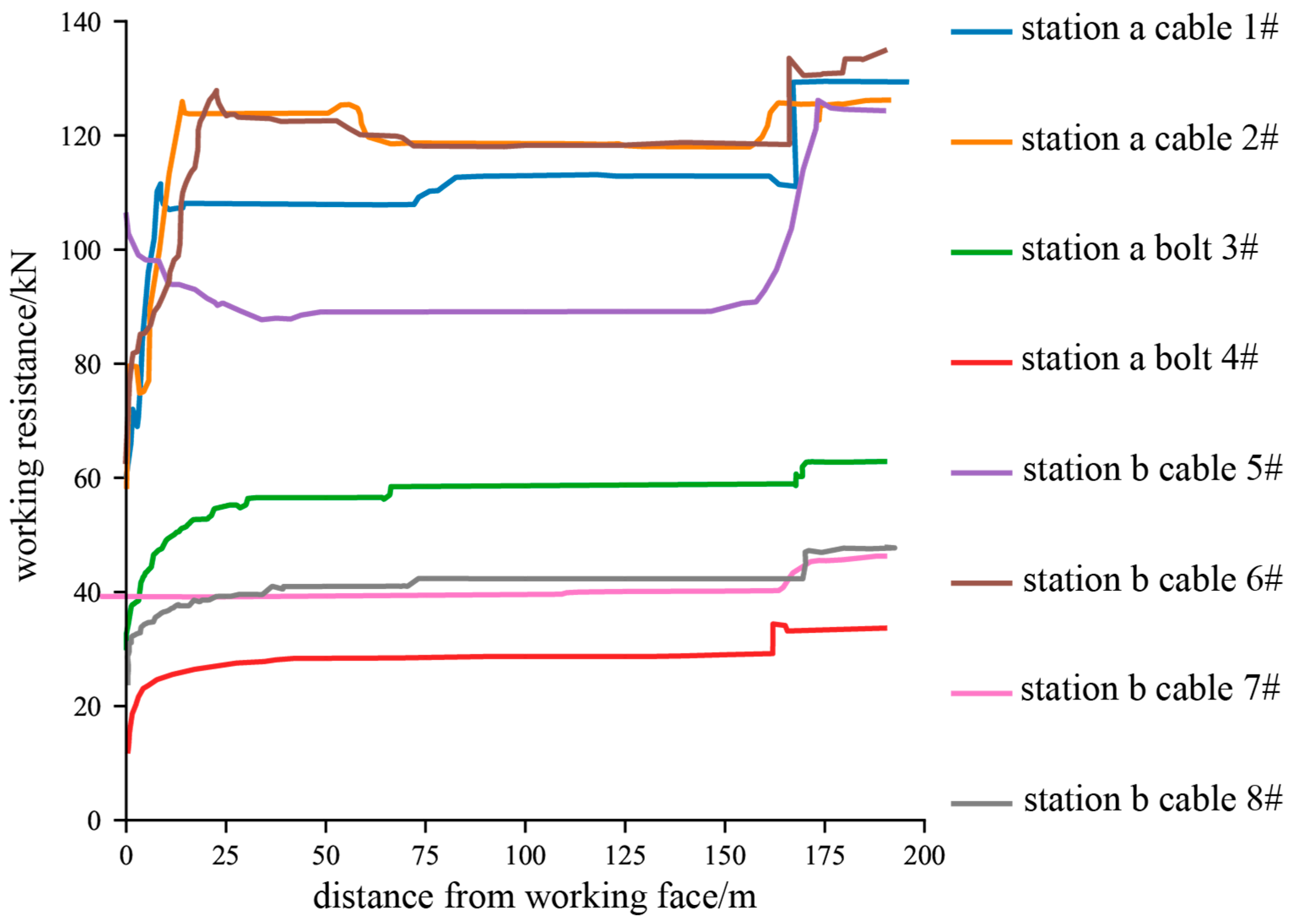

5.2.1. Force Analysis of Anchor

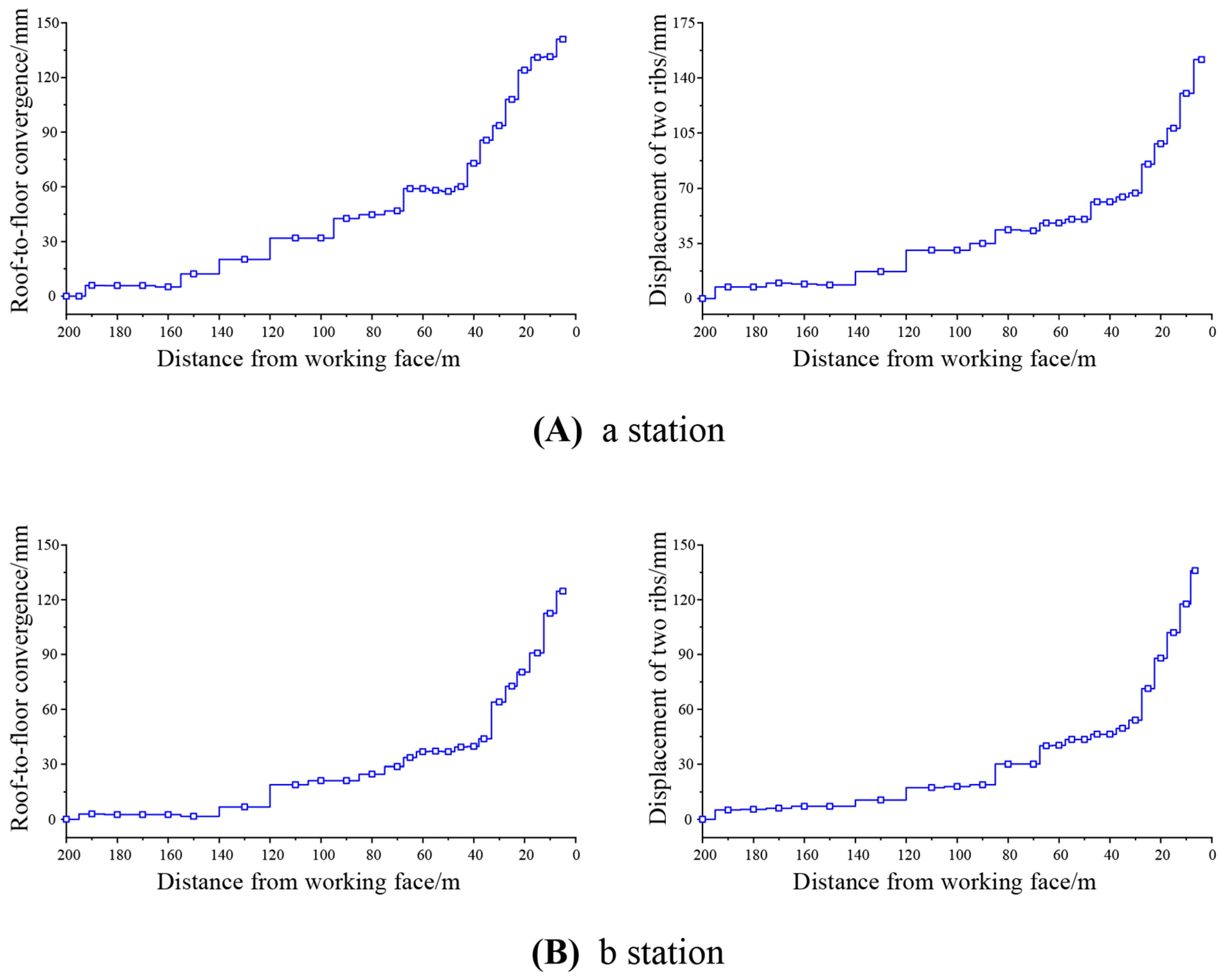

5.2.2. Surrounding Rock Deformation Analysis

5.3. Support Effect Analysis

6. Conclusions

- (1)

