1. Introduction

China is the country most severely threatened by dynamic disasters such as rockburst worldwide. According to statistics, the number of deaths caused by rockburst accidents in coal mines has shown a decreasing trend in the past decade. However, the occurrence of rockburst accidents in coal mines still presents an upward trend. The reason for this is that with the depletion of shallow coal resources in China, coal mining is characterized by an increasing mining depth, more extensive underground excavation, and more frequent coal pillar mining. This leads to increasing difficulties in coal mining and frequent occurrences of dynamic disaster accidents [

1,

2,

3,

4]. In addition, compared to China, other countries may experience fewer rockburst accidents, but the resulting damages and associated mine disasters, such as roof fall and roof caving in longwall mining faces, should not be overlooked [

5]. It is evident that deep coal mine dynamic disasters, including rockbursts, have become a major issue faced by the mining industry, seriously restricting the safe and efficient production of enterprises both domestically and abroad [

6,

7,

8,

9,

10]. In response to this issue, experts from around the world have conducted extensive research on the distribution and evolution of support pressure in comprehensive coal mining faces, and have made some progress in understanding the occurrence mechanism, monitoring, early warning, and prevention of rockbursts [

9,

11,

12,

13,

14,

15,

16].

The distribution of support pressure is the key factor to determine the stability of the working face and ensure the safety of miners. The evolution of the support pressure distribution is affected by many factors, such as the geological structure of the coal seam, the excavation method, the properties of the roof and floor strata, geological fault zones, and the type of filling wall [

17,

18]. Generally, as the work faces the deep coal seam, the support pressure tends to increase due to the increase in the weight of the overlying strata. Continuous monitoring and analysis of the distribution of support pressure is of great significance to predict and prevent the potential failure or collapse of the working face [

19,

20]. Advanced numerical simulation technology, such as finite element analysis, can be used to simulate and understand the distribution of support pressure and its evolution with time, as well as to establish effective models of fractured rock masses to improve execution speed [

21,

22,

23,

24]. Ansys software (

https://www.ansys.com/ Last accessed date: 8 May 2023) can also be utilized to simulate the stress environment of the surrounding rock in a roadway under different filling wall conditions, and subsequently choose the appropriate type of filling wall [

25]. In addition, using SolidWorks software (

https://www.solidworks.com/zh-hans Last accessed date: 10 May 2023), a 3D model of the rock mass can be established, and then the properties of the support pressure region can be analyzed and verified [

14].

Through coal seam stress measurement, anchoring force measurements, roof separation monitoring, microseismic monitoring, and other technologies, the distribution law of coal mine support pressure can be detected. Each technology has its own advantages and limitations in terms of accuracy, ease of use, and costs [

19,

26,

27]. The coal seam stress measurement provides direct information regarding the stress state of the coal seam and surrounding strata, and it can be used to understand the overall distribution of the support pressure of the working face. However, stress measurement requires a comprehensive understanding of the geological structure and properties of coal seams, and cannot provide real-time information regarding the distribution and change in support pressure [

28,

29]. The anchoring force measurement provides real-time information about the distribution of support pressure by measuring the force applied on the support unit of the working face. This technology is relatively easy to implement and can provide valuable information to adjust the support system to respond to changing conditions. However, the quality of the sensor and the calibration of the measuring system may limit the accuracy of the anchoring force measurement [

30,

31]. Roof separation monitoring is used to measure the displacement and deformation of the roof strata in the working face, and can be used to detect a potential roof collapse. This technology is relatively easy to implement and can provide real-time information about the change in support pressure distribution. However, roof separation monitoring cannot provide complete support pressure distribution. It can only provide information about roof strata, but not the overall stress state of coal seams [

32,

33].

Microseismic monitoring includes the use of sensors to detect and record small seismic events, such as those caused by rock fracture or the movement of supporting elements of the working face [

34]. This technology can provide real-time support pressure distribution information and provide valuable insights for the study of the geological structure and properties of coal seams. However, the accuracy of microseismic monitoring may be limited by the quality and location of sensors, and the interpretation of seismic data may require advanced seismological knowledge [

35,

36]. Microseismic technology has been applied in the field of coal mining to monitor and analyze the distribution and evolution of support pressure in working faces [

37]. The application of microseismic technology in coal mining has made encouraging achievements in improving our understanding of the distribution and evolution of support pressure, and in predicting and preventing potential damage or collapse [

38,

39,

40].

Rockburst monitoring is an important part of rockburst control. By using microseismic monitoring, stress monitoring, drilling cuttings monitoring, and other technologies, as well as using a microseismic monitoring system, a stress monitoring system, and other equipment, the distribution and evolution law of the support pressure can be understood [

41,

42]. At the same time, with the development of computer technology, deep learning technology has also rapidly developed in microseismic event classification, positioning, and rockburst monitoring and early warning [

43,

44]. It not only provides a scientific basis for taking reasonable support measures and using coal mining technology, but also effectively improves the safety and stability of a fully mechanized mining face.

Based on this, the North China Institute of Science and Technology collaborated with a certain mine to research the prediction and prevention of rockburst hazards in the vicinity of deep fully mechanized mining faces. In order to understand the evolution and distribution pattern of the surrounding rock supporting pressure at the fully mechanized mining face, this study conducted on-site measurements of microseismic monitoring data during the advancement of the 1300 working face using microseismic monitoring technology. At the same time, a theoretical calculation model of dynamic and static supporting pressure in longwall mining was constructed to calculate and analyze the distribution range and evolution pattern of supporting pressure. Using coal stress monitoring, anchor force monitoring, and other means, as well as CT geophysical prospecting and drilling cuttings measurements, the effectiveness of the microseismic analysis results and the accuracy of the aforementioned theoretical model were further verified. Ultimately, a monitoring and early warning system for rockburst hazards at the fully mechanized mining face was proposed based on the distribution and evolution pattern of the supporting pressure. The research results provide an important theoretical basis and practical experience for the prevention and control of rockburst hazards, and safe, efficient mining of the 1300 primary mining face and other similar faces at the mine. They hold significant reference value and have important scientific significance and practical value for accelerating coal resource development and ensuring safe coal mining.

2. Project Profile

2.1. Introduction of the Test Site

In a certain mine in Shandong, the depth of the coal seams that can be mined is generally between −400 to −1500 m. The main coal resources in the mine are mainly concentrated at the −1000 m level or shallower. The average thickness of coal seams in the mine is 10.15 m, and the coal-bearing coefficient is 4.5%. Layer 3 coal is the main and first coal to be mined, with an average thickness of 6.87 m, accounting for 68% of the average total thickness of the coal seams. The thickness of layer 3 coal is 3.96 to 7.88 m, with an average thickness of 6.87 m, and a unidirectional compressive strength of σc = 15.82 MPa. The tendency index of rockburst is around WET = 4.58, and the coal seam structure is relatively simple.

According to the exposure of the coal seam during the excavation of the roadway, it can be observed that there is a hard coal seam approximately 0.55 m thick at a distance of around 2.3 m from the floor of the coal seam. The coal seam and roof-to-floor at the working face are as follows: main roof, generally more than 10 m of fine sandstone; immediate roof, generally around 1 to 2 m of sandy mudstone; immediate floor, generally about 1 to 6 m of muddy sandstone or mudstone, fine sandstone, and muddy sandstone interbedded; main floor, generally more than 7 m of powder sandstone. It belongs to the structure of soft immediate roof-to-floor and hard main roof-to-floor.