- Comparing the roof full anchor cable support method to the roof bolt and anchor cable combined support method, theoretical analysis of the support function and effect was performed. The roof’s shallow surrounding rock was efficiently restrained from deforming and being damaged by the roof full anchor cable support method, maintaining the roof’s structural integrity. Therefore, full anchor cable support of thick soft rock roof was proposed;

- (2)

- Numerical simulation analysis and comparison of the support effect of roof full anchor cable support and roof bolt-anchor cable support in the mining process showed a relatively high risk of roof instability due to the deformation of the surrounding rock and plastic failure of the bolt-anchor cable support scheme. The roof full anchor cable support scheme can meet the support requirements;

- (3)

- By combining the support experience of the Chaili Coal Mine, the approximate support parameters for the roof and two ribs were determined. Then, nine support schemes were designed for numerical simulations using orthogonal experiments, and the support effectiveness and cost-effectiveness of each scheme were analyzed and compared. Based on the numerical simulation results, the final parameters for the roof’s full anchor cable support were determined as follows: the spacing between the roof anchor cable rows was 1200 × 1000 mm, and the spacing between the two ribs of anchor rod rows was 1200 × 1000 mm;

- (4)

- When the roof full anchor cable support scheme was applied in the 3606 track roadway, the average maximum working resistance of the anchor bolts and anchor cables was 53 KN and 124.5 KN, the convergence of roof-to-floor and two ribs displacement was 132.5 mm and 144 mm, and the deformation rate was 3.68% and 3.13%, respectively. The support resistance maintained a stable working status, and the roadway was well stabilized, proving that the thick soft rock mass roof of the mining roadway was well anchored. The adaptability of the full anchor cable support method for thick soft rock roadway roof support and the rationality of supporting parameters were demonstrated.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yang, R.S.; Li, Y.L.; Wang, M.S.; Zhu, Y.; Cheng, Y.X.; Xiao, C.L.; Zhao, Y. Experimental study on shear mechanical properties of prestressed anchor cables. J. China Univ. Min. Technol. 2018, 47, 1166–1174. [Google Scholar] [CrossRef]

- Li, H. Study on the Lateral Performance and Excavation-Induced Response of Pile Foundations in Soft Soils; Southeast University: Nanjing, China, 2019. [Google Scholar]

- Liang, J. Study on softening critical depth of coal and rock mass in deep mining. China Energy Environ. Prot. 2020, 45, 78–184. [Google Scholar] [CrossRef]

- Li, T.C.; Lu, Z.; Liu, J.Z.; Ma, X. Deformation and failure process analysis of rectangular roadway in muddy weakly cemented soft rock strata. Rock Soil Mech. 2014, 35, 1077–1083. [Google Scholar] [CrossRef]

- Zhou, K.; Yu, F.; Tan, Y.; Zhao, T.; Guo, W. In-situ investigation on fractured evolution law of surrounding rock in weakly cemented soft rock roadway. Energy Sources Part A Recovery Util. Environ. Eff. 2021, 43, 1–13. [Google Scholar] [CrossRef]

- Meng, Q.; Han, L.; Qiao, W.; Lin, D.; Wen, S.; Zhang, J. Deformation failure characteristics and mechanism analysis of muddy weakly cemented soft rock roadway. J. Min. Saf. Eng. 2016, 33, 1014–1022. [Google Scholar] [CrossRef]

- Meng, Q.; Qian, W.; Han, L.; Wei, L.; Wang, C.; Zhou, X. Experimental study on formation mechanism and mechanical properties of regenerated structure of very weak cemented rock mass. Rock Soil Mech. 2020, 41, 799–812. [Google Scholar] [CrossRef]