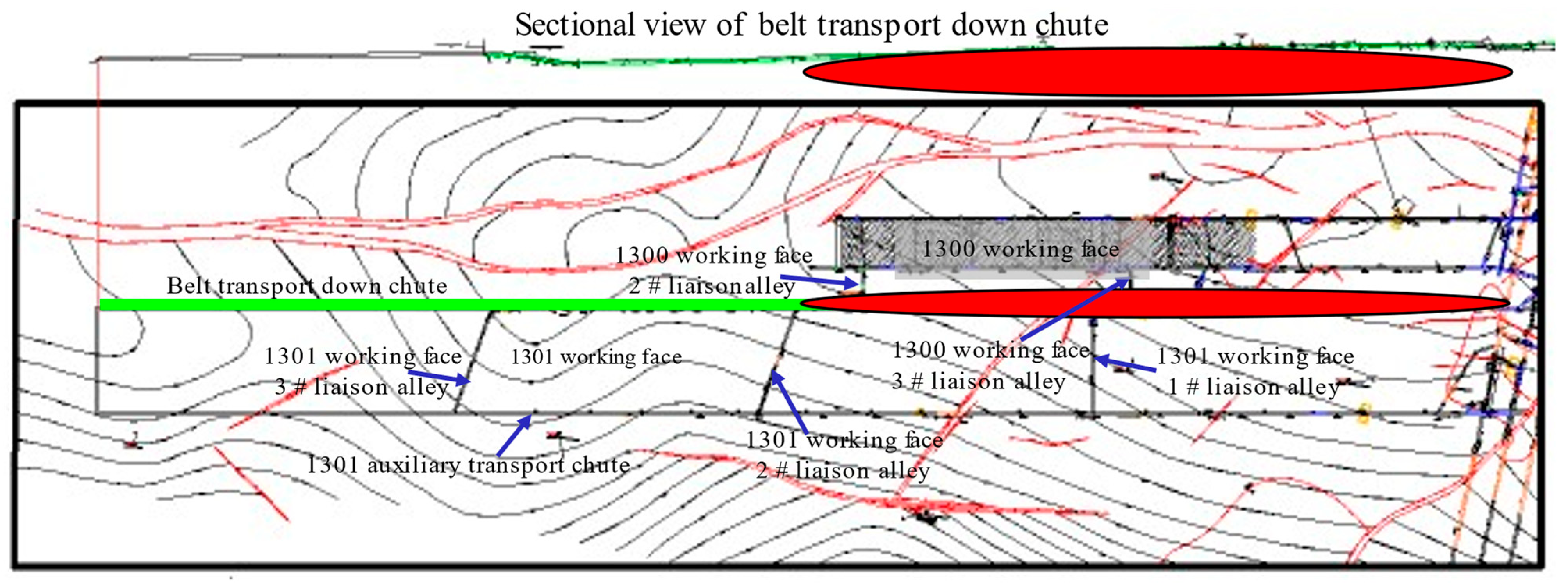

The initial mining face, designated as the 1300 working face, is the first working face located at the southern wing of the upper part of the primary mining area. The length of the working face measures 100 m, while the advance distance of mining operations spans 1263 m. The eastern part of the 1300 working face is the 1301 preparatory working face, and its belt transport down chute serves as the drainage alley for the 1300 face. This face mainly mines three coal seams, which greatly fluctuate along the trough due to structural influences. Both horizontal and inclined coal seams are present in the area. The three coal seams are irregular in direction, tending to the northeast and southeast with dips of 6–12°. The 1301 working face starts opening construction from the south at the door mouth of the second contact tunnel on the east side of the 1300 working face drainage alley, with an opening azimuth of 169°. The west side of the tunnel, 80 m from the 1300 working face, is an auxiliary transportation trough with a depth of 860–920 m. The trough is arranged along the coal seam floor and has a coal body with a thickness of 3–5 m.

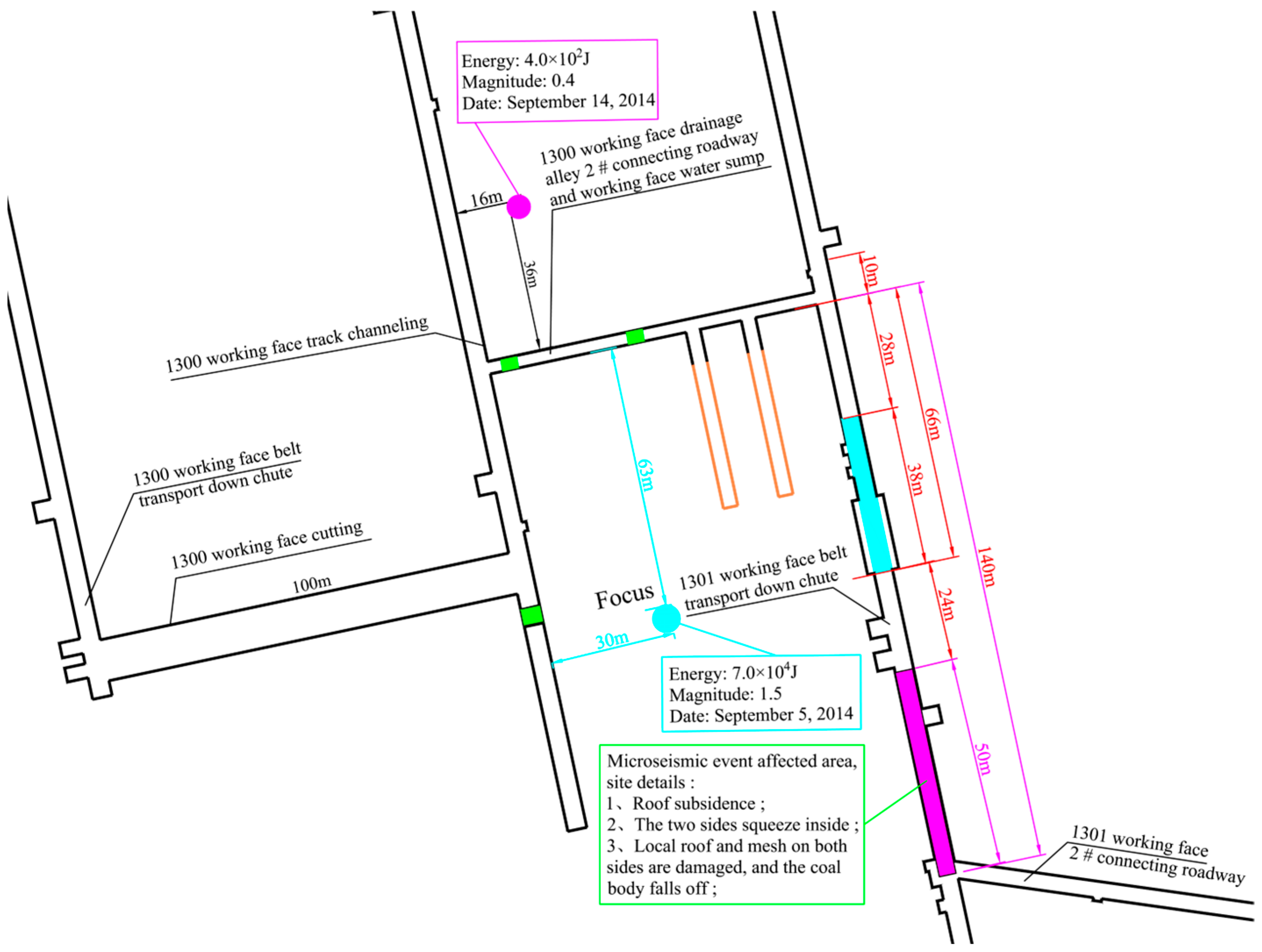

Numerous domestic and international experts have conducted extensive research on this topic, making progress in understanding the mechanisms behind rockburst occurrences, monitoring, early warning, and prevention methods. However, as technology advances, new challenges and complex problems arise, such as the emergence of increasingly novel coal and rock dynamic disasters, such as the rockburst events in the vicinity of the coal mine’s fully mechanized longwall face. As a typical deep mine, this coal mine is seriously affected by rockburst and has suffered several rockburst accidents, as shown in

Figure 1. In the period 2014–2015 alone, there were six rockburst accidents, of which the mining of the 1300 working face, induced by the 1301 working face belt transport down chute, caused four rockburst accidents, causing huge economic losses to the mine and seriously threatening the safety production of the mine.