- He, M.C.; Ma, X.G.; Niu, F.L.; Wang, J.; Liu, Y.X. Adaptability research and application of rapid gob-side entry retaining formed by roof cutting and pressure releasing with composite roof and medium thick coal seam. Chin. J. Rock Mech. Eng. 2018, 37, 2641–2654. [Google Scholar] [CrossRef]

- He, M.; Ma, Z.; Guo, Z.; Chen, S. Key parameters of the gob-side entry retaining formed by roof cutting and pressure release in deep medium thickness coal seams. J. China Univ. Min. Technol. 2018, 47, 468–477. [Google Scholar] [CrossRef]

- He, M.; Qi, G.; Cheng, P.; Zhang, G.; Sun, X. Deformation and damage mechanisms and coupling support design in deep coal roadway with compound roof. Chin. J. Rock Mech. Eng. 2007, 26, 987–993. [Google Scholar]

- He, M.C.; Wang, Y.; Yang, J.; Gao, Y.B.; Gao, Q.; Wang, S.B. Zonal characteristics and its influence factors of working face pressure using roof cutting and pressure relief mining method with no pillar and roadway formed automatically. J. China Univ. Min. Technol. 2018, 47, 1157–1165. [Google Scholar] [CrossRef]

- He, M. Research on deep shaft hoisting dynamics. Adv. Mech. 2021, 51, 702–728. [Google Scholar]

- He, M.-C.; Wang, B.; Tao, Z.-G.; Qiao, Y.-F.; Xiao, Y.-M. Axial compression behavior of adaptive steel arch joint for large-deformation tunnels. China J. Highw. Transp. 2021, 34, 1–10. [Google Scholar] [CrossRef]

- Ma, Z.; Jiang, Y.; Du, W.; Zuo, Y.; Kong, D. Fracture evolution law and control technology of roadways with extra thick soft roof. Eng. Fail. Anal. 2018, 84, 331–345. [Google Scholar] [CrossRef]

- Ma, Z.; Liang, X.; Fu, G.; Zou, Y.; Chen, A.; Guan, R. Experimental and numerical investigation of energy dissipation of roadways with thick soft roofs in underground coal mines. Energy Sci. Eng. 2021, 9, 434–446. [Google Scholar] [CrossRef]

- Su, X.G.; Song, X.M.; Li, H.C.; Yuan, H.H.; Li, B.K. Study on coupled arch-beam support structure of roadway with extra-thick soft compound roof. Rock Mech. Eng. 2014, 33, 1828–1836. [Google Scholar] [CrossRef]

- Hong, Y.; Fulian, H. A new cable truss support system for coal roadways affected by dynamic pressure. Int. J. Min. Sci. Technol. 2012, 22, 624–628. [Google Scholar] [CrossRef]

- Li, W.; Li, X.; Mei, Y.; Wang, G.; Yang, W.; Wang, H. A numerical simulation approach of energy-absorbing anchor bolts for rock engineering. Int. J. Rock Mech. Min. Sci. 2022, 158, 105188. [Google Scholar] [CrossRef]

- Kong, D.; Li, Q.; Wang, N.; Wu, G. Analysis on the Breaking Law of Soft and Thick Roof of Fully Mechanized Top-Coal Caving Face. Geotech. Geol. Eng. 2020, 38, 5941–5953. [Google Scholar] [CrossRef]

- Jiao, Y.; Song, L.; Wang, X.; Adoko, A.C. Improvement of the U-shaped steel sets for supporting the roadways in loose thick coal seam. Int. J. Rock Mech. Min. Sci. 2013, 60, 19–25. [Google Scholar] [CrossRef]

- He, F.L.; Yin, D.P.; Yan, H.; Li, Q.; Yang, H.Z. Experiment of Powerful Anchor Truss Support System Applied to Mining Roof Falling Gateway. Coal Sci. Technol. 2011, 39, 1–5. [Google Scholar] [CrossRef]

- Huang, S.; Zhao, G.; Meng, X.; Cheng, X.; Xu, W.; Liu, G.; Zhu, S. Study of Prevention and Control Technology for Roadway Excavation under the Soft and Extra-Thick Coal Roof in Luling Coal Mine. Processes 2022, 10, 1835. [Google Scholar] [CrossRef]

- Tahmasebinia, F.; Yang, A.; Feghali, P.; Skrzypkowski, K. Structural Evaluation of Cable Bolts under Static Loading. Appl. Sci. 2023, 13, 1326. [Google Scholar] [CrossRef]

- Tahmasebinia, F.; Yang, A.; Feghali, P.; Skrzypkowski, K. A Numerical Investigation to Calculate Ultimate Limit State Capacity of Cable Bolts Subjected to Impact Loading. Appl. Sci. 2023, 13, 15. [Google Scholar] [CrossRef]

- Rizzo, F.; Kopp, G.A.; Giaccu, G.F. Investigation of wind-induced dynamics of a cable net roof with aeroelastic wind tunnel tests. Eng. Struct. 2021, 229, 111569. [Google Scholar] [CrossRef]

- Rizzo, F.; Alessandro, V.D.; Montelpare, S.; Giammichele, L. Computational study of a bluff body aerodynamics: Impact of the laminar-to-turbulent transition modelling. Int. J. Mech. Sci. 2020, 178, 105620. [Google Scholar] [CrossRef]

- Liao, B. Study on Anchor (Cables) Supporting Parameters Design in Large Span Open-Off Rectangular Roadway; Taiyuan University of Technology: Taiyuan, China, 2014. [Google Scholar]

| Distance from Working Face | Roof Displacement Amount/mm | Roof Plastic Zone Range/m | ||

|---|---|---|---|---|

| I | II | I | II | |

| 5 m | 261 | 247 | 3.2 | 2.75 |

| 10 m | 253 | 208 | 3.2 | 2.3 |

| 15 m | 220 | 173 | 2.75 | 2.3 |

| 20 m | 186 | 153 | 2.75 | 1.85 |

| 25 m | 167 | 131 | 2.3 | 1.4 |

| 30 m | 143 | 116 | 1.85 | 1.4 |

| 35 m | 122 | 99 | 1.4 | 0.95 |

| 40 m | 113 | 91 | 1.4 | 0.95 |

| Scheme Number | Length of Anchor Cable/mm | Anchor Cable Spacing/mm | Interval of Anchors/mm |

|---|---|---|---|

| 1 | 5500 | 1000 | 1000(5) |

| 2 | 5500 | 1100 | 1100(5) |

| 3 | 5500 | 1200 | 1100(4) |

| 4 | 6000 | 1000 | 1100(5) |

| 5 | 6000 | 1100 | 1100(4) |

| 6 | 6000 | 1200 | 1000(5) |

| 7 | 6500 | 1000 | 1100(4) |

| 8 | 6500 | 1100 | 1000(5) |

| 9 | 6500 | 1200 | 1100(5) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, Y.; Meng, L.; Zhang, T. Full Anchor Cable Support Mechanism and Application of Roadway with Thick Soft Rock Mass Immediate Roof. Appl. Sci. 2023, 13, 7148. https://doi.org/10.3390/app13127148

Yang Y, Meng L, Zhang T. Full Anchor Cable Support Mechanism and Application of Roadway with Thick Soft Rock Mass Immediate Roof. Applied Sciences. 2023; 13(12):7148. https://doi.org/10.3390/app13127148

Chicago/Turabian StyleYang, Yongjie, Lingren Meng, and Tianli Zhang. 2023. "Full Anchor Cable Support Mechanism and Application of Roadway with Thick Soft Rock Mass Immediate Roof" Applied Sciences 13, no. 12: 7148. https://doi.org/10.3390/app13127148

APA StyleYang, Y., Meng, L., & Zhang, T. (2023). Full Anchor Cable Support Mechanism and Application of Roadway with Thick Soft Rock Mass Immediate Roof. Applied Sciences, 13(12), 7148. https://doi.org/10.3390/app13127148