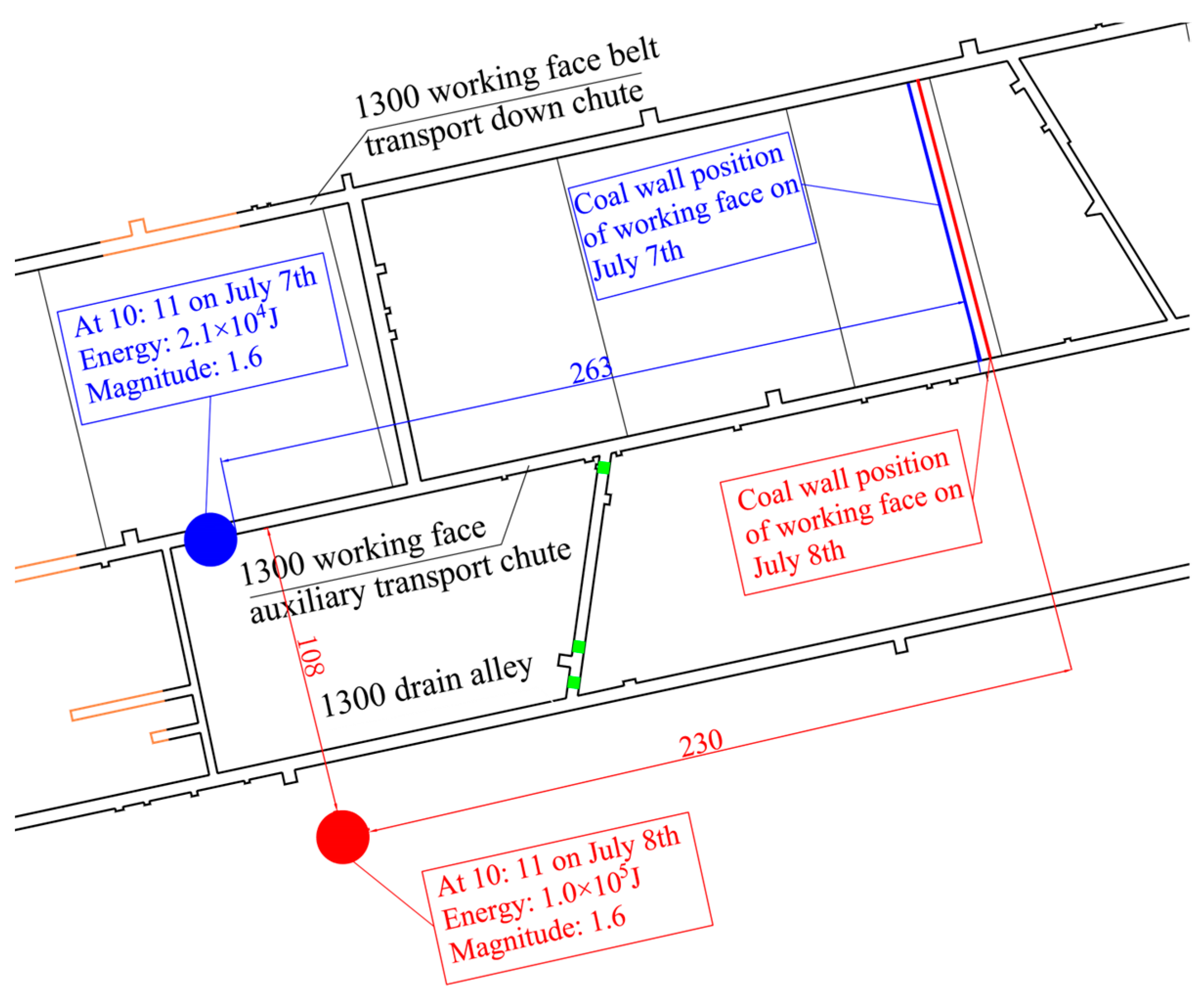

2.2. Rockburst Phenomenon in Adjacent Areas

Since 5 April 2014, various degrees of rockburst events have occurred in the vicinity of the 1300 fully mechanized caving face, which caused varying degrees of damage to the roadway and seriously affected the construction safety of the site.

- (1)

Event I: Rockburst event of the belt transport down chute on the 1301 working face on 5 September 2014

At 13:36 on 5 September 2014, a rockburst event occurred along the belt chute of the 1301 working face. The site monitoring location of the focal point was located in the coal pillar area 80 m south of the No. 2 contact lane of the drainage alley of the 1300 working face and 30 m east of the 1300 working face, as shown in

Figure 2. As a result of the accident, roof subsidence and internal extrusion occurred to different degrees, within the range of 10 m to the north and 120 m to the south of the contact lane 2# of the drainage alley in the 1300 working face. The phenomena of internal extrusion and floor heave occurred in the more serious area (38 m in total), with an internal extrusion volume of 200 mm and a floor heave volume of 150 mm. The local roof and two-sided mesh were damaged by coal body falling. According to the field survey, the roadway with serious damage essentially corresponded to the goaf of the working face.

- (2)

Event II: Rockburst event of the belt transport down chute on the 1301 working face on 14 September 2014

At 0:40 on 14 September 2014, a rockburst event occurred in the belt channeling of the 1301 working face. On 14 September 2014, the event caused a large area of roof subsidence, a two-sided internal extrusion phenomenon, partial roof and two-sided mesh breakage, and coal body falling within 90–140 m (50 m in total) south of contact lane 2# of the drainage alley of the 1300 working face. The event location is shown in

Figure 3.

The incident occurred at the belt transport down chute of the 1301 working face, which was separated by an 80 m mined-out area from the 1300 workface mined-out area. According to traditional theory analysis, the 1301 belt transport down chute should not be easily affected by the lateral support pressure of the 1300 mined-out workface, but in reality, during the process of mining out the 1300 workface, multiple rockburst events and frequent mine pressure appear at the 1301 belt transport down chute, which cannot be explained by traditional theory analysis.

2.3. Mechanism Analysis

Regarding the mechanism of rockbursts, it is generally recognized that they are a stress problem; that is, when the stress in the coal meets the critical stress condition for rockburst, a rockburst will occur. According to traditional rock pressure theory, rockbursts frequently occur within 60 m in advance of the solid roadway in the mining process of deep well working faces, while rockbursts do not frequently occur in other areas. This concept cannot be applied to rockbursts in the vicinity of fully mechanized caving faces. Therefore, although the essence of the rockburst problem in the vicinity of fully mechanized caving faces is still a stress problem, its “force source” is different from the original calculation of lateral abutment pressure, so the evolution and superposition of stress should be considered. According to the mining influence range shown by the above microseismic monitoring results, the lateral abutment pressure of the goaf at the 1300 working face should be greater than 120 m, which is beyond the protection range of the 80 m coal pillar. Therefore, the belt transport down chute in a 1301 working face is under the influence of the lateral abutment pressure in a 1300 goaf.

It can be seen that the root cause of rockbursts in the area adjacent to the fully mechanized caving face (the belt transport down chute in the 1301 working face) is the superposition of the original rock stress in the area and that the lateral abutment pressure in the 1300 goaf exceeds the critical stress condition for rockburst. In the final analysis, the essence of rockburst is still the stress problem. The above abnormal ore pressure phenomenon still needs to be explained from the perspective of stress evolution or superposition. Since the traditional abutment pressure theory cannot explain these phenomena, this paper tries to discuss the evolution law of abutment pressure in longwall stope, hoping to essentially reveal the distribution characteristics of abutment pressure in longwall stope, so as to provide a scientific basis for the prevention and control of rockbursts in deep wells.

Based on this, the North China Institute of Science and Technology and a mine jointly carried out research on the prediction of and prevention technology for rockburst in the area near the fully mechanized caving face of a deep well. Aimed at the issue of rockburst accidents occurring several times near the 1301 belt passage of the 1300 fully mechanized caving face in a mine, taking the evolution and distribution law of abutment pressure in the surrounding rock of the 1300 fully mechanized caving face in the deep well as the breakthrough point and relying on microseismic monitoring technology, the distribution characteristics of abutment pressure in the surrounding rock of 1300 working face were measured and the mechanism of rockburst in the adjacent area was revealed. The dynamic and static abutment pressure calculation models of the longwall stope are constructed to analyze the internal relationship between the advancement of the deep well fully mechanized mining face and the impact pressure in adjacent areas, and a corresponding warning system and prevention measures are proposed.

3. Analysis of Abutment Pressure Evolution Law Based on Microseismic Monitoring

The migration and evolution process of the stress field is intrinsically related to the evolution of the vibration field and the fracture field. The evolution law of abutment pressure in a longwall stope can be revealed by the spatial distribution of the fracture field, and the spatial evolution of the fracture field can be reflected by the results of microseismic monitoring. Therefore, statistical analysis is conducted on the microseismic monitoring data of the 1300 stope working face in the process of advancing, so as to obtain the mining influence range of the fully mechanized caving working face and the microseismic response rule when the working face passes through the fault, which provides a basis for the evolution and distribution characteristics of stope abutment pressure.

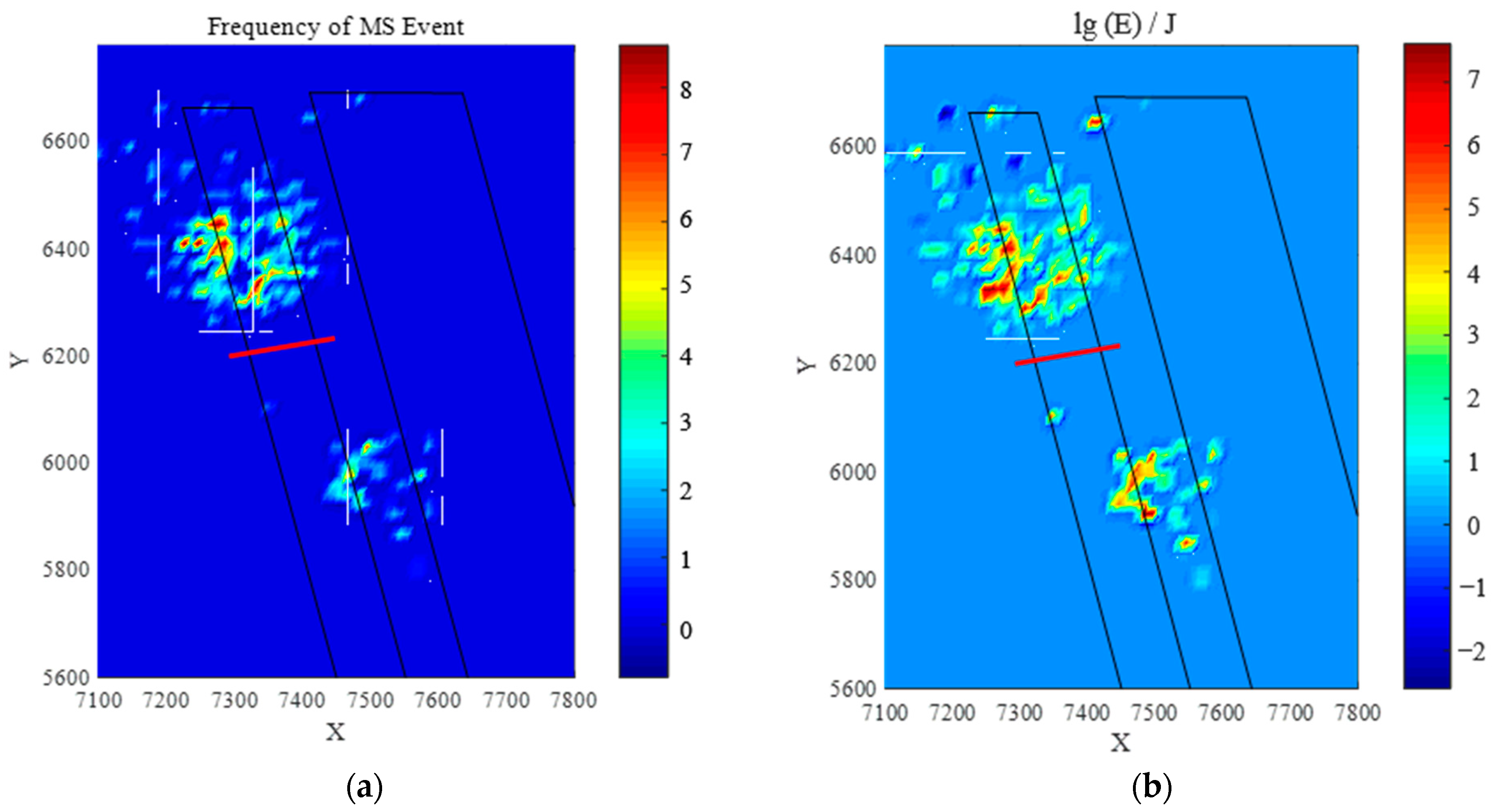

3.1. Analysis of the Mining Influence Range in the Working Face

Taking the microseismic monitoring data from 21 May 2015 to 20 June 2015 as an example, during this period, the working face advanced a total of 87.2 m.

Figure 4 shows the plane projection of microseismic events in this time period. The scatter points with different colors reflect the analysis results of a single microseismic event. The corresponding is the energy magnitude of a single microseismic event, which is taken as lg(E). E represents the magnitude of the seismic event energy, measured in Joules. The advance rupture envelope and lag rupture envelope of the coal and rock mass are shown in the envelope area of the red and green dashed lines, among which the advance severe impact area is delineated by the red solid line, indicating a higher frequency of microseismic events, and the lag severe impact area is located in the green solid line area behind the working face.

As can be seen from

Figure 4, microseismic events are widely distributed, indicating a large mining influence range in the working face, including 430 m in front and 320 m behind the face. There are also a large number of microseismic events outside the auxiliary transportation roadway behind the working face and inside the 80 m coal pillar. This area contains two large faults, Yf1 and Yf2. It is speculated that after the working face passes through the fault, the influence of mining lag induces fault activation again.

Figure 5 shows the profile projection of microseismic events during the mining process of the working face, including the projection along the strike and the dip direction. The red solid line represents the position of the working face, the black solid line represents the unmined coal seam, and the gray solid line represents the completed mining of the coal seam. The evolution of the spatial morphology of the roof and floor of the solid working face in the mining process can be seen in the figure. As can be seen from

Figure 5a, the roof rupture height is about 38 m on average and the floor is about 20 m, and microseismic events are concentrated in the coal pillar area of 80 m. In the 1301 working face, there are concentrated events at the belt transport down chute, indicating that there is a high stress difference near this area. The microseismic activity of the 1300 auxiliary track trough is more intense than that of the belt track trough, which is closely related to the spatial layout of the track trough and the nearby fault activity.

Figure 5b further confirms that the mining influence range is about 320 m behind the working face and 430 m in front of it.

3.2. Analysis of the Microseismic Activity in the Tectonic Region

In order to study the activity signs in the tectonic area during the mining process of the 1300 working face, the microseismic activity in the fault areas of FY15, Yf2, and Yf1 was statistically analyzed. As shown in

Figure 6, the FY15 fault obliques through working faces 1300 and 1301. During the mining process, the 1300 working face successively passed FY15 and Yf1, and was affected by the Yf2 fault. In the early stage of mining, the stope was ahead of the principle of abutment pressure in the fault area, but it still induced the occurrence of a large number of small energy vibration events in the fault area, such as the plane projection of microseismic events from January 2014 to October 2014. With the advancement of the working face (1 January 2014–1 December 2014), the FY15 fault was within the influence range of advanced abatement pressure. Mining induced a few large energy events and a large number of small energy events. The spatial distribution of events was consistent with the fault morphology, indicating that mining induced fault activation. When approaching the FY15 fault (December 2014–31 December 2014), a large number of microseismic events were distributed in the rock mass around the working face, with large energy and small energy microseismic events alternately occurring with irregular frequency. Meanwhile, the advanced abutment pressure induced the Yf2 and Yf1 faults 300 m in front. It is speculated that this phenomenon is influenced by two factors: one is the gradual activation and induction of the major FY15 fault, and the other is the high mining rate of 6.4 m/s.

Due to the violent activity of the fault, the 1300 working face implemented the corresponding safety measures in the mining process, reduced the mining speed of the working face to 4.8 m/s, and stopped production for consolidation in the later stage. At this time, although there were still a large number of microseismic events in the working face, the event energy was small, indicating that the high-stress area around the fault was transferred or weakened under the action of artificial “weak thrust” measures. The high-stress concentration was no longer obvious, and the sudden release of the weakened residual potential energy of coal rock mass was not enough to induce large energy events, which also indicates that the rockburst prevention measures effectively inhibited the occurrence of rockburst, such as during the period 1 January 2015–31 January 2015. After passing through the fault, on the one hand, the working face slowed down the speed of thrust mining, waiting for the full evolution of the overlying strata. Meanwhile, the fault was still in the range of the stope pressure relief zone. Therefore, the microseismic events significantly decreased, and some large energy events were suspected to be a rebalancing of the fault region, such as during the period January 2015–28 February 2015. During the period from January 2015 to 28 February 2015, microseismic activity became active again. On the one hand, the Yf2 and Yf1 faults entered the influence range of advanced abutment pressure; on the other hand, the FY15 fault was under the influence of hysteresis and the severe area.

3.3. Analysis of the Abutment Pressure Distribution Range

The microseismic monitoring system arranged in the field recorded the vibration response of the working face during the mining process. In order to analyze the causes of these accidents, microseismic events were counted on a daily basis and projected onto the planar graph. The results are shown in

Figure 7.

- (1)

Strike abutment pressure distribution

As can be seen in

Figure 7, the spatial distribution of microseismic events in the working face stoping process has typical zoning characteristics, and is closely related to the transfer of the mining stress field. The mining influence range is 150 m in front of the working face, 75 m behind the working face, 120 m outside the auxiliary track channeling, and 80 m outside the belt channeling. According to the principle of microseismic event zoning (the correlation between the distribution density of microseismic events and the “blind area”), it can be inferred from

Figure 7b that the peak position of strike abutment pressure on the working face is 65 m in front.

- (2)

Inclined abutment pressure distribution

Combined with

Figure 7a,c, the lateral abutment pressure distribution characteristics of the working face can be predicted. As shown in the figure, the mining influence range on both sides of solid coal in front of the working face is wider, and the outer side of the auxiliary track channeling (120 m) is wider than that of the belt channeling (80 m). On both sides of the goaf behind the working face, the microseismic response is not obvious in the belt channeling area, but it is more obvious on the track channeling side, especially in the 80 m coal pillar and 1301 belt channeling, where a large number of microseismic events are distributed. According to the corresponding relationship between the fracture position of the upper strata and the stress of coal, it can be inferred that the peak position of lateral abutment pressure in the goaf is about 65 m away from the goaf.

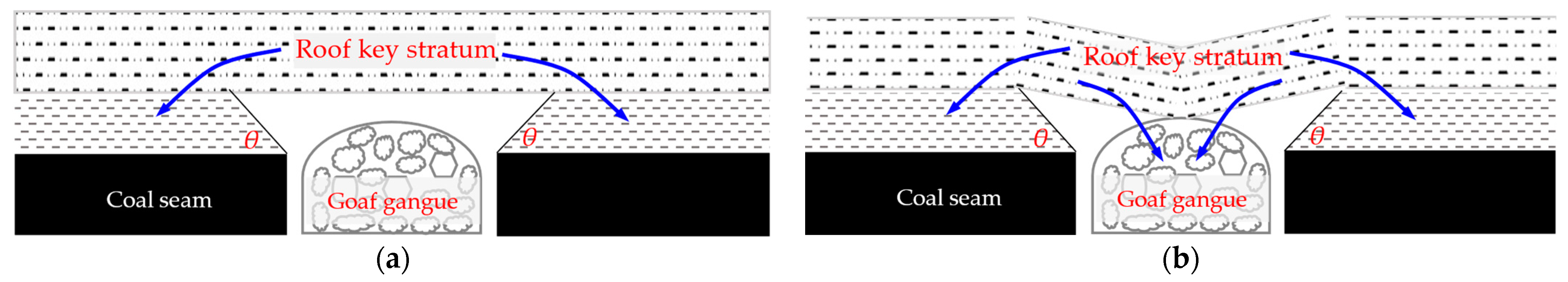

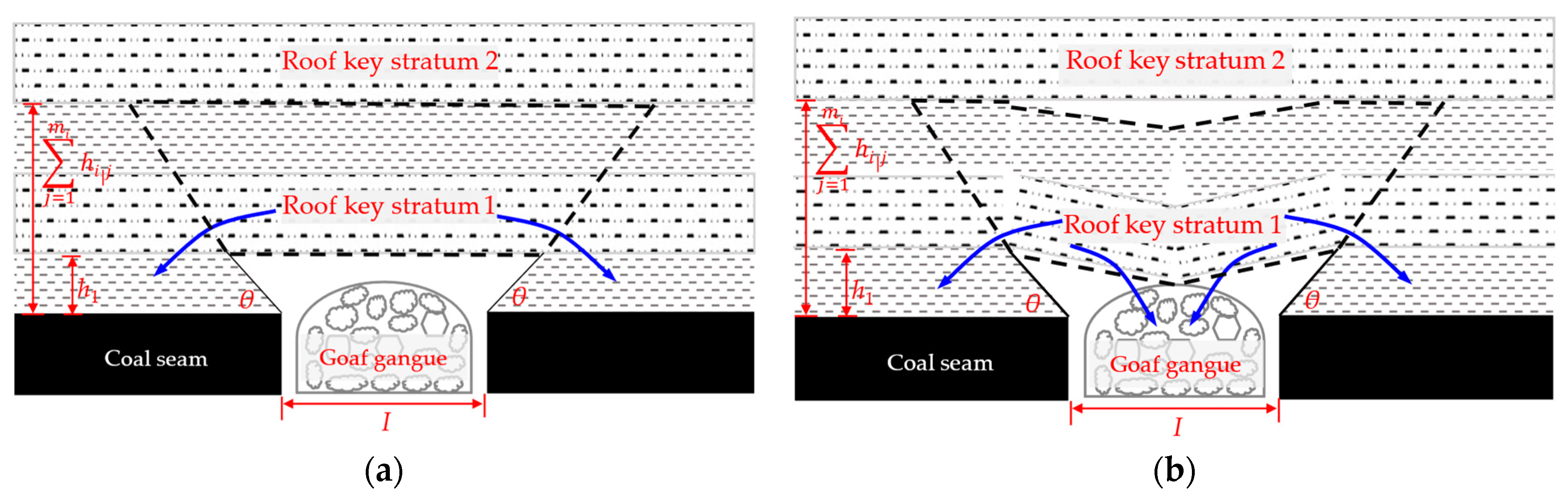

4. Construction of the Dynamic and Static Abutment Pressure Calculation Model

The accurate acquisition of static and static abutment pressure distribution data is the key to carrying out rockburst risk analysis. The stope roof breaks and turns ahead of time, which causes the coal body to deform and yield, causing the coal body to lose its bearing capacity, and causing the stress to transfer to the deep-forming dynamic abutment pressure. With the increase in the mined-out area, the load on the key layer above the fault zone increases, and the load on the key layer supported by the lower rock layer transfers to both sides and in front, forming static abutment pressure. According to the above analysis, the main reason for rockburst in the adjacent area of the fully mechanized caving face is the superposition of static and static abutment pressures. Therefore, the distribution range of abutment pressure will be calculated and its evolution law will be analyzed by means of theoretical derivation and field measurements.

4.1. Static Abutment Pressure Calculation Model

Before and after the goaf is formed, the load of the roof strata to be borne by the coal seam is constant. As shown in

Figure 8, before the goaf is formed, the load of the roof strata is evenly distributed on the coal seam; after the goaf is formed, the load of the roof strata will be transferred to the coal body outside the goaf and the gangue in the goaf.

Abutment pressure

of the coal body on one side of the goaf is composed of dead weight stress

and stress increment

, which can be expressed as:

In the formula, is the common sum (MPa) of the stress increment formed by the load of the overhanging part of each key stratum of the stope or the load of the broken block segment transferred to the coal body on one side, namely, ; is the stress increment (MPa) caused by the load transferred to the coal body on one side by the overhanging part or the broken block section of the i th key stratum, i = 1~m.

- (1)

Gravity stress

The critical stratum in roof strata is the medium of load transfer in roof strata. The static abutment pressure calculation model can be established according to the critical stratum theory and the load transfer characteristics of roof strata, as shown in

Figure 9. Before the critical stratum breaks, half of the load in the overhanging part is transferred to the coal body on one side of the goaf.

Let the load of the hanging part of key stratum i be , then the load transferred to the coal body on one side of the goaf is . is calculated as shown in Equation (2).

Suppose that the distance from the ith key stratum to the coal seam is

Hi, and the rock formation controlled by it has

mi rock layers, denoted as

from bottom to top, then

where,

is the thickness of rock layer (m),

I is the width of working face (m),

θ is the fracture angle, and

is the bulk density.

After the key stratum is broken, half of the load of the broken block section is transferred to the coal body on one side of the goaf. Assuming that the length of the fault block section of the

i th key stratum is

Li and the load is

, then the load

transferred to the coal body on one side of the goaf is transferred.

is calculated as follows:

- (2)

Stress increment

When there are multiple key layers in the stope roof strata, the stress increment generated by each key layer is superimposed, as shown in Equation (4), and

is obtained. The formula for calculating

σq is:

It can be seen that the calculation formula of static abutment pressure is a group of piecework functions. The distribution characteristics of static abutment pressure are related to the fracture angle, the number of key layers, the position of key layers, the thickness of each rock group, the length of the broken block, and the buried depth.

4.2. Dynamic Abutment Pressure Calculation Model

Under the action of abutment pressure, the coal body on both sides or in front of the goaf tends to move to the stope and forms the stress limit equilibrium zone. According to the characteristics of coal wall stress transfer to the deep coal body after yield, a dynamic abutment pressure calculation model is established by using the limit equilibrium method, as shown in

Figure 10, where

is the coal wall support resistance (MPa),

is the distance (m) between the investigation point and the coal wall,

is the distance (m) between the influence of abutment pressure, and

is the distance (m) between the peak position and the coal wall.

is the vertical supporting force of the coal wall (MPa),

is the average bulk density of the overlying rock (MN•m

3),

H is the buried depth of the stope (m),

k is the stress concentration factor, and

is the vertical stress in the coal body (MPa). The influence range of dynamic abutment pressure can be divided into three parts: the 0~

part is the plastic region, and the abutment pressure presents exponential function distribution. The part

~

is the elastic active region, and the abutment pressure is negative exponential function distribution. The part

~

is the stress region of the original rock, and the abutment pressure presents constant function distribution.

Based on the above analysis and considering the boundary conditions, the calculation model of abutment pressure distribution can be obtained as follows:

where,

is the vertical stress of the coal body (MPa),

M is the thickness of the coal seam (m),

f is the friction factor of the layer.

Assume that 0 is the lateral pressure coefficient,

in the elastic region, then

The influence distance of abutment pressure is as follows:

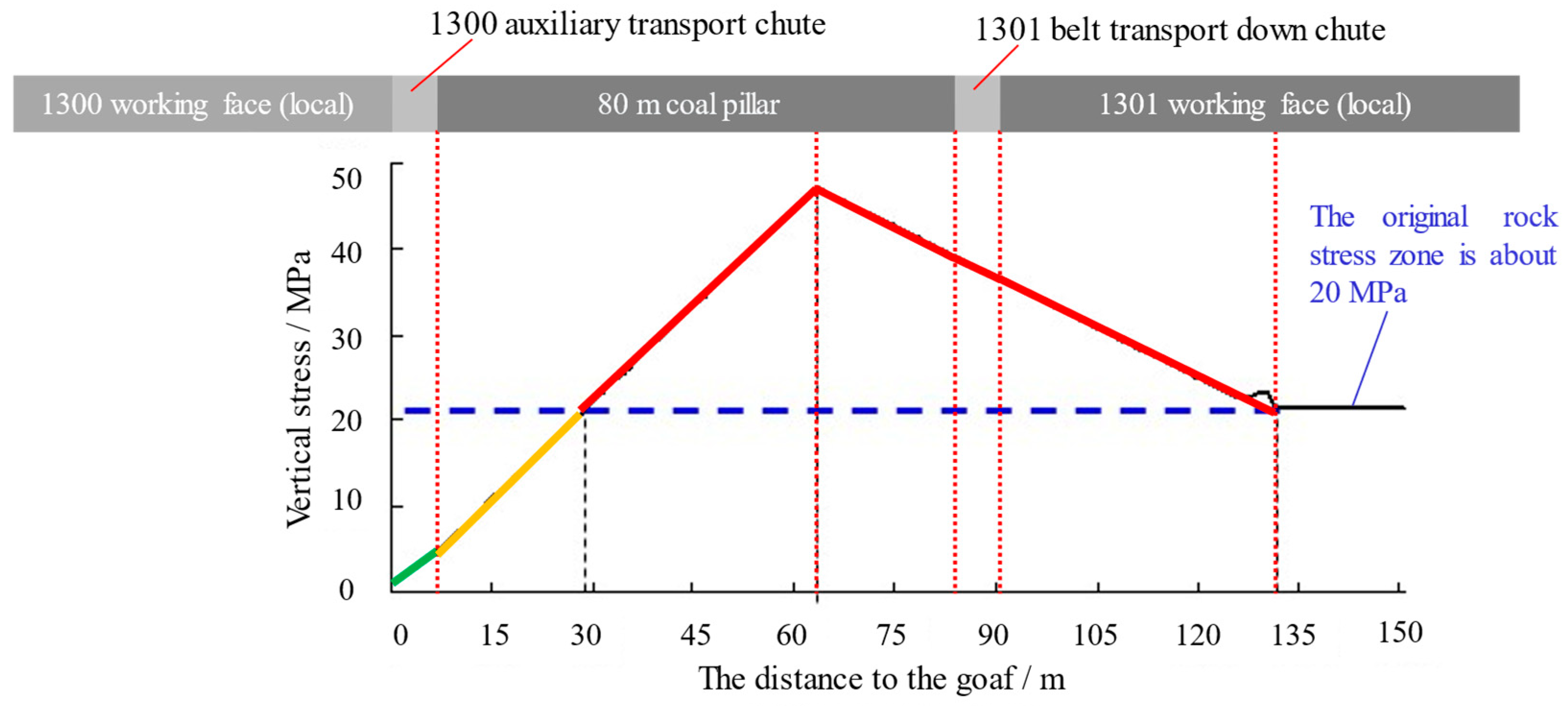

4.3. Case Checking

For a heavy topsoil stope, the rock strata above the rupture range of the roof can be simplified into one rock group. Considering the large thickness of the bedrock, the displacement angle α is around 82°. The mining depth is 860 m and the inclined length of the working face is 100 m. Other calculation conditions are as follows: coal seam thickness

M = 7.0 m, working face depth

H = 860 m, working face width

I = 100 m, overburden average bulk density

= 0.025 MN/m

3, fracture angle

= 82°, layer friction coefficient

f = 0.2, internal friction angle

= 28.5°, and side pressure coefficient

= 0.5. The stress concentration coefficient

k = 2. The vertical supporting force of coal wall

is calculated by the static abutment pressure calculation formula. The calculating interval of the independent variable in the final calculated segment function is:

The calculation process is simplified, and the rock above the fracture range is taken as a rock group, so its thickness M1 is around 800 m. By plugging working face parameters into Equations (5)–(7), and taking rock bulk density

as 2.5 t/m

3, the specific lateral abutment pressure calculation formula can be obtained as follows:

Through calculation, the lateral abutment pressure distribution of the coal body on one side of the 1300 goaf is obtained, as shown in

Figure 11. It can be seen from the figure that the peak position of lateral abutment pressure of the coal body outside the goaf is about 63 m away from the goaf, and the peak value of abutment pressure is about 47 MPa. The low stress area is 0–28 m away from the goaf. The abutment pressure affected area is 28 m–130 m away from the goaf. The original rock stress area is 130 m away from the goaf. This monitoring result is consistent with the mining influence range revealed by the microseismic monitoring results.

The distance between the outer section of the belt transport down chute in the 1301 working face and the 1300 goaf is 80 m, which is just within the influence range of abutment pressure on the side of the 1300 goaf. The vertical stress here is about 40 MPa, much higher than the uniaxial compressive strength of the coal seam, 15 MPa. Therefore, rockburst can easily occur during the driving of the outer section of the belt transport down chute in the 1301 working face.

Based on the above calculation results, the influence areas of the goaf in the 1300 working face are divided, and the final goaf influence danger zone is shown in

Figure 12. It can be seen that the duct of the 1301 belt transport down chute is completely under the influence range of the goaf of the 1300 working face, which further confirms the root cause of the previous multiple rockburst events.

5. Other Monitoring Analysis and Measurement Verification

5.1. Analysis and Comparison of Other Monitoring Means

In order to further verify the accuracy of the above theoretical model and microseismic monitoring results, a comparative analysis was carried out with the results of other on-site monitoring methods, including online stress monitoring, bolt force monitoring, CT detection, etc. At the same time, the stress state of the coal body was measured and tested by the amount of drilling cuttings.

- (1)

Analysis of the results of online stress monitoring methods

According to the analysis of the field observation results, the initial weighting of the 1300 working face on 15 September, the sliding head advance distance (from the original cutting hole) was 36 m, the sliding tail was 41.6 m, and the pressure step was 38.8 m (from the original cutting hole). Through the analysis of the observation results of five consecutive periodic weightings, it is inferred that the pressure step of the 1300 working face is as shown in

Table 1.

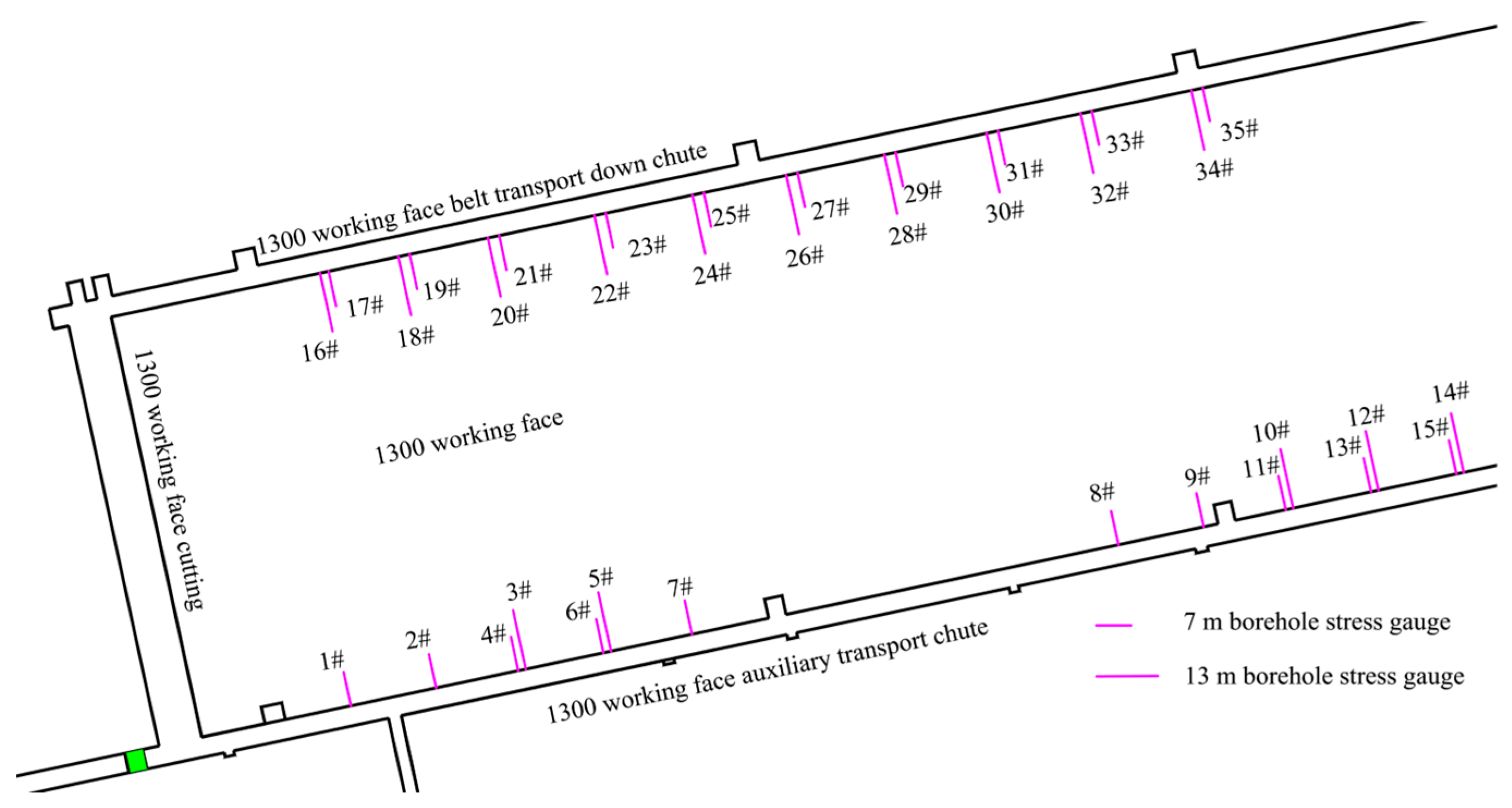

In order to monitor the stress change in the coal body of the 1300 working face in real time, the KJ550 online stress monitoring system was used to monitor the working face in real time. As shown in

Figure 13, the borehole stress meters of the system were placed in the coal seam to be mined in the upper and lower level driveways, with a measurement station spacing of 25 m. As the working face advances, real-time monitoring and early warning of impact pressure were conducted in the advance influence zone of the working face. Measurement point arrangement: a No. 1 measurement station was set up 30 m away from the working face cutting end, and one measurement station was arranged every 25 m outward (with an allowable error of ±3 m). Each measurement station had two measurement points, with borehole stress meters installed at depths of 7 m and 13 m, respectively, and spaced 2 m apart. As the working face advanced, the system was promptly dismantled and moved forward, ensuring a monitoring range of no less than 200 m.

The stress sensor monitoring data showed that the stress began to rise at a distance of about 60 m from the cutting end, reached its peak at about 20 m from the cutting end, and then declined. This preliminary analysis indicated that the impact zone of the 1300 working face was 60 m, and the stress peak appeared at a distance of about 20 m from the working face. However, in complex geological areas, the influence range was larger due to mining-induced stress, reaching approximately 90 m.

- (2)

Analysis of observation results of rockbolt dynamometer

In addition, according to the observation of the rockbolt dynamometer, during most of the observation period, the rockbolt dynamometer hovered around the initial rockbolt force, and the working resistance of the rockbolt near the coal wall of the working face rapidly rose, with typical rising inflection points. At a certain distance from the coal wall of the working face, the working resistance of the rockbolt rod slightly fluctuated. The classification and statistical results of the rockbolt rod working resistance are shown in

Table 2 below.

It can be seen from the statistical results in

Table 2 that the position of the working resistance of the tail entry anchor bolts is about 50 m away from the coal wall of the working face under the influence of mining, and the peak stress is about 29 m. Meanwhile, the working resistance of anchor bolts in the belt transport down chute is affected by mining-induced stress at a distance of approximately 49 m from the coal wall of the working face, with the stress peak occurring around 23 m.

- (3)

Comprehensive comparative analysis results

The field measurement results of the mining influence range and the distribution characteristics of the abutment pressure of the solid working face are summarized and listed in

Table 3. It can be seen from the table that the mining influence range obtained from microseismic monitoring is basically consistent with the corresponding results obtained from dynamic stress monitoring. The distance from the peak position of abutment pressure to the coal wall and the influence range of abutment pressure obtained by microseismic monitoring are larger than those obtained by dynamic stress monitoring. Therefore, it can be inferred that there are two bearing pressures in the surrounding rock of the working face, namely, dynamic bearing pressure and static bearing pressure.

In fact, the commonly mentioned abutment pressure is dynamic abutment pressure, which is formed in a short time with the advancement of the working face. For general working faces, the distance from the strike peak position to the coal wall is about two to three times the mining height, and the distance from the lateral peak position to the goaf is 15 to 20 m. In addition to the dynamic abutment pressure, there is also a static abutment pressure in the surrounding rock of the working face, which is formed by the weight transfer of the high roof. The distance from its peak position to the coal wall is about two to four times the distance from the peak position of the dynamic abutment pressure to the coal wall.

5.2. Analysis of Rockburst Hazard Sources Based on CT Technology

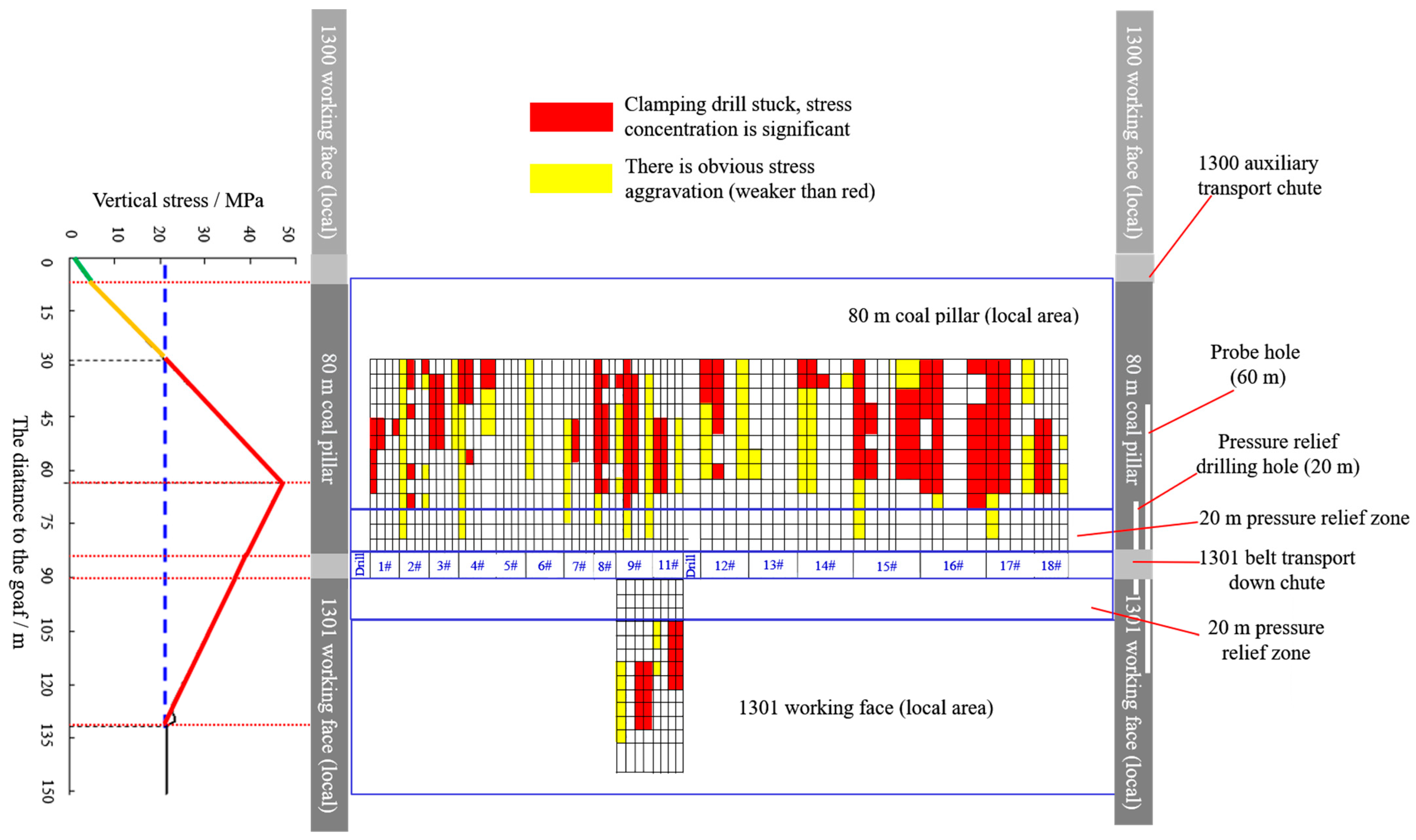

In order to further test the distribution characteristics of lateral abutment pressure in the goaf of the 1300 working face, the distribution characteristics and hazard degree of rockburst hazard sources in the 1301 working face were measured by seismic CT technology.

Figure 14 shows the distribution of rockburst risk index C in the detection area of the 80 m wide coal pillar and the 1301 working face. The magnitude of the hazard index detected by seismic CT is closely related to the degree of stress concentration. Therefore, the magnitude of stress concentration in this area can be inferred from the hazard index of rockburst. The danger index of rockburst in the detection area is represented by blue to red, from small to large (that is, stress distribution from small to large). The maximum value of C in the area is 0.7 and the minimum value is −0.5.

The rockburst hazard index of most areas in the survey area is less than 0.75, but the rockburst hazard index of coal and rock strata in nearly one-fifth of the survey area is 0.5 ≤ C < 0.75, and the above areas are in the middle of the rockburst hazard level. Projecting more than three times the events since 2015 into the C distribution map, it can be seen that the microseismic events are mostly concentrated in the 80 m large coal pillar, the connecting roadway in the 1301 working face, and near the fault structure, especially in the 1301 belt transport down chute. This is because the corresponding area of the coal pillar in the 1301 working face and the 80 m section is comprehensively affected by the lateral bearing pressure, the structure, and other factors of the 1300 working face, the stress distribution is complex, and the risk of rockburst is higher than in other areas, which is consistent with the borehole stress detection results.

In order to verify the conclusion of the seismic CT technology evaluation on the rockburst risk of coal and rock strata, the borehole stress detection test results and seismic CT detection results were compared and analyzed, as shown in

Figure 15. According to the number of drilling cuttings and whether there is a dynamic phenomenon in the process of drilling cuttings, the range of the stress concentration area in the surrounding rock of the roadway is defined. It can be seen from

Figure 14 that within the range detected by the drilling cuttings method, the area where the drilling cuttings exceed the limit or where dynamic phenomena occur is generally consistent with the distribution of the rockburst hazard area detected by the seismic CT technology, which verifies the reliability of the evaluation method.

The adjacent area affected by the lateral abutment pressure of the 1300 goaf was detected using the above two methods. The two methods corroborated the previous analysis results; that is, the distribution range of the lateral abutment pressure of the 1300 working face exceeded the 80 m coal pillar protection area, and the belt transport down chute of the 1301 working face was under the influence range of the lateral abutment pressure, which is the root cause of frequent rockburst events in this area.

5.3. Field Measurement and Inspection of Coal Drilling Cuttings

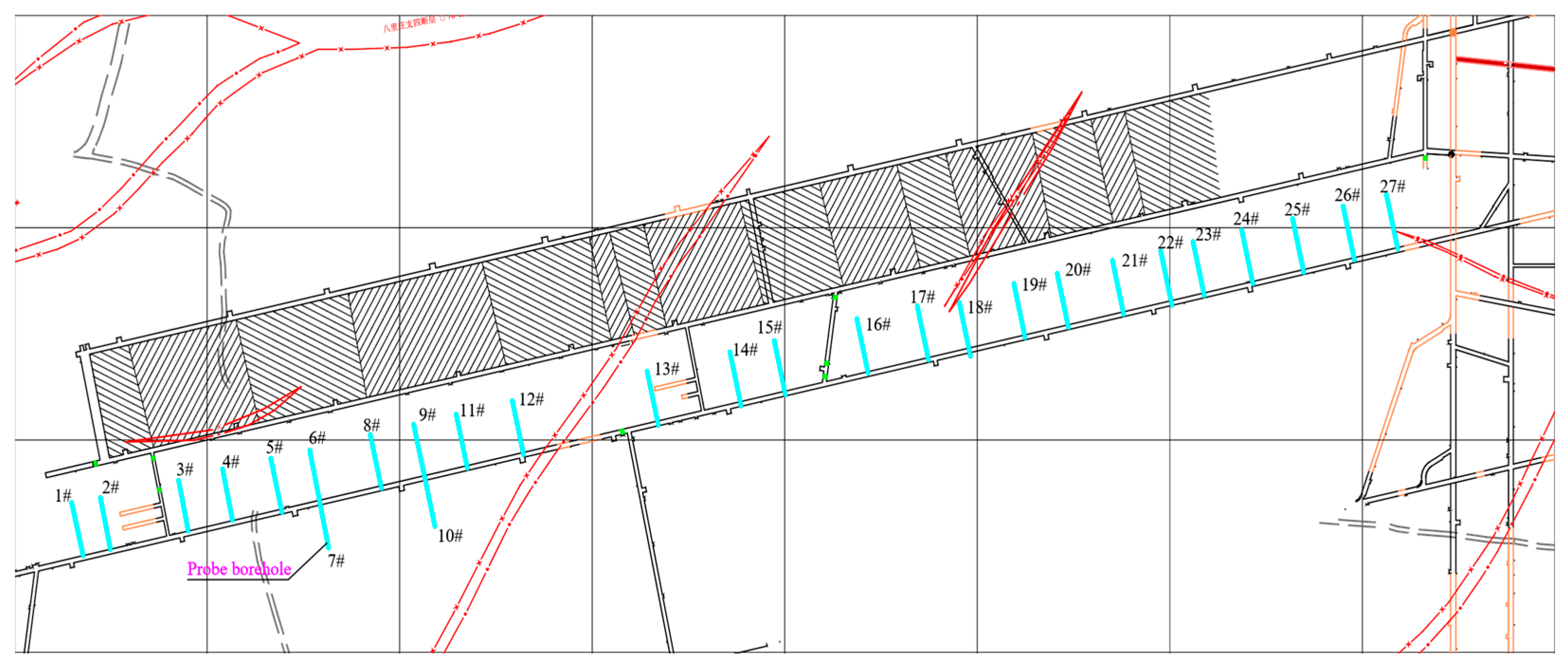

In order to test the correctness of the calculation model of lateral abutment pressure in the longwall stope, an experimental study on coal body stress detection was carried out in the belt transport down chute of the 1301 working face in July 2016; that is, drilling was carried out in the coal pillar area 80 m on both sides and in the 1301 working face near the belt transport down chute; the stress state of this area was tested.

The site drilling construction parameters were as follows: the drilling hole was 1.2–1.5 m above the floor, constructed along the dip angle of the coal seam and perpendicular to the side (the east side is 4–6° lower, the west side is 4–6° upward), the hole depth was 60 m, and the hole diameter was Φ 80 mm. Drilling construction was carried out from south to north in sequence, with a spacing of about 50 m. A total of 17 boreholes were drilled. Except for #7 and #10 boreholes drilled in the 1301 working face, the remaining boreholes #1–#6, #8, #9, and #11–#17 were drilled in the 80-m coal pillar area, as shown in

Figure 16. For the convenience of description, the boreholes are divided into two groups, of which boreholes #1–#6, #8, #9, and #11–#17 in the 80-m coal pillar area are Group A, and the boreholes #7 and #10 in the 1301 working face are Group B.

According to the principle of the drilling cuttings method, there is a quantitative relationship between the quantity and particle size of pulverized coal discharged from the borehole, the relevant dynamic effects (such as the coal gun, the suction drill, and the sticking drill), and the stress state of the coal body. On this basis, in the test process, the coal particle size, the number of coal guns, the strength of coal guns, and the dynamic phenomenon during the drilling process are respectively counted with a unit depth of 5 m to judge and describe the current drilling depth. After the test, the data collected on the site were sorted and analyzed, and the relevant results are shown in

Figure 16. The white, yellow and red areas in the figure represent the stress concentration status in the coal body, in which the white area shows no stress concentration, and the red area is the highly concentrated area.

From an analysis of

Figure 17, it can be seen that the boreholes of Group A in the coal pillar area are essentially in the original rock stress state within the range of 1–20 m, and there is no obvious stress concentration, which is related to the recent boreholes in this area. The 1301 belt in this area was drilled to a depth of 20 m along the inner and outer sides of the belt transport down chute for pressure relief, resulting in the transfer of stress load within 20 m, so a relative 20-m wide “low-pressure zone” appeared in the chart. The stress state in the coal body changes after the hole depth of 20 m. Take 1# drill hole as an example to illustrate that, with the increase in hole depth, the particle size of coal powder changes from powder to small particles, and large particles appear when the hole depth reaches 46 m. The number and strength of coal guns also gradually increase, accompanied by the strong phenomenon of suction drilling. It can be determined that there is still stress concentration in the 80-m coal pillar outside the 1301 belt slot. That is, the range of the lateral abutment pressure in the 1300 goaf is more than 80 m, which exceeds the width of the 80-m protective coal pillar and directly affects the adjacent 1301 working face.

At the same time, the data of the Group B boreholes (7#–10# boreholes) were analyzed. Group B is located in the coal body of the 1301 working face. The analysis results show that the coal body within 60 m of the 1301 working face is still within the influence range of the lateral abutment pressure of the 1300 goaf. In addition to the 80-m coal pillar and the roadway width, the measured lateral abutment pressure of the 1300 goaf is around 80 + 60 + 2 × 4.8 = 150 m. This is consistent with the 130-m results obtained by theoretical calculation, which also proves the correctness of the calculation model of lateral abutment pressure in the fully mechanized caving face.

7. Discussion

Aimed at the problem of multiple rockburst accidents in the adjacent area of a 1300 fully mechanized caving face in a mine, this study considered the evolution and distribution laws of the surrounding rock support pressure in fully mechanized caving faces of deep well as a breakthrough point. Relying on microseismic monitoring technology, it was revealed that the cause of rockbursts in the adjacent area is actually “caused by the evolution superposition of the lateral support pressure of the 1300 stope and the original rock stress along the 1301 belt transport down chute”. The supporting pressure distribution range was preliminarily obtained as 120 m. By constructing the dynamic and static support pressure calculation model of the longwall stope, with the help of CT geophysical exploration and drilling cuttings, as well as other measurement methods, it was found that the 1301 belt transport down chute is in the support pressure influence area (superposition area) of 20 m to 130 m, which further confirmed the validity of the microseismic analysis results and the accuracy of the theoretical model. Finally, combined with the field measurement results and theoretical model calculation, the corresponding rockburst early warning system and prevention measures were put forward. The research results can provide support for the early warning of mining-induced disasters in a working face. Firstly, it is beneficial for coal mining enterprises to optimize the setting of mining speed. Second, it is convenient for mining enterprises to design reasonable support and prevention strategies for rockbursts. The third is to provide theoretical support for mine safety early warnings. In addition, the results of this study not only provide a theoretical basis for the prevention and treatment of rockbursts, but also provide important reference significance for studying the inducing factors of rockbursts and improving the classification and positioning accuracy of microseismic events.

However, there are areas for improvement in this study, specifically: when calculating the theoretical model, the impact of the goaf gangue in the field was not considered. In fact, the goaf gangue affects the formation of overlying strata structures in the mining area, as well as the working conditions of the support [

51]. When calculating the support pressure of the longwall mining area, various factors such as the geological profile, lithology, the mining parameters, and the gangue caving expansion coefficient need to be comprehensively considered [

52]. This paper simplified the theoretical modeling process based on the main force source of rockbursts and the quantitative modeling characteristics, assuming that the content under study was under the condition of sufficient mining in the mining area, and studied the potential for rockbursts and other disaster issues in this process, ignoring the impact of the goaf gangue. In the future, we will further deepen the study of the impact of factors such as the gangue pile, and add other conditions that may affect the results of theoretical model calculation to modify the model, so as to make the obtained support pressure influence range more accurate.